Kinematic Modeling and Simulation of a New Robot for Wingbox Internal Fastening Application

Abstract

1. Introduction

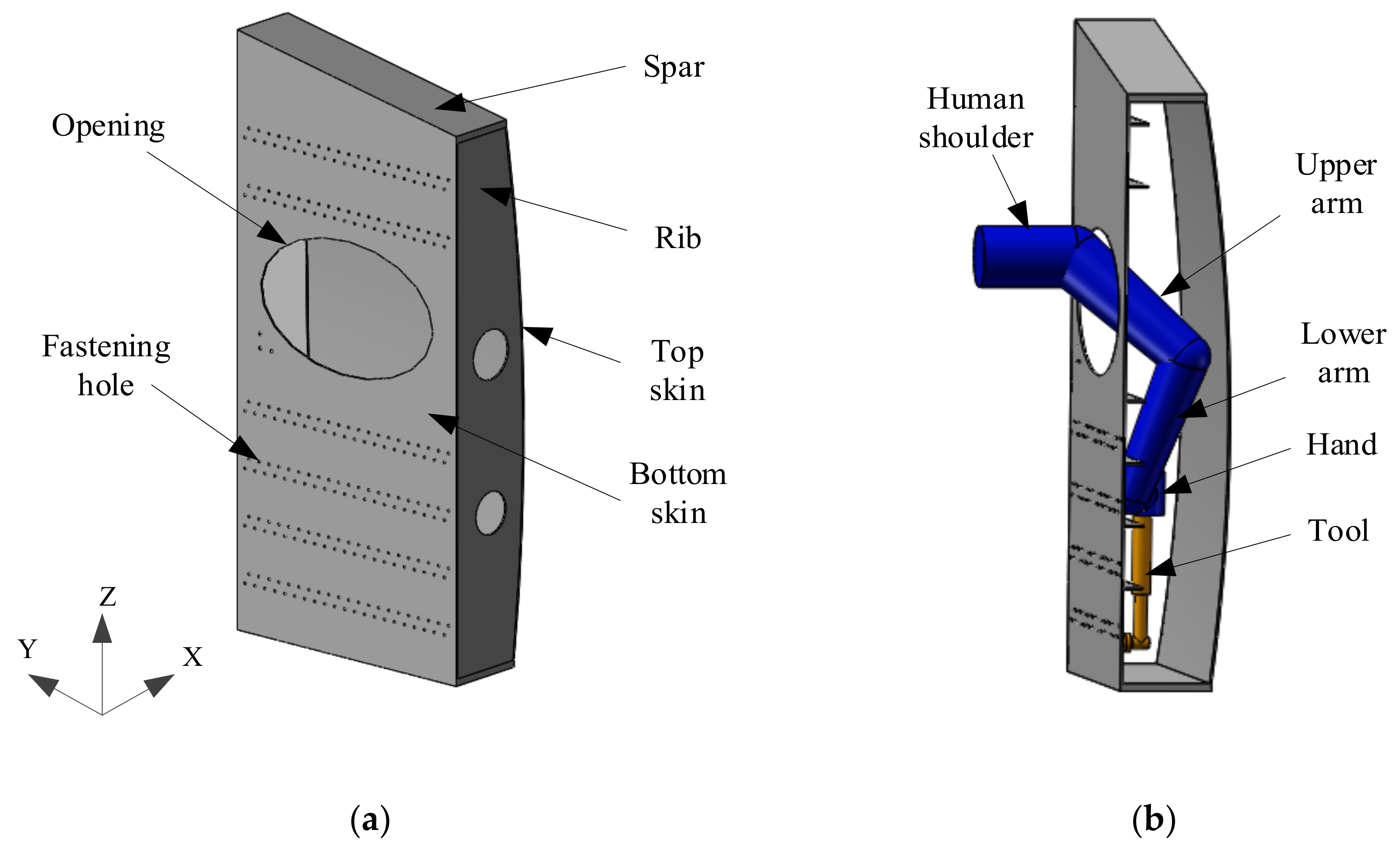

2. Robotic Design of Mechanical System

2.1. Robotic Conception for Internal Fastening

2.2. Robotic Mechanical Design

3. Robotic Control System

4. Kinematic Modeling

4.1. Forward Kinematic Model

4.2. Inverse Kinematic Model

5. Results and Analysis

5.1. Workspace Analysis

5.2. Inverse Kinematic Calculation and Simulation Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, J.; Bi, Y.; Dong, H.; Ke, Y.; Fan, X.; Du, K. Influence of interference fit size on hole deformation and residual stress in hi-lock bolt insertion. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 3296–3305. [Google Scholar] [CrossRef]

- Chen, X.; Tian, W.; Xue, H. Automatic riveting technology and its development in aircraft digital assembly. Aviat. Manuf. Technol. 2016, 5, 52–56. [Google Scholar]

- Gray, T.; Orf, D.; Adams, G. Mobile Automated Robotic Drilling, Inspection, and Fastening; SAE Technical Paper 2013-01-2338; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Xi, F.; Yu, L.; Tu, X. Framework on robotic percussive riveting for aircraft assembly automation. Adv. Manuf. 2013, 1, 112–122. [Google Scholar] [CrossRef]

- Müller, R.; Hörauf, L.; Vette, M.; Martin, J.L.S.; Alzaga, A.; Hohmann, J.; Althoefer, K.; Würdemann, H. Robot guided bolt tensioning tool with adaptive process control for the automated assembly of wind turbine rotor blade bearings. Prod. Eng. Res. Dev. 2014, 8, 755–764. [Google Scholar] [CrossRef]

- Duan, X.; Wang, Y.; Liu, Q.; Li, M.; Kong, X. Manipulation robot system based on visual guidance for sealing blocking plate of steam generator. J. Nucl. Sci. Technol. 2016, 53, 281–288. [Google Scholar] [CrossRef]

- Jiang, J.; Xi, F.; Bi, Y. Design and analysis of a robotic end-effector for automated hi-lok nut installation. Coatings 2022, 12, 904. [Google Scholar] [CrossRef]

- Liu, M.; Liang, X.; Wang, C.; Wang, J. A robotic hi-lite bolts/collars assembly system and control strategy. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics, Macau, China, 5–8 December 2017; pp. 2255–2260. [Google Scholar]

- Zhang, Y.; Song, H.; Guo, X.; Tang, C. Robust object positioning for visual robotics in automatic assembly line under data-scarce environments. Machines 2022, 10, 1079. [Google Scholar] [CrossRef]

- Chu, B.; Jung, K.; Ko, K.H.; Hong, D. Mechanism and analysis of a robotic bolting device for steel beam assembly. In Proceedings of the International Conference on Control, Automation and Systems, Gyeonggi-do, Republic of Korea, 27–30 October 2010; pp. 2351–2356. [Google Scholar]

- Jiang, W.; Zhou, Z.; Yan, Y.; Wu, G.; Yu, L.; Li, H.J.; Chen, W. Fuzzy control-based bolt tightening for power cable maintenance robot. Ind. Robot. Int. J. 2018, 45, 561–571. [Google Scholar] [CrossRef]

- Ali, M.A.; Alshameri, M.A. An intelligent adjustable spanner for automated engagement with multi-diameter bolts/nuts during tightening/loosening process using vision system and fuzzy logic. Int. J. Adv. Manuf. Technol. 2019, 101, 2795–2813. [Google Scholar] [CrossRef]

- Lukić, B.; Jovanović, K.; Žlajpah, L.; Petrič, T. Online Cartesian compliance shaping of redundant robots in assembly tasks. Machines 2023, 11, 35. [Google Scholar] [CrossRef]

- Transeth, A.A.; Pettersen, K.Y.; Liljebäck, P. A survey on snake robot modeling and locomotion. Robotica 2009, 27, 999–1015. [Google Scholar] [CrossRef]

- Wright, C.; Buchan, A.; Brown, B.; Geist, J.; Schwerin, M.; Rollinson, D.; Tesch, M.; Choset, H. Design and architecture of the unified modular snake robot. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, St. Paul, MN, USA, 14–18 May 2012; pp. 4347–4354. [Google Scholar]

- Rollinson, D.; Choset, H. Pipe network locomotion with a snake robot. J. Field Robot. 2016, 33, 322–336. [Google Scholar] [CrossRef]

- Buckingham, R.; Chitrakaran, V.; Conkie, R.; Ferguson, G.; Graham, A.; Lazell, A. Snake-Arm Robots: A New Approach to Aircraft Assembly; SAE Technical Paper Series 2007-01-3870; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Dong, X.; Axinte, D.; Palmer, D.; Cobos, S.; Raffles, M.; Rabani, A.; Kell, J. Development of a slender continuum robotic system for on-wing inspection/repair of gas turbine engines. Robot. Comput. Integr. Manuf. 2017, 44, 218–229. [Google Scholar] [CrossRef]

- Yao, Y.; Du, Z.; Wei, Z. Research on snake-arm robot assembly system. Aviat. Manuf. Technol. 2015, 21, 26–30. [Google Scholar]

- Zheng, Y.; Wu, B.; Chen, Y.; Zeng, L.; Gu, G.; Zhu, X.; Xu, K. Design and validation of cable-driven hyper-redundant manipulator with a closed-loop puller-follower controller. Mechatronics 2021, 78, 102605. [Google Scholar] [CrossRef]

- Jiang, J.; Xi, F.; You, J.; Xue, Q. Mechanical design of a new anthropomorphic robot for fastening in wing-box. In Proceedings of the ASME IDETC-CIE2021, Virtual, 17−19 August 2021. DETC2021-68098. [Google Scholar]

| Link | ai (m) | αi (rad) | di (m) | θi (rad) | Variable Scope (m or rad) |

|---|---|---|---|---|---|

| 1 | 0 | π/2 | d1 | π/2 | [0, 0.65] |

| 2 | 0 | π/2 | 0.15 | θ2 | [−π, π] |

| 3 | 0.11 | 0 | 0 | θ3 | [0, 3π/2] |

| 4 | 0.11 | 0 | 0 | θ4 | [−π, 0] |

| 5 | 0.38 | 0 | 0 | θ5 | [−π/2, π] |

| Positions (Px, Py, Pz) (m) | d1 (m) | θ2 (°) | θ3 (°) | θ4 (°) | θ5 (°) |

|---|---|---|---|---|---|

| P1 (0.15, −0.20, 0.70) | 0.40 | 146.31 | 163.42 | −124.83 | −38.59 |

| P2 (0.15, 0, 0.70) | 0.40 | −180 | 183.06 | −108.80 | −74.26 |

| P3 (0.15, 0.20, 0.70) | 0.40 | −146.31 | 163.42 | −124.83 | −38.59 |

| P4 (0.15, −0.20, 0.10) | 0.40 | 33.69 | 163.42 | −124.83 | −38.59 |

| P5 (0.15, 0, 0.10) | 0.40 | 0 | 183.06 | −108.80 | −74.26 |

| P6 (0.15, 0.20, 0.70) | 0.40 | −33.69 | 163.42 | −124.83 | −38.59 |

| P7 (0.15, −0.20, 0.10) | 0.40 | 21.80 | 63.82 | −63.16 | −0.67 |

| P8 (0.15, −0, 0.10) | 0.40 | 0 | 84.57 | −89.53 | 4.96 |

| P9 (0.15, −0.20, 0.10) | 0.40 | −21.80 | 63.82 | −63.16 | −0.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; You, J.; Bi, Y. Kinematic Modeling and Simulation of a New Robot for Wingbox Internal Fastening Application. Machines 2023, 11, 753. https://doi.org/10.3390/machines11070753

Jiang J, You J, Bi Y. Kinematic Modeling and Simulation of a New Robot for Wingbox Internal Fastening Application. Machines. 2023; 11(7):753. https://doi.org/10.3390/machines11070753

Chicago/Turabian StyleJiang, Jiefeng, Jingjing You, and Yunbo Bi. 2023. "Kinematic Modeling and Simulation of a New Robot for Wingbox Internal Fastening Application" Machines 11, no. 7: 753. https://doi.org/10.3390/machines11070753

APA StyleJiang, J., You, J., & Bi, Y. (2023). Kinematic Modeling and Simulation of a New Robot for Wingbox Internal Fastening Application. Machines, 11(7), 753. https://doi.org/10.3390/machines11070753