Abstract

Optical mirrors have high requirements for surface precision, requiring ultra-precision processing. The revolving movement of a computer-controlled optical surfacing (CCOS) grinding system will induce vibrations in a five-degrees-of-freedom hybrid processing robot (5-DOF-HPR) and a flexible support system (FSS) in a large optical mirror processing system (LOMPS). As a result, the mirror surface will vibrate, which will ultimately affect the surface accuracy of the final optical mirror. Therefore, the differential equation representing the vibration of the 5-DOF-HPR is established based on the spatial beam unit, which transforms the generalized coordinates into modal coordinates, thereby removing the coupling terms of the vibration differential under generalized coordinates. At the same time, a dynamic analysis of the CCOS grinding system is performed, and the magnitude and direction of the centrifugal force and reaction force are calculated. Then, the natural frequencies of the 5-DOF-HPR and the FSS are measured experimentally and compared with the simulation results; thus, the accuracy and effectiveness of the model are verified. Finally, the vibration characteristics of the processed optical mirrors under different influencing factors are obtained. A theoretical and experimental basis for parameter optimization and path planning of the LOMPS is provided to improve the surface accuracy of the processed optical mirror.

1. Introduction

With the help of evolving technology, modern optical mirrors are being developed with larger apertures and higher precision, among which free-form optical mirrors are widely used. Therefore, a large optical mirror processing system (LOMPS) that is suitable for large sizes, aspherical, high-efficiency, and precise delivery is an urgent technological need. To address this, a LOMPS was designed, which consisted of three heterogeneous robots: a five-degrees-of-freedom hybrid processing robot (5-DOF-HPR), a flexible support system (FSS), and a computer-controlled optical surfacing (CCOS) grinding system. The 5-DOF-HPR can drive the CCOS grinding system to the processing position; the FSS grinding system can adjust the position and posture of the supported optical mirror, and as the support stiffness is adjustable, the CCOS grinding system can perform real-time adjustment of speed and polishing pressure [1]. The four processing steps of the mirror surface—rough grinding, milling, fine grinding, and polishing—can be completed by the LOMPS [2,3]. As the three robots collaborate, the task allocation, path planning, spatial orientation, multiple disturbance mechanisms, and instantaneous dynamic characteristics of each robot vary [4,5]. In particular, in terms of vibration characteristics, because the CCOS grinding system uses a double planetary rotation structure, the revolution of the object generates periodic loads on the parallel robot and optical mirror, and resonance may occur, thereby affecting the surface accuracy of the optical mirror surface [6]. Therefore, it is necessary to analyze the dynamic characteristics of the LOMPS, predict the vibration and deformation trends of the processing system, and avoid resonance. This approach mitigates errors induced by the processing system vibrations, thereby enhancing processing efficiency, surface quality, and geometric precision of the optical mirror [7].

In recent years, many scholars have conducted analyses and research on the dynamic characteristics of different types of robots. To improve the productivity rate without any loss of positioning accuracy, Ariano et al. studied the vibration behavior of industrial manipulator Racer-7-1.4 to reduce its residual vibration and execution time [8]. Hwang et al. established a precise dynamic model of a cable-driven parallel robot under constrained conditions and obtained the natural frequency relative to the position of the end effector, which provided a favorable understanding for the establishment of a vibration suppression scheme [9]. Zhang et al. studied the problem of residual vibration caused by the joint flexibility of a 6-DOF industrial robot and proposed an adaptive input shaping method to suppress the residual vibration [10]. To study the natural frequency and vibration characteristics of the manipulator under the impact of collision, Min et al. proposed a method for estimating the vibration mode of the manipulator structure based on the peak frequency [11]. Yoon et al. proposed a method to reduce the residual vibration of a manipulated object by optimizing the acceleration/deceleration time using the object’s natural frequency [12]. Based on the Stewart platform, Wu et al. discussed the effects of strut masses and payload on the natural frequency and dynamic isotropy index, and optimized vibration isolation [13]. Yang et al. formulated a fourth-order periodic time-varying nonlinear dynamic equation for a spin spherical capsule robot subjected to complex external torque utilizing Euler dynamics principles. The dynamic characteristics of the robot were subsequently validated through experimental investigations [14].

Many scholars have tested different research methods when analyzing the dynamic characteristics of robots with different configurations. Tang et al. conducted an analysis of the influence of robot posture on the dynamic flexibility of the end effector based on the robot’s end effector relative dynamic compliance index. This research provides theoretical guidance for enhancing the vibration resistance and dynamic performance of traditional cleaning robots [15]. Hoevenaars et al. presented a novel natural frequency analysis method for parallel manipulators that focused on the lowest natural frequencies and expressed the corresponding eigenmodes in an end effector Cartesian reference frame [16]. Ma et al. used operator algebra to derive the equation of motion required to study the dynamics of a space manipulator [17]. Wu et al. used a variety of techniques to modify the finite element model, and the results showed that the improved model could predict the vibration characteristics of an experimental crane with satisfactory accuracy [18]. Nguyen et al. presented a Gaussian process, regression-based approach to model the dynamic properties of a 6-DOF industrial robot within its workspace in order to determine the discrete sampling modal parameters of the robot structure through an experimental modal analysis and accurately predict its modal parameters at different points in the workspace [19]. Ganesh et al. used the stiffness matrix and dynamic mass matrix to obtain the natural frequency and global natural frequency index of a parallel machine tool [20]. Dong et al. proposed a semi-analytical method for robot elastic dynamics based on the screw theory to calculate low-order natural frequencies and vibration shapes and achieved good results [21].

A support cylinder was used as the support element in the FSS. Owing to the different working principles of mechanical–electric industrial robots, the above dynamic characteristics research methods were not suitable. Therefore, many scholars have conducted extensive research on the dynamic characteristics of hydraulic systems. Yang et al. calculated the natural frequency of the robot legs throughout the entire motion cycle of the robot. With the goal of increasing the natural frequency, the leg structure of the robot was optimized [22]. Li et al. analyzed the natural frequency and vibration mode of a hydraulic demolition robot using the finite element method. The optimized design of the prototype provided a theoretical basis and reference for our experimental mode [23]. Guan et al. analyzed the dynamic response characteristics and natural frequencies of a column hydraulic cylinder and balance hydraulic cylinder and improved the structural parameters to increase their natural frequency [24]. Lin et al. conducted an analysis of the impact of structural parameters on the high- and low-frequency dynamic characteristics of a novel bell plate hydraulic suspension system. They compared the influence of varying numbers of bell plates on the dynamic performance of hydraulic supports across different frequency ranges [25]. To investigate the dynamic operational characteristics of hydraulic support lifting, Xie et al. established a rigid flexible coupling dynamic simulation model of the hydraulic support system. They subsequently collected and analyzed the operational characteristic parameters of the hydraulic support [26]. Xu et al. proposed a less modified measurement scheme to accurately obtain the dynamic characteristics of the cylinder block and analyzed its dynamic characteristics under different working pressures [27]. Tao et al. conducted an independent impedance analysis of various structures within magneto-strictive electro-hydraulic actuators, the natural frequencies and dynamic characteristics of manifolds, hydraulic cylinders, and accumulators. Their findings provide theoretical guidance for optimizing the structure and performance of these actuators [28].

The above scholars analyzed the natural frequency, vibration suppression, and modal information of parallel machine tools, hydraulic systems, and industrial robots through different methods and achieved significant results. However, their research focused on a single robot: there was no in-depth research on a system composed of multiple heterogeneous robots. In addition, the external excitations provided during most of the modal test analyses were only artificial vibration excitations in the laboratory environment, and the respective dynamic characteristics of the robots during the working process were not used as influencing factors for the disturbance analysis of multirobot systems. In practical applications, there has been no analysis or research on the vibration characteristics of the workpiece to be processed. However, optical mirrors require high surface accuracy, and the mirror material is brittle. These factors may affect the surface accuracy of the optical mirror and even cause the mirror surface to be scrapped because of excessive vibration during processing. Therefore, modal analyses and experiments on the LOMPS will significantly advance large optical mirror processing.

In this study, the dynamic characteristics of the LOMPS, which is composed of three heterogeneous robots, namely a 5-DOF-HPR, FSS, and CCOS grinding system, were studied and analyzed. First, the vibration differential equation of the 5-DOF-HPR was established based on the spatial beam unit. Then, combined with the finite element method, the vibration model of the FSS was established. At the same time, a dynamic analysis of the revolution of the CCOS grinding system was performed, and the magnitude and direction of the centrifugal force and reaction force under the generalized coordinates were calculated. Then, the natural frequencies of the 5-DOF-HPR and FSS were measured experimentally and compared with the simulation results, and the accuracy and effectiveness of the model were verified. Finally, the amplitudes of the processed optical mirrors at different operating speeds of the 5-DOF-HPR, different support heights of the FSS, and different revolution speeds of the CCOS grinding system were measured, and the vibration characteristics of the processed optical mirrors under different influencing factors were obtained. The proposed method provided a theoretical basis for analyzing the vibration characteristics of the LOMPS and improving the surface accuracy of the processed mirror. It also provided an experimental basis for research on the dynamic characteristics of a machining system composed of multiple heterogeneous robots, such as machine–electro-hydraulic collaborative work. At the same time, it also provided a research basis for the feasibility of precision machining of multiconfiguration robots in complex disturbance environments.

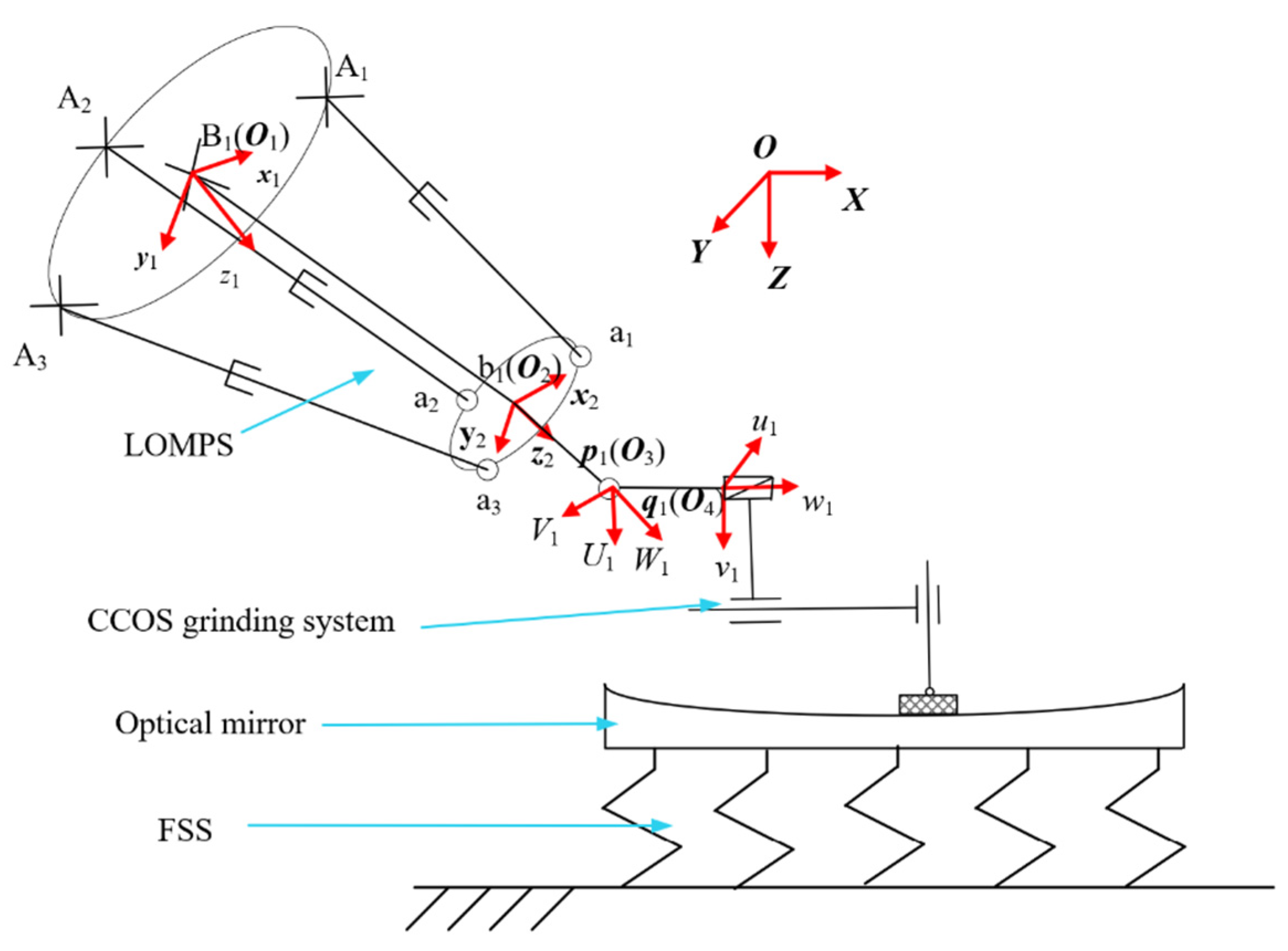

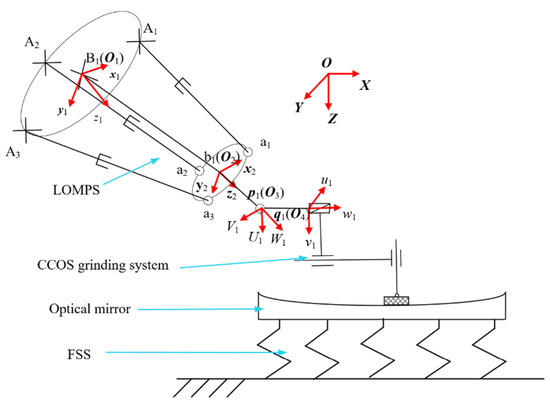

2. Composition of the LOMPS

The 5-DOF-HPR drives the CCOS grinding system to the processing position. The support stiffness of the FSS is adjustable, and the CCOS grinding system can adjust the grinding speed, eccentricity, and polishing pressure. The topology of the LOMPS is shown in Figure 1. The effective operational envelope of the engineered machining robot is a truncated cylinder with a base radius of 815 mm, a minimum height of 200 mm on the Z-axis, and a maximum height of 1250 mm on the Z-axis. The flexible hydraulic support system can accommodate optical mirrors with a maximum diameter of 1250 mm, and the support height can be adjusted within a range of −1 mm to 1 mm.

Figure 1.

Topological structure of the LOMPS.

2.1. 5-DOF-HPR

During processing, the grinding head must be capable of reaching any position with any attitude. As a result the robot required at least 5 DOF. The 5-DOF robot is composed of a 3-DOF parallel manipulator and a 2-DOF series manipulator.

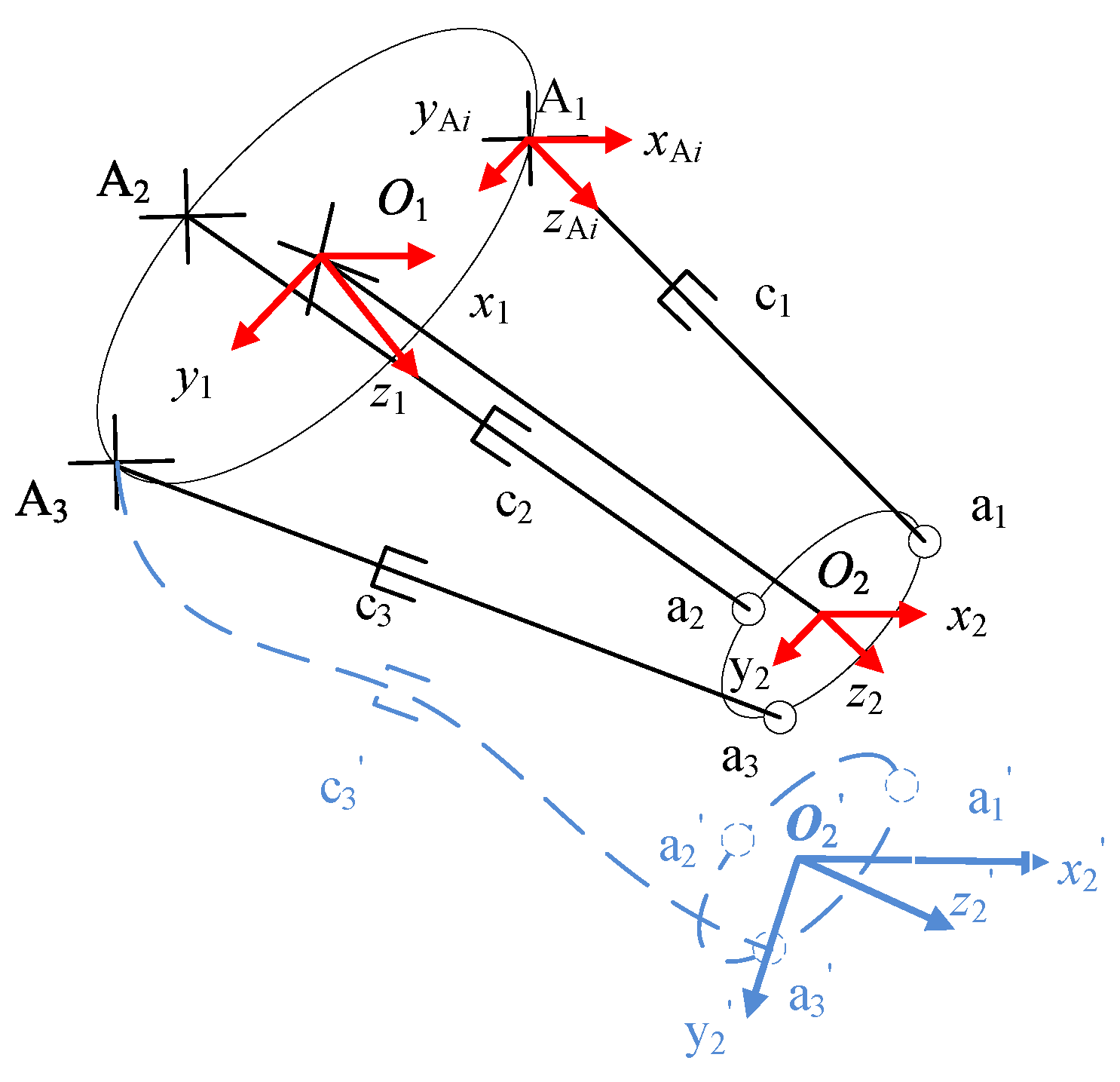

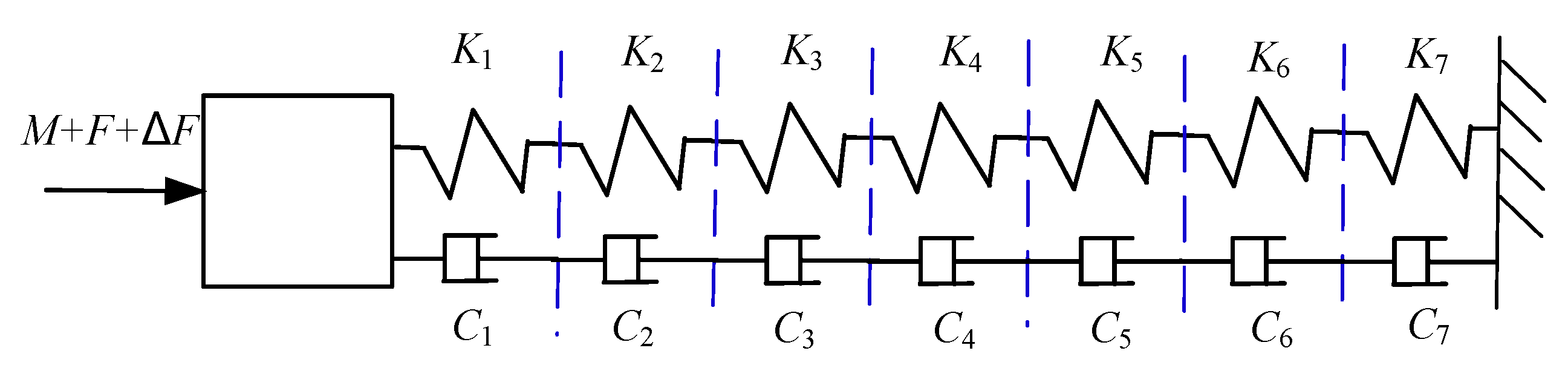

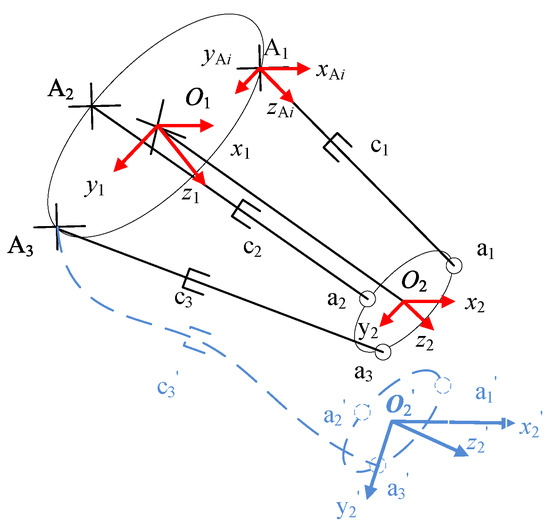

Establish a fixed coordinate system O1-x1y1z1 and a moving coordinate system O2-x2y2z2 on the center points of the fixed platform and the moving platform respectively. O1 and O2 are the origin; y1 points to O1A3; z1 points to O1 O2; and z1 and y2 follow the right-hand rule.

The conjoined coordinate systems of the two rotating heads are established, and the conjoined coordinate system of the first rotating head is O3-U1V1W1, where O3 is at intersection point P1 of the first and second rotating heads. The direction of the W1-axis points to O2O3; the U1-axis is collinear with the axis of the secondary rotating shaft; and the V1-axis follows the right-hand rule. The fixed coordinate system O4-u1v1w1 of the secondary rotating head is established at the connection point between the secondary rotating head and the CCOS grinding system, where the w1-axis and O3O4 are collinear, v1 is collinear with the rotation axis of the secondary rotating shaft, and the u1-axis follows the right-hand rule.

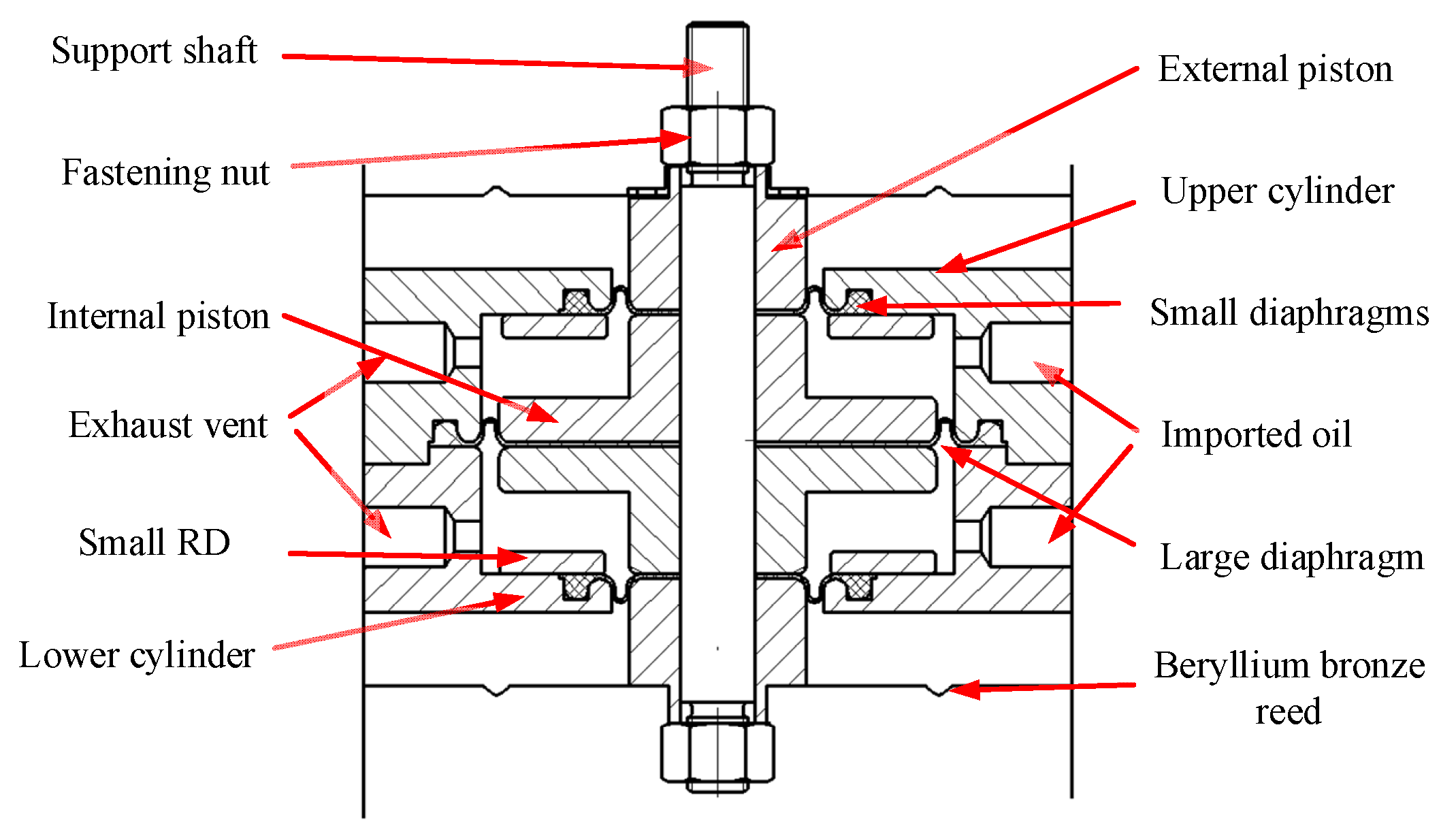

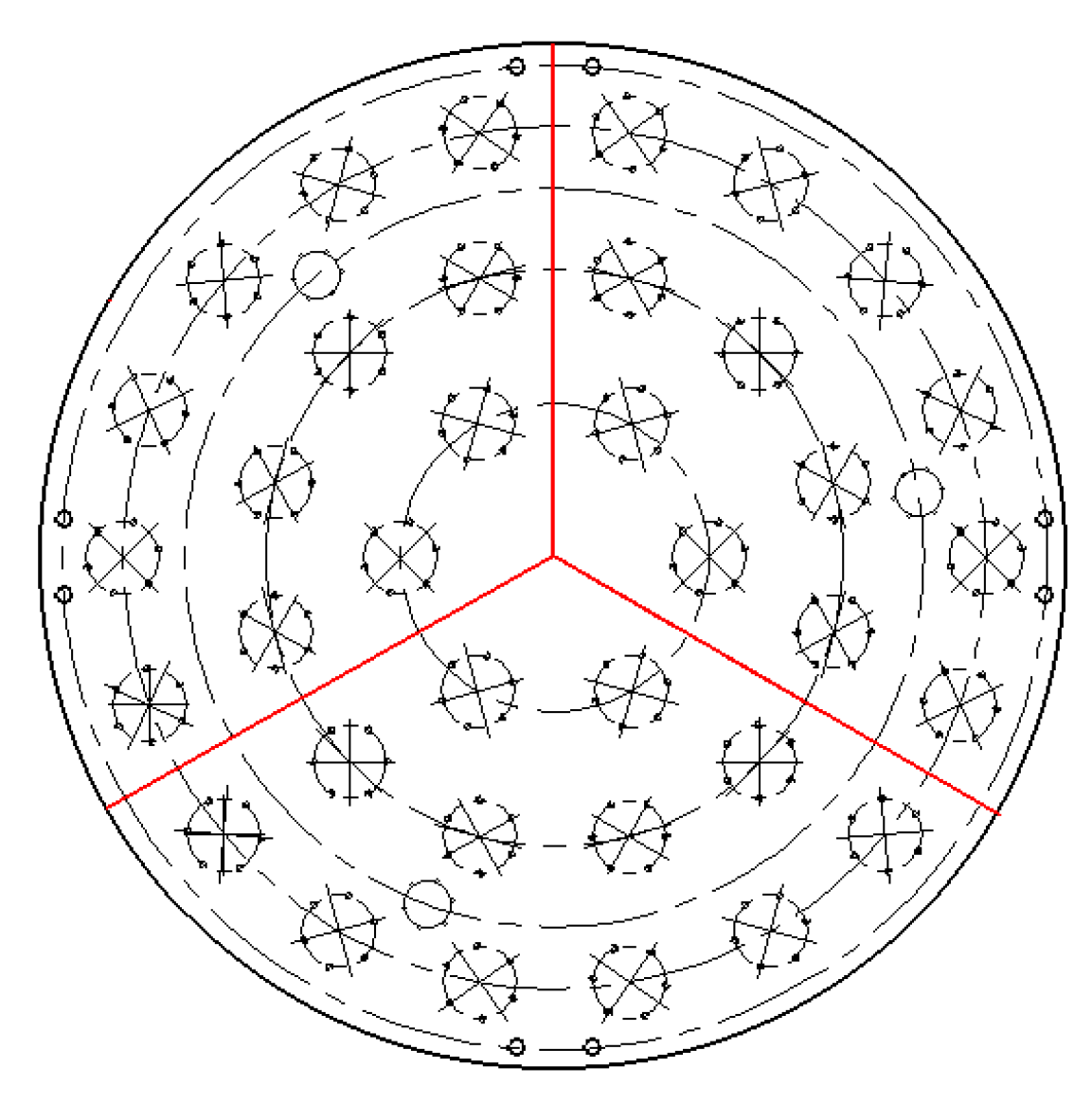

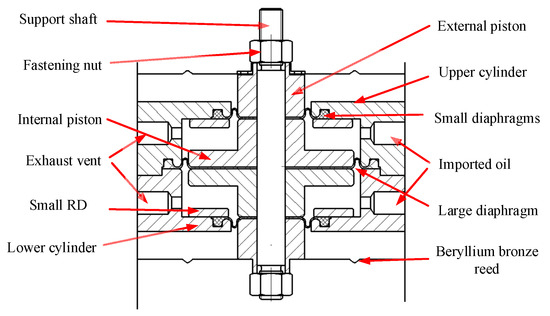

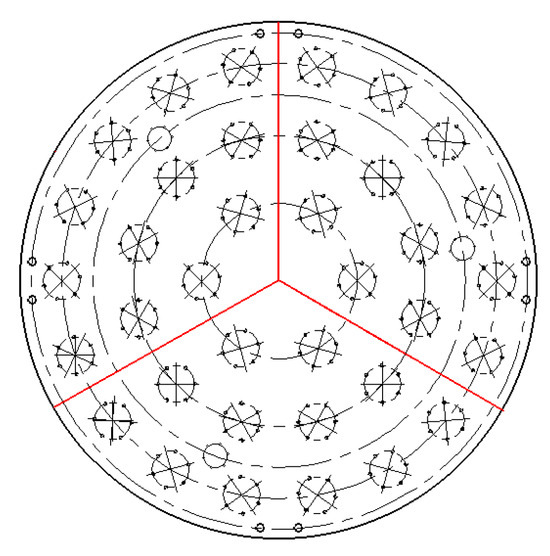

2.2. FSS

The support point of the FSS was supported by a diaphragm cylinder, which is simplified as a support spring in Figure 1. The structure and distribution of the diaphragm cylinder are shown in Figure 2. The large and small diaphragms make the support cylinder form two chambers, and the beryllium bronze reed restricts the swing of the support shaft. As shown in Figure 3, the 36 cylinders were divided into three sectors. The support height and rigidity of the support cylinder could be controlled; thus, the posture of the optical mirror could be adjusted.

Figure 2.

Structure of diaphragm cylinder.

Figure 3.

Arrangement diagram of support cylinders.

2.3. CCOS Grinding System

The CCOS grinding system consisted of two motors: a revolution motor and a rotation motor. The rotation motor was eccentrically arranged relative to the revolution motor, and the distance between the axis of the two motors could be adjusted using an eccentric adjustment device. The rotation motor was connected to the grinding disc through a pneumatic pressure device, and the air pressure can be adjusted. Through the Preston equation, the relationship between the speed and pressure and the removal amount is:

where K is a proportional constant, V is the polishing speed, P is the positive pressure. And the removal amount Δz of the surface material of a processing element, as shown in Equation (2).

3. Dynamic Characteristic Analysis of LOMPS

During the operation of the LOMPS, the robots affected each other. As these three robots had different configurations, their dynamic characteristics were also completely different. Therefore, it was also necessary to analyze the three robots separately during the dynamic analysis process.

3.1. Dynamic Characteristic Analysis of the 5-DOF-HPR

3.1.1. Element Division and Establishment of Element Dynamics

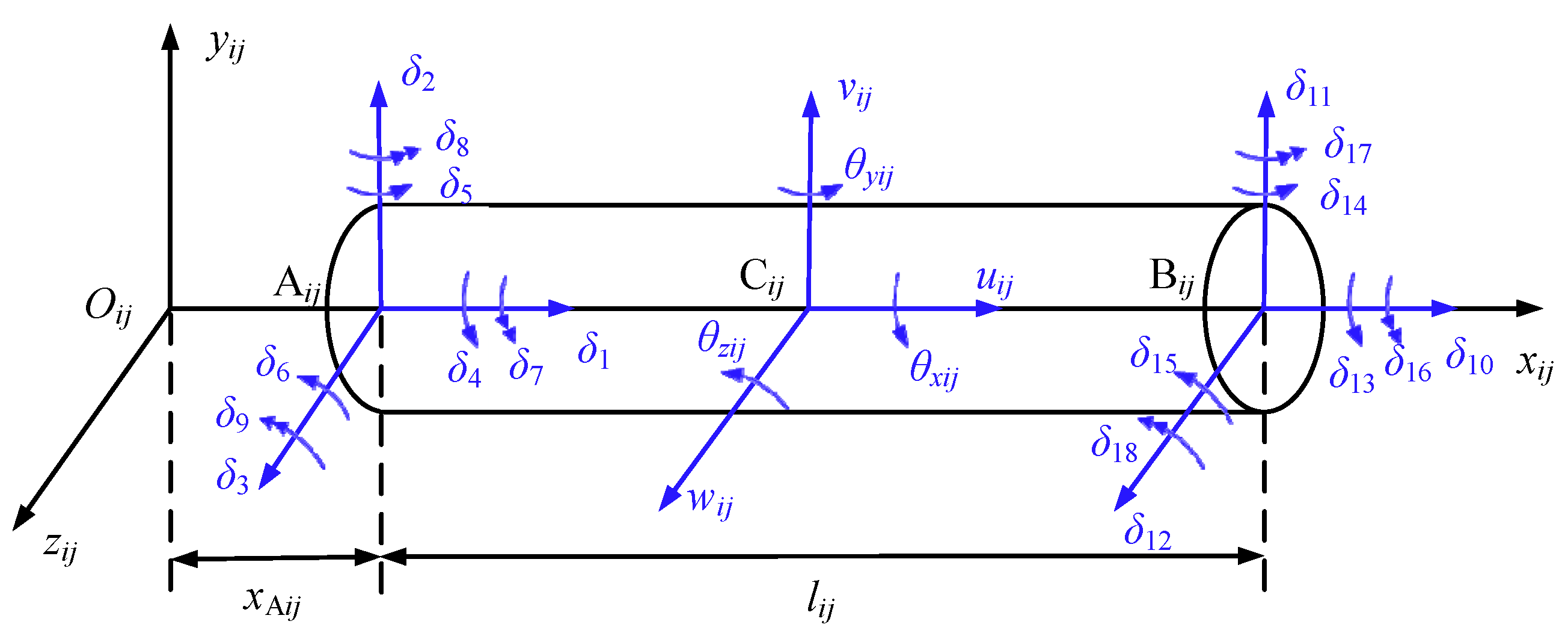

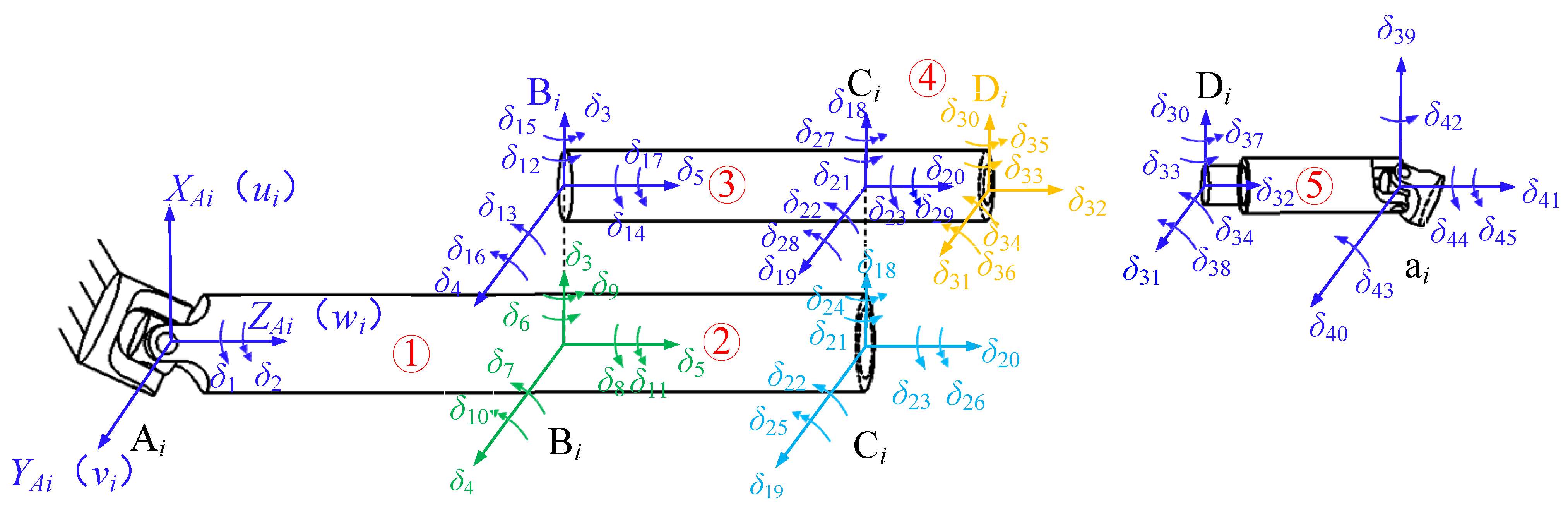

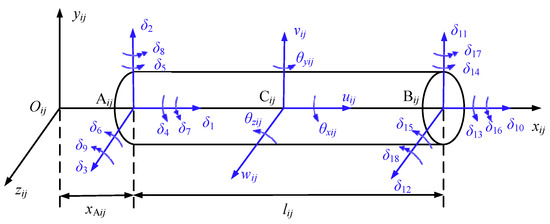

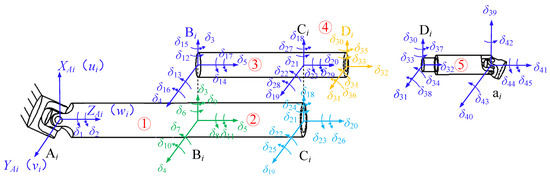

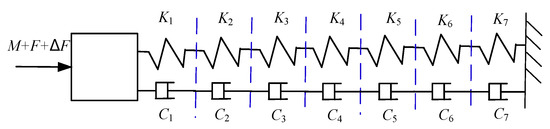

When a beam in space is deformed, the component elements of the beam are forced to undergo deformation. Here, the j-th unit model on the i-th branch was selected for analysis. A model of the spatial beam element is shown in Figure 4.

Figure 4.

Generalized coordinates of beam element.

The element coordinate system Oij-xijyijzij on the element node was established, and the element coordinate system coincided with the branch chain coordinate system. was used as the generalized coordinate vector for the beam element. Among them, δ1–δ3 and δ10–δ12 represented the elastic displacements of the element nodes along the xij-, yij-, and zij-axes; δ4–δ6 and δ13–δ15 represented the elastic rotation angles of the element nodes along the xij-, yij-, and zij-axes, and δ7–δ9 and δ16–δ18 represented the curvature of the element nodes.

The unit kinetic energy T and the unit variable performance V are respectively,

where , Me is the element mass matrix, Ke is the element stiffness matrix, , , , and are the rigid body velocities along the x-, y-, and z-axes at the cell node Aij, respectively; , , and are the rigid body velocities along the x-, y-, and z-axes at the cell node Bij, respectively; and , , and are the rigid body angular velocities along the x-, y-, and z-axes at the cell node Aij, respectively.

From the Lagrange equation,

The dynamic equation of the element is obtained.

where Ce is the element damping matrix, Fe is the element generalized external force (including force and moment), Pe is the force between beam elements, and Qe is the rigid body inertial force array of the system element.

The transformation matrix from the element coordinate system to the fixed coordinate system is introduced, and the elastic dynamic equation of the element in the fixed coordinate system is obtained.

where, , , , and .

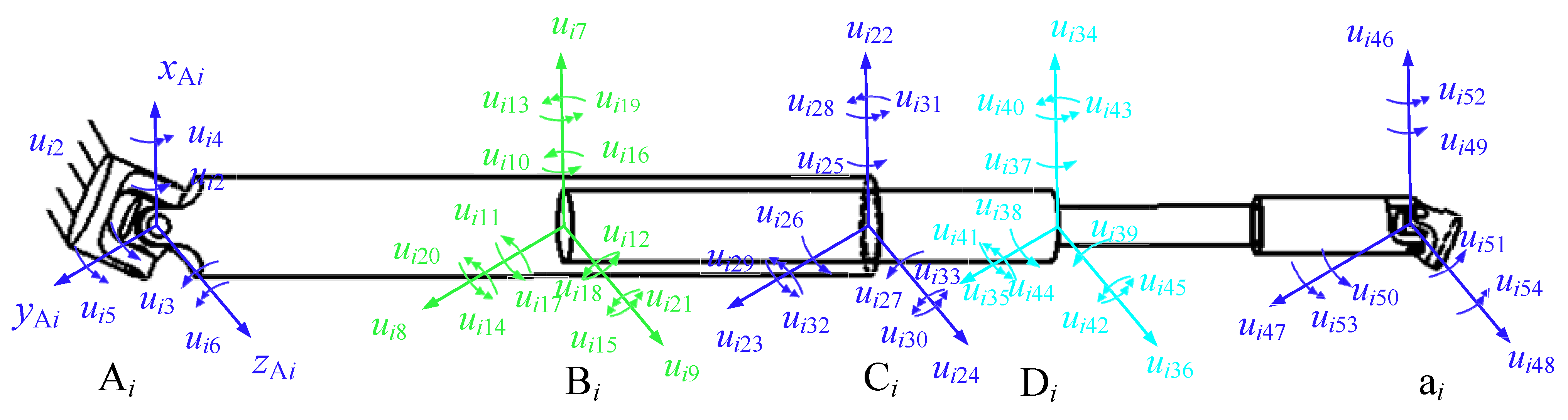

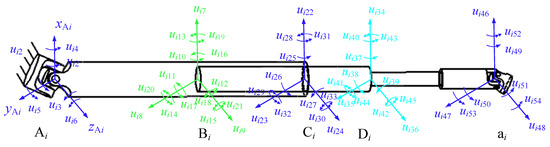

3.1.2. Elastic Dynamic Analysis of UPS Branch Chain

As shown in Figure 5, the UPS branch chain can be regarded as composed of a swing rod, telescopic rod, and composite ball hinge. The swing rod is divided into ① and ② parts; the telescopic rod is divided into ③ and ④ parts, and ② in the swing rod coincides with ③ in the telescopic rod. As there were degrees of freedom in the mechanism, the stiffness matrix was singular. The BiCi of the moving pair could be regarded as a rigid connection to eliminate the rigid degrees of freedom; hence, the moving mechanism could be regarded as an “instantaneous structure” in a short period of time. Ai was a Hooke joint connecting the UPS and the fixed platform. As the Hooke hinge connection can be regarded as a composite of two rotation pairs whose axes are perpendicular to one another, the curvature of the two equivalent rotation pairs at the Ai node was zero. Ai was connected to a fixed platform; therefore, the elastic displacement at point Ai and the elastic rotation angle in the two rotation directions were also zero. In other words, there were only two generalized coordinates for the elastic rotation angle and curvature around the ZAi-axis at point Ai. The coupling technology of finite element node degrees of freedom was used to model the relationship between the telescopic rod and the swing rod. Point Bi on the swing rod and Bi on the telescopic rod were 3-DOF couplings, and their elastic displacements were the same. There was a 6-DOF coupling between Ci on the swing rod and Ci on the telescopic rod, and its elastic displacement and elastic rotation angle were the same. There was a fixed connection between Di on the swing rod and Di on the composite ball hinge, and there was a DOF around the ZAi direction, so its elastic displacement and elastic rotation angle were the same. And the rotation angle and curvature in the ZAi direction were zero. Point ai was a composite spherical hinge, and only the rotation angle and curvature around the ZAi-axis were non-zero elastic deformations: the rest were zero. As shown in Figure 6, the deformation of the branched chain can be represented by ui1–ui48.

Figure 5.

Generalized coordinates of UPS branch chain in the element coordinate system.

Figure 6.

Generalized coordinates of UPS branch chain in reference coordinate system.

The element coordinate system Ai-xAiyAizAi was established at Ai of the AiBi element, and the posture of the coordinate system was the same as that of the fixed coordinate system Ai-uiviwi (i = 1, 2, 3) of the UPS branch chain. Similarly, the element coordinate system was also established at nodes Bi, Ci, Di, and ai. Then, the posture transformation matrix from the element coordinate system Ai-xAiyAizAi to the reference coordinate system O1-x1y1z1 could be expressed as

As the attitude transformation matrix was an orthogonal matrix, the attitude transformation matrices from the reference coordinates O1-x1y1z1 to the Ai, Bi, Ci, and Di coordinate systems were as follows:

Then, the transformation relationship between the element generalized coordinate system and the system generalized coordinate system of element components ①, ②, ③, ④, and ⑤ is as follows:

where δ is the element generalized coordinate and u is the system generalized coordinate.

The dynamic equation of elements ①, ②, ③, ④, and ⑤ is as follows:

where is the mass matrix of the component, is the damping matrix of the component, is the stiffness matrix of the component, is the generalized coordinates of the element at the k-th component, is the external load, is the force exerted by other components of the system, and is the inertia force of the rigid body.

The dynamic equation of the branched chain Aiai in the system coordinates can be obtained by assembling the unit components ①, ②, ③, ④, and ⑤.

where is the mass matrix of branch chain i, is the damping matrix of branch chain i, is the stiffness matrix of branch chain i, is the node system coordinate of branch chain i, is the applied load of branch chain i, is the force exerted on the branch chain i by other components of the system, and is the rigid body inertia force of branch chain i.

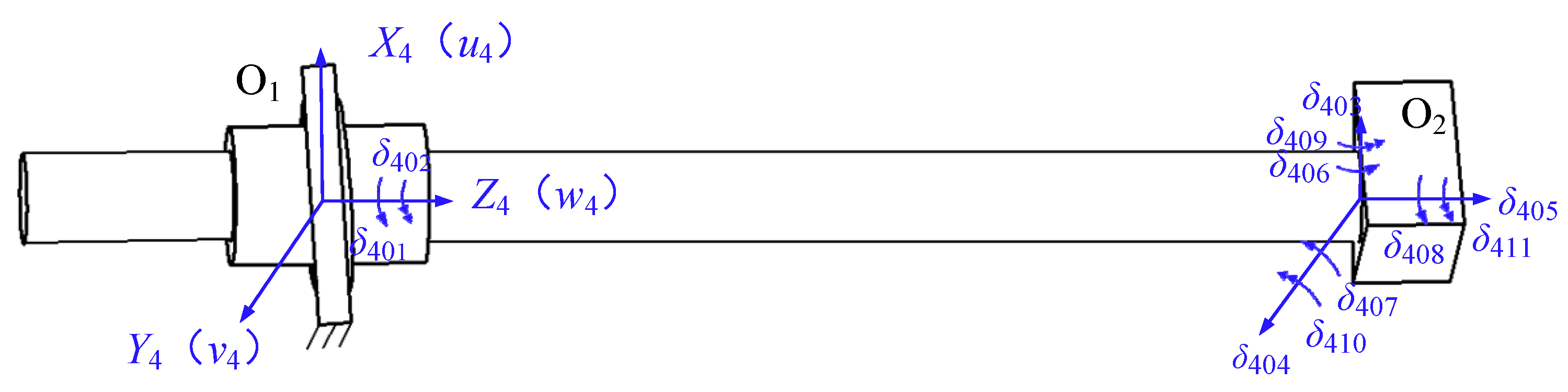

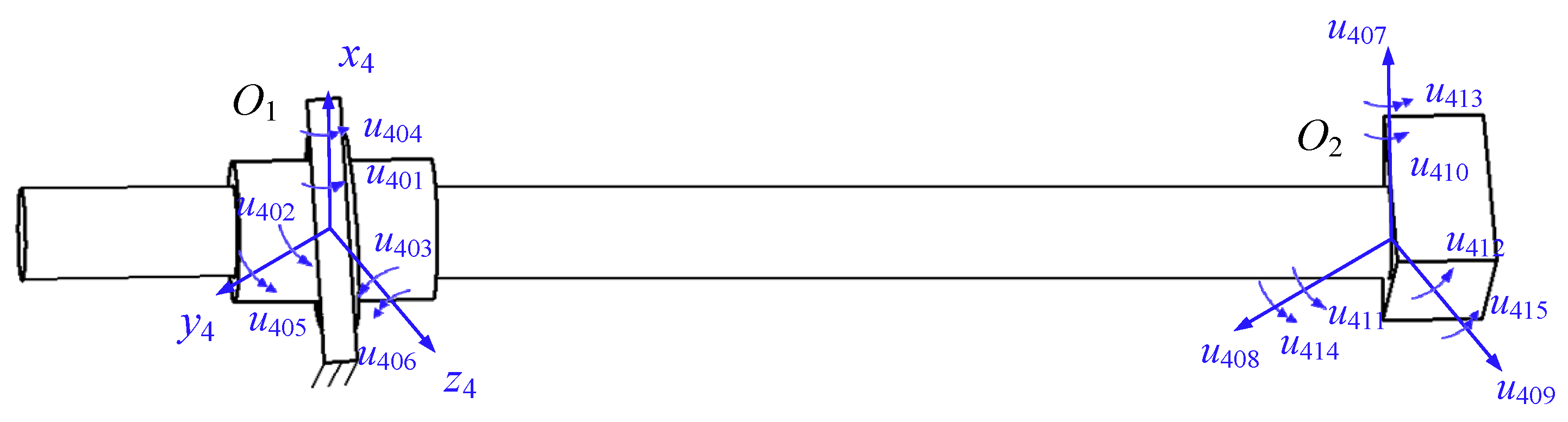

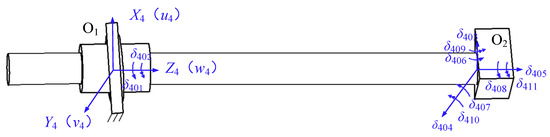

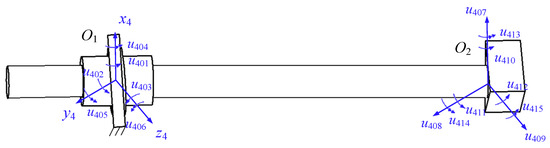

3.1.3. Elastic Dynamic Analysis of UP Branch Chain

The restrained branch UP was connected to a moving pair and static platform at the center point O1 of the static platform through the hook hinge; thus, UP branch O1O2 could be regarded as a beam element. The generalized coordinates of O1 were the same as those of Ai. Thus, UP branch O1O2 had 11 nonzero generalized coordinates. The generalized coordinates of UP restrained chain in element coordinate system and reference coordinate system are shown in Figure 7 and Figure 8.

Figure 7.

Generalized coordinates of UP restrained chain in element coordinate system.

Figure 8.

Generalized coordinates of UP restrained chain in reference coordinate system.

The element coordinate system O1-u4v4w4 was established at the O1 point of the UP-constraint branch. Then, the posture transformation matrix from the element coordinate system to the reference coordinate system O1-x4y4z4 could be expressed as

The transformation relationship between the generalized coordinate system of the element and the generalized coordinate system of the UP branch chain is as follows:

Then, the dynamic equation of the constrained branch chain in the system coordinates is given as:

where is the mass matrix of the constrained branch chain, is the damping matrix of the constrained branch chain, is the stiffness matrix of the constrained branch chain, is the node system coordinate of the constrained branch chain, is the applied load of the constrained branch chain, is the force exerted on the constrained branch chain by other components of the system, and is the rigid body inertia force of the constrained branch chain.

3.1.4. Constraints for the 5-DOF-HPR

The stiffness of the moving platform was much greater than that of the branch chain component. Therefore, the elastic deformation of the moving platform could be ignored. The rigid body in space had six independent DOFs, so the displacement of the moving platform and each branch chain connection node was not independent. It was a function of six independent parameters of the moving platform and satisfied the following conditions. (1) Kinematic constraints: the displacement of the connection point between the branch chain and moving platform must be consistent with the displacement of the connection point between the moving platform and branch chain; (2) Dynamic constraints: the sum of the forces of each branch chain on the moving platform should be balanced with the external force and inertial force acting on the moving platform. The constraint relationship between the moving platform and the branch chain is shown in Figure 9.

Figure 9.

Constraint relationship between moving platform and branch chain (The light blue part of the figure is the displacement caused by elastic deformation of the component).

Suppose the transformation rotation matrix of the dynamic coordinate system O2-x2y2z2 relative to the fixed coordinate system O1-x1y1z1 is . Assuming that the actual posture of the moving platform is at O2, the actual posture of the moving platform changes slightly (δα, δβ, δγ, δx2, δy2, and δz2) owing to the elastic deformation of the system branch chain, making the O2 point move to O2′; the transformation matrix from coordinate system O2-x2y2z2 to coordinate system O2′-x2′y2′z2′ is ∆R.

Given the minimal deformation of the parallel module, the alternations in the orientation and position parameters of the moving platform resulting from the elastic deformation of the branch chain approached negligibility. Applying Taylor’s formula and McLaughlin’s expansion, it can be concluded that:

The coordinate transformation matrix can be rewritten as:

Therefore, the coordinate transformation matrix from the coordinate system O2′-x2′y2′z2′ after elastic deformation to the reference coordinate system O1-x1y1z1 can be expressed as

Then, the expression of the coordinate system O2′-x2′y2′z2′ in the reference coordinate system O1-x1y1z1 is

Further

where E denotes the identity matrix. In the fixed coordinate system O1-x1y1z1, the above equation can be expressed as:

The equation of motion is abbreviated as:

where qai is the elastic displacement of point ai and q0 denotes the three displacements and three rotation variables of the moving platform. Jai is a kinematic constraint matrix.

Considering the Z-Y-X Euler angles (α, β, γ) to represent the attitude of the moving platform a1a2a3, the coordinate system O2-x2y2z2 fixed to the moving platform can be obtained from the fixed coordinate system O1-x1y1z1 by rotating angle α around the Z-axis, angle β around the Y-axis, and angle γ around the X-axis. Then, the posture transformation matrix from the system coordinate U0 to element coordinate δ0 for the displacement change of movable platform a1a2a3 caused by the elastic deformation of each branch chain component is as follows:

Then,

where , δ0 = [δ01 δ02 δ03 δ04 δ05 δ06]T, δ0 is the displacement change of the movable platform caused by the elastic deformation of each branch chain component in the local coordinate system O2′-x2′y2′z2′, and U0 = [u1 u2 u3 u4 u5 u6]T, where U0 is the displacement of the movable platform caused by the deformation of each branch chain component in the fixed coordinate system O1-x1y1z1.

The coupling effect between the nominal motion and the micro motion of the moving platform caused by the elastic deformation of the branched-chain components is not considered. From the foregoing analysis, in the reference coordinate system O1-x1y1z1, the speed and acceleration of the moving platform can be expressed as

The dynamic equation of the moving platform of the system can be obtained as

where ∑FO1x, ∑FO1y, and ∑FO1z are the components of the external force acting on the moving platform in the X-, Y-, and Z-axis directions; ∑MO1x, ∑MO1y, and ∑MO1z are the components of the external torque acting on the moving platform around the X-, Y-, and Z-axes; ∑Fix, ∑Fiy, and ∑Fiz are the components of the resultant force of each branch chain acting on the moving platform in the X-, Y-, and Z-axis directions; ∑Mix, ∑Miy, and ∑Miz are the components of the torque of each branch chain acting on the moving platform around the X-, Y-, and Z-axes; Ixx, …, Izz are the moments of inertia and product of inertia of the moving platform; and m0 is the mass of the moving platform.

This equation can be abbreviated (under dynamic constraint conditions) as:

where M0 is the generalized mass matrix of the moving platform, f0 is the resultant force matrix of the branched chain acting on the moving platform; F0 is the resultant force matrix of the external force acting on the moving platform, and is the nominal acceleration array of the moving platform.

3.1.5. System Dynamics Equation

Using the system dynamics constraint equations and combining the dynamic equations of each branch chain, the dynamic equation of the system can be expressed as

where M is the total mass matrix, C is the total damping matrix, K is the total stiffness matrix, F is the generalized force matrix, is the rigid body acceleration matrix, U is the generalized coordinate array, and is the elastic acceleration array.

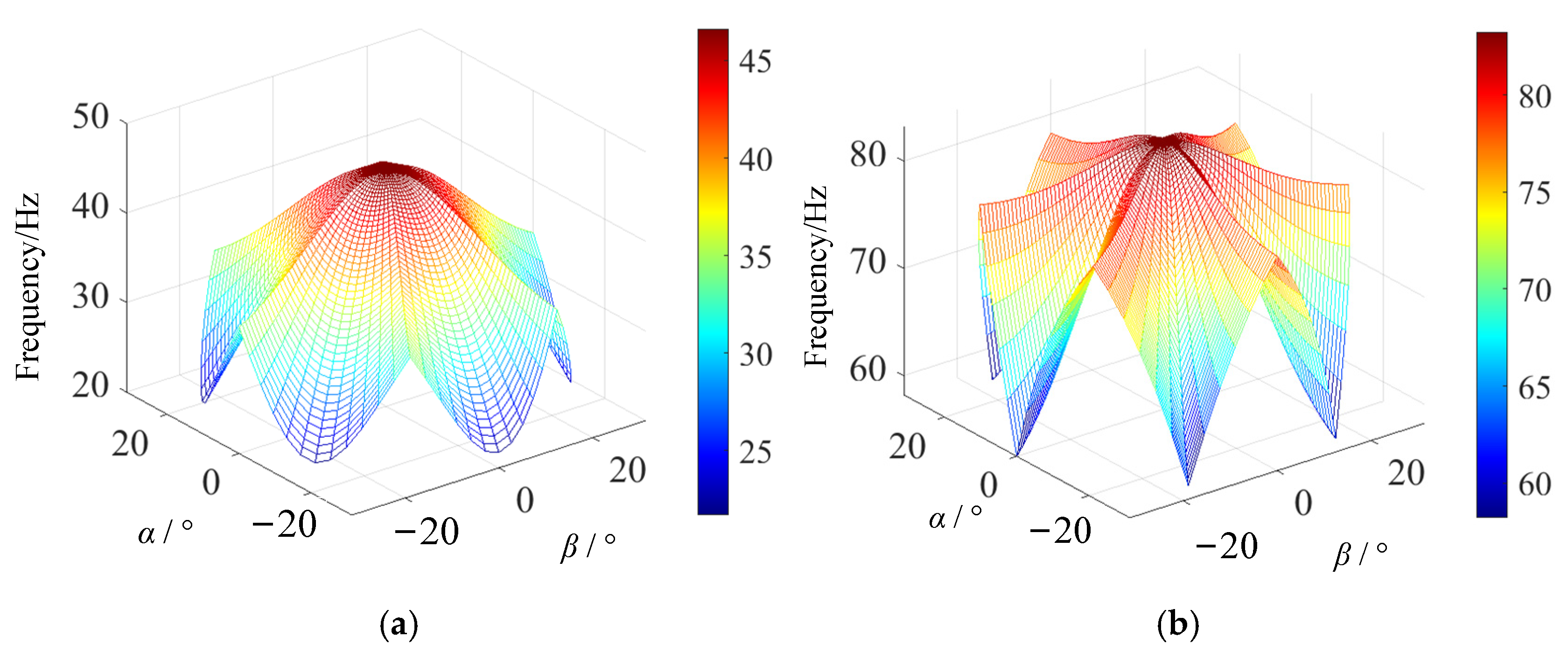

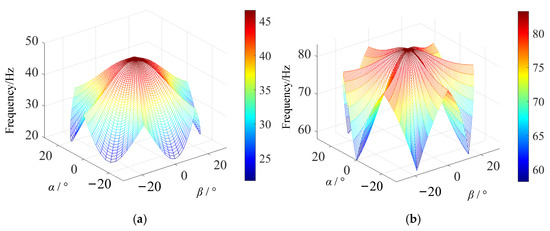

The natural frequency of the 5-DOF-HPR was analyzed according to the established model. The natural frequency of the testing machine was related to its position and posture in the workspace. In the simulation, the parameters of the robot in the workspace were α = −30°–30°, β = −30°–30°, Z = 1400 mm, α1 = 0°, and α2 = 4°. α, β, and Z were the pose parameters of the robot in its fixed coordinate system; α1 was the angle of the first rotating head; and α2 was the angle of the secondary rotating head.

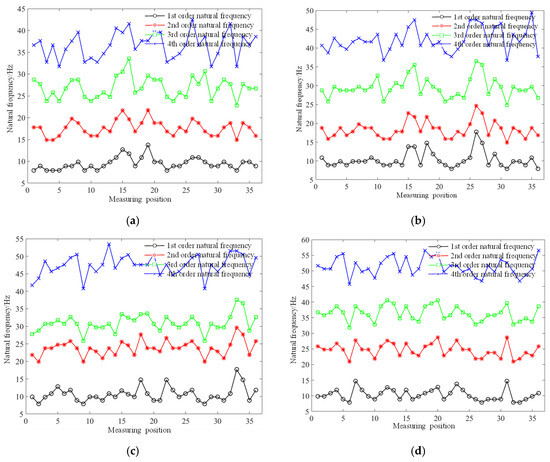

According to the simulation results shown in Figure 10, the first four natural frequencies of the 5-DOF-HPR all presented a convex shape in the middle and a concave shape around the periphery, and the higher the order of the natural frequency, the larger the frequency span became. The first natural frequency ranged from 23 to 47 Hz; the second natural frequency ranged from 58 to 83 Hz; the third natural frequency ranged from 75 to 117 Hz; and the fourth natural frequency ranged from 110 to 158 Hz. As the first four natural frequencies varied from α = −30° to 30° and β = −30° to 30°, the natural frequency exhibited a wide range of sudden changes, and the second- and third-order natural frequencies were the most obvious.

Figure 10.

Initial four natural frequency models of the 5-DOF-HPR. (a) First-order natural frequency. (b) Second-order natural frequency. (c) Third-order natural frequency. (d) Fourth-order natural frequency.

3.2. Dynamic Characteristics Analysis of the FSS

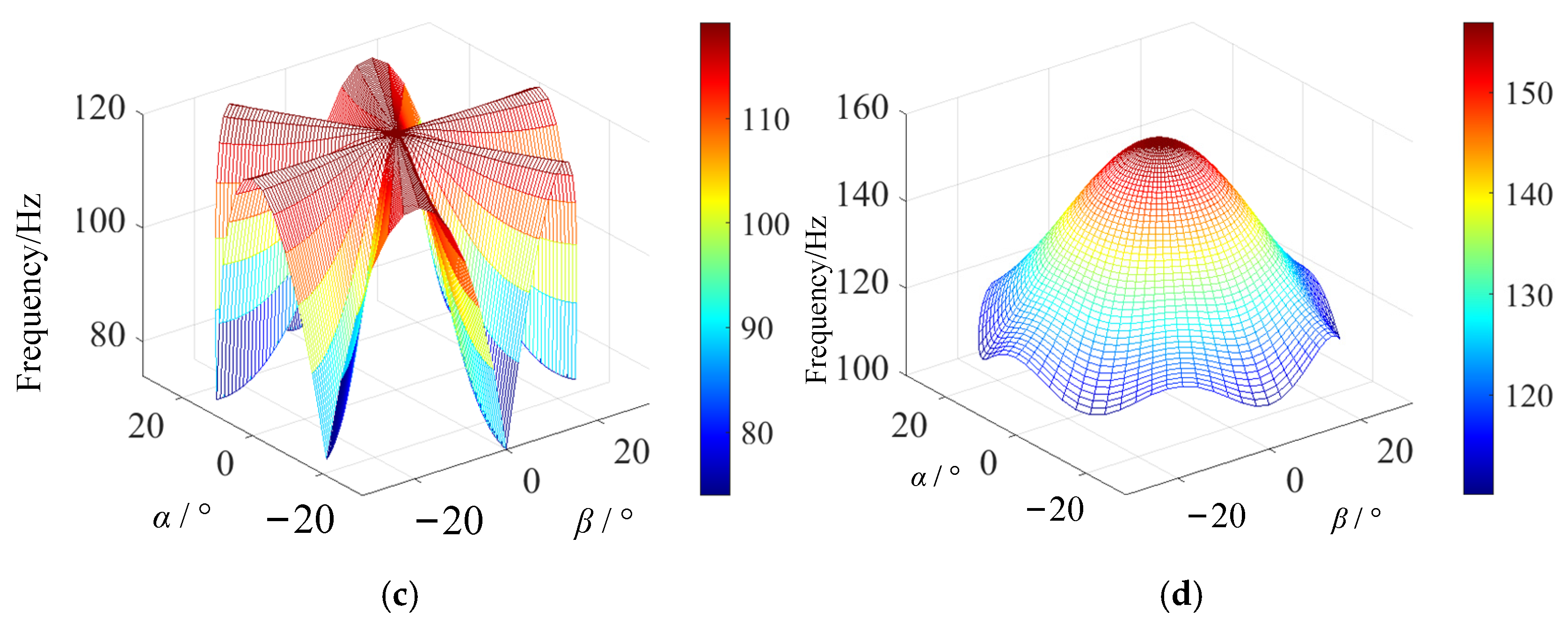

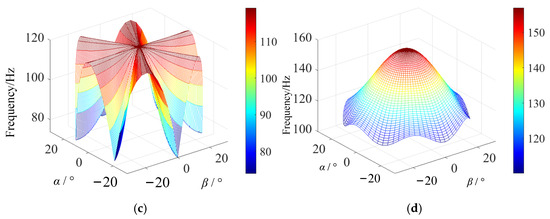

The support cylinder must maintain a constant pressure during the working process, so it was assumed that the hydraulic oil in the FSS did not flow, allowing the fluid characteristics to be ignored during the analysis. The chamber filled with hydraulic oil was analyzed as a flexible component, so the entire cylinder could be simplified as a series of multiple springs and dampers.

The 36 support cylinders were simplified into 36 sets of springs and dampers, and the stiffness of each support cylinder was Kn (n = 1, 2, …, 36).

As shown in Figure 11, M is the weight of the piston; F is the load applied by the optical mirror; ∆F is the local force applied by the polishing disc; K1 is the stiffness of the beryllium bronze reed in the upper chamber; K2 is the stiffness of the small diaphragm in the upper chamber; K3 is the stiffness of the hydraulic oil in the upper chamber; K4 is the stiffness of the large diaphragm; K5 is the stiffness of the hydraulic oil in the lower chamber; K6 is the stiffness of the small diaphragm in the lower chamber; and K7 is the stiffness of the beryllium bronze reed in the lower chamber. C1–C7 denote the damping of each component.

Figure 11.

Spring model of support cylinder.

During the working process, the displacement of the support cylinder can be expressed as:

where is the displacement of the support cylinder; is the volume change of the upper chamber; is the volume change of the lower chamber; and S is the cross-sectional area of the support piston.

When the support shaft of the support cylinder changes , the volume of the upper and lower chambers can be expressed as:

where and are the structural parameters of the support cylinder; m and n indicate the number of radial and axial structural parameters of the support cylinder; is the extension quantity of the small rolling diaphragm in the upper chamber; is the extension quantity of the small rolling diaphragm in the lower chamber; is the extension quantity of the large rolling diaphragm; is the compression quantity of the small rolling diaphragm in the upper chamber; is the compression quantity of the small rolling diaphragm in the lower chamber; is the compression quantity of the large rolling diaphragm; and Rp is the chamfer radius of the chamber.

Then, the hydraulic stiffnesses of the upper and lower chambers, respectively, are:

where βe is the effective bulk modulus of elasticity of hydraulic oil.

According to the equation of the volume elastic coefficient, the effective volume elastic modulus of hydraulic oil can be expressed as:

The force required for the deformation of the beryllium bronze reed and rolling diaphragm in the positive and negative directions was analyzed using a finite element model to calculate the stiffnesses K1, K2, and K4.

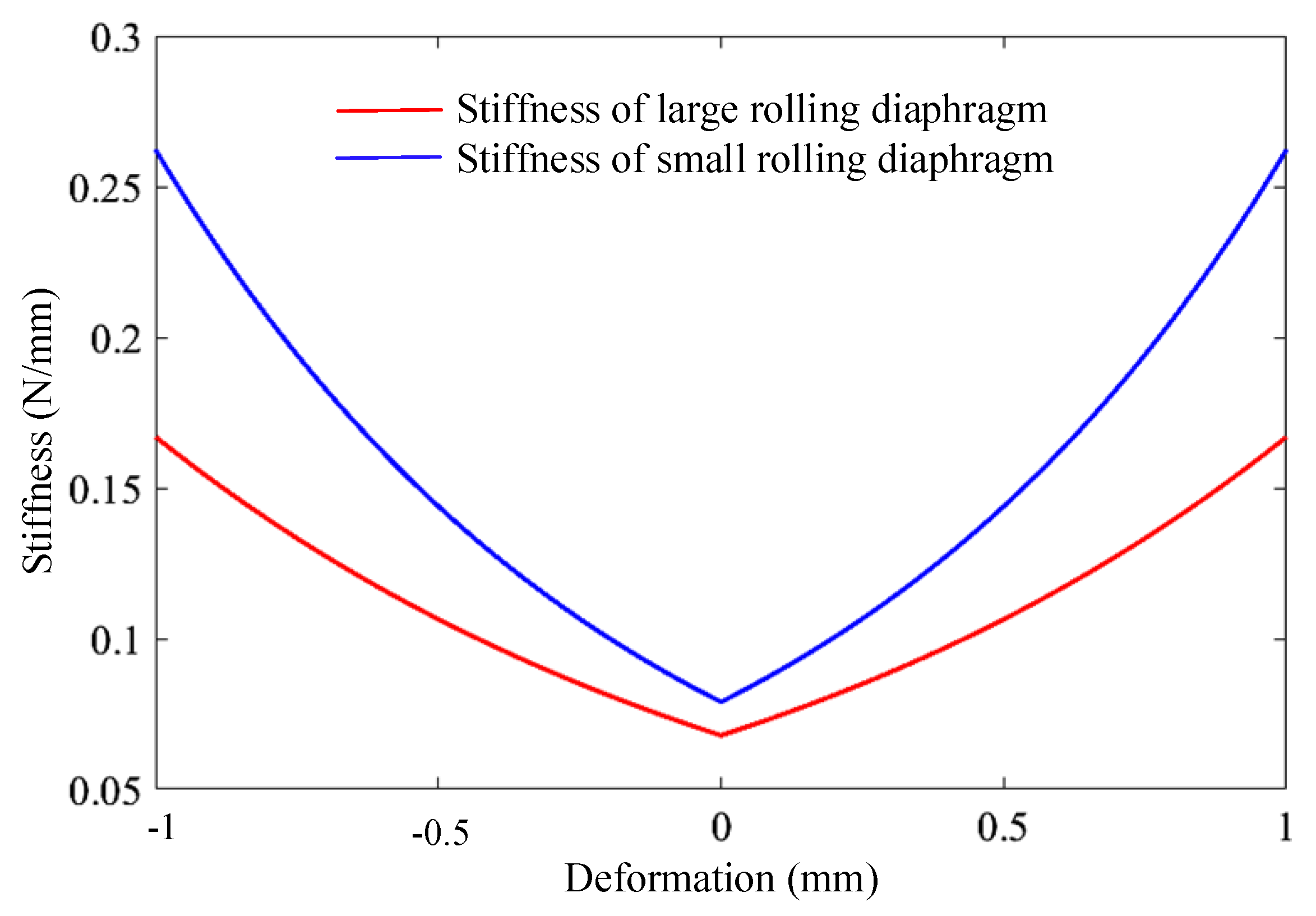

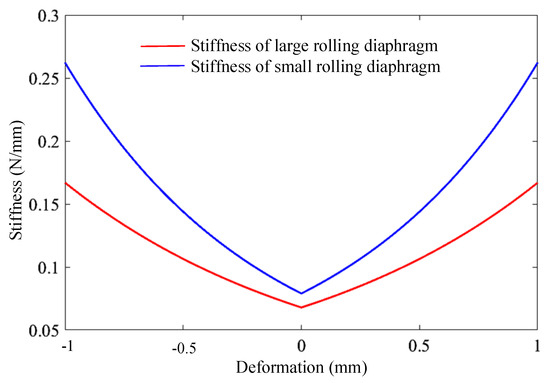

When operating in the autonomous constant-pressure support mode, the FSS exhibits stiffness curves for both large and small diaphragms at varying deformations (Figure 12). The red curve is the stiffness curve of the large rolling diaphragm, and the blue curve is the deformation curve of the small rolling diaphragm. It can be seen from the change in the curve that, although the rolling diaphragm is a nonlinear structure perpendicular to the deformation direction, its stiffness is approximately the same when the deformation in the positive and negative directions is the same.

Figure 12.

Stiffnesses of large and small rolling diaphragms.

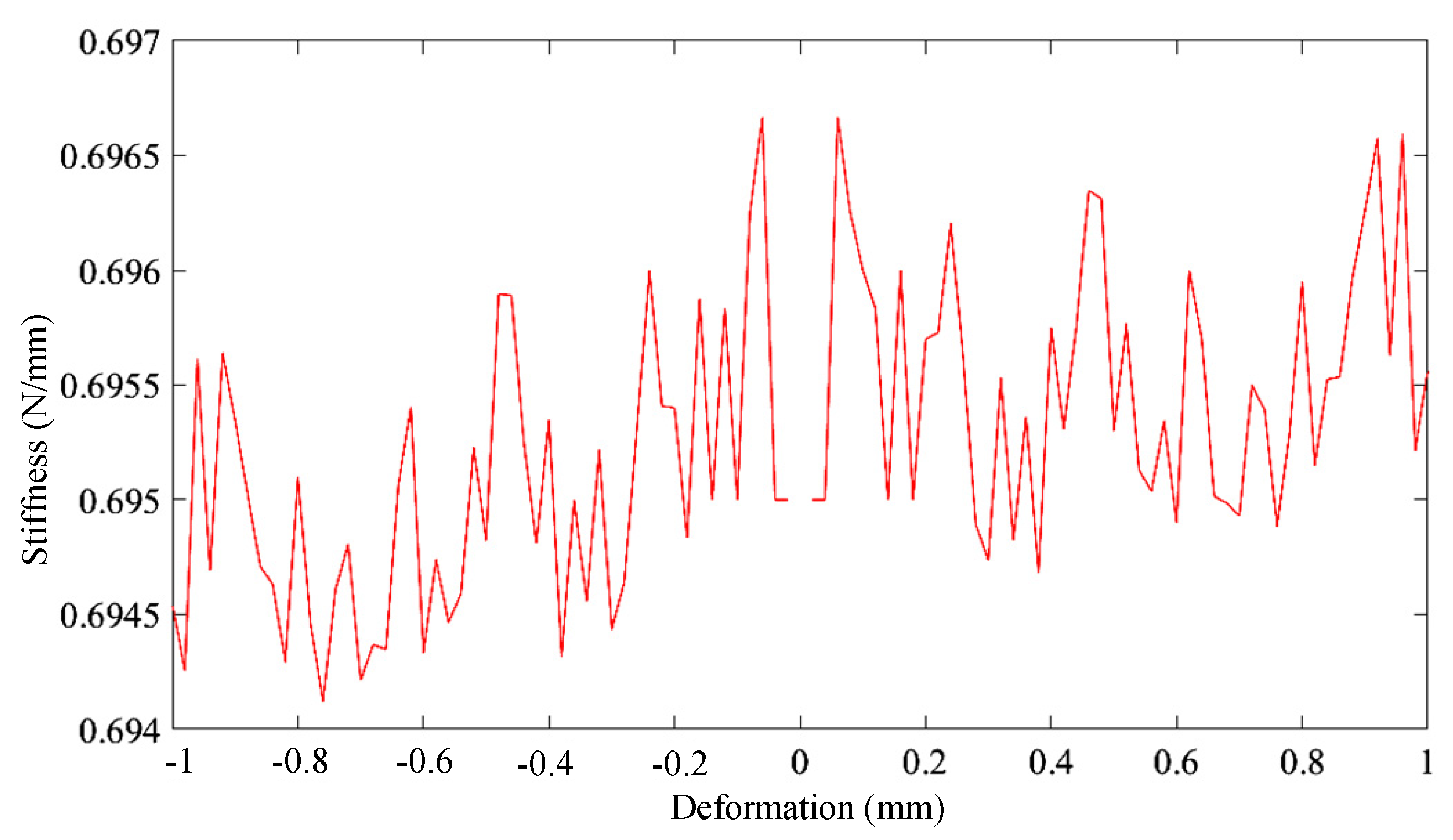

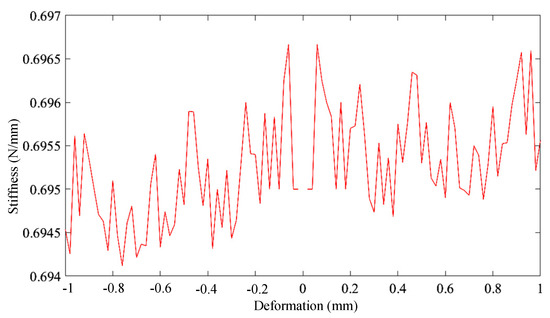

The change in the stiffness of the beryllium–bronze spring from −1 mm to 1 mm deformation was analyzed using ANSYS 2022.R1, as shown in Figure 13. It can be seen from the curve that the stiffness of beryllium–bronze reed fluctuated within 0.6940–0.6965 N/mm, regardless of the movement in the positive or negative direction, and its fluctuation range was only 0.0025 N/mm. Within the allowable error range, the stiffness of beryllium bronze reed in the stroke range can be considered a constant value.

Figure 13.

Stiffness of beryllium bronze reed.

Then, the natural frequency of the hydraulic system is:

where K0 is the stiffness matrix of the support cylinder and m0 is the mass matrix of the support cylinder.

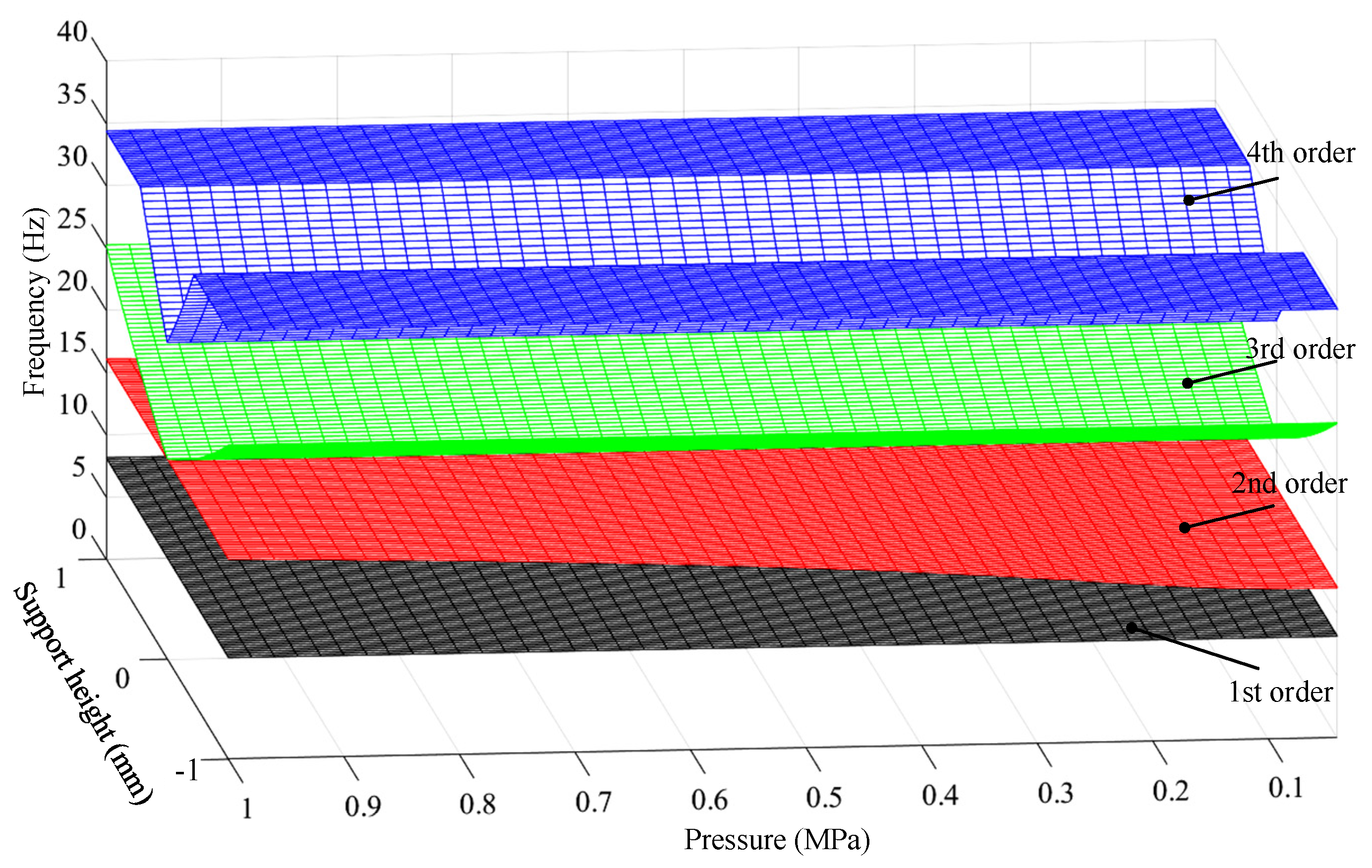

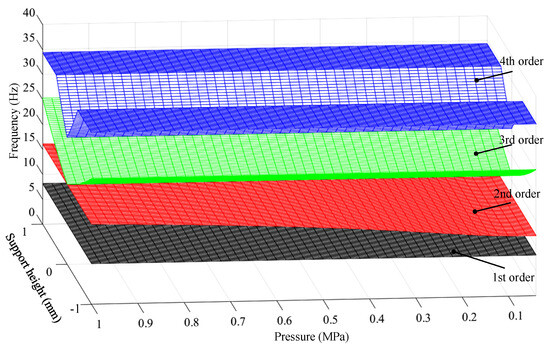

According to the established model, the natural frequency of the support cylinder was analyzed. The first four natural frequencies of the support cylinder at different support heights and working pressures are shown in Figure 14. The first-order natural frequency ranged from 8.0 to 8.3 Hz; the second-order natural frequency ranged from 12 to 16.5 Hz; the third-order natural frequency ranged from 16 to 25.5 Hz; and the fourth-order natural frequency ranged from 25.5 to 35 Hz. The changing trends of the first four natural frequencies are symmetrical structures in the positive and negative directions of motion. Therefore, in the follow-up research work, it is only necessary to analyze the motion of the FSS in one direction. The first and second frequencies changed relatively smoothly. The third and fourth natural frequencies had a greater curvature in the direction of the support height displacement. When the support pressure was changed, the natural frequency changes were not obvious.

Figure 14.

Natural frequency of support cylinder.

3.3. Dynamic Characteristics Analysis of the CCOS Grinding System

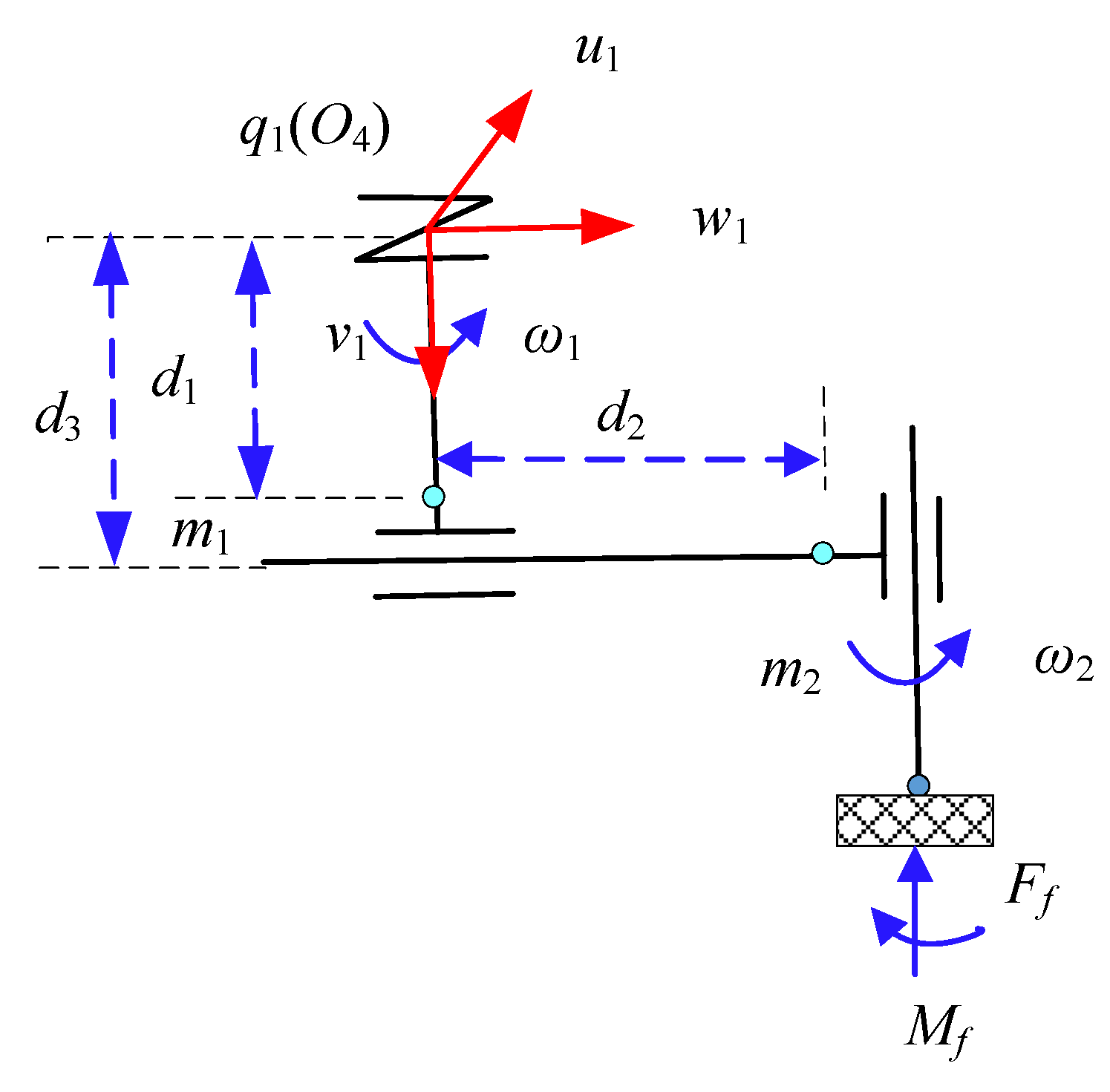

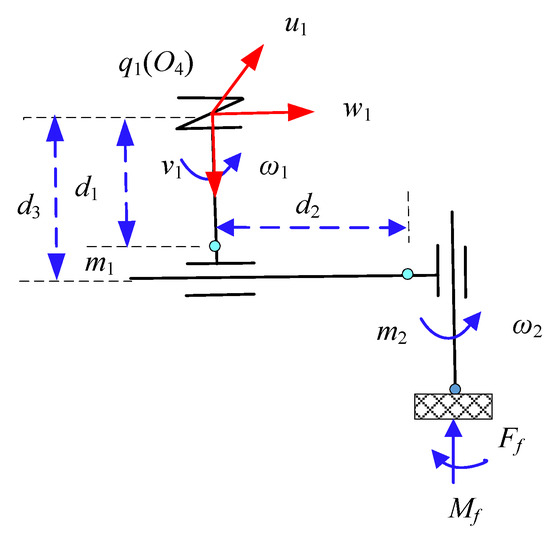

As the revolution motor rotates, the planetary polishing tool system generates force and torque on the 5-DOF-HPR. The force analysis of the CCOS grinding system is shown in Figure 15.

Figure 15.

Force analysis of CCOS grinding system.

In the revolution module, the speed of the revolution motor is ω1; the total mass of the module is m1; and the mass center is located on the axis of the revolution motor. The mass center coordinate m1 is in the coordinate system O4-u1v1w1. In the rotation module, the total mass of the module is m2; the center of mass is located on the eccentric rod; its distance from the axis of the revolution motor is d2, and the center of mass coordinate m2 is in the coordinate system O4-u1v1w1. When the revolution motor rotates, it produces a centrifugal force Fml. At the same time, the tool system bears the reaction force Fif from the mirror and its own gravity. The equations of centrifugal force, reaction force, and gravity are as follows:

where Sm is the contact area between the grinding disc and the mirror and Pm is the cylinder pressure.

During processing, assuming that the angle between the eccentric rod and the original position is ω1t and the direction of the force is in the coordinate system O4-u1v1w1, the centrifugal force Fml and the reaction force Fif are expressed as:

where eml is the direction vector of the centrifugal force and eif is the direction vector of the reaction force.

4. Dynamic Characteristic Measurement Experiment

4.1. Natural Frequency Measurement Experiment of the LOMPS

In the context of optical mirror processing, robotic systems may experience resonance due to natural frequencies at various orientations, resulting in additional forces being exerted on the end effector during grinding operations. These unintended forces can significantly impact the quality of large-scale optical mirror processing systems. Consequently, it is imperative to conduct comprehensive dynamic characteristic analyses to establish a solid foundation for subsequent trajectory planning and optimization. The modal test was carried out by pulse excitation, and the hammering mode was used as the excitation input. An LC-2 force hammer (Donghua Test, Taizhou, China) was used as the exciting hammer, and its sensor was a YDL-4X piezoelectric quartz force sensor (Donghua Test, China). The collected force signal was transformed, processed, and amplified through a DHF-7 charge amplifier (Donghua Test, China), and the signal was transmitted to the tester. The acceleration sensors were a 608A11 ICP single-axis acceleration (Donghua Test, China) sensor and 605B31 ICP three-axis acceleration (Donghua Test, China) sensor from the PCB Company. The DH5923N tester (Donghua Test, China) and DHDAS analysis software (DHDAS V1.3) were used for the test and analysis system. The collected signal was recorded and processed by a tester, and it was further processed, converted, and calculated using analytical software. The natural frequency, vibration mode, and other modal parameters of the testing machine system were obtained. The experimental prototype is illustrated in Figure 16.

Figure 16.

Experimental prototype.

4.1.1. Modal Experiment of the 5-DOF-HPR

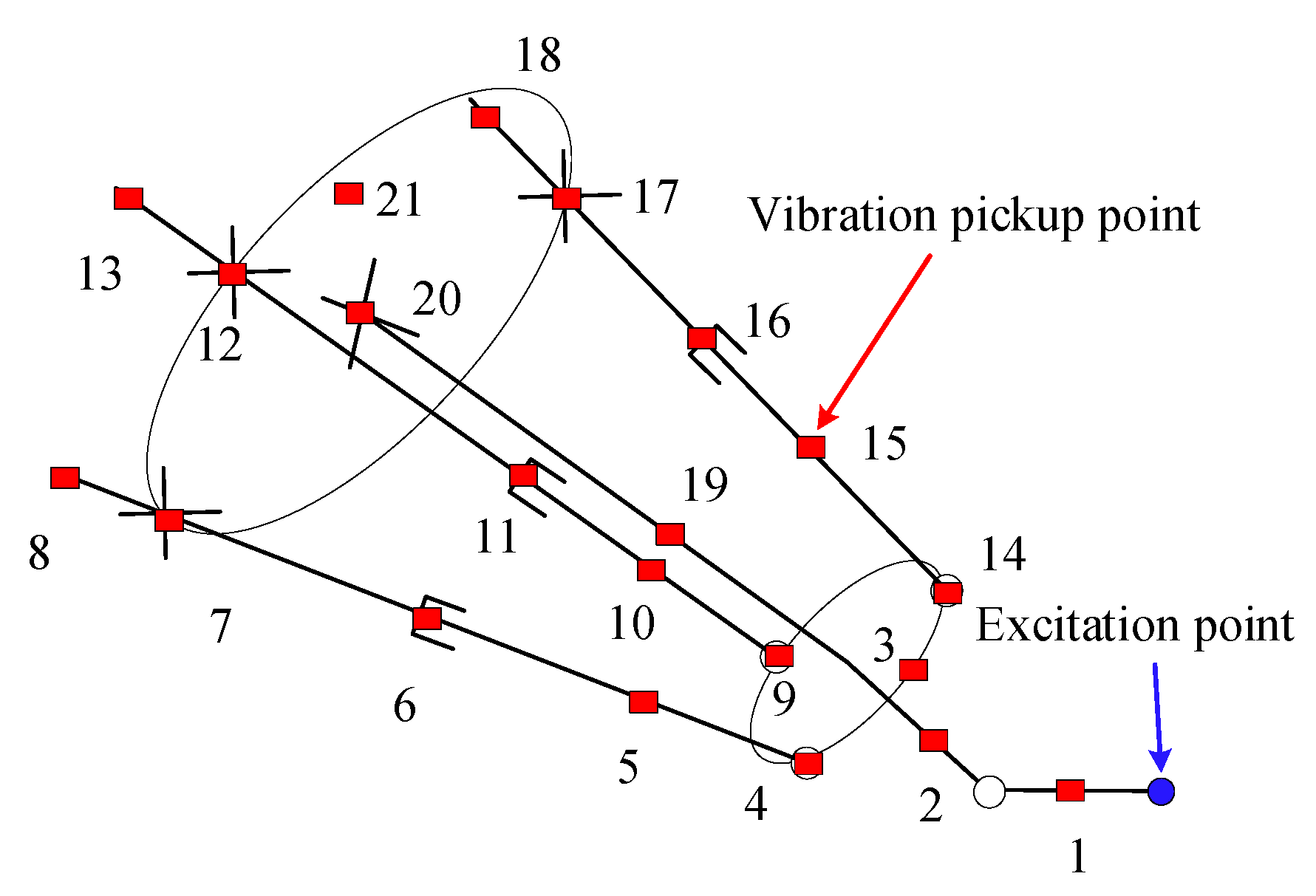

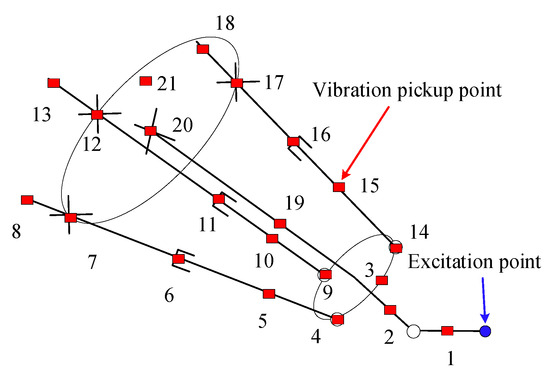

During the experiment, the excitation point was located at the end of the secondary rotating head, and the vibration pickup points were arranged at the secondary rotating head, first rotating head, moving platform, compound spherical hinge, telescopic rod, telescopic sleeve, Hooke hinge, and drive motor. Each measuring point measured the acceleration response in the X, Y, and Z directions. The layout of the measuring points of the experimental prototype is shown in Figure 17. To avoid the randomness of the collected data, five hammering experiments were carried out at each vibration measuring point. The modal information of four different postures was collected, and the average value was taken as the final experimental result.

Figure 17.

Distribution of vibration measuring points.

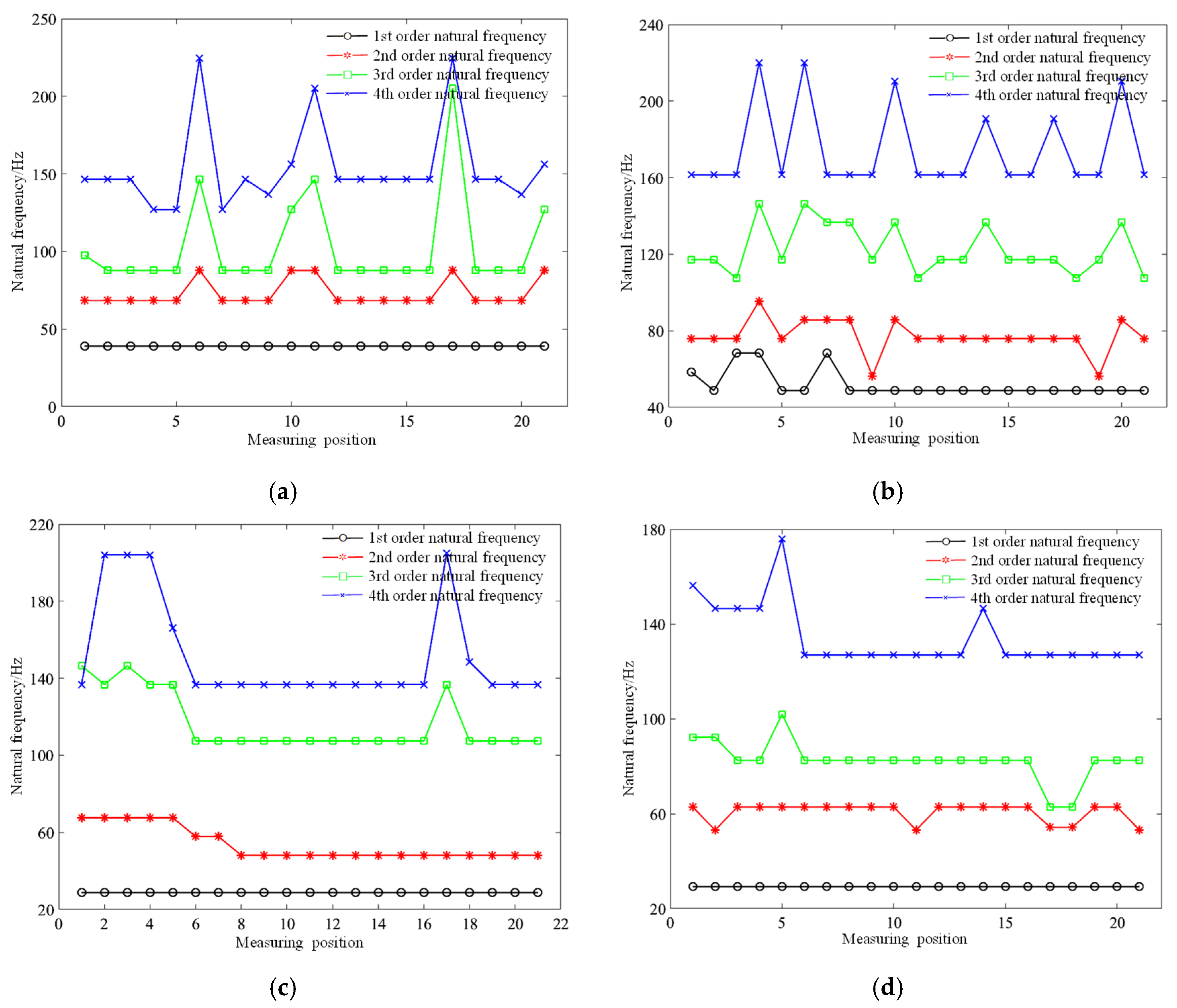

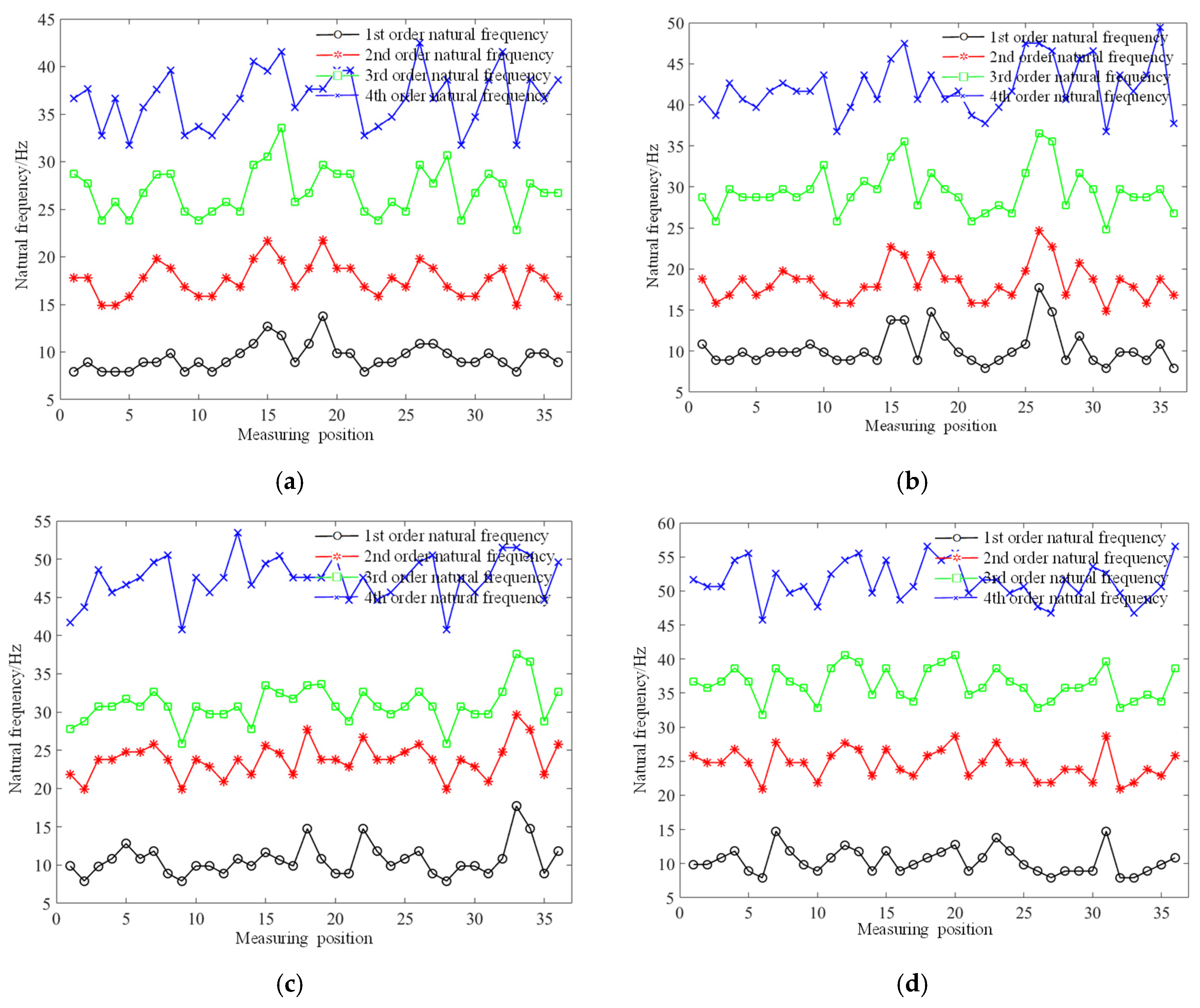

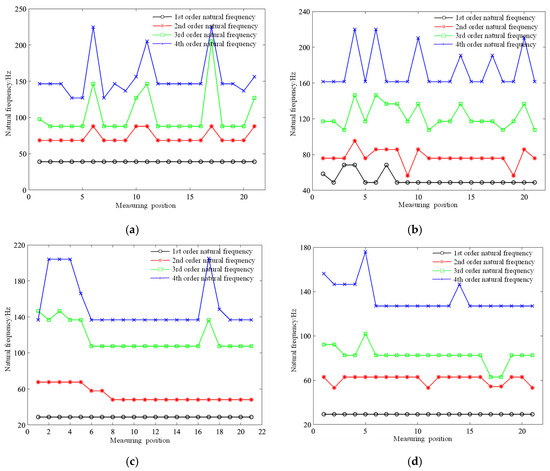

DHDAS software was used to calculate and analyze the measured data. The first four natural frequencies of the testing machine in four typical postures were measured. Posture 1: α = 0°, β = −15°, Z = 1200 mm, α1 = 0°, α2 = 12°; Posture 2: α = 35°, β = 0°, Z = 1400 mm, α1 = −4°, α2 = −9°; Posture 3: α = 0°, β = 20°, Z = 1250 mm, α1 = 0°, α2 = 24°; and Posture 4: α = 0°, β = 0°, Z = 1600 mm, α1 = 0°, α2 = 0°. The experimental results are shown in Figure 18.

Figure 18.

First four natural frequencies of 5-DOF-HPR. (a) Natural frequency of posture 1. (b) Natural frequency of posture 2. (c) Natural frequency of posture 3. (d) Natural frequency of posture 4.

As shown in Figure 18, although the collected experimental data of the first four natural frequencies of the four different postures fluctuated, they were all stable at a certain value. Through the analysis, it can be concluded that this was because the selected time was different when fast Fourier transform was performed using DHDAS, resulting in inconsistent natural frequencies or loss of certain natural frequencies. Therefore, the frequency that appeared more frequently was regarded as the natural frequency value of this order. A comparison between the first four natural frequencies and the simulation values of the 5-DOF-HPR is shown in Table 1.

Table 1.

Natural frequencies of typical poses of the 5-DOF-HPR.

The data presented in Table 1 demonstrate that the error of the first four natural frequencies measured by the experiments were within 13.4%. These errors were due to the simplifying assumptions when establishing the elastodynamic model, and there were some errors between the actual pose of the robot and the model parameters. In summary, the error was within an acceptable range, and the natural frequency of the system calculated by the simulation reflected the actual natural frequency of the testing machine system to a certain extent, which verified the accuracy of the elastodynamic model of the 5-DOF-HPR. Further analysis of the first four natural frequencies of the 5-DOF-HPR at four different positions showed that, when the 5-DOF-HPR was in different positions, there was a large difference between the natural frequencies, especially when the range ratio of the first natural frequency reached 151%. The resonance phenomenon in the workspace should be avoided when path planning and parameter setting of the 5-DOF hybrid robot are carried out.

4.1.2. Modal Experiment of the FSS

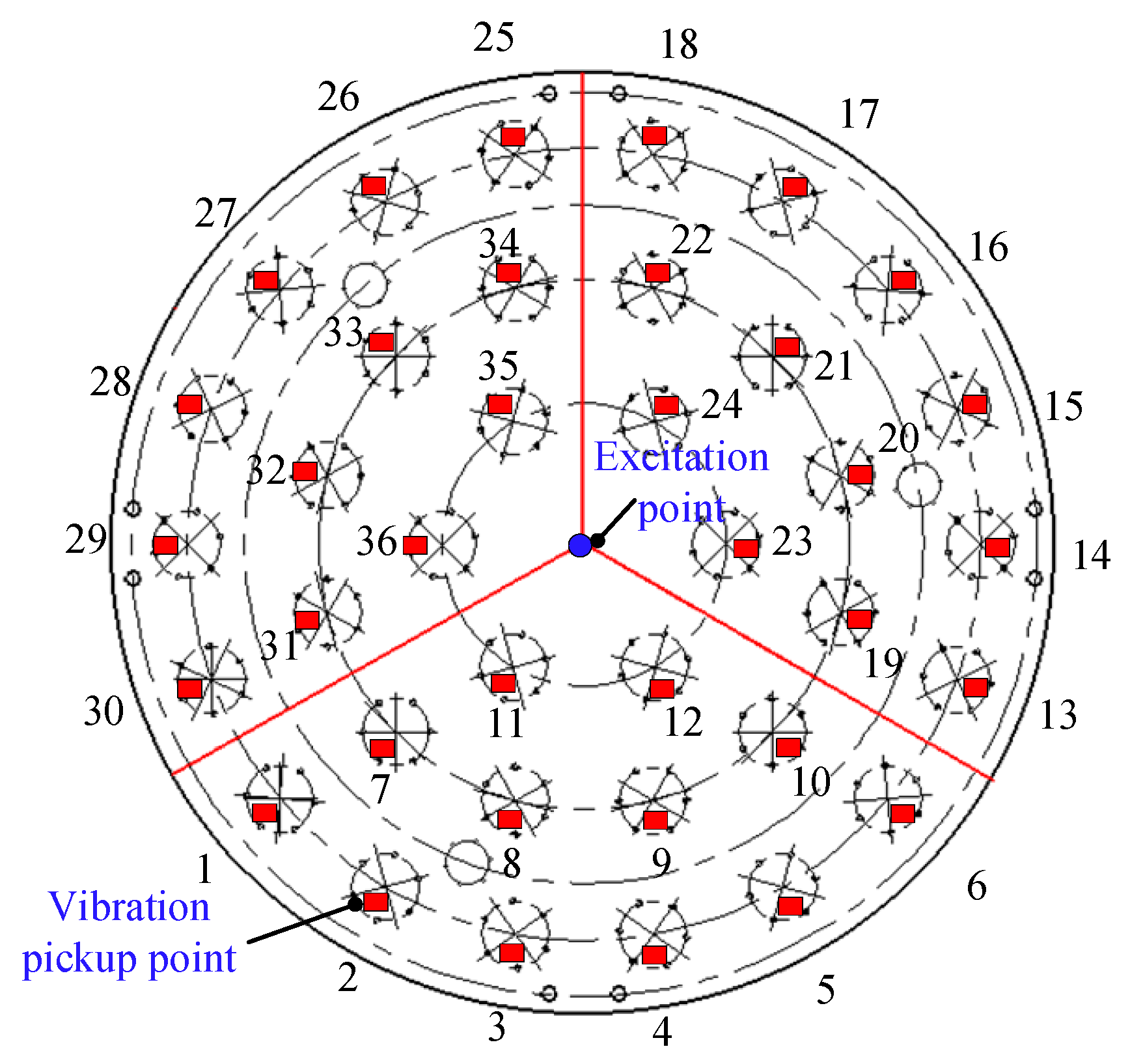

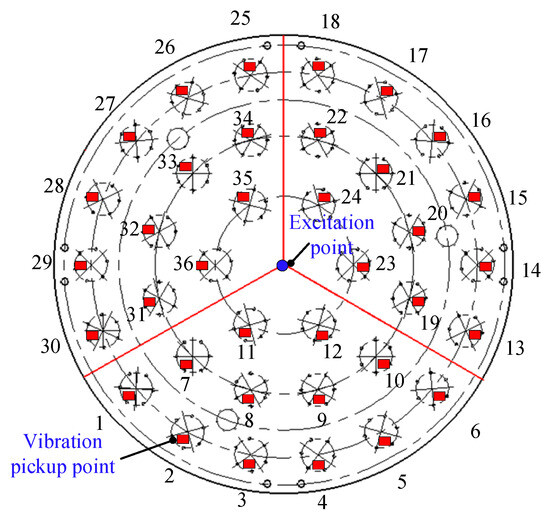

The locations of the excitation point and vibration measurement points of the modal experiment of the FSS are shown in Figure 19. The excitation point was selected as the center of the support base plate, and the vibration measurement points were the support cylinders.

Figure 19.

Vibration measurement points and excitation point location of the FSS.

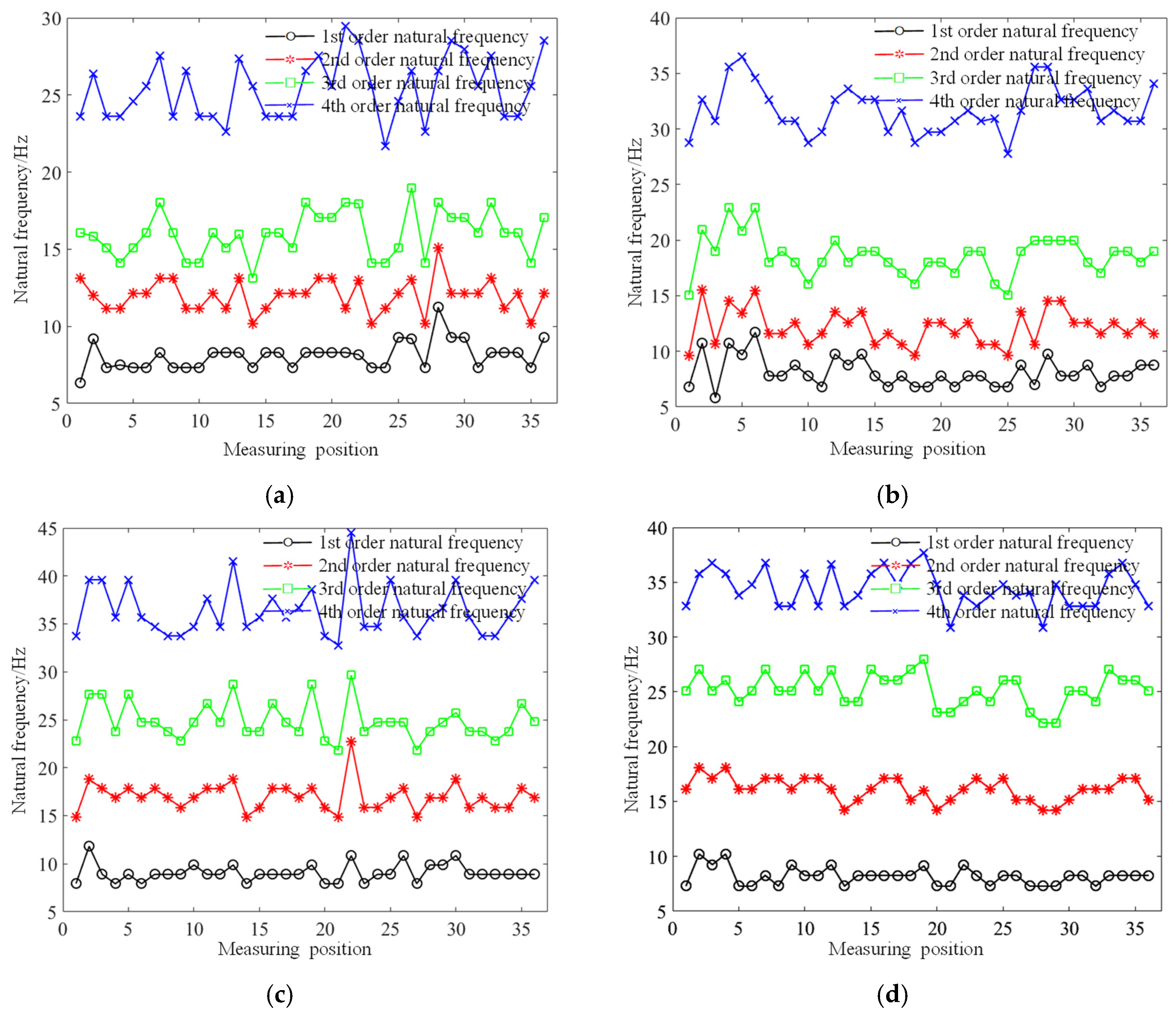

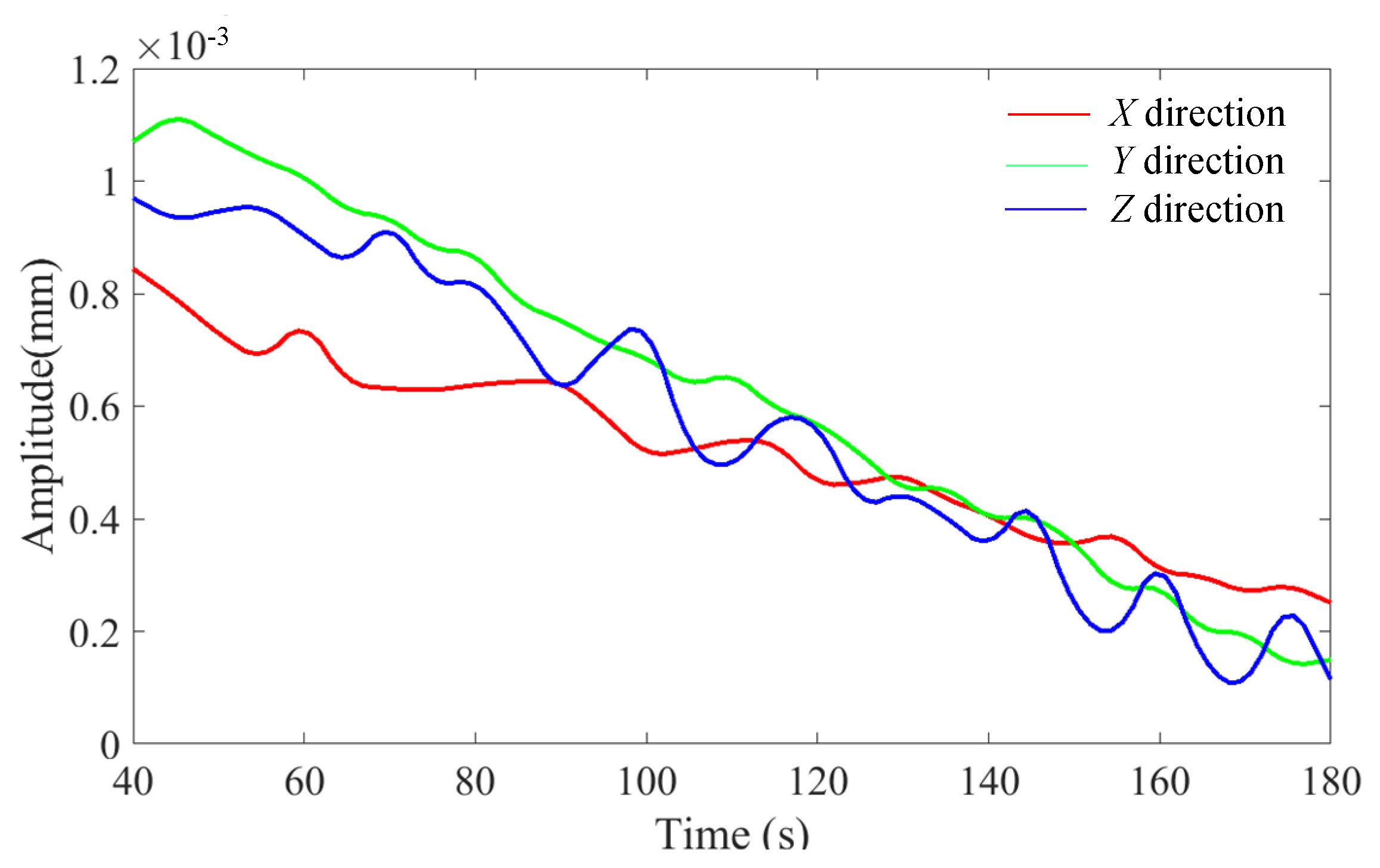

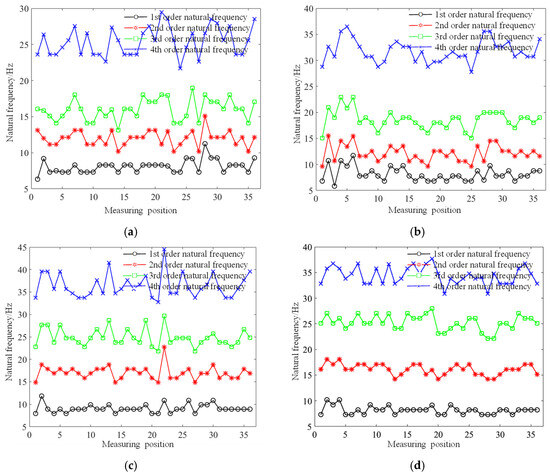

According to the simulation results summarized in Section 3.2, the natural frequency of the support cylinder was mainly affected by the support height, and the change in the support pressure did not affect it. Therefore, during the experiment, the support pressure of the FSS was maintained at 0.5 MPa, and the support height was varied. The experimental process was the same as that described in Section 4.1.1. Each vibration measurement point was subjected to five hammering experiments. The modal information of four different postures was collected, and the average value was taken as the final experimental result. The experimental results are presented in Figure 20. The analysis method was the same as that in Section 4.1.1, and the comparison between the first four natural frequencies and simulation values of the FSS is shown in Table 2.

Figure 20.

First four natural frequencies of FSS. (a) Displacement of the FSS of 0 mm. (b) Displacement of the FSS of 0.35 mm. (c) Displacement of the FSS of 0.70 mm. (d) Displacement of the FSS of 1.00 mm.

Table 2.

Natural frequencies of typical postures of FSS.

It can be seen from Table 2 that the errors of the first four natural frequencies measured by the experiments were within 16% compared with the simulation data. This was due to the simplification of some parts in the vibration differential equation modeling of the FSS. In addition, the beryllium bronze reed and rolling diaphragms were non-linear elastic deformation components. When analyzing them, the finite-element method was used to analyze their stiffness, and there were some errors. In addition, the working pressure of the FSS was relatively low and was easily affected by environmental temperature, vibration, and other factors, potentially contributing significantly to the error. In summary, the error was within an acceptable range. The natural frequency calculated by simulation reflected the actual natural frequency of the FSS to a certain extent, which verified the accuracy of the elastodynamic model of the FSS.

Further analysis of the first four natural frequencies of the FSS in four different positions showed that, when the support displacement of the FSS increased, all the natural frequencies increased, except for the first natural frequency, which was basically unchanged. This was caused by the nonlinear elastic deformation of the beryllium bronze spring and the rolling diaphragm. The greater the deformation was, the greater the stiffness that was overcome, and the natural frequency also increased. During the working process of the FSS, the support height should be appropriately increased in the positive direction or decreased in the negative direction, when the support conditions permit, to increase the natural frequency of the FSS.

4.1.3. Modal Experiment of the FSS and “Mirror”

In the experiment, an aluminum plate was installed on the FSS instead of a mirror. The positions of the excitation point and the vibration measurement points on the aluminum plate coincided with the vertical projection of the excitation point and the vibration measurement points of the bottom support in Figure 19. Similarly, five hammering experiments were carried out at each vibration measuring point. The modal information at four different positions was collected, and the average value was taken as the final experimental result. The experimental results are presented in Figure 21.

Figure 21.

First four natural frequencies of FSS and “mirror”. (a) Displacement of the FSS of 0 mm. (b) Displacement of the FSS of 0.35 mm. (c) Displacement of the FSS of 0.70 mm. (d) Displacement of the FSS of 1.00 mm.

As shown in Table 3, it can be seen that the first four natural frequencies increased compared with the FSS alone. This was because the installation of the mirror constrained each support point of the FSS, resulting in a constraint relationship between the vibration of each support cylinder. In addition, the natural frequency of the FSS and “mirror” was related to the quality, density, and size of the mirror. Therefore, in the process of optical mirror processing, to understand the natural frequency of the FSS and “mirror”, it is necessary to analyze the system according to the specific mirror surface to be processed to ensure the accuracy of the processing system.

Table 3.

Natural frequencies of typical postures of FSS and “mirror”.

4.2. Amplitude Experiment

The validity and accuracy of the mathematical model were further verified by collecting the vibration state of the mirror of the LOMPS under different working conditions. During the experiment, a 3-DOF acceleration sensor was installed on the mirror, and the vibration information of the mirror in the X-, Y-, and Z-directions was collected.

4.2.1. Amplitude of the 5-DOF-HPR at Different Running Speeds

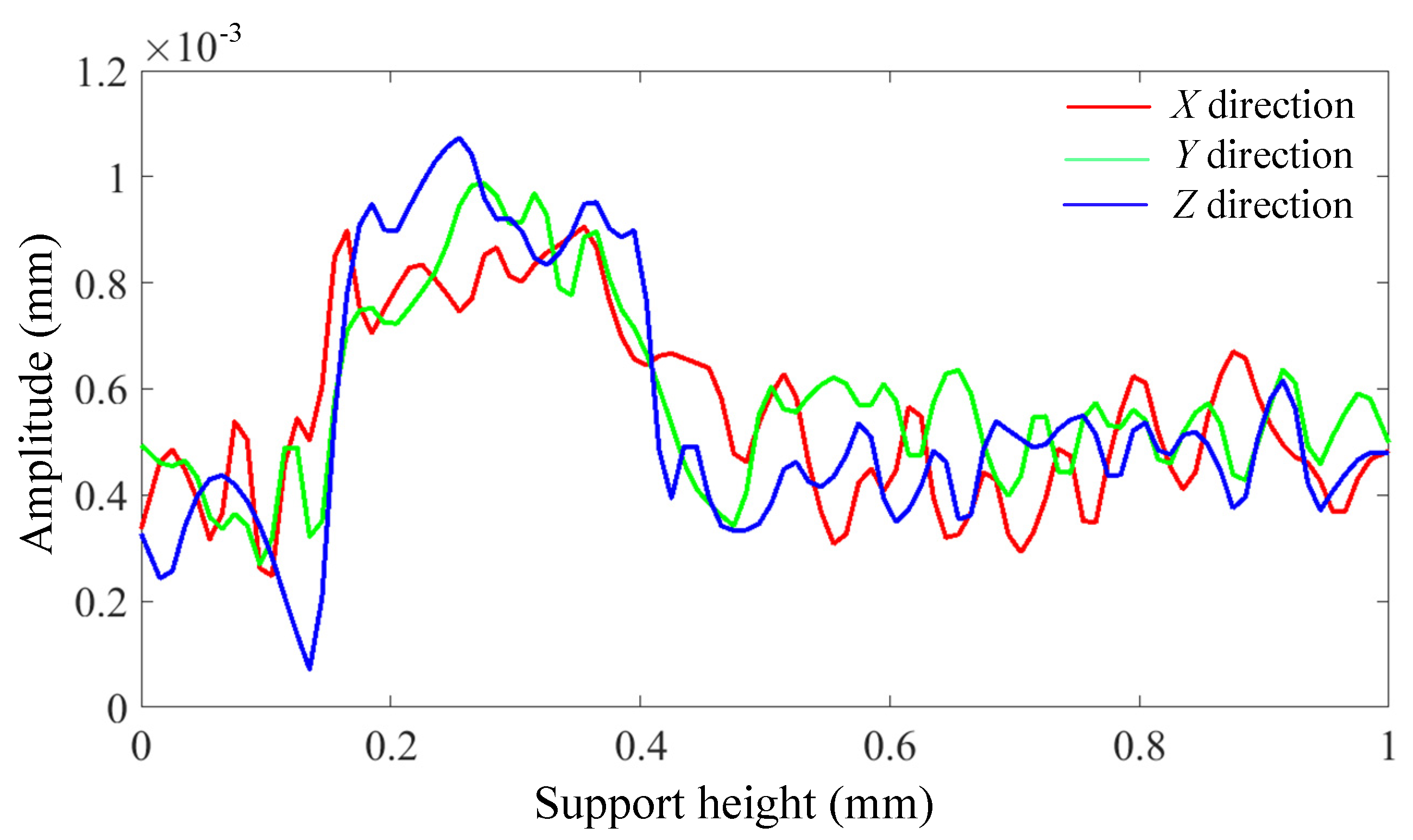

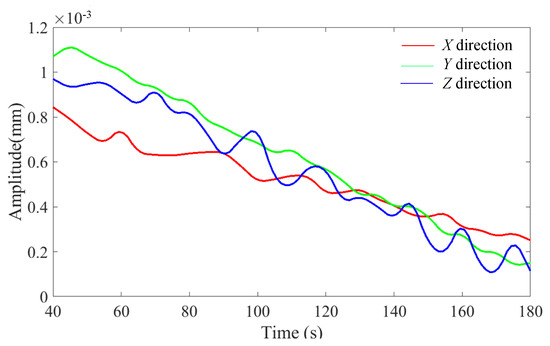

During optical mirror processing, the dwell time at each point was determined by the running speed of the 5-DOF-HPR. The length of the robot’s dwell time directly impacted the amount of mirror removal. To determine the optimal running speed of 5-DOF-HPR, avoid the resonance of the LOMPS, and improve the accuracy of the mirror to be processed, it is necessary to carry out further experimental acquisition of the amplitude of the mirror at different speeds. Through the control, the support height of the FSS was maintained at 0.8 mm, a grinding force of 20 N was applied to the CCOS grinding system, and the rotation speed was 30 Hz. The optical mirror machining robot was made to walk in a circle with a diameter of 400 mm on the mirror, and the amplitude of the mirror to be machined was measured by changing the running time of the 5-DOF-HPR. In the world coordinate system, the trajectory curve is as follows:

The vibration information collected by the 5-DOF-HPR walking through the trajectory given by Equation (33) at 40–180 s is shown in Figure 22. When the running time changed, although the collected vibration amplitude fluctuated and the robot moved faster, the amplitude of the machined mirror in the X-, Y-, and Z-directions increased. During the working process, the operating speed of the 5-DOF-HPR should be reduced as much as possible on the premise of satisfying the processing technology and residence time requirements.

Figure 22.

Amplitude of the 5-DOF-HPR at different speeds.

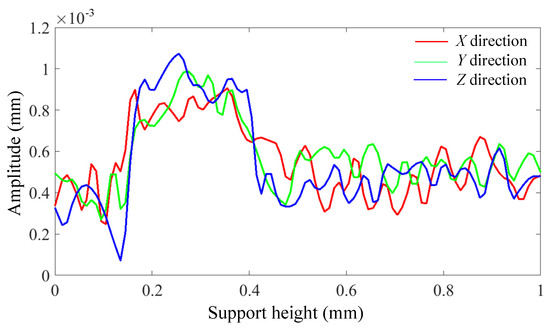

4.2.2. Amplitude Under Different Support Heights

In the experimental process with different support heights, the 5-DOF-HPR completed the circular trajectory in 140 s, and the speed of the CCOS grinding system was 30 Hz. The amplitudes of different support heights were measured by changing the support height of the FSS. The experimental results are presented in Figure 23.

Figure 23.

Amplitude of the FSS under different support heights.

According to the experimental results collected in Figure 23, when the support height of the FSS was 0.3 mm, the amplitude of the machined mirror increased significantly. This was because the rotation speed of the CCOS grinding system was set to 30 Hz, and the FSS exhibited a resonance phenomenon, which further verified the accuracy and validity of the established mathematical model. In the working process of the LOMPS, on the premise of meeting the requirements of the processing technology and support height, the revolution frequency of the CCOS grinding system should avoid the natural frequency of FSS and “mirror”, so as to avoid resonance and reduce the processing accuracy of the optical mirror.

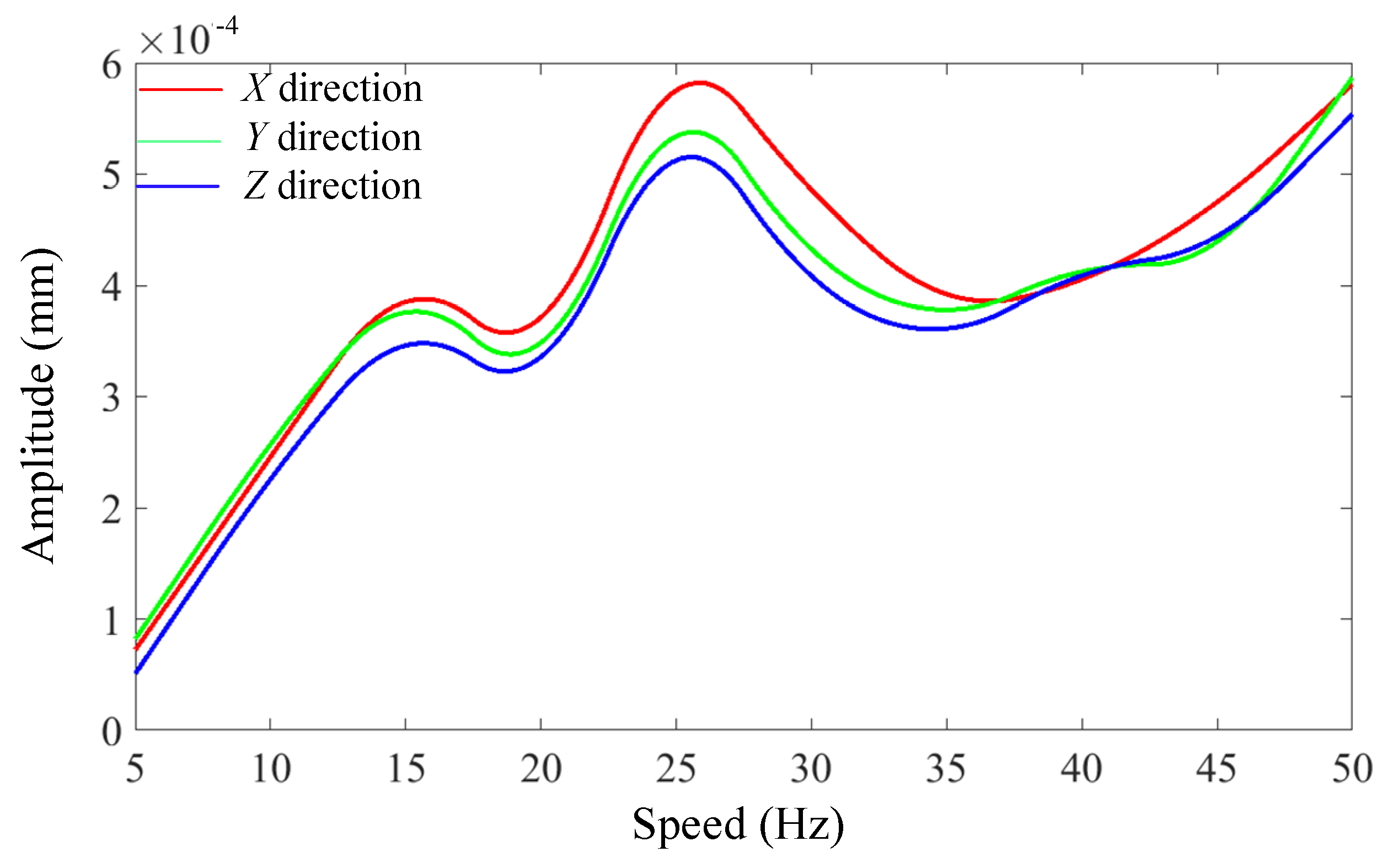

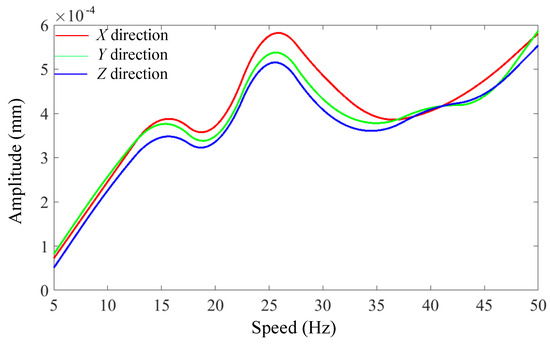

4.2.3. Amplitude of the CCOS Grinding System at Different Speeds

During the experiment, the 5-DOF-HPR completed a circular trajectory in 140 s. The support height of the FSS was 1 mm. The vibration information of the processed mirror was measured by changing the revolution frequency of the CCOS grinding system.

From the test results in Figure 24, it can be seen that, when the revolution frequency of the CCOS grinding system was 15, 25, and 50 Hz, the amplitude of the processed mirror significantly increased. This was related to the resonance of the first-order natural frequencies of the 5-DOF-HPR and the first-order natural frequencies of the FSS. In order to avoid the resonance of the machined mirror, the common speed of the CCOS grinding system should be adjusted according to the natural frequency of the FSS and the natural frequency of the 5-DOF-HPR to avoid the resonance of the machined mirror.

Figure 24.

Amplitude of the CCOS grinding system at different speeds.

5. Conclusions

To improve the processing accuracy of the LOMPS, the perturbation relationship of the natural frequency of the robots to the processed, the mirror surface, and the vibration coupling between the robots were studied. The vibration differential equations of each robot were established and simulated. Then, it was verified through experiments that the error between the experimental natural frequency of the 5-DOF-HPR and the simulation result was within 12.5%, and the error between the experimental natural frequency and the simulation result of the FSS was less than 16%. Compared with the first four natural frequencies of the bottom support and mirror, the natural frequency of the bottom support increased. Thus, the validity and accuracy of the established mathematical model were verified, providing a basis for follow-up research on path planning and control systems of the LOMPS. Finally, the amplitude of the machined mirror under different speeds of the 5-DOF-HPR, different support heights of the FSS, and different rotational speeds of the CCOS grinding system were measured, and the vibration characteristics of the machined mirror under different influencing factors were analyzed. The experimental results showed that, when the revolution frequency of the CCOS grinding system was close to the natural frequency of the 5-DOF-HPR and the natural frequency of the FSS, the resonance phenomenon occurred, resulting in an increase in amplitude.

The proposed method provides a theoretical basis for analyzing the vibration characteristics of the LOMPS and improving the surface accuracy of the processed mirror. It also provides an experimental basis for research on the dynamic characteristics of a machining system composed of multiple heterogeneous robots, such as this machine–electro-hydraulic collaborative work. At the same time, it also demonstrates the feasibility of precision machining of multiconfiguration robots in complex disturbance environments.

Author Contributions

Conceptualization, Z.J.; methodology, Z.Y.; software, Z.J.; validation, Z.J. and F.L.; formal analysis, Z.J.; investigation, H.L.; resources, Z.J. and Z.Y.; data curation, H.L.; writing—original draft preparation, Z.J.; writing—review and editing, Z.Y.; visualization, H.L.; supervision, Z.Y.; project administration, Z.Y.; funding acquisition, Z.J., H.L. and Z.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Doctoral Scientific Research Foundation of Suzhou University, grant number 2023BSK016 (Z.J.); the Key Project of Natural Science Research in Universities of Anhui Province, grant number 2022AH051380 (Z.Y.), 2023AH052237 (H.L.), and 2024AH051812 (Z.J.); the Excellent Scientific Research and Innovation Teams in Anhui Province’s Universities, grant number 2023AH010055 (Z.J., Z.Y.); the Key Research and Development Program Projects in Anhui Province, grant number 2023t070200 (Z.Y.); the Anhui Province Higher Education Provincial Quality Engineering Project, grant number 2023sdxx088 (Z.Y., Z.J.) and 2023cyts045 (Z.Y., Z.J.).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Fuchao Liu was employed by the company Shandong Xinsha Monorail Transport Equipment Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

| CCOS | Computer-Controlled Optical Surfacing |

| 5-DOF-HPR | Five-Degrees-of-Freedom Hybrid Processing Robot |

| FSS | Flexible Support System |

| LOMPS | Large Optical Mirror Processing System |

References

- Jin, Z.J.; Cheng, G.; Guo, F.; Chen, S.B. Human-machine-environment information fusion and control compensation strategy for large optical mirror processing system. Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci. 2020, 35, 2507–2523. [Google Scholar] [CrossRef]

- Jiang, B.C.; Zhao, D.W.; Wang, B.Q.; Zhao, H.J.; Liu, Y.H.; Lu, X.C. Flatness maintenance and roughness reduction of silicon mirror in chemical mechanical polishing process. Sci. China-Technol. Sci. 2020, 63, 166–172. [Google Scholar] [CrossRef]

- Kong, Y.X.; Cheng, G.; Guo, F.; Gu, W.; Zhang, L.B. Inertia matching analysis of a 5-DOF hybrid optical machining manipulator. J. Mech. Sci. Technol. 2019, 33, 4991–5002. [Google Scholar] [CrossRef]

- Sun, T.; Lian, B.B.; Song, Y.M.; Feng, L. Elastodynamic optimization of a 5-DoF parallel kinematic machine considering parameter uncertainty. IEEE-ASME Trans. Mechatron. 2019, 24, 315–325. [Google Scholar] [CrossRef]

- Lin, C.J.; Wang, H.C.; Wang, C.C. Automatic calibration of tool center point for six degree of freedom robot. Actuators 2023, 12, 107. [Google Scholar] [CrossRef]

- He, F.X.; Dai, L.; Chen, Q.S.; Liu, Y.; Luo, Z. Three-dimensional stability analysis of robotic machining process. Ind. Robot.-Int. J. Robot. Res. Appl. 2020, 47, 82–89. [Google Scholar] [CrossRef]

- Gierlak, P.; Warminski, J. Analysis of bifurcation vibrations of an industrial robot arm system with joints compliance. Appl. Sci. 2023, 13, 11941. [Google Scholar] [CrossRef]

- Ariano, A.; Perna, V.; Senatore, A.; Scatigno, R.; Nicolo, F.; Fazioli, F.; Avallone, G.; Pesce, S.; Gagliano, A. Simulation and experimental validation of novel trajectory planning strategy to reduce vibrations and improve productivity of robotic manipulator. Electronics 2020, 9, 581. [Google Scholar] [CrossRef]

- Hwang, S.W.; Bak, J.H.; Yoon, J.; Park, J.H. Oscillation Reduction and frequency analysis of under-constrained cable-driven parallel robot with three cables. Robotica 2020, 38, 375–395. [Google Scholar] [CrossRef]

- Zhang, T.; Lin, K.Y.; Zhang, A.M. Research on flexible dynamics of a 6-DOF industrial robot and residual vibration control with a pre-adaptive input shaper. J. Mech. Sci. Technol. 2019, 33, 1875–1889. [Google Scholar] [CrossRef]

- Min, F.Y.; Wang, G.; Liu, N. Collision detection and identification on robot manipulators based on vibration analysis. Sensors 2019, 19, 1080. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.J.; Chung, S.Y.; Kang, H.S.; Hwang, M.J. Trapezoidal motion profile to suppress residual vibration of flexible object moved by robot. Electronics 2019, 8, 30. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, K.P.; Jiao, J.; Cao, D.Q.; Chi, W.C.; Tang, J. Dynamic isotropy design and analysis of a six-DOF active micro-vibration isolation manipulator on satellites. Robot. Comput.-Integr. Manuf. 2018, 49, 408–425. [Google Scholar]

- Yang, H.Y.; Zhou, Z.G.; Dang, Y.G.; Wang, X.Y.; Li, G.G.; Xu, Z.D. Nonlinear dynamics characteristics of a magnetically actuated dual-spin capsule robot. Nonlinear Dyn. 2023, 111, 20771–20792. [Google Scholar] [CrossRef]

- Tang, X.W.; Li, Z.P.; Yan, R.; Peng, F.Y.; Fan, Z. Operational impact excitation method for milling robot end frequency response function identification under movement state and pose-dependent dynamic compliance analysis. J. Manuf. Sci. Eng.-Trans. ASME 2023, 145, 034501. [Google Scholar] [CrossRef]

- Hoevenaars, A.G.L.; Krut, S.; Herder, J.L. Jacobian-based natural frequency analysis of parallel manipulators. Mech. Mach. Theory 2020, 148, 103775. [Google Scholar] [CrossRef]

- Ma, S.G.; Liang, B.; Wang, T.S. Dynamic analysis of a hyper-redundant space manipulator with a complex rope network. Aerosp. Sci. Technol. 2020, 100, 105768. [Google Scholar] [CrossRef]

- Wu, J.J. Finite element analysis and vibration testing of a three-dimensional crane structure. Measurement 2006, 39, 740–749. [Google Scholar] [CrossRef]

- Nguyen, V.; Cvitanic, T.; Melkote, S. Data-driven modeling of the modal properties of a six-degrees-of-freedom industrial robot and its application to robotic milling. J. Manuf. Sci. Eng.-Trans. ASME 2019, 141, 121006. [Google Scholar] [CrossRef]

- Ganesh, S.S.; Rao, A.B.K. Design optimization of a 2-DOF parallel kinematic machine based on natural frequency. J. Mech. Sci. Technol. 2020, 34, 835–841. [Google Scholar] [CrossRef]

- Dong, C.L.; Liu, H.T.; Huang, T.; Chetwynd, D.G. A screw theory-based semi-analytical approach for elastodynamics of the tricept robot. J. Mech. Robot.-Trans. ASME 2019, 11, 031005. [Google Scholar] [CrossRef]

- Yang, Q.J.; Zhu, R.; Niu, Z.G.; Chen, C.; Mao, Q.; Zheng, Y.J. Natural frequency analysis of hydraulic quadruped robot and structural optimization of the leg. J. Dyn. Syst. Meas. Control-Trans. ASME 2020, 142, 011009. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Zhang, K.; Wang, Z.Q.; Lu, J.X. Design and analysis of demolition robot arm based on finite element method. Adv. Mech. Eng. 2019, 11, 1–9. [Google Scholar] [CrossRef]

- Guan, E.G.; Miao, H.H.; Li, P.B.; Liu, J.H.; Zhao, Y.Z. Dynamic model analysis of hydraulic support. Adv. Mech. Eng. 2019, 11, 168781401882014. [Google Scholar] [CrossRef]

- Lin, Z.H.; Huang, Y.D. Effect of bell plate structure on high- and low-frequency characteristics of hydraulic mount. Appl. Rheol. 2024, 34, 20240014. [Google Scholar] [CrossRef]

- Xie, B.W.; Yang, Y. Study on working characteristics of 4-column hydraulic support in lifting-lowering-moving state based on microcontact theory and rigid-flexible-mechanical-hydraulic coupling simulation model. Actuators 2024, 13, 193. [Google Scholar] [CrossRef]

- Xu, H.G.; Zhang, J.H.; Sun, G.M.; Huang, W.D.; Huang, X.C.; Lyu, F.; Xu, B.; Su, Q. The direct measurement of the cylinder block dynamic characteristics based on a non-contact method in an axial piston pump. Measurement 2021, 167, 108279. [Google Scholar] [CrossRef]

- Tao, M.L.; Lin, F.; Shu, L.; Deng, H.B.; Zhang, Y.H. Research on impedance network modeling and output characteristics of magnetostrictive electro-hydraulic actuator. J. Adv. Mech. Des. Syst. Manuf. 2023, 17, 2023. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).