Dynamic Characteristics of the Chain Drive System under Multiple Working Conditions

Abstract

:1. Introduction

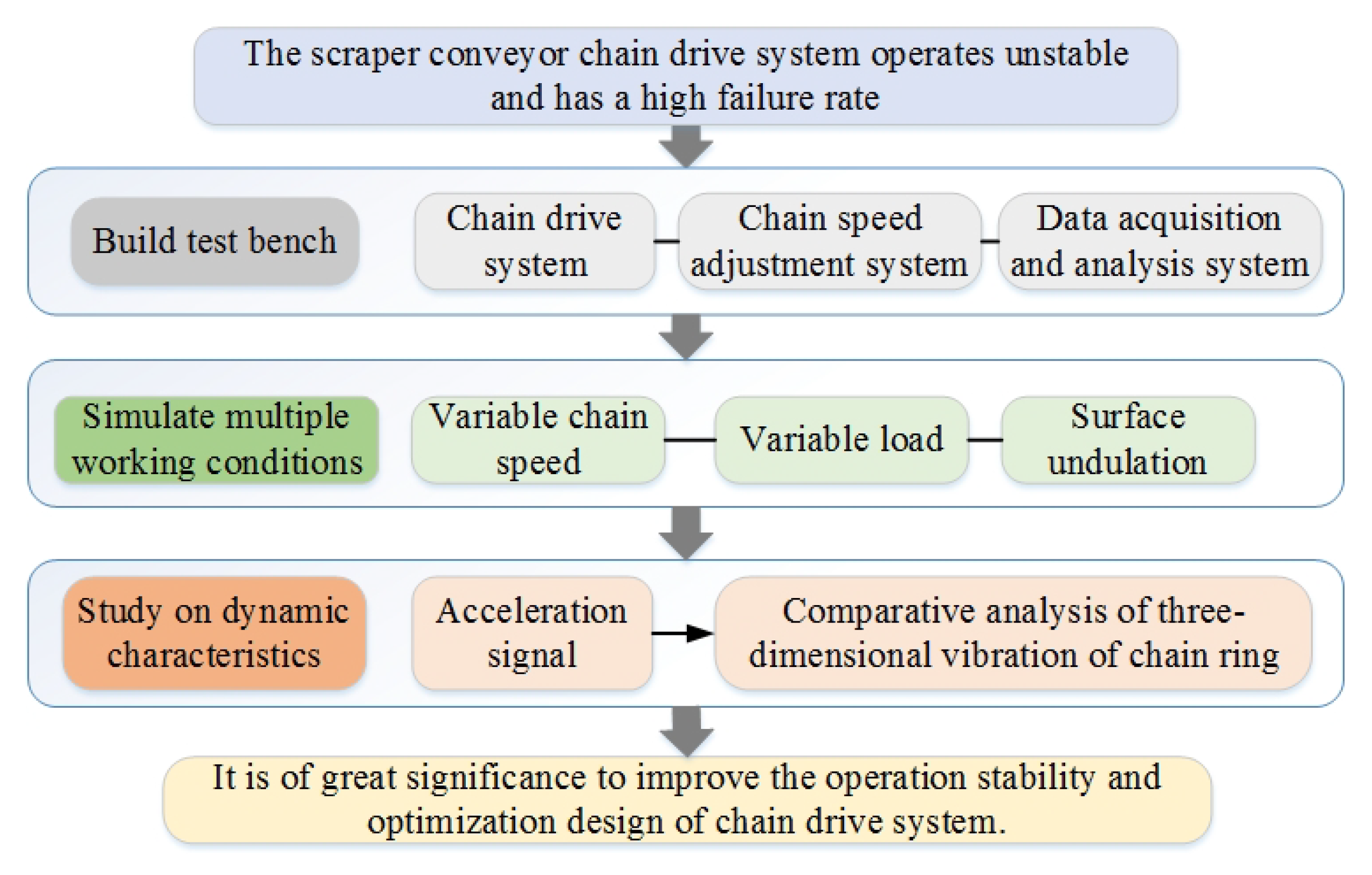

2. Research Methods

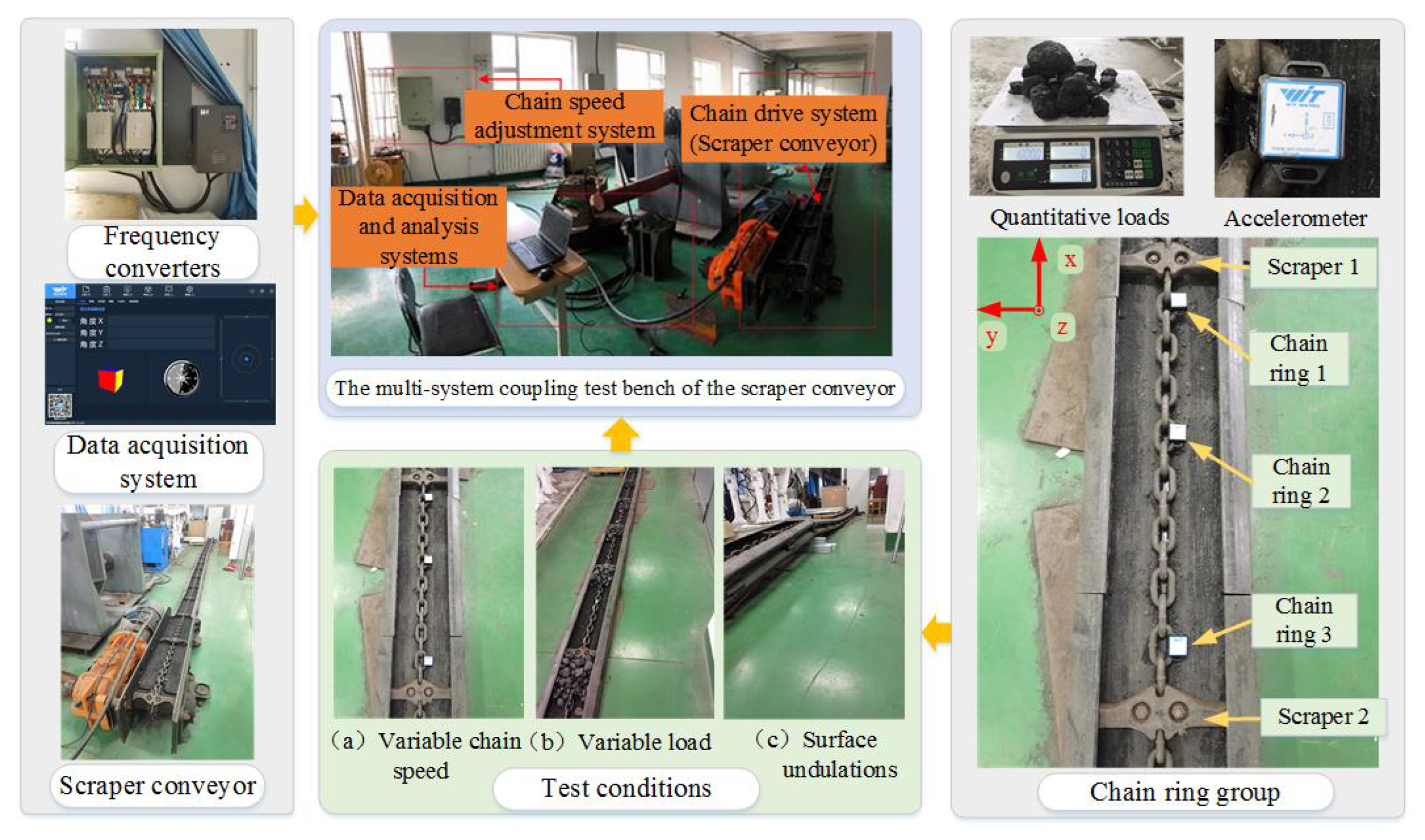

2.1. Build Test Bench

2.2. Test Scheme

3. Results and Discussion

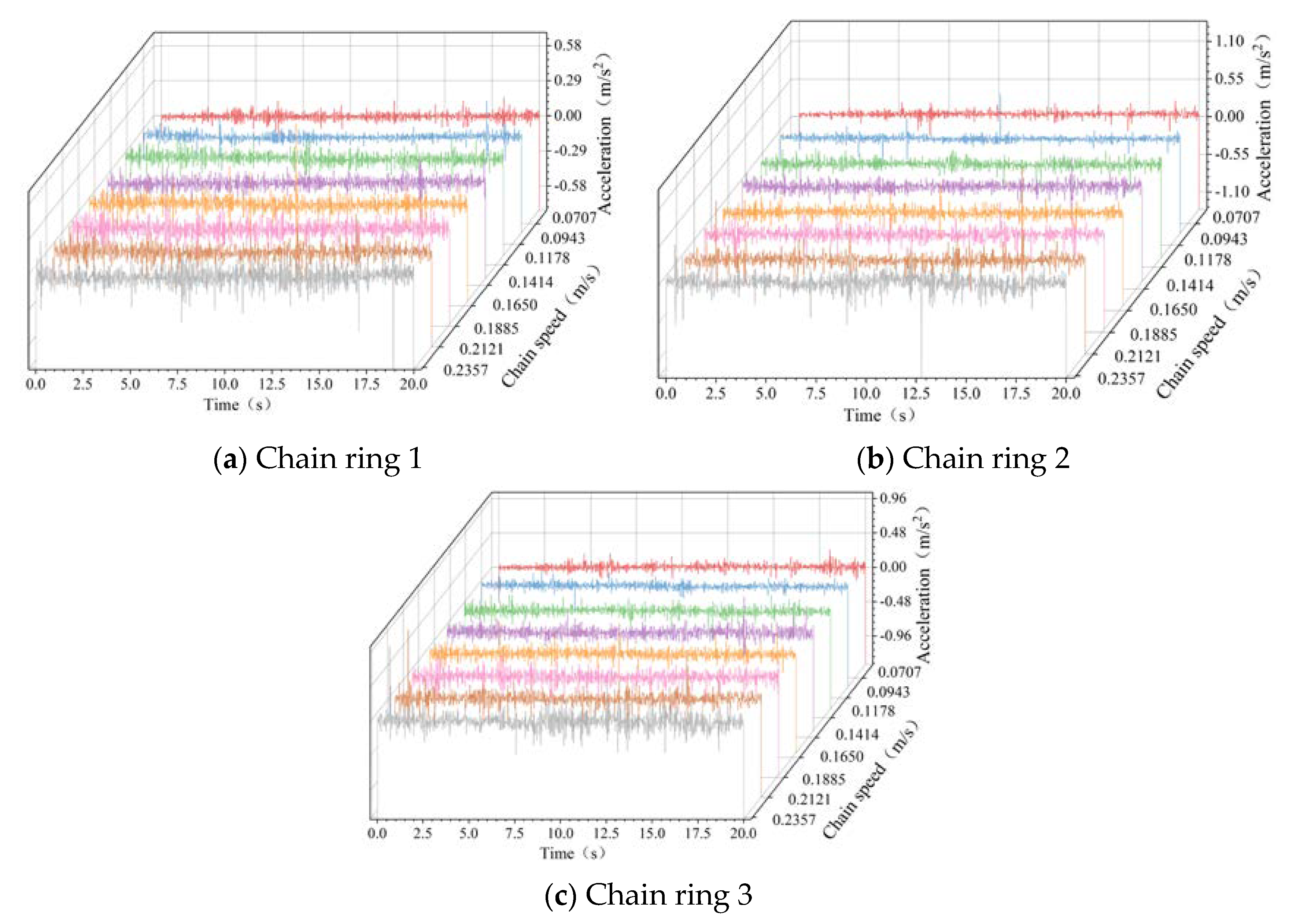

3.1. Variable Chain Speed Conditions

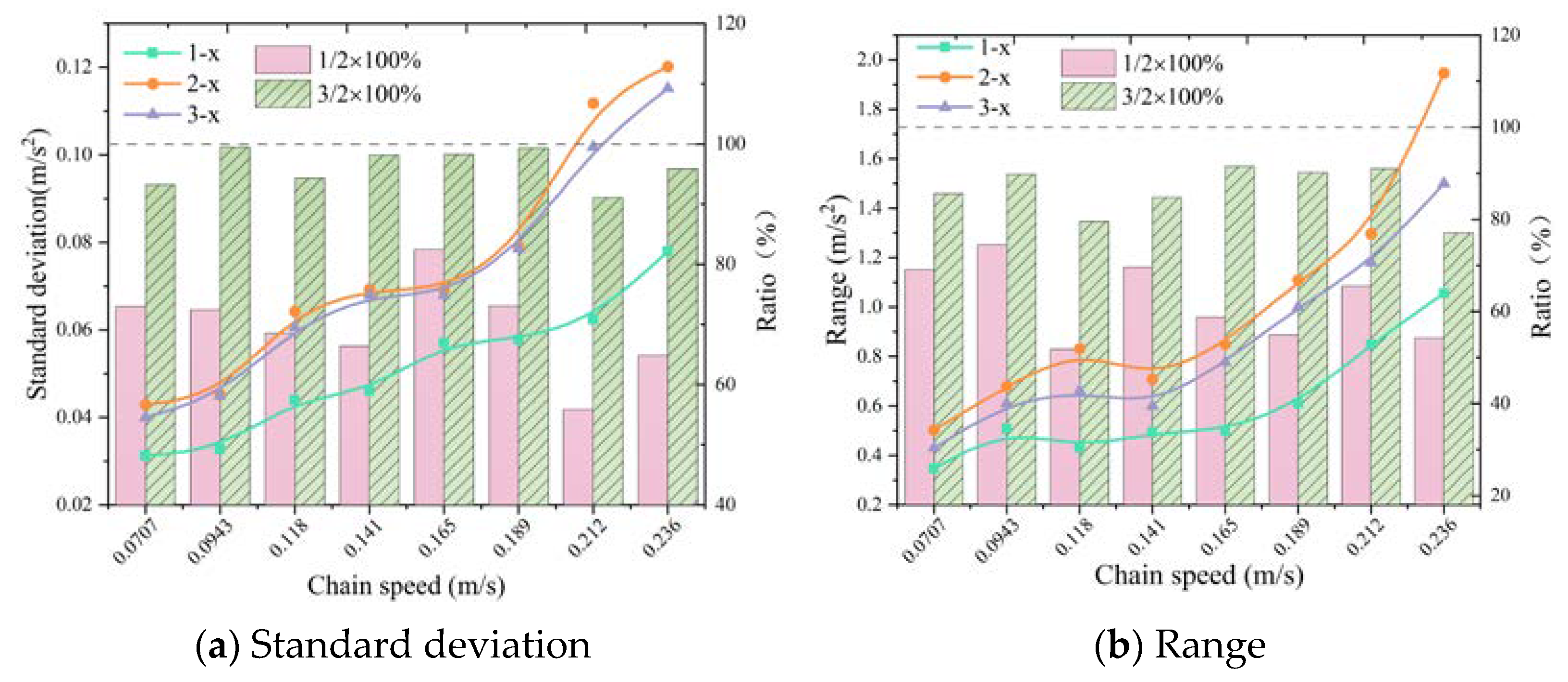

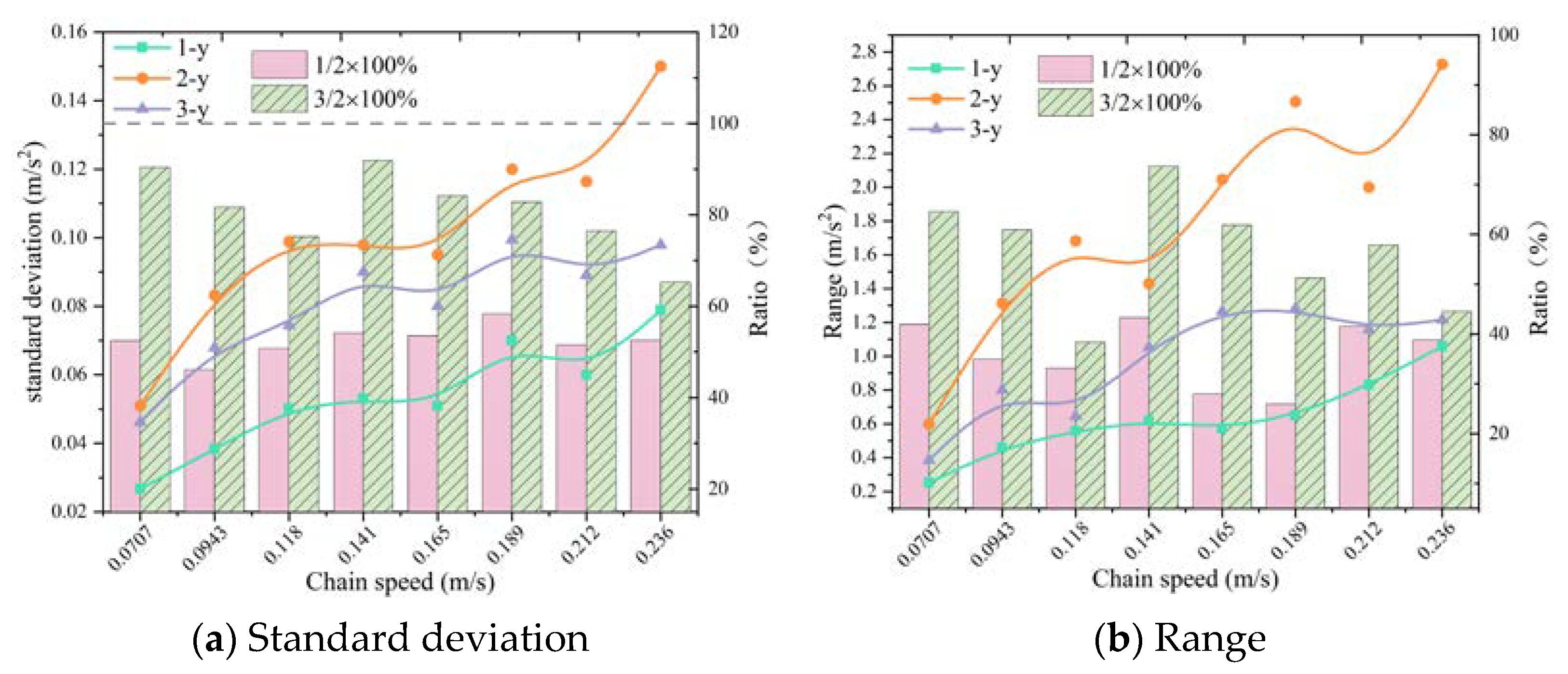

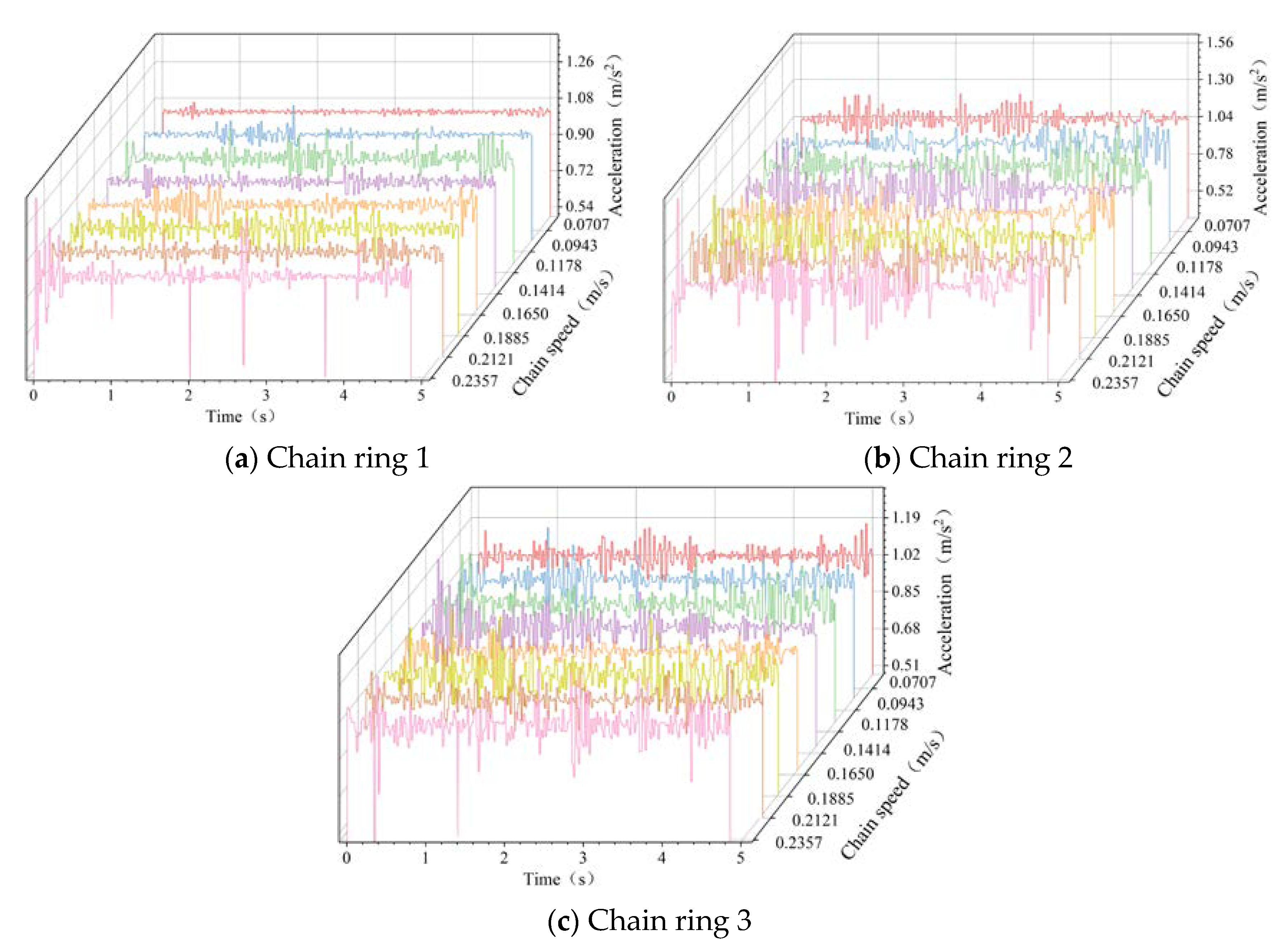

3.1.1. Running Direction

3.1.2. Transverse Direction

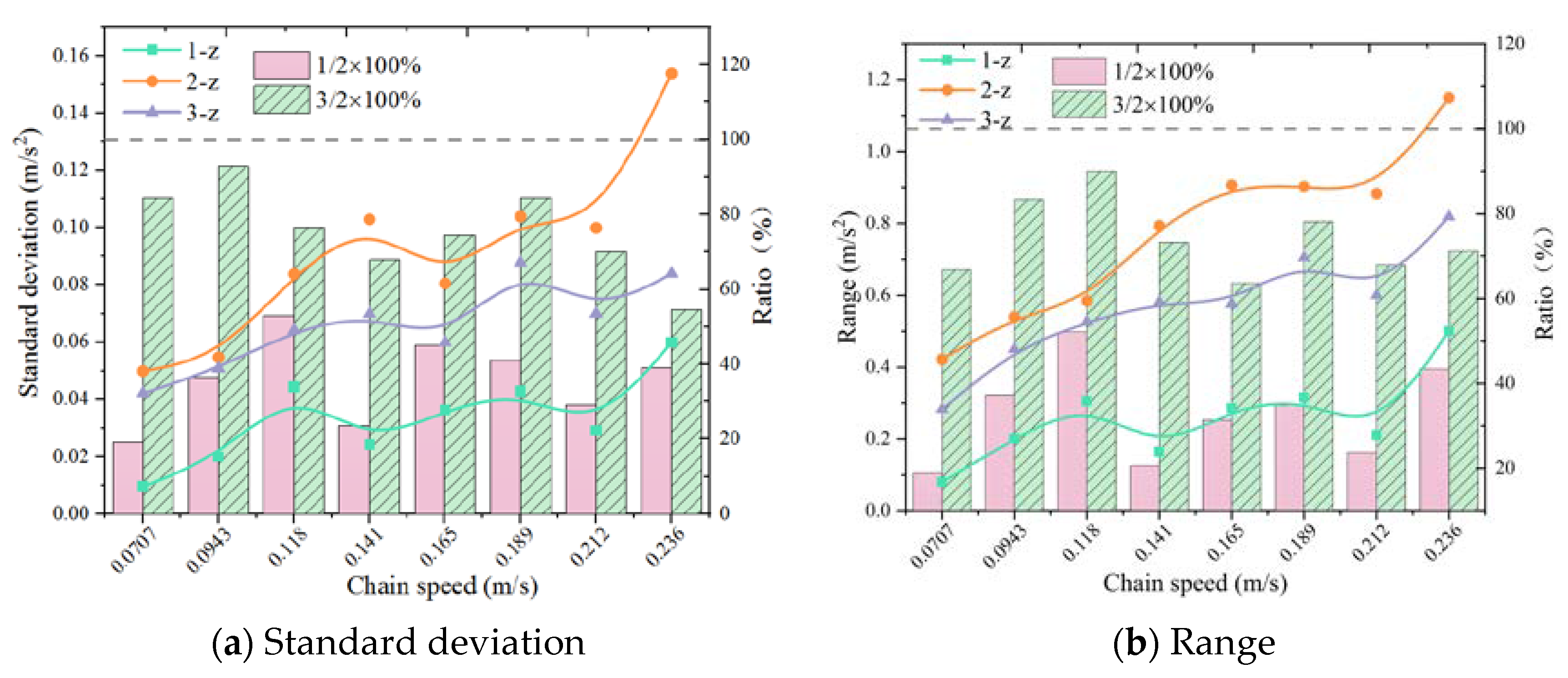

3.1.3. Longitudinal Direction

3.1.4. Three-Way Comparative Analysis

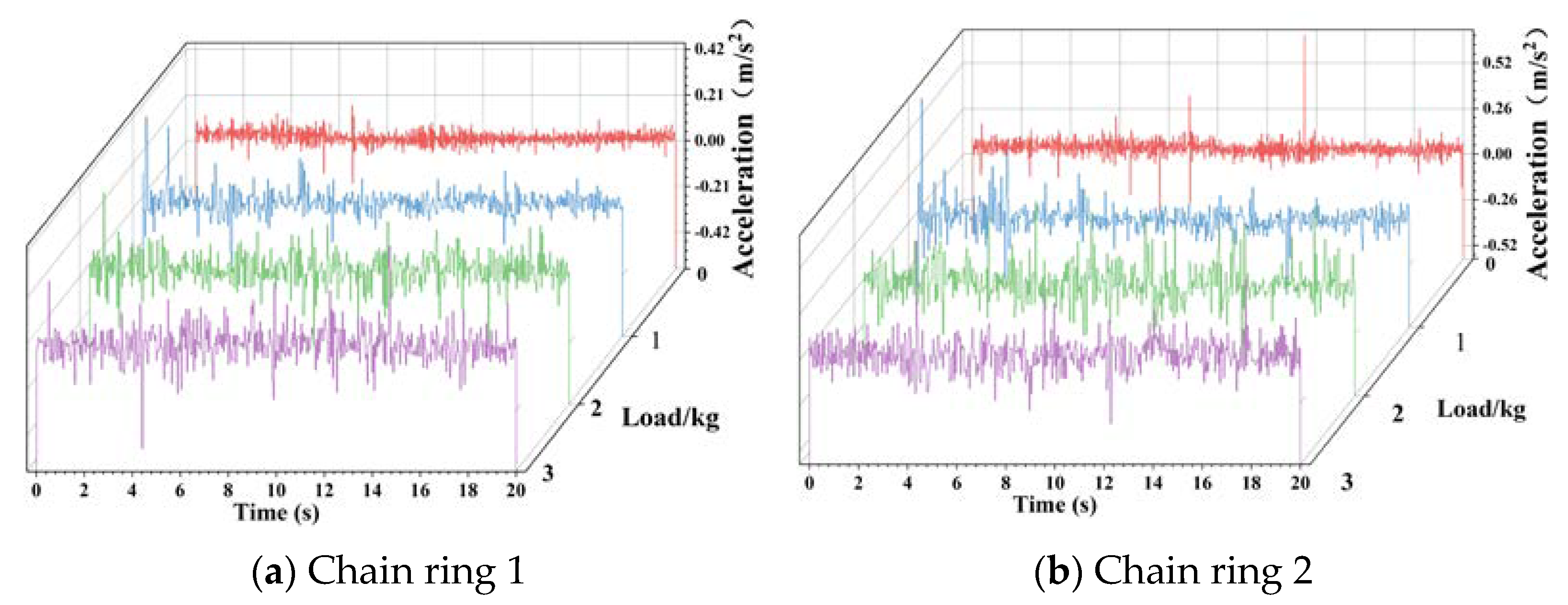

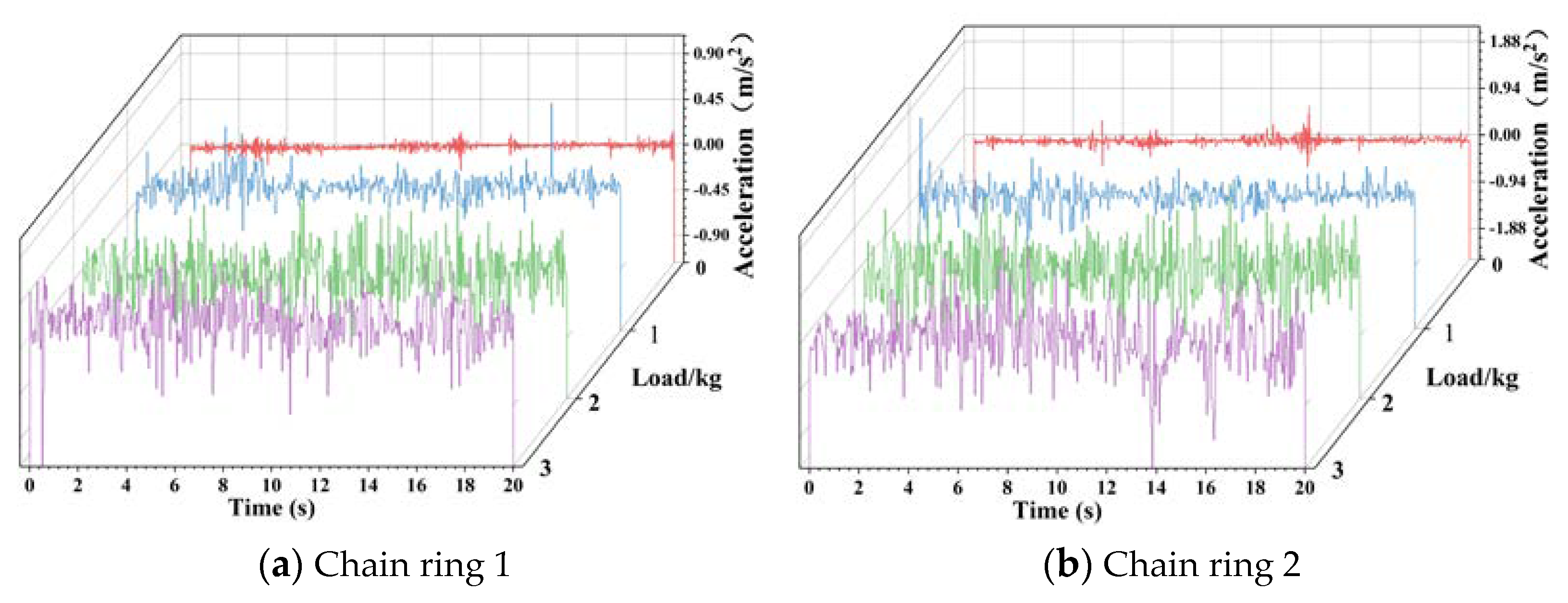

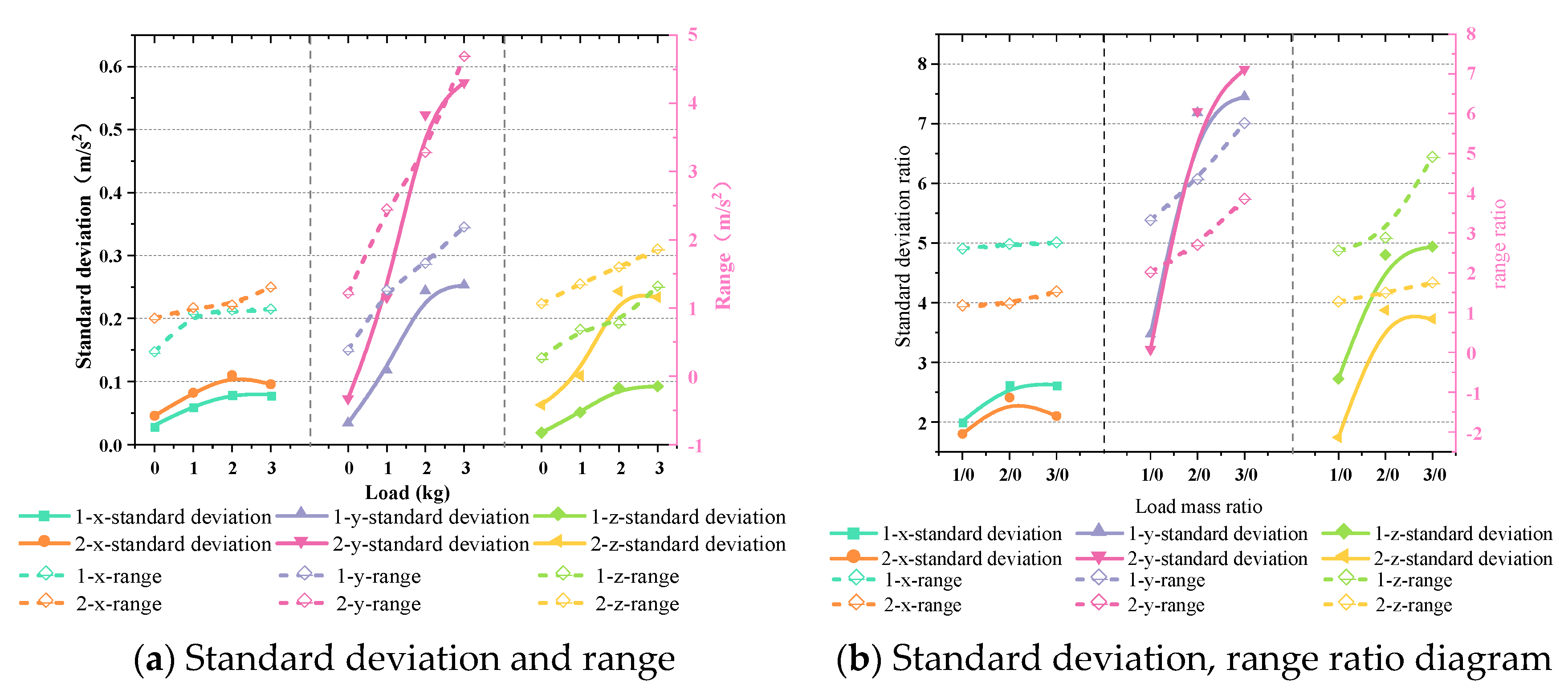

3.2. Variable Load Conditions

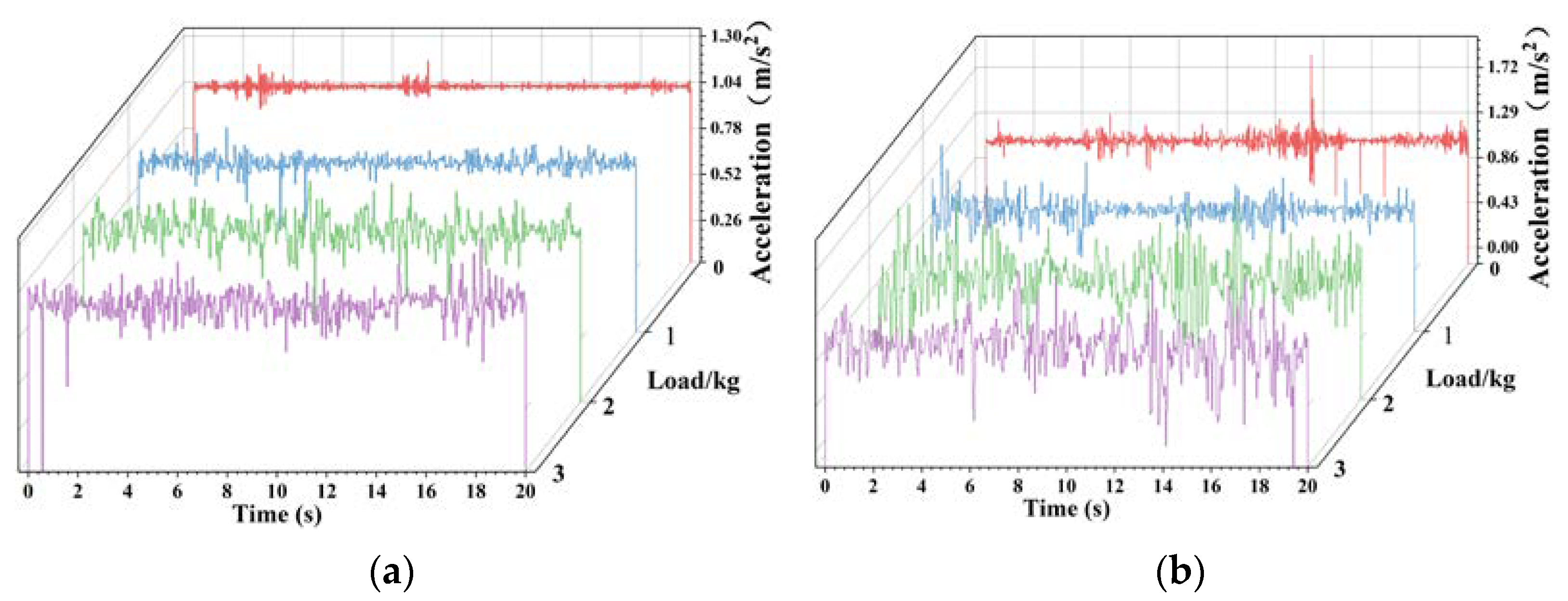

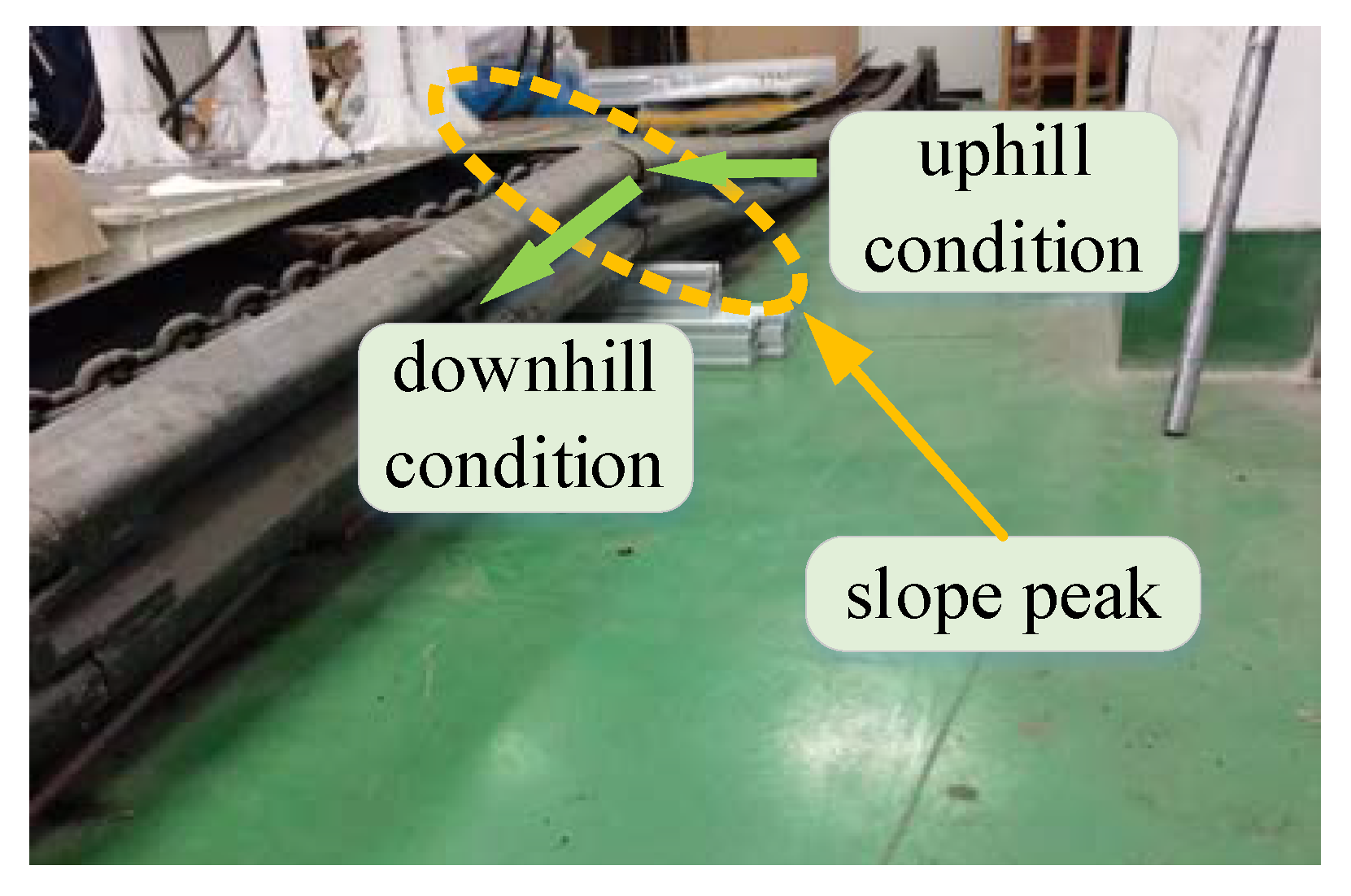

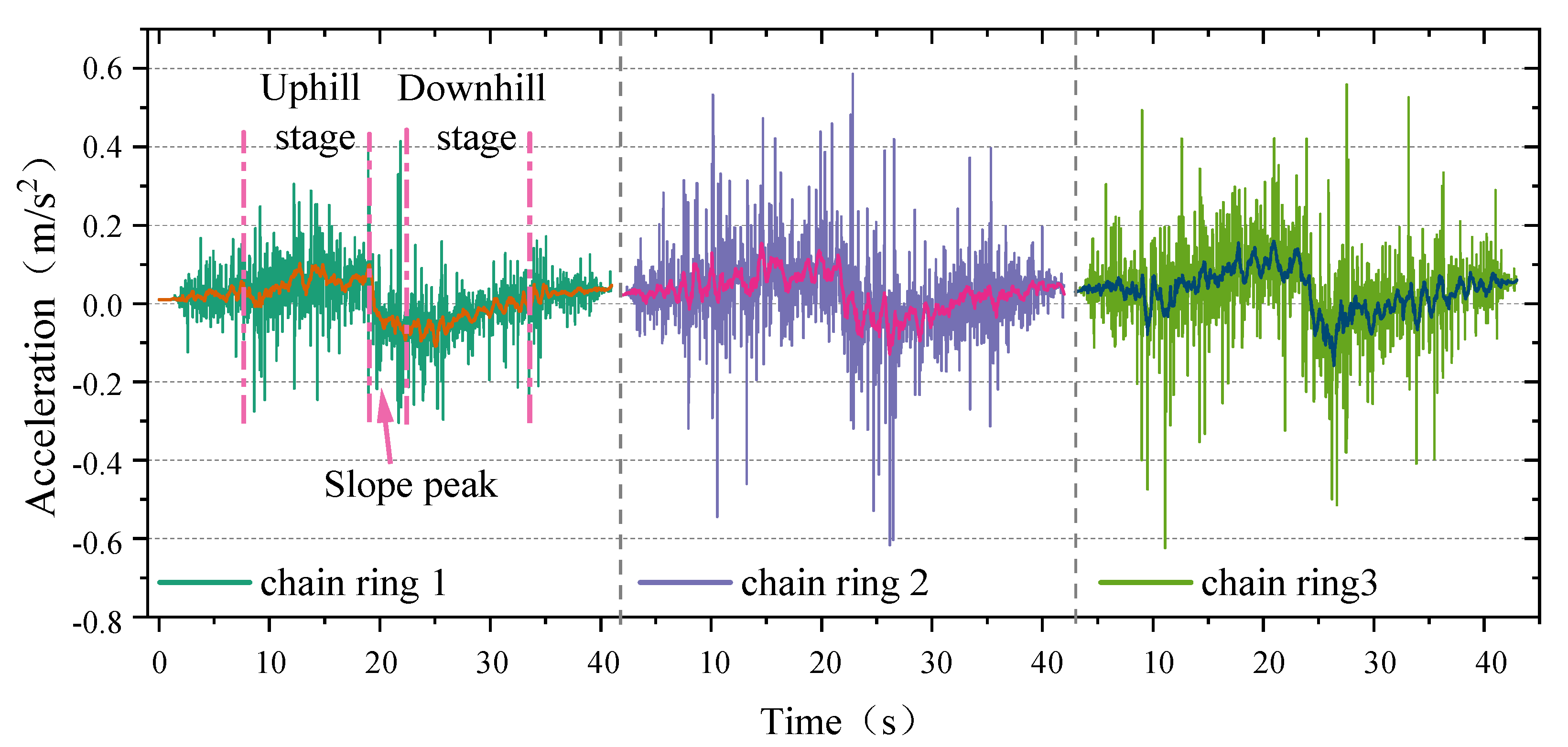

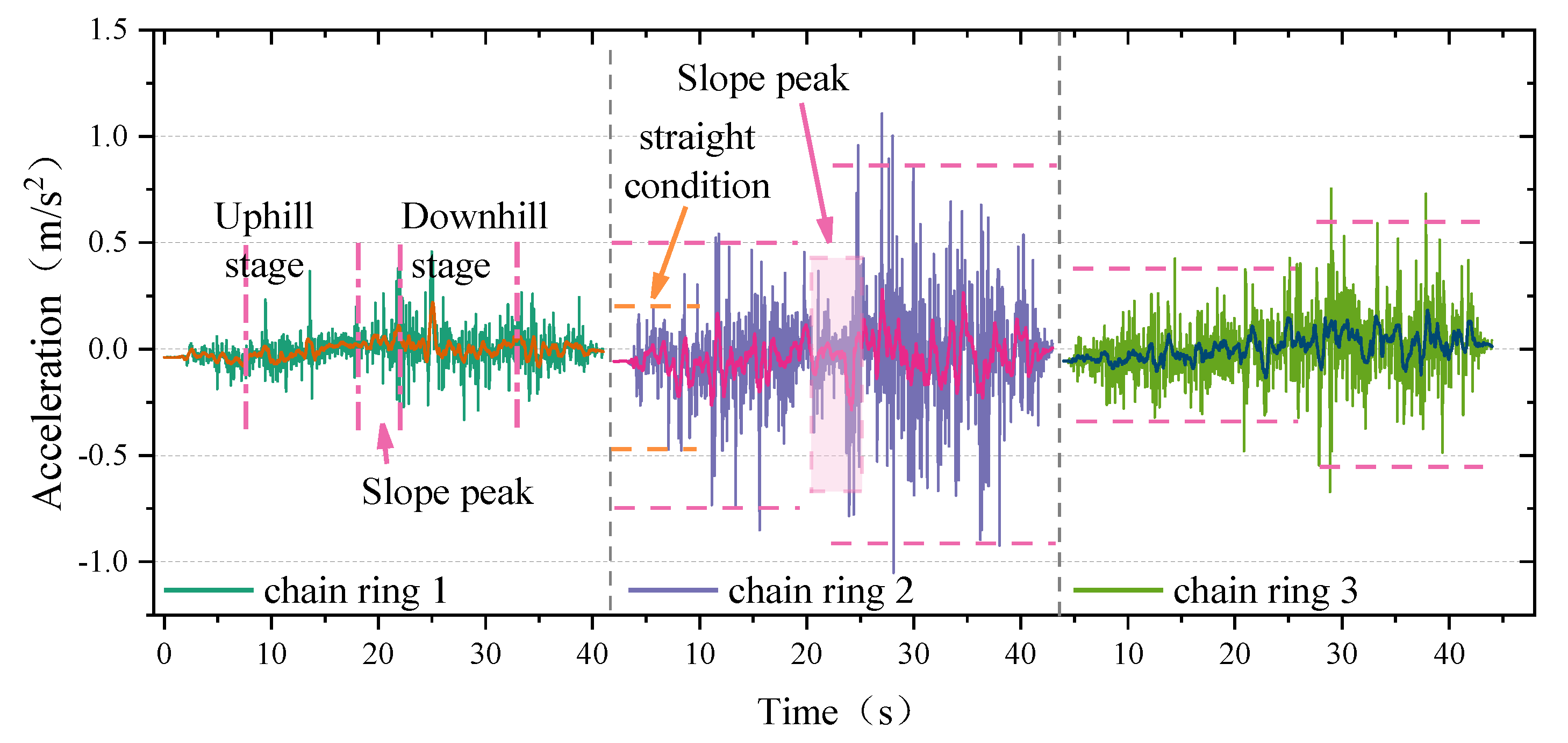

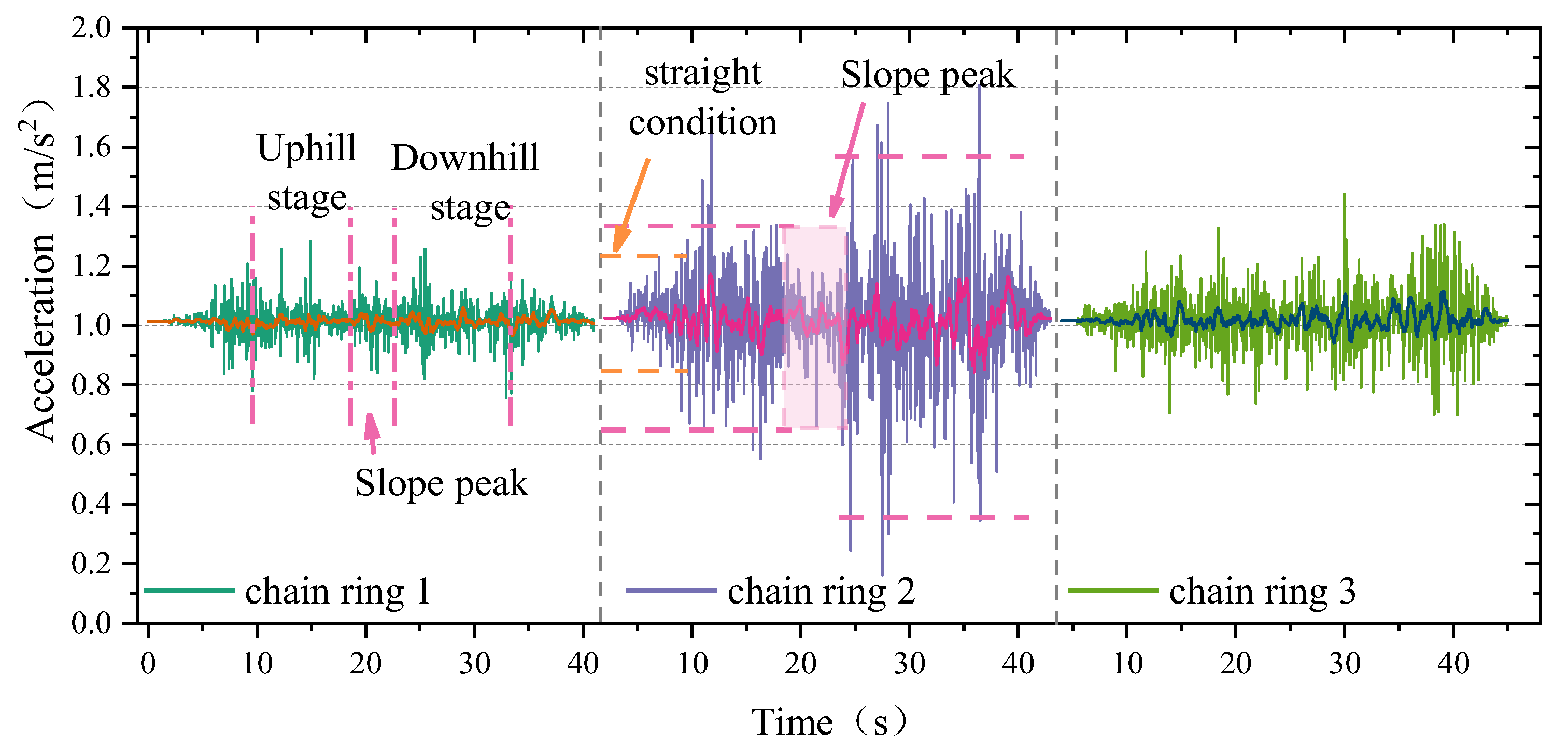

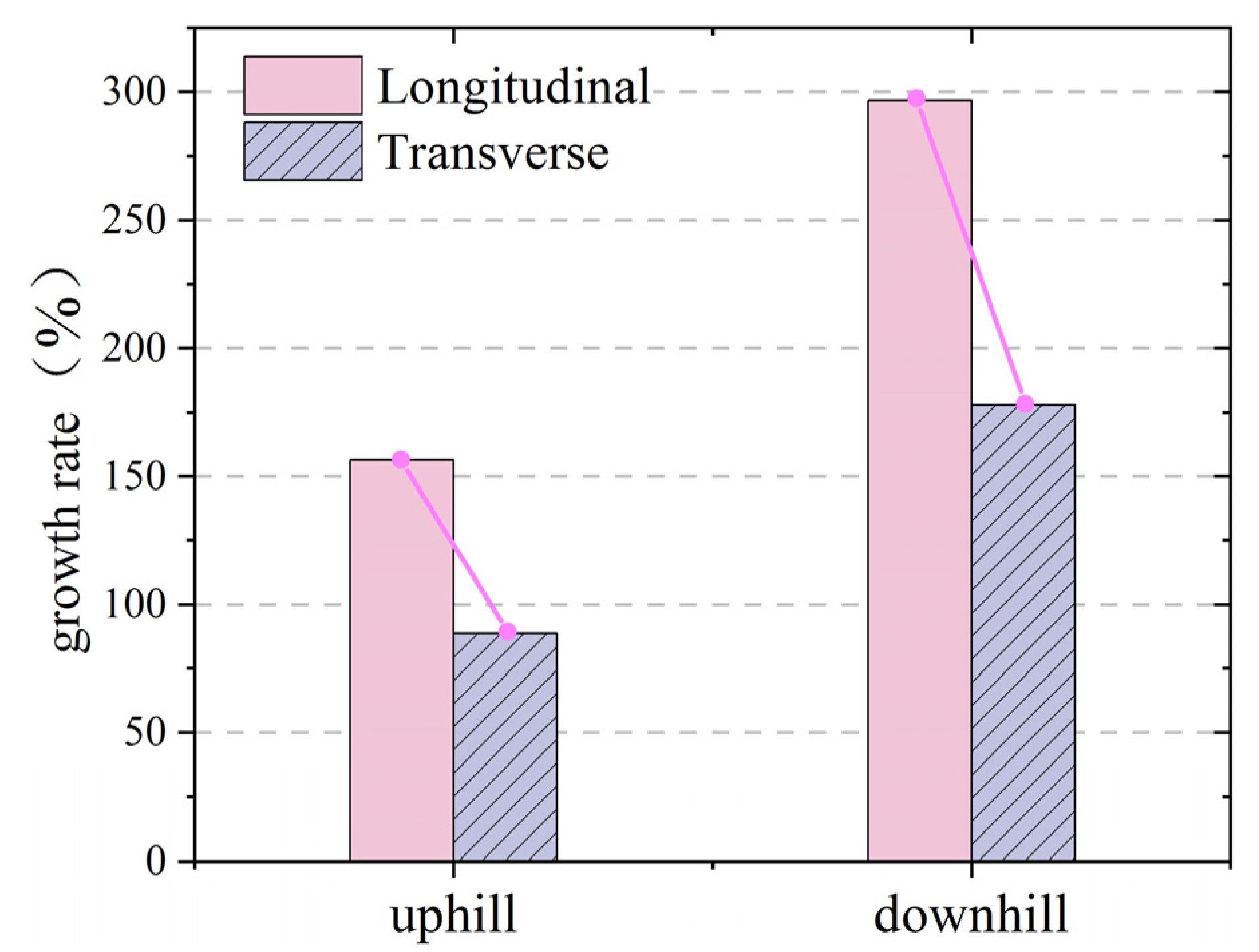

3.3. Surface Undulation Conditions

3.3.1. Running Direction

3.3.2. Transverse Direction

3.3.3. Longitudinal Direction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Szurgacz, D.; Zhironkin, S.; Cehlár, M.; Vöth, S.; Spearing, S.; Ma, L.Q. A Step-by-Step Procedure for Tests and Assessment of the Automatic Operation of a Powered Roof Support. Energies 2021, 26, 697. [Google Scholar] [CrossRef]

- Zhang, Q.; Gu, J.Y.; Liu, J.M.; Tian, Y. Temperature effect on the impact characteristics of mine ring chain under different working conditions. Strength Mater. 2021, 53, 189–197. [Google Scholar] [CrossRef]

- Li, S.; Zhu, Z.; Lu, H.; Shen, G. Time-dependent reliability and optimal design of scraper chains based on fretting wear process. Eng. Comput. 2021, 38, 3673–3693. [Google Scholar] [CrossRef]

- Li, S.; Zhu, Z.C.; Lu, H.; Shen, G. A system reliability-based design optimization for the scraper chain of scraper conveyors with dependent failure modes. Eksploatacja i Niezawodność 2019, 21, 92–402. [Google Scholar]

- He, H.; Zhao, S.F.; Guo, W.; Wang, Y.; Xing, Z.X.; Wang, P.F. Multi-fault recognition of gear based on wavelet image fusion and deep neural network. AIP Adv. 2021, 11, 125025. [Google Scholar] [CrossRef]

- Ren, W.J.; Wang, L.; Mao, Q.H.; Jiang, S.B.; Huang, S. Coupling properties of chain drive system under various and eccentric loads. Int. J. Simul. Model 2020, 19, 643–654. [Google Scholar] [CrossRef]

- Zhang, P.L.; Li, B.; Wang, X.W.; Liu, C.Y.; Bi, W.J.; Ma, H.Z. The loading characteristics of bulk coal in the middle trough and its influence on rigid body parts. Stroj. Vestn.-J. Mech. Eng. 2020, 66, 114–126. [Google Scholar] [CrossRef]

- Jiang, S.B.; Huang, S.; Zeng, Q.L.; Wang, C.L.; Gao, K.D.; Zhang, Y.Q. Dynamic properties of chain drive system considering multiple impact factors. Int. J. Simul. Model 2022, 21, 284–295. [Google Scholar] [CrossRef]

- Świder, J.; Herbuś, K.; Szewerda, K. Dynamic analysis of scraper conveyor operation with external loads. MATEC Web Conf. EDP Sci. 2017, 94, 01009. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.S.; Li, B.; Liang, C.; Wang, X.W.; Li, J.H. Response Analysis of a Scraper Conveyor under Chain Faults Based on MBD-DEM-FEM. J. Mech. Eng. 2021, 67, 501–515. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, R.X.; Tian, Y. Scraper conveyor structure improvement and performance comparative analysis. Strength Mater. 2020, 52, 683–690. [Google Scholar] [CrossRef]

- Dai, K.; Zhu, Z.; Shen, G.; Li, X.; Tang, Y.; Wang, W. Modeling and Adaptive Tension Control of Chain Transmission System With Variable Stiffness and Random Load. IEEE Trans. Ind. Electron. 2021, 69, 8335–8345. [Google Scholar] [CrossRef]

- Yuan, P.F.; He, B.Y.; Zhang, L.H. Planar dynamic modelling of round link chain drives considering the irregular polygonal action and guide rail. Proc. Inst. Mech. Eng. Part K-J. Multi-Body Dyn. 2021, 235, 338–352. [Google Scholar] [CrossRef]

- Shprekher, D.M.; Babokin, G.I.; Kolesnikov, E.B.; Ovsyannikov, D.S. Research of load unbalance of a two-motor variable frequency dtive for scraper conveyor. Izvestiya Vysshikh Uchebnykh Zavedenii Elektromekhanika 2021, 64, 37–45. [Google Scholar] [CrossRef]

- Shprekher, D.M.; Babokin, G.I.; Zelenkov, A.V.; Ovsyannikov, D.S. Universal computer model for studying the dynamics of a two-motor scraper conveyor. Izvestiya Vysshikh Uchebnykh Zavedenii Elektromekhanika 2021, 64, 56–64. [Google Scholar]

- Zhang, X.; Li, W.; Zhu, Z.C.; Jiang, F. Fault detection for scraper chain using an observer based tension distribution estimation algorithm. Curr. Sci. 2020, 118, 1792–1802. [Google Scholar] [CrossRef]

- Kuczaj, M.; Wieczorek, A.N.; Konieczny, Ł.; Burdzik, R.; Wojnar, G.; Filipowicz, K.; Głuszek, G. Research on Vibroactivity of Toothed Gears with Highly Flexible Metal Clutch under Variable Load Conditions. Sensors 2022, 23, 287. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.B.; Lv, R.B.; Wan, L.R.; Mao, Q.H.; Zeng, Q.L.; Gao, K.D.; Yang, Y. Dynamic characteristics of the chain drive system of scraper conveyor based on the speed difference. IEEE Access 2020, 8, 168650–168658. [Google Scholar] [CrossRef]

- Jiang, S.B.; Ren, W.J.; Mao, Q.H.; Zeng, Q.L.; Yu, P.F.; Gao, K.D.; Wang, L. Dynamic analysis of the scraper conveyor under abnormal operating conditions based on the vibration and speed characteristics. Shock Vib. 2021, 2021, 8887744. [Google Scholar] [CrossRef]

- Jiang, S.B.; Huang, S.; Mao, Q.H.; Zeng, Q.L.; Gao, K.D.; Lv, J.W. Dynamic Properties of Chain Drive in a Scraper Conveyor under Various Working Conditions. Machines 2022, 10, 579. [Google Scholar] [CrossRef]

- Wojnar, G.; Burdzik, R.; Wieczorek, A.N.; Konieczny, Ł. Multidimensional data interpretation of vibration signals registered in different locations for system condition monitoring of a three-stage gear transmission operating under difficult conditions. Sensors 2021, 21, 7808. [Google Scholar] [CrossRef]

- Zhao, S.F.; Wang, P.F.; Li, S.J. Study on the fault diagnosis method of scraper conveyor gear under time-varying load condition. Appl. Sci. 2020, 10, 5053. [Google Scholar] [CrossRef]

- Szewerda, K.; Świder, J.; Herbuś, K. Analysis of impact of longitudinal inclination of a chain conveyor on dynamical phenomena during operation. MATEC Web Conf. 2017, 94, 01010. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Cui, H.W.; Lian, Z.S.; Wang, Q.L. Modeling and optimization of soft start-up for hydroviscous drive applied to scraper conveyor. Math. Probl. Eng. 2019, 2019, 6131364. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Bao, J.S.; Ge, S.R.; Yin, Y.; Wang, S.B.; Zhang, L. Simulation and experimental study on electromechanical coupling model of permanent magnet direct drive system for scraper conveyor. J. China Coal Soc. 2020, 45, 2127–2139. [Google Scholar]

- Zhang, X.; Ma, Y.; Li, Y.T.; Zhang, C.J.; Jia, C.X. Tension prediction for the scraper chain through multi-sensor information fusion based on improved Dempster-Shafer evidence theory. Alex. Eng. J. 2023, 64, 41–54. [Google Scholar] [CrossRef]

- Yao, Y.P.; Liu, W.L.; Gao, Z.P. Impact damage to the middle trough of a scraper conveyor based on the engineering discrete element method and orthogonal matrix analysis. PLoS ONE 2022, 17, e0266831. [Google Scholar] [CrossRef]

- Zhuang, M.; Li, G.; Ding, K.X.; Xu, G.S. Optimized design of mechanical chain drive based on a wireless sensor network data algorithm. J. Sens. 2021, 2021, 2901624. [Google Scholar] [CrossRef]

- Liu, Z.X.; Xie, C.X.; Mao, J.; Xie, M. Analysis of Longitudinal and Torsional Pendulum Coupling Vibration of Scraper Conveyor Under Material Loading Condition. J. Vib. Meas. Diagn. 2019, 39, 147–152. [Google Scholar]

- Wang, D.G.; Zhang, J.; Zhu, Z.C.; Gang, S.; Xiang, L. Crack initiation characteristics of ring chain of heavy-duty scraper conveyor under time-varying loads. Adv. Mech. Eng. 2019, 11, 1687814019880366. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Li, W.; Zhu, Z.C.; Yang, S.G.; Jiang, F. Fault detection for the scraper chain based on vibration analysis using the adaptive optimal kernel time-frequency representation. Shock Vib. 2019, 2019, 6986240. [Google Scholar] [CrossRef] [Green Version]

| Model of Scraper Conveyor | SGD320/17B |

|---|---|

| Rated power of motor (kW) | 18.5 |

| Speed of variable frequency motor (rpm) | 1470 |

| Working length of scraper (m) | 12 |

| Middle chute size (length × width × height, mm) | 600 × 320 × 156 |

| Rated chain speed (m/s) | 0.59 |

| Chain specification | 14 × 50 |

| Breaking force of ring chain (kN) | >250 |

| Number of sprocket teeth | 6 |

| Transmission ratio of reducer | 24.95 |

| Operating voltage (V) | 380 |

| Model of Acceleration Sensor | BWT901BLECL5.0 |

|---|---|

| Operating current (mA) | 15 |

| Output frequency (Hz) | 0.2~200 |

| Connection with the host computer | bluetooth |

| frequency/Hz | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| chain speed/(m/s) | 0.0707 | 0.0943 | 0.118 | 0.141 | 0.165 | 0.189 | 0.212 | 0.236 |

| Variable Chain Speed/(m/s) | Variable Load/kg | Surface Undulation/(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.0707 | 0.0943 | 0.118 | 0.141 | 0 | 1 | 2 | 3 | 0 | 120 |

| 0.165 | 0.189 | 0.212 | 0.236 | ||||||

| Chain Speed/(m/s) | Chain Ring 1/(m/s2) | Chain Ring 2/(m/s2) | Chain Ring 3/(m/s2) |

|---|---|---|---|

| 0.0707 | 0.347 | 0.502 | 0.43 |

| 0.2357 | 1.031 | 1.947 | 1.5 |

| Ratio Type | Standard Deviation (m/s2) | Range (m/s2) | |||||

|---|---|---|---|---|---|---|---|

| Running Direction | Transverse Direction | Longitudinal Direction | Running Direction | Transverse Direction | Longitudinal Direction | ||

| 1 kg/0 kg | chain ring 1 | 2.01 | 3.47 | 2.73 | 2.61 | 3.33 | 2.56 |

| chain ring 2 | 1.8 | 3.22 | 1.74 | 1.18 | 2.02 | 1.28 | |

| 2 kg/0 kg | chain ring 1 | 2.64 | 7.18 | 4.8 | 2.72 | 4.36 | 2.88 |

| chain ring 2 | 2.41 | 7.2 | 3.88 | 1.23 | 2.7 | 1.5 | |

| 3 kg/0 kg | chain ring 1 | 2.63 | 7.45 | 4.94 | 2.76 | 5.76 | 4.91 |

| chain ring 2 | 2.1 | 7.91 | 3.72 | 1.53 | 3.86 | 1.75 | |

| Stage | Chain Ring 1 | Chain Ring 2 | Chain Ring 3 |

|---|---|---|---|

| uphill | 0.305 | 0.545 | 0.42 |

| downhill | 0.304 | 0.604 | 0.559 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Huang, S.; Zeng, Q.; Chen, S.; Lv, J.; Zhang, Y.; Qu, W. Dynamic Characteristics of the Chain Drive System under Multiple Working Conditions. Machines 2023, 11, 819. https://doi.org/10.3390/machines11080819

Jiang S, Huang S, Zeng Q, Chen S, Lv J, Zhang Y, Qu W. Dynamic Characteristics of the Chain Drive System under Multiple Working Conditions. Machines. 2023; 11(8):819. https://doi.org/10.3390/machines11080819

Chicago/Turabian StyleJiang, Shoubo, Shuan Huang, Qingliang Zeng, Shaojie Chen, Jinwang Lv, Yuqi Zhang, and Wei Qu. 2023. "Dynamic Characteristics of the Chain Drive System under Multiple Working Conditions" Machines 11, no. 8: 819. https://doi.org/10.3390/machines11080819

APA StyleJiang, S., Huang, S., Zeng, Q., Chen, S., Lv, J., Zhang, Y., & Qu, W. (2023). Dynamic Characteristics of the Chain Drive System under Multiple Working Conditions. Machines, 11(8), 819. https://doi.org/10.3390/machines11080819