Optimization Design and Pressure Fluctuation Suppression Based on Orthogonal Method for a Centrifugal Compressor

Abstract

:1. Introduction

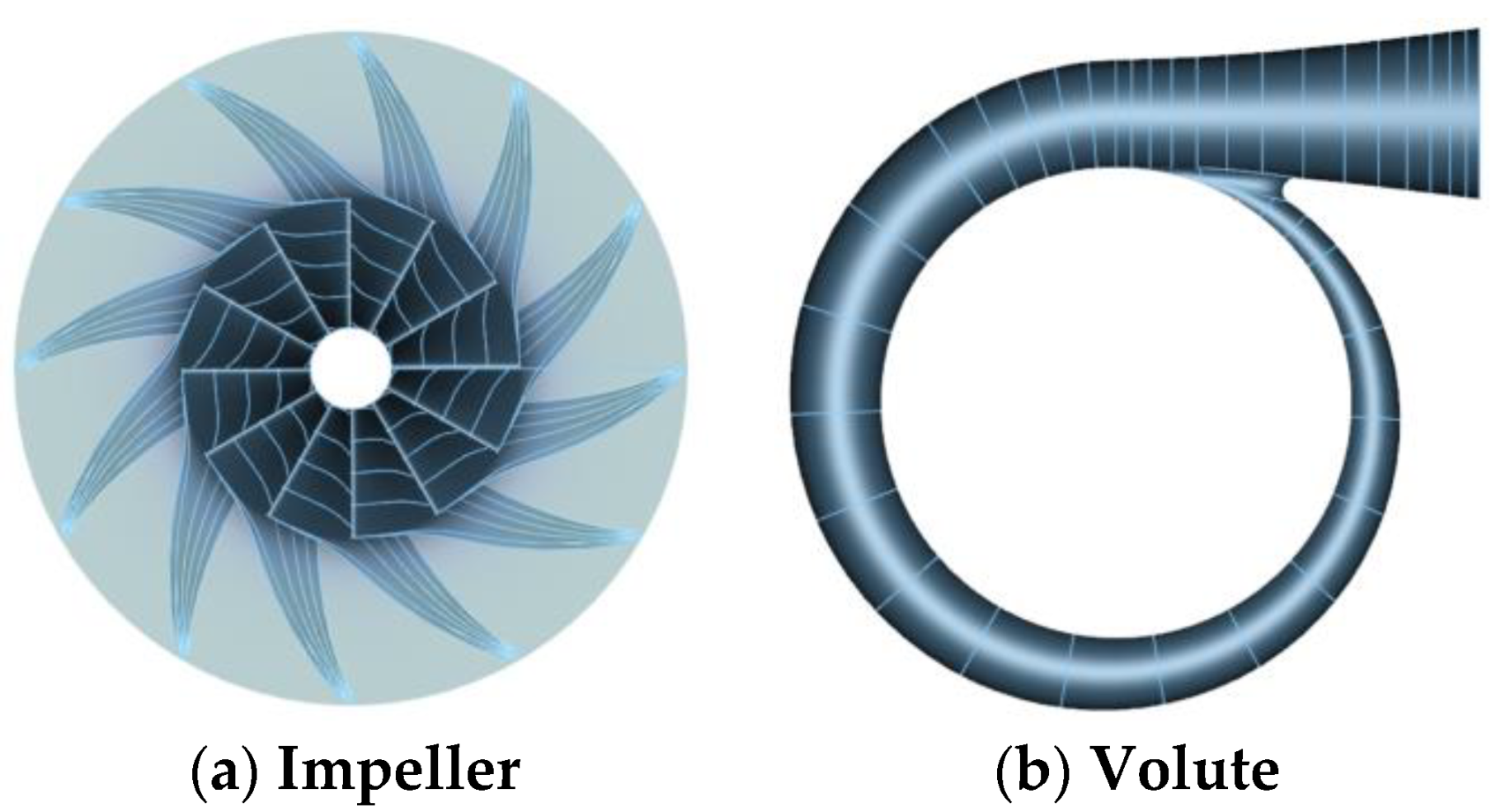

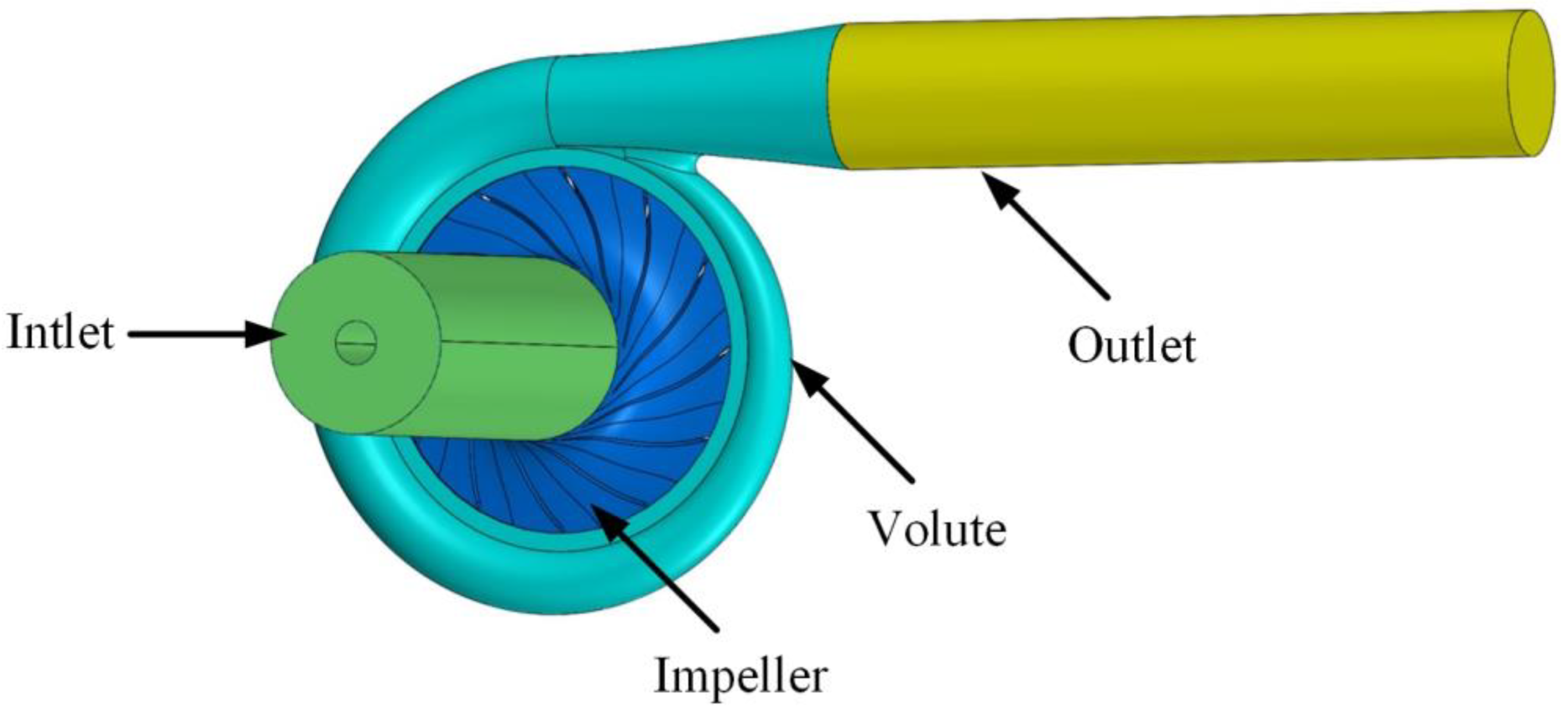

2. Aerodynamic Design

2.1. Design Parameter

2.2. Design Process

2.3. Design Result

3. Numerical Simulation and Experimental Measurement

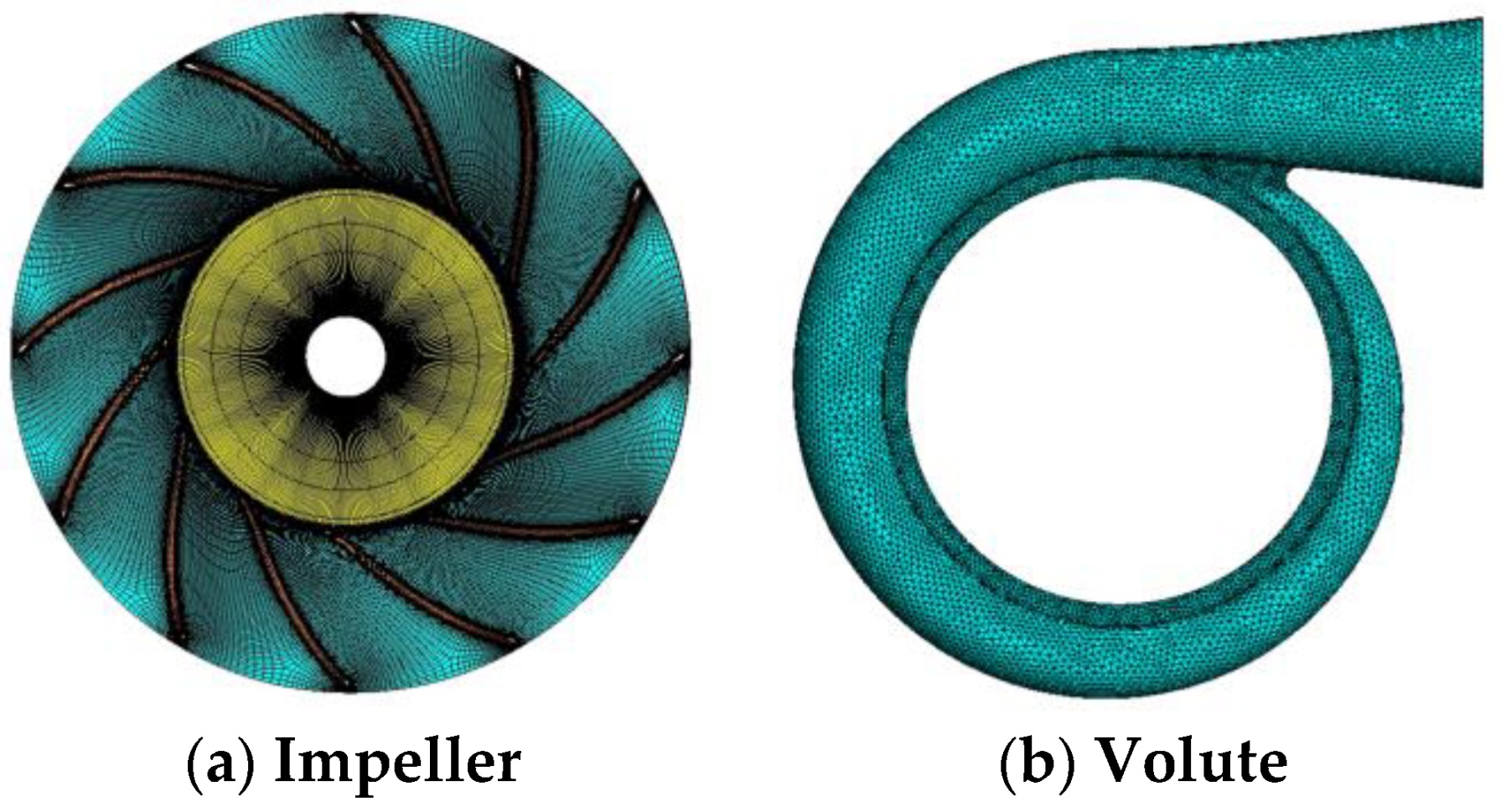

3.1. Computational Domain and Grid

3.2. Grid Independence Verification

3.3. Computational Settings

3.4. Numerical Simulation Results

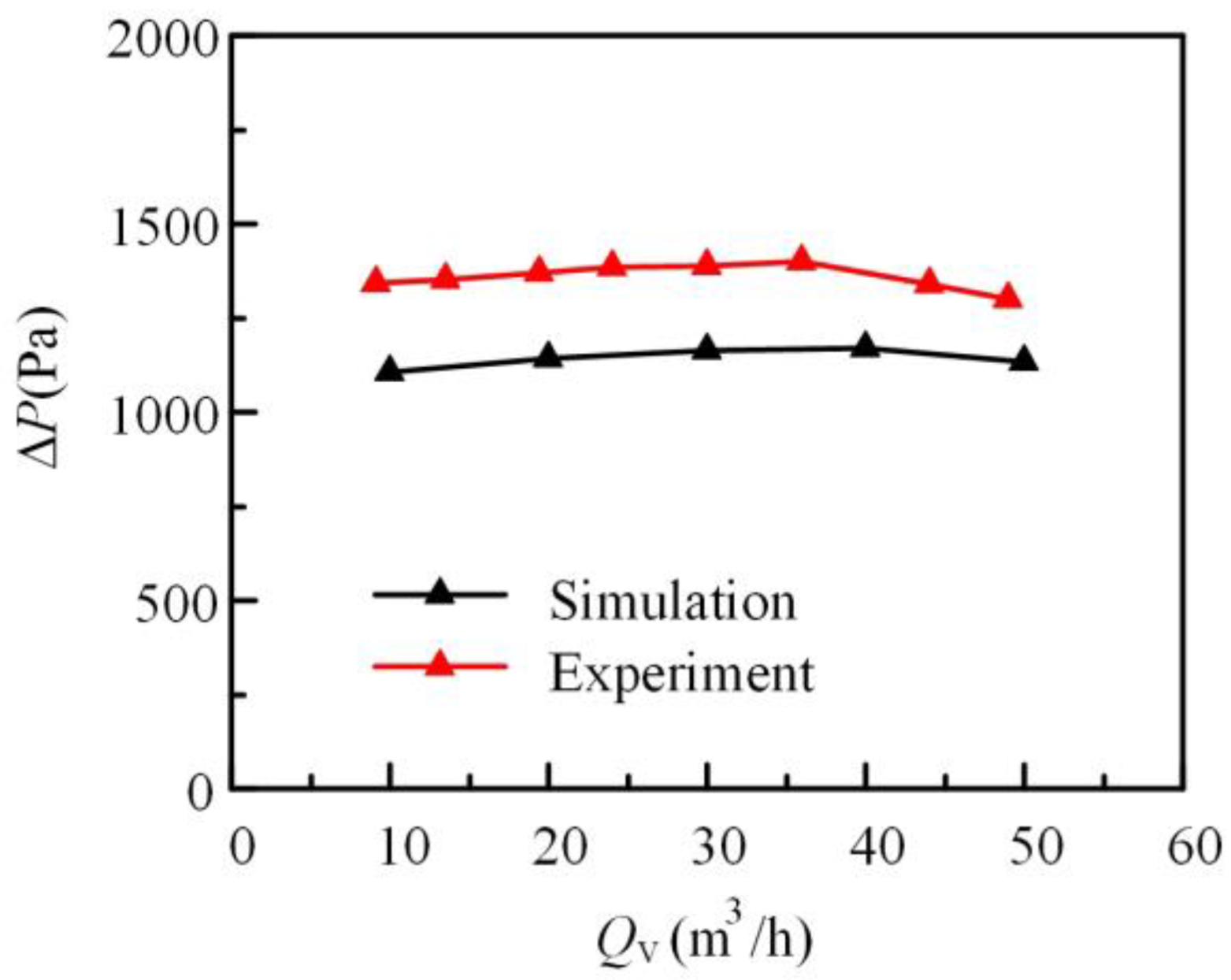

3.5. Experiment Measurement

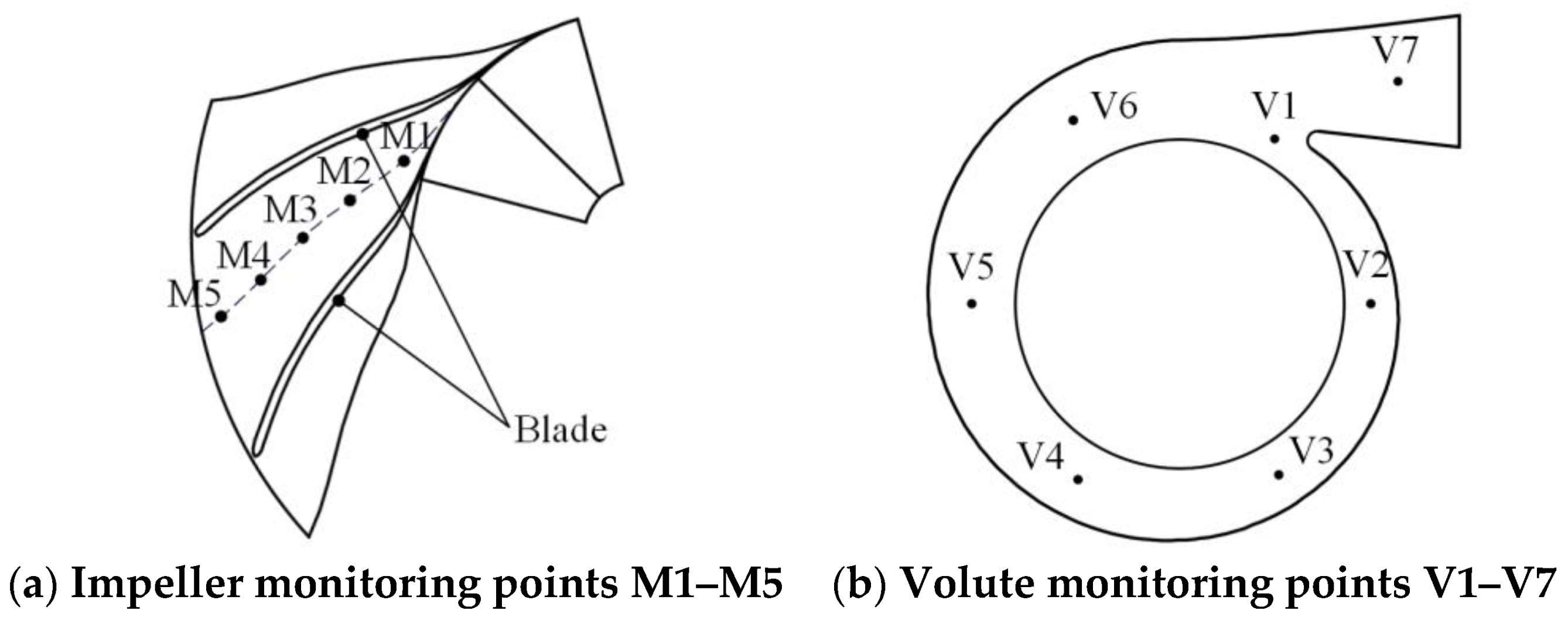

4. Orthogonal Optimization and Pressure Fluctuation

4.1. Multiple Parameter Optimization

4.2. Pressure Fluctuation Suppression

5. Conclusions

- (1)

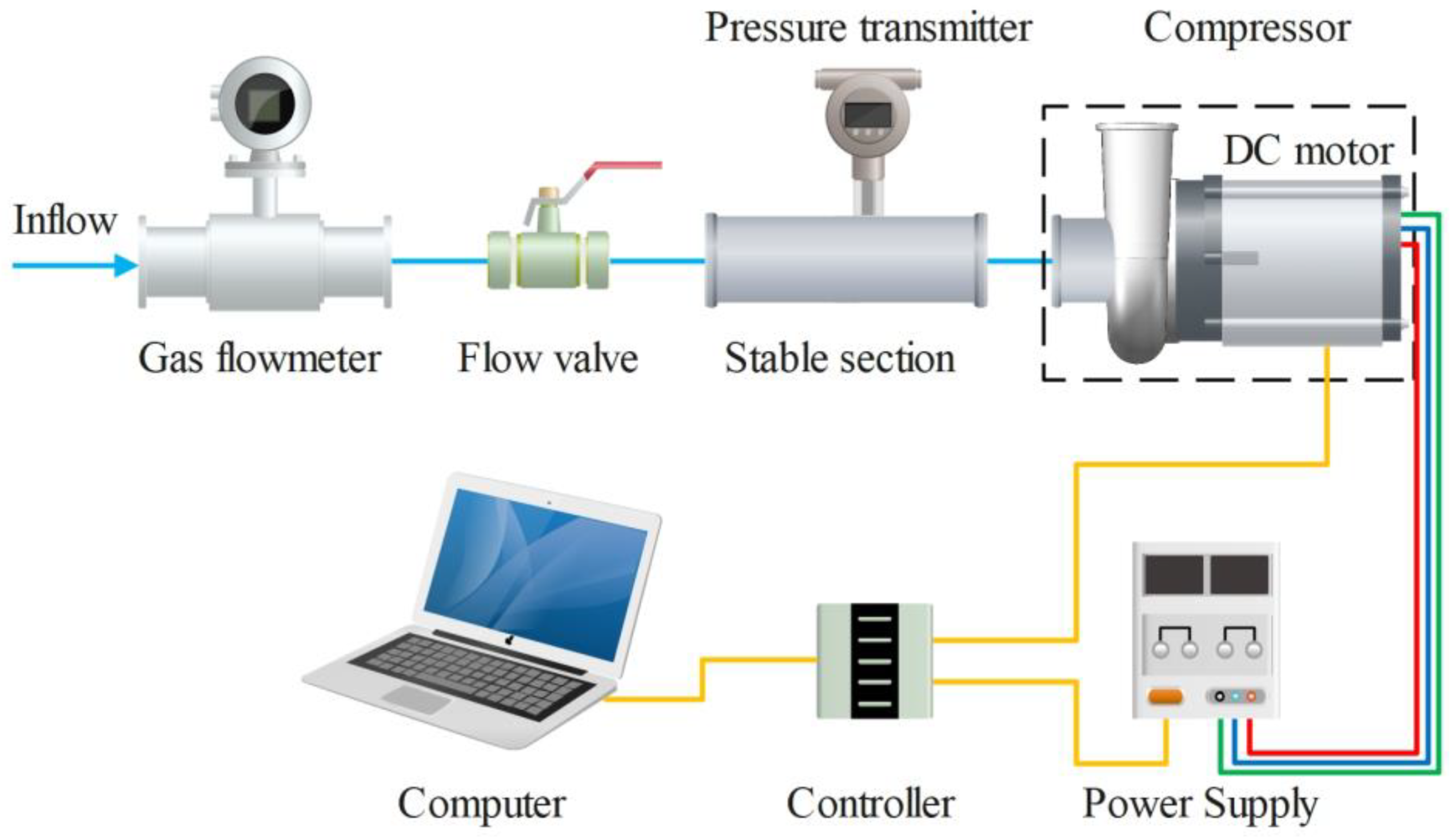

- A test rig for the aerodynamic performance of the centrifugal air compressor is established, including a pipeline, gas flowmeter, flow regulating valve, pressure transmitter, centrifugal compressor, controller, DC power supply and computer. A baseline centrifugal compressor is designed and measured in the test rig, and its rated rotation speed, flowrate and pressure ratio are 50,000 r/min, 0.1 kg/s, and 1.5, respectively.

- (2)

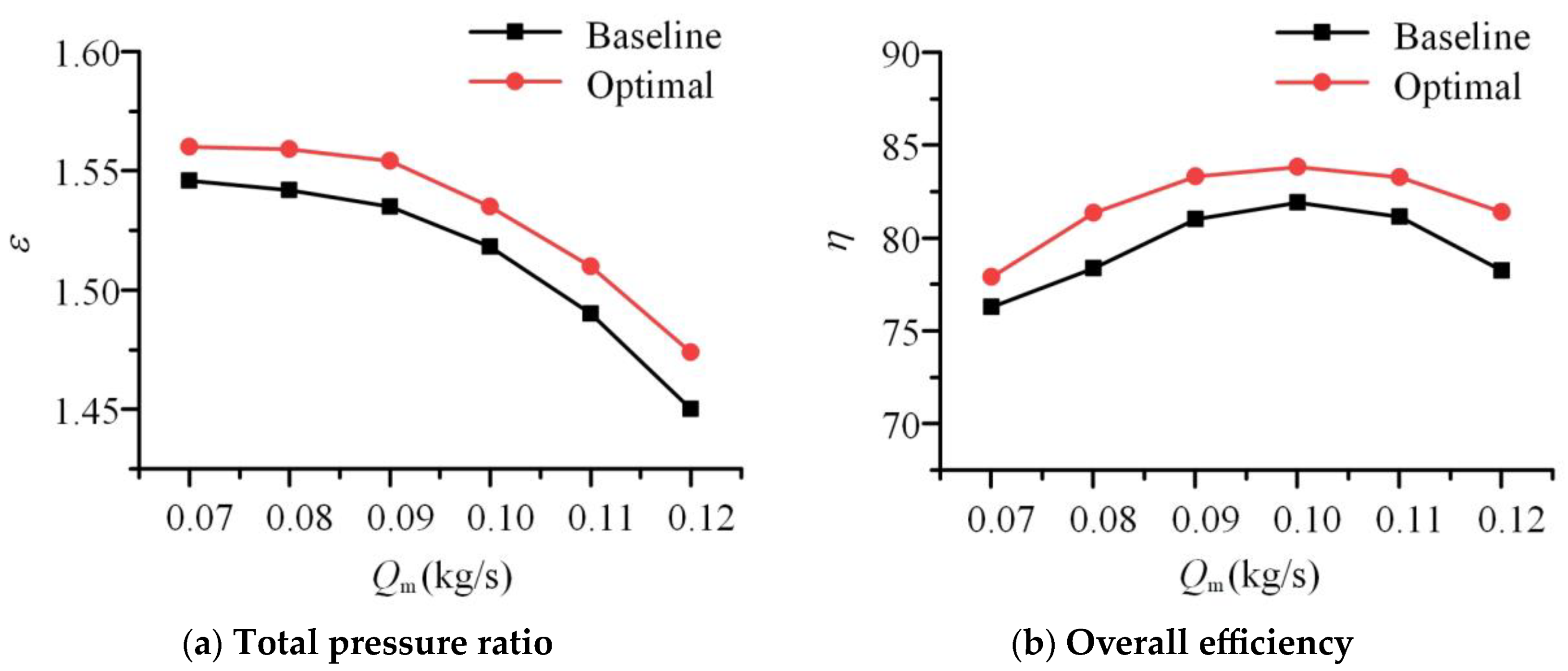

- Four optimization parameters—including blade number, blade angle at inlet, blade angle at outlet and wrap angle—are chosen, and three levels for the optimization parameters are determined by experience. According to a range analysis of the orthogonal method, the influence level of optimization parameters on efficiency is sorted by blade number, blade angle at inlet, blade angle at outlet and wrap angle. The number of blades has the greatest impact on compressor efficiency due to its ability to control the flow field, and the blade angle also has a great impact on compressor efficiency due to the work principle of the Euler equation. The energy performance of the optimal compressor is significantly improved than that of the baseline compressor at design point of flow rate, which is 0.1 kg/s. The efficiencies of the baseline compressor and optimal compressor are 81.3% and 83.8%, respectively, improving by 2.5%.

- (3)

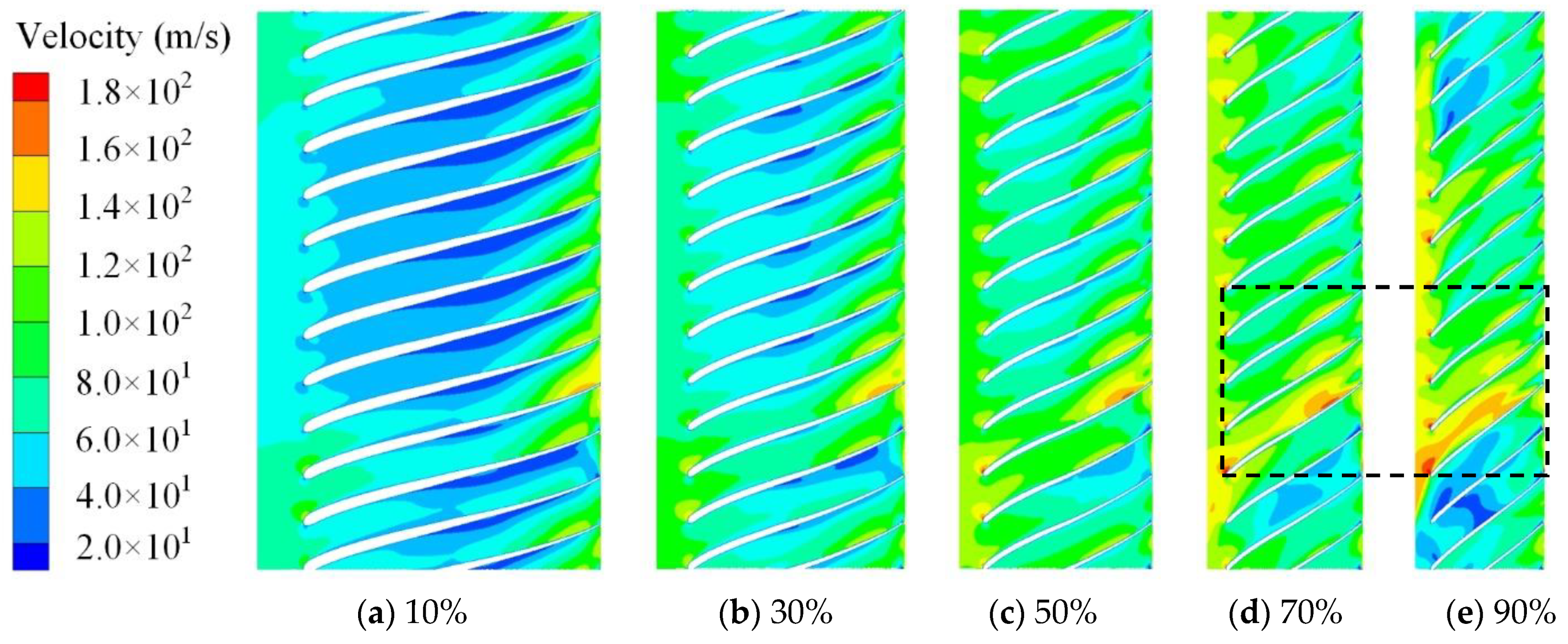

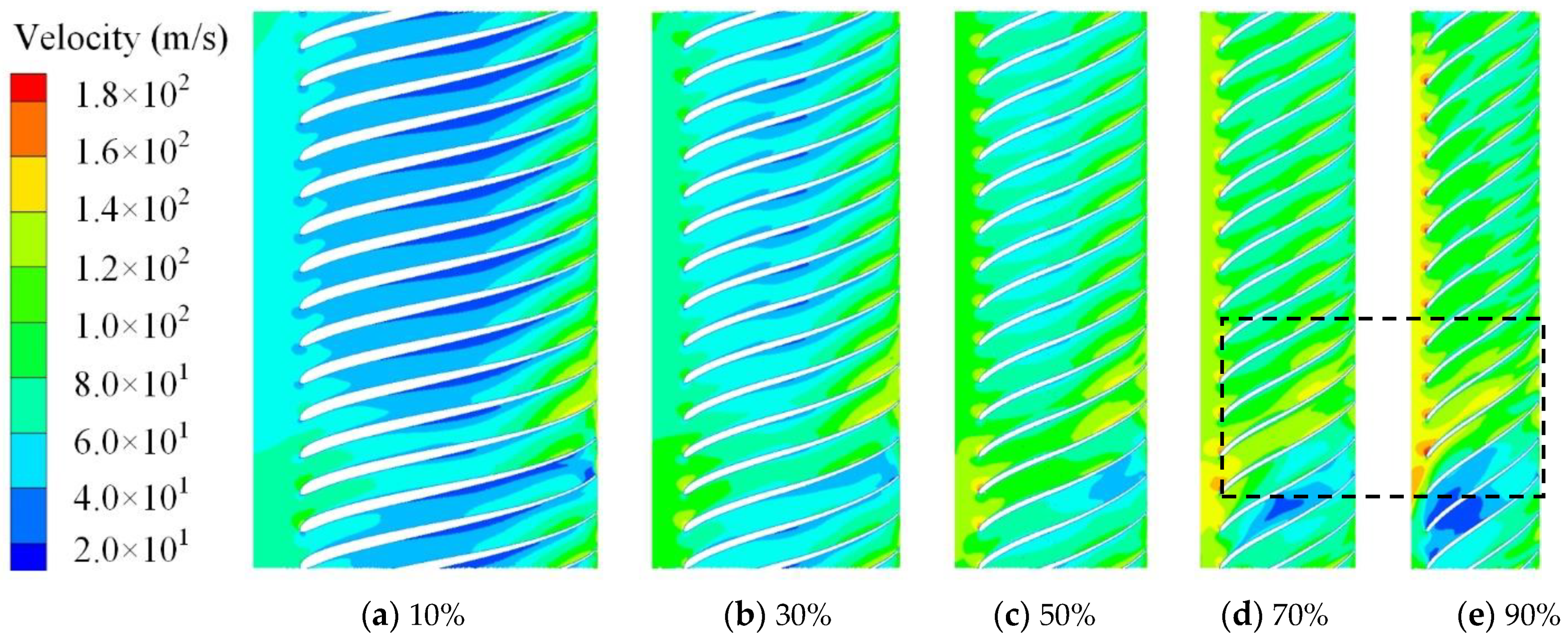

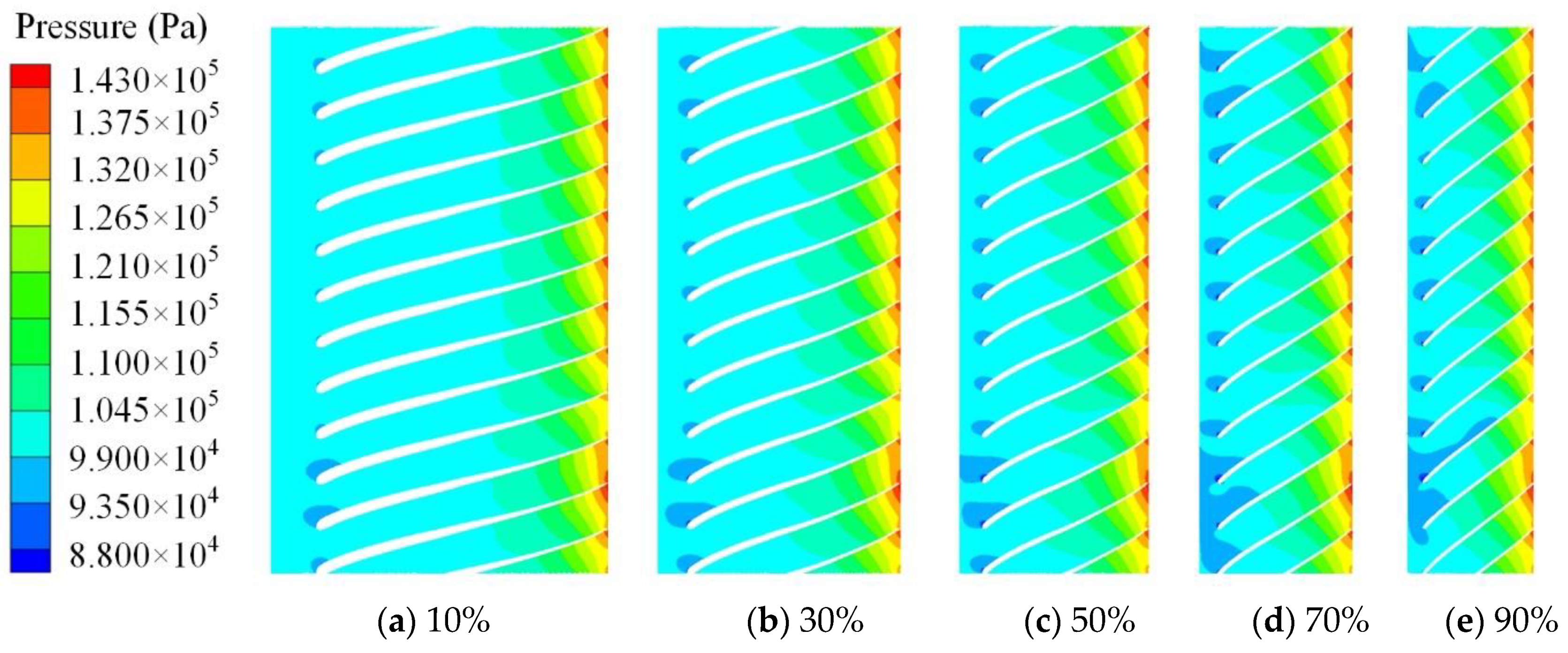

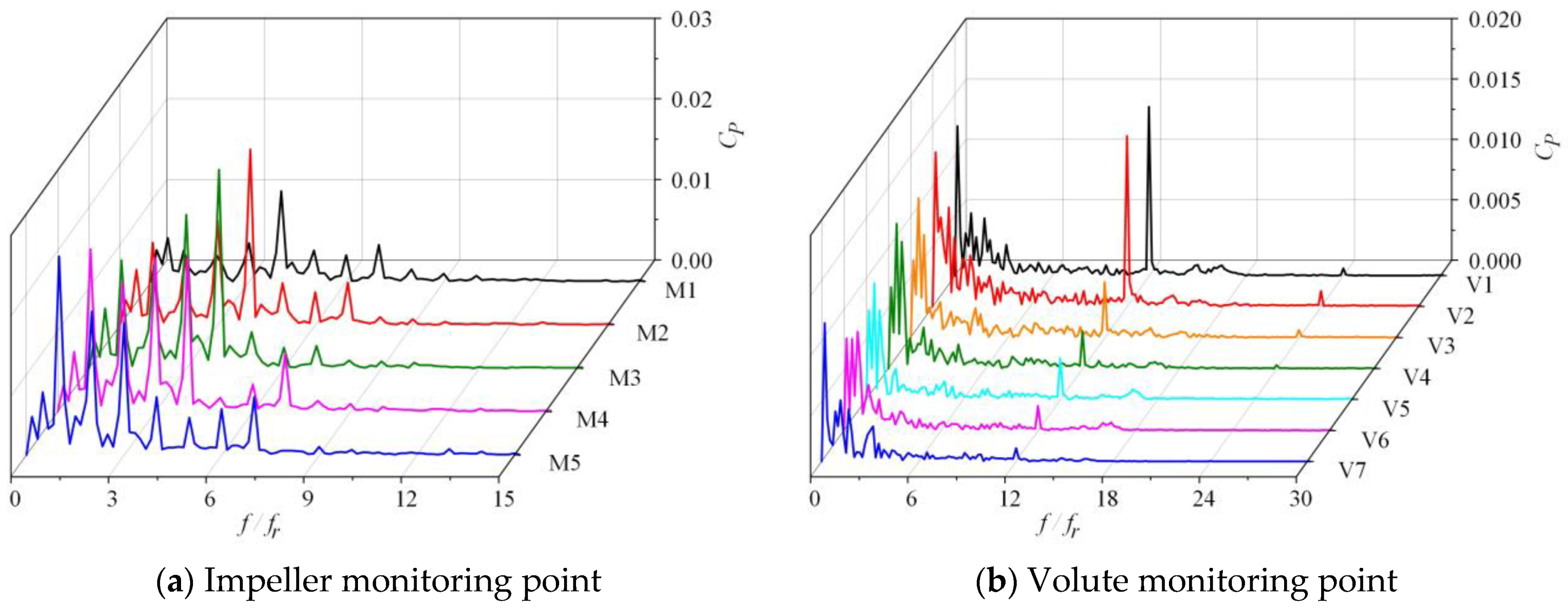

- The frequency domain of pressure fluctuation in the centrifugal compressor is related to the stator-rotor interaction. The peak value of pressure fluctuation amplitude occurs at the rotation frequency of 833 Hz and its harmonic frequency. After optimization, the matching between the impeller and the volute is improved, and the intensity of pressure pulsation is reduced. The impeller structure is optimized based on the orthogonal method, the flow separation phenomenon at the impeller outlet is suppressed and the local high-speed area in the flow channel is reduced, which leads to the low-pressure area being correspondingly reduced. The pressure gradient in the flow channel is more uniform, and the intensity of pressure pulsation is reduced. In comparison to the baseline compressor, the pressure fluctuation amplitude of the optimal compressor is obviously reduced, especially near the volute tongue. The peak of the pressure fluctuation coefficient at point M1 is decreased by 35.1%, and the peak of the pressure fluctuation coefficient at point V1 is decreased by 70.5%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garche, J.; Bonhoff, K.; Ehret, O.; Tillmetz, W. The German National Innovation Programme Hydrogen and Fuel Cell Technology. Fuel Cells 2010, 9, 192–196. [Google Scholar] [CrossRef]

- Gao, H. China’s energy transformation under the targets of peaking carbon emissions and carbon neutral. Int. Pet. Econ. 2021, 29, 1–6. [Google Scholar]

- He, X.; Zheng, X. Mechanisms of sweep on the performance of transonic compressor impellers. J. Propuls. Power 2016, 32, 1220–1229. [Google Scholar] [CrossRef]

- Li, H.; Yang, Z.; Jiang, C.; Hong, W. Study on Containment Structure of Aeroengine Air Turbine Starter. Aeroengine 2019, 45, 51–57. [Google Scholar]

- Ahluwalia, R.K. Performance and cost of automotive fuel cell systems with ultra-low platinum loadings. J. Power Sources 2011, 196, 4619–4630. [Google Scholar] [CrossRef]

- Jiao, K.; Xuan, J.; Du, Q.; Bao, Z.; Xie, B.; Wang, B.; Zhao, Y.; Fan, L.; Wang, H.; Hou, Z.; et al. Designing the next generation of proton-exchange membrane fuel cells. Nature 2021, 595, 361–369. [Google Scholar] [CrossRef]

- Fang, Y.; Cheng, J.; Liu, S.; Chen, G.; Huang, D.; Sheng, X. Research Status and Prospect of China’s Hydrogen Fuel Cell Vehicle Industry. Contemp. Chem. Res. 2022, 118, 183–185. [Google Scholar]

- Jewell, J.; McCollum, D.; Emmerling, J.; Bertram, C.; Gernaat, D.E.; Krey, V.; Paroussos, L.; Berger, L.; Fragkiadakis, K.; Keppo, I.; et al. Limited emission reductions from fuel subsidy removal except in energy-exporting regions. Nature 2018, 554, 229–233. [Google Scholar] [CrossRef]

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Env. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Itaoka, K.; Saito, A.; Sasaki, K. Public perception on hydrogen infrastructure in Japan: Influence of rollout of commercial fuel cell vehicles. Int. J. Hydrog. Energy 2017, 42, 7290–7296. [Google Scholar] [CrossRef]

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Eberle, U.; Müller, B.; von Helmolt, R. Fuel cell electric vehicles and hydrogen infrastructure: Status 2012. Energy Env. 2012, 5, 8780–8798. [Google Scholar] [CrossRef]

- Marconcini, M.; Rubechini, F.; Arnone, A.; Ibaraki, S. Numerical Analysis of the Vaned Diffuser of a Transonic Centrifugal Compressor. J. Turbomach. 2010, 132, 041012. [Google Scholar] [CrossRef]

- Krain, H.; Hoffmann, B. Flow Study of a Redesigned High Pressure Ratio Centrifugal Compressor. J. Propuls. Power 2008, 24, 7. [Google Scholar] [CrossRef]

- Hildebrandt, A.; Genrup, M. Numerical Investigation of the Effect of Different Back Sweep Angle and Exducer Width on the Impeller Outlet Flow Pattern of a Centrifugal Compressor with Vaneless Diffuser. J. Turbomach. 2007, 129, 1077–1086. [Google Scholar] [CrossRef]

- Ha, K.K.; Jeong, T.B.; Kang, S.H.; Kim, H.J.; Won, K.M.; Park, C.Y.; Jung, W.Y.; Cho, K.Y. Experimental Investigation on Aero-Acoustic Characteristics of a Centrifugal Compressor for the Fuel-Cell Vehicle. J. Mech. Sci. Technol. 2013, 27, 3287–3297. [Google Scholar] [CrossRef]

- Ha, K.K.; Lee, C.H.; Kim, C.M.; Kim, S.H.; Ahn, B.K. A Study on the Characteristics of an Oil-Free Centrifugal Compressor for Fuel-Cell Vehicles. SAE Int. J. Altern. Powertrains 2016, 5, 167–174. [Google Scholar] [CrossRef]

- Zhao, D.; Hua, Z.; Liang, Y.; Chen, F. Centrifugal Air Compressor Characteristic Research on the Fuel Cells in the Aircraft. Aviat. Sci. Technol. 2017, 2, 64–68. [Google Scholar]

- Zhu, G.H.; Qiu, T.H.; Xie, M. The Analysis of Aerodynamic Load For High Speed Centrifugal Compressor Blade. Adv. Mater. Res. 2013, 675, 103–106. [Google Scholar] [CrossRef]

- Zuo, S.; Wei, K.; Wu, X.; Nie, Y.; Xu, S. Multi-objective parameter optimization of centrifugal compressor impeller using Kriging model. J. Agric. Eng. 2016, 1, 77–82. [Google Scholar]

- Lu, Y.; Tan, L.; Han, Y.; Liu, M. Cavitation-vibration correlation of a mixed flow pump under steady state and fast start-up conditions by experiment. Ocean Eng. 2022, 251, 111158. [Google Scholar] [CrossRef]

- Sun, W.; Tan, L. Cavitation-Vortex-Pressure fluctuation interaction in a centrifugal pump using bubble rotation modified cavitation model under partial load. J. Fluids Eng.-Trans. ASME 2020, 142, 051206. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, W.; Wang, C.; Guo, T.; Zou, P. Influence of impeller and guide vane blade number on pressure fluctuation in mixed flow pump. J. Drain. Irrig. Mach. Eng. 2012, 30, 167–170. [Google Scholar]

- Zhou, P.J.; Wang, F.J.; Yang, Z.J.; Mou, J.G. Investigation of rotating stall for a centrifugal pump impeller using various SGS models. J. Hydrodyn. 2017, 29, 235–242. [Google Scholar] [CrossRef]

- Zhou, P.J.; Wang, F.J.; Yao, Z.F. Study on effects of blade number on stall characteristics for centrifugal pump impeller. J. Mech. Eng. 2016, 52, 207–215. [Google Scholar] [CrossRef]

- Li, H.; Zhang, X.; Guo, C.; Zhang, X. Acoustic resonance analysis for centrifugal compressors and experiment verification. J. Mech. Eng. 2014, 50, 73–79. [Google Scholar] [CrossRef]

- Zhang, Y.; Bao, P.; Wan, Y.; Xu, S. Modeling and Analysis of Air Supply System of Polymer Electrolyte Membrane Fuel Cell System. Energy Procedia 2017, 142, 1053–1058. [Google Scholar] [CrossRef]

- Konno, N.; Mizuno, S.; Nakaji, H.; Ishikawa, Y. Development of compact and high-performance fuel cell stack. SAE Mobilus 2015, 4, 123–129. [Google Scholar] [CrossRef]

- Liu, M.; Han, Y.; Tan, L.; Lu, Y.; Ma, C.; Gou, J. Theoretical prediction model of transient performance for a mixed flow pump under fast start-up conditions. Phys. Fluids 2023, 35, 025125. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Design method of controllable blade angle and orthogonal optimization of pressure rise for a multiphase pump. Energies 2018, 11, 1048. [Google Scholar] [CrossRef]

- Dai, Z.; Tan, L.; Han, B.; Han, S. Multi-parameter optimization design of axial flow pump based on orthogonal method. Energies 2022, 15, 9379. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, J.; Zhang, W.; Liu, B. Multiparameter and multiobjective optimization design based on orthogonal method for mixed flow fan. Energies 2020, 13, 2819. [Google Scholar] [CrossRef]

- Xiao, W.; Tan, L. Design method of controllable velocity moment and optimization of pressure fluctuation suppression for a multiphase pump. Ocean Eng. 2021, 220, 108402. [Google Scholar] [CrossRef]

- Tang, H.; He, F. Numerical simulation of flow field in centrifugal pump. Water Pump Technol. 2002, 2, 3–9. [Google Scholar]

- Tang, X.; Gu, N.; Wang, W.; Wang, Z.; Peng, R. Aerodynamic robustness optimization and design exploration of centrifugal compressor impeller under uncertainties. Int. J. Heat Mass Transf. 2021, 180, 121799. [Google Scholar] [CrossRef]

| Design Parameters | Value |

|---|---|

| Rated speed N0 | 50,000 r/min |

| Mass flow Qm | 0.1 kg/s |

| Inlet temperature T0 | 293.15 K |

| Inlet pressure P0 | 101,325 Pa |

| Total pressure ratio ε | 1.5 |

| Structural Parameters | Value |

|---|---|

| Impeller inlet diameter | 50 mm |

| Impeller outlet diameter | 100 mm |

| Impeller outlet width | 5 mm |

| Blade inlet installation angle | 50° |

| Blade outlet installation angle | 60° |

| Blade wrap angle | 60° |

| Level | Blade Number (A) | Blade Angle at Inlet/° (B) | Blade Angle at Outlet/° (C) | Wrap Angle/° (D) |

|---|---|---|---|---|

| 1 | 9 | 40 | 45 | 40 |

| 2 | 12 | 50 | 60 | 50 |

| 3 | 15 | 60 | 75 | 60 |

| Scheme | A | B/° | C/° | D/° | /% | |

|---|---|---|---|---|---|---|

| 1 | 9 | 40 | 45 | 40 | 1.435 | 79.25 |

| 2 | 9 | 50 | 60 | 50 | 1.447 | 79.60 |

| 3 | 9 | 60 | 75 | 60 | 1.463 | 77.74 |

| 4 | 12 | 40 | 60 | 60 | 1.52 | 82.20 |

| 5 | 12 | 50 | 75 | 40 | 1.556 | 80.20 |

| 6 | 12 | 60 | 45 | 50 | 1.492 | 80.75 |

| 7 | 15 | 40 | 75 | 50 | 1.58 | 82.01 |

| 8 | 15 | 50 | 45 | 60 | 1.532 | 83.12 |

| 9 | 15 | 60 | 60 | 40 | 1.558 | 80.81 |

| Average Value | A/% | B/% | C/% | D/% |

|---|---|---|---|---|

| k1 | 78.86 | 81.18 | 81.04 | 80.09 |

| k2 | 81.05 | 80.97 | 80.87 | 80.82 |

| k3 | 82.01 | 79.77 | 80.01 | 81.02 |

| R | 3.15 | 1.41 | 1.03 | 0.93 |

| Scheme | A | B/° | C/° | D/° | /% | |

|---|---|---|---|---|---|---|

| Baseline | 12 | 50 | 60 | 60 | 1.518 | 81.3 |

| Optimal | 15 | 40 | 45 | 60 | 1.535 | 83.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Tan, L.; Yang, D.; Liu, B.; Fan, H.; Li, H. Optimization Design and Pressure Fluctuation Suppression Based on Orthogonal Method for a Centrifugal Compressor. Machines 2023, 11, 559. https://doi.org/10.3390/machines11050559

Zhao H, Tan L, Yang D, Liu B, Fan H, Li H. Optimization Design and Pressure Fluctuation Suppression Based on Orthogonal Method for a Centrifugal Compressor. Machines. 2023; 11(5):559. https://doi.org/10.3390/machines11050559

Chicago/Turabian StyleZhao, Huanxin, Lei Tan, Dangguo Yang, Bing Liu, Honggang Fan, and Hongshuai Li. 2023. "Optimization Design and Pressure Fluctuation Suppression Based on Orthogonal Method for a Centrifugal Compressor" Machines 11, no. 5: 559. https://doi.org/10.3390/machines11050559

APA StyleZhao, H., Tan, L., Yang, D., Liu, B., Fan, H., & Li, H. (2023). Optimization Design and Pressure Fluctuation Suppression Based on Orthogonal Method for a Centrifugal Compressor. Machines, 11(5), 559. https://doi.org/10.3390/machines11050559