AI-Assisted 3D Modeling Strategy for Microstructure-Based Functional Surfaces Using ChatGPT and Random Forest

Abstract

:1. Introduction

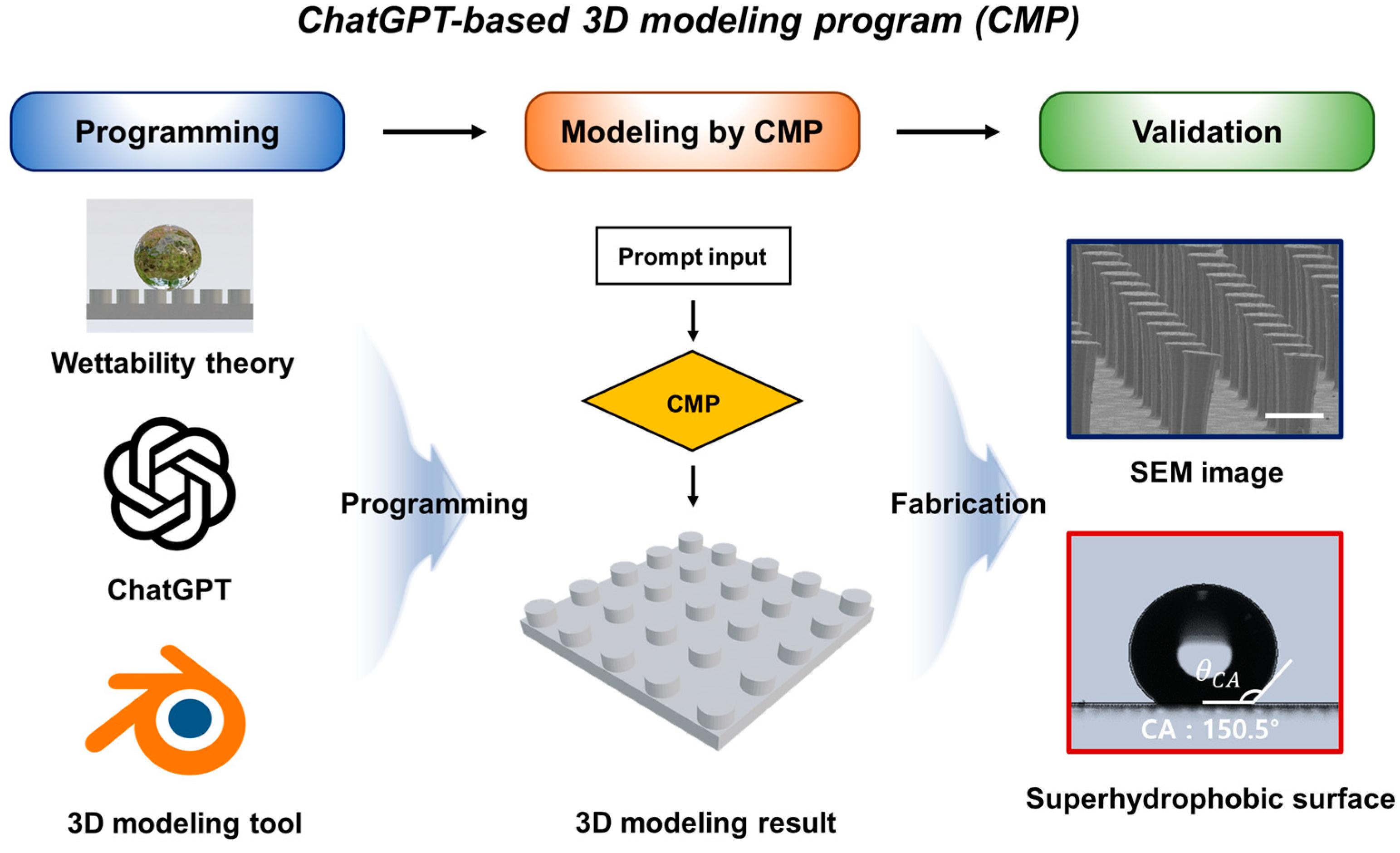

2. Experimental Sections

2.1. Fabrication of Master Mold

2.2. Fabrication of Superhydrophobic Surface with PDMS

2.3. Measurement

3. Results and Discussion

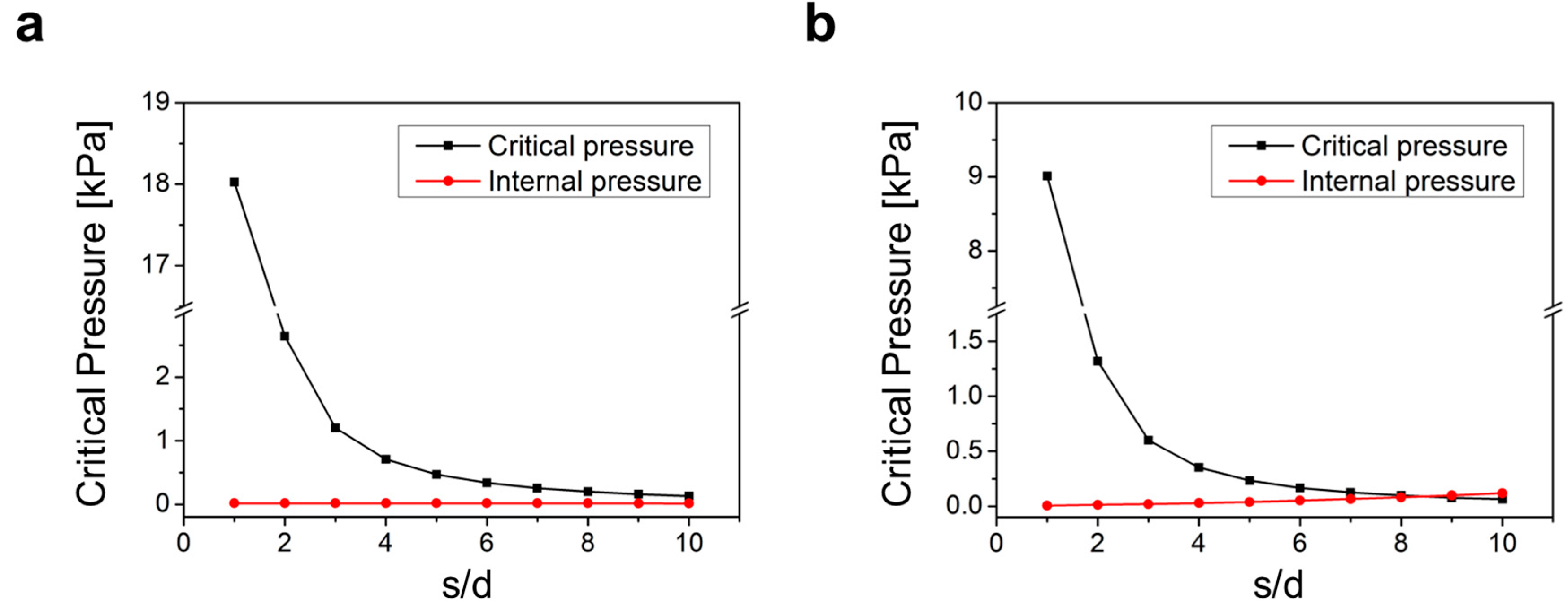

3.1. Wetting Transition Theory

3.2. Modified Wettability Theory

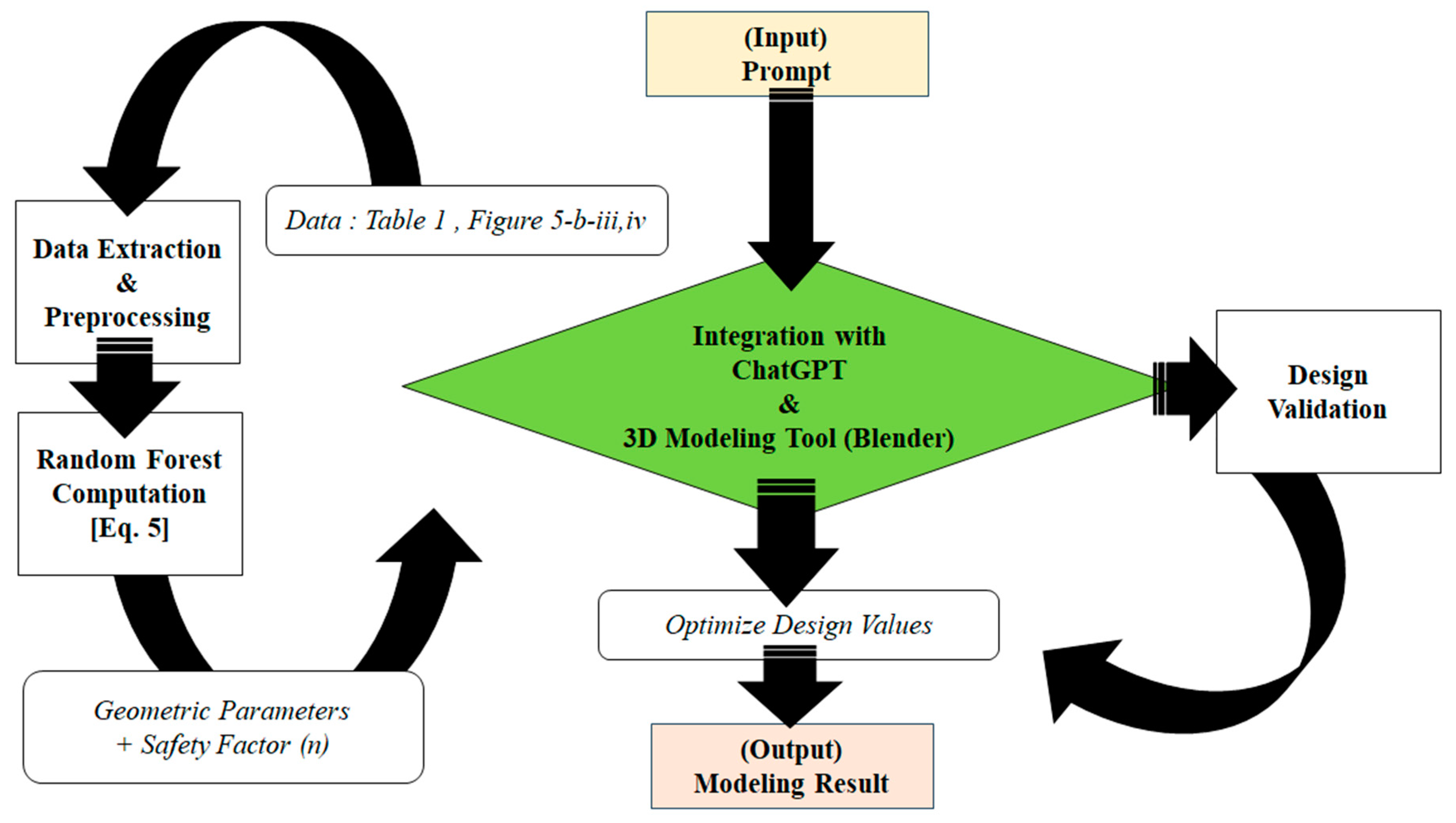

3.3. Programming

3.3.1. Data Preprocessing and Classification

3.3.2. ChatGPT-Based Modeling Program (CMP)

3.4. Validation

4. Conclusions

Future Directions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alghazzawi, T.F. Advancements in CAD/CAM technology: Options for practical implementation. J. Prosthodont. Res. 2016, 60, 72–84. [Google Scholar] [CrossRef]

- Abduo, J.; Lyons, K.; Bennamoun, M. Trends in computer-aided manufacturing in prosthodontics: A review of the available streams. Int. J. Dent. 2014, 2014, 783948. [Google Scholar] [CrossRef] [PubMed]

- Sarcar, M.; Rao, K.M.; Narayan, K.L. Computer Aided Design and Manufacturing; PHI Learning Pvt. Ltd.: Delhi, India, 2008. [Google Scholar]

- Li, J.; Lim, K.; Yang, H.; Ren, Z.; Raghavan, S.; Chen, P.-Y.; Buonassisi, T.; Wang, X. AI applications through the whole life cycle of material discovery. Matter 2020, 3, 393–432. [Google Scholar] [CrossRef]

- Vaishya, R.; Javaid, M.; Khan, I.H.; Haleem, A. Artificial Intelligence (AI) applications for COVID-19 pandemic. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 337–339. [Google Scholar] [CrossRef]

- López, C. Artificial intelligence and advanced materials. Adv. Mater. 2023, 35, 2208683. [Google Scholar] [CrossRef] [PubMed]

- Sha, W.; Guo, Y.; Yuan, Q.; Tang, S.; Zhang, X.; Lu, S.; Guo, X.; Cao, Y.-C.; Cheng, S. Artificial intelligence to power the future of materials science and engineering. Adv. Intell. Syst. 2020, 2, 1900143. [Google Scholar] [CrossRef]

- Singh, A.V.; Rosenkranz, D.; Ansari, M.H.D.; Singh, R.; Kanase, A.; Singh, S.P.; Johnston, B.; Tentschert, J.; Laux, P.; Luch, A. Artificial intelligence and machine learning empower advanced biomedical material design to toxicity prediction. Adv. Intell. Syst. 2020, 2, 2000084. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Wetting study of patterned surfaces for superhydrophobicity. Ultramicroscopy 2007, 107, 1033–1041. [Google Scholar] [CrossRef]

- 1Bico, J.; Thiele, U.; Quéré, D. Wetting of textured surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2002, 206, 41–46. [Google Scholar]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Ciasca, G.; Businaro, L.; Papi, M.; Notargiacomo, A.; Chiarpotto, M.; De Ninno, A.; Palmieri, V.; Carta, S.; Giovine, E.; Gerardino, A. Self-assembling of large ordered DNA arrays using superhydrophobic patterned surfaces. Nanotechnology 2013, 24, 495302. [Google Scholar] [CrossRef]

- McHale, G. Cassie Wenzel: Were They Really So Wrong? Langmuir 2007, 23, 8200–8205. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Young, T. An essay on the cohesion of fluids. In Proceedings of the Abstracts of the Papers Printed in the Philosophical Transactions of the Royal Society of London; The Royal Society: London, UK, 1832; pp. 171–172. [Google Scholar]

- Peta, K. Multiscale Wettability of Microtextured Irregular Surfaces. Materials 2024, 17, 5716. [Google Scholar] [CrossRef] [PubMed]

- Biau, G.; Scornet, E. A random forest guided tour. Test 2016, 25, 197–227. [Google Scholar] [CrossRef]

- Testas, A. Random Forest Classification with Scikit-Learn and PySpark. In Distributed Machine Learning with PySpark: Migrating Effortlessly from Pandas and Scikit-Learn; Springer: Berlin/Heidelberg, Germany, 2023; pp. 243–258. [Google Scholar]

- Díaz Lantada, A.; Franco-Martínez, F.; Hengsbach, S.; Rupp, F.; Thelen, R.; Bade, K. Artificial Intelligence Aided Design of Microtextured Surfaces: Application to Controlling Wettability. Nanomaterials 2020, 10, 2287. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.-S.; Yu, Y.; Zhao, Z.-H. Effects of hydraulic pressure on the stability and transition of wetting modes of superhydrophobic surfaces. Langmuir 2005, 21, 12207–12212. [Google Scholar] [CrossRef]

- Park, C.I.; Jeong, H.E.; Lee, S.H.; Cho, H.S.; Suh, K.Y. Wetting transition and optimal design for microstructured surfaces with hydrophobic and hydrophilic materials. J. Colloid Interface Sci. 2009, 336, 298–303. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Kang, B.S.; Kwak, M.K. Facile design and realization of extremely water-repellent surface by mimicking the greta oto’s wings. Int. J. Mech. Sci. 2022, 222, 107218. [Google Scholar] [CrossRef]

- Saha, A.A.; Mitra, S.K.; Tweedie, M.; Roy, S.; McLaughlin, J. Experimental and numerical investigation of capillary flow in SU8 and PDMS microchannels with integrated pillars. Microfluid. Nanofluidics 2009, 7, 451–465. [Google Scholar] [CrossRef]

- Jung, Y.; Bhushan, B. Wetting behaviour during evaporation and condensation of water microdroplets on superhydrophobic patterned surfaces. J. Microsc. 2008, 229, 127–140. [Google Scholar] [CrossRef]

- Ulrich, S.; Stoll, S.; Pefferkorn, E. Computer simulations of homogeneous deposition of liquid droplets. Langmuir 2004, 20, 1763–1771. [Google Scholar] [CrossRef]

- Annavarapu, R.K.; Kim, S.; Wang, M.; Hart, A.J.; Sojoudi, H. Explaining evaporation-triggered wetting transition using local force balance model and contact line-fraction. Sci. Rep. 2019, 9, 405. [Google Scholar] [CrossRef] [PubMed]

- Montero de Hijes, P.; Shi, K.; Noya, E.G.; Santiso, E.; Gubbins, K.; Sanz, E.; Vega, C. The Young–Laplace equation for a solid–liquid interface. J. Chem. Phys. 2020, 153, 191102. [Google Scholar] [CrossRef]

- Erbil, H.Y.; McHale, G.; Newton, M. Drop evaporation on solid surfaces: Constant contact angle mode. Langmuir 2002, 18, 2636–2641. [Google Scholar] [CrossRef]

- Drevon, D.; Fursa, S.R.; Malcolm, A.L. Intercoder reliability and validity of WebPlotDigitizer in extracting graphed data. Behav. Modif. 2017, 41, 323–339. [Google Scholar] [CrossRef]

- Gao, J.; Zhao, J.; Liu, L.; Xue, W. Dimensional effects of polymer pillar arrays on hydrophobicity. Surf. Eng. 2016, 32, 125–131. [Google Scholar] [CrossRef]

- Lee, J.B.; Gwon, H.R.; Lee, S.H.; Cho, M. Wetting transition characteristics on microstructured hydrophobic surfaces. Mater. Trans. 2010, 51, 1709–1711. [Google Scholar] [CrossRef]

- Yeo, J.; Choi, M.J.; Kim, D.S. Robust hydrophobic surfaces with various micropillar arrays. J. Micromech. Microeng. 2010, 20, 025028. [Google Scholar] [CrossRef]

- Kameya, Y. Wettability modification of polydimethylsiloxane surface by fabricating micropillar and microhole arrays. Mater. Lett. 2017, 196, 320–323. [Google Scholar] [CrossRef]

- Achiam, J.; Adler, S.; Agarwal, S.; Ahmad, L.; Akkaya, I.; Aleman, F.L.; Almeida, D.; Altenschmidt, J.; Altman, S.; Anadkat, S. Gpt-4 technical report. arXiv 2023, arXiv:2303.08774. [Google Scholar]

- Kojima, T.; Gu, S.S.; Reid, M.; Matsuo, Y.; Iwasawa, Y. Large language models are zero-shot reasoners. Adv. Neural Inf. Process. Syst. 2022, 35, 22199–22213. [Google Scholar]

- White, J.; Fu, Q.; Hays, S.; Sandborn, M.; Olea, C.; Gilbert, H.; Elnashar, A.; Spencer-Smith, J.; Schmidt, D.C. A prompt pattern catalog to enhance prompt engineering with chatgpt. arXiv 2023, arXiv:2302.11382. [Google Scholar]

- Chen, H.; Muros-Cobos, J.L.; Amirfazli, A. Contact angle measurement with a smartphone. Rev. Sci. Instrum. 2018, 89, 035117. [Google Scholar]

- Kabir, H.; Garg, N. Machine learning enabled orthogonal camera goniometry for accurate and robust contact angle measurements. Sci. Rep. 2023, 13, 1497. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noh, Y.; Park, S.; Lee, S. AI-Assisted 3D Modeling Strategy for Microstructure-Based Functional Surfaces Using ChatGPT and Random Forest. Machines 2024, 12, 930. https://doi.org/10.3390/machines12120930

Noh Y, Park S, Lee S. AI-Assisted 3D Modeling Strategy for Microstructure-Based Functional Surfaces Using ChatGPT and Random Forest. Machines. 2024; 12(12):930. https://doi.org/10.3390/machines12120930

Chicago/Turabian StyleNoh, Younghun, Sucheong Park, and Sungho Lee. 2024. "AI-Assisted 3D Modeling Strategy for Microstructure-Based Functional Surfaces Using ChatGPT and Random Forest" Machines 12, no. 12: 930. https://doi.org/10.3390/machines12120930

APA StyleNoh, Y., Park, S., & Lee, S. (2024). AI-Assisted 3D Modeling Strategy for Microstructure-Based Functional Surfaces Using ChatGPT and Random Forest. Machines, 12(12), 930. https://doi.org/10.3390/machines12120930