An Integrated Co-Design Optimization Toolchain Applied to a Conjugate Cam-Follower Drivetrain System

Abstract

1. Introduction

- (i)

- (ii)

- A pre-processor extracts the parametric Differential-Algebraic Equations (DAE) in symbolic form from Simscape. These white-box model equations can then be directly used in the gradient-based optimization problems listed next. They enable efficient (high-order) derivative evaluations through algorithmic differentiation [17]. This allows the optimization problems to run efficiently, eliminating the need for the use of (approximate) finite difference-based methods [18] or surrogate modelling [19] to derive the gradients [20].

- (iii)

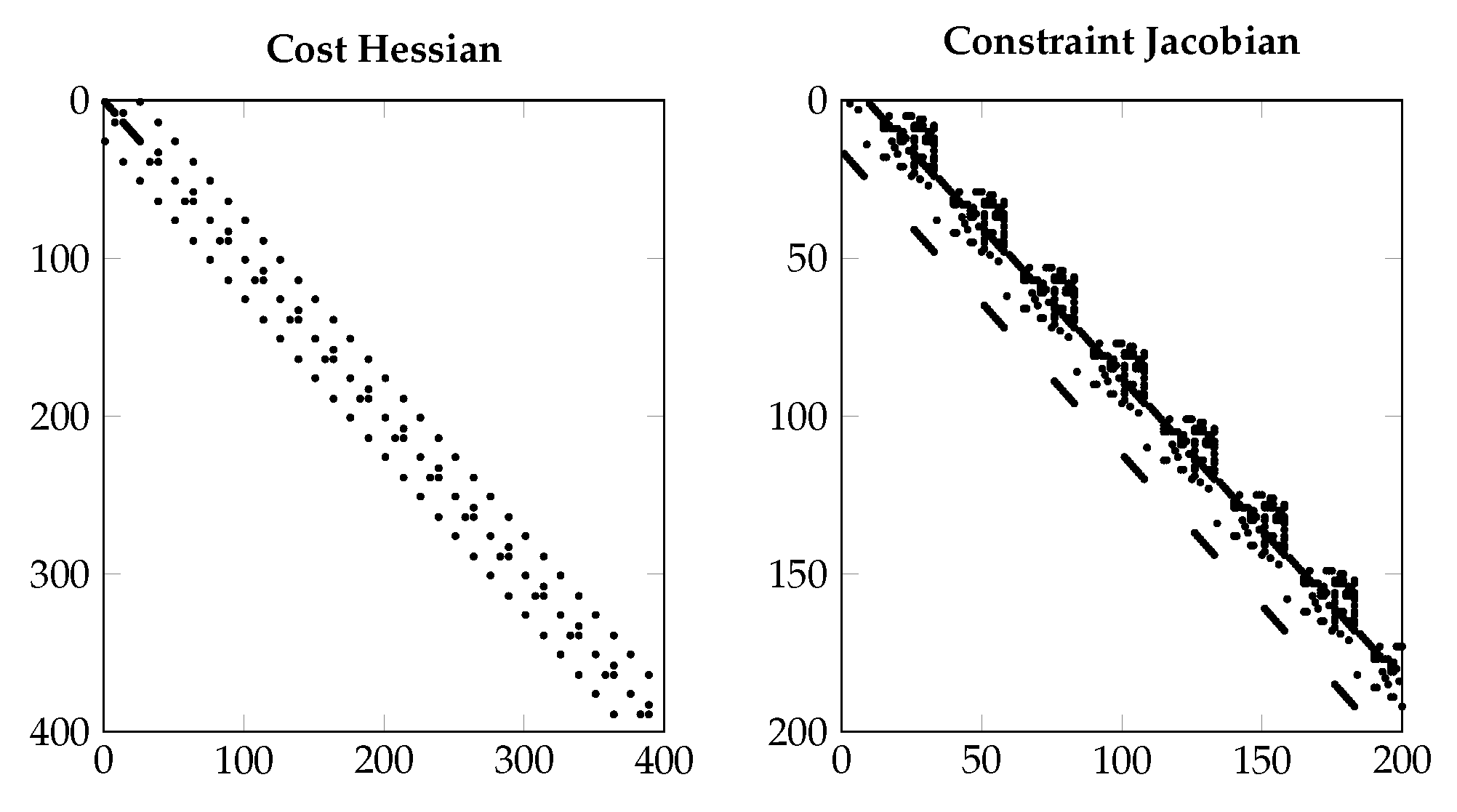

- Using the model, an Optimal Control Problem (OCP) is solved which optimizes the dynamic response and controls of the considered system according to a cost function and a set of constraints. A direct transcription of the OCP into a large-but-sparse Non-Linear Program (NLP) is performed using CasADi [17] and solved with IPOPT [21]. This approach scales well with horizon size and model order [22], and yields fast convergence.

- (iv)

- A co-design optimization is performed in a single optimization problem (i.e., a direct approach); design parameters are added as additional degrees of freedom in the NLP that encodes the OCP. Although a more complicated problem has to be solved, it can yield the optimal results significantly faster compared to a nested approach ([23,24]), as the optimization problem has to be solved only once.

2. Cam-Follower Drivetrain Model

- Industrial and commercial machinery for goods and services, for example, shoe making, steel, and weaving mill equipment, as well as paper printing presses.

- Agricultural machinery and robotics for pick-and-place or cyclic operations.

- Microelectromechanical systems (MEMS) for accurate micromachinery in miniature control systems.

- Automotive performance and optimization, such as in high-speed automotive valve operating systems.

- The input torque element;

- Damping elements representing the input–output dissipating energy;

- The inertia element of the conjugate cams and follower bodies;

- The conjugate cam-follower (interaction) element.

2.1. The Cam and Follower Inertia Parameterization

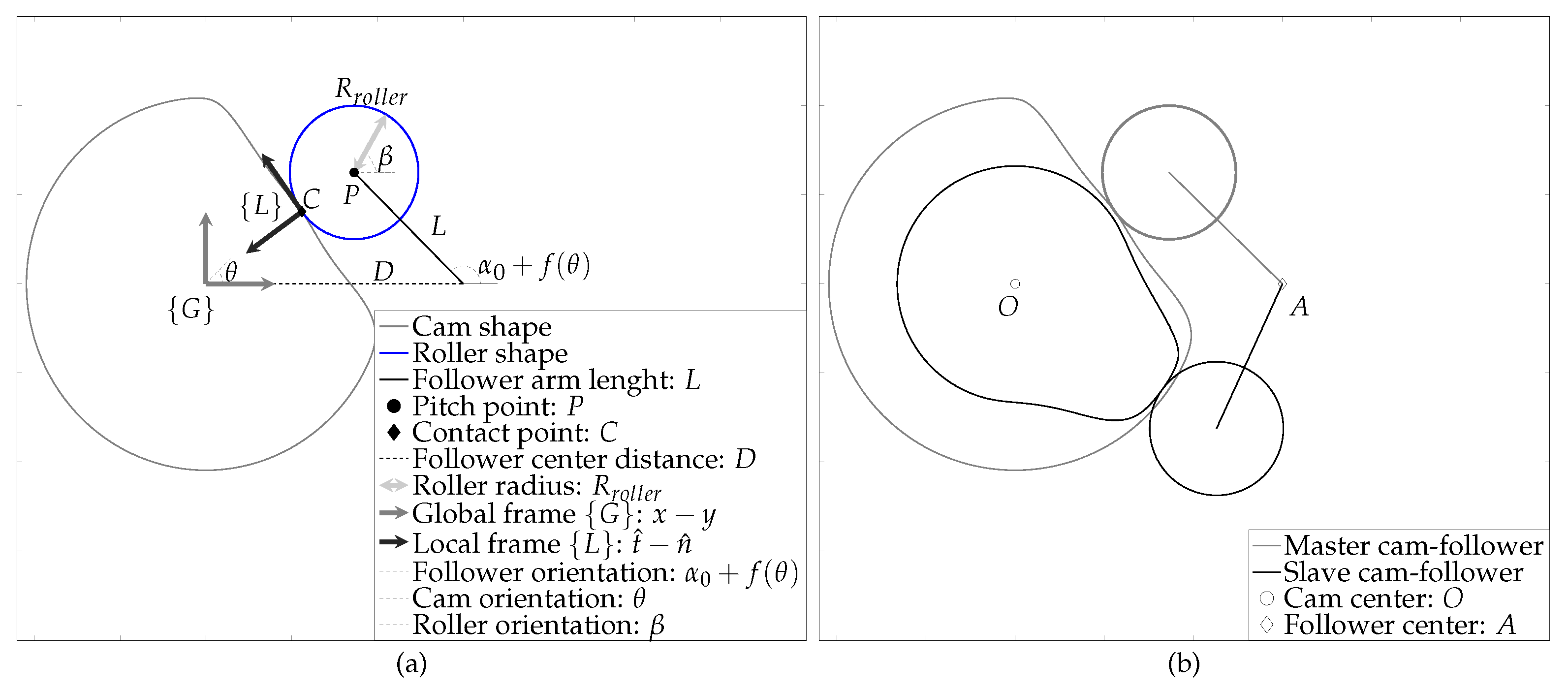

2.2. The Parameterized Cam-Follower Contact Element

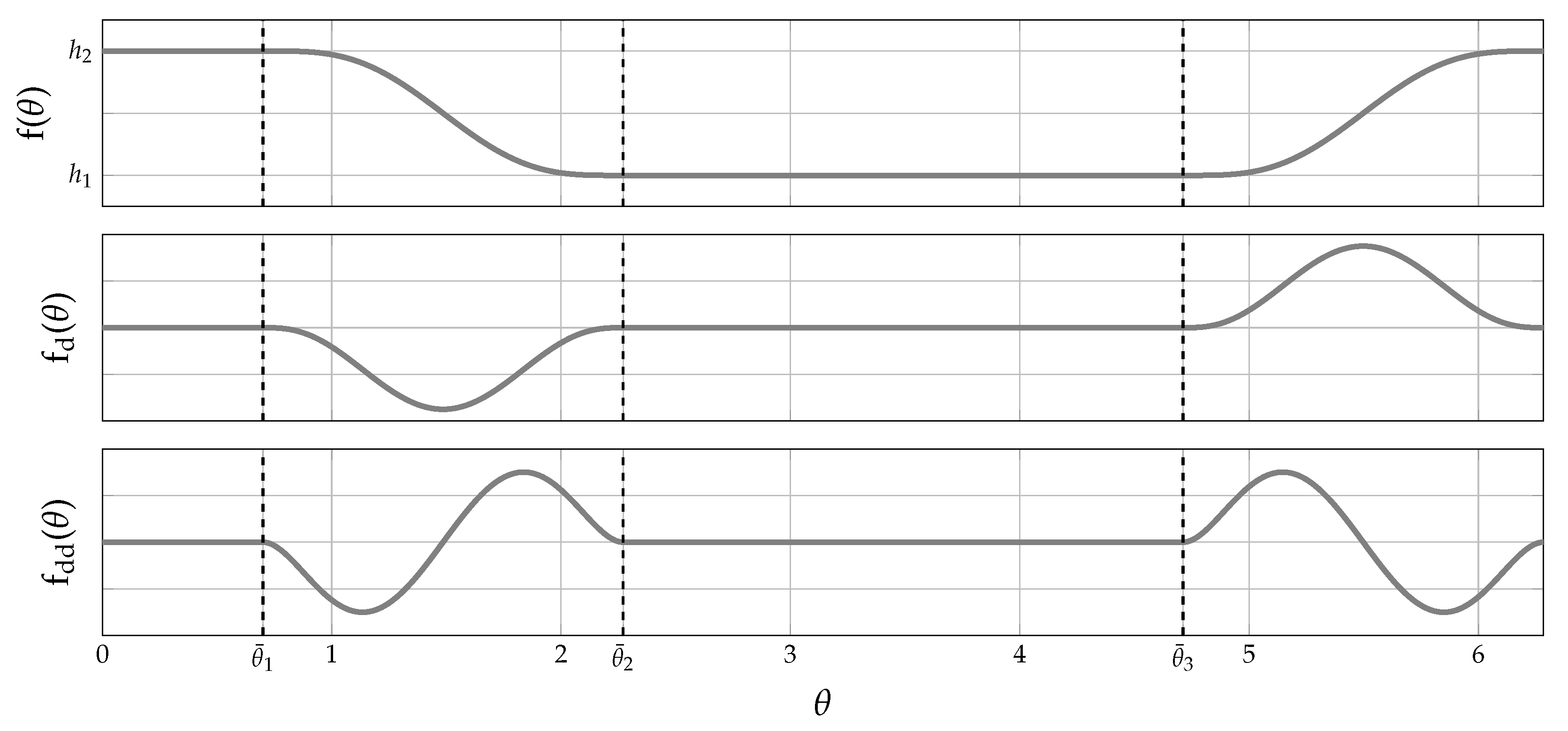

2.2.1. Piece-Wise Polynomial Follower Law

2.2.2. Cam-Follower: Non-Linear Contact Force Model

2.2.3. The Conjugate Cam-Follower Dynamic Equations

3. DriveTrain Co-Design Toolchain

- Creation of a high-fidelity drivetrain model in MATLAB Simscape.

- Extraction of symbolic equations from the Simscape model using the developed tool Simscape2CasADi. More information about this tool is provided in Section 3.1.

- Formulation of the optimization problems. A user-friendly interface is provided to set up the optimization problems. Two types of optimization problems are considered:

- Optimal control; see Section 3.2. In this case, the controls of the model are optimized according to a user-defined cost function and set of constraints.

- Concurrent design (co-design); see Section 3.3. In this case, both the controls and specific model parameters are optimized according to a cost function and a number of constraints defined by the user.

3.1. Simscape2CasADi: Extracting Symbolic Equations from Simscape

- C-code generation is performed on the Simulink model;

- The Simscape part of the C-code is parsed;

- A MATLAB class that implements , and using CasADi [17] symbols is created;

- The index of the DAE is optionally reduced with the help of MATLAB’s Symbolic Toolbox.

3.2. Optimal Control

3.2.1. Continuous-Time Optimal Control Problem

3.2.2. Transcription of the Continuous OCP to a Discrete-Time OCP

3.3. Concurrent Design with Optimal Control

3.4. Implementation in the Toolchain

- First, we initialize the Matlab class implementing the DriveTrain Co-Design toolchain.

- The second step is to supply a model to the toolchain. A manually derived model in the from of a DAE can be supplied. Alternatively, the proposed equation extraction from Simscape (using Simscape2CasADi) can be used. In the latter case, the user provides a Simulink model that includes a parameter file. Afterwards, the extracted model is returned as a Matlab structure that contains the extracted DAE model as a CasADi function (implementing Equation (17a)–(17c)) and a vector denoting the names of the extracted states, inputs, outputs, and parameters.

- Next, an OCP/co-design problem is initialized. The Matlab structure obtained in the previous step can then be directly loaded in by the toolchain to embed the model dynamics.

- If a co-design problem is considered, the user has to define which model parameters have to be optimized, along with their lower and upper bounds. If an OCP is considered, this option can be skipped.

- Next, the number of samples N and the sampling time have to be defined, along with a transcription method of choice:

- Multiple shooting with an integrator of choice (e.g., forward Euler, backward Euler, etc.);

- Direct collocation with a degree of choice.

- Lastly, the optimization problems are solved (by default, using IPOPT [21]), and the results are returned in a Matlab structure, which can then be visualized.

- Prior to solving, an initial guess for the optimization variables can be provided by the user in order to enhance the convergence of the solver.

4. Model Validation, Toolchain Application, and Results

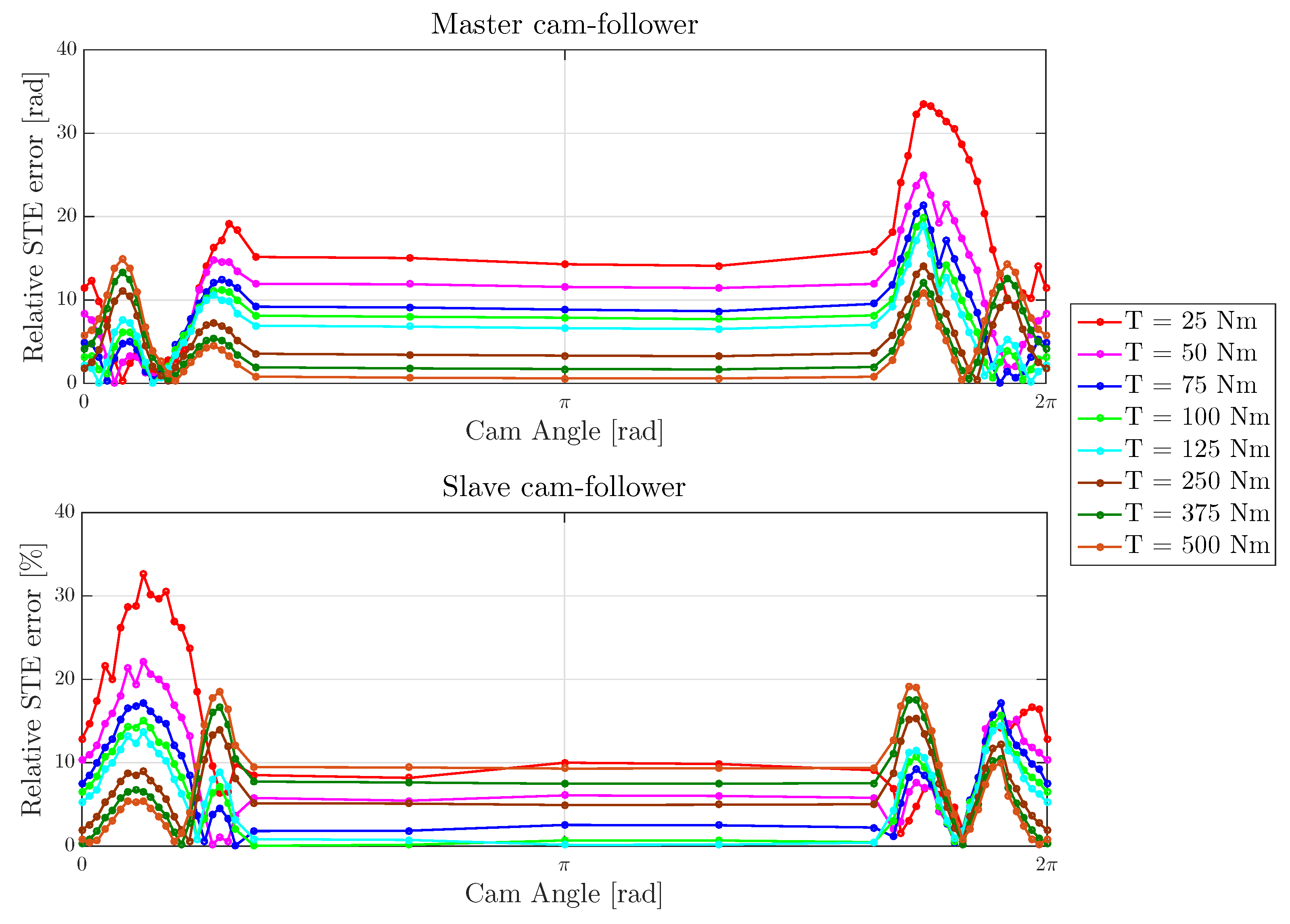

4.1. Conjugate Cam-Follower Model Validation

4.2. Cam-Follower Model Equation Extraction

4.3. Application of the Optimal Control and Design Optimization Problems

4.3.1. Optimal Control

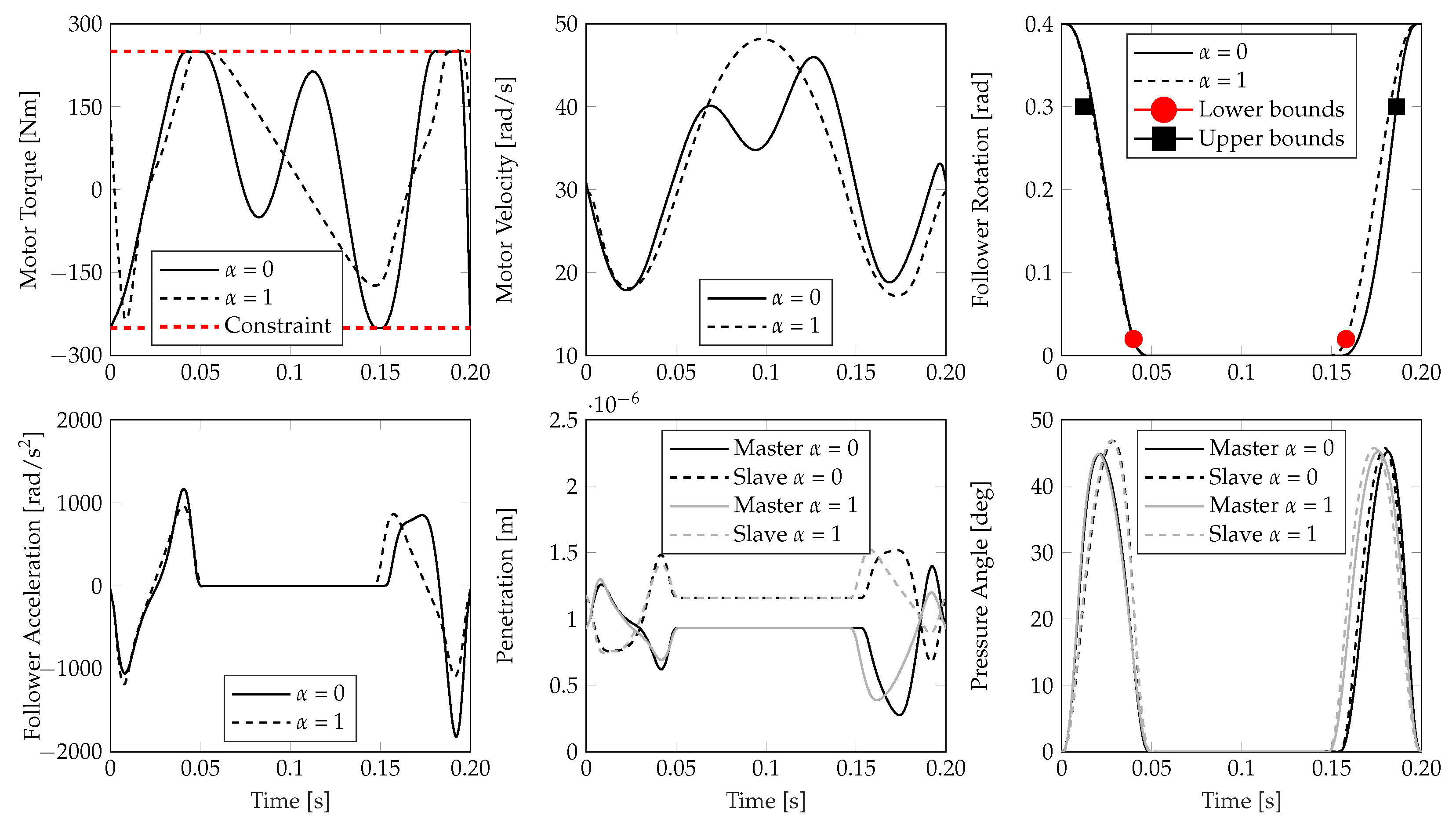

- Periodic results are obtained for both cases in terms of input and state responses.

- The results for the case where are fairly symmetric over the time axis in terms of motor velocity and follower accelerations, whereas the result for has more oscillations and shows quite a large peak in follower accelerations at the end of the time horizon, which minimizes energy at the cost of higher accelerations.

- For both cases, the penetration is well above 0. This is caused by the fact that the value of the preload is chosen rather conservatively in order to disallow separation of the contacting bodies, thereby circumventing discontinuities in motion and energy transfer.

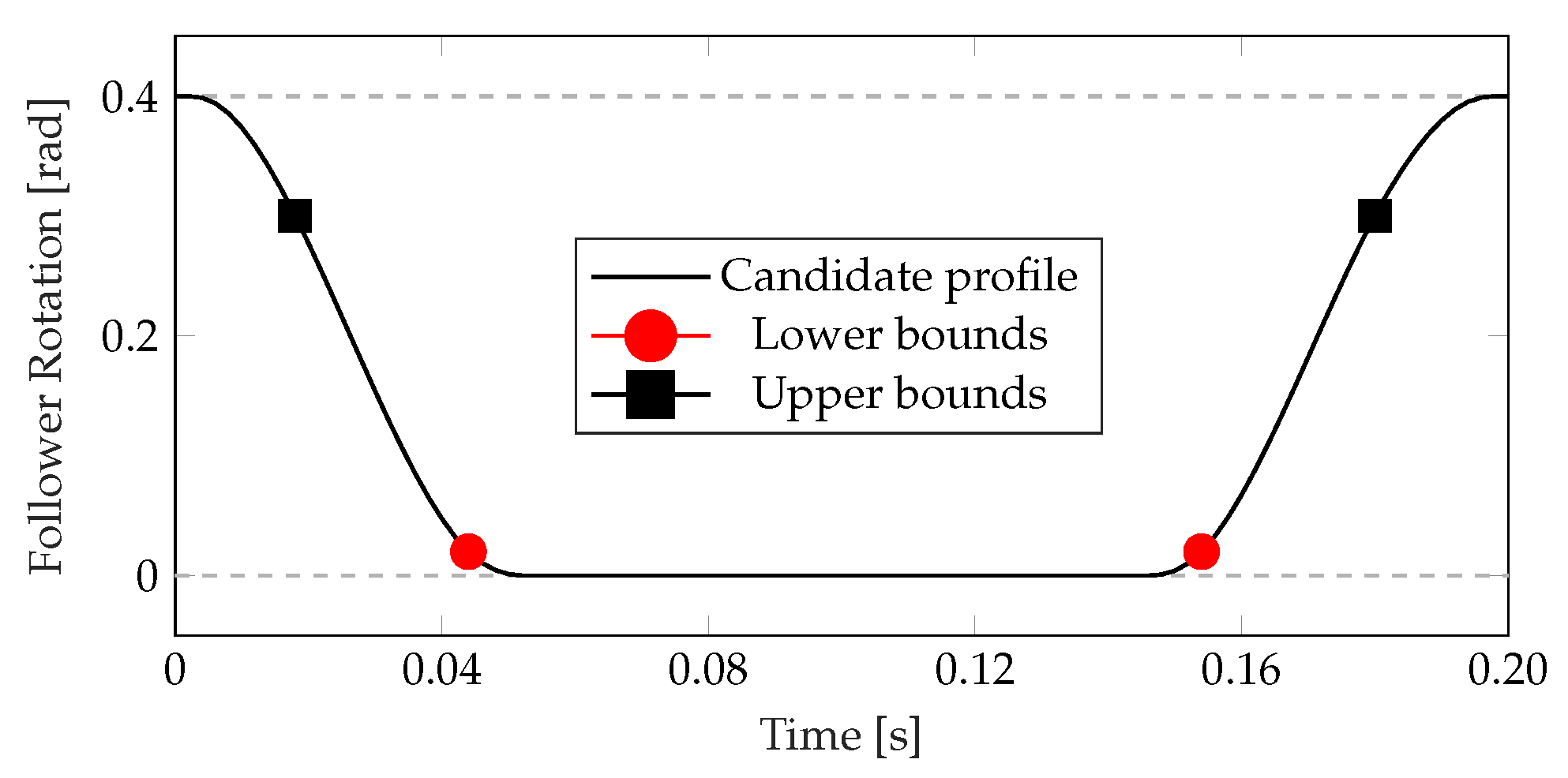

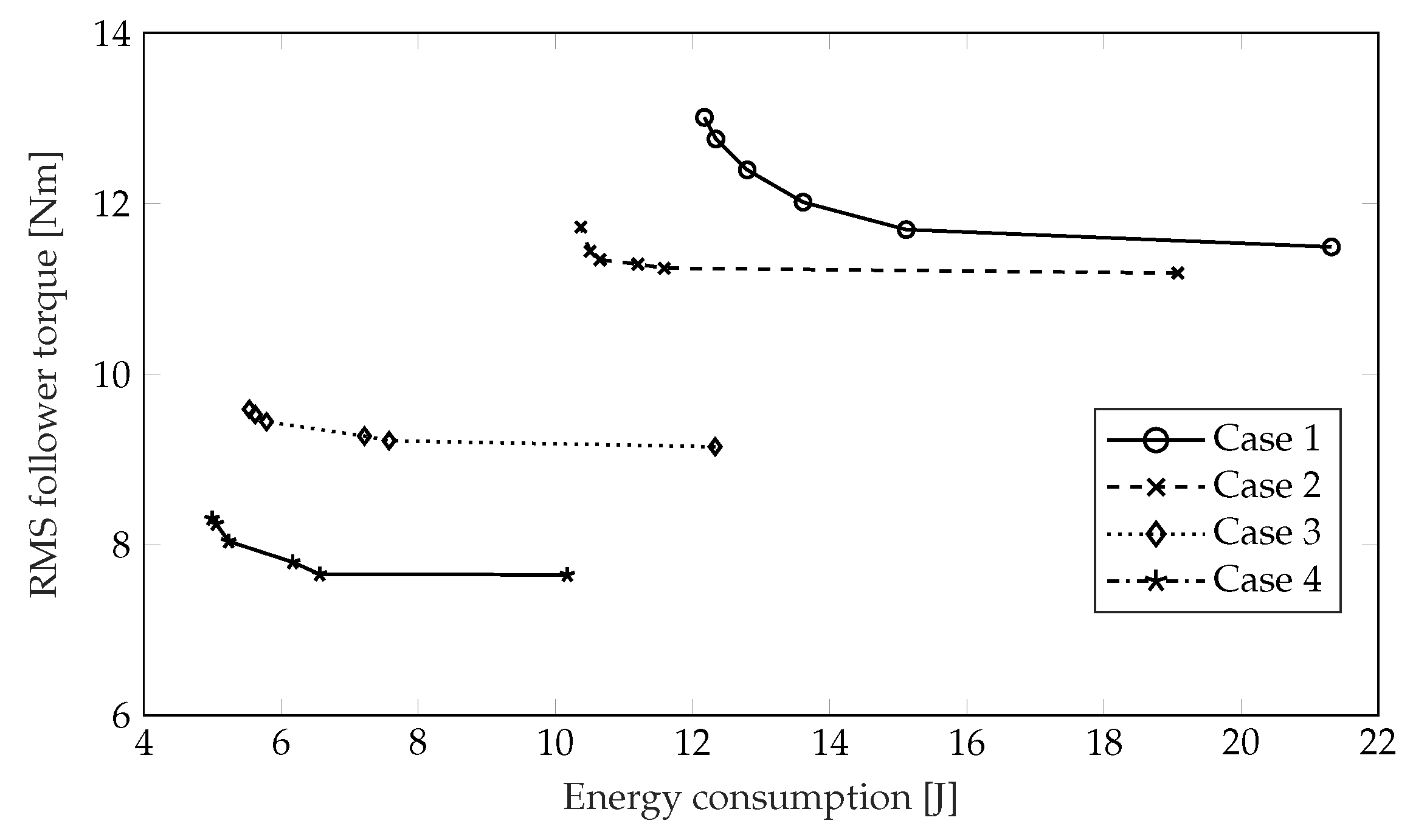

4.3.2. Co-Design

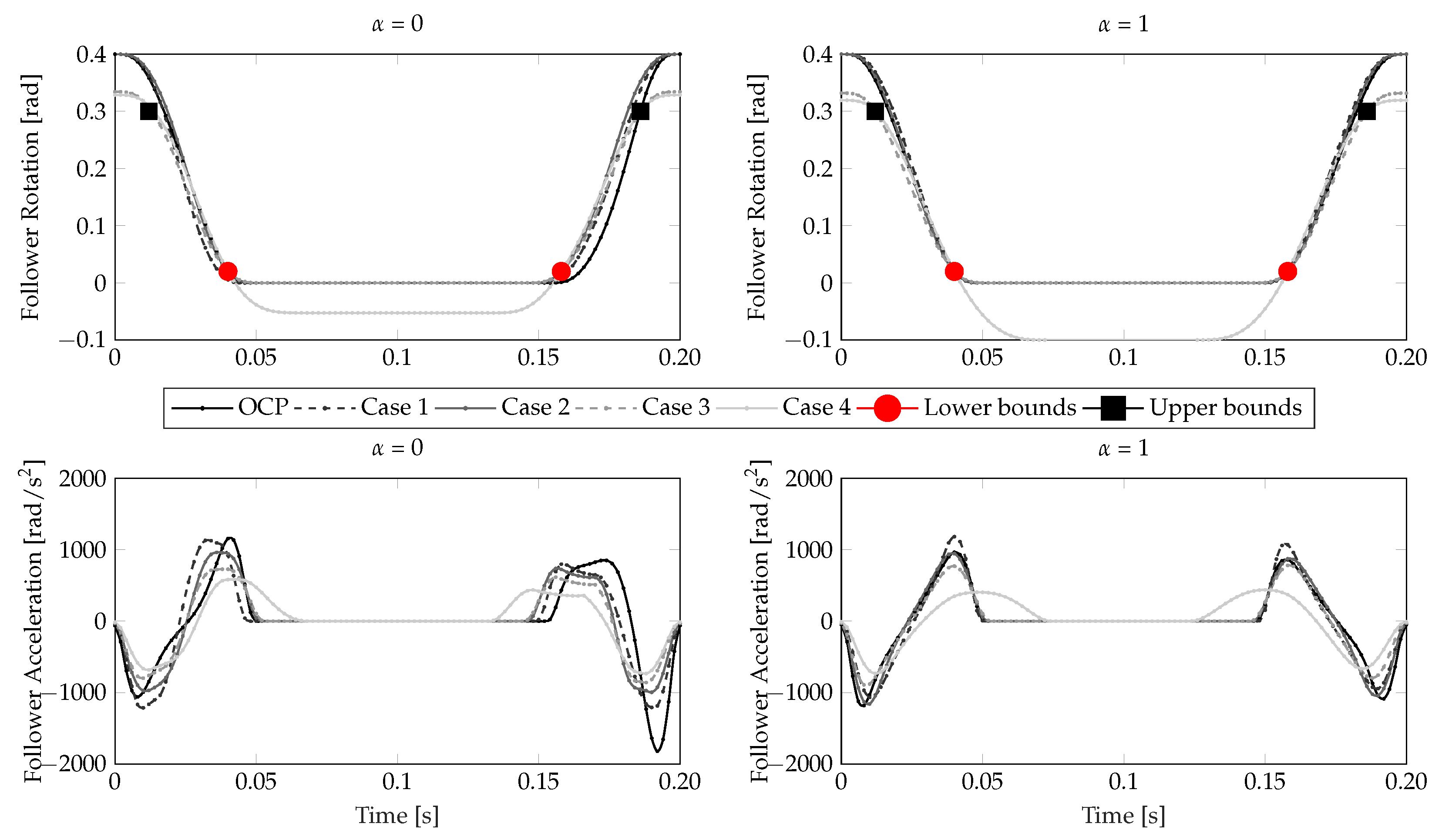

- Figure 13 shows the follower rotation and follower acceleration. Particularly in case 4, where is additionally optimized, a significant reduction in the follower acceleration (RMS, peak-to-peak) is obtained. For this case, “touches” the four-point constraints (Equation (28d)), whereas for in other cases this is not always true.

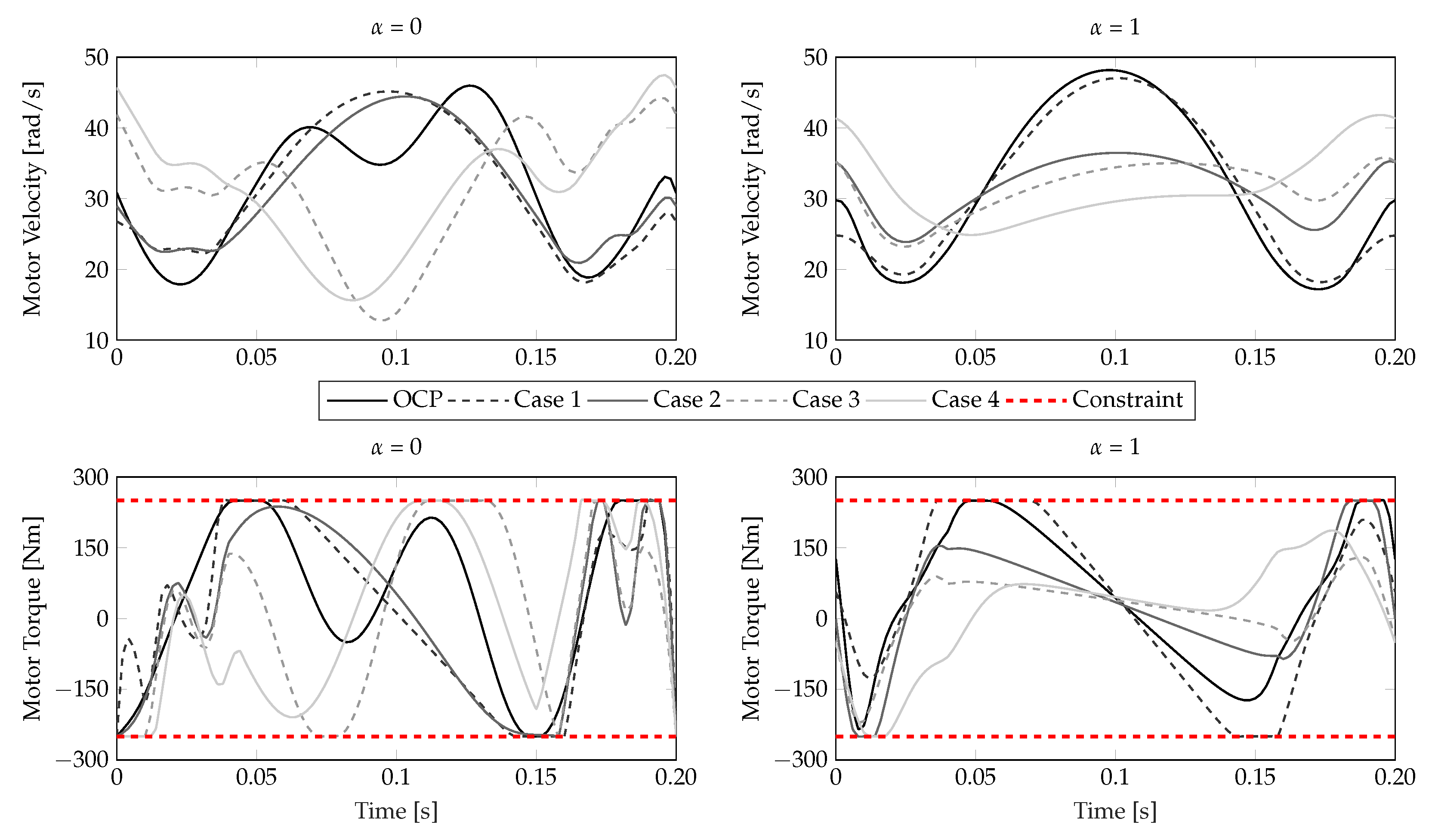

- Figure 14 shows the resulting motor velocities and motor torques. For , the motor velocity seems to behave in an almost anti-phase manner in cases 3 and 4 compared to the results of the OCP (cases 1 and 2). For , the motor velocity profiles are somewhat flattened in case 3 and 4. For , more oscillations are present in the signals compared to the case where .

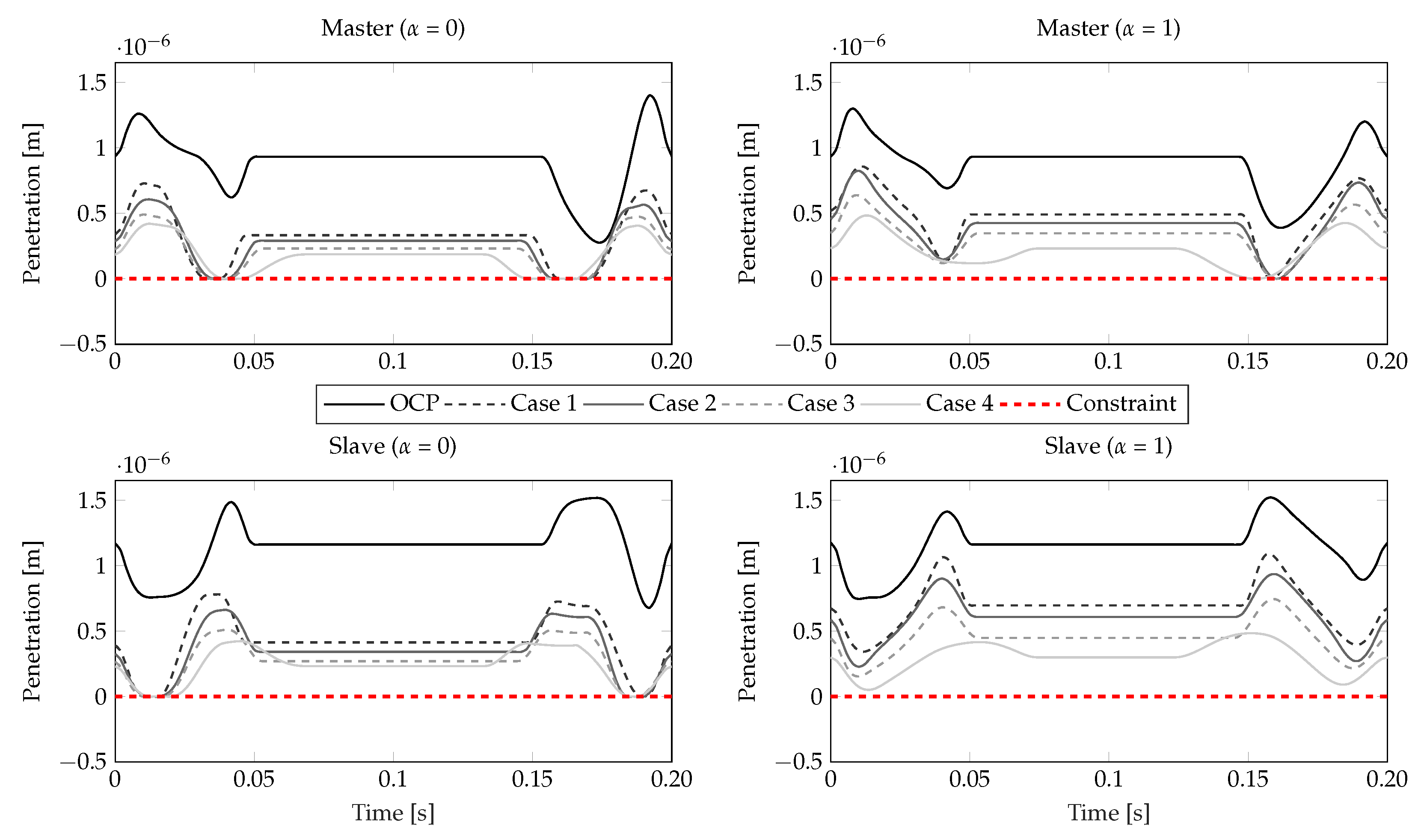

- The resulting penetration is shown in Figure 15. It can be seen that the penetration is well above zero for the OCP case, whereas for the co-design cases the penetration profiles move towards the lower bound of 0. This yields a lower energy and required torque for the target follower motion while maintaining contact between the bodies, thereby circumventing discontinuities in motion and energy transfer due to the applied lower bound.

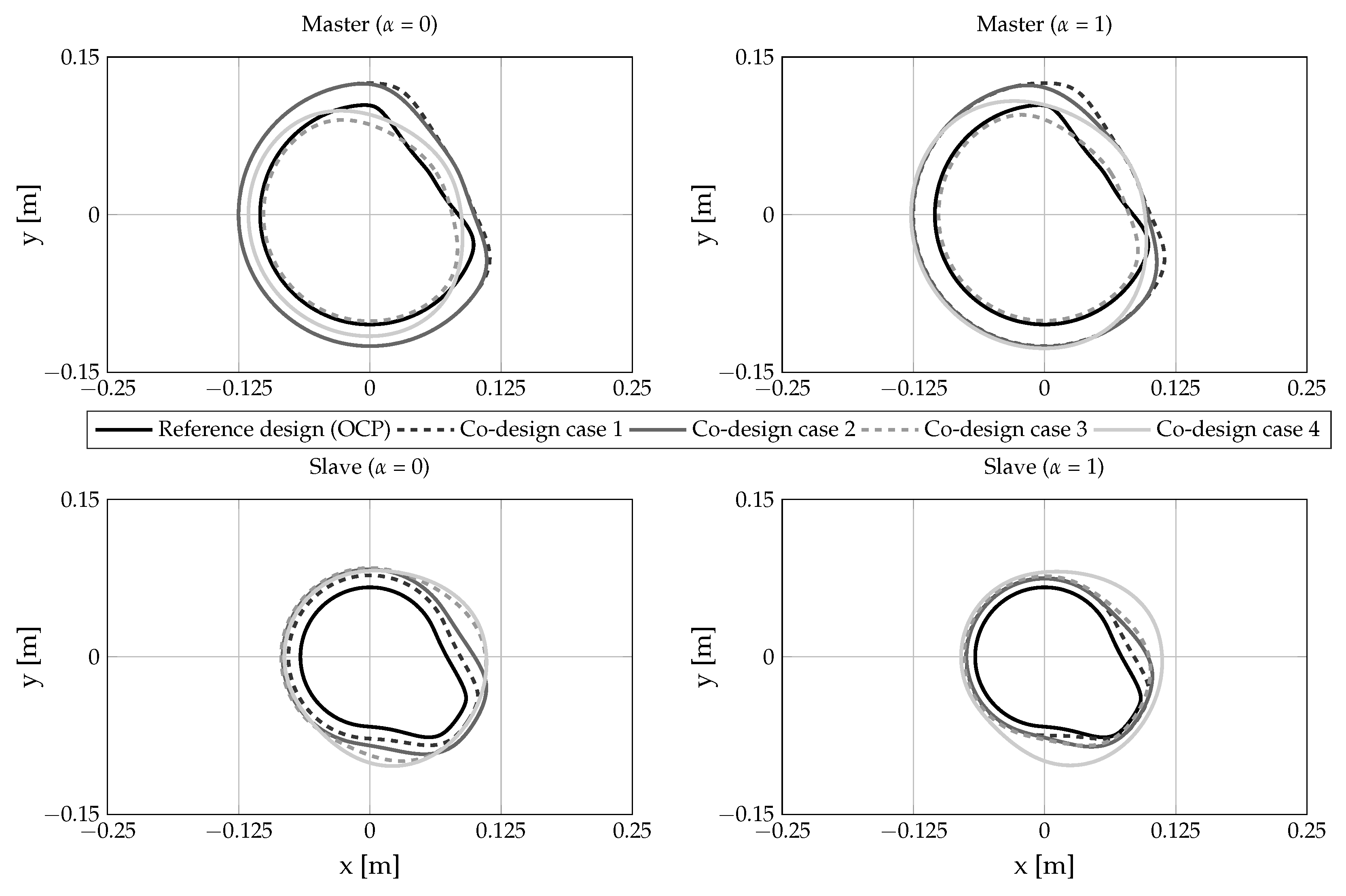

- The resulting shapes of the master and follower cams for each of the four co-design cases are shown in Figure 16 along with the reference design used for the OCP. In general, smoother geometries are obtained for higher case numbers compared to the reference design, which is due to the applied constraints on follower displacement (Equation (28d)). For co-design cases 1 and 2, the shapes remain rather similar to the reference design (OCP), although the absolute sizes are increased for both the master and the slave cam. For cases 3 and 4, the solutions lead to different cam designs overall due to the additional freedom in .

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FEM | Finite Element Method |

| LPM | Lumped Paramter Model |

| DC | Direct Current |

| n-D | n-dimensional space |

| DAE | Differential Algebraic Equation |

| ODE | Ordinary Differential Equation |

| OCP | Optimal Control Problem |

| NLP | Non-Linear Program |

| MEMS | Micro-Electronic Mechanical System |

| MPC | Model Predictive Control |

| PID | Proportional Integral Derivative |

| CAD | Computer-Aided Design |

| STE | Static Transmission Error |

| MPC | Multi-Point Contraint |

| integer numbers set | |

| real numbers set | |

| scalar | |

| column vector | |

| 3D vector | |

| 3D unit vector | |

| right-handed orthonormal axes system | |

| matrix | |

| lower bound | |

| upper bound | |

| inverse matrix operator | |

| time step | |

| , | time derivatives |

| total derivative | |

| partial derivative |

Appendix A. Analytical Inverse Kinematic Solution of the Cam-Follower System

Appendix A.1. Step 1: Calculation of the Pitch Point P and Its Derivatives Expressed in the Global Frame

Appendix A.2. Step 2: Compute the Angle ϕ n and Its Derivative

Appendix A.3. Step 3: Compute the Kinematic Contact Point C and Its Derivative with Respect to the Follower Center A

Appendix A.4. Step 4: Compute the Non-Kinematic Contact Point C′ and Its Derivative with Respect to the Follower Center A

Appendix A.5. Step 5: Transform All Variables to the Local Frame

Appendix A.6. Step 6: Compute the Contact Point Velocity and Project it onto the Tangential Axis

Appendix B. Design Parameters Resulting from the Optimization Solutions

[deg] | [deg] | [rad] | [m] | [m] | [m] | |

|---|---|---|---|---|---|---|

| LB | 110 | −160 | 0.14 | 0.08 | 0.08 | |

| UB | 160 | −110 | 0.20 | 0.20 | 0.20 | |

| 110 | −130.2 | 4.54 × | 0.171 | 0.08 | 0.0857 | |

| 110 | −130.09 | 4.56 × | 0.171 | 0.08 | 0.0860 | |

| 110 | −128.26 | 4.60 × | 0.171 | 0.08 | 0.0867 | |

| 110 | −130.02 | 4.85 × | 0.171 | 0.08 | 0.0859 | |

| 110 | −130.02 | 5.17 × | 0.171 | 0.08 | 0.0859 | |

| 110 | −132.75 | 7.6 × | 0.171 | 0.08 | 0.08 |

[deg] | [deg] | [rad] | D [m] | [m] | [m] | [rad] | |

|---|---|---|---|---|---|---|---|

| LB | 110 | −160 | 0.14 | 0.08 | 0.08 | 0 | |

| UB | 160 | −110 | 0.20 | 0.20 | 0.20 | ||

| 110 | −126.45 | 3.79 × | 0.171 | 0.08 | 0.0871 | [1.23, 3.71, 1.33] | |

| 110 | −124.79 | 3.95 × | 0.172 | 0.08 | 0.0819 | [1.25, 3.59, 1.42] | |

| 110 | −126.18 | 4.0 × | 0.172 | 0.08 | 0.0812 | [1.25, 3.59, 1.43] | |

| 110 | −126.88 | 4.14 × | 0.172 | 0.08 | 0.0831 | [1.35, 3.38, 1.55] | |

| 110 | −128.61 | 4.2 × | 0.172 | 0.08 | 0.0867 | [1.36, 3.34, 1.57] | |

| 110 | −133.01 | 6.64 × | 0.172 | 0.08 | 0.08 | [1.42, 3.28, 1.57] |

[deg] | [deg] | [rad] | D [m] | [m] | [m] | [rad] | [m] | |

|---|---|---|---|---|---|---|---|---|

| LB | 110 | −160 | 0.14 | 0.08 | 0.08 | 0 | 0.3 | |

| UB | 160 | −110 | 0.20 | 0.20 | 0.20 | 0.5 | ||

| 112.08 | −125.58 | 3.08 × | 0.147 | 0.08 | 0.083 | [1.74, 2.38, 2.15 ] | 0.334 | |

| 112.04 | −126.1 | 3.14 × | 0.147 | 0.08 | 0.083 | [1.75, 2.30, 2.21 ] | 0.333 | |

| 112.17 | −126.17 | 3.2 × | 0.147 | 0.08 | 0.083 | [1.76, 2.20, 2.31 ] | 0.332 | |

| 112.31 | −124.41 | 3.15 × | 0.147 | 0.08 | 0.084 | [1.29, 3.11, 1.87] | 0.330 | |

| 112.37 | −122.81 | 3.2 × | 0.147 | 0.08 | 0.086 | [1.32, 3.07, 1.88 ] | 0.330 | |

| 112.25 | −131.32 | 5.03 × | 0.147 | 0.08 | 0.08 | [1.40, 3.09, 1.77] | 0.331 |

[deg] | [deg] | [rad] | D [m] | [m] | [m] | [rad] | [m] | [m] | |

|---|---|---|---|---|---|---|---|---|---|

| LB | 110 | −160 | 0.14 | 0.08 | 0.08 | 0 | 0.3 | −0.1 | |

| UB | 160 | −110 | 0.20 | 0.20 | 0.20 | 0.5 | 0.1 | ||

| 111.15 | −124.8 | 2.63 × | 0.157 | 0.08 | 0.08 | [2.26, 1.49, 2.52] | 0.381 | −0.052 | |

| 111.08 | −125.25 | 2.67 × | 0.158 | 0.08 | 0.08 | [2.28, 1.43, 2.56] | 0.383 | −0.054 | |

| 111.07 | −124.21 | 2.64 × | 0.161 | 0.08 | 0.08 | [2.29, 1.35, 2.63 ] | 0.394 | −0.067 | |

| 110.88 | −122.98 | 2.62 × | 0.164 | 0.08 | 0.08 | [2.09, 1.62, 2.56] | 0.409 | −0.086 | |

| 110.83 | −121.83 | 2.69 × | 0.166 | 0.08 | 0.08 | [2.14, 1.4, 2.70 ] | 0.420 | −0.099 | |

| 110.91 | −123.52 | 3.38 × | 0.166 | 0.08 | 0.08 | [2.18, 1.45, 2.64] | 0.419 | −0.1 |

References

- Taub, A.I. Automotive materials: Technology trends and challenges in the 21st century. MRS Bull. 2006, 31, 336–343. [Google Scholar] [CrossRef]

- Broy, M.; Kirstan, S.; Krcmar, H.; Schätz, B. What is the benefit of a model-based design of embedded software systems in the car industry? In Emerging Technologies for the Evolution and Maintenance of Software Models; IGI Global: Hershey, PA, USA, 2012; pp. 343–369. [Google Scholar]

- Reedy, J.; Lunzman, S. Model Based Design Accelerates the Development of Mechanical Locomotive Controls; Technical report; SAE Technical Paper: Warrendale, PA, USA, 2010. [Google Scholar]

- Struss, P.; Price, C. Model-based systems in the automotive industry. AI Mag. 2003, 24, 17. [Google Scholar]

- Kang, Y.H.; Huang, H.C.; Yang, B.Y. Optimal Design and Dynamic Analysis of a Spring-Actuated Cam-Linkage Mechanism in a Vacuum Circuit Breaker. Machines 2023, 11, 150. [Google Scholar] [CrossRef]

- Chen, C.Y.; Cheng, C.C. Integrated design for a mechatronic feed drive system of machine tools. In Proceedings of the 2005 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Chongqing, China, 20–23 September 2005; pp. 588–593. [Google Scholar]

- Fathy, H.K.; Reyer, J.A.; Papalambros, P.Y.; Ulsov, A. On the coupling between the plant and controller optimization problems. In Proceedings of the 2001 American Control Conference.(Cat. No. 01CH37148), Arlington, VA, USA, 25–27 June 2001; Volume 3, pp. 1864–1869. [Google Scholar]

- Silvas, E.; Hofman, T.; Murgovski, N.; Etman, L.P.; Steinbuch, M. Review of optimization strategies for system-level design in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2016, 66, 57–70. [Google Scholar] [CrossRef]

- Haemers, M.; Derammelaere, S.; Rosich, A.; Ionescu, C.M.; Stockman, K. Towards a generic optimal co-design of hardware architecture and control configuration for interacting subsystems. Mechatronics 2019, 63, 102275. [Google Scholar] [CrossRef]

- Yang, Y.P.; Chen, Y.A. Multiobjective optimization of hard disk suspension assemblies: Part II—Integrated structure and control design. Comput. Struct. 1996, 59, 771–782. [Google Scholar] [CrossRef]

- Alyaqout, S.F.; Papalambros, P.Y.; Ulsoy, A.G. Combined robust design and robust control of an electric DC motor. IEEE/ASME Trans. Mechatronics 2010, 16, 574–582. [Google Scholar] [CrossRef]

- Allison, J.T.; Guo, T.; Han, Z. Co-design of an active suspension using simultaneous dynamic optimization. J. Mech. Des. 2014, 136, 081003. [Google Scholar] [CrossRef]

- Yan, H.S.; Yan, G.J. Integrated control and mechanism design for the variable input-speed servo four-bar linkages. Mechatronics 2009, 19, 274–285. [Google Scholar] [CrossRef]

- Herber, D.R.; Allison, J.T. Nested and simultaneous solution strategies for general combined plant and control design problems. J. Mech. Des. 2019, 141, 011402. [Google Scholar] [CrossRef]

- Hassell, T.J.; Weaver, W.W.; Oliveira, A.M. Using Matlab’s Simscape modeling environment as a simulation tool in power electronics and electrical machines courses. In Proceedings of the 2013 IEEE Frontiers in Education Conference (FIE), Oklahoma City, OK, USA, 23–26 October 2013; pp. 477–483. [Google Scholar]

- Li, C. Development of Simscape simulation model for power system stability analysis. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012; pp. 1–4. [Google Scholar]

- Andersson, J.A.E.; Gillis, J.; Horn, G.; Rawlings, J.B.; Diehl, M. CasADi—A software framework for nonlinear optimization and optimal control. Math. Program. Comput. 2019, 11, 1–36. [Google Scholar] [CrossRef]

- Neidinger, R.D. Introduction to automatic differentiation and MATLAB object-oriented programming. SIAM Rev. 2010, 52, 545–563. [Google Scholar] [CrossRef]

- Qiao, P.; Wu, Y.; Ding, J.; Zhang, Q. A new sequential sampling method of surrogate models for design and optimization of dynamic systems. Mech. Mach. Theory 2021, 158, 104248. [Google Scholar] [CrossRef]

- Falisse, A.; Serrancolí, G.; Dembia, C.L.; Gillis, J.; De Groote, F. Algorithmic differentiation improves the computational efficiency of OpenSim-based trajectory optimization of human movement. PLoS ONE 2019, 14, e0217730. [Google Scholar] [CrossRef] [PubMed]

- Wächter, A.; Biegler, L.T. On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math. Program. 2006, 106, 25–57. [Google Scholar] [CrossRef]

- Andersson, J. A General-Purpose Software Framework for Dynamic Optimization (Een Algemene Softwareomgeving Voor Dynamische Optimalisatie). Ph.D. Thesis, KU Leuven University, Leuven, Belgium, 2013. [Google Scholar]

- Rayner, R.M.; Sahinkaya, M.N.; Hicks, B. Improving the design of high speed mechanisms through multi-level kinematic synthesis, dynamic optimization and velocity profiling. Mech. Mach. Theory 2017, 118, 100–114. [Google Scholar] [CrossRef]

- Ouyang, T.; Wang, P.; Huang, H.; Zhang, N.; Chen, N. Mathematical modeling and optimization of cam mechanism in delivery system of an offset press. Mech. Mach. Theory 2017, 110, 100–114. [Google Scholar] [CrossRef]

- Shi, X.D.; Shen, S.H.; Chai, C.W. Application of Conjugate Cam Design Software Platform in Die Cutting Platen Press Mechanism. Appl. Mech. Mater. 2012, 127, 207–213. [Google Scholar] [CrossRef]

- Jin, H.; Cui, Y.; Li, J. Design and analysis of cam cutting mechanism with oscillating follower for PC steel bars. Adv. Mech. Eng. 2017, 9, 1687814017737253. [Google Scholar] [CrossRef]

- Rothbart, H. Cam Design Handbook; McGraw-Hill Handbooks; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Yousuf, L.S. Detachment Detection in Cam Follower System Due to Nonlinear Dynamics Phenomenon. Machines 2021, 9, 349. [Google Scholar] [CrossRef]

- Jensen, P.W. Cam Design and Manufacture; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Lee, T.M.; Lee, D.Y.; Lee, H.C.; Yang, M.Y. Design of cam-type transfer unit assisted with conjugate cam and torque control cam. Mech. Mach. Theory 2009, 44, 1144–1155. [Google Scholar] [CrossRef]

- Norton, R. Design of Machinery: An Introduction to the Synthesis and Analysis of Mechanisms and Machines; McGraw-Hill series in mechanical engineering; McGraw-Hill Higher Education: New York, NY, USA, 2003. [Google Scholar]

- Nguyen, V.T.; Kim, D.J. Flexible cam profile synthesis method using smoothing spline curves. Mech. Mach. Theory 2007, 42, 825–838. [Google Scholar] [CrossRef]

- Hidalgo-Martínez, M.; Sanmiguel-Rojas, E.; Burgos, M. Design of cams with negative radius follower using Bézier curves. Mech. Mach. Theory 2014, 82, 87–96. [Google Scholar] [CrossRef]

- Zhou, C.; Hu, B.; Chen, S.; Ma, L. Design and analysis of high-speed cam mechanism using Fourier series. Mech. Mach. Theory 2016, 104, 118–129. [Google Scholar] [CrossRef]

- Müller, M.; Hüsing, M.; Beckermann, A.; Corves, B. Linkage and Cam Design with MechDev Based on Non-Uniform Rational B-Splines. Machines 2020, 8, 5. [Google Scholar] [CrossRef]

- Wriggers, P. Computational Contact Mechanics; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Weber, C.; Banaschek, K.; Niemann, G. Formänderung und Profilrücknahme bei Gerad-und Schrägverzahnten Rädern; Vieweg-Verlag: Braunschweig, Germany, 1955. [Google Scholar]

- Johnson, K.L.; Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Gillis, J. Effortless NLP modeling with CasADi’s Opti stack. In Proceedings of the Benelux Meeting on Systems and Control, Soesterberg, The Netherlands, 27–29 March 2018. [Google Scholar]

- Gillis, J.; Kikken, E. Symbolic Equation Extraction from SimScape. In Proceedings of the Benelux Meeting on Systems and Control, Soesterberg, The Netherlands, 27–29 March 2018. [Google Scholar]

- Gillis, J. Practical Methods for Approximate Robust Periodic Optimal Control of Nonlinear Mechanical Systems. Ph.D. Thesis, KU Leuven University, Leuven, Belgium, 2015. [Google Scholar]

- Bock, H.G.; Plitt, K.J. A multiple shooting algorithm for direct solution of optimal control problems. IFAC Proc. Vol. 1984, 17, 1603–1608. [Google Scholar] [CrossRef]

- van de Wijdeven, J.; Bosgra, O.H. Using basis functions in iterative learning control: Analysis and design theory. Int. J. Control 2010, 83, 661–675. [Google Scholar] [CrossRef]

- Camacho, E.F.; Alba, C.B. Model Predictive Control; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Fritzson, P. Introduction to Modeling and Simulation of Technical and Physical Systems with Modelica; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Miller, S.; Soares, T.; Van Weddingen, Y.; Wendlandt, J. Modeling flexible bodies with simscape multibody software. An Overview of Two Methods for Capturing the Effects of Small Elastic Deformations; MathWorks: Natick, MA, USA, 2017. [Google Scholar]

- Croes, J. Virtual Sensing in Mechatronic Systems. State Estimation Using System Level Models. Ph.D. Thesis, KU Leuven University, Leuven, Belgium, 2017. [Google Scholar]

| Polynomial Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sectors | ||||||||

| 1 | + | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | + | 0 | 0 | 0 | −35 | 84 | −70 | 20 |

| 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 4 | 0 | 0 | 0 | 35 | −84 | 70 | −20 | |

| Symbol | Master Value | Slave Value | Unit |

|---|---|---|---|

| 37.5 × | 37.5 × | m | |

| D | 150 × | 150 × | m |

| L | 89.2 × | 89.2 × | m |

| B | 34.5 × | 34.5 × | m |

| 1.96 | −2.40 | rad |

| Symbol | Value | Unit |

|---|---|---|

| 0 | rad | |

| 0.4 | rad | |

| [0 1.12 4.04 5.16] | rad |

| Symbol | Value | Unit |

|---|---|---|

| 7829 | kg/m | |

| E | 200 × | MPa |

| 0.3 | - |

[deg] | [deg] | [rad] | [m] | [m] | [m] | [rad] | [m] | [m] | |

|---|---|---|---|---|---|---|---|---|---|

| Lower bound | 110 | 110 | 1 × | 0.14 | 0.08 | 0.08 | 0 | 0.3 | −0.1 |

| Upper bound | 160 | 160 | 1 × | 0.20 | 0.20 | 0.20 | 0.5 | 0.1 | |

| Case 1 | × | × | × | × | × | × | |||

| Case 2 | × | × | × | × | × | × | × | ||

| Case 3 | × | × | × | × | × | × | × | × | |

| Case 4 | × | × | × | × | × | × | × | × | × |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adduci, R.; Willems, J.; Kikken, E.; Gillis, J.; Croes, J.; Desmet, W. An Integrated Co-Design Optimization Toolchain Applied to a Conjugate Cam-Follower Drivetrain System. Machines 2023, 11, 486. https://doi.org/10.3390/machines11040486

Adduci R, Willems J, Kikken E, Gillis J, Croes J, Desmet W. An Integrated Co-Design Optimization Toolchain Applied to a Conjugate Cam-Follower Drivetrain System. Machines. 2023; 11(4):486. https://doi.org/10.3390/machines11040486

Chicago/Turabian StyleAdduci, Rocco, Jeroen Willems, Edward Kikken, Joris Gillis, Jan Croes, and Wim Desmet. 2023. "An Integrated Co-Design Optimization Toolchain Applied to a Conjugate Cam-Follower Drivetrain System" Machines 11, no. 4: 486. https://doi.org/10.3390/machines11040486

APA StyleAdduci, R., Willems, J., Kikken, E., Gillis, J., Croes, J., & Desmet, W. (2023). An Integrated Co-Design Optimization Toolchain Applied to a Conjugate Cam-Follower Drivetrain System. Machines, 11(4), 486. https://doi.org/10.3390/machines11040486