Low-Cost Digital Twin Approach and Tools to Support Industry and Academia: A Case Study Connecting High-Schools with High Degree Education

Abstract

:1. Introduction

1.1. Problem Statement

1.2. Research Aim

1.3. Research Objectives and Scope

- Developing Specialized ICT skills with ROS Integration—Establish a seamless connection between ROS and the digital twin prototype, enabling the exchange of real-time data and communication between the simulation environment and robotic systems. Working on this integration will allow students to practice specialized ICT skills and soft ICT skills.

- Fostering Critical Thinking with ROS-based Control Algorithms—Develop and integrate ROS-based control algorithms for the digital twin models, ensuring that the virtual representations accurately mimic the behavior of their real-world counterparts. This work will allow students to practice critical thinking, as well as apply science and mathematics to real-world scenarios.

- Promoting ITC skills with CAD and 3D Printing—Design virtual models using CAD and Unity software. By designing models both in CAD and Unity, students will learn about the benefits of using digital manufacturing tools. Students will also learn how Industry 4.0 incorporates additive manufacturing concepts at a lower cost and increases productivity.

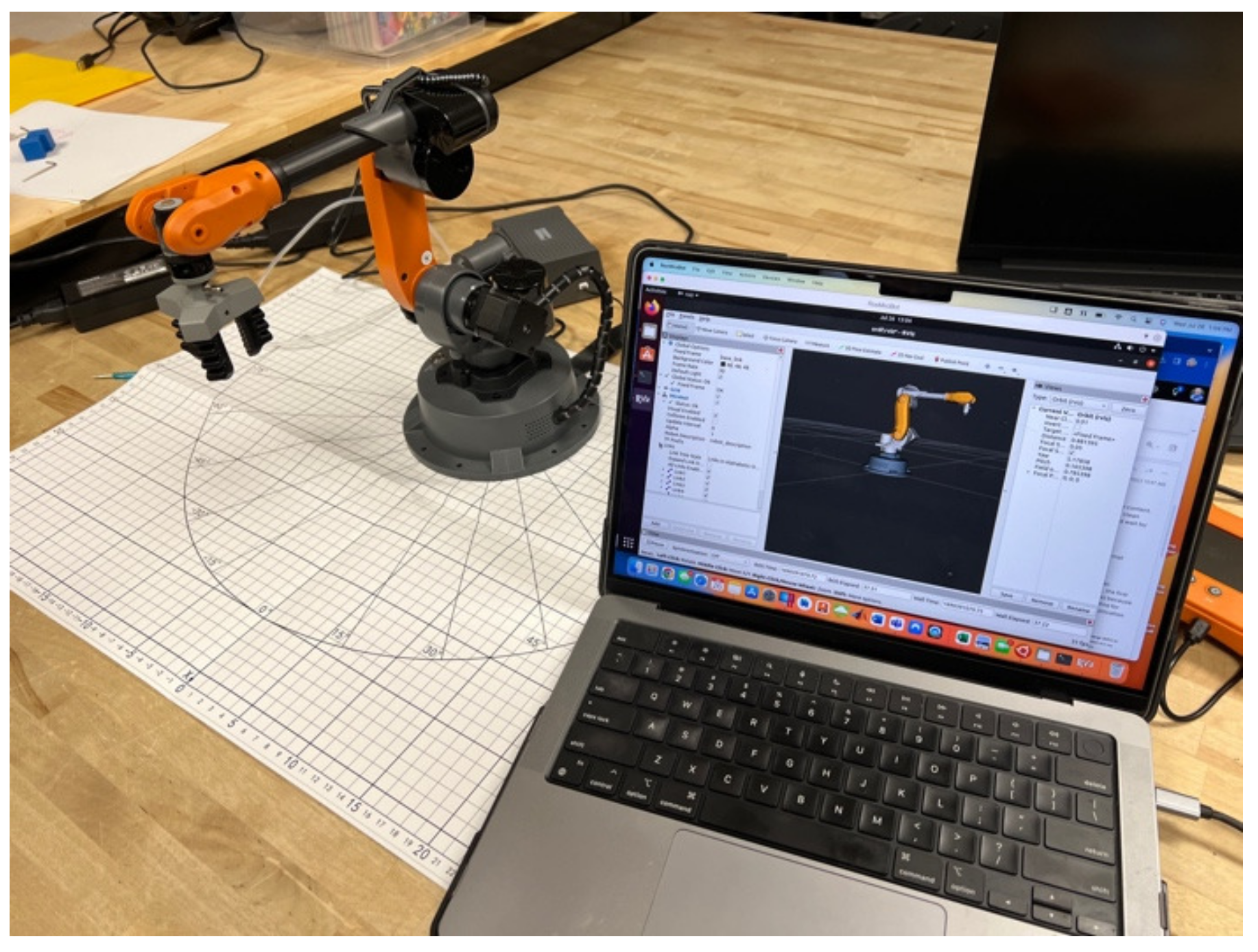

- Building STEM Skills with Physical Prototype Implementation—Build or set up a physical, small-scale pick-and-place prototype using hardware and software that is accessible and cost-effective for secondary educational institutions. This robotic protype will expose students to Industry 4.0 robotic technologies, as well as allow for hands-on application of specialized ICT and engineering skills.

2. Literature Review

2.1. Robotics and Industry 4.0

2.2. Robotic Technologies Challenges

2.3. Future Workforce Talent Development

2.4. Literature Gaps

3. Methodology

3.1. Unity–ROS Integration for Digital Twin Prototype

3.2. Physics-Based Simulation in Unity/ROS

3.3. ROS-Based Control Algorithms

3.4. Virtualization, CAD Design, and 3D Printing Applications

3.5. Physical Prototype Engineering

4. Case Studies

4.1. Specialized ICT Skills with ROS

4.2. Critical Thinking with ROS-Based Control Algorithms

4.3. ITC Skill Exposure with CAD and 3D Printing

4.4. Building STEM Skills with Physical Prototype Implementation

4.5. Exploring Automation Limitations without ROS/Unity Integration

4.6. Exploring Communication Limitation without ROS/Unity Integration

5. Results

5.1. Qualitative Results

- The application of computer-aided design with the low-cost digital twin prototype exposed students to digital manufacturing concepts. Digital manufacturing is a foundational component of Industry 4.0. [13]. Through the virtual CAD design of the digital twin prototype, students started to understand how these digital tools create more intelligent and automated manufacturing systems. Exposure to digital tools under the umbrella of computer-aided manufacturing generated discussions about various career opportunities that may not have been introduced or discussed otherwise.

- The application of additive manufacturing (3D printing), sensors, robotic components, and vision tracking in the low-cost digital twin prototype introduced the concepts of intelligent automation. By students learning how to work with and apply these various technologies with a hands-on, working prototype, students gained more exposure to these technologies and transformed their own perceptions, social norms, and stereotypes regarding robotic applications. Some students were excited to see robotic technologies without “wheels,” focusing substantial time and attention on machine vision, robotic manipulators, and soft grippers.

- Working with the programming and communication connectivity behind the low-cost digital twin prototype helped students to build the skills necessary for Industry 4.0. By having to program, configure, and virtualize the digital twin prototype, students developed their information communication technology (ICT) skills. Some students deepened their ICT skills through programming; however, all students broadened their ICT skills and more importantly practiced interdisciplinary skills, such as complex problem solving, critical thinking, creativity, collaboration, emotional intelligence, and decision making. The building of the prototype and the challenge of causing the manipulator to pick up an object fostered teamwork and collaboration in the student groups.

- Through the process of implementing a low-cost, digital twin prototype, students were exposed to exciting technological areas, such as digital manufacturing, digital twins, and intelligent automation. More importantly, they learned about potential roles in the future workforce and the skills required to be successful in the industrial revolution of Industry 4.0. Whether the digital twin prototype is fully or partially operational, the process of designing, building, and operating the digital twin prototype exposed students to the vast career potential found in the “T” and “E” of STEM.

5.2. Quantitative Results

6. Conclusions

7. Further Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ustundag, A.; Cevikan, E. Industry 4.0: Managing The Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-319-57869-9. [Google Scholar]

- Karacay, G. Talent Development for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Cevik, K.; Ustundag, A.; Kadaifci, C.; Oztaysi, B. The Changing Role of Engineering Education in Industry 4.0 Era. In Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3319578699/978-3319578693. [Google Scholar]

- Jackson, A.; Mentzer, N.; Kramer-Bottiglio, R. Pilot analysis of the impacts of soft robotics design on high-school student engineering perceptions. Int. J. Technol. Des. Educ. 2019, 29, 1083–1104. [Google Scholar] [CrossRef]

- Ustundag, A.; Cevikcan, E.; Bayram, B.; İnce, G. Advances in Robotics in the Era of Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3319578699/978-3319578693. [Google Scholar]

- Cruz RJ M, d.a.; Tonin, L.A. Systematic review of the literature on Digital Twin: A discussion of contributions and a framework proposal. Gestão Produção 2022, 29, e9621. [Google Scholar] [CrossRef]

- Sørensen, J.V.; Ma, Z.; Jørgensen, B.N. Potentials of game engines for wind power digital twin development: An investigation of the Unreal Engine. Energy Inform. 2022, 5, 1–30. [Google Scholar] [CrossRef]

- Clausen CS, B.; Ma, Z.G.; Jørgensen, B.N. Can we benefit from game engines to develop digital twins for planning he deployment of photovoltaics? Energy Inform. 2022, 5, 1–26. [Google Scholar] [CrossRef]

- Yun, H.; Park, D. Virtualization of self-driving algorithms by interoperating embedded controllers on a game engine for a digital twining autonomous vehicle. Electronics 2021, 10, 2102. [Google Scholar] [CrossRef]

- Unity-Technologies. Unity-Robotics-Hub. 2023. Available online: https://github.com/Unity-Technologies/Unity-Robotics-Hub (accessed on 13 July 2023).

- Scott, H.; Foote, T. “Wiki.” Ros.org, Open Robotics, 2 November 2022. Available online: http://wiki.ros.org/ROS/Tutorials (accessed on 12 July 2023).

- WLKata Mirobot 6DOF Mini Robotic Arm. Available online: https://www.wlkata.com/pages/pg-mirobot-intro (accessed on 23 July 2023).

- AcmeRobotics. FTC Dashboard Online. Available online: https://acmerobotics.github.io/ (accessed on 13 July 2023).

- Guerra-Zubiaga, D.A.; Briceno, S. Product Lifecycle Management Tools to Support Next Generation of Mechatronic Systems in Aerospace Industry. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 58356, p. V002T02A078. [Google Scholar]

- Schwab, K. The Fourth Industrial Revolution; Crown: New York, NY, USA, 2017. [Google Scholar]

- Vex V5 Workcell Educational Kit. Available online: https://www.vexrobotics.com/v5-workcell.html#attr-vex_kit_contents (accessed on 13 July 2023).

| Criteria | CryEngine | Godot | Unity | Unreal Engine |

|---|---|---|---|---|

| Ease of Use | Quite complete software, but with a high degree of complexity in terms of its interface and use | Very simple and intuitive interface and use | Very simple and intuitive interface and use | Relatively complex interface and usage |

| Availability of resources | Average amount of content (assets and ready-made materials) available on the internet | Large amount of content (assets and ready-made materials) available on the internet | Large amount of content (assets and ready-made materials) available on the internet | Large amount of content (assets and ready-made materials) available on the internet |

| Documentation | Available on the website | Available on the website | Available on the website | Available on the website |

| User community | Forum with up-to-date discussions, but with an average number of active members | Forum with up-to-date discussions, and a large number of active members | Forum with up-to-date discussions, and a large number of active members | Forum with up-to-date discussions, and a large number of active members |

| Importing Data | Compatible | Compatible | Compatible | Compatible |

| Importing 3D files | Compatible | Compatible | Compatible | Compatible |

| Importing images | Compatible | Compatible | Compatible | Compatible |

| Importing sounds | Compatible | Compatible | Compatible | Compatible |

| Creation of Cameras | Compatible | Compatible | Compatible | Compatible |

| Creation of Animations | Compatible | Compatible | Compatible | Compatible |

| Trigger of Events | Compatible | Compatible | Compatible | Compatible |

| Physics Elements | Compatible | Compatible | Compatible | Compatible |

| Use of code language | C++ | Own language, GDScript | C++ | C# |

| Learning Objectives and Outcomes | Responses |

|---|---|

| Prior Industry 4.0 knowledge | 4 out of 25 |

| Change in perception of future career opportunities | 18 out of 25 |

| Change in perception of robotics and its applications | 17 out of 25 |

| Positive feedback on learning about digital twins | 19 out of 25 |

| Positive feedback on learning about additive manufacturing | 22 out of 25 |

| Positive feedback on learning about CAD/virtual simulations | 20 out of 25 |

| Positive feedback on learning about ROS | 23 out of 25 |

| Positive feedback on additional lessons about Industry 4.0 | 20 out of 25 |

| Positive feedback on benefits of learning Industry 4.0 trends | 21 out of 25 |

| Positive feedback on this form of robotic technologies versus mobile robotics or robotic competitions | 24 out of 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acker, J.; Rogers, I.; Guerra-Zubiaga, D.; Tanveer, M.H.; Moghadam, A.A.A. Low-Cost Digital Twin Approach and Tools to Support Industry and Academia: A Case Study Connecting High-Schools with High Degree Education. Machines 2023, 11, 860. https://doi.org/10.3390/machines11090860

Acker J, Rogers I, Guerra-Zubiaga D, Tanveer MH, Moghadam AAA. Low-Cost Digital Twin Approach and Tools to Support Industry and Academia: A Case Study Connecting High-Schools with High Degree Education. Machines. 2023; 11(9):860. https://doi.org/10.3390/machines11090860

Chicago/Turabian StyleAcker, James, Ishmael Rogers, David Guerra-Zubiaga, Muhammad Hassan Tanveer, and Amir Ali Amiri Moghadam. 2023. "Low-Cost Digital Twin Approach and Tools to Support Industry and Academia: A Case Study Connecting High-Schools with High Degree Education" Machines 11, no. 9: 860. https://doi.org/10.3390/machines11090860

APA StyleAcker, J., Rogers, I., Guerra-Zubiaga, D., Tanveer, M. H., & Moghadam, A. A. A. (2023). Low-Cost Digital Twin Approach and Tools to Support Industry and Academia: A Case Study Connecting High-Schools with High Degree Education. Machines, 11(9), 860. https://doi.org/10.3390/machines11090860