Advanced Manufacturability of Electrical Machine Architecture through 3D Printing Technology

Abstract

:1. Introduction

- (i)

- Efficient Low-Volume Production: AM emerges as a cost-effective solution for manufacturing low volumes of intricately designed parts, seamlessly accommodating unique and complex geometries. This versatility is particularly beneficial in scenarios requiring tailored components with minimized production runs.

- (ii)

- Optimized Design and Weight Efficiency: This facet holds substantial promise, particularly within aviation and space sectors, where refined designs and reduced weight translate directly to substantial fuel economies and diminished carbon emissions. AM empowers the realization of such optimization by enabling intricate structures that were previously unattainable through conventional techniques.

- (iii)

- Sustainable Technological Approach: Diverging from traditional subtractive manufacturing methods, AM stands out as a champion of sustainability with its near-zero waste generation. This ecological disposition aligns AM with other green energy technologies, contributing to a more environmentally conscious industrial landscape.

- (iv)

- Streamlined Component Integration: The concept of part consolidation underscores the capacity to merge disparate components into a singular unified part. This consolidation not only simplifies manufacturing but also drastically curtails assembly and repair durations. By eliminating intricate interconnections, AM-driven consolidation expedites processes while enhancing overall operational efficiency.

- (v)

- In summary, the industrial implications of AM span a spectrum of advantages. These include economical low-volume production, profound design optimization fostering weight reduction and efficiency gains, alignment with environmentally friendly practices due to minimal waste generation, and the transformational potential of part consolidation for augmented assembly and repair workflows. Each of these dimensions amplifies the significance of AM as a disruptive force that is reshaping manufacturing paradigms across various sectors.

- Comprehensive Integration of AM and Electrical Machines: While existing review articles focus on specific aspects, such as the construction of electrical machines or metal additive manufacturing, this review uniquely integrates both Additive Manufacturing (AM) techniques and their applications in various components of electrical machines. This work provides a holistic perspective that covers magnetic materials, windings, thermal management, and the intricate interplay of these aspects.

- Advanced Manufacturability Emphasis: This review article specifically centers on the concept of “advanced manufacturability” through AM techniques. It delves into how AM can optimize manufacturing processes, facilitate the creation of intricate designs, and ultimately enhance the overall performance, efficiency, and sustainability of electrical machines.

- Focus on Emerging Trends and up-to-date Innovations: This work aims to provide readers with insights into the latest advancements and trends in AM for electrical machines. By doing so, it highlights cutting-edge research and sheds light on the evolving landscape of AM techniques, enabling researchers and practitioners to stay up-to-date with the rapidly developing field.

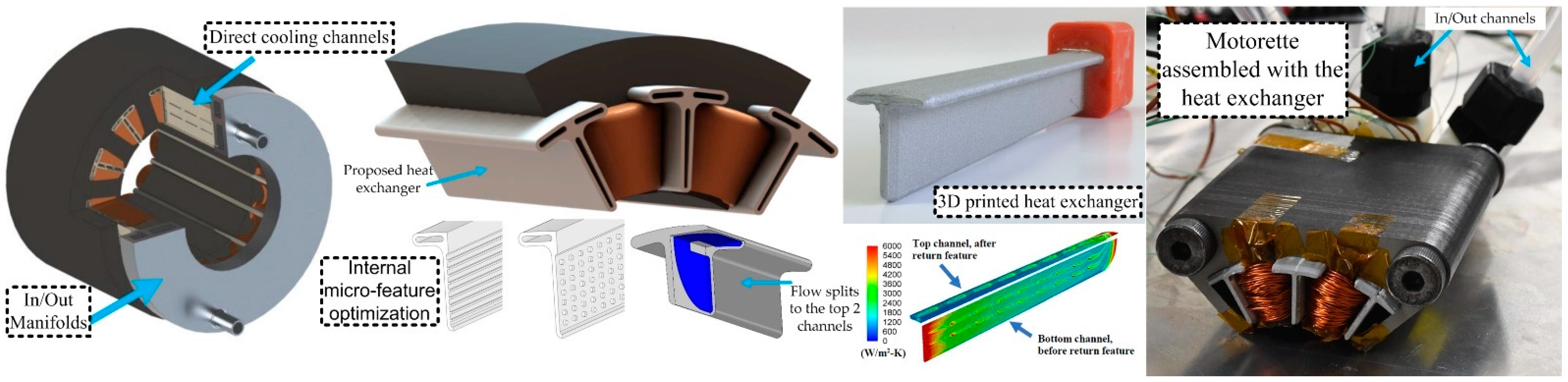

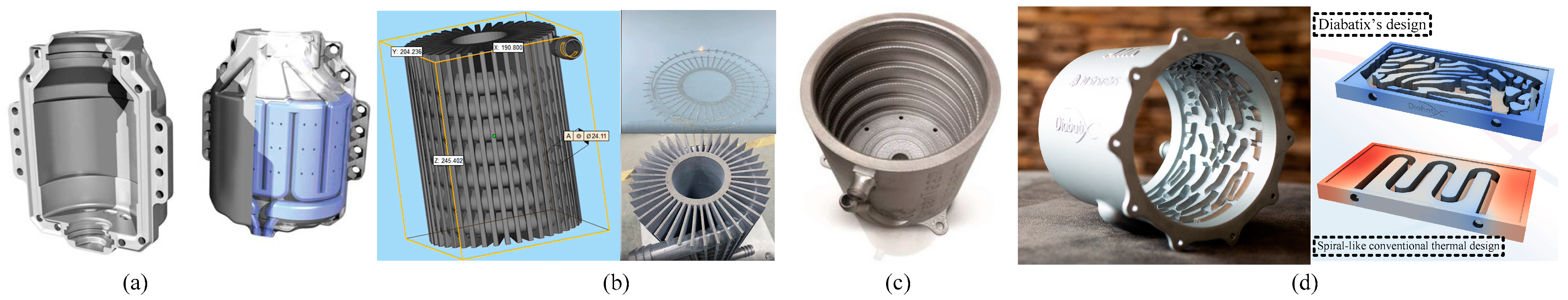

- Thermal Management Emphasis: This review explores the significant role of AM in revolutionizing thermal management strategies for electrical machines. It delves into the intricate cooling channel designs, 3D-printed ceramic heat exchangers, and novel housing designs that contribute to enhanced thermal efficiency and power density.

- Interdisciplinary Perspective: While existing reviews focus on specific components or technologies, this work takes an interdisciplinary approach by addressing the interplay between magnetic materials, windings, and thermal dynamics in electrical machines. It highlights how AM impacts all these aspects collectively.

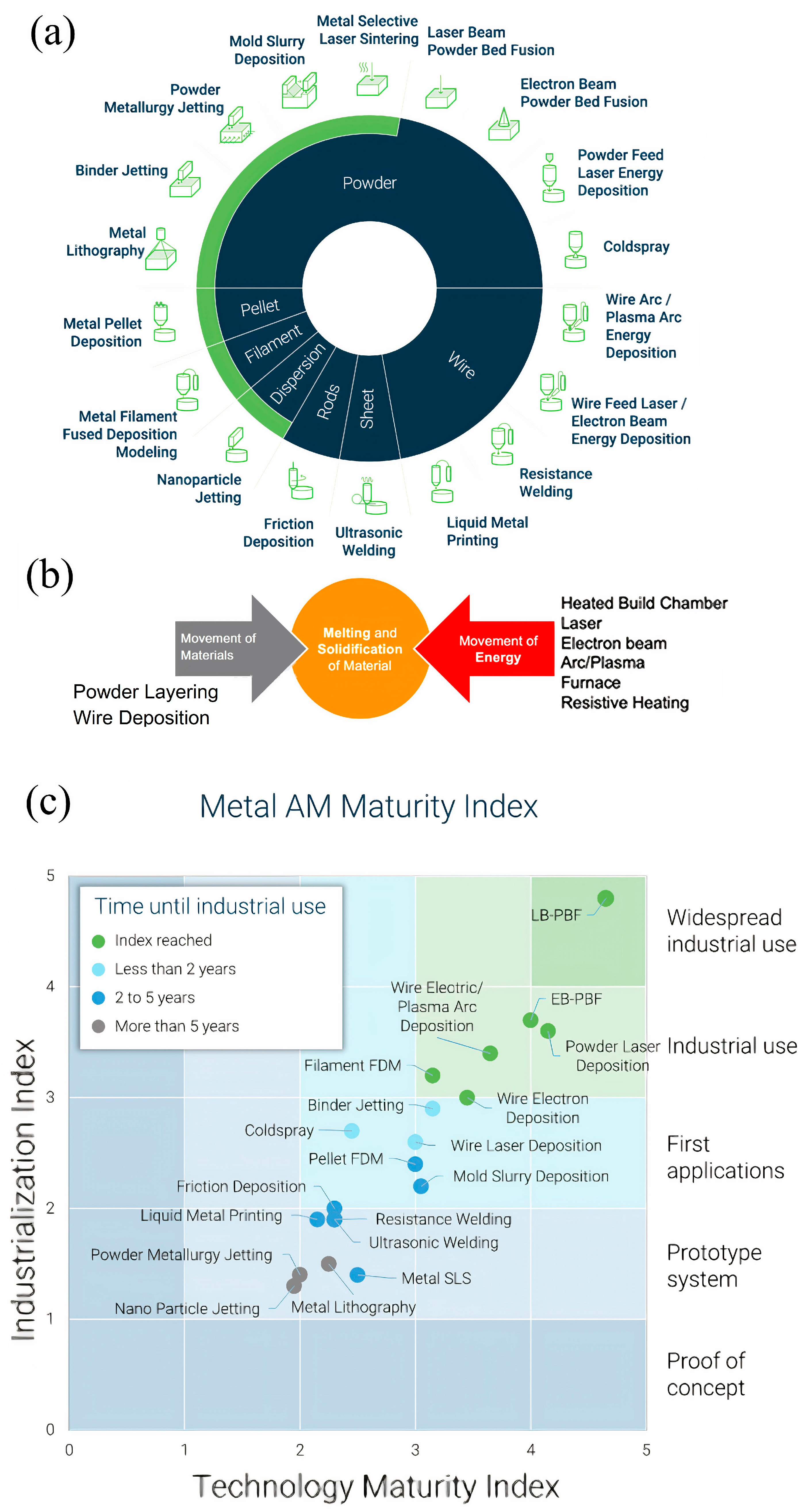

2. Various 3D Printing Techniques

- Powder Bed Fusion (PBF): PBF techniques use a bed of metal powder, selectively fusing or melting the powder particles with a laser or electron beam to create each layer.

- Material Extrusion (ME): This category involves the deposition of metal material through a nozzle, similar to Fused Deposition Modeling (FDM) in polymer 3D printing.

- Directed Energy Deposition (DED): DED involves the focused delivery of energy (often laser or electron beam) to fuse or deposit material as it is extruded or blown onto the work surface.

- Binder Jetting (BJ): In binder jetting, metal powder layers are selectively bound together using a liquid binder, and the excess powder is removed after each layer.

- Sheet Lamination (SL): SL techniques create metal parts by layering and bonding sheets or foils of metal material using various methods such as ultrasonic welding or adhesive bonding.

- Material Jetting (MJ): MJ operates similarly to inkjet printing, where droplets of metal material are deposited and selectively solidified by heat or light to build the part layer by layer.

- Vat Photopolymerization (VP): VP utilizes a photosensitive resin that is selectively solidified or cured using a light source, typically a laser or UV light, to build metal parts layer by layer.

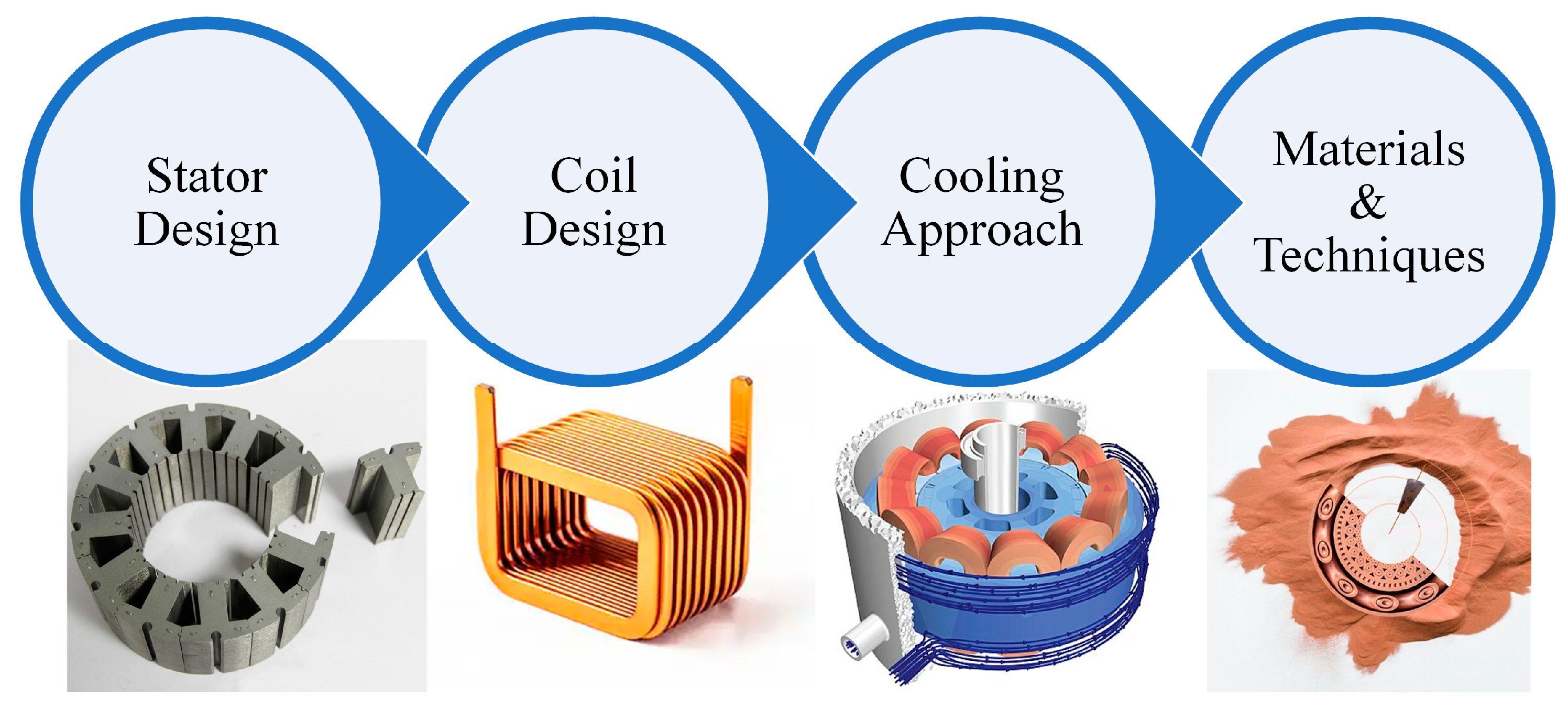

3. Generalized Approach for 3D-Printed Coil and Cooling Designs

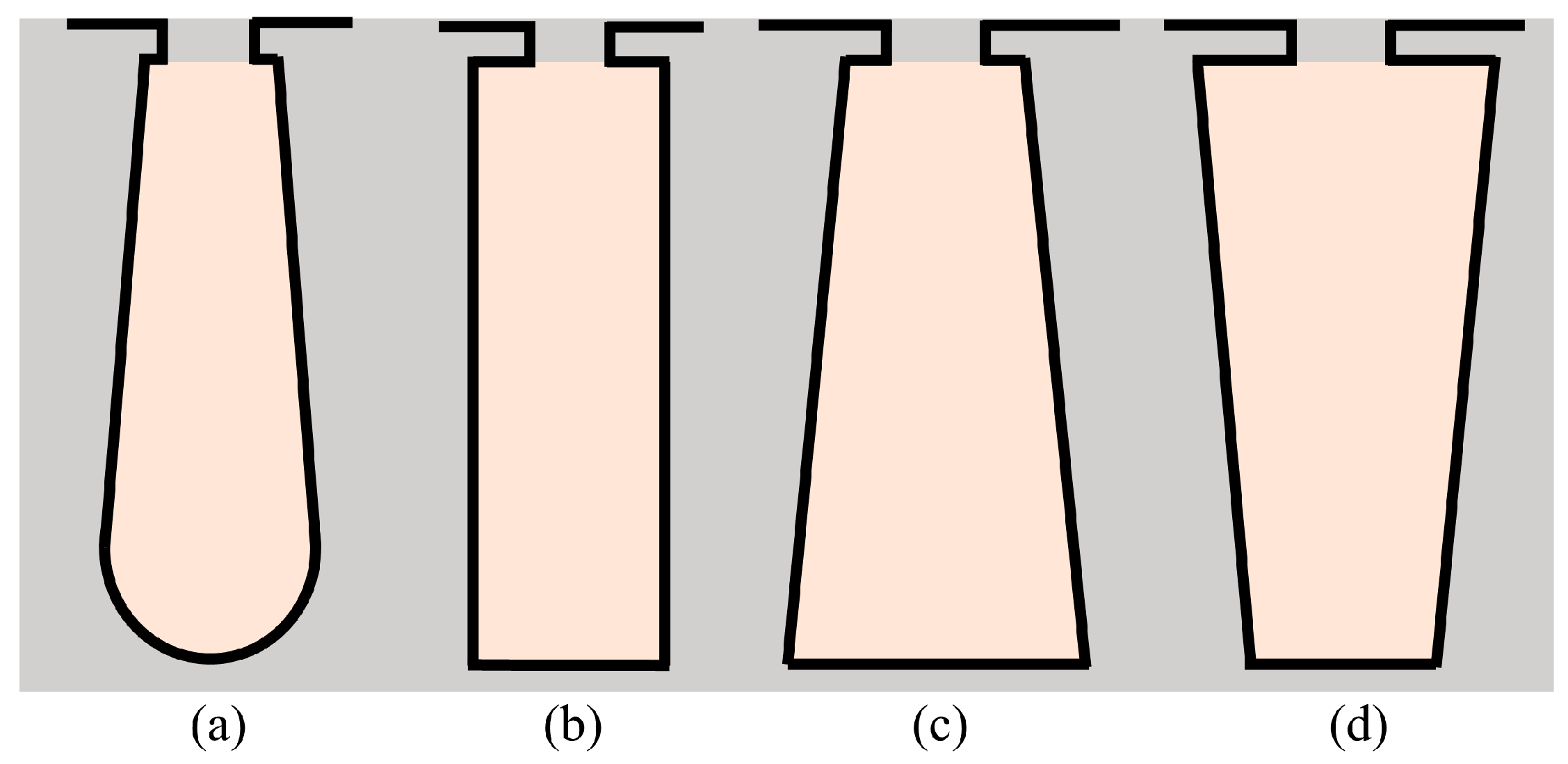

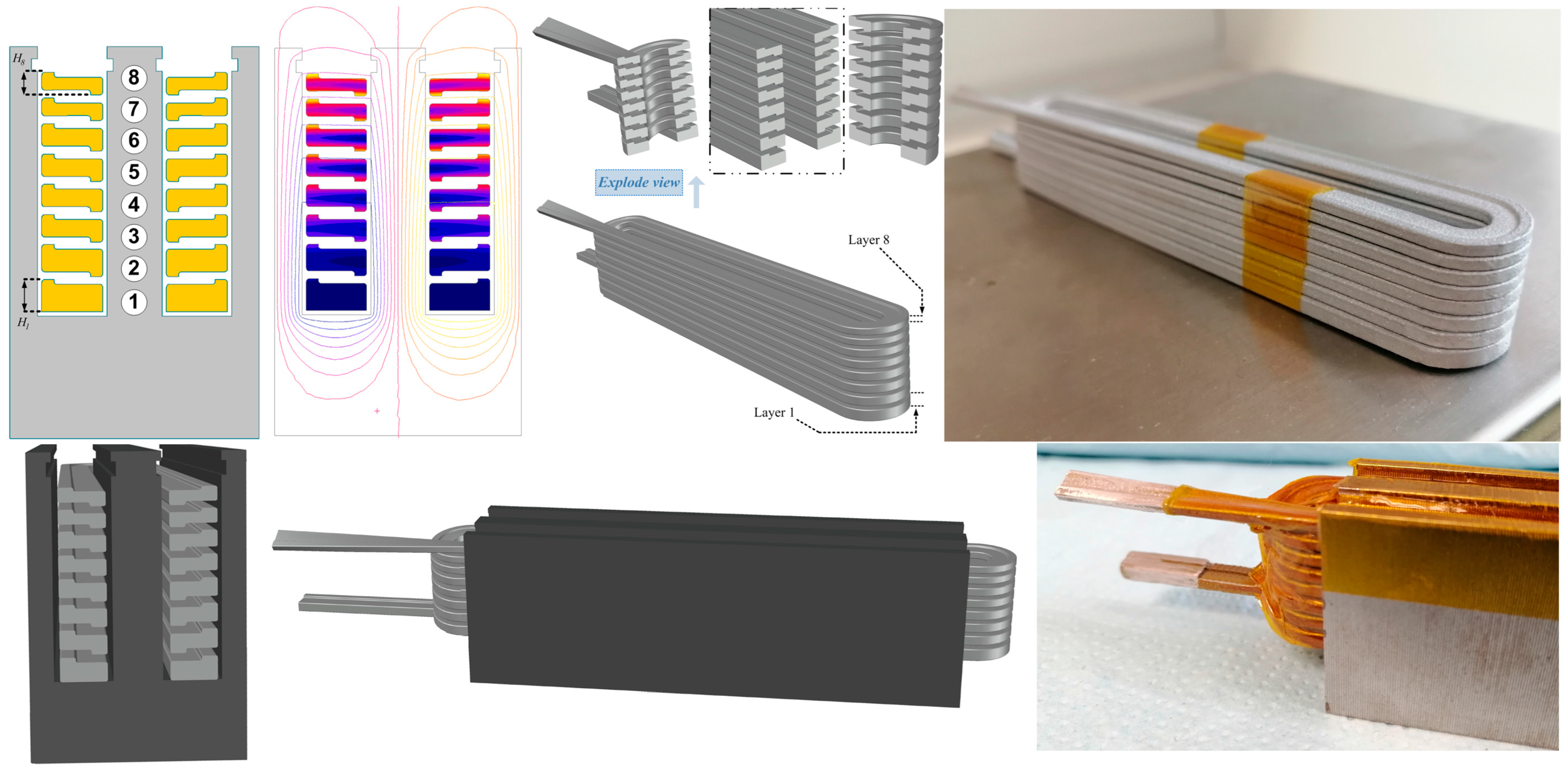

3.1. Stator Design and Slot Shape

- Round [Figure 4a]: Round slots are commonly used in electrical machines because they offer good space utilization and can provide a more uniform magnetic field distribution. However, round slots can also result in high eddy current losses in the 3D-printed coils and increased manufacturing complexity due to the need for curved walls. Typically, this design is used for stranded winding.

- Rectangular [Figure 4b]: Rectangular slots offer relatively better space utilization and better fill factors. They can also reduce eddy current losses compared to round slots. However, rectangular slots can lead to uneven magnetic flux distribution and increased leakage flux, especially near the slot opening. Typically, this design is used for hairpin winding with a single layer.

- Trapezoidal [Figure 4c,d]: Trapezoidal slots offer the best space utilization and the highest fill factor. However, they can also result in high eddy current losses and increased manufacturing complexity of the 3D-printed coils due to the angled walls. Typically, this design is more useful for double-layer windings.

3.2. Winding Configuration and Coil Dimensions

3.3. Cooling Approaches

- Direct cooling tube involves placing a tube in direct contact with the stator or winding to transfer heat away from the component. This method is simple and easy to implement but may result in uneven cooling and reduced efficiency.

- Integrated cooling channels involve embedding channels into the stator or winding to circulate a coolant through the component. This method is more complex than a direct cooling tube but can provide more efficient and uniform cooling.

- End-winding cooling involves creating a separate cooling system for the winding ends. This method can reduce the temperature rise at the end-winding and improve the component’s reliability.

3.4. Material, Printing Technique, and Limitations

- Material form: There are various options available, including metal powders, filaments, and powder pastes. The choice of material can impact the performance and cost. For example, printing with copper powder can result in higher conductivity but may be more expensive than printing with aluminum or its alloys [20,21].

- Cost-effectiveness: The economic feasibility of material choices is a crucial aspect. While copper and its alloys offer excellent electrical conductivity, their higher cost may lead to the consideration of alternative materials, such as aluminum and its alloys, which strike a balance between performance and cost.

- Accuracy and precision: Printing techniques such as Robocasting, Fused Filament Fabrication (FFF), and Selective Laser Melting (SLM) are commonly used to create 3D-printed coils and cooling systems. Robocasting is suitable for printing complex shapes and geometries, while FFF is more suitable for printing larger parts. SLM is suitable for printing metal parts with high accuracy and precision [24].

- Reflectivity: Highly reflective materials, such as copper and aluminum, can reflect the laser beam in SLM, resulting in poor printing quality. However, this issue can be addressed by adding anti-reflective additives or using alternative printing techniques, such as Electron Beam Melting (EBM) [25].

- Thermal Conductivity: In addition to electrical properties, thermal conductivity is also vital. Efficient heat dissipation is essential to ensure the coil’s long-term performance and reliability. The material used in coils must possess adequate thermal conductivity to manage heat effectively.

- Post-processing: 3D-printed coils require post-processing steps, such as heat treatment or surface finishing, to achieve the desired mechanical and electrical properties. The choice of printing technique and material can affect the ease and cost of post-processing [26].

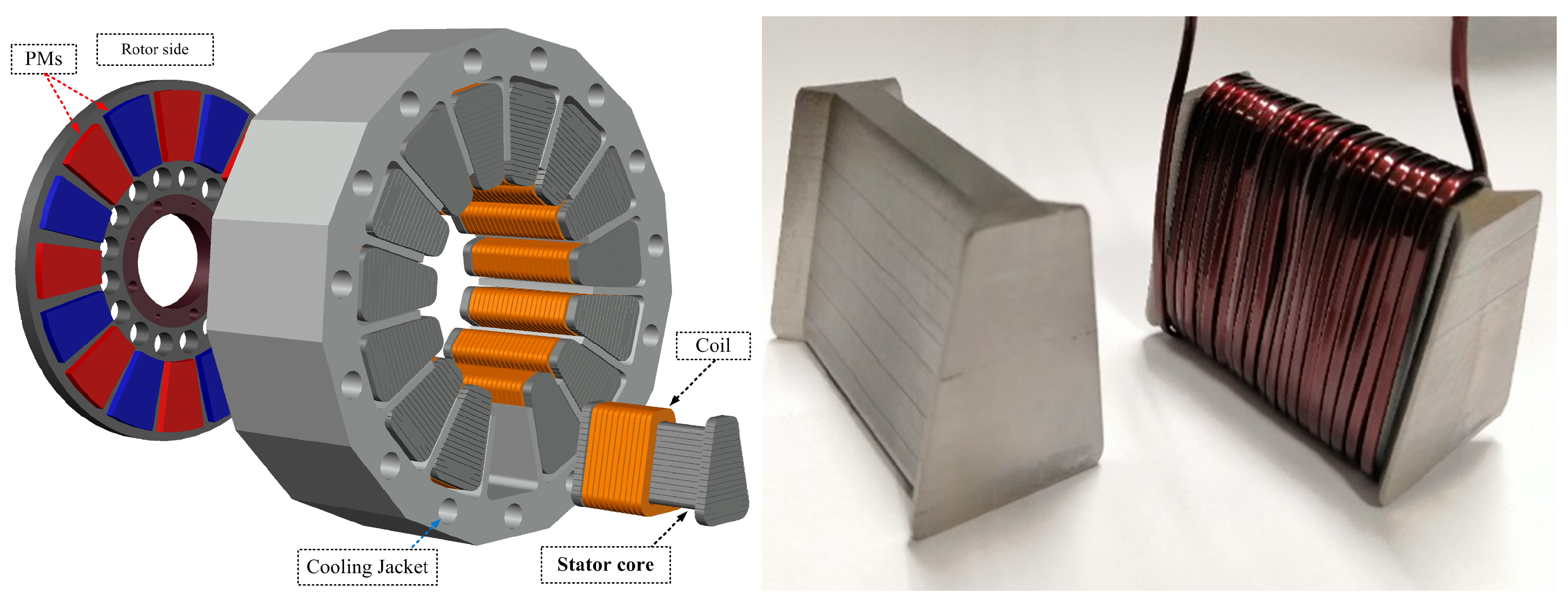

4. Additively Printed Electrical Machines

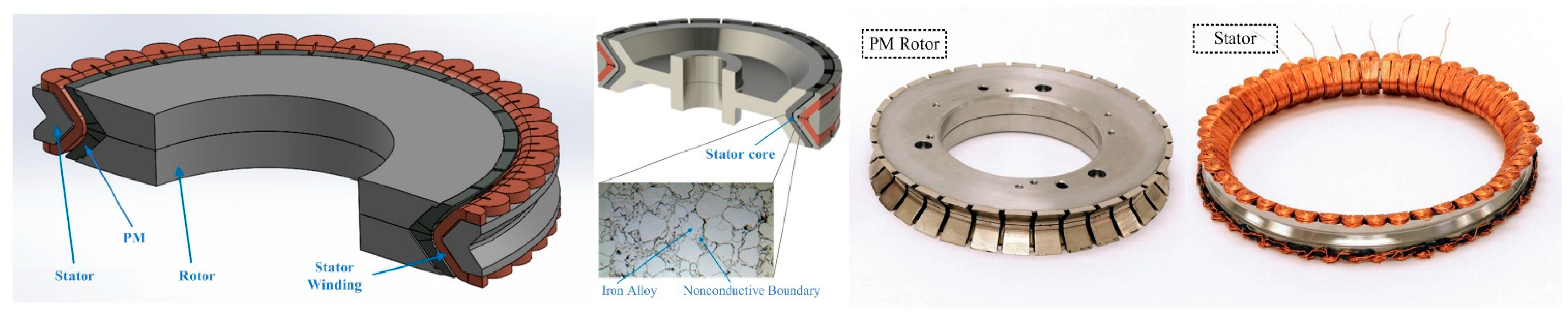

4.1. Magnetic Materials

- Magnetic Property Manipulation: An advantage of metal AM lies in its ability to seamlessly blend diverse metal powders, allowing precise modulation of magnetic properties. This encompassing control extends to factors such as high-saturation magnetization and minimized iron losses. Examples of such amalgamations include cobalt–iron or nickel–iron alloys [30,31,32]. Table 2 and Table 3 show the magnetic properties of different AM soft magnetic materials [33,34,35,36,37,38] and hard magnetic materials [39,40,41,42,43,44,45,46,47], respectively.

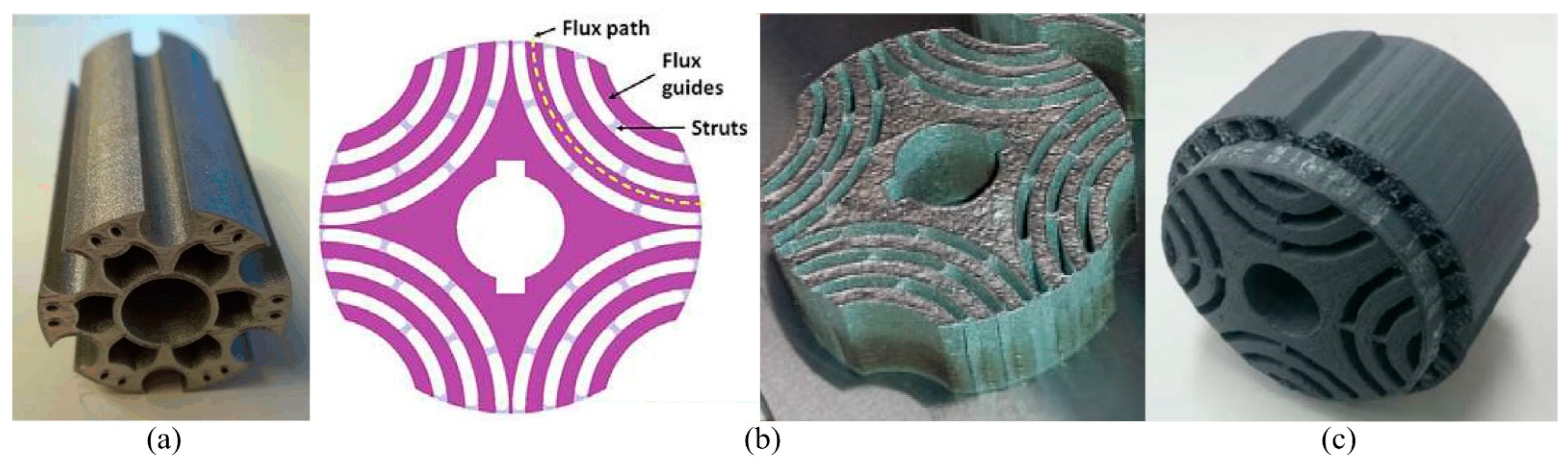

- Intricate Flux Path Construction: The versatility of metal AM substantially loosens dimensional constraints, permitting the construction of complex flux paths. This feature stands in contrast to conventional stacked silicon steel laminations [48].

- Innovative Cooling Channel Integration: One remarkable facet is the simplified integration of cooling channels within the machine core [49].

- Mechanical Enhancement: Metal AM extends its influence beyond the magnetic domain, addressing the mechanical intricacies associated with moving parts within the machine. This influence is harnessed by meticulously controlling material microstructure and fillet percentages, enabling manipulation of physical attributes such as weight and mechanical strength [50,51].

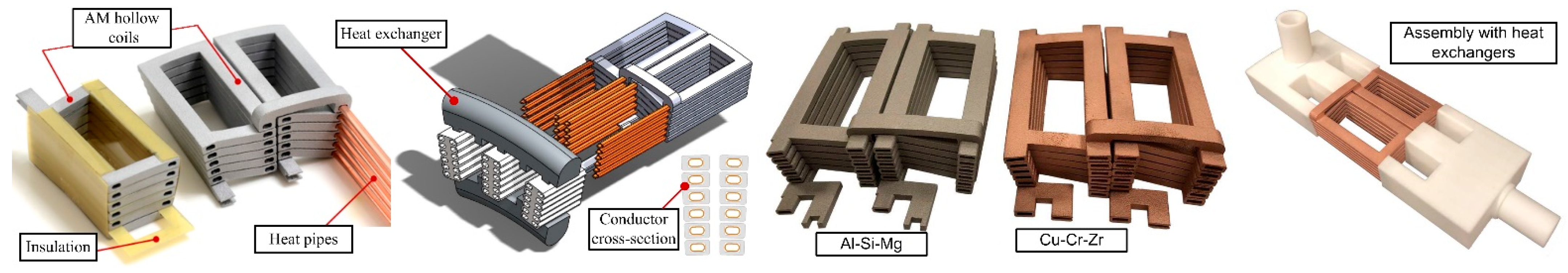

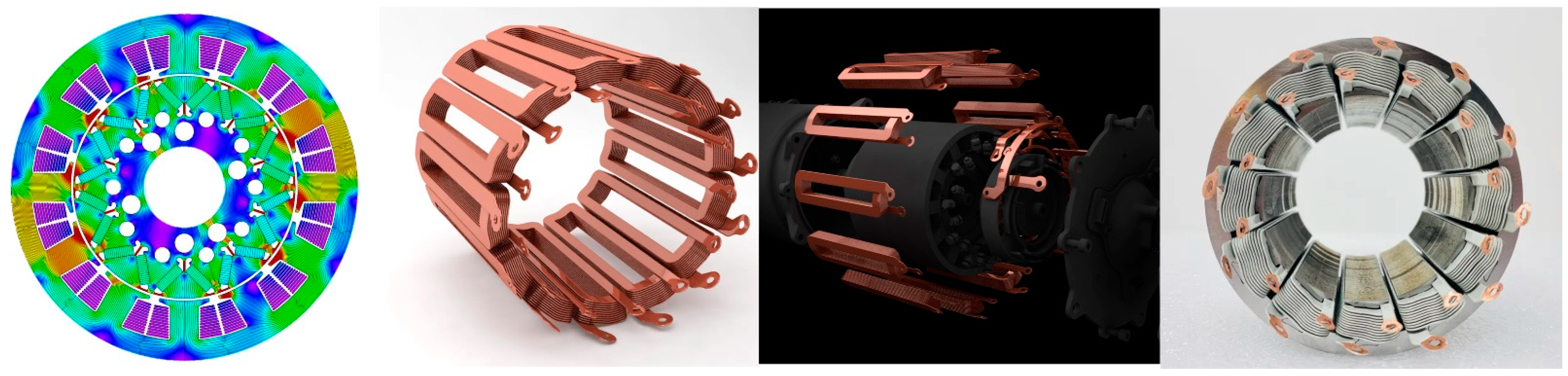

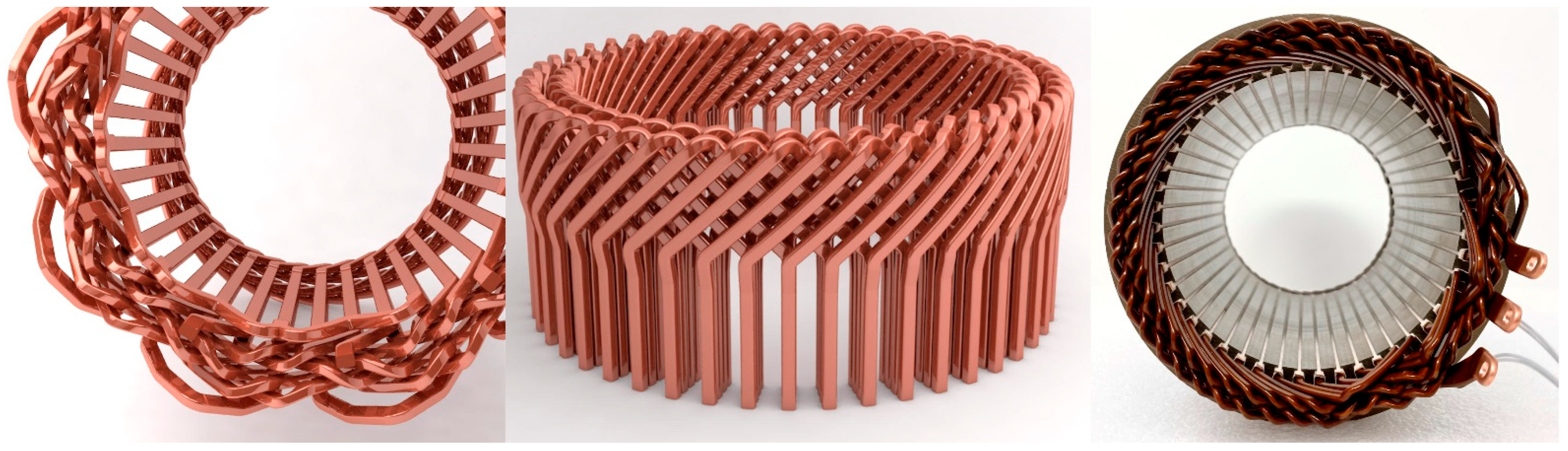

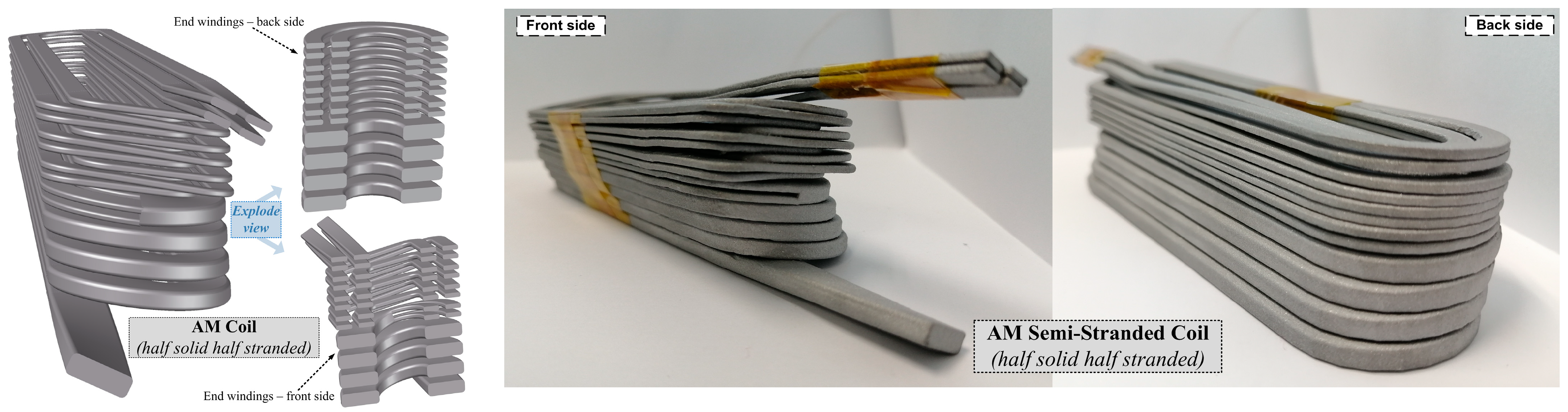

4.2. Windings

- Enhanced Flexibility: The inherent flexibility of AM empowers the design of coil cross-section areas with a heightened slot fill factor, while concurrently optimizing thermal behavior.

- Tailored End Windings: The customization potential extends to end windings, where a remarkable 50% of their length can be adapted [61]. This substantial tailoring translates into pronounced reductions in machine weight and volume, amplifying overall efficiency.

- Simultaneous Winding and Insulation: Specific methodologies enable the simultaneous printing of both the winding and insulation, streamlining the manufacturing process and enhancing efficiency.

- Elevated Operating Temperatures: AM facilitates the utilization of powdered temperature-resistant materials like ceramics, eliminating the need for conventional coatings such as enamel, resin, or polymers. This strategic shift opens avenues for achieving higher operational temperatures that were previously constrained by material limitations. Conventional processing techniques for materials like ceramics are hindered by their high melting points, a challenge surmounted by AM.

- Precision Electric Property Control: The manipulation of winding electric properties, such as conductivity, becomes a reality through the adaptation of material microstructure or the incorporation of distinct materials, illustrating the depth of control offered by AM.

4.3. Thermal Management and Cooling

5. Future Research Scope and Challenges

- Material Availability and Diversity: One of the significant limitations of metal AM lies in the availability of printable materials. While AM offers unique advantages in design flexibility and complexity, the range of materials suitable for these processes remains limited. This limitation directly impacts the variety of electrical machine components that can be effectively manufactured using AM. To address this challenge, researchers and industry professionals must collaborate to expand the selection of printable materials, enabling a broader array of applications and improved performance.

- Post-Processing and Density Variability: Many metal AM processes necessitate post-processing steps to achieve the desired mechanical properties and surface finish. However, the extent of post-processing required varies based on the material and process used. This variability influences the density and performance of the manufactured components. Overcoming this challenge involves developing standardized post-processing procedures and optimization techniques to ensure consistent and predictable outcomes, thus enhancing the reliability of AM-manufactured electrical machine parts.

- Print Parameters and Component Build: The parameters employed during the printing process—such as print speed, print resolution, print strategy, and print bed position—significantly impact the quality and properties of the resulting components. Understanding the intricate interplay between these parameters and the final component’s attributes is crucial for achieving desired outcomes. Research efforts should focus on optimizing these parameters to strike a balance between precision, efficiency, and material properties, thereby refining the overall AM manufacturing process.

- Outer Space Manufacturing: A visionary avenue for future research involves exploring the feasibility of manufacturing electrical machine components using AM techniques in outer space environments. As space exploration and utilization expand, the demand for on-site manufacturing capabilities becomes more pronounced. Investigating the adaptability of AM to extraterrestrial conditions presents a unique set of challenges and opportunities, with potential implications for future space missions and infrastructure development.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassõlkin, A. State of the Art of Additively Manufactured Electromagnetic Materials for Topology Optimized Electrical Machines. Addit. Manuf. 2022, 55, 102778. [Google Scholar] [CrossRef]

- Kareem, F.A.; Michael, P.A. An Investigation on Applications of Additive Manufacturing of Electrical Machines. Mater. Today Proc. 2022, 58, 86–90. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A Review on Selective Laser Sintering/Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Selema, A.; Osheba, D.S.M.; Tahoon, S.M.R.; El-Shanawany, M.M. Design and Analysis of a Three-phase Brushless Flux Switching Generator for Aircraft Ground Power Units. IET Electr. Power Appl. 2019, 13, 154–161. [Google Scholar] [CrossRef]

- El-Refaie, A.; Osama, M. High Specific Power Electrical Machines: A System Perspective. CES Trans. Electr. Mach. Syst. 2019, 3, 88–93. [Google Scholar] [CrossRef]

- Selema, A. Development of a Three-Phase Dual-Rotor Magnetless Flux Switching Generator for Low Power Wind Turbines. IEEE Trans. Energy Convers. 2020, 35, 828–836. [Google Scholar] [CrossRef]

- Wang, H.; Lamichhane, T.N.; Paranthaman, M.P. Review of Additive Manufacturing of Permanent Magnets for Electrical Machines: A Prospective on Wind Turbine. Mater. Today Phys. 2022, 24, 100675. [Google Scholar] [CrossRef]

- Ghassemi, M. High Power Density Technologies for Large Generators and Motors for Marine Applications with Focus on Electrical Insulation Challenges. High Volt. 2020, 5, 7–14. [Google Scholar] [CrossRef]

- AM-Power-Report Metal Additive Manufacturing Technology. Available online: https://additive-manufacturing-report.com/additive-manufacturing-metal-technology/ (accessed on 10 May 2023).

- Xu, W. Direct Additive Manufacturing Techniques for Metal Parts: SLM, EBM, Laser Metal Deposition. In Encyclopedia of Materials: Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 2022; pp. 290–318. [Google Scholar]

- Gonzalez-Gutierrez, J. Indirect Additive Manufacturing Techniques for Metal Parts: Binder-Based Additive Manufacturing Techniques. In Encyclopedia of Materials: Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 2022; pp. 319–329. [Google Scholar]

- Praet, K. Van Tips and Tricks for Metal 3D Printing: Recoaters. Available online: https://www.materialise.com/en/blog/metal-3D-printing-recoaters (accessed on 10 May 2023).

- Khorasani, A.; Gibson, I.; Veetil, J.K.; Ghasemi, A.H. A Review of Technological Improvements in Laser-Based Powder Bed Fusion of Metal Printers. Int. J. Adv. Manuf. Technol. 2020, 108, 191–209. [Google Scholar] [CrossRef]

- BeAM Directed Energy Deposition—Synergy Additive Manufacturing. Available online: https://synergyadditive.com/directed-energy-deposition/ (accessed on 10 May 2023).

- Taminger, K.M.B.; Manufacturing, D.D. Electron Beam Additive Manufacturing. Available online: https://www.sciaky.com/additive-manufacturing/electron-beam-additive-manufacturing-technology (accessed on 10 May 2023).

- Bambach, M. Metal Additive Manufacturing: Chapter 5: Laser-Based Metal Additive Manufacturing. Available online: https://www.metal-am.com/metal-additive-manufacturing-magazine/ (accessed on 10 May 2023).

- Zou, Y. Cold Spray Additive Manufacturing: Microstructure Evolution and Bonding Features. Accounts Mater. Res. 2021, 2, 1071–1081. [Google Scholar] [CrossRef]

- Additivemanufacturing.media AM 101: NanoParticle Jetting (NPJ). Available online: https://www.additivemanufacturing.media/articles/am-101-nanoparticle-jetting-npj (accessed on 10 May 2023).

- Wu, F.; EL-Refaie, A.M.; Al-Qarni, A. Additively Manufactured Hollow Conductors for High Specific Power Electrical Machines: Aluminum vs. Copper. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 4397–4404. [Google Scholar]

- Guo, M.; Gu, D.; Xi, L.; Zhang, H.; Zhang, J.; Yang, J.; Wang, R. Selective Laser Melting Additive Manufacturing of Pure Tungsten: Role of Volumetric Energy Density on Densification, Microstructure and Mechanical Properties. Int. J. Refract. Met. Hard Mater. 2019, 84, 105025. [Google Scholar] [CrossRef]

- Ambruş, S.; Muntean, R.; Codrean, C.; Uţu, I.-D. Influence of Printing Conditions on the Mechanical Properties of Copper-Polylactic Acid Composites Obtained by 3D Printing Fused Deposition Modelling. Mater. Today Proc. 2023, 72, 580–585. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, R.; Singh Chohan, J. Multi-Objective Optimization of 3D Printing Process Using Genetic Algorithm for Fabrication of Copper Reinforced ABS Parts. Mater. Today Proc. 2022, 48, 981–988. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, W.; Xi, J.; Li, H.; Ren, F. Development of Copper Powder Paste for Direct Printing and Soft Mold Casting. Addit. Manuf. 2020, 31, 100992. [Google Scholar] [CrossRef]

- Huo, J.; Zhang, G. New Process for Integrated Manufacturing of Copper Alloy Shells by Bimetal 3D Printing Remanufacturing Technology. Energy Rep. 2022, 8, 11052–11063. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.-F.; Lu, Y.F. Laser 3D Printing of Complex Copper Structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Karakurt, I.; Lin, L. 3D Printing Technologies: Techniques, Materials, and Post-Processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Fish, G.E. Soft Magnetic Materials. Proc. IEEE 1990, 78, 947–972. [Google Scholar] [CrossRef]

- Wrobel, R.; Mecrow, B. Additive Manufacturing in Construction of Electrical Machines—A Review. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019; pp. 15–22. [Google Scholar]

- Ito, H.; Saito, M.; Miyamachi, T.; Komori, F.; Koganezawa, T.; Mizuguchi, M.; Kotsugi, M. Fabrication of L 1-Type FeCo Ordered Structure Using a Periodic Ni Buffer Layer. AIP Adv. 2019, 9, 045307. [Google Scholar] [CrossRef]

- Harris, V.G.; Chen, Y.; Yang, A.; Yoon, S.; Chen, Z.; Geiler, A.L.; Gao, J.; Chinnasamy, C.N.; Lewis, L.H.; Vittoria, C.; et al. High Coercivity Cobalt Carbide Nanoparticles Processed via Polyol Reaction: A New Permanent Magnet Material. J. Phys. D Appl. Phys. 2010, 43, 165003. [Google Scholar] [CrossRef]

- Khazdozian, H.A.; Manzano, J.S.; Gandha, K.; Slowing, I.I.; Nlebedim, I.C. Recycled Sm-Co Bonded Magnet Filaments for 3D Printing of Magnets. AIP Adv. 2018, 8, 056722. [Google Scholar] [CrossRef]

- Johnson, F.; Osama, M.; Jassal, A.K.; Adharapurapu, R.R. Method of Heat-Treating Additively-Manufactured Ferromagnetic Components. U.S. Patent 10,946,444, 16 March 2021. [Google Scholar]

- Riipinen, T.; Metsä-Kortelainen, S.; Lindroos, T.; Keränen, J.S.; Manninen, A.; Pippuri-Mäkeläinen, J. Properties of Soft Magnetic Fe-Co-V Alloy Produced by Laser Powder Bed Fusion. Rapid Prototyp. J. 2019, 25, 699–707. [Google Scholar] [CrossRef]

- Goll, D.; Schuller, D.; Martinek, G.; Kunert, T.; Schurr, J.; Sinz, C.; Schubert, T.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive Manufacturing of Soft Magnetic Materials and Components. Addit. Manuf. 2019, 27, 428–439. [Google Scholar] [CrossRef]

- Garibaldi, M. Laser Additive Manufacturing of Soft Magnetic Cores for Rotating Electrical Machinery: Materials Development and Part Design. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2018. [Google Scholar]

- Zhang, B.; Fenineche, N.-E.; Liao, H.; Coddet, C. Magnetic Properties of In-Situ Synthesized FeNi3 by Selective Laser Melting Fe-80%Ni Powders. J. Magn. Magn. Mater. 2013, 336, 49–54. [Google Scholar] [CrossRef]

- Zhang, B.; Fenineche, N.-E.; Liao, H.; Coddet, C. Microstructure and Magnetic Properties of Fe–Ni Alloy Fabricated by Selective Laser Melting Fe/Ni Mixed Powders. J. Mater. Sci. Technol. 2013, 29, 757–760. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Shafer, C.S.; Elliott, A.M.; Siddel, D.H.; McGuire, M.A.; Springfield, R.M.; Martin, J.; Fredette, R.; Ormerod, J. Binder Jetting: A Novel NdFeB Bonded Magnet Fabrication Process. JOM 2016, 68, 1978–1982. [Google Scholar] [CrossRef]

- Jaćimović, J.; Binda, F.; Herrmann, L.G.; Greuter, F.; Genta, J.; Calvo, M.; Tomše, T.; Simon, R.A. Net Shape 3D Printed NdFeB Permanent Magnet. Adv. Eng. Mater. 2017, 19, 1700098. [Google Scholar] [CrossRef]

- Pigliaru, L.; Rinaldi, M.; Ciccacci, L.; Norman, A.; Rohr, T.; Ghidini, T.; Nanni, F. 3D Printing of High Performance Polymer-Bonded PEEK-NdFeB Magnetic Composite Materials. Funct. Compos. Mater. 2020, 1, 4. [Google Scholar] [CrossRef]

- Gandha, K.; Li, L.; Nlebedim, I.C.; Post, B.K.; Kunc, V.; Sales, B.C.; Bell, J.; Paranthaman, M.P. Additive Manufacturing of Anisotropic Hybrid NdFeB-SmFeN Nylon Composite Bonded Magnets. J. Magn. Magn. Mater. 2018, 467, 8–13. [Google Scholar] [CrossRef]

- Lamarre, J.-M.; Bernier, F. Permanent Magnets Produced by Cold Spray Additive Manufacturing for Electric Engines. J. Therm. Spray Technol. 2019, 28, 1709–1717. [Google Scholar] [CrossRef]

- Sonnleitner, K.; Huber, C.; Teliban, I.; Kobe, S.; Saje, B.; Kagerbauer, D.; Reissner, M.; Lengauer, C.; Groenefeld, M.; Suess, D. 3D Printing of Polymer-Bonded Anisotropic Magnets in an External Magnetic Field and by a Modified Production Process. Appl. Phys. Lett. 2020, 116, 092403. [Google Scholar] [CrossRef]

- Ma, B.M.; Herchenroeder, J.W.; Smith, B.; Suda, M.; Brown, D.N.; Chen, Z. Recent development in bonded NdFeB magnets. J. Magn. Magn. Mater. 2002, 239, 418–423. [Google Scholar] [CrossRef]

- White, E.M.H.; Kassen, A.G.; Simsek, E.; Tang, W.; Ott, R.T.; Anderson, I.E. Net Shape Processing of Alnico Magnets by Additive Manufacturing. IEEE Trans. Magn. 2017, 53, 2101606. [Google Scholar] [CrossRef]

- White, E.; Rinko, E.; Prost, T.; Horn, T.; Ledford, C.; Rock, C.; Anderson, I. Processing of Alnico Magnets by Additive Manufacturing. Appl. Sci. 2019, 9, 4843. [Google Scholar] [CrossRef]

- Pham, T.; Kwon, P.; Foster, S. Additive Manufacturing and Topology Optimization of Magnetic Materials for Electrical Machines—A Review. Energies 2021, 14, 283. [Google Scholar] [CrossRef]

- Wits, W.W.; Jafari, D. Experimental Performance of a 3D-Printed Hybrid Heat Pipe-Thermosyphon for Cooling of Power Electronics. In Proceedings of the 2018 24rd International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Stockholm, Sweden, 26–28 September 2018; IEEE: Piscataway, NJ, USA; pp. 1–6. [Google Scholar]

- Wrobel, R.; Mecrow, B. A Comprehensive Review of Additive Manufacturing in Construction of Electrical Machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064. [Google Scholar] [CrossRef]

- Lammers, S.; Adam, G.; Schmid, H.J.; Mrozek, R.; Oberacker, R.; Hoffmann, M.J.; Quattrone, F.; Ponick, B. Additive Manufacturing of a Lightweight Rotor for a Permanent Magnet Synchronous Machine. In Proceedings of the 2016 6th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 November–1 December 2016; pp. 41–45. [Google Scholar]

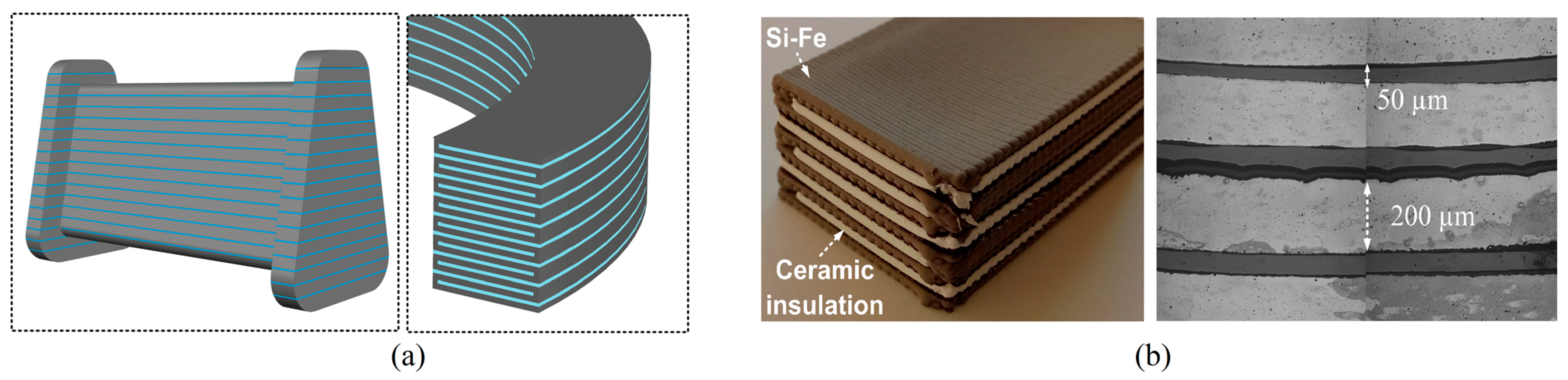

- Selema, A.; Beretta, M.; Ibrahim, M.N.; Verwimp, J.; Rombouts, M.; Vleugels, J.; Kestens, L.A.I.; Sergeant, P. Material Engineering of 3D-Printed Silicon Steel Alloys for the Next Generation of Electrical Machines and Sustainable Electromobility. J. Magn. Magn. Mater. 2023, 584, 171106. [Google Scholar] [CrossRef]

- Metsä-Kortelainen, S.; Lindroos, T.; Savolainen, M.; Jokinen, A.; Revuelta, A.; Pasanen, A.; Ruusuvuori, K.; Pippuri, J. Manufacturing of Topology Optimized Soft Magnetic Core through 3D Printing. In NAFEMS Exploring the Design Freedom of Additive Manufacturing through Simulation; VTT Technical Research Centre of Finland: Helsinki, Finland, 2016. [Google Scholar]

- Freeman, F.S.H.B.; Lincoln, A.; Sharp, J.; Lambourne, A.; Todd, I. Exploiting Thermal Strain to Achieve an In-Situ Magnetically Graded Material. Mater. Des. 2019, 161, 14–21. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Jhong, K.J.; Cheng, C.-W.; Huang, P.-W.; Tsai, M.-C.; Lee, W.-H. Metal 3D Printing of Synchronous Reluctance motor. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taiwan, China, 14–17 March 2016; pp. 1125–1128. [Google Scholar]

- Urbanek, S.; Frey, P.; Magerkohl, S.; Zimmer, D.; Tasche, L.; Schaper, M.; Ponick, B. Design and Experimental Investigation of an Additively Manufactured PMSM Rotor. In Proceedings of the 2021 IEEE International Electric Machines & Drives Conference (IEMDC), Hartford, CT, USA, 17–20 May 2021; pp. 1–6. [Google Scholar]

- Hosek, M.; Krishnasamy, J.; Sah, S.; Bashaw, T. Spray-Formed Hybrid-Field Electric Motor. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar]

- Selema, A.; Beretta, M.; Van Coppenolle, M.; Tiismus, H.; Kallaste, A.; Ibrahim, M.; Rombouts, M.; Vleugels, J.; Kestens, L.; Sergeant, P. Evaluation of 3d-Printed Magnetic Materials for Additively-Manufactured Electrical Machines. J. Magn. Magn. Mater. 2023, 569, 170426. [Google Scholar] [CrossRef]

- Beretta, M.; Kolli, S.; Selema, A.; Sergeant, P.; Kestens, L.A.I.; Rombouts, M.; Vleugels, J. Process Optimization and Characterization of Dense Pure Copper Parts Produced by Paste-Based 3D Micro-Extrusion. Addit. Manuf. 2023, 73, 103670. [Google Scholar] [CrossRef]

- Selema, A.; Gulec, M.; Ibrahim, M.N.; Sprangers, R.; Sergeant, P. Selection of Magnet Wire Topologies With Reduced AC Losses for the Windings of Electric Drivetrains. IEEE Access 2022, 10, 121531–121546. [Google Scholar] [CrossRef]

- Jagdale, V.; Tangudu, J. Topology Optimized End Winding for Additively Manufactured Induction Motor with Distributed Winding; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

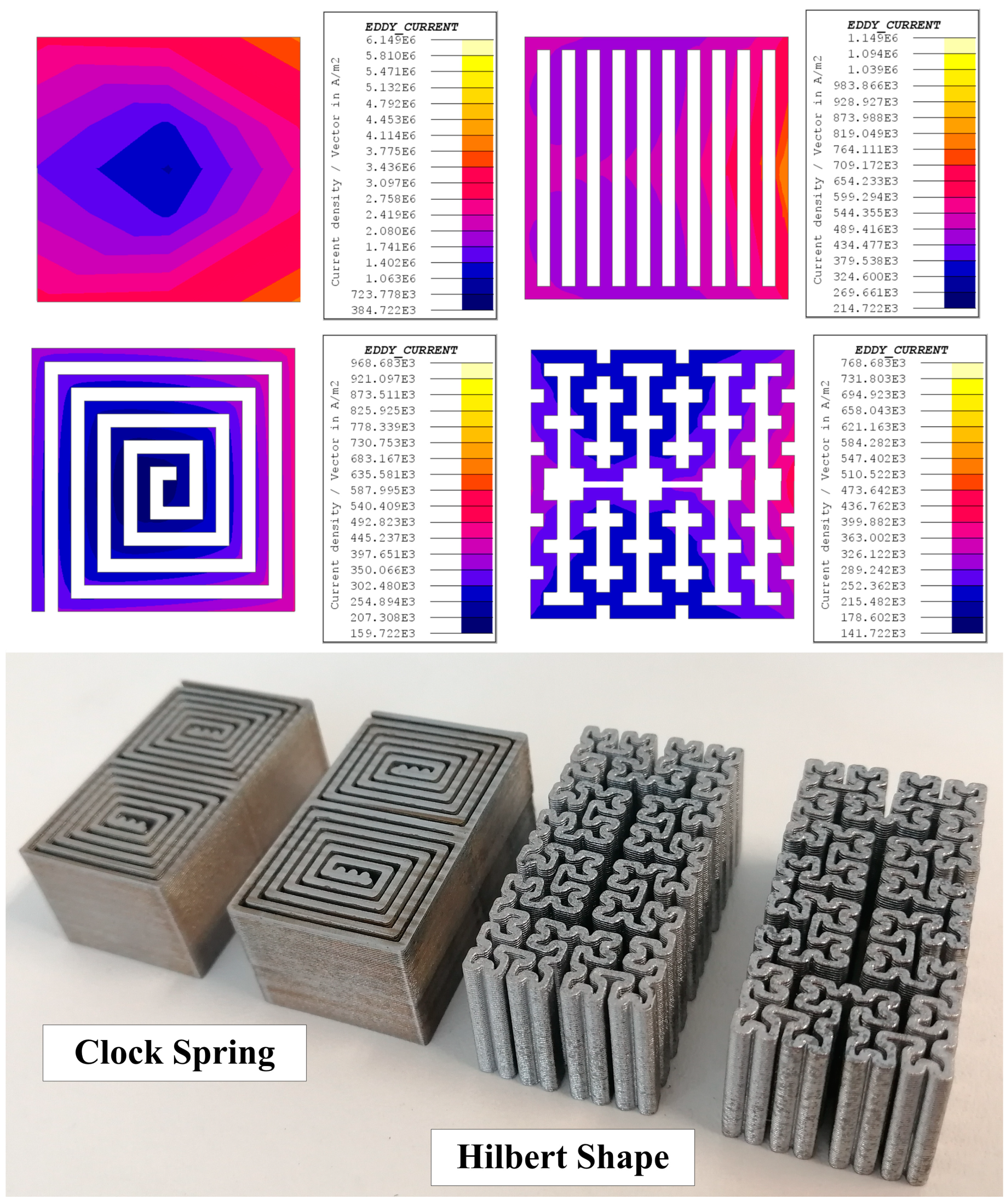

- Simpson, N.; North, D.J.; Collins, S.M.; Mellor, P.H. Additive Manufacturing of Shaped Profile Windings for Minimal AC Loss in Electrical Machines. IEEE Trans. Ind. Appl. 2020, 56, 2510–2519. [Google Scholar] [CrossRef]

- Simpson, N.; Mellor, P.H. Additive Manufacturing of Shaped Profile Windings for Minimal AC Loss in Electrical Machines. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, ON, USA, 23–27 September 2018; pp. 5765–5772. [Google Scholar]

- Ayat, S.; Simpson, N.; Daguse, B.; Rudolph, J.; Lorenz, F.; Drury, D. Design of Shaped-Profile Electrical Machine Windings for Multi-Material Additive Manufacture. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 1554–1559. [Google Scholar]

- Robinson, John, Nick Simpson Functional Multi-Material Coil Winding and TPMS Heat Exchanger. Available online: https://www.wlv.ac.uk/research/institutes-and-centres/centre-for-engineering-innovation-and-research/amfm-research-group/ (accessed on 10 May 2023).

- Additive Drives. Racing Engine with 3D-Printed Coils. Available online: https://www.additive-drives.de/en/project/racing-engine/ (accessed on 10 May 2023).

- Additive Drives. 3D-Printed Hairpin Windings for E-Traction Motors. Available online: https://www.additive-drives.de/en/project/e-traction-motor/ (accessed on 10 May 2023).

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Additively Manufactured Ultralight Shaped-Profile Windings for HF Electrical Machines and Weight-Sensitive Applications. IEEE Trans. Transp. Electrif. 2022, 8, 4313–4324. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Development of Novel Semi-Stranded Windings for High Speed Electrical Machines Enabled by Additive Manufacturing. Appl. Sci. 2023, 13, 1653. [Google Scholar] [CrossRef]

- Diabatix Efficient Thermal Design. Available online: https://www.diabatix.com/blog (accessed on 10 May 2023).

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Ceramic 3D Printed Direct Winding Heat Exchangers for Improving Electric Machine Thermal Management. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, September 29–32 October 2019; pp. 769–776. [Google Scholar]

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Cooling of Windings in Electric Machines via 3-D Printed Heat Exchanger. IEEE Trans. Ind. Appl. 2020, 56, 4718–4726. [Google Scholar] [CrossRef]

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Cooling of Windings in Electric Machines via 3D Printed Heat Exchanger. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September2018; pp. 229–235. [Google Scholar]

- Silbernagel, C. Nottingham PhD Student Wins Additive World Design Challenge Award. Available online: https://exchange.nottingham.ac.uk/blog/%0Aphd-student-wins-additive-world-design-challenge-award/ (accessed on 10 May 2023).

- HBD Metal 3D Printing Advantages. 2021. Available online: https://en.hb3dp.com/app1.html (accessed on 21 December 2022).

- EPMA. Cooling Jacket with Internal Helix Structure. 2021. Available online: https://www.epma.com/spotlight-on-pm/cooling-jacket-with-internal-helix-structure (accessed on 10 May 2023).

- Lieven Vervecken, Diabatix Artificial Intelligence Is Driving Better Cooling for Critical EV Components. Available online: https://www.diabatix.com/blog/ai-driving-better-ev-cooling (accessed on 10 May 2023).

| Properties (after Heat Treatment) | Al-Si-Mg | Cu-Cr-Zr |

|---|---|---|

| Electrical conductivity | 27.0%IACS | 89.3%IACS |

| Thermal conductivity | 173 W/(mK) | 265 W/(mK) |

| Temperature coefficient | 0.00410/K | 0.00393/K |

| Mass Density | 2670 kg/m3 | 8910 kg/m3 |

| Yield strength | 248.1 MPa | 200 MPa |

| Material Compositions | µmax & Saturation Flux Density (Ms) | Hysteresis Losses | AM Technique | Heat Treatment | Ref. |

|---|---|---|---|---|---|

| 50Fe-49.9Co-0.1Si | µmax = 2600 Ms = 2.35 T | Comparable to Vacoflux 50 | SLM | 1100 °C for 4 h | [33] |

| Fe-49Co-2V | µmax = 13,000 | higher than a laminated sample @ 1.5T, 10/50 Hz | L-PBF | 700 °C for 2 h | [34] |

| FeSi6.7 | µmax = 31,000 | 0.70 W/kg @ 1.0 T, 50 Hz | L-PBF | 1150 °C for 1 h | [35] |

| Fe-6.9%wt.Si | µmax = 24,000 | 4.0 W/kg @ 1.0 T, 50 Hz | SLM | 1150 °C for 1 h | [36] |

| Fe-80%Ni | Ms = 550 Am2/kg | BH loop is available Losses are not calculated | SLM | non | [37] |

| Ni-Fe14-Cu5-Mo4 | Ms = 0.33 T | BH loop is available Losses are not calculated | SLM | non | [38] |

| Material Compositions | AM Methods | Remanence Br (G) | Coercivity Hci (A/m) | Max. Processing Temp. | Ref. |

|---|---|---|---|---|---|

| NdFeB | BJT *1 | 3000 | 9000 | 150 °C | [39] |

| NdFeB | L-PBF | 5900 | 8734 | 900 °C | [40] |

| NdFeB | FFF *4 | 690 | 5190 | 525 °C | [41] |

| NdFeB + SmFeN | BAAM *2 | 2800–11,000 | 10,800–11,100 | 204 °C | [42] |

| NdFeB-Al | CS *3 | 4900 | 11,000 | 800 °C | [43] |

| Ferrites | FFF | 2200 | 3530 | 300 °C | [44] |

| SmCo5 | FFF | 880 | 8970 | 160 °C | [45] |

| AlNiCo 8 | DED *5 | 9200 | 1850 | 1250 °C | [46] |

| AlNiCo 9 | DED | 7200 | 1600 | 1215 °C | [47] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selema, A.; Ibrahim, M.N.; Sergeant, P. Advanced Manufacturability of Electrical Machine Architecture through 3D Printing Technology. Machines 2023, 11, 900. https://doi.org/10.3390/machines11090900

Selema A, Ibrahim MN, Sergeant P. Advanced Manufacturability of Electrical Machine Architecture through 3D Printing Technology. Machines. 2023; 11(9):900. https://doi.org/10.3390/machines11090900

Chicago/Turabian StyleSelema, Ahmed, Mohamed N. Ibrahim, and Peter Sergeant. 2023. "Advanced Manufacturability of Electrical Machine Architecture through 3D Printing Technology" Machines 11, no. 9: 900. https://doi.org/10.3390/machines11090900

APA StyleSelema, A., Ibrahim, M. N., & Sergeant, P. (2023). Advanced Manufacturability of Electrical Machine Architecture through 3D Printing Technology. Machines, 11(9), 900. https://doi.org/10.3390/machines11090900