Analytic and Data-Driven Force Prediction for Vacuum-Based Granular Grippers

Abstract

:1. Introduction—Graspability Prediction

1.1. Graspability Prediction—Approaches and the State of the Art

1.2. Simulations

1.3. Gripper-Specific Analytical Parameters

1.4. Model-Free Prediction and Machine Learning

1.5. Similarity-Based Prediction

1.6. Summary of the State of the Art

2. Materials and Methods

2.1. Examined Gripper

2.2. Gripper-Specific Previous Research

- Is the geometry grippable? (Is the object surface > 90% airtight?)

- Which Ccombined is achievable for this geometry?

2.3. Assessment and Selection of Possible Gripping Prediction Approaches for the Examined Gripper

2.3.1. Applicability and Challenges of Simulations and Model-Free Approaches

2.3.2. Selection of Prediction Methods Based on Similarity and Feature Extraction

2.3.3. Structure and Further Procedure

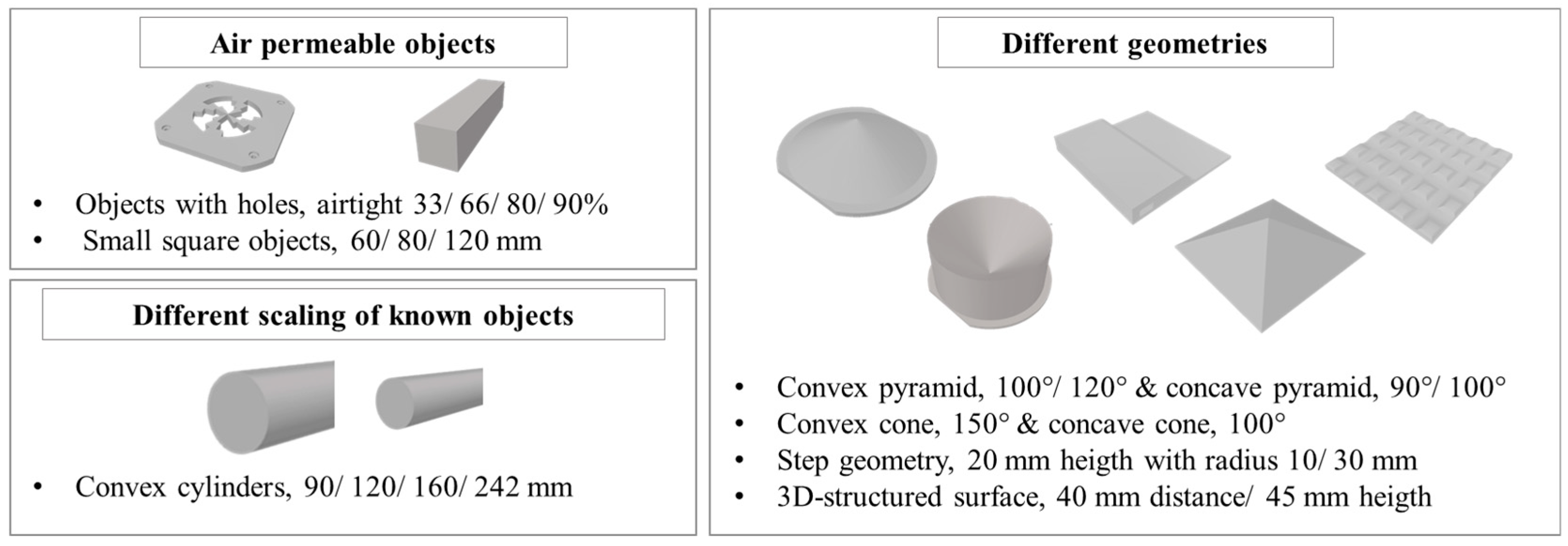

2.4. Examined Object Datasets

2.4.1. Training

2.4.2. Validation

3. Prediction Approaches and Results

3.1. Analytical Contact Score

- Identification of air permeability;

- Identification of locations, where the gripper is capable of creating an interface with the surface contour.

3.1.1. Procedure for the Calculation of the Analytical Contact Score

3.1.2. Detecting Air Permeability

3.1.3. Detecting Gripper Surfaces in Contact with the Object

3.1.4. Calibration to Training Data

3.2. CPD-Based Similarity

Procedure for the Methodology Using CPD-Based Similarity

3.3. Results and Comparison with Validation Objects

3.3.1. Validation Objects with Geometries Resulting in Air Permeability

3.3.2. Validation Objects with Geometries Differing from the Training Dataset

3.3.3. Validation Objects with Geometries Similar to the Training Data, but with Different Scaling

4. Discussion and Further Possibilities

4.1. CPD Improvements—Additional Factors and Parameters

4.2. CPD Improvements—Continuous Retraining

4.3. Analytical Contact Score Improvements—Detection of Enclosed Concave Geometry Segments

4.4. Analytical Contact Score Improvements—Area-Based Weighting of the Contact Score

4.5. Analytical Contact Score Improvements—Adaption for the Bordering Value towards a Cumulative Trained Value

4.6. Improvements for Both Approaches—Preliminary Classification with Sa_permeability

4.7. Improvements for Both Approaches—Adaption of a Three-Dimensional Base Grid

4.8. Improvements for Both Approaches—Curating Training Data for the Optimization of Specific Processes

4.9. Improvements for Both Approaches—Adaption of the Prediction Models towards Different Designs and Configurations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Cordeiro, A.; Rocha, L.F.; Costa, C.; Costa, P.; Silva, M.F. Bin Picking Approaches Based on Deep Learning Techniques: A State-of-the-Art Survey. In Proceedings of the 2022 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Santa Maria da Feira, Portugal, 29–30 April 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 110–117, ISBN 978-1-6654-8217-2. [Google Scholar]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, e1707035. [Google Scholar] [CrossRef] [PubMed]

- Zaidi, S.; Maselli, M.; Laschi, C.; Cianchetti, M. Actuation Technologies for Soft Robot Grippers and Manipulators: A Review. Curr. Robot. Rep. 2021, 2, 355–369. [Google Scholar] [CrossRef]

- Gabriel, F. Methodenentwicklung zur Energieeffizienzsteigerung in der vakuumbasierten Handhabung. Ph.D. Dissertation, TU Braunschweig, Braunschweig, Germany, 2022. [Google Scholar]

- Bohg, J.; Morales, A.; Asfour, T.; Kragic, D. Data-Driven Grasp Synthesis—A Survey. IEEE Trans. Robot. 2014, 30, 289–309. [Google Scholar] [CrossRef]

- Li, S.; Huang, Z.; Du, T.; Su, H.; Tenenbaum, J.B.; Gan, C. Contact Points Discovery for Soft-Body Manipulations with Differentiable Physics. arXiv 2022, arXiv:2205.02835. [Google Scholar]

- Bhagawati, M.; Zaman, M.; Deka, R.; Bora, K.; Gogoi, P.; Das, M.; Arora, N. Design and Finite Element Analysis of a Mechanical Gripper. In Modeling, Simulation and Optimization; Smart Innovation, Systems and Technologies; Springer: Singapore, 2022; Volume 292. [Google Scholar]

- Bernardin, A.; Duriez, C.; Marchal, M. An Interactive Physically-based Model for Active Suction Phenomenon Simulation. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1466–1471, ISBN 978-1-7281-4004-9. [Google Scholar]

- Hudoklin, J.; Seo, S.; Kang, M.; Seong, H.; Luong, A.T.; Moon, H. Vacuum Suction Cup Modeling for Evaluation of Sealing and Real-Time Simulation. IEEE Robot. Autom. Lett. 2022, 7, 3616–3623. [Google Scholar] [CrossRef]

- Goldfeder, C.; Ciocarlie, M.; Peretzman, J.; Dang, H.; Allen, P.K. Data-driven grasping with partial sensor data. In Proceedings of the 2009 International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 1278–1283. [Google Scholar]

- Kroemer, O.; Niekum, S.; Konidaris, G. A Review of Robot Learning for Manipulation: Challenges, Representations, and Algorithms. J. Mach. Learn. Res. 2021, 22, 1395–1476. [Google Scholar]

- Sahbani, A.; El-Khoury, S.; Bidaud, P. An Overview of 3D Object Grasp Synthesis Algorithms. Robot. Auton. Syst. 2012, 60, 326–336. [Google Scholar] [CrossRef]

- Prattichizzo, D.; Malvezzi, M.; Gabiccini, M.; Bicchi, A. On the manipulability ellipsoids of underactuated robotic hands with compliance. Robot. Auton. Syst. 2012, 60, 337–346. [Google Scholar] [CrossRef]

- Zhang, H.; Peeters, J.; Demeester, E.; Kellens, K. A CNN-Based Grasp Planning Method for Random Picking of Unknown Objects with a Vacuum Gripper. J. Intell. Robot. Syst. 2021, 103, 64. [Google Scholar] [CrossRef]

- Ferrari, C.; Canny, J. Planning optimal grasps. In Proceedings of the 1992 IEEE Conference on Robotics and Automation, Nice, France, 12–14 May 1992. [Google Scholar]

- Jiang, P.; Oaki, J.; Ishihara, Y.; Ooga, J.; Han, H.; Sugahara, A.; Tokura, S.; Eto, H.; Komoda, K.; Ogawa, A. Learning Suction Graspability Considering Grasp Quality and Robot Reachability for Bin-Picking. Front. Neurorobot. 2022, 16, 806898. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Tang, C.; Chu, F.-J.; Xu, R.; Vela, P.A. Primitive Shape Recognition for Object Grasping. arXiv 2022, arXiv:2201.00956. [Google Scholar]

- Mahler, J.; Matl, M.; Satish, V.; Danielczuk, M.; DeRose, B.; McKinley, S.; Goldberg, K. Learning ambidextrous robot grasping policies. Sci. Robot. 2019, 4, eaau4984. [Google Scholar] [CrossRef] [PubMed]

- Bello, S.A.; Yu, S.; Wang, C.; Adam, J.M.; Li, J. Review: Deep Learning on 3D Point Clouds. Remote Sens. 2020, 12, 1729. [Google Scholar] [CrossRef]

- Lenz, I.; Lee, H.; Saxena, A. Deep learning for detecting robotic grasps. Int. J. Robot. Res. 2015, 34, 705–724. [Google Scholar] [CrossRef]

- Tajima, S.; Wakamatsu, S.; Abe, T.; Tennomi, M.; Morita, K.; Ubata, H.; Okamura, A.; Hirai, Y.; Morino, K.; Suzuki, Y.; et al. Robust bin-picking system using tactile sensor. Adv. Robot. 2019, 34, 439–453. [Google Scholar] [CrossRef]

- Chen, S.; Hong, J.; Liu, X.; Li, J.; Zhang, T.; Wang, D.; Guan, Y. A Framework for 3D Object Detection and Pose Estimation in Unstructured Environment Using Single Shot Detector and Refined LineMOD Template Matching. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 499–504, ISBN 978-1-7281-0303-7. [Google Scholar]

- Huang, J.; You, S. Point Cloud Matching based on 3D Self-Similarity. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition Workshops, Providence, RI, USA, 16–21 June 2012. [Google Scholar]

- Myronenko, A.; Song, X. Point set registration: Coherent point drift. IEEE Trans. Pattern Anal. Mach. Intell. 2010, 32, 2262–2275. [Google Scholar] [CrossRef] [PubMed]

- Gabriel, F.; Roemer, M.; Bobka, P.; Droeder, K. Model-based grasp planning for energy-efficient vacuum-based handling. CIRP Ann. 2021, 70, 1–4. [Google Scholar] [CrossRef]

- Rodriguez, D.; Cogswell, C.; Koo, S.; Behnke, S. Transferring Grasping Skills to Novel Instances by Latent Space Non-Rigid Registration. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 4229–4236, ISBN 978-1-5386-3081-5. [Google Scholar]

- Löchte, C.W. Formvariable Handhabung Mittels Granulatbasierter Niederdruckflächensauger. Ph.D. Dissertation, TU Braunschweig, Braunschweig, Germany, 2016. [Google Scholar]

- Dröder, K.; Dietrich, F.; Löchte, C.; Hesselbach, J. Model based design of process-specific handling tools for workpieces with many variants in shape and material. CIRP Ann. 2016, 65, 53–56. [Google Scholar] [CrossRef]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal robotic gripper based on the jamming of granular material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- FORMHAND Automation GmbH. FH-R150. Available online: https://www.formhand.de/produkte (accessed on 1 December 2021).

- Wacker, C.; Dierks, N.; Illgen, J.; Kwade, A.; Dröder, K. Empirically adapted model for the Handling of Variable Geometries with Vacuum-based Granulate Grippers. In Annals of Scientific Society for Assembly, Handling and Industrial Robots 2022; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Wacker, C.; Dierks, N.; Kwade, A.; Dröder, K. Experimental assessment and prediction of design parameter influences on a specific vacuum-based granular gripper. Robomech J. 2024, 11, 1. [Google Scholar] [CrossRef]

| Category | Analytical Contact Score | CPD Comparison |

|---|---|---|

| Applicability to: Variations of known geometries New geometries Air-permeable geometries | RMSE:

| RMSE:

|

| Weaknesses |

|

|

| Required time for real-life application |

|

|

| Applicability for different gripping configurations |

|

|

| Applicability | Adaption | Potential | Hinderance |

|---|---|---|---|

| CPD | Additional factors and parameters | Some potential for an increased prediction quality, based on number of training objects | Required amount of training geometries would be very large |

| CPD | Continuous retraining | High potential for a continuously improved prediction quality | Continuously increasing calculation time |

| ACS | Detection of enclosed concave geometry segments | High potential for an increased prediction quality specifically for concave geometries | Increased calculation time |

| ACS | Area-based weighting of the contact score | Some potential for an increased prediction quality, based on number of training objects | Required amount of training geometries would be very large |

| ACS | Adaption of the bordering value towards a cumulative trained value | Some potential for an increased prediction quality | Increased calculation time |

| ACS and CPD | Preliminary classification with Sa_permeability | High potential for an increased prediction quality for handling processes with air-permeable surfaces | Only applicable for handling processes with air-permeable surfaces |

| ACS and CPD | Adaption of a three-dimensional base grid | Some potential for an increased prediction quality | Largely increased calculation time |

| ACS and CPD | Curation of training data for the optimization of specific processes | Some potential for an increased prediction quality specific to an application combined with reduced calculation time | Usability of grippability prediction is then reduced to the specific application ->Reduced versatility |

| ACS and CPD | Adaption of the prediction models towards grippers with different designs and configurations | Potential for a specific selection of an optimal gripper setup with granular materials and membranes for a specific handling application | Requires training data for the new gripper configurations |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wacker, C.; Dierks, N.; Kwade, A.; Dröder, K. Analytic and Data-Driven Force Prediction for Vacuum-Based Granular Grippers. Machines 2024, 12, 57. https://doi.org/10.3390/machines12010057

Wacker C, Dierks N, Kwade A, Dröder K. Analytic and Data-Driven Force Prediction for Vacuum-Based Granular Grippers. Machines. 2024; 12(1):57. https://doi.org/10.3390/machines12010057

Chicago/Turabian StyleWacker, Christian, Niklas Dierks, Arno Kwade, and Klaus Dröder. 2024. "Analytic and Data-Driven Force Prediction for Vacuum-Based Granular Grippers" Machines 12, no. 1: 57. https://doi.org/10.3390/machines12010057

APA StyleWacker, C., Dierks, N., Kwade, A., & Dröder, K. (2024). Analytic and Data-Driven Force Prediction for Vacuum-Based Granular Grippers. Machines, 12(1), 57. https://doi.org/10.3390/machines12010057