Statistical Evaluation of the Impacts Detection Methodology (IDM) to Detect Critical Damage Occurrences during Quay Cranes Handling Operations

Abstract

:1. Introduction

- When the crane lowers the spreader on the ship towards the container, there is always a chance that the spreader impacts the container with a higher force.

- If the crane operator correctly aims the spreader, all four hooks of the spreader engage in the hooking sockets of the container and the remaining vibration is generated by the contact surfaces between the container and the spreader’s mechanical parts. These low oscillations are not considered a problem state.

- When the spreader mechanisms are aimed wrongfully, the hooks encounter the container first, then the rest of the spreader contacting surfaces damaging the container’s structural elements. After a hooking failure, the operator must raise the spreader a bit and re-attempt to hooking procedure, delaying operations.

- to further demonstrate the efficiency of the IDM detecting true physical impacts during handling operations from the ships and to provide statistically proven evidence that the problem area is too big to be discarded by the community, requiring the involvement of many engineers and specialists working with dynamic and control systems, mechanics and structural engineering, signal processing and data mining tools.

2. Materials and Methods

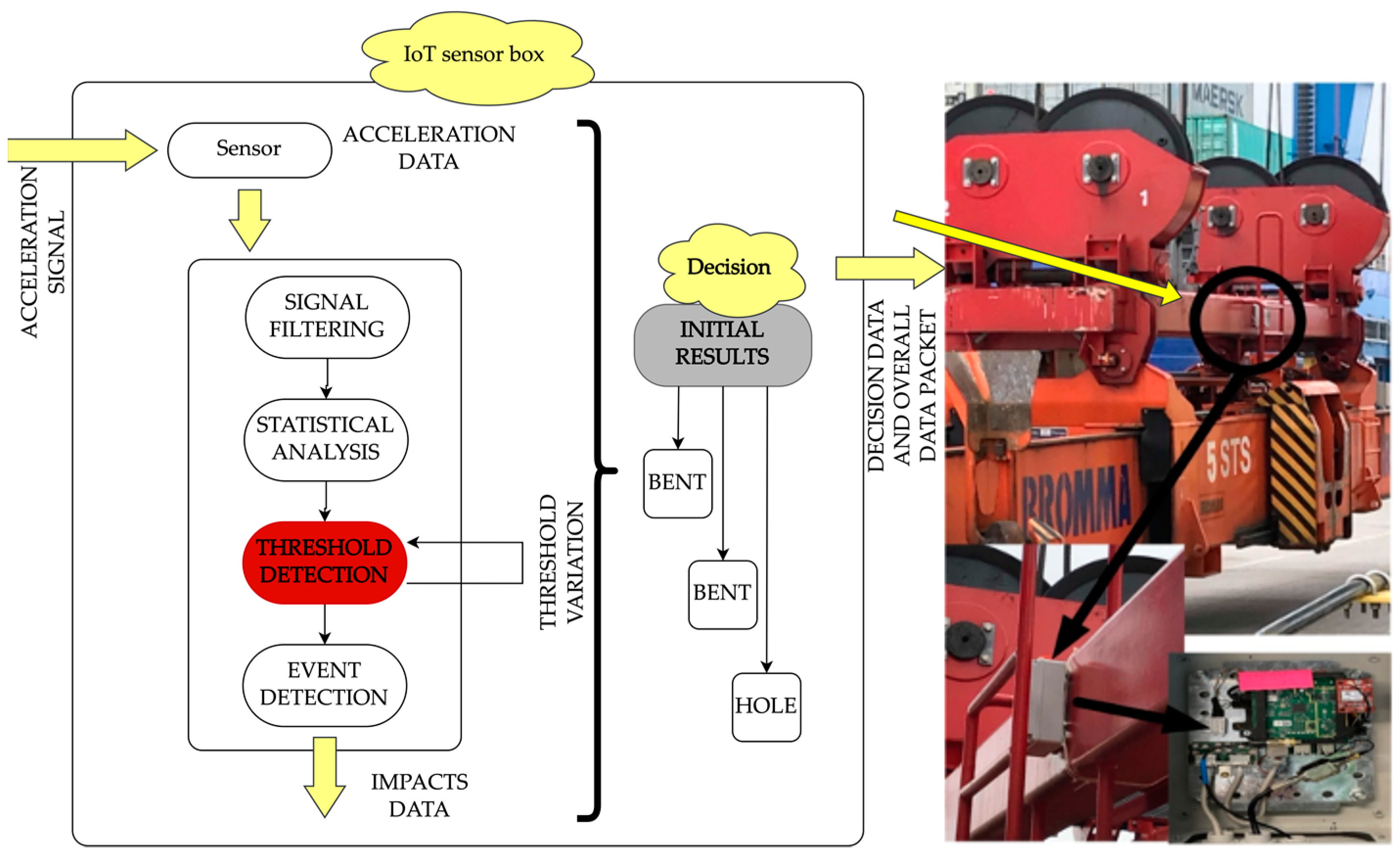

2.1. Detection Technique

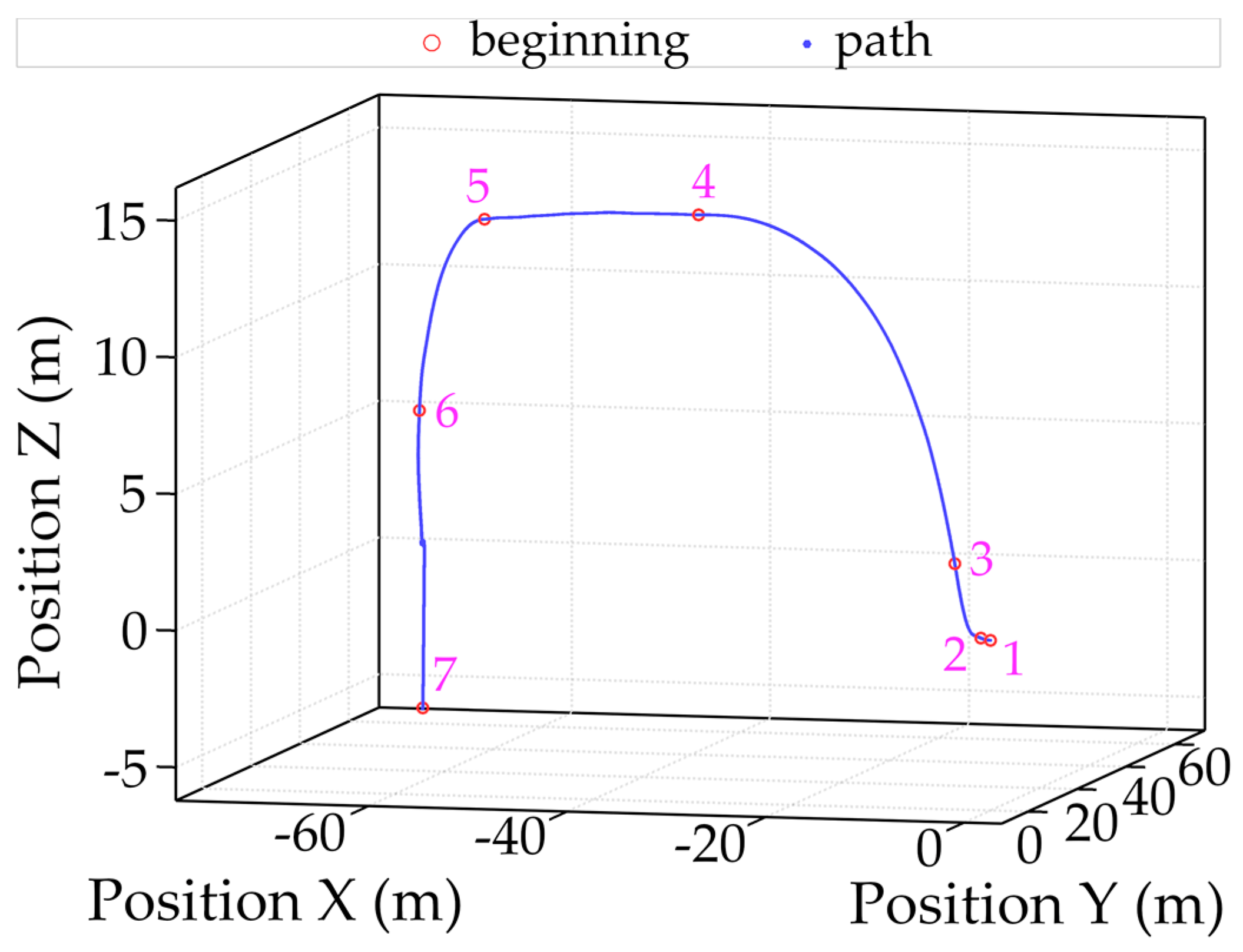

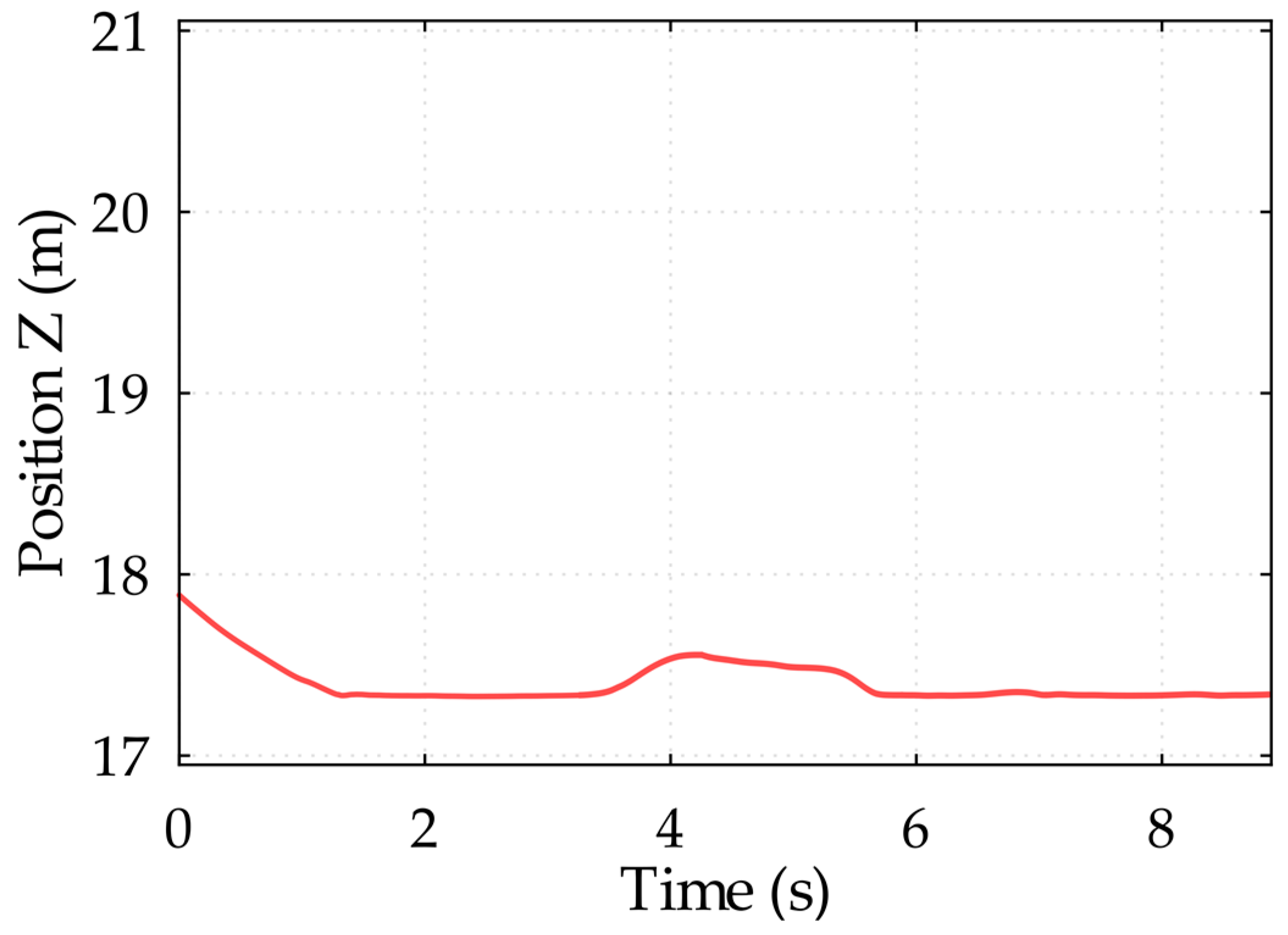

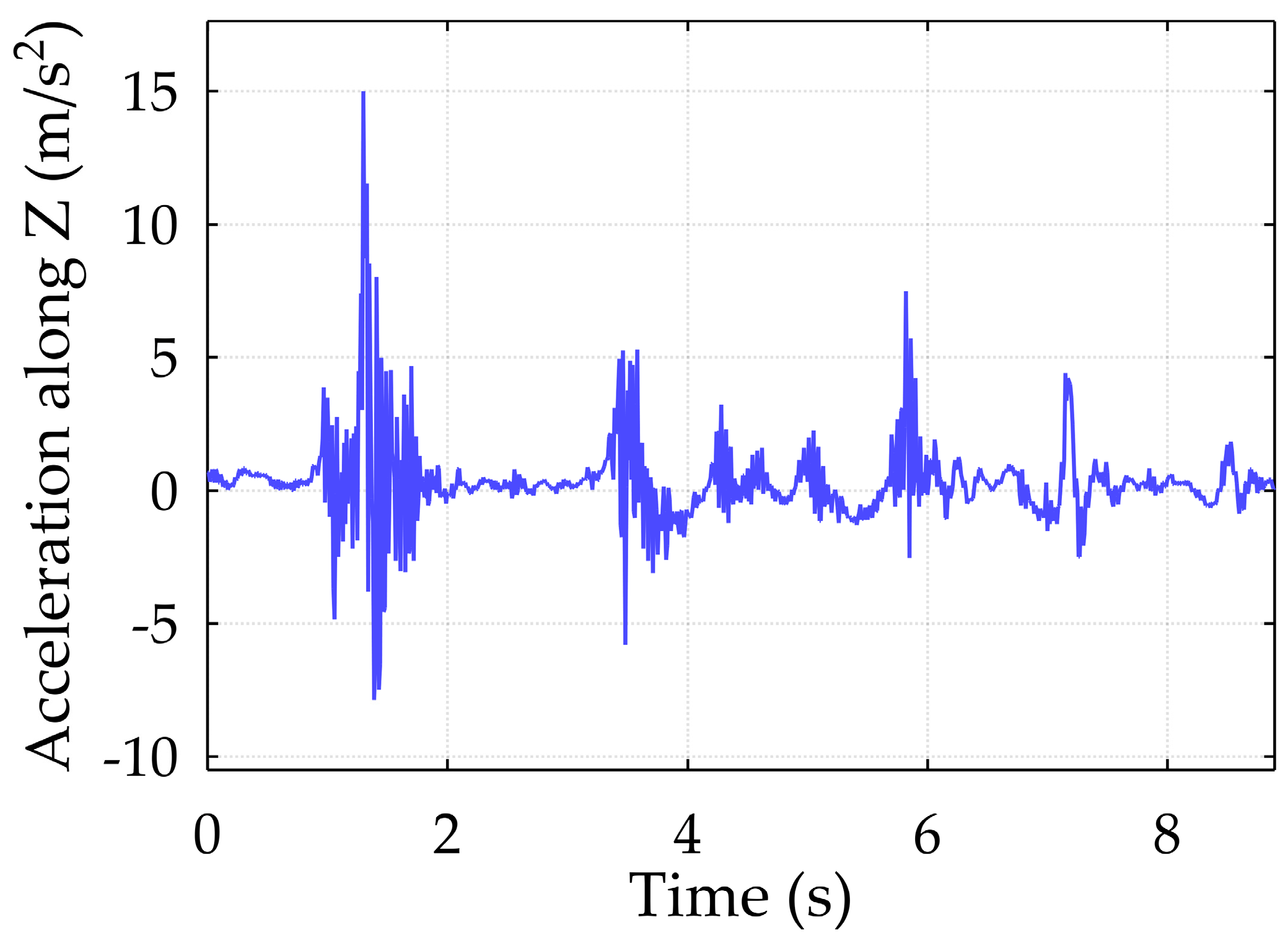

2.2. Assessment of the Operation

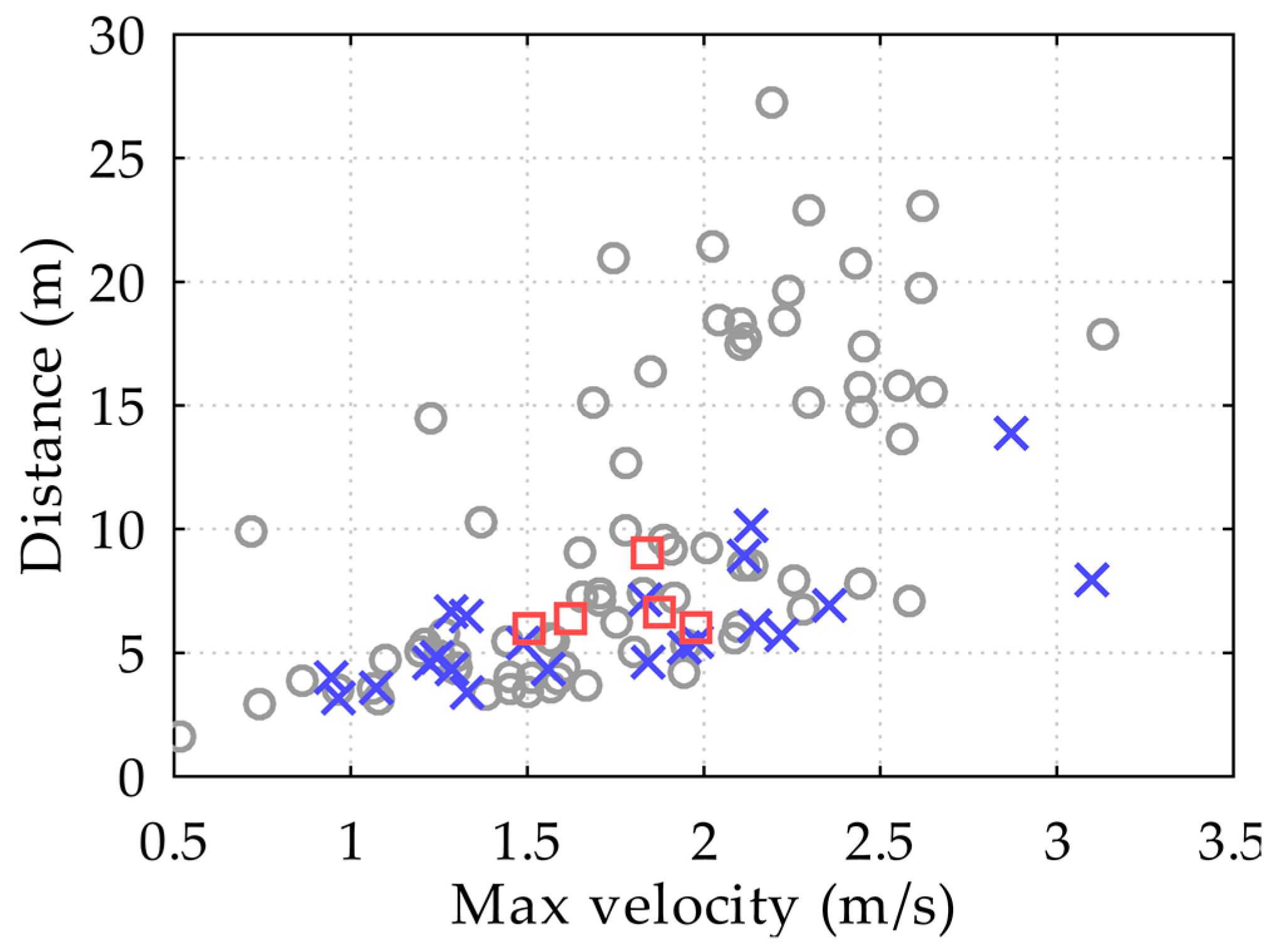

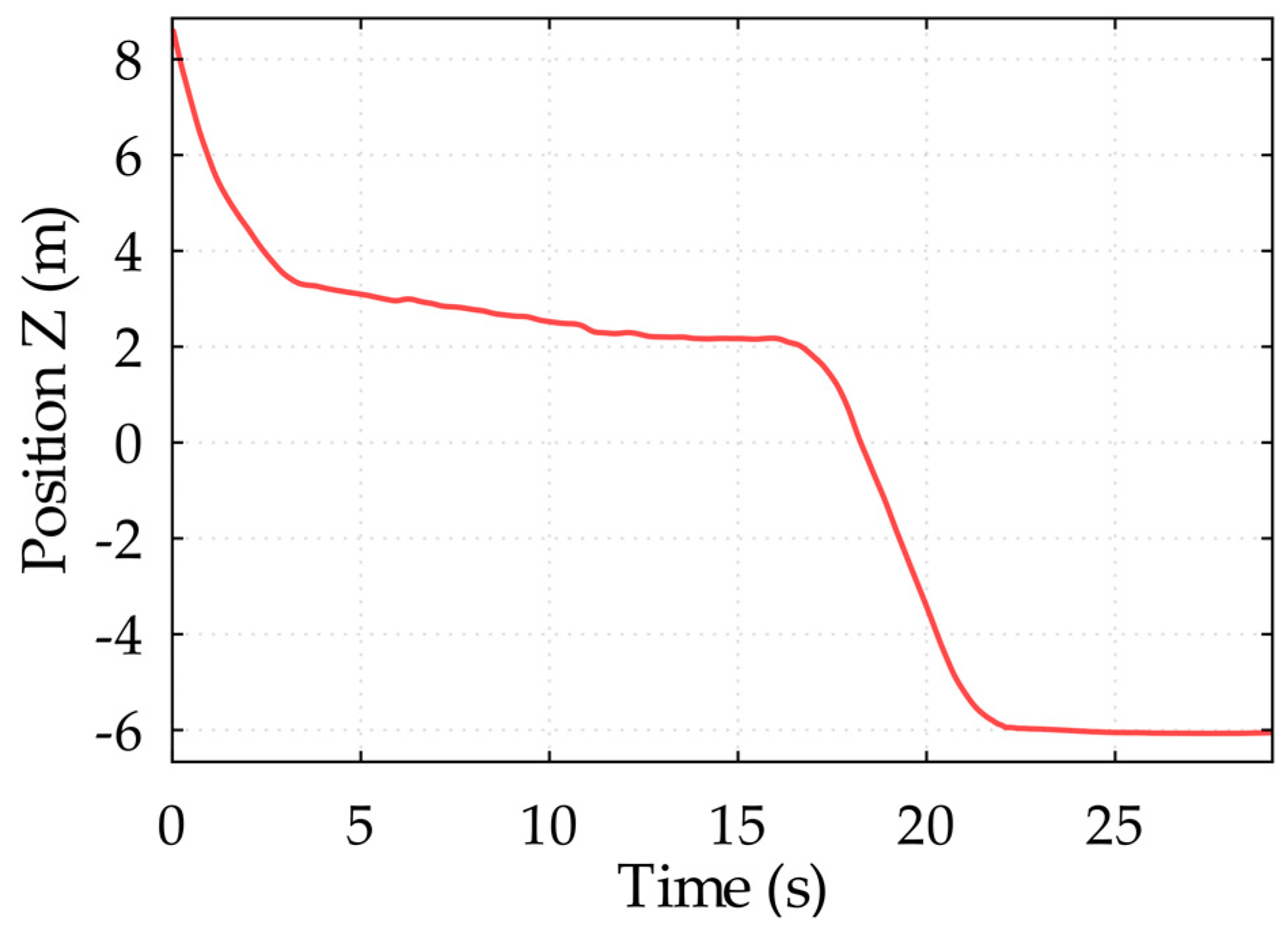

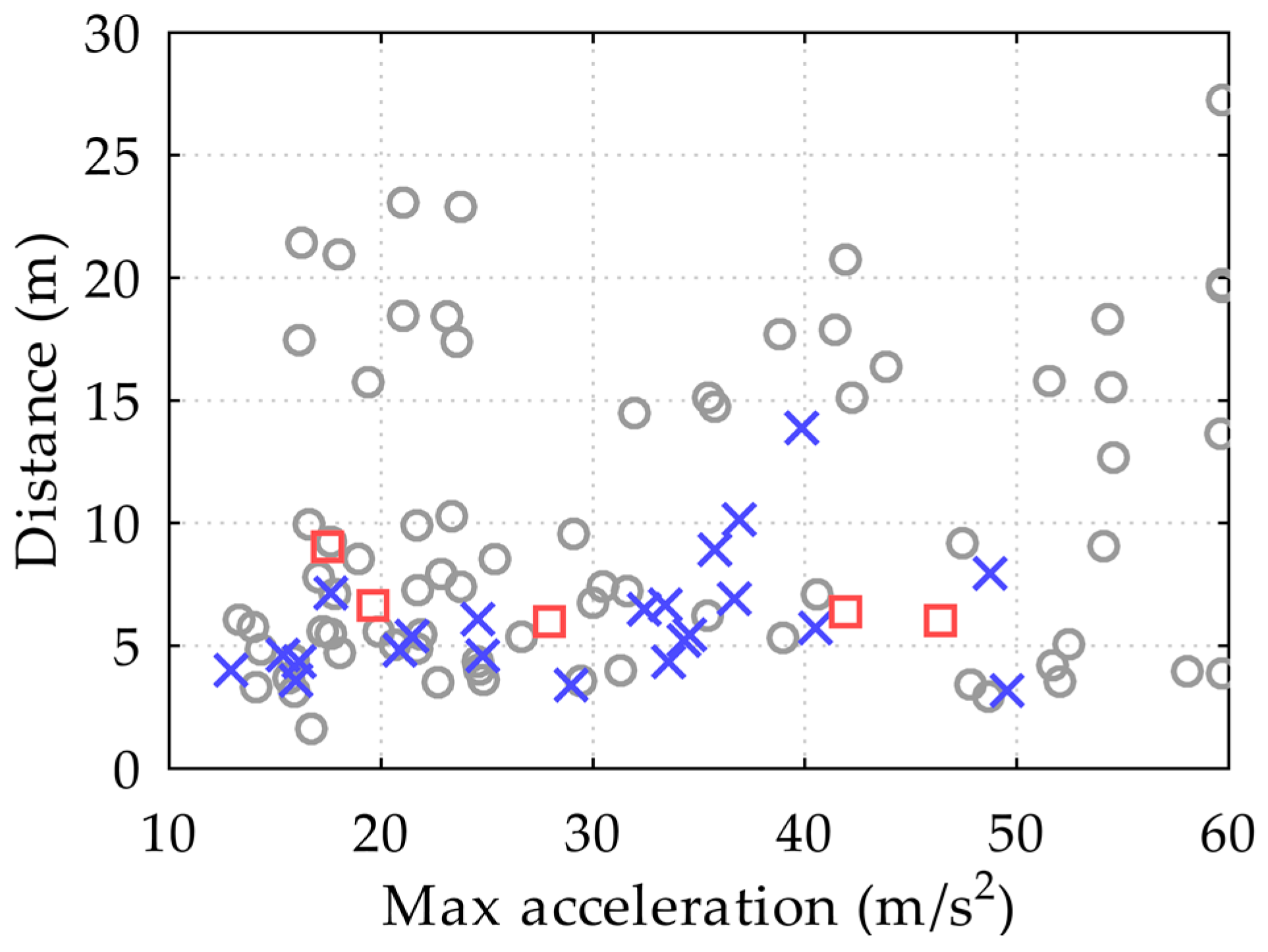

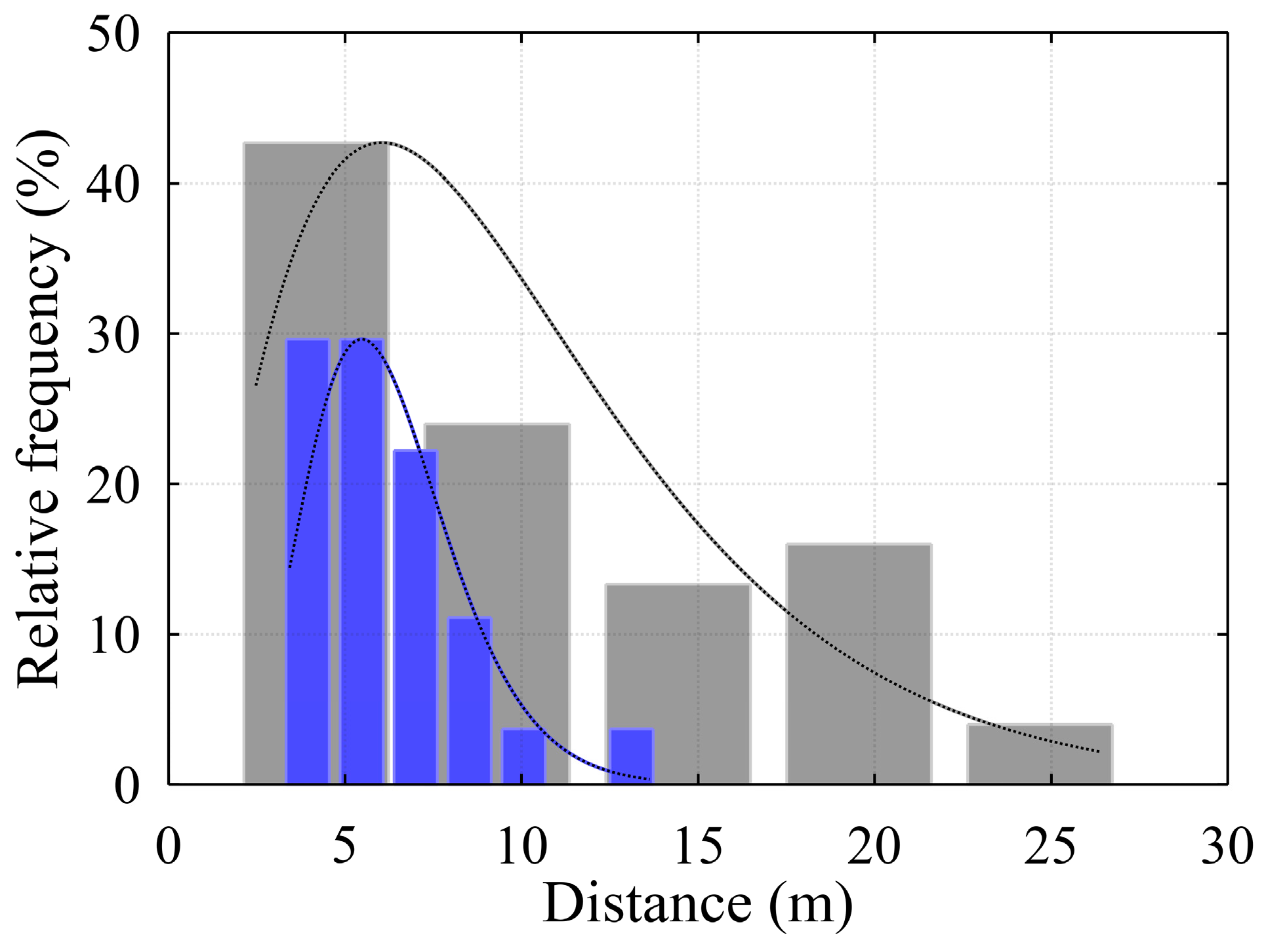

- the vertical lowering distance of the spreader.

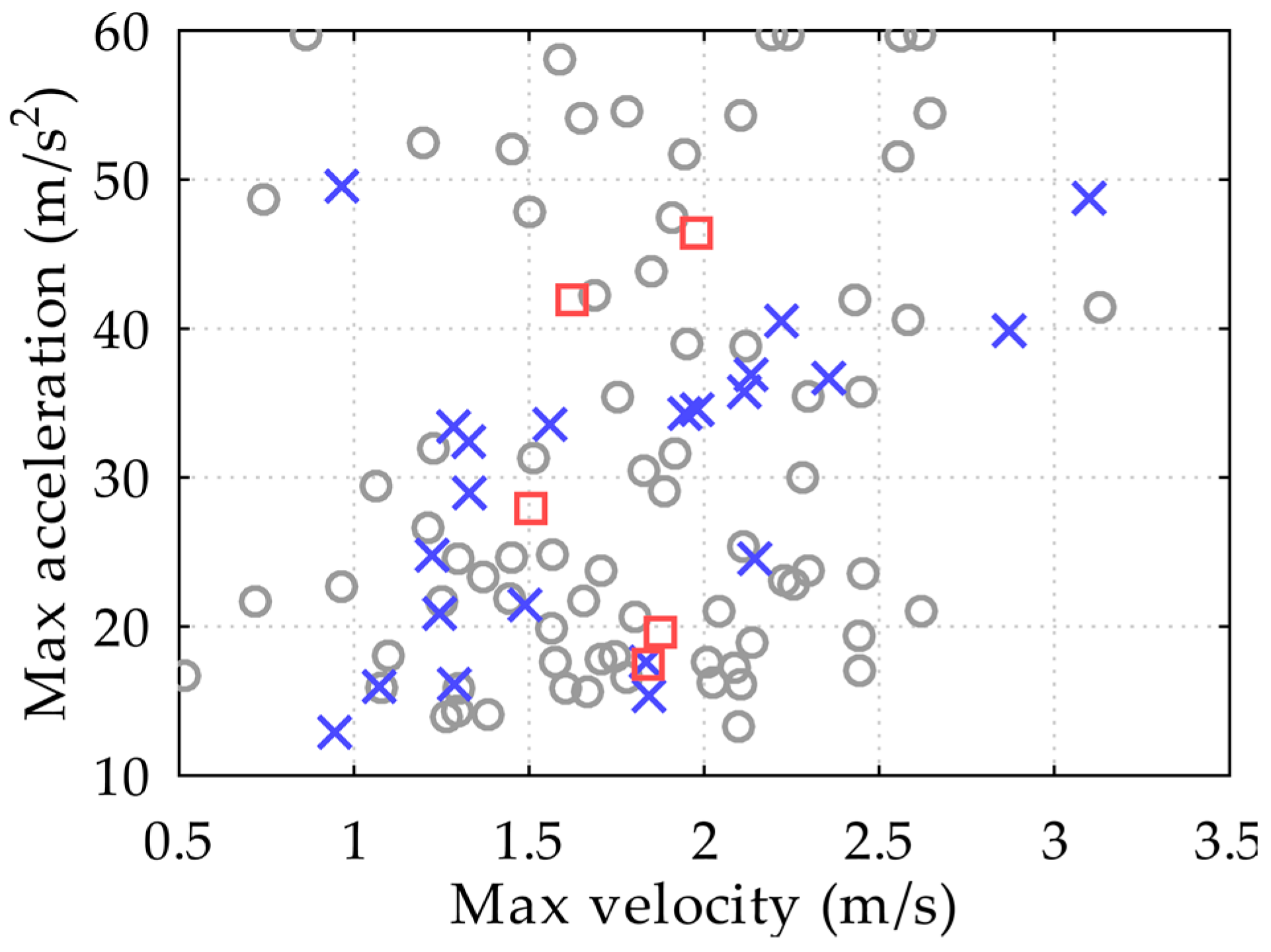

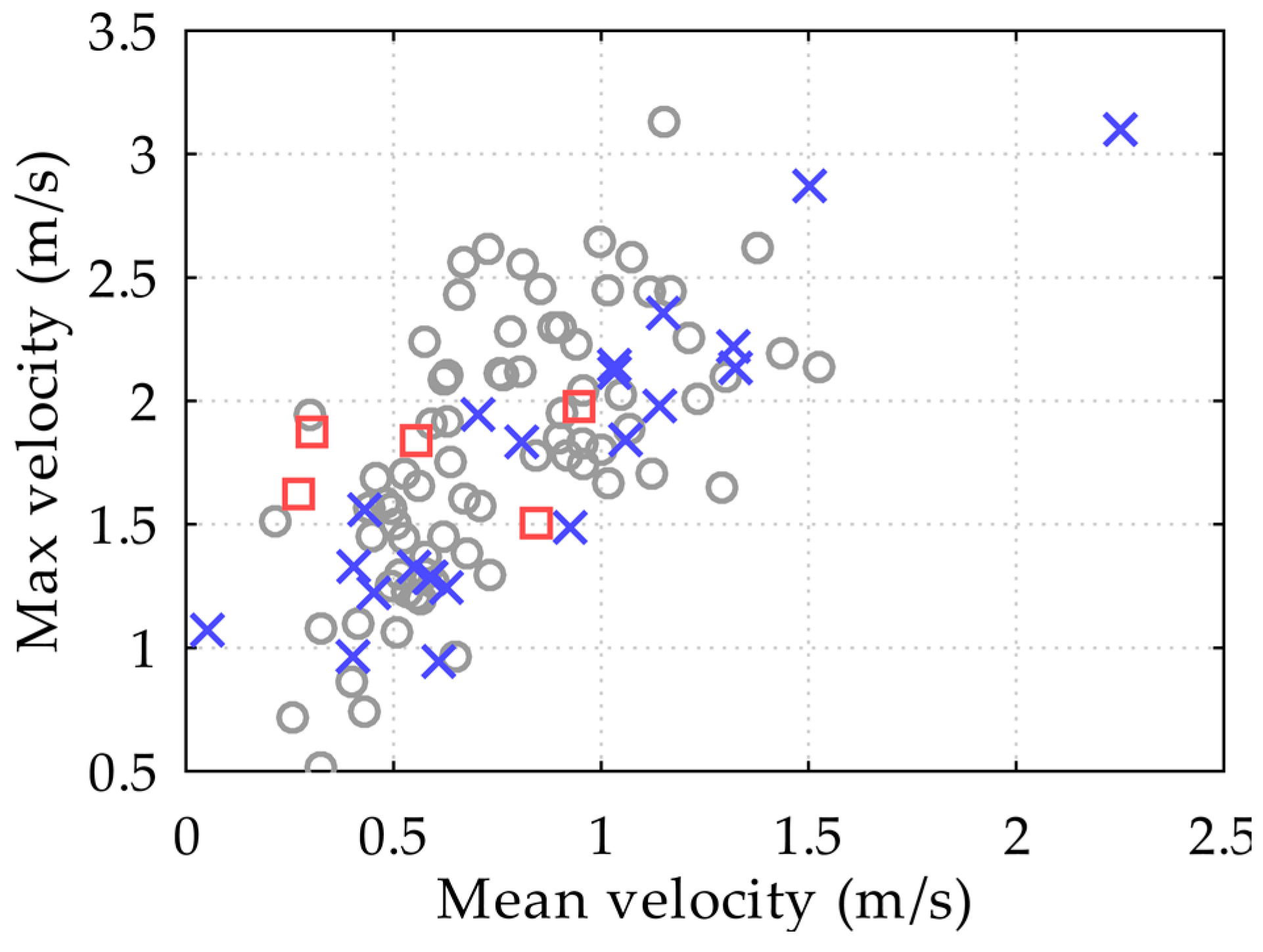

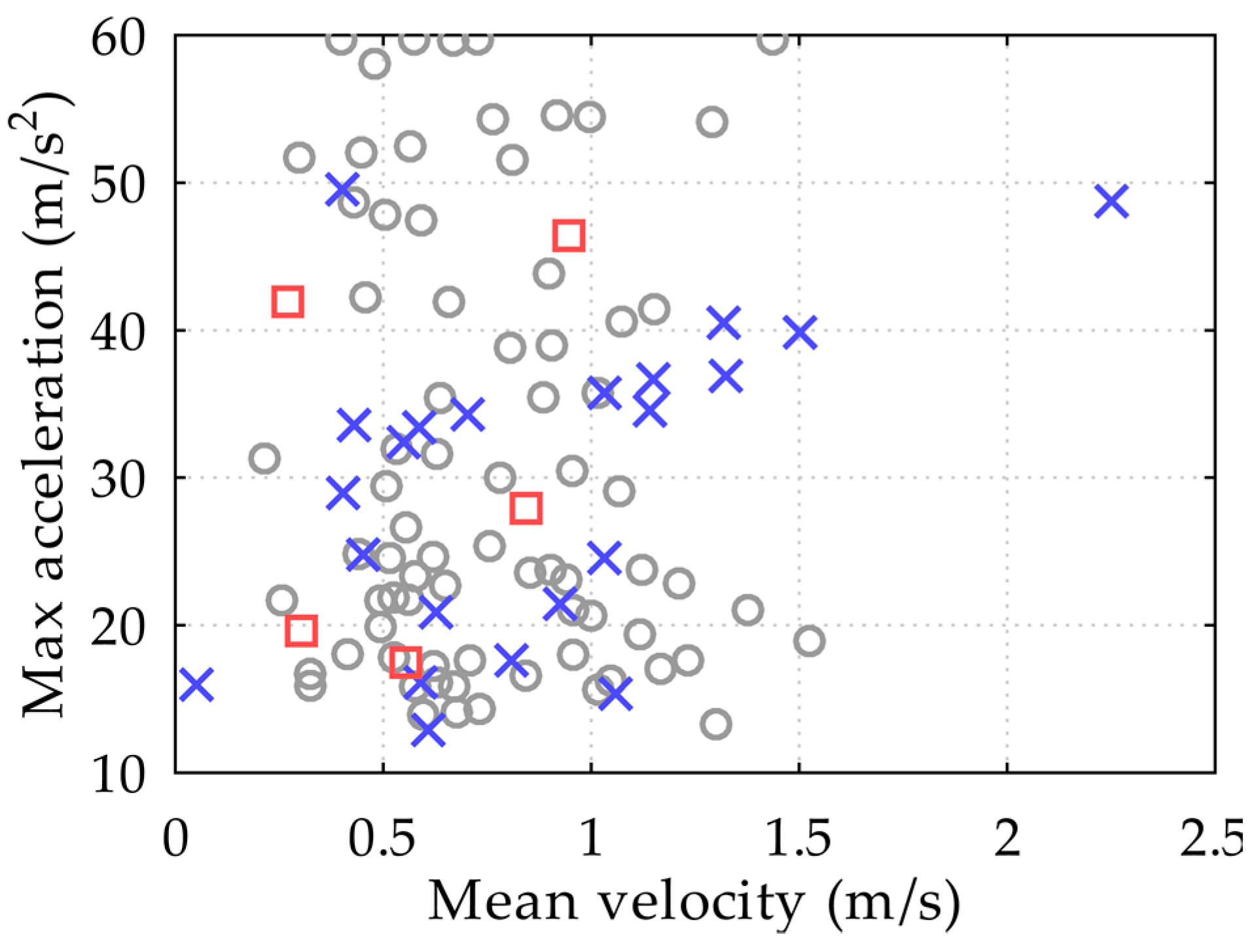

- the maximum lowering speed of the spreader.

- the average lowering speed of the spreader.

- the maximum amplitude of shock-induced acceleration oscillations during the first contact.

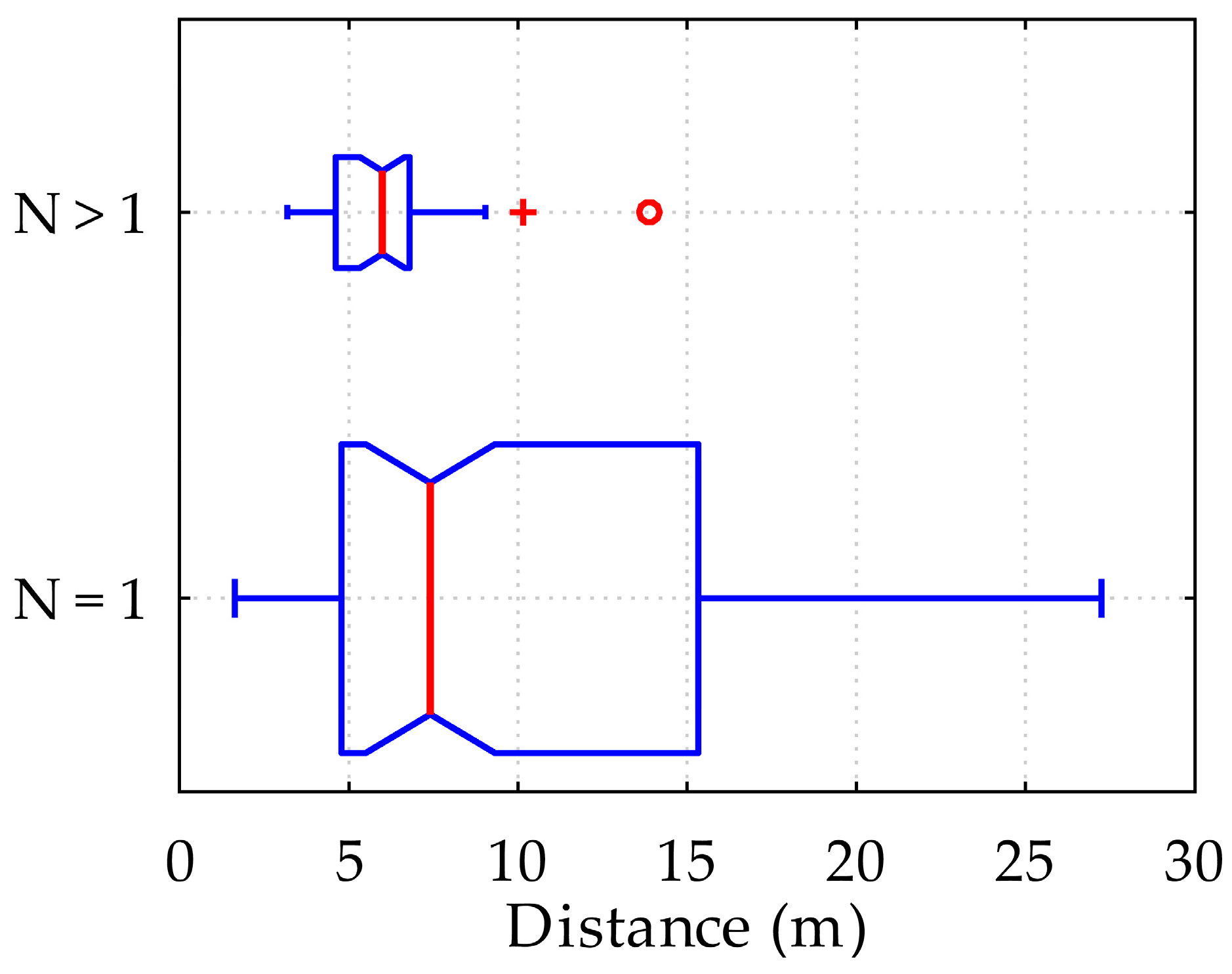

- the number of container hooking attempts.

3. Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hoffmann, N.; Stahlbock, R.; Voß, S. A Decision Model on the Repair and Maintenance of Shipping Containers. J. Shipp. Trade 2020, 5, 22. [Google Scholar] [CrossRef]

- American Bureau of Shippins. Certification of Container Securing Systems. 2019. Available online: https://safety4sea.com/wp-content/uploads/2019/11/abs-guide-for-certification-of-container-securing-systems-2019_09.pdf (accessed on 7 March 2023).

- Parreño-Torres, C.; Çalık, H.; Alvarez-Valdes, R.; Ruiz, R. Solving the Generalized Multi-Port Container Stowage Planning Problem by a Matheuristic Algorithm. Comput. Oper. Res. 2021, 133, 105383. [Google Scholar] [CrossRef]

- Lu, H.; Wang, S. A Study on Multi-ASC Scheduling Method of Automated Container Terminals Based on Graph Theory. Comput. Ind. Eng. 2019, 129, 404–416. [Google Scholar] [CrossRef]

- Chu, Y.; Zhang, X.; Yang, Z. Multiple Quay Cranes Scheduling for Double Cycling in Container Terminals. PLoS ONE 2017, 12, e0180370. [Google Scholar] [CrossRef] [Green Version]

- Mi, C.; Huang, Y.; Liu, H.; Yang, S.; Mi, W. Study on Target Detection & Recognition Using Laser 3D Vision Systems for Automatic Ship Loader. Sens. Transducers 2013, 158, 436–442. [Google Scholar]

- Mi, C.; Zhang, Z.; He, X.; Huang, Y.; Mi, W. Two-Stage Classification Approach for Human Detection in Camera Video in Bulk Ports. Polish Marit. Res. 2015, 22, 163–170. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Gao, J.; Zeng, Q.; Sun, Y. Multitype Damage Detection of Container Using CNN Based on Transfer Learning. Math. Probl. Eng. 2021, 2021, 5395494. [Google Scholar] [CrossRef]

- Lee, J. Deep Learning–Assisted Real-Time Container Corner Casting Recognition. Int. J. Distrib. Sens. Networks 2019, 15. [Google Scholar] [CrossRef]

- Abdullahi, A.M.; Mohamed, Z.; Selamat, H.; Pota, H.R.; Zainal Abidin, M.S.; Ismail, F.S.; Haruna, A. Adaptive Output-Based Command Shaping for Sway Control of a 3D Overhead Crane with Payload Hoisting and Wind Disturbance. Mech. Syst. Signal Process. 2018, 98, 157–172. [Google Scholar] [CrossRef]

- Smoczek, J.; Szpytko, J. Evolutionary Algorithm-Based Design of a Fuzzy TBF Predictive Model and TSK Fuzzy Anti-Sway Crane Control System. Eng. Appl. Artif. Intell. 2014, 28, 190–200. [Google Scholar] [CrossRef]

- Yoon, H.; Hwang, Y.; Cha, E. Real-Time Container Position Estimation Method Using Stereo Vision for Container Auto-Landing System. In Proceedings of the ICCAS 2010, Gyeonggi-do, Republic of Korea, 27–30 October 2010; pp. 872–876. [Google Scholar]

- Lajjam, A.; El Merouani, M.; Tabaa, Y.; Medouri, A. A New Approach for Sequencing Loading and Unloading Operations in the Seaside Area of a Container Terminal. Int. J. Supply Oper. Manag. 2014, 1, 328–346. [Google Scholar]

- Kim, Y.S.; Shim, H.; Yoshihara, H.; Fujioka, N.; Kasahara, H.; Sul, S.K. A New Vision-Sensorless Anti-Sway Control System for Container Cranes. Conf. Rec.—IAS Annu. Meet. IEEE Ind. Appl. Soc. 2003, 1, 262–269. [Google Scholar] [CrossRef]

- Andersen, I.M.V.; Jensen, J.J. Measurements in a Container Ship of Wave-Induced Hull Girder Stresses in Excess of Design Values. Mar. Struct. 2014, 37, 54–85. [Google Scholar] [CrossRef]

- Szyszko, M. Physico-Mechanical Wear Processes of Cell Guides in Container Ships -Phenomenology. Solid State Phenom. 2015, 225, 145–150. [Google Scholar] [CrossRef]

- Kugler, M.; Brandenburg, M.; Limant, S. Automizing the Manual Link in Maritime Supply Chains? An Analysis of Twistlock Handling Automation in Container Terminals. Marit. Transp. Res. 2021, 2, 100017. [Google Scholar] [CrossRef]

- Arena, A.; Casalotti, A.; Lacarbonara, W.; Cartmell, M.P. Dynamics of Container Cranes: Three-Dimensional Modeling, Full-Scale Experiments, and Identification. Int. J. Mech. Sci. 2015, 93, 8–21. [Google Scholar] [CrossRef]

- Maghsoudi, M.J.; Ramli, L.; Sudin, S.; Mohamed, Z.; Husain, A.R.; Wahid, H. Improved Unity Magnitude Input Shaping Scheme for Sway Control of an Underactuated 3D Overhead Crane with Hoisting. Mech. Syst. Signal Process. 2019, 123, 466–482. [Google Scholar] [CrossRef]

- Ileš, Š.; Matuško, J.; Kolonić, F. Sequential Distributed Predictive Control of a 3D Tower Crane. Control Eng. Pract. 2018, 79, 22–35. [Google Scholar] [CrossRef]

- Mahmood, S.; Hasan, R.; Ullah, A.; Sarker, K.U. SMART Security Alert System for Monitoring and Controlling Container Transportation. In Proceedings of the 2019 4th MEC International Conference on Big Data and Smart City (ICBDSC), Muscat, Oman, 15–16 January 2019. [Google Scholar] [CrossRef]

- Jakovlev, S.; Eglynas, T.; Voznak, M.; Jusis, M.; Partila, P.; Tovarek, J.; Jankunas, V. Detection of Physical Impacts of Shipping Containers during Handling Operations Using the Impact Detection Methodology. J. Mar. Sci. Eng. 2022, 10, 1250. [Google Scholar] [CrossRef]

- Zaja, M.; Roži, T.; Jakovlev, S.; Eglynas, T.; Jusis, M.; Voznak, M.; Partila, P.; Tovarek, J. Detecting Physical Impacts to the Corners of Shipping Containers during Handling Operations Performed by Quay Cranes. J. Mar. Sci. Eng. 2023, 11, 794. [Google Scholar] [CrossRef]

- Jakovlev, S.; Voznak, M. Auto-Encoder-Enabled Anomaly Detection in Acceleration Data: Use Case Study in Container Handling Operations. Machines 2022, 10, 734. [Google Scholar] [CrossRef]

- Bukkapatnam, S.T.S.; Mukkamala, S.; Kunthong, J.; Sarangan, V.; Komanduri, R. Real-Time Monitoring of Container Stability Loss Using Wireless Vibration Sensor Tags. In Proceedings of the 2009 IEEE International Conference on Automation Science and Engineering, Bangalore, India, 22–25 August 2009; pp. 221–226. [Google Scholar] [CrossRef]

- Lauf, J.O.; Sauff, H. Secure Lightweight Tunnel for Monitoring Transport Containers. In Proceedings of the 2007 Third International Conference on Security and Privacy in Communications Networks and the Workshops—SecureComm 2007, Nice, France, 17–21 September 2007; pp. 484–493. [Google Scholar] [CrossRef]

- Lin, G.; Pritoni, M.; Chen, Y.; Granderson, J. Development and Implementation of Fault-Correction Algorithms in Fault Detection and Diagnostics Tools. Energies 2020, 13, 2598. [Google Scholar] [CrossRef]

- Klinger, C. Failures of Cranes Due to Wind Induced Vibrations. Eng. Fail. Anal. 2014, 43, 198–220. [Google Scholar] [CrossRef]

- Kim, G.; Uddin, M.K.; Hong, B. Design and Implementation of Sensor Tag Middleware for Monitoring Containers in Logistics Systems. In Proceedings of the 2009 Third International Conference on Sensor Technologies and Applications, Athens, Greece, 18–23 June 2009; pp. 393–398. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakovlev, S.; Eglynas, T.; Jankunas, V.; Voznak, M.; Jusis, M.; Partila, P.; Tovarek, J. Statistical Evaluation of the Impacts Detection Methodology (IDM) to Detect Critical Damage Occurrences during Quay Cranes Handling Operations. Machines 2023, 11, 638. https://doi.org/10.3390/machines11060638

Jakovlev S, Eglynas T, Jankunas V, Voznak M, Jusis M, Partila P, Tovarek J. Statistical Evaluation of the Impacts Detection Methodology (IDM) to Detect Critical Damage Occurrences during Quay Cranes Handling Operations. Machines. 2023; 11(6):638. https://doi.org/10.3390/machines11060638

Chicago/Turabian StyleJakovlev, Sergej, Tomas Eglynas, Valdas Jankunas, Miroslav Voznak, Mindaugas Jusis, Pavol Partila, and Jaromir Tovarek. 2023. "Statistical Evaluation of the Impacts Detection Methodology (IDM) to Detect Critical Damage Occurrences during Quay Cranes Handling Operations" Machines 11, no. 6: 638. https://doi.org/10.3390/machines11060638

APA StyleJakovlev, S., Eglynas, T., Jankunas, V., Voznak, M., Jusis, M., Partila, P., & Tovarek, J. (2023). Statistical Evaluation of the Impacts Detection Methodology (IDM) to Detect Critical Damage Occurrences during Quay Cranes Handling Operations. Machines, 11(6), 638. https://doi.org/10.3390/machines11060638