PDA Nanoparticle-Induced Lubricating Film Formation in Marine Environments: An Active Approach

Abstract

1. Introduction

2. Methodology

2.1. Raw Materials

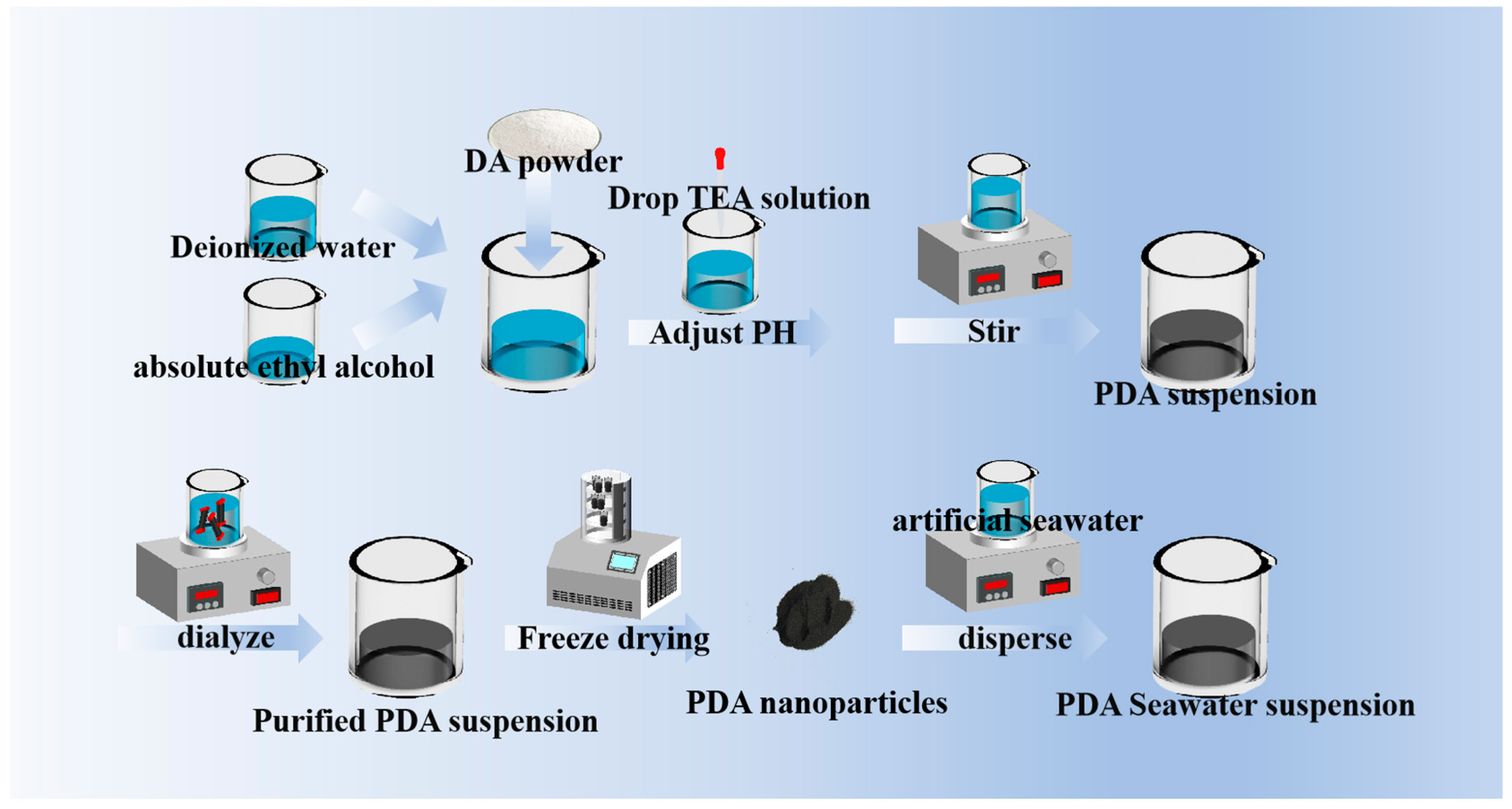

2.2. Preparation of PDA Nanoparticles and Composites

2.3. Characterization of PDA Nanoparticles and Worn Surfaces

2.4. Friction and Wear Testing

2.5. Worn Surfaces

3. Results

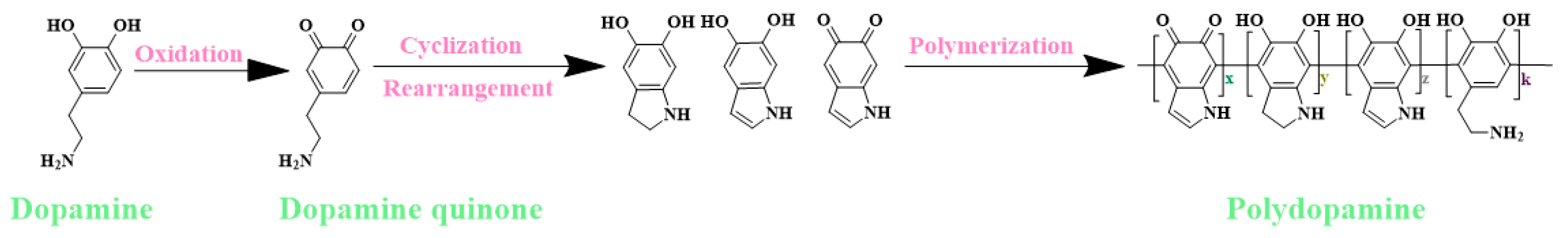

3.1. Analysis and Characterization of PDA Microspheres

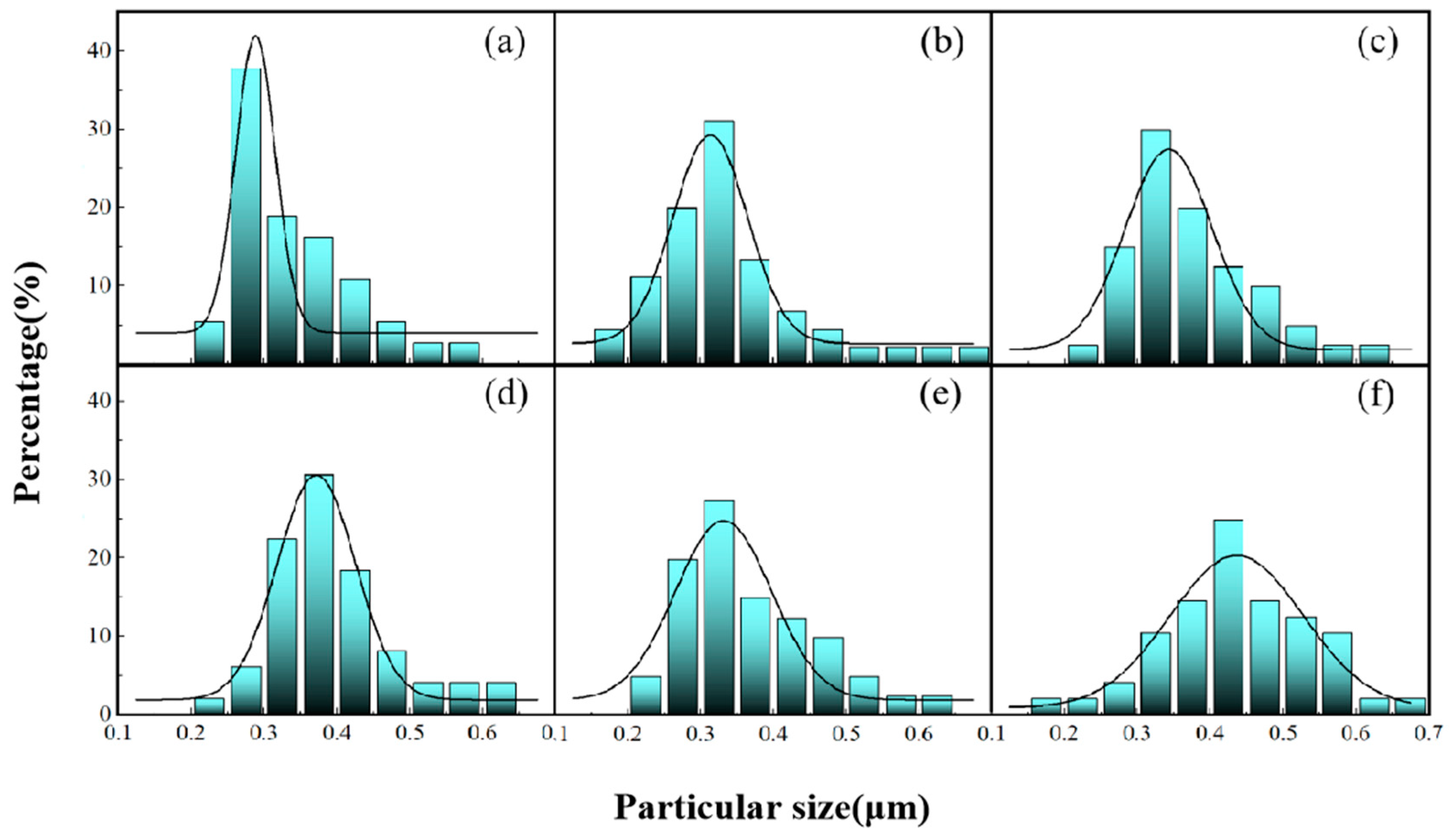

3.2. Effect of Stirring Rate on Particle Size of PDA Microspheres

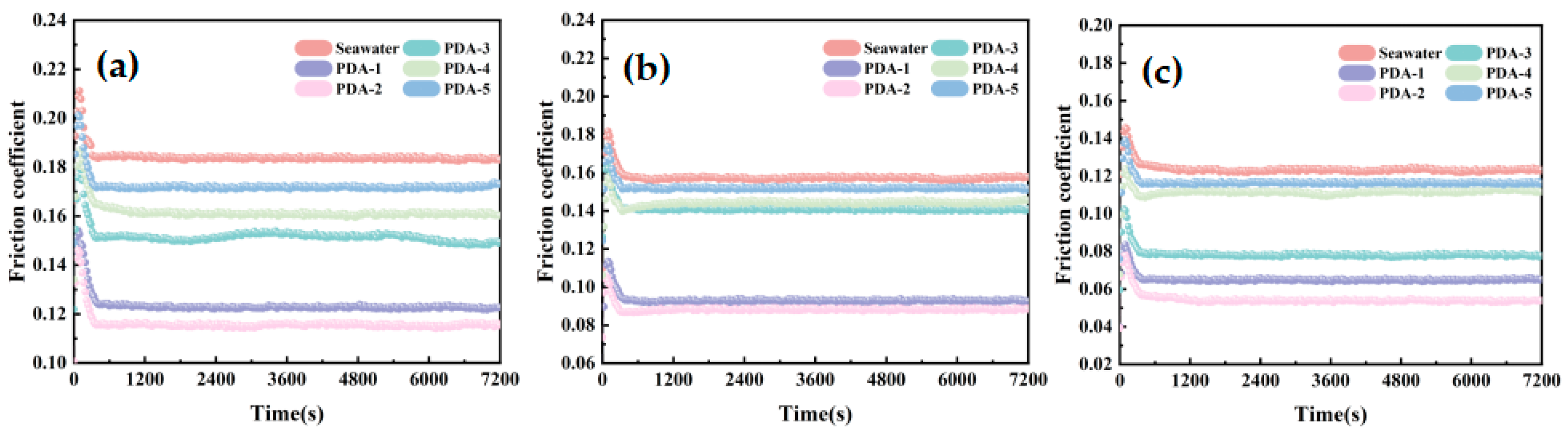

3.3. Analysis of Friction Coefficients

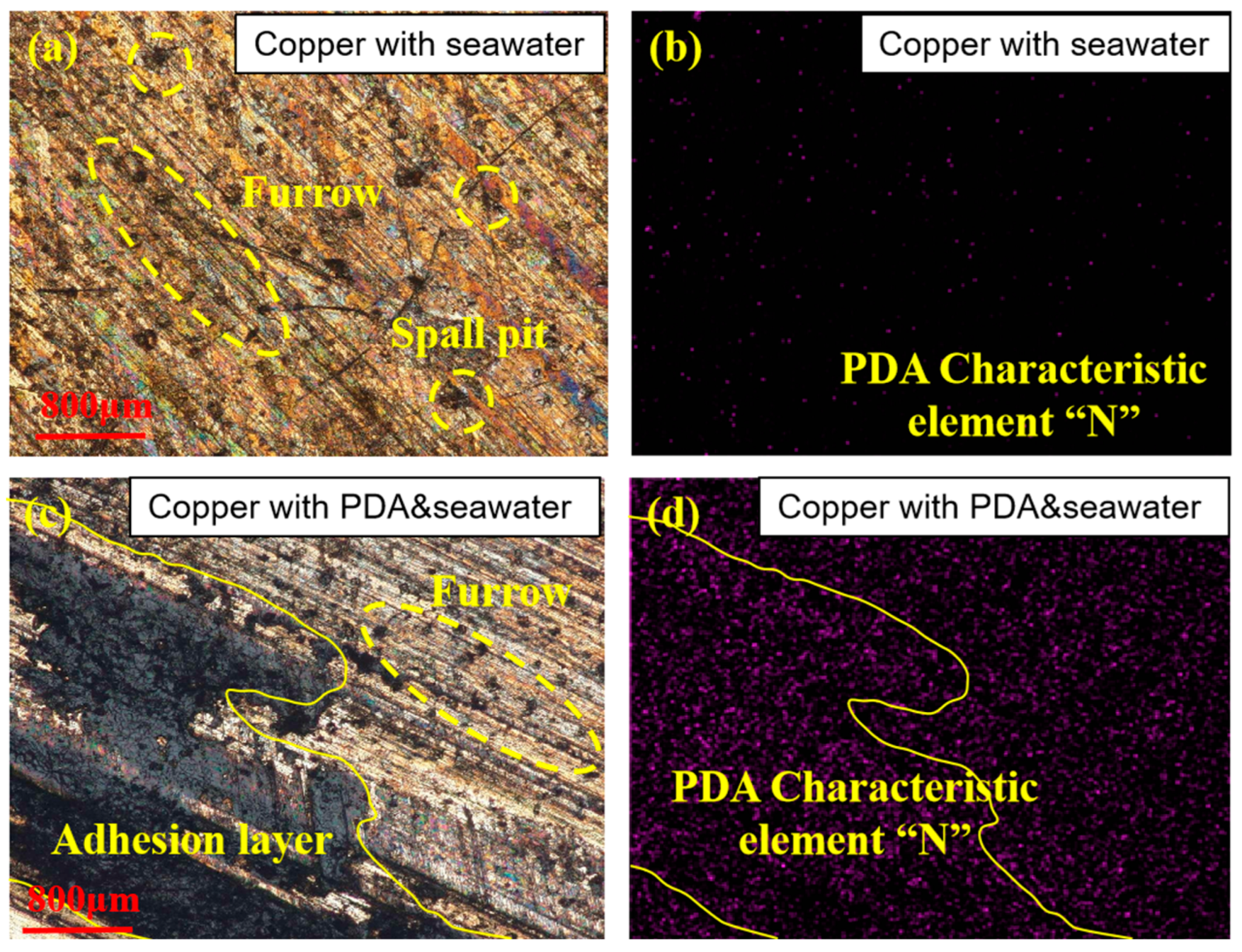

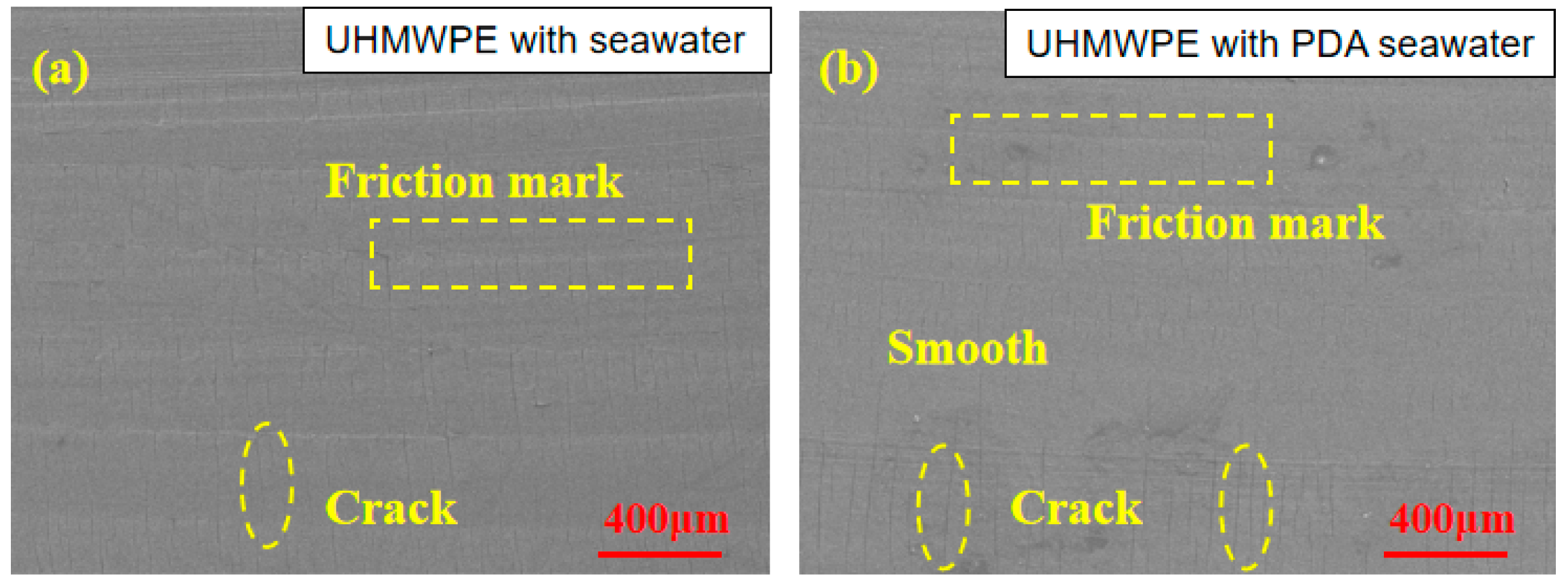

3.4. Analysis of Worn Surfaces

4. Discussion

5. Conclusions

- (1)

- PDA nanoparticles effectively enhance the lubricating ability of seawater under almost all experimental conditions, with the optimal concentration of PDA nanoparticles being 0.25 mg/mL;

- (2)

- Compared to the seawater environment, PDA nanoparticle seawater suspensions exhibit superior lubricating abilities, characterized by a lower friction coefficient, reduced wear rate, and smoother surface wear;

- (3)

- Compared to UHMWPE disks, PDA nanoparticles exhibit stronger adhesion on the worn surface of copper balls. A large adhesive layer is observed, and the adhesion strength between PDA and copper balls is sufficient to withstand frictional shear forces. Conversely, the adhesion strength between PDA and UHMWPE disks is relatively weaker, making it challenging to withstand strong shear forces during friction;

- (4)

- The synergistic effect of the biomimetic adhesion and hydration lubrication of PDA nanoparticles is the primary mechanism for enhancing tribological performance, ensuring long-lasting, stable, and targeted water lubrication throughout the friction process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Ouyang, W.; Cheng, Q.; Li, J.; Cheng, Q.; Li, R. Influences of bidirectional shaft inclination on lubrication and dynamic characteristics of the water-lubricated stern bearing. Mech. Syst. Signal Process. 2022, 169, 108623. [Google Scholar] [CrossRef]

- Lin, C.G.; Zou, M.S.; Zhang, H.C.; Qi, L.B.; Liu, S.X. Influence of different parameters on nonlinear friction-induced vibration characteristics of water lubricated stern bearings. Int. J. Nav. Archit. Ocean. Eng. 2021, 13, 746–757. [Google Scholar] [CrossRef]

- Jin, L.; Scheerer, H.; Andersohn, G.; Oechsner, M.; Hellmann, D. Experimental study on the tribochemical smoothening process between self-mated silicon carbide in a water-lubricated surface-contact reciprocating test. Friction 2018, 7, 181–191. [Google Scholar] [CrossRef]

- Savio, D.; Falk, K.; Moseler, M. Slipping domains in water-lubricated microsystems for improved load support. Tribol. Int. 2018, 120, 269–279. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, Z.; Yang, Z.; Wang, C.; Yuan, C. Study on tribological properties of a novelcomposite by filling microcapsules into UHMWPE matrix for water lubrication. Tribol. Int. 2021, 153, 106629. [Google Scholar] [CrossRef]

- McGhee, E.O.; Pitenis, A.A.; Urueña, J.M.; Schulze, K.D.; McGhee, A.J.; O’Bryan, C.S.; Bhattacharjee, T.; Angelini, T.E.; Sawyer, W.G. In situ, measurements of contact dynamics in speed-dependent hydrogel friction. Biotribology 2018, 13, 23–29. [Google Scholar] [CrossRef]

- Cao, Y.; Kampf, N.; Kosinska, M.K.; Steinmeyer, J.; Klein, J. Interactions between bilayers of phospholipids mixture extracted from human osteoarthritic synovial fluid. Biotribology 2021, 25, 100157. [Google Scholar] [CrossRef]

- Wang, C.; Bai, X.; Guo, Z.; Dong, C.; Yuan, C. A strategy that combines a hydrogel and graphene oxide to improve the water-lubricated performance of ultrahigh molecular weight polyethylene. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106207. [Google Scholar] [CrossRef]

- Mu, L.W.; Feng, X.; Shi, Y.J.; Wang, H.Y.; Lu, X.H. Friction and Wear Behaviors of Solid Lubricants/Polyimide Composites in Liquid Mediums. Mater. Sci. Forum 2010, 654–656, 2763–2766. [Google Scholar] [CrossRef]

- Seror, J.; Zhu, L.; Goldberg, R.; Day, A.J.; Klein, J. Supramolecular synergy in the boundary lubrication of synovial joints. Nat. Commun. 2015, 6, 6497. [Google Scholar] [CrossRef]

- Lee, S.L. A Proposed Model of Boundary Lubrication by Synovial Fluid: Structuring of Boundary Water. J. Biomech. Eng. 2010, 101, 185. [Google Scholar] [CrossRef]

- Xue, G.; Zhang, Y.; Xie, T.; Zhang, Z.; Liu, Q.; Li, X.; Gou, X. Cell adhesion-mediated piezoelectric self-stimulation on polydopamine-modified poly(vinylidene fluoride) membranes. ACS Appl. Mater. Interfaces 2021, 13, 17361–17371. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Lee, S.; Kim, C.; Shin, H. One-step harvest and delivery of micropatterned cell sheets mimicking the multi-cellular microenvironment of vascularized tissue. ActaBiomater 2021, 132, 176–187. [Google Scholar] [CrossRef] [PubMed]

- Sa, R.; Wei, Z.; Yan, Y.; Wang, L.; Wang, W.; Zhang, L.; Ning, N.; Tian, M. Catechol and poxy functionalized ultrahigh molecular weight polyethylene (UHMWPE) fibers with improved surface activity and interfacial adhesion. Compos. Sci. Technol. 2015, 113, 54–62. [Google Scholar] [CrossRef]

- Huang, M.; Yao, Z.; Wu, Q.; Zheng, Y.; Liu, J.; Li, C. Robustness-heterogeneity-induced ultrathin 2D structure in Li plating for highly reversible Li-metal batteries. ACS Appl. Mater. Interfaces 2020, 12, 46132–46145. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, F.K.; Han, Y.; Gaikwad, R.; Leonenko, Z.; Zhao, B. Surface and tribological behaviors of the bioinspired polydopamine thin films under dry and wet conditions. Biomacromolecules 2013, 14, 394–405. [Google Scholar] [CrossRef]

- Songfeng, E.; Shi, L.; Guo, Z. Tribological properties of self-assembled gold nanoparticles on silicon with polydopamine as the adhesion layer. Appl. Surf. Sci. 2014, 292, 750–755. [Google Scholar]

- Ou, J.; Wang, Y.; Li, C.; Wang, F.; Xue, M.; Wang, J. Tribological behaviors of a novel trilayer nanofilm: The influence of outer chain length and interlayer thickness. Surf. Interface Anal. 2013, 45, 1182–1187. [Google Scholar] [CrossRef]

- Mi, Y.; Wang, Z.; Liu, X.; Yang, S.; Wang, H.; Ou, J.; Li, Z.; Wang, J. A simple and feasible in-situ reduction route for preparation of graphene lubricant films applied to a variety of substrates. J. Mater. Chem. 2012, 22, 8036. [Google Scholar] [CrossRef]

- Ou, J.; Liu, L.; Wang, J.; Wang, F.; Xue, M.; Li, W. Fabrication and Tribological Investigation of a Novel Hydrophobic Polydopamine/Graphene Oxide Multilayer Film. Tribol. Lett. 2012, 48, 407–415. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Hu, M.; Zheng, Z.; Wang, K.; Li, X. Preparation of Ni/graphene hydrophobic composite coating with micro-nano binary structure by poly-dopamine modification. Surf. Coat. Technol. 2018, 353, 1–7. [Google Scholar] [CrossRef]

- Wang, C.; Bai, X.; Dong, C.; Guo, Z.; Yuan, C. Friction properties of polyacrylamide hydrogel particle/HDPE composite under water lubrication. Polymer 2019, 180, 121703. [Google Scholar] [CrossRef]

- Chen, G.; Jin, B.; Zhao, J.; Li, Y.; He, Y.; Luo, J. Efficient one-pot synthesis of mussel-inspired Cu- doped polydopamine nanoparticles with enhanced lubrication under heavy loads. Chem. Eng. J. 2021, 426, 131287. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Z.; Yang, M.; Yuan, J.; Li, P.; Chen, Z.; Men, X. Surface modification of YS-20 with polydopamine for improving the tribological properties of polyimide composites. Friction 2022, 10, 411–421. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, J.; Chen, K.; Liu, S.; Zhang, M.; He, Y.; Luo, J. Ultrastable lubricating properties of robust self-repairing tribofilms enabled by in situ-assembled polydopamine nanoparticles. Langmuir 2020, 36, 852–861. [Google Scholar] [CrossRef]

- Tian, Q.; Jia, X.; Yang, J.; Wang, S.; Li, Y.; Shao, D.; Song, H. Polydopamine-stabilized ZIF-8: Improved water stability and lubrication performance. Appl. Surf. Sci. 2022, 578, 152120. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Ge, Z.; Wang, C.; Xi, Y. PDA Nanoparticle-Induced Lubricating Film Formation in Marine Environments: An Active Approach. Machines 2024, 12, 817. https://doi.org/10.3390/machines12110817

Zou X, Ge Z, Wang C, Xi Y. PDA Nanoparticle-Induced Lubricating Film Formation in Marine Environments: An Active Approach. Machines. 2024; 12(11):817. https://doi.org/10.3390/machines12110817

Chicago/Turabian StyleZou, Xinqi, Zhenghao Ge, Chaobao Wang, and Yuyang Xi. 2024. "PDA Nanoparticle-Induced Lubricating Film Formation in Marine Environments: An Active Approach" Machines 12, no. 11: 817. https://doi.org/10.3390/machines12110817

APA StyleZou, X., Ge, Z., Wang, C., & Xi, Y. (2024). PDA Nanoparticle-Induced Lubricating Film Formation in Marine Environments: An Active Approach. Machines, 12(11), 817. https://doi.org/10.3390/machines12110817