Hybridization of a Backhoe Loader: Electric Drive System Design

Abstract

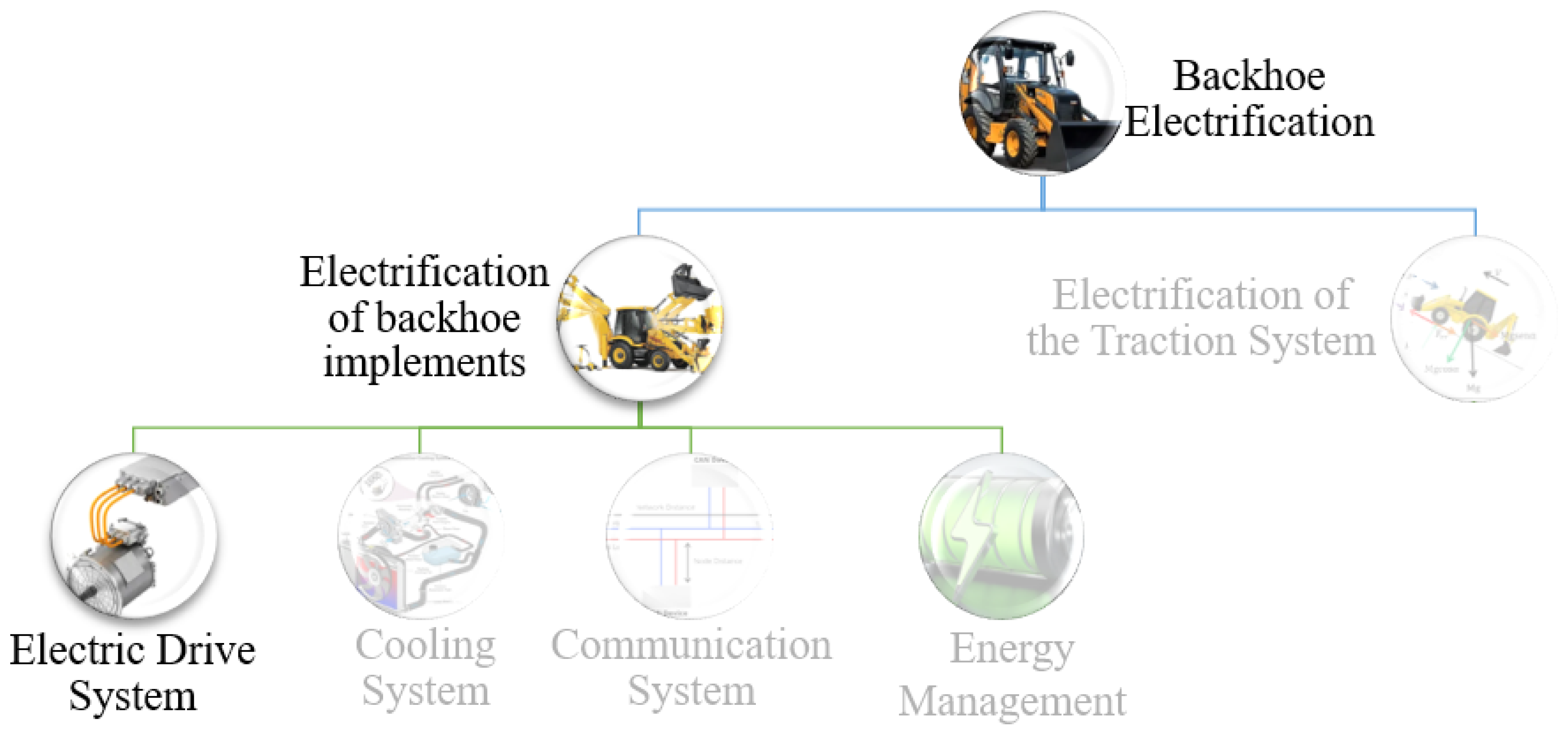

:1. Introduction

2. Technical Standards

3. Hybridization Strategies

3.1. Parallel Configuration

3.2. Series Configuration

3.3. Series-Parallel Configuration

4. Working Power

5. Power Components Design

5.1. Batteries and Battery Management System

- Number of cells compatible with the battery bank;

- Protection functions: connection to the power relay and, for plug-in vehicles, control of battery charger activation.

5.2. Electric Machines and Inverters

5.3. Power Cables

5.4. DC/DC Converters

6. Design of Switching and Protection Components

6.1. High Voltage Interlock Loop (HVIL)

6.2. Insulation Monitoring Device (IMD)

6.3. Pre-Charge Circuit

- Maximum voltage;

- Maximum energy;

- Power overload capacity of the resistors during the pre-charge period (energy dissipation capacity).

6.4. Main Protection Circuit

- For analysis of the charging process, the battery bank admits a current of 444.4 A (max. 10 min.) or 277.8 A (continuous) in the condition of minimum voltage of the pack (72 V) that matches with the worst case in terms of current values.

- For the discharge process, the battery bank is capable of much higher current values in short time intervals. As the fuse is a fast-acting one, care must be taken to ensure that improper actuation does not occur within these limits.

7. Key Points for Electric Drive System Design

- I.

- Define the hybridization strategy by observing cost and degrees of freedom.

- II.

- Check the power of the operation performed by the HCM.

- III.

- Define the size of the battery bank according to the desired maximum volume.

- Define the BMS that meets the specifications of the battery bank.

- IV.

- Define electrical machines, inverters, and dc/dc converters based on operating power and battery bank voltage.

- Check whether the electrical machine delivers the power and torque required for operation at the desired operating speed.

- Check whether the inverters and dc/dc converters have the desired communication protocol.

- V.

- Define high voltage cables in compliance with current regulations.

- To reduce the cross-section of the cables, use insulation material that withstands higher temperatures.

- VI.

- Define protection and switching elements.

- Establish the proper HVIL and IMD to protect users and service technicians.

- Correctly specify the pre-charge resistors according to the maximum voltage, maximum energy, and power overload capacity.

- Check if the main fuse operates both in nominal operation and in motor overloads, without it tripping in advance.

8. Test Bench

9. PMSM Drive Modeling, Control and Simulation

9.1. Plant Model Description

9.2. Control Description

9.3. Controllers Adjust

- The current controller gains were chosen to locate the poles of (9) spaced a decade apart, with the fastest one being ten times slower than the switching frequency () of 16 kHz, which is also the sampling frequency () of this part of the control;

- The speed controller gains were chosen to have a dynamic stiffness (10) with fastest pole ten times slower than the sampling frequency (128 Hz, in this case) and to be spaced a decade apart;

- MTPA is not applied, since the motor is of the axial flux type with almost no reluctance torque ();

- The FWC gains were designed to maintain the d-axis current control loop speed (i.e., ), to keep the poles of (13) and (14) in frequencies 5 and 20 times less than (12). The anti-windup gain was chosen to be simultaneously high enough to avoid the integration of error during the saturation and sufficiently limited to allow a fast transition from the saturated to the unsaturated mode.

- For the current, they use a unit called quants that is constant. The only exception is the output of the FWC, which uses Ampere;

- For the voltage, they use a unit also called quants. However, it is not the same unit from the current and, furthermore, it is proportional to the measured dc voltage;

- For the speed, the controller uses rpm instead of rad/s.

9.4. Simulation Results

- Two-Level Converter Block: This block implements a three-phase, two level converter according to the one resented in Figure 11. Its inputs are the switches gating signals and it has five electrical ports: two for the dc link and three for the ac terminals.

- Series RLC Branch Block: It implements the differential equations of a series connected circuit composed by a resistor, a capacitor, and an inductor. It is used to model the capacitive dc link (refer to Figure 11).

- DC Voltage Source Block: It implements an ideal dc voltage source. This is used to model the voltage source used in the experimental set-up (see Section 10).

10. Experimental Results

11. Discussions

12. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| APM | Auxiliary Power Module. |

| BMS | Battery Management System. |

| CAN | Controller Area Network. |

| DC | Direct Current. |

| EPR | Ethylene Propylene Rubber. |

| FOC | Field Oriented Control. |

| FWC | Field Weakening Control. |

| HCM | Hybrid Construction Machinery. |

| HVDU | High Voltage Distribution Unit. |

| HVIL | High Voltage Interlock Loop. |

| ICE | Internal Combustion Engine. |

| IMD | Insulation Monitoring Device. |

| LC | Liquid Cooled. |

| LV | Low Voltage. |

| MTPA | Maximum Torque Per Ampere. |

| PMSM | Permanent Magnet Synchronous Machine. |

| PVC | Polyvinyl Chloride. |

| SoC | State of Charge. |

| XLPE | High-density crosslinked polyethylene. |

References

- Davis, S.C.; Boundy, R.G. Transportation Energy Databook: Edition 40. 2022. Available online: https://tedb.ornl.gov/wp-content/uploads/2022/03/TEDB_Ed_40.pdf (accessed on 25 January 2023).

- Liu, Y.; Li, Z.; Chen, Y.; Zhao, K. A Novel Fuel-Cell Electric Articulated Vehicle and Its Drop-and-Pull Transport System. Energies 2020, 13, 3632. [Google Scholar] [CrossRef]

- Mendes, F.E.G.; Brandao, D.I.; Maia, T.; de Filho, J.C.B. Off-Road Vehicle Hybridization Methodology Applied to a Tractor Backhoe Loader. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Somà, A. Trends and Hybridization Factor for Heavy-Duty Working Vehicles. In Hybrid Electric Vehicles; InTech: London, UK, 2017; pp. 3–32. [Google Scholar] [CrossRef] [Green Version]

- Masrur, M.A. Hybrid and Electric Vehicle (HEV/EV) Technologies for Off-Road Applications. Proc. IEEE 2021, 109, 1077–1093. [Google Scholar] [CrossRef]

- Munoz, L.E.; Blanco, J.C.; Barreto, J.P.; Rincon, N.A.; Roa, S.D. Conceptual design of a hybrid electric off-road vehicle. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012; pp. 1–8. [Google Scholar] [CrossRef]

- Rossi, C.; Pontara, D.; Falcomer, C.; Bertoldi, M.; Mandrioli, R. A Hybrid–Electric Driveline for Agricultural Tractors Based on an e-CVT Power-Split Transmission. Energies 2021, 14, 6912. [Google Scholar] [CrossRef]

- Gao, Y.; Ehsani, M. Parametric design of the traction motor and energy storage for series hybrid off-road and military vehicles. IEEE Trans. Power Electron. 2006, 21, 749–755. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L.; Bolognani, S.; Bettella, F.; Gatto, A. Electrification of agricultural machinery: A feasibility evaluation. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Dalboni, M.; Santarelli, P.; Patroncini, P.; Soldati, A.; Concari, C.; Lusignani, D. Electrification of a Compact Agricultural Tractor: A Successful Case Study. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Ge, L.; Quan, L.; Zhang, X.; Zhao, B.; Yang, J. Efficiency improvement and evaluation of electric hydraulic excavator with speed and displacement variable pump. Energy Convers. Manag. 2017, 150, 62–71. [Google Scholar] [CrossRef]

- Liao, Y.G.; O’Malley, M.; Quail, A. Experimental evaluation of parallel hybrid medium-duty tactical truck. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Zhao, D.; Stobart, R.; Dong, G.; Winward, E. Real-time energy management for diesel heavy duty hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2015, 23, 829–841. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Murphey, Y.L.; Masrur, M.A. Intelligent Energy Management and Optimization in a Hybridized All-Terrain Vehicle With Simple On–Off Control of the Internal Combustion Engine. IEEE Trans. Veh. Technol. 2016, 65, 4584–4596. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, J.; Du, S.; Ma, H.; Zhao, W.; Li, H. Energy Management Strategies for Hybrid Construction Machinery: Evolution, Classification, Comparison and Future Trends. Energies 2019, 12, 2024. [Google Scholar] [CrossRef] [Green Version]

- Regulation No. 100 Rev.3-Uniform Provisions Concerning the Approval of Vehicles with Regard to Specific Requirements for the Electric Power Train. Available online: https://unece.org/transport/documents/2022/03/standards/regulation-no-100-rev3 (accessed on 26 January 2023).

- ISO 6469-2; Electrically Propelled Road Vehicles—Safety specifications—Part 2: Vehicle Operational Safety. Available online: https://www.iso.org/standard/81346.html (accessed on 26 January 2023).

- ISO 6469-3:2021; Electrically Propelled Road Vehicles—Safety Specifications—Part 3: Electrical Safety. Available online: https://www.iso.org/standard/81746.html (accessed on 26 January 2023).

- ISO 6722-1:2011; Road Vehicles—60 V and 600 V Single-Core Cables—Part 1: Dimensions, Test Methods and Requirements for Copper Conductor Cables. Available online: https://www.iso.org/standard/50022.html (accessed on 26 January 2023).

- ISO 17409:2020; Electrically Propelled Road Vehicles—Conductive Power Transfer—Safety Requirements. Available online: https://www.iso.org/standard/72880.html (accessed on 26 January 2023).

- ISO 15118-1:2019; Road Vehicles—Vehicle to Grid Communication Interface—Part 1: General Information and Use-Case Definition. Available online: https://www.iso.org/standard/69113.html (accessed on 26 January 2023).

- ISO 26262-1:2018; Road Vehicles—Functional Safety—Part 1: Vocabulary. Available online: https://www.iso.org/standard/68383.html (accessed on 26 January 2023).

- BS EN 60529:1992+A2:2013; Degrees of Protection Provided by Enclosures (IP Code). Available online: https://www.en-standard.eu/bs-en-60529-1992-a2-2013-degrees-of-protection-provided-by-enclosures-ip-code (accessed on 26 January 2023).

- BS EN IEC 61851-1:2019; Electric Vehicle Conductive Charging System General Requirement. Available online: https://www.en-standard.eu/bs-en-iec-61851-1-2019-electric-vehicle-conductive-charging-system-general-requirements (accessed on 26 January 2023).

- IEC 62485-3:2014; Safety Requirements for Secondary Batteries and Battery Installations—Part 3: Traction Batteries. Available online: https://webstore.iec.ch/publication/7092 (accessed on 26 January 2023).

- SAE J2344; Guidelines for Electric Vehicle Safety. Available online: https://www.sae.org/standards/content/j2344_202010/ (accessed on 26 January 2023).

- SAE J1797; Recommended Practice for Packaging of Electric Vehicle Battery Modules (STABILIZED Aug 2016). Available online: https://www.sae.org/standards/content/j1797_201608/ (accessed on 26 January 2023).

- SAE J1939; Serial Control and Communications Heavy Duty Vehicle Network—Top Level Document. Available online: https://www.sae.org/standards/content/j1939_201808/ (accessed on 26 January 2023).

- Palavicino, P.C.; Sarlioglu, B.; Bobba, D.; Lee, W.; Minav, T. Eletrification of Hydraulic Systems using High Efficiency Permanent Magnet Motors. In Proceedings of the 12th International Fluid Power Conference (12th IFK), Dresden, Germany, 12–14 October 2020. [Google Scholar]

- Un-Noor, F.; Scora, G.; Wu, G.; Boriboonsomsin, K.; Perugu, H.; Collier, S.; Yoon, S. Operational Feasibility Assessment of Battery Electric Construction Equipment Based on In-Use Activity Data. Transp. Res. Rec. 2021, 2675, 809–820. [Google Scholar] [CrossRef]

- Kagoshima, M.; Sora, T.; Komiyama, M. Power Source Device for Working Machine. U.S. Patent 7525206B2, 28 April 2009. [Google Scholar]

- Wang, J.; Yang, Z.; Liu, S.; Zhang, Q.; Han, Y. A comprehensive overview of hybrid construction machinery. Adv. Mech. Eng.. 2016, 8, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Immonen, P. Energy Efficiency of a Diesel-Electric Mobile Working Machine. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2013. Available online: https://lutpub.lut.fi/bitstream/handle/10024/90573/isbn9789522654151.pdf?isAllowed=y&sequence=2 (accessed on 27 February 2023).

- Ratzinger, J.M.; Buchberger, S.; Eichlseder, H. Electrified powertrains for wheel-driven non-road mobile machinery. Automot. Engine Technol. 2021, 6, 1–13. [Google Scholar] [CrossRef]

- Jalil, N.; Kheir, N.A.; Salman, M. A rule-based energy management strategy for a series hybrid vehicle. In Proceedings of the 1997 American Control Conference (Cat. No.97CH36041), Albuquerque, NM, USA, 6 June 1997; Volume 1, pp. 689–693. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Hu, B. A review of developments in energy storage systems for hybrid excavators. Autom. Constr. 2017, 80, 1–10. [Google Scholar] [CrossRef]

- Dong, J.; Huang, Y.; Jin, L.; Lin, H. Comparative Study of Surface-Mounted and Interior Permanent-Magnet Motors for High-Speed Applications. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- He, T.; Zhu, Z.; Eastham, F.; Wang, Y.; Bin, W.; Wu, D.; Gong, L.; Chen, J. Permanent Magnet Machines for High-Speed Applications. World Electr. Veh. J. 2022, 13, 18. [Google Scholar] [CrossRef]

- Sitapati, K.; Krishnan, R. Performance comparisons of radial and axial field, permanent-magnet, brushless machines. IEEE Trans. Ind. Appl. 2001, 37, 1219–1226. [Google Scholar] [CrossRef]

- Huang, R.; Song, Z.; Zhao, H.; Liu, C. Overview of Axial-Flux Machines and Modeling Methods. IEEE Trans. Transp. Electrif. 2022, 8, 2118–2132. [Google Scholar] [CrossRef]

- Hayes, J.; Goodarzi, G. Electric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell Vehicles; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Aghabali, I.; Bauman, J.; Kollmeyer, P.J.; Wang, Y.; Bilgin, B.; Emadi, A. 800-V Electric Vehicle Powertrains: Review and Analysis of Benefits, Challenges, and Future Trends. IEEE Trans. Transp. Electrif. 2021, 7, 927–948. [Google Scholar] [CrossRef]

- EMRAX Innovative E-Motors EMRAX 228. Available online: http://emrax.com/e-motors/emrax-228/ (accessed on 27 January 2023).

- Reimers, J.; Dorn-Gomba, L.; Mak, C.; Emadi, A. Automotive Traction Inverters: Current Status and Future Trends. IEEE Trans. Veh. Technol. 2019, 68, 3337–3350. [Google Scholar] [CrossRef]

- Emsiso emDrive 500. Available online: https://www.emdrive-mobility.com/portfolio/emdrive-500/ (accessed on 29 January 2023).

- CANopen—The Standardized Embedded Network. Available online: https://www.can-cia.org/canopen/ (accessed on 29 January 2023).

- Coroflex—High-Voltage and Charging Cables. Available online: https://www.coroflex-cable.com/en/high-voltage-cables (accessed on 27 January 2023).

- Power Cable Product Families. Available online: https://www.belden.com/products/cable/power-cable (accessed on 26 January 2023).

- DC/DC Converter 1000W Isolated 74-162 Volts. Available online: https://www.evwest.com/catalog/product_info.php?cPath=33&products_id=546&osCsid=19d45f613fc078cf0276c4ab8e9e7940 (accessed on 1 February 2023).

- TESLA Tech Note: HVIL Diagnostic Guide. Available online: https://static.nhtsa.gov/odi/tsbs/2014/SB-10052449-4313.pdf (accessed on 28 January 2023).

- IEC 61557-8:2014; Electrical Safety in Low Voltage Distribution Systems up to 1000 V a.c. and 1500 V d.c.-Equipment for Testing, Measuring or Monitoring of Protective Measures—Part 8: Insulation Monitoring Devices for IT Systems. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2014.

- ISO ISO 8820-8:2012; Road vehicles—Fuse-links—Part 8: Fuse-Links with Bolt-in Contacts (Type H and J) with Rated Voltage of 450 V. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO/TS 16949:2009; Quality Management Systems—Particular Requirements for the Application of ISO 9001:2008 for Automotive Production and Relevant Service Part Organizations. Available online: https://www.iso.org/standard/52844.html (accessed on 28 January 2023).

- Regenerative Frequency Converter CFW-11—User’s Manual. Available online: https://static.weg.net/medias/downloadcenter/h65/h1e/WEG-10005022198-14064791-r00-CFW11RB-users-manual-en.pdf (accessed on 30 January 2023).

- Adler Electric AE3 EV Fuse. Available online: https://www.adlerelectric.com/products/detail/151 (accessed on 30 January 2023).

- Littelfuse DCNSEV30-B-DCNSEV30 Series. Available online: https://www.littelfuse.com/products/dc-solenoids-and-relays/high-voltage-dc-contactor-relays/dcnsev30/dcnsev30-b.aspx (accessed on 31 January 2023).

- TE Connectivity HSA5027RJ Datasheet. Available online: https://www.te.com/usa-en/product-3-1625984-9.html (accessed on 31 January 2023).

- Bussmann Series High Speed Fuses-FWH-300A. Available online: https://www.eaton.com/us/en-us/skuPage.FWH-300A.specifications.html (accessed on 31 January 2023).

- TE Connectivity-EV200AAANA. Available online: https://www.te.com/usa-en/product-1618002-7.html (accessed on 31 January 2023).

- Novotny, D.W.; Lipo, T.A. Vector Control and Dynamics of AC Drives; Oxford University Press: New York, NY, USA, 1996; p. 440. [Google Scholar]

- Slemon, G.R. Dynamic Relations for Drive Systems. In Electric Machines and Drives; Addison-Wesley Publishing Company: Reading, PA, USA, 1992; pp. 354–360. [Google Scholar]

- Yuniarto, M.N.; Sidharta, I.; Yohanes, Y.; Nugraha, Y.U. On the Development and Experimental Validation of a Novel and Intuitive Interior Permanent Magnet Synchronous Motor Controller for Electric Vehicle Application. World Electr. Veh. J. 2022, 13, 107. [Google Scholar] [CrossRef]

- Parreiras, T.M.; Brandão, D.A.L.; Maia, T.A.C.; Pires, I.A.; Nascimento, A.; Cardoso, B.J. Field Weakening Strategies to Suppress Intermediate DC-DC Conversion Stages in Hybrid Construction Machinery. In Proceedings of the 2022 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Haining, China, 28–31 October 2022. [Google Scholar]

- Leonhard, W. Control of a Separately Excited DC Machine. In Control of Electrical Drives, 3rd ed.; Springer: Berlin, Germany, 2001; pp. 77–96. [Google Scholar]

- Franklin, G.F.; Powell, J.D.; Emani-Naeini, A. Basic Properties of Feedback. In Feedback Control of Dynamic Systems, 4th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002; pp. 200–269. [Google Scholar]

- Lorenz, R.D.; Lipo, T.A.; Novotny, D.W. Motion control with induction motors. Proc. IEEE 1994, 82, 1215–1240. [Google Scholar] [CrossRef]

- The MathWorks, Inc. Simulink-Simulation and Model-Based Design. Available online: https://www.mathworks.com/products/simulink.html (accessed on 24 March 2023).

- The MathWorks, Inc. Specialized Power Systems: Model Electrical Power Systems Using Specialized Components and Algorithms. Available online: https://www.mathworks.com/help/sps/specialized-power-systems.html (accessed on 24 March 2023).

| Standard | Title | Last Version |

|---|---|---|

| Regulation No. 100 [17] | Uniform provisions concerning the approval of vehicles with regard to specific requirements for the electric power train | 2022 |

| ISO 6469-2:2022 [18] | Electrically propelled road vehicles—Safety specifications—Part 2: Vehicle operational safety | 2022 |

| ISO 6469-3:2021 [19] | Electrically propelled road vehicles—Safety specifications—Part 3: Electrical safety | 2021 |

| ISO 6722-1:2011 [20] | Road vehicles—60 V and 600 V single-core cables—Part 1: Dimensions, test methods and requirements for copper conductor cables | 2011 |

| ISO 17409:2020 [21] | Electrically propelled road vehicles—Conductive power transfer—Safety requirements | 2020 |

| ISO 15118-1:2019-1 [22] | Road vehicles—Vehicle to grid communication interface—Part 1: General information and use-case definition | 2019 |

| ISO 26262-1:2018 [23] | Road vehicles—Functional safety—Part 1: Vocabulary | 2018 |

| BS EN 60529:1992+A2:2013 [24] | Degrees of protection provided by enclosures (IP Code) | 2013 |

| BS EN IEC 61851-1:2019 [25] | Electric vehicle conductive charging system—General requirements | 2019 |

| IEC 62485-3:2014 [26] | Safety requirements for secondary batteries and battery installations—Part 3: Traction batteries | 2013 |

| SAE J2344 [27] | Guidelines for Electric Vehicle Safety | 2020 |

| SAE J1797 [28] | Recommended Practice for Packaging of Electric Vehicle Battery Modules(STABILIZED Aug 2016) | 2016 |

| SAE J1939 [29] | Serial Control and Communications Heavy Duty Vehicle Network—Top Level Document | 2018 |

| Cycle | (kW) | (kW) | Cycle | (kW) | (kW) |

|---|---|---|---|---|---|

| 1 | 34.4 | 15.3 | 9 | 32.8 | 17.2 |

| 2 | 34.6 | 20.9 | 10 | 34.6 | 18.6 |

| 3 | 33.6 | 19.0 | 11 | 33.5 | 17.1 |

| 4 | 32.9 | 16.6 | 12 | 32.9 | 17.8 |

| 5 | 34.8 | 19.6 | 13 | 32.2 | 19.6 |

| 6 | 35.3 | 15.7 | 14 | 32.0 | 16.9 |

| 7 | 32.5 | 20.1 | 15 | 31.7 | 16.0 |

| 8 | 33.8 | 17.8 | 16 | 30.5 | 6.9 |

| Modules in series | 4 |

| Capacity | 5.2 kWh |

| Energy density | 198 Wh/kg |

| Minimum voltage | 72 V |

| Maximum voltage | 100.8 V |

| Nominal voltage | 88.8 V |

| Nominal current | 233 A |

| Maximum discharge power (3 s) | 120 kW |

| Continuous discharge power | 20 kW |

| Maximum power charge (10 min) | 32 kW |

| Continuous charge power | 20 kW |

| Discharge current (10 s) | 1000 A |

| Weight | 105.2 kg |

| Dimensions | 0.68 × 0.30 × 0.32 m |

| Volume | 65.3 l |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| 10.3 H | H | ||

| 1 | |||

| 50.6 Ω/s | |||

| 49.5 Nm/rad | |||

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| 1 | 2 | ||

| 3 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brandao, D.A.d.L.; Ramos, M.d.F.; Parreiras, T.M.; Maia, T.A.C.; Pires, I.A.; Corrêa, T.P.; Cardoso Filho, B.d.J.; Nascimento, A. Hybridization of a Backhoe Loader: Electric Drive System Design. Machines 2023, 11, 471. https://doi.org/10.3390/machines11040471

Brandao DAdL, Ramos MdF, Parreiras TM, Maia TAC, Pires IA, Corrêa TP, Cardoso Filho BdJ, Nascimento A. Hybridization of a Backhoe Loader: Electric Drive System Design. Machines. 2023; 11(4):471. https://doi.org/10.3390/machines11040471

Chicago/Turabian StyleBrandao, Dener A. de L., Mariana de F. Ramos, Thiago M. Parreiras, Thales A. C. Maia, Igor A. Pires, Tomás P. Corrêa, Braz de J. Cardoso Filho, and Anderson Nascimento. 2023. "Hybridization of a Backhoe Loader: Electric Drive System Design" Machines 11, no. 4: 471. https://doi.org/10.3390/machines11040471

APA StyleBrandao, D. A. d. L., Ramos, M. d. F., Parreiras, T. M., Maia, T. A. C., Pires, I. A., Corrêa, T. P., Cardoso Filho, B. d. J., & Nascimento, A. (2023). Hybridization of a Backhoe Loader: Electric Drive System Design. Machines, 11(4), 471. https://doi.org/10.3390/machines11040471