Hybrid 3D Printing of Functional Smart Hinges

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. SMP Ink Characterization

2.3. Printing System and Filament Printing Protocol

2.4. Characterization of Self-Supporting Capability

2.5. Hinge 3D Printing, Characterization, and Application

2.6. Statistical Analysis

3. Results

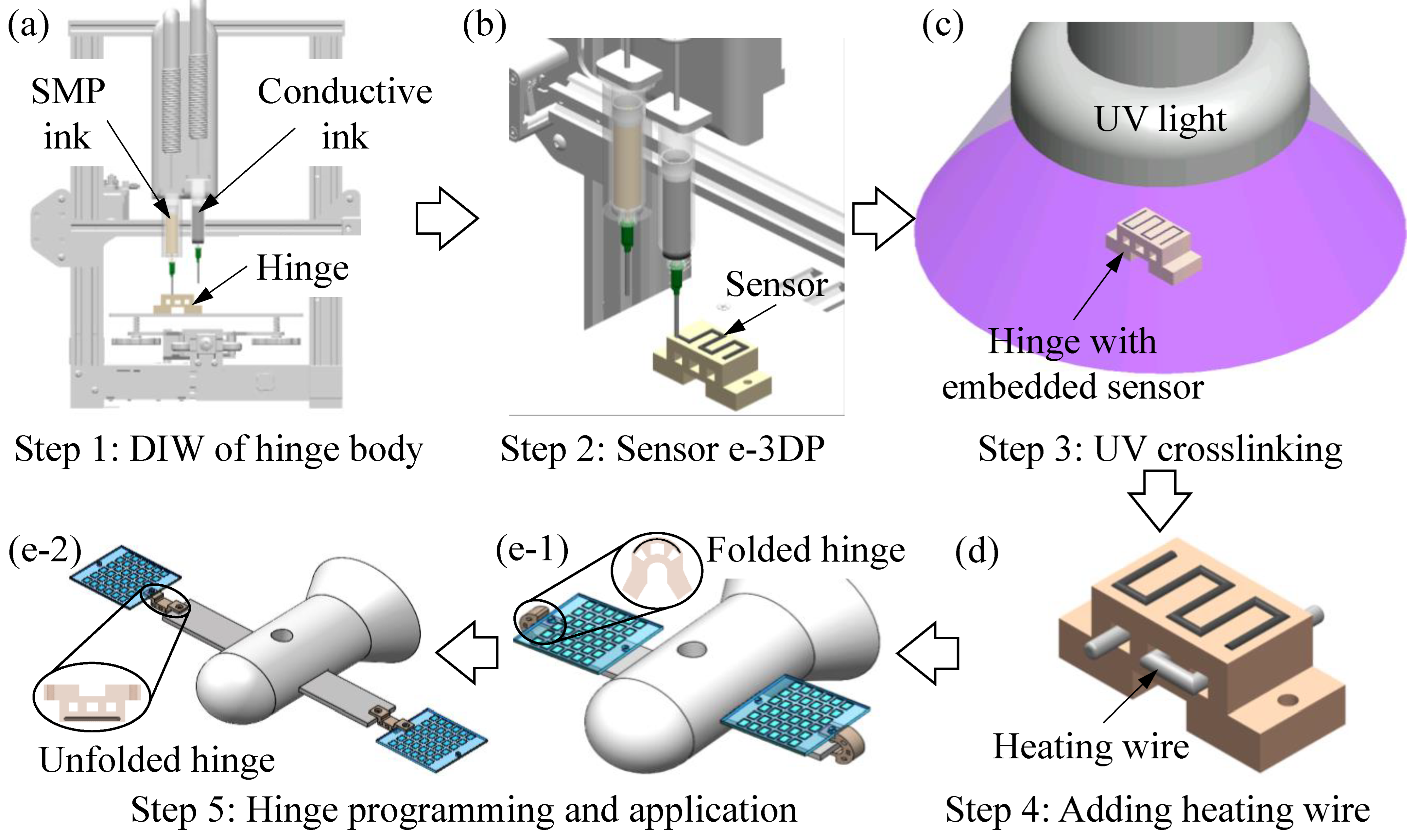

3.1. Mechanism of the Proposed 3D Printing Method

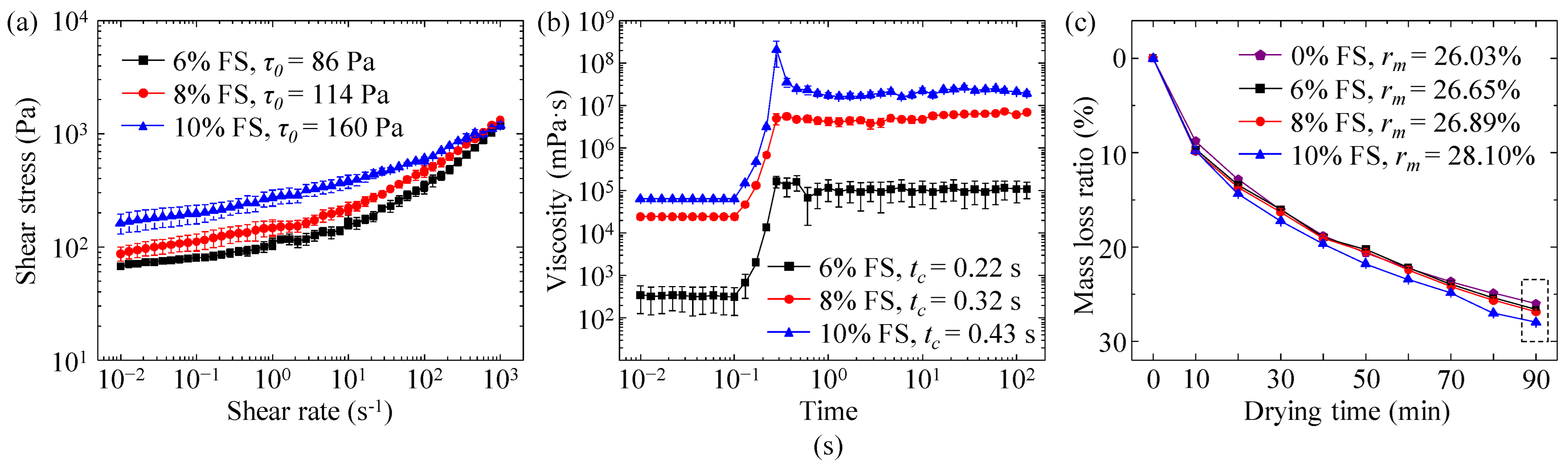

3.2. Effects of FS Concentrations on the Rheological and Dry-Out Properties of SMP Inks

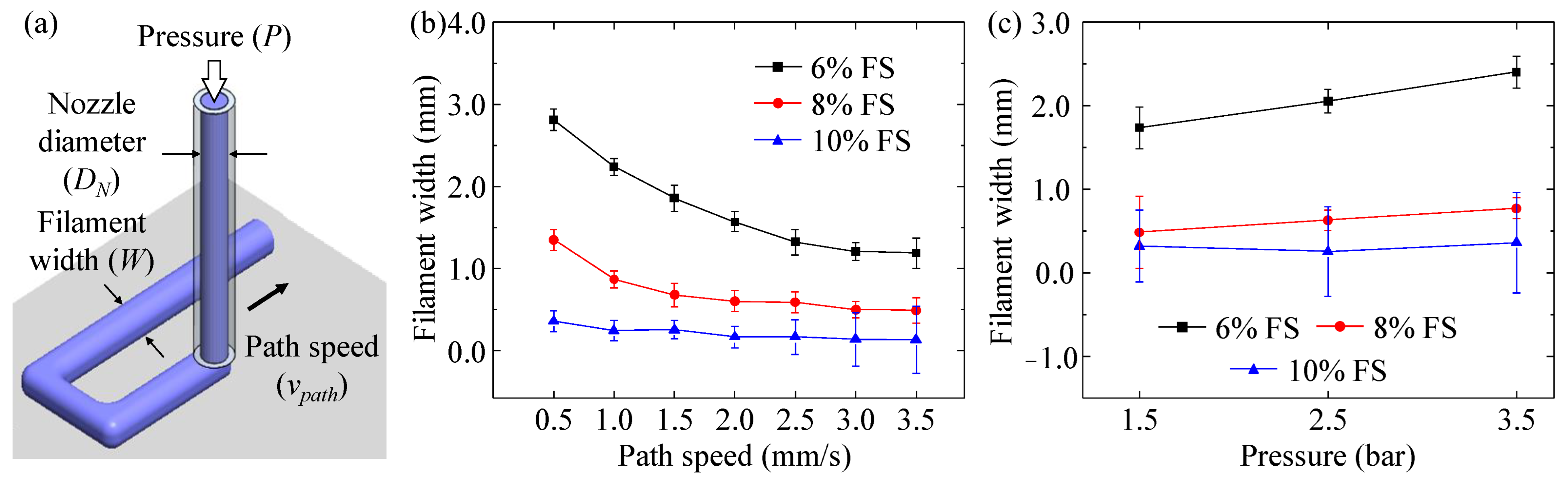

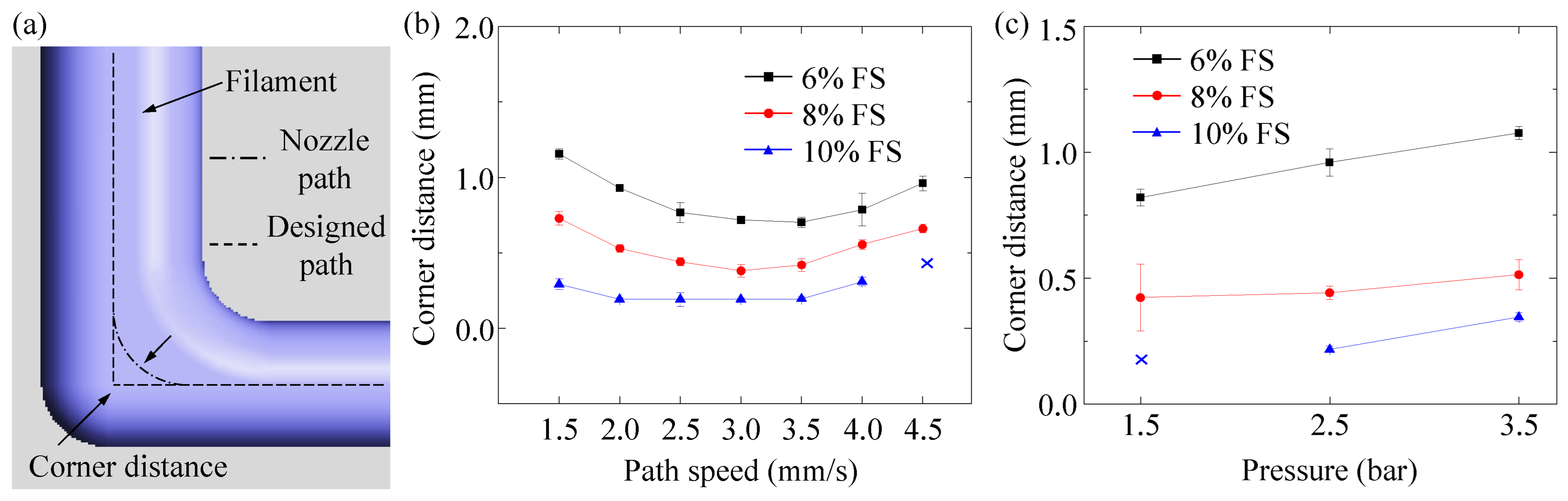

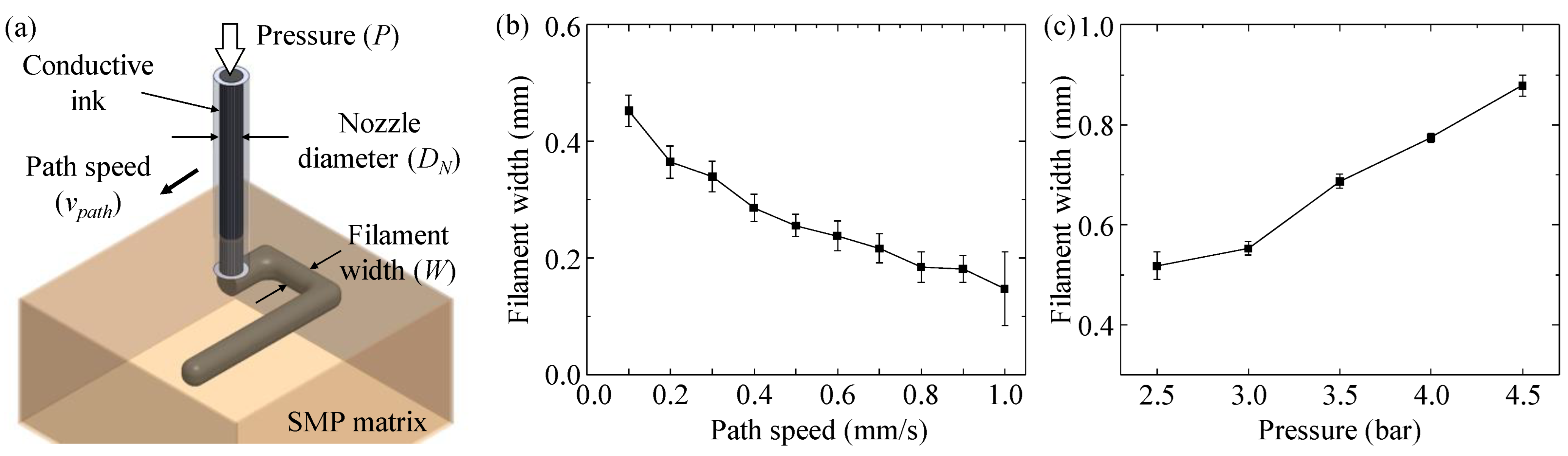

3.3. Filament Printing in DIW and E-3DP

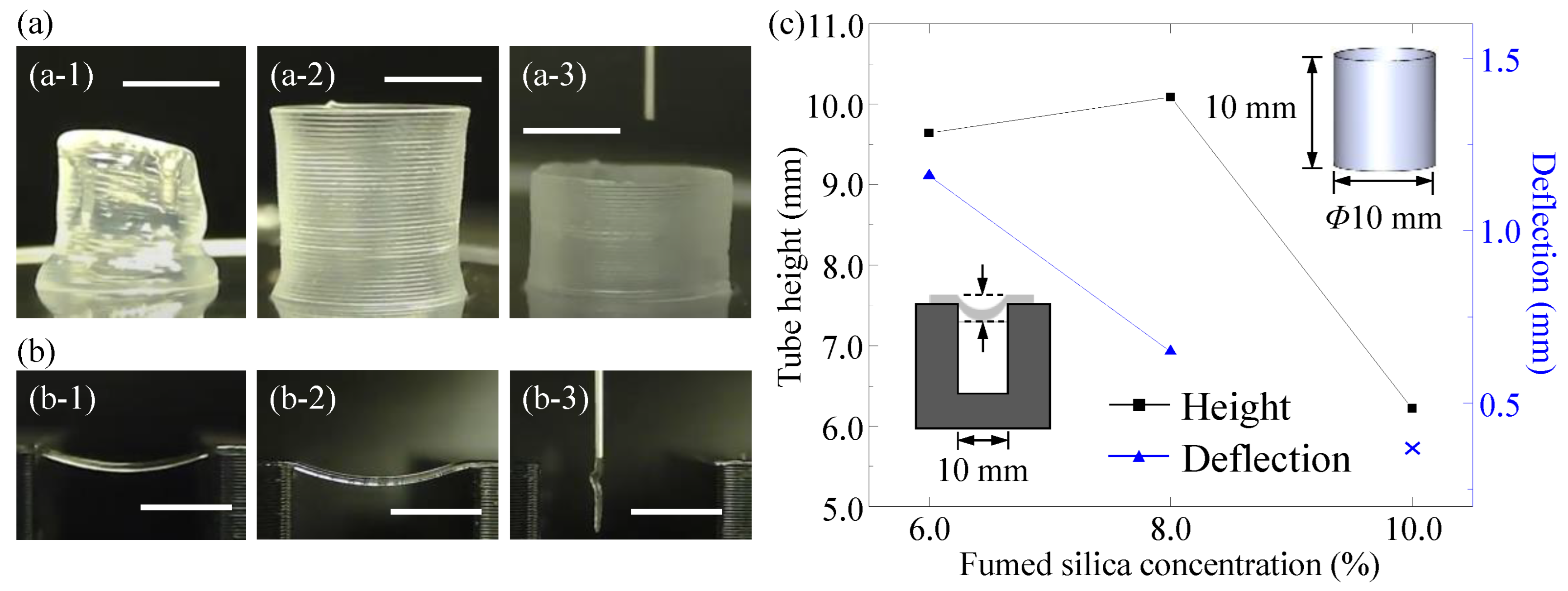

3.4. Characterization of Self-Supporting Capability

3.5. Smart Hinge Printing and Performance Testing

3.6. Smart Hinge Application Testing

4. Conclusions and Future Work

- The concentration of FS was found to have a significant impact on the properties of the SMP ink. Specifically, a lower FS concentration resulted in lower yield stress, shorter thixotropic response time, and lower mass loss over time.

- An 8% FS concentration was chosen as the ideal concentration to achieve better control over filament geometries and exhibited the best self-supporting capability.

- The resistance of the hinge was measured using the e-3DP strain sensor and voltage divider, and the smart hinges were able to deploy mock solar panels on a mock space shuttle.

- This method holds great promise for manufacturing diverse functional devices with embedded sensors in the future.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Asar, A.; Irfan, M.S.; Khan, K.A.; Zaki, W.; Umer, R. Self-sensing shape memory polymer composites reinforced with functional textiles. Compos. Sci. Technol. 2022, 221, 109219. [Google Scholar] [CrossRef]

- Booth, R.E.; Khanna, C.; Schrickx, H.M.; Siddika, S.; Al Shafe, A.; O’Connor, B.T. Electrothermally actuated semitransparent shape memory polymer composite with application as a wearable touch sensor. ACS Appl. Mater. Interfaces 2022, 14, 53129–53138. [Google Scholar] [CrossRef] [PubMed]

- Lantada, A.D.; De Blas Romero, A.; Tanarro, E.C. Micro-vascular shape-memory polymer actuators with complex geometries obtained by laser stereolithography. Smart Mater. Struct. 2016, 25, 065018. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Panahi-Sarmad, M.; Dong, K.; Li, R.; Chen, T.; Xiao, X. Tracing evolutions in electro-activated shape memory polymer composites with 4D printing strategies: A systematic review. Compos. Part Appl. Sci. Manuf. 2021, 147, 106444. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Raasch, J.; Ivey, M.; Aldrich, D.; Nobes, D.S.; Ayranci, C. Characterization of polyurethane shape memory polymer processed by material extrusion additive manufacturing. Addit. Manuf. 2015, 8, 132–141. [Google Scholar] [CrossRef]

- Herath, M.; Emmanuel, C.; Jeewantha, J.; Epaarachchi, J. In-Situ Performance Evaluation of Large Shape Memory Polymer Components via Distributed Optical Fibre Sensors. In Proceedings of the 2021 10th International Conference on Information and Automation for Sustainability (ICIAfS), Negambo, Sri Lanka, 11–13 August 2021. [Google Scholar]

- Ke, D.; Chen, Z.; Momo, Z.Y.; Jiani, W.; Xuan, C.; Xiaojie, Y.; Xueliang, X. Recent advances of two-way shape memory polymers and four-dimensional printing under stress-free conditions. Smart Mater. Struct. 2020, 29, 023001. [Google Scholar] [CrossRef]

- Liu, Y.; Lv, H.; Lan, X.; Leng, J.; Du, S. Review of electro-active shape-memory polymer composite. Compos. Sci. Technol. 2009, 69, 2064–2068. [Google Scholar] [CrossRef]

- Mu, T.; Liu, L.; Lan, X.; Liu, Y.; Leng, J. Shape memory polymers for composites. Compos. Sci. Technol. 2018, 160, 169–198. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Zhang, B.; Li, H.; Cheng, J.; Ye, H.; Sakhaei, A.H.; Yuan, C.; Rao, P.; Zhang, Y.; Chen, Z.; Wang, R.; et al. Mechanically robust and UV-curable shape-memory polymers for digital light processing based 4D printing. Adv. Mater. 2021, 33, 2101298. [Google Scholar] [CrossRef]

- Lan, X.; Liu, L.; Pan, C.; Li, F.; Liu, Z.; Hou, G.; Sun, J.; Dai, W.; Wang, L.; Yue, H.; et al. Smart solar array consisting of shape-memory releasing mechanisms and deployable hinges. AIAA J. 2021, 59, 2200–2213. [Google Scholar] [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.B.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akbari, S.; Sakhaei, A.H.; Kowsari, K.; Yang, B.; Serjouei, A.; Yuanfang, Z.; Ge, Q. Enhanced multimaterial 4D printing with active hinges. Smart Mater. Struct. 2018, 27, 065027. [Google Scholar] [CrossRef]

- Sokolowski, W.; Metcalfe, A.; Hayashi, S.; Yahia, L.; Raymond, J. Medical applications of shape memory polymers. Biomed. Mater. Bristol Engl. 2007, 2, S23–S27. [Google Scholar] [CrossRef]

- Lendlein, A.; Langer, R. Biodegradable, elastic shape-memory polymers for potential biomedical applications. Science 2002, 296, 1673–1676. [Google Scholar] [CrossRef]

- Nohut, S.; Schwentenwein, M. Vat photopolymerization additive manufacturing of functionally graded materials: A review. J. Manuf. Mater. Process 2022, 6, 17. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Z.; Zhang, J.; Wang, X.; Xu, Y.; Ding, N.; Peng, Z. Vat photopolymerization 3D printing of advanced soft sensors and actuators: From architecture to function. Adv. Mater. Technol. 2021, 6, 2001218. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3D printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Karapidakis, E.; Moutsopoulou, A. Functionality versus sustainability for PLA in MEX 3D printing: The impact of generic process control factors on flexural response and energy efficiency. Polymers 2023, 15, 1232. [Google Scholar] [CrossRef]

- Kumaresan, R.; Samykano, M.; Kadirgama, K.; Ramasamy, D.; Keng, N.W.; Pandey, A.K. 3D printing technology for thermal application: A brief review. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 83, 84–97. [Google Scholar] [CrossRef]

- Nam, S.; Pei, E. The influence of shape changing behaviors from 4D printing through material extrusion print patterns and infill densities. Materials 2020, 13, 3754. [Google Scholar] [CrossRef]

- Garcia, R.C.A.; Kim, H.; Garcia, D.M.F.; Chavez, L.; Castañeda, M.; Tseng, T.-L.B.; Lin, Y. Characterization of shape memory polymer parts fabricated using material extrusion 3D printing technique. Rapid Prototyp. J. 2018, 25, 322–331. [Google Scholar] [CrossRef]

- Sun, Y.; Lueth, T.C. Enhancing torsional stiffness of continuum robots using 3-D topology optimized flexure joints. In IEEE/ASME Transactions on Mechatronics; IEEE: Piscataway, NJ, USA, 2023; pp. 1–9. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Recovery of Particle Reinforced Composite 3D Printing Filament from Recycled Industrial Polypropylene and Glass Fibre Waste. In Proceedings of the 8th World Congress on Mechanical, Chemical, and Material Engineering (MCM’22), Prague, Czech Republic, 31 July–2 August 2022. [Google Scholar] [CrossRef]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct ink writing based 4D printing of materials and their applications. Adv. Sci. 2020, 7, 2001000. [Google Scholar] [CrossRef]

- Valentin, N.; Hua, W.; Kasar, A.K.; Raymond, L.; Menezes, P.L.; Jin, Y. Direct ink writing to fabricate porous acetabular cups from titanium alloy. Bio-Des. Manuf. 2023, 6, 121–135. [Google Scholar] [CrossRef]

- Baniasadi, H.; Ajdary, R.; Trifol, J.; Rojas, O.J.; Seppälä, J. Direct ink writing of aloe vera/cellulose nanofibrils bio-hydrogels. Carbohydr. Polym. 2021, 266, 118114. [Google Scholar] [CrossRef]

- Shiwarski, D.J.; Hudson, A.R.; Tashman, J.W.; Feinberg, A.W. Emergence of FRESH 3D printing as a platform for advanced tissue biofabrication. APL Bioeng. 2021, 5, 010904. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; He, N. A mini-review of embedded 3D printing: Supporting media and strategies. J. Mater. Chem. B 2020, 8, 10474–10486. [Google Scholar] [CrossRef]

- Hua, W.; Mitchell, K.; Kariyawasam, L.S.; Do, C.; Chen, J.; Raymond, L.; Valentin, N.; Coulter, R.; Yang, Y.; Jin, Y. Three-dimensional printing in stimuli-responsive yield-stress fluid with an interactive dual microstructure. ACS Appl. Mater. Interfaces 2022, 14, 39420–39431. [Google Scholar] [CrossRef]

- Kuang, X.; Chen, K.; Dunn, C.K.; Wu, J.; Li, V.C.F.; Qi, H.J. 3D printing of highly stretchable, shape-memory, and self-healing elastomer toward novel 4D printing. ACS Appl. Mater. Interfaces 2018, 10, 7381–7388. [Google Scholar] [CrossRef]

- Chen, Q.; Sukmanee, T.; Rong, L.; Yang, M.; Ren, J.; Ekgasit, S.; Advincula, R. A dual approach in direct ink writing of thermally cured shape memory rubber toughened epoxy. ACS Appl. Polym. Mater. 2020, 2, 5492–5500. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Zhang, C.; Qu, M.; Fu, X.; Lin, J. Review on microscale sensors with 3D engineered structures: Fabrication and applications. Small Methods 2022, 6, 2101384. [Google Scholar] [CrossRef] [PubMed]

- Hua, W.; Mitchell, K.; Raymond, L.; Valentin, N.; Coulter, R.; Jin, Y. Embedded 3D printing of PDMS-based microfluidic chips for biomedical applications. J. Manuf. Sci. Eng. 2022, 145, 011002. [Google Scholar] [CrossRef]

- Jin, Y.; Song, K.; Gellermann, N.; Huang, Y. Printing of hydrophobic materials in fumed silica nanoparticle suspension. ACS Appl. Mater. Interfaces 2019, 11, 29207–29217. [Google Scholar] [CrossRef]

- Jiang, F.; Zhou, M.; Drummer, D. Effects of fumed silica on thixotropic behavior and processing window by UV-assisted direct ink writing. Polymers 2022, 14, 3107. [Google Scholar] [CrossRef]

- Chung, S.-C.; Hahm, W.-G.; Im, S.-S. Poly(ethylene terephthalate)(PET) nanocomposites filled with fumed silicas by melt compounding. Macromol. Res. 2002, 10, 221–229. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, C.; Chai, W.; Compaan, A.; Huang, Y. Self-supporting nanoclay as internal scaffold material for direct printing of soft hydrogel composite structures in air. ACS Appl. Mater. Interfaces 2017, 9, 17456–17465. [Google Scholar] [CrossRef]

- Sakhakarmy, M.; Tian, S.; Raymond, L.; Xiong, G.; Chen, J.; Jin, Y. Printability study of self-supporting graphene oxide-laponite nanocomposites for 3D printing applications. Int. J. Adv. Manuf. Technol. 2021, 114, 343–355. [Google Scholar] [CrossRef]

- Xie, H.; Yang, K.-K.; Wang, Y.-Z. Photo-cross-linking: A powerful and versatile strategy to develop shape-memory polymers. Prog. Polym. Sci. 2019, 95, 32–64. [Google Scholar] [CrossRef]

- Truby, R.L.; Wehner, M.; Grosskopf, A.K.; Vogt, D.M.; Uzel, S.G.M.; Wood, R.J.; Lewis, J.A. Soft somatosensitive actuators via embedded 3D printing. Adv. Mater. 2018, 30, 1706383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saramito, P. A new elastoviscoplastic model based on the Herschel–bulkley viscoplastic model. J. Non-Newton. Fluid Mech. 2009, 158, 154–161. [Google Scholar] [CrossRef] [Green Version]

- Jamorin International. Available online: https://jamorin.com/products/tert-butyl-acrylate-tba/#:~:text=tert%2DButyl%20Acrylate%20(TBA)%20is%20an%20ester%20of%20acrylic,and%20a%20long%20hydrophobic%20group (accessed on 10 June 2023).

- Australian Government Department of Climate Change, Energy, the Environment and Water. Available online: https://www.dcceew.gov.au/environment/protection/npi/substances/fact-sheets/acrylic-acid#:~:text=As%20a%20volatile%20organic%20compound,low%20growth%20rate%20in%20plants (accessed on 10 June 2023).

- U.S. Environmental Protection Agency. Available online: https://www.epa.gov/indoor-air-quality-iaq/technical-overview-volatile-organic-compounds#:~:text=Volatile%20organic%20compounds%2C%20or%20VOCs,of%20temperature%20and%20pressure3 (accessed on 10 June 2023).

- Jin, Y.; Chai, W.; Huang, Y. Printability study of hydrogel solution extrusion in nanoclay yield-stress bath during printing-then-gelation biofabrication. Mater. Sci. Eng. C 2017, 80, 313–325. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Xiong, R.; Antonelli, P.J.; Long, C.J.; McAleer, C.W.; Hickman, J.J.; Huang, Y. Nanoclay suspension-enabled extrusion bioprinting of three-dimensional soft structures. J. Manuf. Sci. Eng. 2021, 143, 313–325. [Google Scholar] [CrossRef]

- Wei, X.; Li, H.; He, X.; Li, Z.; Ye, H.; Xue, W.; Ge, Q. Shape Memory Polymer-Based Stiffness Variable Soft Actuator Via Digital Light Processing-Based 3D Printing. In Proceedings of the 2021 27th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021. [Google Scholar]

- All About Circuits. Available online: https://www.allaboutcircuits.com/tools/voltage-divider-calculator/ (accessed on 29 March 2023).

- Qiu, L.; Yue, X.; Xie, Z. Design and analysis of multicavity flexure hinge (MCFH) based on three-dimensional continuum topology optimization. Mech. Mach. Theory 2019, 139, 21–33. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raymond, L.; Bandala, E.; Hua, W.; Mitchell, K.; Tsabedze, T.; Leong, K.; Zhang, J.; Jin, Y. Hybrid 3D Printing of Functional Smart Hinges. Machines 2023, 11, 686. https://doi.org/10.3390/machines11070686

Raymond L, Bandala E, Hua W, Mitchell K, Tsabedze T, Leong K, Zhang J, Jin Y. Hybrid 3D Printing of Functional Smart Hinges. Machines. 2023; 11(7):686. https://doi.org/10.3390/machines11070686

Chicago/Turabian StyleRaymond, Lily, Erick Bandala, Weijian Hua, Kellen Mitchell, Thulani Tsabedze, Kaitlin Leong, Jun Zhang, and Yifei Jin. 2023. "Hybrid 3D Printing of Functional Smart Hinges" Machines 11, no. 7: 686. https://doi.org/10.3390/machines11070686

APA StyleRaymond, L., Bandala, E., Hua, W., Mitchell, K., Tsabedze, T., Leong, K., Zhang, J., & Jin, Y. (2023). Hybrid 3D Printing of Functional Smart Hinges. Machines, 11(7), 686. https://doi.org/10.3390/machines11070686