Experimental Analysis of Rolling Torque and Thermal Inlet Shear Heating in Tapered Roller Bearings

Abstract

:1. Introduction

1.1. State of the Art

| Author | Equations | Applicability Range |

|---|---|---|

| Aihara, 1987 [12] | The equations were experimentally validated under conditions: Axial load ∈ [0.45 to 1.2 GPa] Rolling speed ∈ [100 to 3000 rpm] Oil type ∈ [Gear oil (80 W)] Oil temperature ∈ [50 to 80 °C] Lubricated condition ∈ [Fully flooded] | |

| Zhou and Hoepprich, 1991 [13] | The equations were experimentally validated under conditions: Axial load ∈ [0.85 to 1.47 GPa] Rolling speed ∈ [100 to 8000 rpm] Oil type ∈ [SAE20, Vactra oil] Oil temperature ∈ [50 °C] Lubricated condition ∈ [Fully flooded] | |

| H. Matsuyama (1998–2001) [14,23,24] | The equations were experimentally validated under conditions: Axial load ∈ [0.3 to 1.3 GPa] Rolling speed ∈ [100 to 1500 rpm] Oil type ∈ [Paraffin-based, traction oil] Oil temperature ∈ [26 °C] Lubricated condition ∈ [Fully flooded] | |

| Houpert 2002 [25] | The equations were experimentally validated under conditions: Axial load ∈ [3500 N] Radial load ∈ [4250 N] Rolling speed ∈ [100 to 4500 rpm] Oil type ∈ [ATF oil] Oil temperature ∈ [50 °C] Lubricated condition ∈ [Fully flooded] | |

| SKF 2003–2004 [15] | The equations were validated for all types of roller bearings and are applicable to both grease- and oil-lubricated bearings under constant loads in magnitude and direction. | |

1.2. Goal of the Paper

2. Materials and Methods

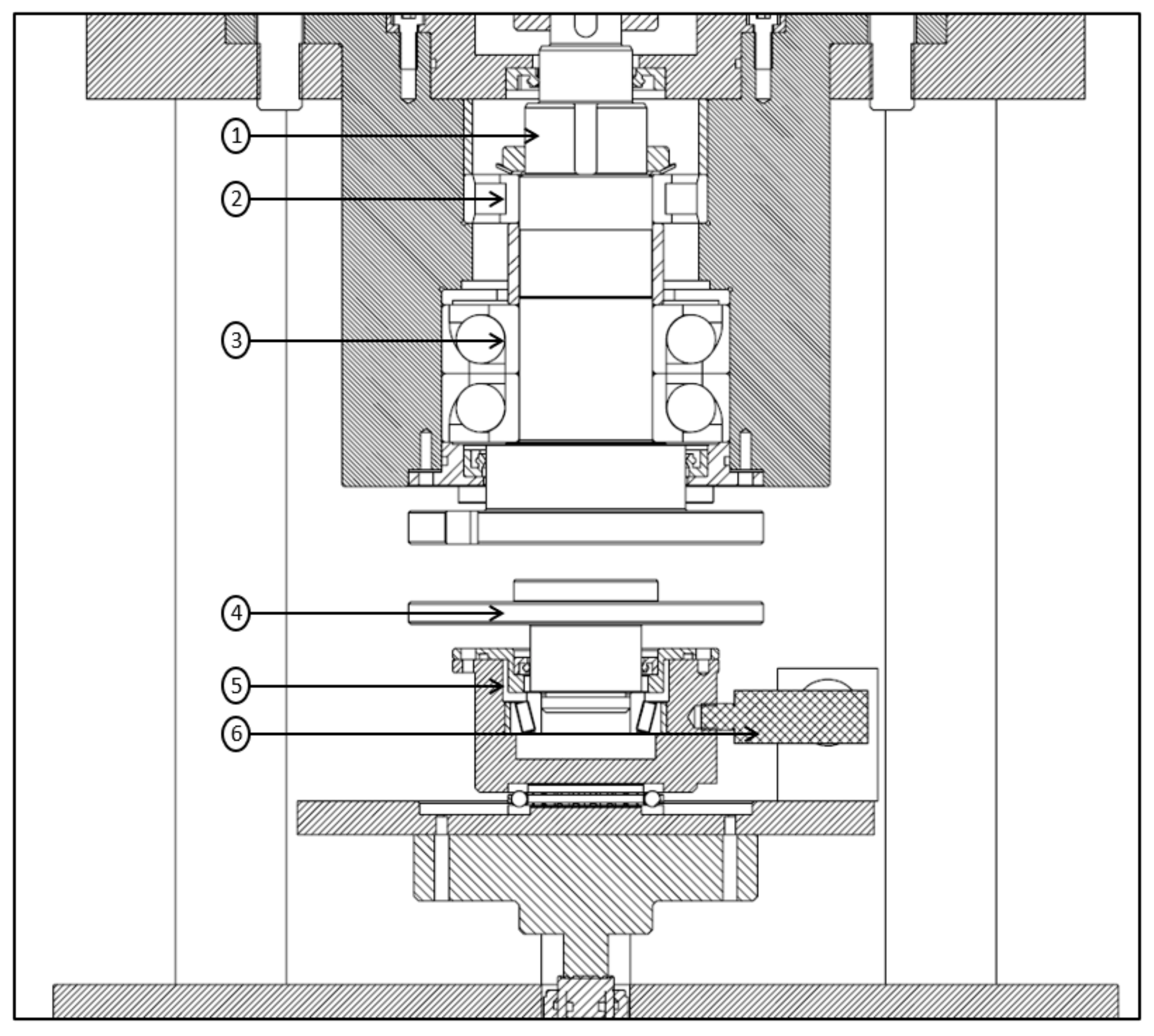

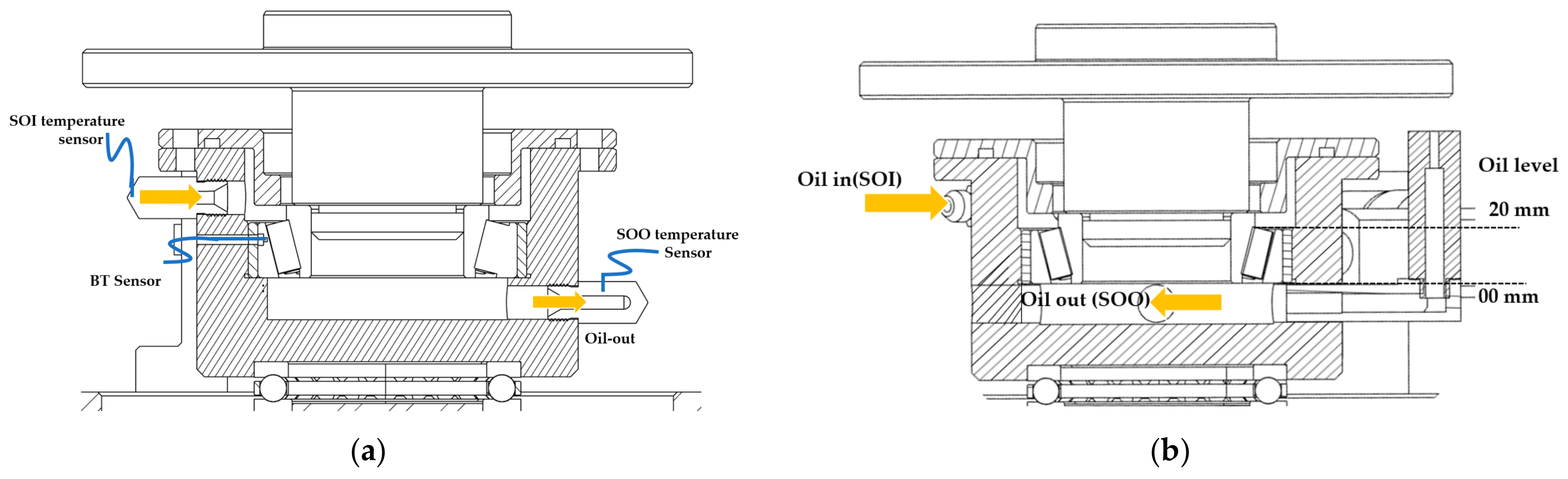

2.1. Experimental Setup

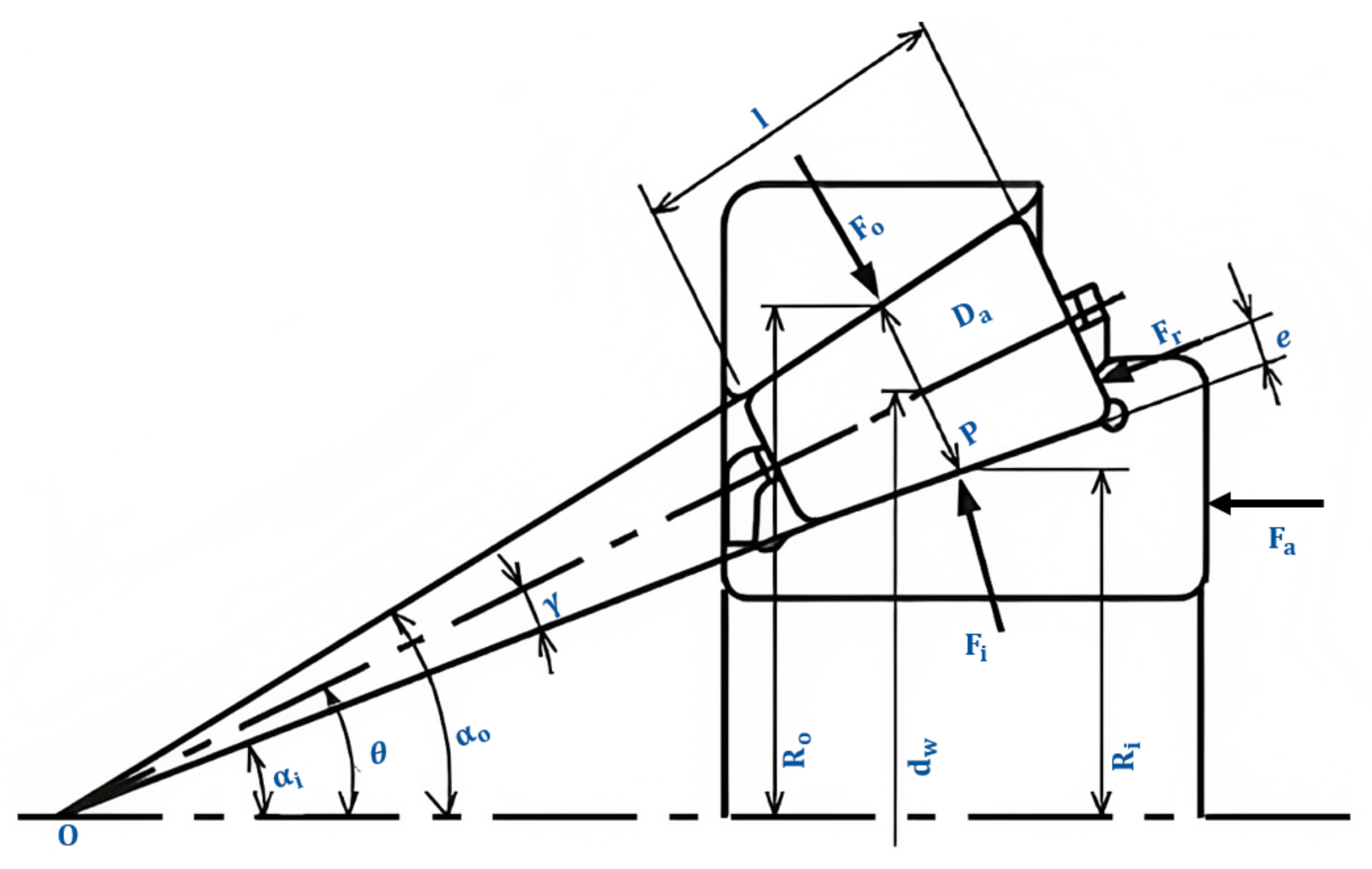

2.2. Test-Bearing Geometry and Forces

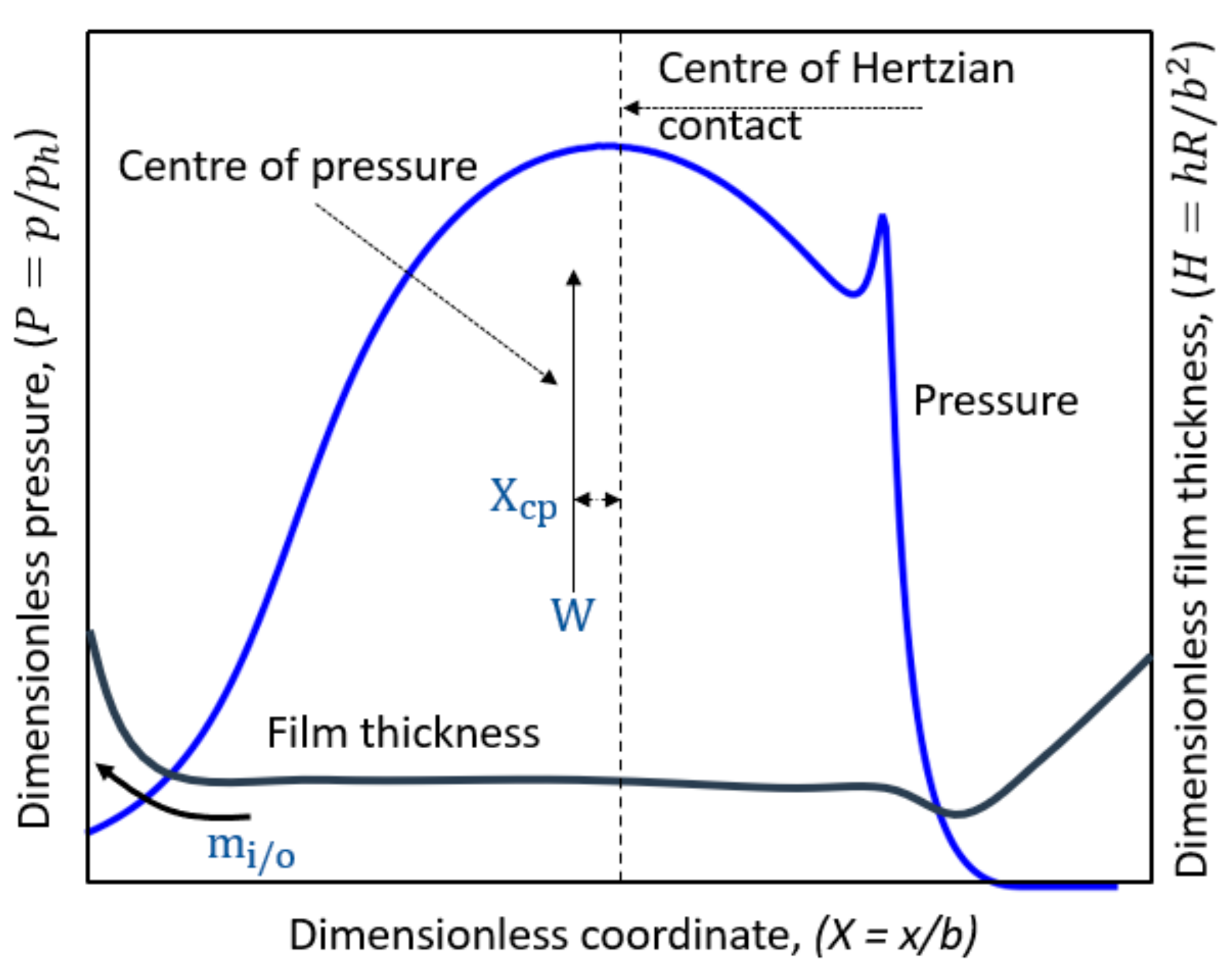

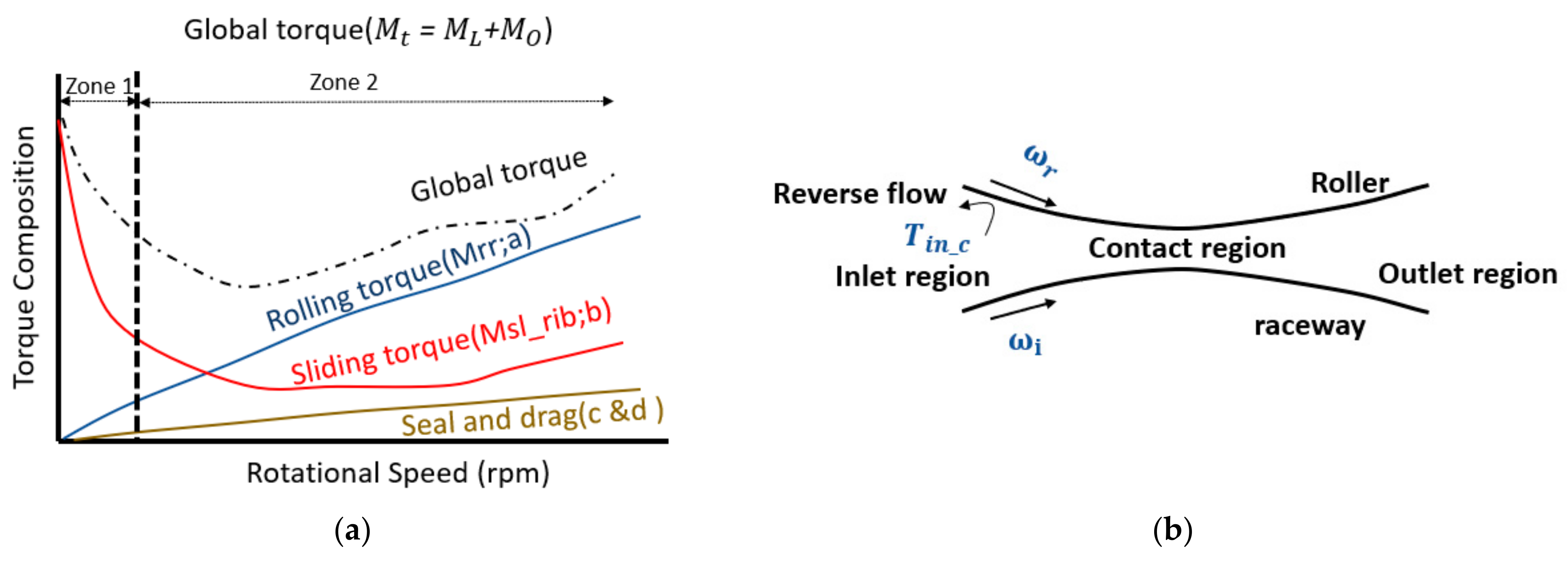

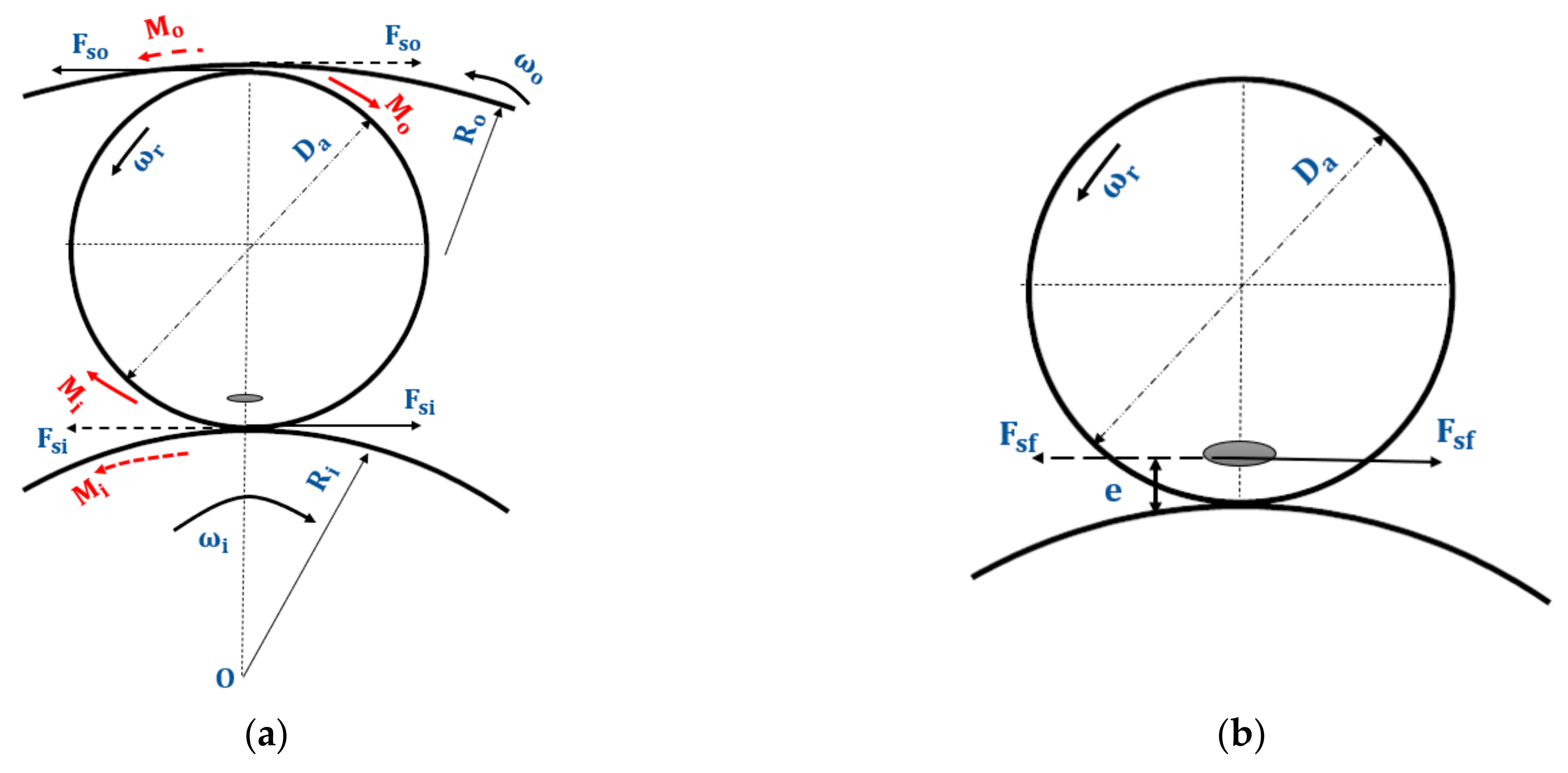

2.2.1. Theoretical Analysis of Viscous Rolling Resistance (, )

2.2.2. Sliding Friction in Roller End and Rib Contacts ()

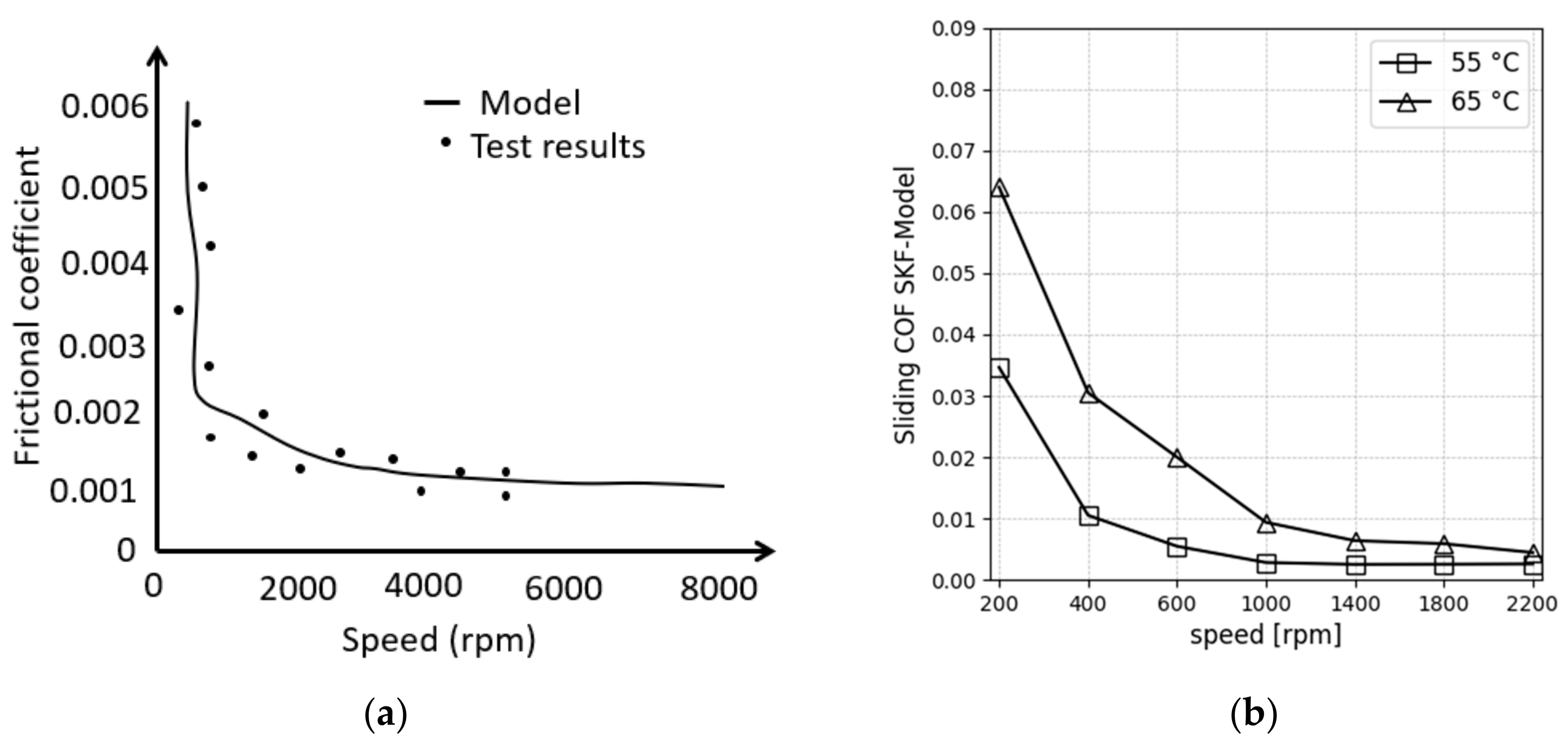

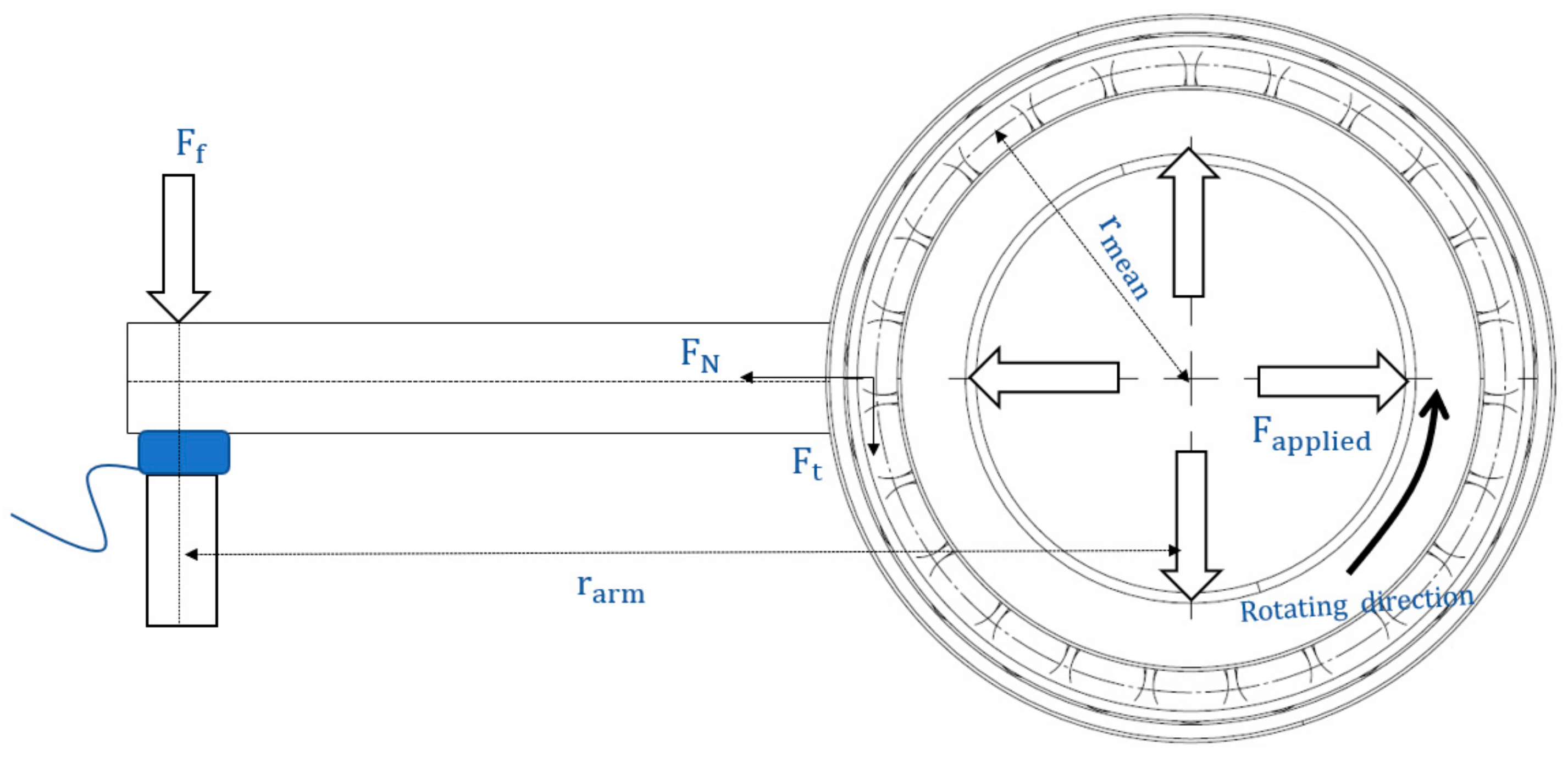

2.3. Frictional Measurements Using RBT Setup

2.4. Importance of Thermal Reduction Factor on Raceway Friction Prediction

3. Design of Experiments and Methodology

| Algorithm 1. Procedure for thermal inlet study. |

| Conduct run-in procedure |

| Experiments to determine the optimal flow rate to minimize drag, i.e., for |

| Experiments for all U, G & W: |

| Measure the total torque |

| Calculate using (Equations (15)–(17)) |

| Calculate (Equation (21)) |

| Calculate thermal inlet shear heating factor (Equation (22)) |

| Result: Thermal inlet shear heating, , effect on raceway torque |

4. Experimental Results

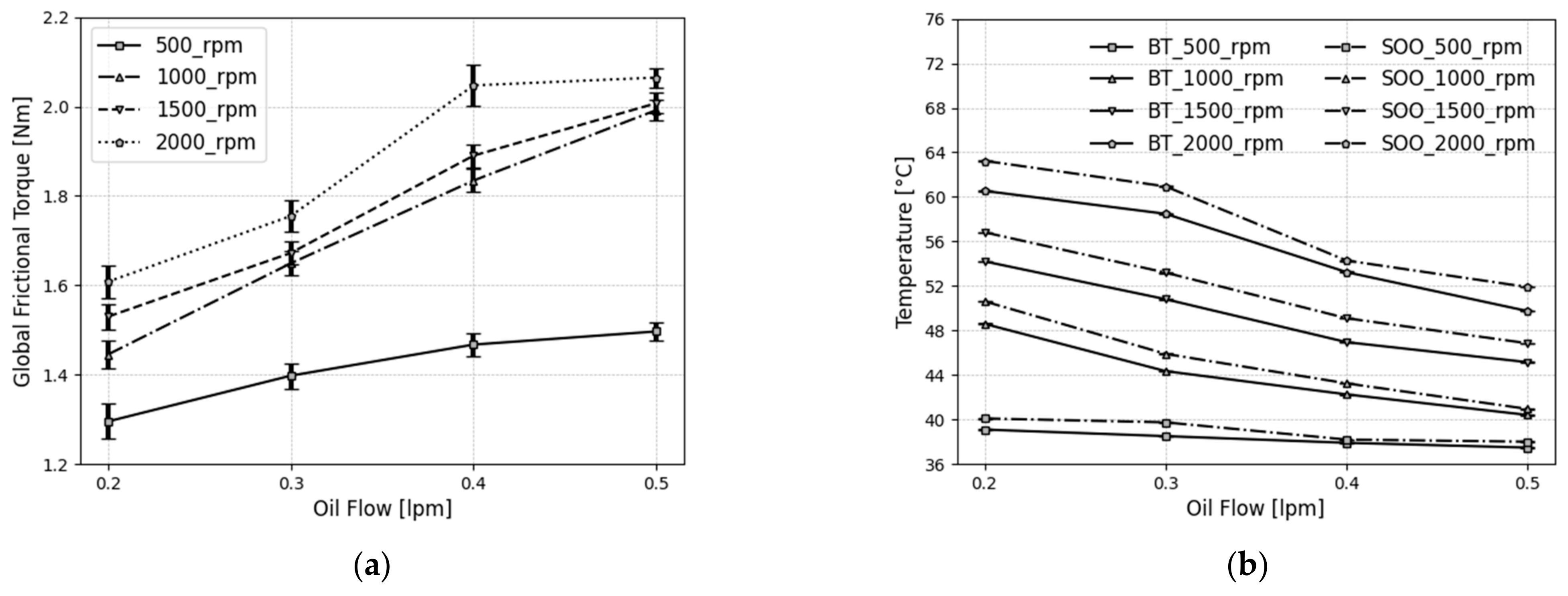

4.1. Determination of Optimum Oil-Flow Rate

4.2. Measurements of the Total Torque

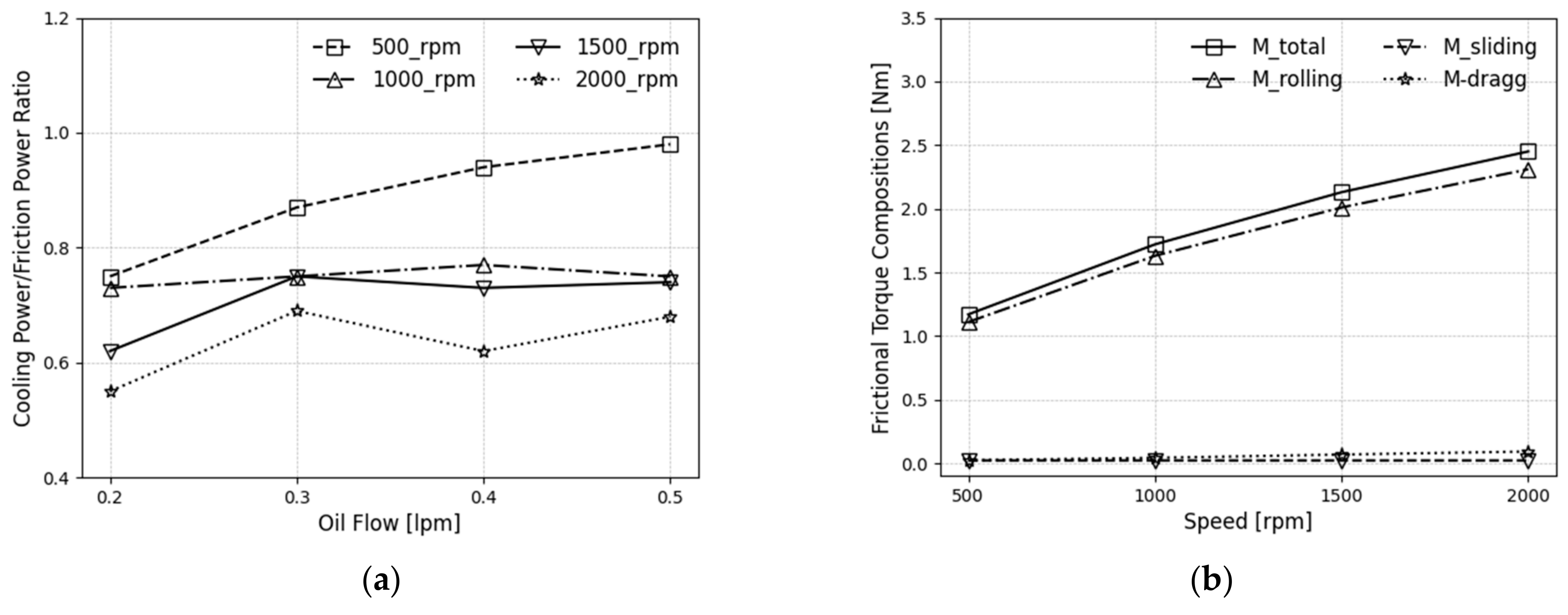

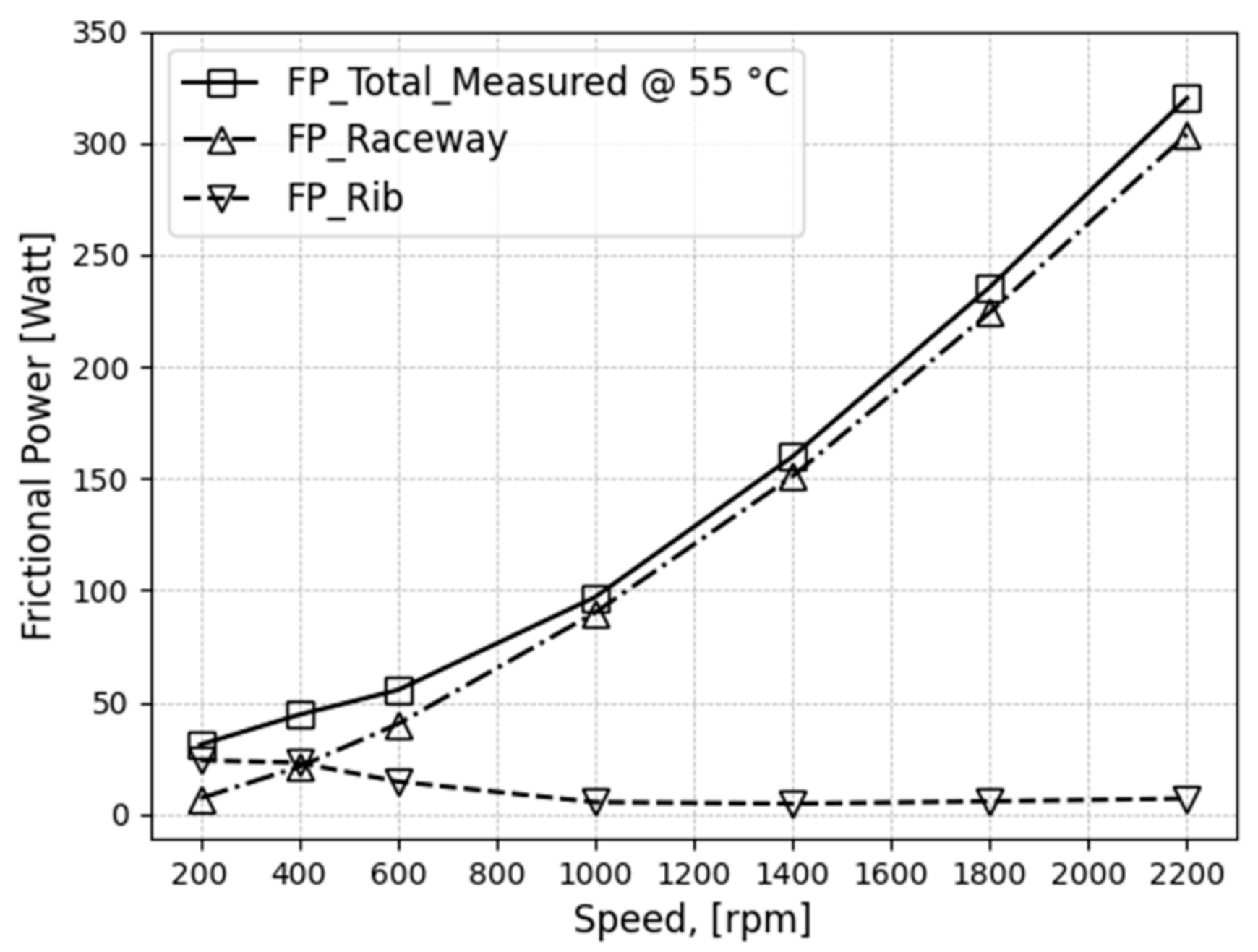

4.3. Roller-Rib Sliding Torque

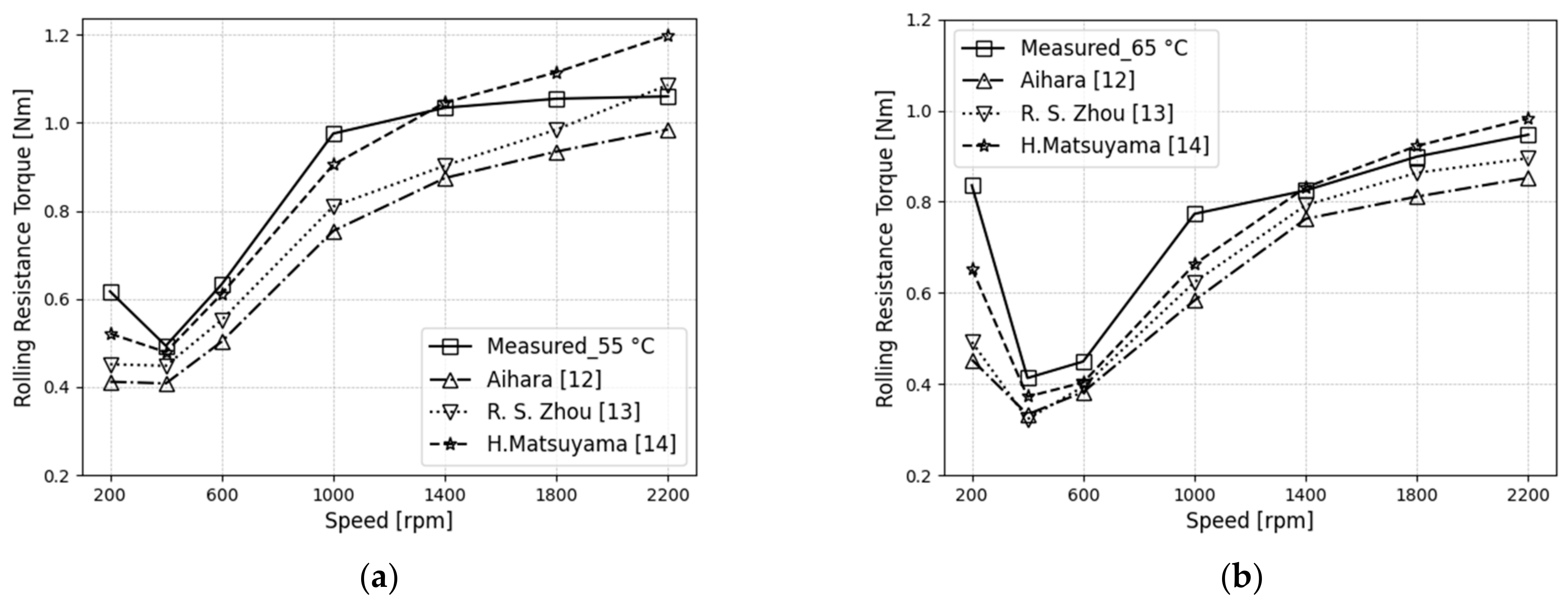

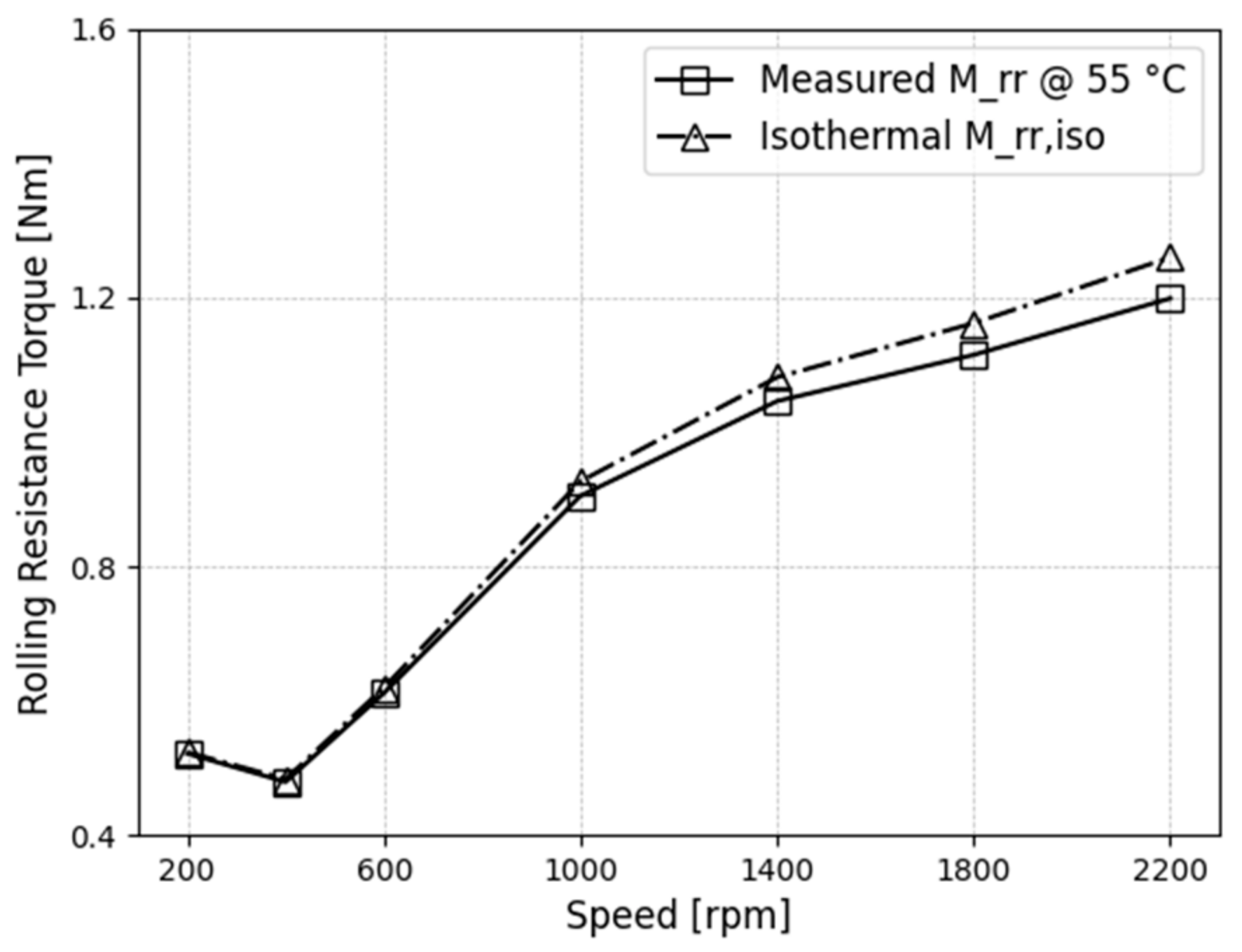

4.4. Rolling Resistance Torque

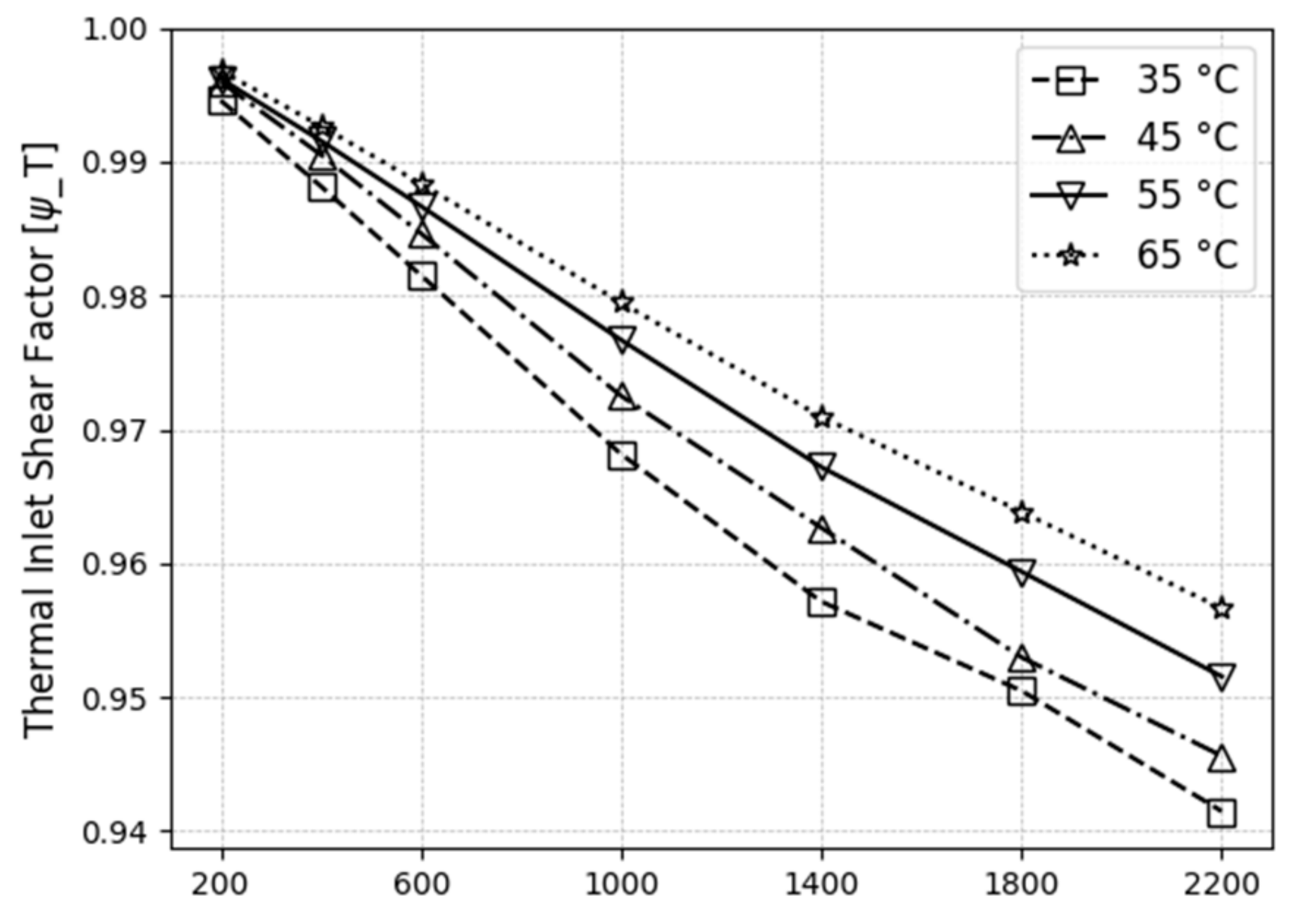

4.5. Thermal Inlet Shear Factor

5. Conclusions

- In the first part of the study, experiments were performed to determine the optimal oil-flow rate that minimizes drag-loss contributions in the global frictional torque while ensuring adequate lubrication and thermal equilibrium. Following that, a comparison was made between the global friction results and the global SKF friction model.

- The predicted global frictional loss by the SKF model for velocities below 400 rpm (referred to as the starting zone) were found to be 15% lower than the experimental values. However, for rotational velocities above 400 rpm (referred to as the running zone), the predicted values fell within a range of 5% to 8% of the experimental values. In this study, rolling friction and sliding-rib friction were identified as the primary contributors to the frictional torque of TRBs.

- The rolling-resistance torque of the TRB was measured for different operating conditions and compared to the theoretical EHL rolling-torque models of Table 1. The model of Matsuyama exhibited a strong predictive capability and demonstrated good agreement with the experimental results.

- Under fully flooded conditions, the EHL rolling torque exhibits a significant increase with increasing dimensionless speed parameter U. This is due to a significant shift of the pressure centre of the hydrodynamic pressure distribution towards the inlet, resulting in an increase in .

- The effect of the dimensionless material parameter G on the rolling torque is relatively small. As G increases, the rolling torque decreases for oil temperatures below 45 °C in this work. However, for oil temperatures above 45 °C, G slightly increases the raceway torque at lower U. The effects of G and W on are minor, whereas the effect of U is significant.

- The thermal inlet shear factor plays a crucial role in rolling friction. For higher rotational velocities, the decrease of rotational torque due to shear heating was estimated to be in the order 6–8%.

- Analysis of frictional power reveals that the TRB experiences heating at low speeds is primarily due to mixed lubrication friction between the roller and rib contact. At higher velocities, ELH friction becomes dominant and rises quickly with velocity, whereas the rib-raceway friction decreases as it shifts from mixed to full film lubrication.

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ATF | Automatic Transmission Fluid |

| b | Hertzian half width contact (m) |

| Constants determined from the experiments. | |

| Pitch circle diameter (m) | |

| E | Rib contact height and roller end (m) |

| Ex | Base of natural logarithm = 2.718 |

| Central film thickness of the oil (m) | |

| K | Thermal conductivity of the oil (W/m/°C) |

| L | Effective roller length (m) |

| Dimensionless viscous-rolling resistance | |

| Moment at the rib contact | |

| N | Rotational speed (rpm) |

| P | Pressure (Pa) |

| Maximum contact pressure (Pa) | |

| Length of measuring lever arm (m) | |

| Mean radius of TRB (m) | |

| Mean surface velocity (m/s) | |

| W | Load-per-unit length (Nm) |

| X | Coordinate of rolling direction |

| X coordinate of center of pressure, m | |

| B | Exponent of asperity load |

| BT | Bearing temperature |

| Weighting factor used to integrate P | |

| COF | Coefficient of friction |

| D | Dynamic load rating |

| Mean roller diameter (m) | |

| Equivalent young’s modulus (Pa) | |

| EHL | Elasto–Hydrodynamic Lubrication |

| Axial load (N) | |

| Mean asperity contacts | |

| Frictional force (N) | |

| Normal load (N) | |

| Load on the roller-end rib (N) | |

| Sliding friction in the raceway roller contact area (N) | |

| Sliding friction in the raceway roller contact area (N) | |

| Sliding friction in the roller end-rib contact area (N) | |

| Tangential force (N) | |

| G | Dimensionless material parameter |

| Limiting elastic shear modulus (N/m2) | |

| L | Thermal-loading factor () |

| Load-dependent frictional loss (Nm) | |

| Load-independent frictional loss (Nm) | |

| Viscous-rolling resistance (Nm) of inner/outer raceway (Nm) | |

| Global frictional torque (Nm) | |

| Rolling-resistance torque (Nm) | |

| Sliding friction in the roller end and rib contacts (Nm) | |

| P | Dimensionless pressure |

| RBT | Roller-bearing tribometer |

| Ri | Mean inner-raceway radius (m) |

| Mean outer-raceway radius (m) | |

| Equivalent radius of roller-raceway (inner, outer) contacts (m) | |

| Re | Equivalent radius in the rolling direction (m) |

| SRR | Slide-to-roll ratio |

| SOI | Supply-oil inlet |

| SOO | Supply-oil outlet |

| TEHL | Thermo–Elasto–Hydrodynamic Lubrication |

| Temperature of oil at the entry of the Hertzian contact (). | |

| Rolling tangential force (N) | |

| TRB | Tapered roller bearing |

| H | Dimensionless oil-film thickness (m) |

| U | Dimensionless speed parameter |

| W | Dimensionless load parameter |

| X | Dimensionless coordinate |

| Dimensionless x coordinate of center of pressure | |

| Z | Number of rollers |

| U | Dimensionless speed parameter |

| Operating viscosity of the oil at atmospheric pressure (Pas) | |

| Pressure viscosity coefficient of lubricant (Pa−1) | |

| Temperature-viscosity coefficient of the lubricant (). | |

| Fluid film factor for rib contacts | |

| Surface film constant | |

| Critical shear stress of the material (N/m2) | |

| Yield stress of the material (N/m2) | |

| Angular velocity of roller (rad/s) | |

| Angular velocity of the inner ring (rad/s) | |

| Thermal reduction factor of rib contact | |

| Thermal reduction factor of raceway | |

| Kinematic replenishment/starvation reduction factor | |

| Frictional coefficient of the rib | |

| Sliding friction coefficient in full film | |

| Shear stress (N/m2) | |

| Limiting shear stress (N/m2) | |

| Shear rate | |

| Constant depending on speed; 0.12 for ; 0.15 for | |

| Weight factor for the sliding friction coefficient | |

| Bearing type and geometry | |

| Inner raceway angle (rad) | |

| Outer raceway angle (rad) | |

| Dimensionless constant |

Appendix A

| Murch Wilson | )) |

| Thermal inlet shear factor | |

| Patir and Cheng | |

| Hamrock Dowson’s | |

| Bair and Winder’s | |

| Reynolds | |

| Dimensionless oil-film thickness | |

| Force equilibrium |

Appendix B. Test-Bearing Geometry and Forces

Appendix C. Sliding Rib Forces and Moment

References

- Dowson, D.; Higginson, G.R. Reflections on Early Studies of Elasto-Hydrodynamic Lubrication. Solid Mech. Its Appl. 2006, 134, 3–21. [Google Scholar] [CrossRef]

- Dowson, D. Elastohydrodynamic and Micro-Elastohydrodynamic Lubrication. Wear 1995, 190, 125–138. [Google Scholar] [CrossRef]

- Gohar, R.; Cameron, A. The Mapping of Elastohydrodynamic Contacts. Wear 1968, 11, 387. [Google Scholar] [CrossRef]

- Neurouth, A.; Changenet, C.; Ville, F.; Arnaudon, A. Thermal Modeling of a Grease Lubricated Thrust Ball Bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 1266–1275. [Google Scholar] [CrossRef]

- Niel, D.; Changenet, C.; Ville, F.; Octrue, M. A New Test Rig to Study Rolling Element Bearing Thermomechanical Behavior. In Proceedings of the International Gear Conference, Villeurbanne, France, 27–29 August 2018; pp. 121–133. [Google Scholar] [CrossRef]

- Pinel, S.I.; Signer, H.R.; Zaretsky, E.V. Design and Operating Characteristics of High-Speed, Small-Bore Ball Bearings. Taylor Fr. Online 2008, 41, 423–434. [Google Scholar] [CrossRef]

- Doll, G.L. Causes and Effects of Bearing Damage. In Rolling Bearing Tribology; Elsevier: Amsterdam, The Netherlands, 2023; pp. 205–231. [Google Scholar] [CrossRef]

- Doll, G.L. Mitigation of Rolling Bearing Damage Modes. In Rolling Bearing Tribology; Elsevier: Amsterdam, The Netherlands, 2023; pp. 233–252. [Google Scholar] [CrossRef]

- Dhanola, A.; Garg, H.C. Tribological Challenges and Advancements in Wind Turbine Bearings: A Review. Eng. Fail. Anal. 2020, 118, 104885. [Google Scholar] [CrossRef]

- Hammami, M.; Martins, R.; Fernandes, C.; Seabra, J.; Abbes, M.S.; Haddar, M. Friction Torque in Rolling Bearings Lubricated with Axle Gear Oils. Tribol. Int. 2018, 119, 419–435. [Google Scholar] [CrossRef]

- Graf, S.; Werner, M.; Koch, O.; Götz, S.; Sauer, B. Breakdown Voltages in Thrust Bearings: Behavior and Measurement. Tribol. Trans. 2023, 66, 488–496. [Google Scholar] [CrossRef]

- Aihara, S. A New Running Torque Formula for Tapered Roller Bearings Under Axial Load. J. Tribol. 1987, 109, 471–477. [Google Scholar] [CrossRef]

- Zhou, R.S.; Hoeprich, M.R. Torque of Tapered Roller Bearings. J. Tribol. 1991, 113, 590–597. [Google Scholar] [CrossRef]

- Matsuyama, H.; Kamamoto, S. Analysis of Frictional Torque in Raceway Contacts of Tapered Roller Bearings. KOYO Eng. J. Engl. Ed. 2001, 159, 53–60. [Google Scholar]

- SKF Group. Rolling Element Bearings Catalogue; SKF: Göteborg, Sweden, 2018; pp. 1–1722. [Google Scholar]

- Harris, T.A.; Kotzalas, M.N. Rolling Bearing Analysis Essential Concepts of Bearing Technology; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Palmgren, A. Ball and Roller Bearing Engineering; SKF Industries Inc.: Philadelphia, PA, USA, 1959. [Google Scholar]

- Murch, L.E.; Wilson, W.R.D. A Thermal Elastohydrodynamic Inlet Zone Analysis. J. Lubr. Technol. 1975, 97, 212–216. [Google Scholar] [CrossRef]

- Goksem, P.G.; Hargreaves, R.A. The Effect of Viscous Shear Heating on Both Film Thickness and Rolling Traction in an EHL Line Contact—Part I: Fully Flooded Conditions. J. Lubr. Technol. 1978, 100, 346–352. [Google Scholar] [CrossRef]

- Goksem, P.G.; Hargreaves, R.A. The Effect of Viscous Shear Heating on Both Film Thickness and Rolling Traction in an EHL Line Contact—Part II: Starved Conditions. J. Lubr. Technol. 1978, 100, 353–358. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Bair, S.; Jacobson, B. Chapter 5 Rheological Models for Non-Newtonian Fluids. In Rheology and Elastohydrodynamic Lubrication; Tribology Series; Elsevier: Amsterdam, The Netherlands, 1991; Volume 19, pp. 53–68.

- Matsuyama, H.; Kamamoto, S.; Asano, K. The Analysis of Frictional Torque for Tapered Roller Bearings Using EHD Theory. SAE Trans. 1998, 107, 320–329. [Google Scholar]

- Matsuyama, H. High Efficiency and Tribology in Rolling Bearings. JTEKT Eng. J. 2012, 1009, 108–113. [Google Scholar]

- Houpert, L. Ball Bearing and Tapered Roller Bearing Torque: Analytical, Numerical and Experimental Results. Tribol. Trans. 2002, 45, 345–353. [Google Scholar] [CrossRef]

- Gradu, M. Tapered Roller Bearings with Improved Efficiency and High Power Density for Automotive Transmissions. SAE Tech. Pap. 2000, 109, 1696–1705. [Google Scholar] [CrossRef]

- Schwarz, M.; Liebrecht, J.; Gonda, A.; Sauer, B. A Study on the Frictional Torque and Temperature Behavior in Tapered Roller Bearings. Forschungsvereinigung Antriebstechnik E.V. 2018, 3, 31–39. [Google Scholar]

- Liu, Y.; Fan, X.; Wang, J.; Liu, X. An Investigation for the Friction Torque of a Tapered Roller Bearing Considering the Geometric Homogeneity of Rollers. Lubricants 2022, 10, 154. [Google Scholar] [CrossRef]

- Liu, X.; Long, T.; Li, X.; Guo, F. Thermal EHL Analysis of the Inner Ring Rib and Roller End in Tapered Roller Bearings with the Carreau Model. Front. Manuf. Technol. 2023, 2, 29. [Google Scholar] [CrossRef]

- Van Wittenberghe, J.; Ost, W.; Rezaei, A.; De Baets, P.; Zsidai, L.; Kalácska, G. Test Setup for Friction Force Measurements of Large-Scale Composite Bearings. Exp. Tech. 2009, 33, 45–50. [Google Scholar] [CrossRef]

- Tong, V.-C.; Hong, S.-W. The Effect of Angular Misalignment on the Running Torques of Tapered Roller Bearings. Tribol. Int. 2016, 95, 76–85. [Google Scholar] [CrossRef]

- Jiang, Z.; Huang, X.; Zhu, H.; Jiang, R.; Du, S. A New Method for Contact Characteristic Analysis of the Tapered Roller Bearing in Wind Turbine Main Shaft. Eng. Fail. Anal. 2022, 141, 106729. [Google Scholar] [CrossRef]

- Liebrecht, J.; Si, X.; Sauer, B.; Schwarze, H. Investigation of Drag and Churning Losses on Tapered Roller Bearings. Stroj. Vestn. J. Mech. Eng. 2015, 61, 399–408. [Google Scholar] [CrossRef] [Green Version]

- Marchesse, Y.; Changenet, C.; Ville, F. Drag Power Loss Investigation in Cylindrical Roller Bearings Using CFD Approach. Tribol. Trans. 2019, 62, 403–411. [Google Scholar] [CrossRef]

- Wilson, W.R.D.; Sheu, S. Effect of Inlet Shear Heating Due to Sliding on Elastohydrodynamic Film Thickness. J. Lubr. Tech. 1983, 105, 187–188. [Google Scholar] [CrossRef]

- NSK Rolling Bearings; General Lubrication Engineering Practice; Springer: Berlin/Heidelberg, Germany, 2015.

- Dindar, A.; Hong, I.; Garg, A.; Kahraman, A. A Methodology to Measure Power Losses of Rolling Element Bearings under Combined Radial and Axial Loading Conditions. Tribol. Trans. 2022, 65, 137–152. [Google Scholar] [CrossRef]

- Bhushan, B.; Ko, P.L. Introduction to Tribology; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Vengudusamy, B.; Enekes, C.; Spallek, R. On the Film Forming and Friction Behaviour of Greases in Rolling/Sliding Contacts. Tribol. Int. 2019, 129, 323–337. [Google Scholar] [CrossRef]

- Spikes, H. Basics of EHL for Practical Application. Lubr. Sci. 2015, 27, 45–67. [Google Scholar] [CrossRef] [Green Version]

| Bearing | Roller Bearing |

|---|---|

| Axial Load | 2.5–45 kN |

| Oil flow to test bearing | 0.07 to 3 lpm |

| Oil temperature | 30 °C to 80 °C |

| FVA 3A | Units | |

|---|---|---|

| Oil type | Paraffin-based solvent raffinate | |

| Density | 884.1 | kg/m3 |

| Viscosity at 40 °C | 90.02 | mm2/s |

| Viscosity at 100 °C | 10.41 | mm2/s |

| Viscosity index | 97 | -- |

| Viscosity-pressure Coefficient (at 200 MPa) | 2.16 × 103 bar−1 @ 25 °C 1.58 × 103 bar−1 @ 80 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manjunath, M.; Fauconnier, D.; Ost, W.; De Baets, P. Experimental Analysis of Rolling Torque and Thermal Inlet Shear Heating in Tapered Roller Bearings. Machines 2023, 11, 801. https://doi.org/10.3390/machines11080801

Manjunath M, Fauconnier D, Ost W, De Baets P. Experimental Analysis of Rolling Torque and Thermal Inlet Shear Heating in Tapered Roller Bearings. Machines. 2023; 11(8):801. https://doi.org/10.3390/machines11080801

Chicago/Turabian StyleManjunath, Manjunath, Dieter Fauconnier, Wouter Ost, and Patrick De Baets. 2023. "Experimental Analysis of Rolling Torque and Thermal Inlet Shear Heating in Tapered Roller Bearings" Machines 11, no. 8: 801. https://doi.org/10.3390/machines11080801

APA StyleManjunath, M., Fauconnier, D., Ost, W., & De Baets, P. (2023). Experimental Analysis of Rolling Torque and Thermal Inlet Shear Heating in Tapered Roller Bearings. Machines, 11(8), 801. https://doi.org/10.3390/machines11080801