Machine Learning, Mechatronics, and Stretch Forming: A History of Innovation in Manufacturing Engineering

Abstract

:1. Introduction

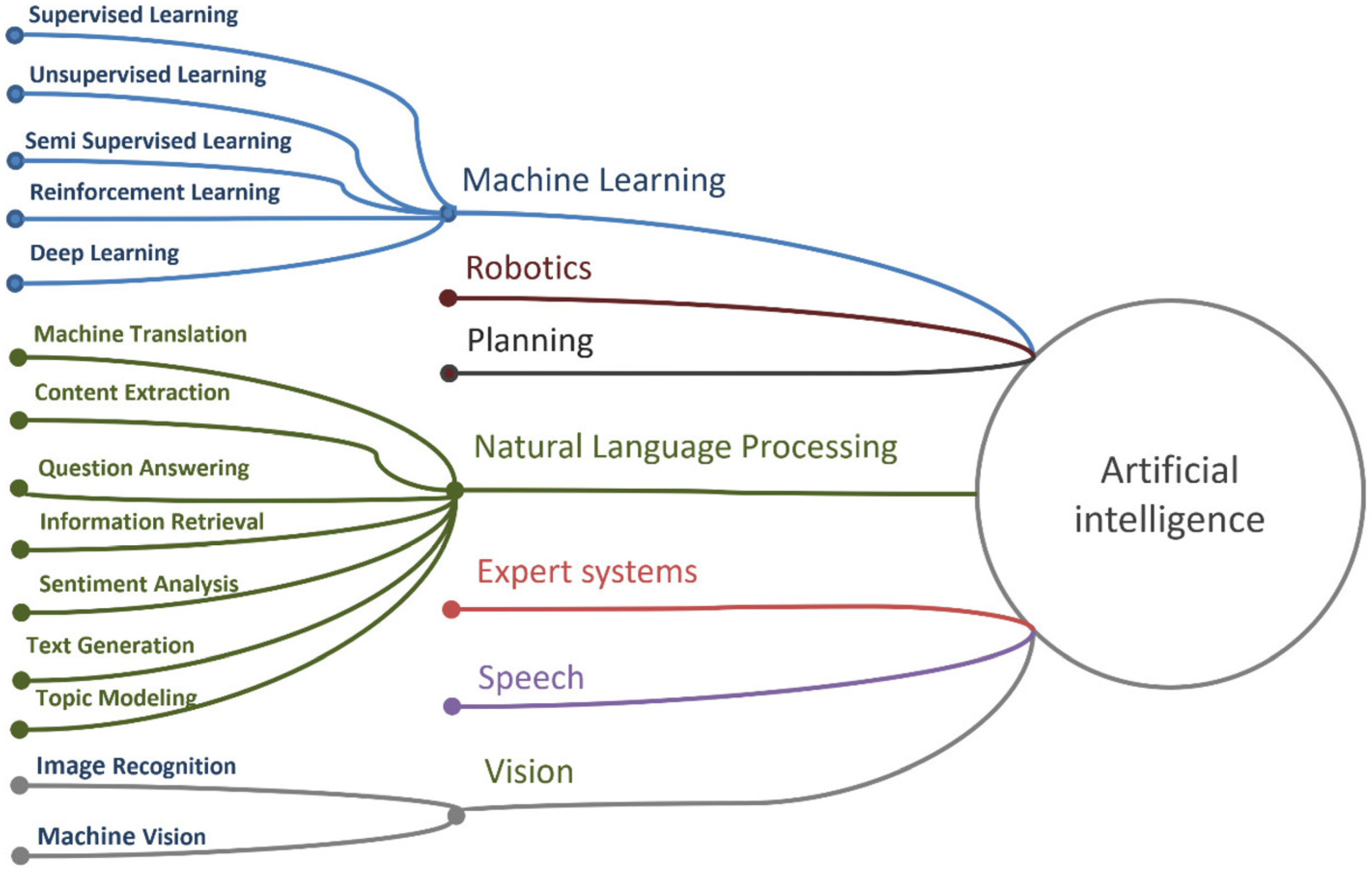

- In the case of machine learning, the topics analyzed in this subsection focus on various algorithms, including rough set theory, learning methods, reinforcement learning, fuzzy logic systems, neural force control frameworks, artificial evolution simulations, neural networks, genetic algorithms, pattern recognition, AI in transportation, machine learning’s impact on society and industry, the complexity of ML systems, brain–computer interfaces, humanoid control, structural component design, metaheuristics, mineral resource estimation, deep learning frameworks, automatic defect detection in infrastructure, quality inspection in manufacturing, software quality and ML, defect recognition on steel surfaces, and AI implementation challenges;

- In the case of mechatronics, being multidisciplinary, this subsection focuses on various aspects such as robotics research and development, 3D noncontact sensor systems, self-organizing manipulators, collision behavior simulation, robot navigation, robot control and learning techniques, cooperative mobile robotics, motion planning techniques, controllers for acrobots, real-time, hierarchical, sensor-based robotic system architecture, plan-n-scan, and a constructive control approach for legged robots. It also explores disruptions in multi-robotic systems and the development of reconfigurable machines;

- The subsection related to stretch forming focuses on topics about various aspects of sheet metal forming, including material properties and the use of flexible manufacturing systems, the development, and usage of finite element method software, digital processing for sheet forming, fracture prediction, and optimization of process parameters. Additionally, this study explored the formability of aluminum, titanium, and steel alloys and the design of vertical wall manufacturing.

2. Basics and Beginnings

2.1. Machine Learning

2.2. Mechatronics

2.3. Stretch Forming

3. Summary of the 2010s—More Industrial Processes Require Improved Algorithms

3.1. Machine Learning Advances

3.2. Mechatronics

3.3. Stretch Forming as a Computer-Aided Manufacturing Process

4. Recent Developments—Using Autonomous Processes

5. Future Directions of Research

- Integrating machine learning algorithms into mechatronic systems enables real-time monitoring and control of stretch-forming processes. By incorporating sensor data from different stages, such as force, strain, and temperature, the machine learning model can be enhanced. Machine learning is essential for advancing material characterization and design in the context of stretch forming;

- By predicting material properties trained on extensive datasets of material properties and forming data, machine learning models can predict the behavior of new materials under stretch-forming conditions;

- By utilizing large amounts of manufacturing and real-time sensor data to predict material behavior during forming, it is possible to anticipate material performance, thus enabling fine-tuning the process parameters for desired outcomes;

- It is also possible to explore the potential of machine learning in structural component design, such as stress pattern analysis and material performance optimization, particularly in fiber-reinforced polymer composites. Through the use of machine learning algorithms, engineers can uncover intricate connections between material properties and structural behavior, resulting in components that are not only more efficient but also lighter;

- By utilizing anomaly detection algorithms, sensor data can be analyzed to detect defects early on, allowing for timely corrective measures to be implemented;

- By using machine learning, it is possible to enhance process parameters such as tool path, forming speed, and blank holder pressure. This optimization can result in higher product quality, waste reduction, and improved efficiency;

- Developing smart and adaptive tooling for stretch forming can be achieved through the use of mechatronic systems; possible approaches include embedding sensors in the tooling to enable real-time feedback on the forming process, facilitating adjustments to the tool shape for precise forming of complex geometries, such as utilizing piezoelectric actuators or modular and reconfigurable tooling systems controlled by mechatronic systems could push a step forward the development of tools for various part geometries, enhancing flexibility and minimizing downtime;

- Creating products with ease of manufacturing in mind. Designers can enhance component optimization for functionality and manufacturability by integrating machine learning with CAD software;

- Exploring the potential of integrating machine learning algorithms into industrial robots opens up possibilities for complex tasks such as metal forming and production line automation and communication. Through the utilization of machine learning, industrial robots can enhance their ability to analyze intricate data patterns, resulting in heightened accuracy and efficiency across a range of manufacturing procedures;

- Research on enhancing brain–computer interface (BCI) technology has the potential to revolutionize communication and control of external devices. By the integration of advanced machine learning algorithms and multi-sensor data fusion techniques, BCI systems have the potential to enhance human–machine interaction across a wide range of domains;

- It is essential to thoroughly examine the ethical and societal consequences of incorporating AI applications to promote responsible technological progress. By addressing both technical obstacles and societal effects, researchers and developers can establish frameworks and guidelines to guarantee the ethical implementation of AI systems. This will help cultivate trust and accountability in their utilization across different domains.

6. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mukhamediev, R.I.; Symagulov, A.; Kuchin, Y.; Yakunin, K.; Yelis, M. From Classical Machine Learning to Deep Neural Networks: A Simplified Scientometric Review. Appl. Sci. 2021, 11, 5541. [Google Scholar] [CrossRef]

- Nassehi, A.; Zhong, R.Y.; Li, X.; Epureanu, B.I. Chapter 11—Review of Machine Learning Technologies and Artificial Intelligence in Modern Manufacturing Systems. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Mourtzis, D., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 317–348. ISBN 978-0-12-823657-4. [Google Scholar]

- Tercan, H.; Meisen, T. Machine Learning and Deep Learning Based Predictive Quality in Manufacturing: A Systematic Review. J. Intell. Manuf. 2022, 33, 1879–1905. [Google Scholar] [CrossRef]

- Palm, G. Warren McCulloch and Walter Pitts: A Logical Calculus of the Ideas Immanent in Nervous Activity. In Proceedings of the Brain Theory, Trieste, Italy, 1–4 October 1984; Palm, G., Aertsen, A., Eds.; Springer: Berlin/Heidelberg, Germany, 1986; pp. 229–230. [Google Scholar]

- Turing, A.M. I.—Computing Machinery and Intelligence. Mind 1950, LIX, 433–460. [Google Scholar] [CrossRef]

- Schaeffer, J. Samuel’s Checkers Player. In Encyclopedia of Cognitive Science; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; ISBN 9780470018866. [Google Scholar]

- Sanger, T.; Baljekar, P.N. The Perceptron: A Probabilistic Model for Information Storage and Organization in the Brain. Psychol. Rev. 1958, 65, 386–408. [Google Scholar]

- Cover, T.; Hart, P. Nearest Neighbor Pattern Classification. IEEE Trans. Inf. Theory 1967, 13, 21–27. [Google Scholar] [CrossRef]

- Werbos, P.J. Generalization of Backpropagation with Application to a Recurrent Gas Market Model. Neural Netw. 1988, 1, 339–356. [Google Scholar] [CrossRef]

- Moravec, H.P. The Stanford Cart and the CMU Rover. In Autonomous Robot Vehicles; Cox, I.J., Wilfong, G.T., Eds.; Springer: New York, NY, USA, 1990; pp. 407–419. ISBN 978-1-4613-8997-2. [Google Scholar]

- Umbrello, S. AI Winter. In Encyclopedia of Artificial Intelligence: The Past, Present, and Future of AI; Klein, M., Frana, P., Eds.; ABC-CLIO: Santa Barbara, CA, USA, 2021. [Google Scholar]

- Toosi, A.; Bottino, A.G.; Saboury, B.; Siegel, E.; Rahmim, A. A Brief History of AI: How to Prevent Another Winter (A Critical Review). PET Clin. 2021, 16, 449–469. [Google Scholar] [CrossRef]

- Grzymala-Busse, J.W. Knowledge Acquisition under Uncertainty—A Rough Set Approach. J. Intell. Robot. Syst. 1988, 1, 3–16. [Google Scholar] [CrossRef]

- Pawlak, Z. Rough Sets. Int. J. Comput. Inf. Sci. 1982, 11, 341–356. [Google Scholar] [CrossRef]

- Pau, L.F. Sensor Data Fusion. J. Intell. Robot. Syst. 1988, 1, 103–116. [Google Scholar] [CrossRef]

- Tourassis, V.D. Computer Control of Robotic Manipulators Using Predictors. J. Intell. Robot. Syst. 1989, 2, 261–275. [Google Scholar] [CrossRef]

- Shoureshi, R.; Momot, M.; Mitchell, O.R.; Feddema, J. Vision-Based Intelligent Control for Automated Assembly. J. Intell. Robot. Syst. 1989, 2, 153–170. [Google Scholar] [CrossRef]

- Badami, V.V.; Nielsen, P.; Comly, J.B. An Intelligent Controller for Process Automation. J. Intell. Robot. Syst. 1991, 4, 55–73. [Google Scholar] [CrossRef]

- Kang, H.; Vachtsevanos, G. Fuzzy Hypercubes: Linguistic Learning/Reasoning Systems for Intelligent Control and Identification. J. Intell. Robot. Syst. 1993, 7, 215–232. [Google Scholar] [CrossRef]

- Wu, C.-J. A Learning Fuzzy Algorithm for Motion Planning of Mobile Robots. J. Intell. Robot. Syst. 1994, 11, 209–221. [Google Scholar] [CrossRef]

- Janabi-Sharifi, F. Collision: Modeling, Simulation and Identification of Robotic Manipulators Interacting with Environments. J. Intell. Robot. Syst. 1995, 13, 1–44. [Google Scholar] [CrossRef]

- Brown, S.C.; Passino, K.M. Intelligent Control for an Acrobot. J. Intell. Robot. Syst. 1997, 18, 209–248. [Google Scholar] [CrossRef]

- Pons, J.L.; Ceres, R.; Jiménez, A.R.; Calderón, L.; Martin, J.M. Nonlinear Performance Index (Npi): A Tool for Manipulator Dynamics Improvement. J. Intell. Robot. Syst. 1997, 18, 277–287. [Google Scholar] [CrossRef]

- Buckmann, O.; Krömker, M.; Berger, U. An Application Platform for the Development and Experimental Validation of Mobile Robots for Health Care Purposes. J. Intell. Robot. Syst. 1998, 22, 331–350. [Google Scholar] [CrossRef]

- Pao, Y.-H. Autonomous Machine Learning of Effective Control Strategies with Connectionist-Net. J. Intell. Robot. Syst. 1988, 1, 35–53. [Google Scholar] [CrossRef]

- Ribeiro, C.H.C. Embedding a Priori Knowledge in Reinforcement Learning. J. Intell. Robot. Syst. 1998, 21, 51–71. [Google Scholar] [CrossRef]

- Nürnberger, A.; Nauck, D.; Kruse, R. Neuro-Fuzzy Control Based on the NEFCON-Model: Recent Developments. Soft Comput. 1999, 2, 168–182. [Google Scholar] [CrossRef]

- Lin, S.-T.; Tzeng, S.-J. Neural Network Force Control for Industrial Robots. J. Intell. Robot. Syst. 1999, 24, 253–268. [Google Scholar] [CrossRef]

- Zavlangas, P.G.; Tzafestas, S.G. Industrial Robot Navigation and Obstacle Avoidance Employing Fuzzy Logic. J. Intell. Robot. Syst. 2000, 27, 85–97. [Google Scholar] [CrossRef]

- Eng, K.; Robertson, A.P.; Blackman, D.R. Managing Complexity in Large Learning Robotic Systems. J. Intell. Robot. Syst. 2000, 27, 263–273. [Google Scholar] [CrossRef]

- Lee, M.-R.; Rhee, H. The Effect of Evolution in Artificial Life Learning Behavior. J. Intell. Robot. Syst. 2001, 30, 399–414. [Google Scholar] [CrossRef]

- Vijayakumar, S.; D’souza, A.; Shibata, T.; Conradt, J.; Schaal, S. Statistical Learning for Humanoid Robots. Auton. Robot. 2002, 12, 55–69. [Google Scholar] [CrossRef]

- Loo, C.K.; Mandava, R.; Rao, M.V.C. A Hybrid Intelligent Active Force Controller for Articulated Robot Arms Using Dynamic Structure Neural Network. J. Intell. Robot. Syst. 2004, 40, 113–145. [Google Scholar] [CrossRef]

- Samanta, B.; Al-Balushi, K.R.; Al-Araimi, S.A. Artificial Neural Networks and Genetic Algorithm for Bearing Fault Detection. Soft Comput. 2006, 10, 264–271. [Google Scholar] [CrossRef]

- Rubinstein, A. Modeling Bounded Rationality; MIT Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Tsang, E.P.K. Computational Intelligence Determines Effective Rationality. Int. J. Autom. Comput. 2008, 5, 63–66. [Google Scholar] [CrossRef]

- Doitsidis, L.; Tsourveloudis, N.C.; Piperidis, S. Evolution of Fuzzy Controllers for Robotic Vehicles: The Role of Fitness Function Selection. J. Intell. Robot. Syst. 2009, 56, 469. [Google Scholar] [CrossRef]

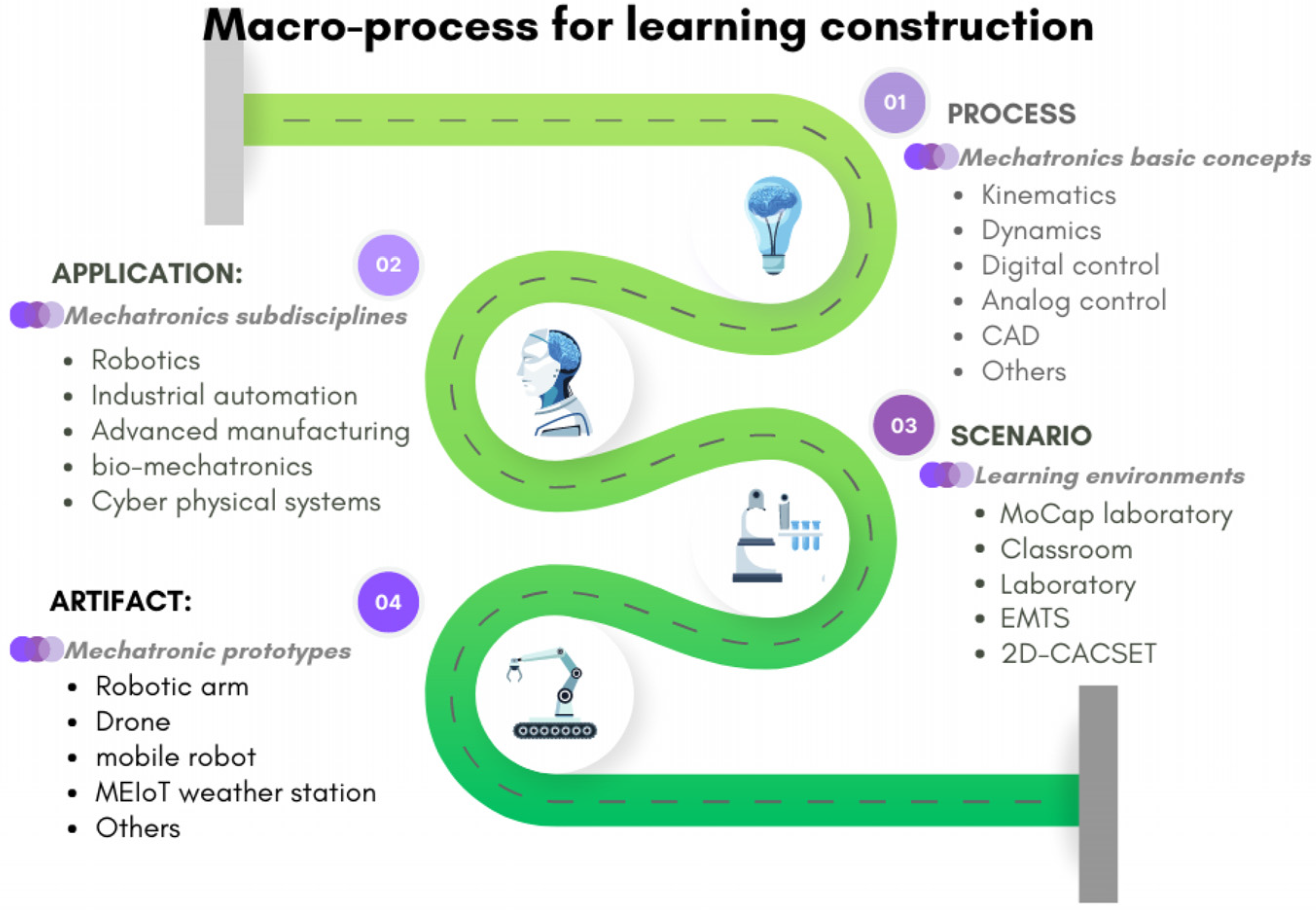

- Lopez-Neri, E.; Luque-Vega, L.F.; González-Jiménez, L.E.; Guerrero-Osuna, H.A. Design and Implementation of a Robotic Arm for a MoCap System within Extended Educational Mechatronics Framework. Machines 2023, 11, 893. [Google Scholar] [CrossRef]

- Atashzar, S.F.; Carriere, J.; Tavakoli, M. Review: How Can Intelligent Robots and Smart Mechatronic Modules Facilitate Remote Assessment, Assistance, and Rehabilitation for Isolated Adults with Neuro-Musculoskeletal Conditions? Front. Robot. AI 2021, 8, 610529. [Google Scholar] [CrossRef]

- Bradley, D. Mechatronics—More Questions than Answers. Mechatronics 2010, 20, 827–841. [Google Scholar] [CrossRef]

- Milecki, A. 45 Years of Mechatronics—History and Future. In Proceedings of the Progress in Automation, Robotics and Measuring Techniques, Warsaw, Poland, 18–20 March 2015; Szewczyk, R., Zieliński, C., Kaliczyńska, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 127–136. [Google Scholar]

- Ceccarelli, M. Advances in the Mechanical Design of Robots. Inventions 2018, 3, 10. [Google Scholar] [CrossRef]

- Czichos, H. Systems Thinking in Health Technology. In Introduction to Systems Thinking and Interdisciplinary Engineering; Czichos, H., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 113–115. ISBN 978-3-031-18239-6. [Google Scholar]

- Ollero, A.; Boverie, S.; Goodall, R.; Sasiadek, J.; Erbe, H.; Zuehlke, D. Mechatronics, robotics and components for automation and control ifac cc milestone report. IFAC Proc. Vol. 2005, 38, 1–13. [Google Scholar] [CrossRef]

- Tomizuka, M. Mechatronics: From the 20th to 21st Century. Control Eng. Pract. 2002, 10, 877–886. [Google Scholar] [CrossRef]

- Yousef Ibrahim, M. Mechatronics: Opportunities and Challenges for Tertiary Education. IFAC Proc. Vol. 2000, 33, 1055–1060. [Google Scholar] [CrossRef]

- Schiehlen, W. From Cybernetics to Mechatronics: Seven Decades of Interdisciplinary Engineering. PAMM 2019, 19, e201900108. [Google Scholar] [CrossRef]

- Fukuda, T.; Nakagawa, S. Approach to the Dynamically Reconfigurable Robotic System. J. Intell. Robot. Syst. 1988, 1, 55–72. [Google Scholar] [CrossRef]

- Valavanis, K.P.; Yuan, P.H. Hardware and Software for Intelligent Robotic Systems. J. Intell. Robot. Syst. 1989, 1, 343–373. [Google Scholar] [CrossRef]

- Siciliano, B. Kinematic Control of Redundant Robot Manipulators: A Tutorial. J. Intell. Robot. Syst. 1990, 3, 201–212. [Google Scholar] [CrossRef]

- Megahed, S.M. Inverse Kinematics of Spherical Wrist Robot Arms: Analysis and Simulation. J. Intell. Robot. Syst. 1992, 5, 211–227. [Google Scholar] [CrossRef]

- Fiala, J.; Wavering, A.J. Experimental Evaluation of Cartesian Stiffness Control on a Seven Degree-of-Freedom Robot Arm. J. Intell. Robot. Syst. 1992, 5, 5–24. [Google Scholar] [CrossRef]

- Nicosia, S.; Tornambè, A.; Valigi, P. State Estimation in Robotic Manipulators: Some Experimental Results. J. Intell. Robot. Syst. 1993, 7, 321–351. [Google Scholar] [CrossRef]

- Castro, E.; Seereeram, S.; Singh, J.; Desrochers, A.A.; Wen, J.T. A Real-Time Computer Controller for a Robotic Filament Winding System. J. Intell. Robot. Syst. 1993, 7, 73–93. [Google Scholar] [CrossRef]

- Amirat, M.Y.; Pontnau, J.; Artigue, F. A Three-Dimensional Measurement System for Robot Applications. J. Intell. Robot. Syst. 1994, 9, 291–299. [Google Scholar] [CrossRef]

- Xue, G.; Fukuda, T.; Asama, H. Error Recovery in the Assembly of a Self-Organizing Manipulator by Using Active Visual and Force Sensing. Auton. Robot. 1995, 1, 179–186. [Google Scholar] [CrossRef]

- Tsai, D.-M. A Three-Dimensional Machine-Vision Approach for Automatic Robot Programming. J. Intell. Robot. Syst. 1995, 12, 23–48. [Google Scholar] [CrossRef]

- Ratering, S.; Gini, M. Robot Navigation in a Known Environment with Unknown Moving Obstacles. Auton. Robot. 1995, 1, 149–165. [Google Scholar] [CrossRef]

- Racković, M. Construction of a Translator for Robot-Programming Languages. J. Intell. Robot. Syst. 1996, 15, 209–232. [Google Scholar] [CrossRef]

- Abouelsoud, A.A.; Sultan, M.A.; Hassan, M.F. Linear State Feedback Regulator for Rigid Link Manipulators. J. Intell. Robot. Syst. 1996, 15, 291–305. [Google Scholar] [CrossRef]

- Cao, Y.U.; Fukunaga, A.S.; Kahng, A. Cooperative Mobile Robotics: Antecedents and Directions. Auton. Robot. 1997, 4, 7–27. [Google Scholar] [CrossRef]

- Prabhu, S.M.; Garg, D.P. Artificial Neural Network Based Robot Control: An Overview. J. Intell. Robot. Syst. 1996, 15, 333–365. [Google Scholar] [CrossRef]

- Lee, J.-K.; Cho, H.S. Mobile Manipulator Motion Planning for Multiple Tasks Using Global Optimization Approach. J. Intell. Robot. Syst. 1997, 18, 169–190. [Google Scholar] [CrossRef]

- Matía, F.; Jiménez, A. Multisensor Fusion: An Autonomous Mobile Robot. J. Intell. Robot. Syst. 1998, 22, 129–141. [Google Scholar] [CrossRef]

- Hebert, T.; Valavanis, K.; Kolluru, R. A Real-Time, Hierarchical, Sensor-Based Robotic System Architecture. J. Intell. Robot. Syst. 1998, 21, 1–27. [Google Scholar] [CrossRef]

- Renton, P.; Greenspan, M.; ElMaraghy, H.A.; Zghal, H. Plan-N-Scan: A Robotic System for Collision-Free Autonomous Exploration and Workspace Mapping. J. Intell. Robot. Syst. 1999, 24, 207–234. [Google Scholar] [CrossRef]

- M’Sirdi, N.K.; Manamanni, N.; El Ghanami, D. Control Approach for Legged Robots with Fast Gaits. J. Intell. Robot. Syst. 2000, 27, 321–343. [Google Scholar] [CrossRef]

- Gustafson, S.; Gustafson, D.A. Issues in the Scaling of Multi-Robot Systems for General Problem Solving. Auton. Robot. 2006, 20, 125–136. [Google Scholar] [CrossRef]

- Orebäck, A.; Christensen, H.I. Evaluation of Architectures for Mobile Robotics. Auton. Robot. 2003, 14, 33–49. [Google Scholar] [CrossRef]

- Bi, Z.M.; Lang, S.Y.T.; Verner, M.; Orban, P. Development of Reconfigurable Machines. Int. J. Adv. Manuf. Technol. 2008, 39, 1227–1251. [Google Scholar] [CrossRef]

- Wu, J.-H.; Pen, C.-C.; Jiang, J.-A. Applications of the Integrated High-Performance CMOS Image Sensor to Range Finders—From Optical Triangulation to the Automotive Field. Sensors 2008, 8, 1719–1739. [Google Scholar] [CrossRef] [PubMed]

- Grigoras, C.C.; Zichil, V.; Chirita, B.; Ciubotariu, V.A. Adaptive Stretch-Forming Process: A Computer Vision and Statistical Analysis Approach. Machines 2021, 9, 357. [Google Scholar] [CrossRef]

- Gotoh, M.; Kim, Y.; Yamashita, M. A Fundamental Study of Can Forming by the Stretch-Drawing Process. J. Mater. Process Technol. 2003, 138, 545–550. [Google Scholar] [CrossRef]

- Bayoumi, A.E.; Joshi, R. On the Formability/Instability of Stretch-Forming Sheet Metals. Appl. Mech. Rev. 1992, 45, S154–S164. [Google Scholar] [CrossRef]

- Groche, P.; Bäcker, F. Springback in Stringer Sheet Stretch Forming. CIRP Ann. 2013, 62, 275–278. [Google Scholar] [CrossRef]

- Kuboki, T.; Jin, Y.; Murata, M. Prediction of Stress—Strain Diagram from Forming Load in Stretch Forming. Int. J. Mech. Sci. 2012, 60, 46–53. [Google Scholar] [CrossRef]

- Gray, L.G.; Smith, H.P. Stretch-Forming Machine. US2739634A, 27 March 1956. [Google Scholar]

- Schulz, P.; Hoffman, D. Materials Research for High Speed Civil Transport and Generic Hypersonics: Metals Durability; National Aeronautics and Space Administration, Langley Research Center: Hampton, VA, USA, 1996. [Google Scholar]

- Abu Samk, K.; Yu, B.; Hibbard, G.D. Architectural Design in Stretch-Formed Microtruss Composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 955–961. [Google Scholar] [CrossRef]

- Satoh, J.; Gotoh, M.; Maeda, Y. Stretch-Drawing of Titanium Sheets. J. Mater. Process Technol. 2003, 139, 201–207. [Google Scholar] [CrossRef]

- El-Domiaty, A.A.; Shabara, M.A.N.; Al-Ansary, M.D. Determination of Stretch-Bendability of Sheet Metals. Int. J. Adv. Manuf. Technol. 1996, 12, 207–220. [Google Scholar] [CrossRef]

- Vlahovic, D.; Liewald, M. Benchmarking Methods for Short Cycle Stretch-Forming. Int. J. Mater. Form. 2008, 1, 193–196. [Google Scholar] [CrossRef]

- Lee, J.; Barlat, F. Analytical Approach to Failure Determination of Advanced High-Strength Steel in Stretch-Bending Mode. Steel Res. Int. 2021, 92, 2000124. [Google Scholar] [CrossRef]

- Kurukuri, S.; Miroux, A.; Wisselink, H.; van den Boogaard, T. Simulation of Stretch Forming with Intermediate Heat Treatments of Aircraft Skins. Int. J. Mater. Form. 2011, 4, 129–140. [Google Scholar] [CrossRef]

- Wu, R.; Zeng, L.; Fan, J.; Peng, Z.; Zhao, Y. Composition, Heat Treatment, Microstructure and Loading Condition Based Machine Learning Prediction of Creep Life of Superalloys. Mech. Mater. 2023, 187, 104819. [Google Scholar] [CrossRef]

- Huang, Y.-M. Finite Element Analysis of Axisymmetric Sheet Stretching Process. Int. J. Adv. Manuf. Technol. 2007, 33, 1114–1121. [Google Scholar] [CrossRef]

- Nakamachi, E. A Finite Element Simulation of the Sheet Metal Forming Process. Int. J. Numer. Methods Eng. 1988, 25, 283–292. [Google Scholar] [CrossRef]

- Keum, Y.T.; Wagoner, R.H. A Finite Element Program for Simulating Sheet-Metal Stretch Forming Processes. KSME J. 1992, 6, 6–15. [Google Scholar] [CrossRef]

- Yan, A.-M.; Klappka, I. Springback in Stretch Forming Process of Aeronautic Panel Production by Finite Element Simulation. Int. J. Mater. Form. 2008, 1, 201–204. [Google Scholar] [CrossRef]

- Takuda, H.; Mori, K.; Fujimoto, H.; Hatta, N. Fracture Prediction in Stretch Forming Using Finite Element Simulation Combined with Ductile Fracture Criterion. Arch. Appl. Mech. 1997, 67, 143–150. [Google Scholar] [CrossRef]

- Chen, K.-S.; Ou, K.-S. Chapter 17—MEMS Residual Stress Characterization: Methodology and Perspective. In Handbook of Silicon Based MEMS Materials and Technologies, 2nd ed.; Tilli, M., Motooka, T., Airaksinen, V.-M., Franssila, S., Paulasto-Kröckel, M., Lindroos, V., Eds.; William Andrew Publishing: Boston, MA, USA, 2015; pp. 398–412. ISBN 978-0-323-29965-7. [Google Scholar]

- Hsu, T.C.; Shang, H.M. Mechanics of Sheet Metal Formed by Hydraulic Pressure into Axisymmetrical Shells. Exp. Mech. 1976, 16, 337–342. [Google Scholar] [CrossRef]

- Magee, C.L.; Davies, R.G.; Beardmore, P. Factors Influencing Automotive Application of High Strength Steels. JOM 1980, 32, 28–35. [Google Scholar] [CrossRef]

- Lee, D. Computer-Aided Control of Sheet Metal Forming Processes. JOM 1982, 34, 20–29. [Google Scholar] [CrossRef]

- Farah, B.N. Expert Systems: An Application in Flexible Manufacturing. J. Intell. Robot. Syst. 1988, 1, 73–88. [Google Scholar] [CrossRef]

- Joshi, R.B.; Bayoumi, A.E.; Zbib, H.M. The Use of Digital Processing in Studying Stretch-Forming Sheet Metal. Exp. Mech. 1992, 32, 117–123. [Google Scholar] [CrossRef]

- ASTM E643-15; Standard Test Method for Ball Punch Deformation of Metallic Sheet Material. Book of Standards Volume: 03.01; ASTM: West Conshohocken, PA, USA, 2016.

- Ren, B.; Morris, J.G.; Beaudoin, A.J. The Influence of the Crystallographic Texture on the Biaxial Stretchability of AA 5182 Sheet. JOM 1996, 48, 22–25. [Google Scholar] [CrossRef]

- Chen, W.; Yang, J.; Wu, X.; Lu, D.; Guo, W. Finite Element Simulations of Sheet Metal Forming under Complex Strain Paths. Front. Mech. Eng. China 2007, 2, 399–403. [Google Scholar] [CrossRef]

- Papaioanu, A.; Liewald, M. Further Development of the SCS Stretch-Forming Technology with Assistance of Forming Simulation. Int. J. Mater. Form. 2010, 3, 155–158. [Google Scholar] [CrossRef]

- Paunoiu, V.; Cekan, P.; Gavan, E.; Nicoara, D. Numerical Simulations in Reconfigurable Multipoint Forming. Int. J. Mater. Form. 2008, 1, 181–184. [Google Scholar] [CrossRef]

- Panda, S.K.; Kumar, D.R. Study of Formability of Tailor-Welded Blanks in Plane-Strain Stretch Forming. Int. J. Adv. Manuf. Technol. 2009, 44, 675–685. [Google Scholar] [CrossRef]

- IBM. What Is Supervised Learning? Available online: https://www.ibm.com/topics/supervised-learning (accessed on 15 January 2024).

- Maulud, D.; Abdulazeez, A.M. A Review on Linear Regression Comprehensive in Machine Learning. J. Appl. Sci. Technol. Trends 2020, 1, 140–147. [Google Scholar] [CrossRef]

- Maalouf, M. Logistic Regression in Data Analysis: An Overview. Int. J. Data Anal. Tech. Strateg. 2011, 3, 281–299. [Google Scholar] [CrossRef]

- Blockeel, H.; Devos, L.; Frénay, B.; Nanfack, G.; Nijssen, S. Decision Trees: From Efficient Prediction to Responsible AI. Front. Artif. Intell. 2023, 6, 1124553. [Google Scholar] [CrossRef] [PubMed]

- Smith, R.E.; Jiang, M.K.; Bacardit, J.; Stout, M.; Krasnogor, N.; Hirst, J.D. A Learning Classifier System with Mutual-Information-Based Fitness. Evol. Intell. 2010, 3, 31–50. [Google Scholar] [CrossRef]

- Cervantes, J.; Garcia-Lamont, F.; Rodríguez-Mazahua, L.; Lopez, A. A Comprehensive Survey on Support Vector Machine Classification: Applications, Challenges and Trends. Neurocomputing 2020, 408, 189–215. [Google Scholar] [CrossRef]

- Zhang, Z. Introduction to Machine Learning: K-Nearest Neighbors. Ann. Transl. Med. 2016, 4, 218. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Shen, W. A Review of Ensemble Learning Algorithms Used in Remote Sensing Applications. Appl. Sci. 2022, 12, 8654. [Google Scholar] [CrossRef]

- Bergmann, D. What Is Semi-Supervised Learning? Available online: https://www.ibm.com/topics/semi-supervised-learning (accessed on 15 January 2024).

- Cascante-Bonilla, P.; Tan, F.; Qi, Y.; Ordonez, V. Curriculum Labeling: Revisiting Pseudo-Labeling for Semi-Supervised Learning. Proc. AAAI Conf. Artif. Intell. 2020, 35, 6912–6920. [Google Scholar] [CrossRef]

- Zhang, X.; Zou, Y.; Li, S. Semi-Supervised Generative Adversarial Network with Guaranteed Safeness for Industrial Quality Prediction. Comput. Chem. Eng. 2021, 153, 107418. [Google Scholar] [CrossRef]

- IBM. What Is Unsupervised Learning? Available online: https://www.ibm.com/topics/unsupervised-learning (accessed on 15 January 2024).

- Ikotun, A.M.; Ezugwu, A.E.; Abualigah, L.; Abuhaija, B.; Heming, J. K-Means Clustering Algorithms: A Comprehensive Review, Variants Analysis, and Advances in the Era of Big Data. Inf. Sci. 2023, 622, 178–210. [Google Scholar] [CrossRef]

- Märzinger, T.; Kotík, J.; Pfeifer, C. Application of Hierarchical Agglomerative Clustering (HAC) for Systemic Classification of Pop-Up Housing (PUH) Environments. Appl. Sci. 2021, 11, 11122. [Google Scholar] [CrossRef]

- Chen, Y. DBSCAN Is Semi-Spectral Clustering. In Proceedings of the 2020 6th International Conference on Big Data and Information Analytics (BigDIA), Shenzhen, China, 4–6 December 2020; pp. 257–264. [Google Scholar]

- Greenacre, M.; Groenen, P.J.F.; Hastie, T.; D’Enza, A.I.; Markos, A.; Tuzhilina, E. Principal Component Analysis. Nat. Rev. Methods Primers 2022, 2, 100. [Google Scholar] [CrossRef]

- Mummert, T.; Subramanian, D.; Vu, L.; Pham, N. What Is Reinforcement Learning? Available online: https://developer.ibm.com/learningpaths/get-started-automated-ai-for-decision-making-api/what-is-automated-ai-for-decision-making (accessed on 15 January 2024).

- Watkins, C.J.C.H.; Dayan, P. Q-Learning. Mach. Learn. 1992, 8, 279–292. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Li, T.-H.S.; Lin, C.-J. Backward Q-Learning: The Combination of Sarsa Algorithm and Q-Learning. Eng. Appl. Artif. Intell. 2013, 26, 2184–2193. [Google Scholar] [CrossRef]

- Zhang, Z.; Zou, Y.; Lai, J.; Xu, Q. M2DQN: A Robust Method for Accelerating Deep Q-Learning Network. In Proceedings of the 2023 15th International Conference on Machine Learning and Computing, Zhuhai, China, 17–20 February 2023. [Google Scholar]

- Dong, R.; Du, J.; Liu, Y.; Heidari, A.A.; Chen, H. An Enhanced Deep Deterministic Policy Gradient Algorithm for Intelligent Control of Robotic Arms. Front. Neuroinform. 2023, 17, 1096053. [Google Scholar] [CrossRef] [PubMed]

- Jeong, G.-M.; Ahn, H.-S.; Choi, S.-I.; Kwak, N.; Moon, C. Pattern Recognition Using Feature Feedback: Application to Face Recognition. Int. J. Control Autom. Syst. 2010, 8, 141–148. [Google Scholar] [CrossRef]

- Dai, C.; Long, Z.; Xie, Y.; Xue, S. Research on the Filtering Algorithm in Speed and Position Detection of Maglev Trains. Sensors 2011, 11, 7204–7218. [Google Scholar] [CrossRef] [PubMed]

- Hou, H.; Jin, L.; Niu, Q.; Sun, Y.; Lu, M. Driver Intention Recognition Method Using Continuous Hidden Markov Model. Int. J. Comput. Intell. Syst. 2011, 4, 386–393. [Google Scholar] [CrossRef]

- Nebot, À.; Mugica, F.; Castro, F.; Acosta, J. Genetic Learning of Fuzzy Parameters in Predictive and Decision Support Modelling. Int. J. Comput. Intell. Syst. 2012, 5, 387–402. [Google Scholar] [CrossRef]

- Bagchi, S. Distributed Computation Using Evolutionary Consciousness: An Approach. Int. J. Comput. Intell. Syst. 2015, 8, 928–942. [Google Scholar] [CrossRef]

- Pérez-Ortiz, M.; Jiménez-Fernández, S.; Gutiérrez, P.A.; Alexandre, E.; Hervás-Martínez, C.; Salcedo-Sanz, S. A Review of Classification Problems and Algorithms in Renewable Energy Applications. Energies 2016, 9, 607. [Google Scholar] [CrossRef]

- Bouchemal, B.; Zaatri, A. Image-Based Control for Cable-Based Robots. Int. J. Control Autom. Syst. 2014, 12, 118–125. [Google Scholar] [CrossRef]

- Liu, Z.; Li, X.; Li, F.; Wei, X.; Zhang, G. Fast and Flexible Movable Vision Measurement for the Surface of a Large-Sized Object. Sensors 2015, 15, 4643–4657. [Google Scholar] [CrossRef]

- Lepot, M.; Aubin, J.-B.; Clemens, F.H.L.R. Interpolation in Time Series: An Introductive Overview of Existing Methods, Their Performance Criteria and Uncertainty Assessment. Water 2017, 9, 796. [Google Scholar] [CrossRef]

- Tejedor, J.; Macias-Guarasa, J.; Martins, H.F.; Pastor-Graells, J.; Corredera, P.; Martin-Lopez, S. Machine Learning Methods for Pipeline Surveillance Systems Based on Distributed Acoustic Sensing: A Review. Appl. Sci. 2017, 7, 841. [Google Scholar] [CrossRef]

- Chang, C.-W.; Lee, H.-W.; Liu, C.-H. A Review of Artificial Intelligence Algorithms Used for Smart Machine Tools. Inventions 2018, 3, 41. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, X.; Zhang, S.; Wang, H.; Zhang, W. Neural Machine Reading Comprehension: Methods and Trends. Appl. Sci. 2019, 9, 3698. [Google Scholar] [CrossRef]

- Liu, H.; Lang, B. Machine Learning and Deep Learning Methods for Intrusion Detection Systems: A Survey. Appl. Sci. 2019, 9, 4396. [Google Scholar] [CrossRef]

- Carvalho, D.V.; Pereira, E.M.; Cardoso, J.S. Machine Learning Interpretability: A Survey on Methods and Metrics. Electronics 2019, 8, 832. [Google Scholar] [CrossRef]

- Hamouche, E.; Loukaides, E.G. Classification and Selection of Sheet Forming Processes with Machine Learning. Int. J. Comput. Integr. Manuf. 2018, 31, 921–932. [Google Scholar] [CrossRef]

- Salem, F.A.; Mahfouz, A. Mechatronics Subsystems’ Classification, Role, Selection Criteria and Synergistic Integration in Overall System Design. Am. J. Educ. Sci. 2016, 2, 16–28. [Google Scholar]

- Salem, F.A. The Role of Control System/Algorithm Subsystems in Mechatronics Systems Design. J. Multidiscip. Eng. Sci. Technol. 2015, 2, 2717–2732. [Google Scholar]

- Scalera, L.; Palomba, I.; Wehrle, E.; Gasparetto, A.; Vidoni, R. Natural Motion for Energy Saving in Robotic and Mechatronic Systems. Appl. Sci. 2019, 9, 3516. [Google Scholar] [CrossRef]

- Chen, S.; Li, S.; Liu, B.; Lou, Y.; Liang, Y. Self-Learning Variable Structure Control for a Class of Sensor-Actuator Systems. Sensors 2012, 12, 6117–6128. [Google Scholar] [CrossRef]

- Fontana, M.; Salsedo, F.; Bergamasco, M. Novel Magnetic Sensing Approach with Improved Linearity. Sensors 2013, 13, 7618–7632. [Google Scholar] [CrossRef]

- Liu, Y.; Han, H.; Liu, T.; Yi, J.; Li, Q.; Inoue, Y. A Novel Tactile Sensor with Electromagnetic Induction and Its Application on Stick-Slip Interaction Detection. Sensors 2016, 16, 430. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Abbod, M.; Shieh, J.-S. Integrations between Autonomous Systems and Modern Computing Techniques: A Mini Review. Sensors 2019, 19, 3897. [Google Scholar] [CrossRef] [PubMed]

- Ljung, L. Some Classical and Some New Ideas for Identification of Linear Systems. J. Control Autom. Electr. Syst. 2013, 24, 3–10. [Google Scholar] [CrossRef]

- Kluyskens, V.; Van Verdeghem, J.; Dehez, B. Experimental Investigations on Self-Bearing Motors with Combined Torque and Electrodynamic Bearing Windings. Actuators 2019, 8, 48. [Google Scholar] [CrossRef]

- Filice, L.; Fratini, L.; Micari, F. Analysis of Material Formability in Incremental Forming. CIRP Ann. 2002, 51, 199–202. [Google Scholar] [CrossRef]

- Harfoush, A.; Haapala, K.R.; Tabei, A. Application of Artificial Intelligence in Incremental Sheet Metal Forming: A Review. Procedia Manuf. 2021, 53, 606–617. [Google Scholar] [CrossRef]

- Araghi, B.T.; Manco, G.L.; Bambach, M.; Hirt, G. Investigation into a New Hybrid Forming Process: Incremental Sheet Forming Combined with Stretch Forming. CIRP Ann. 2009, 58, 225–228. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.-Z.; Li, R. Numerical Investigation for the Flexible Stretch-Stamp Forming Process of Sheet Metal. Adv. Mech. Eng. 2019, 11, 1687814018819287. [Google Scholar] [CrossRef]

- Morales-Palma, D.; Martínez-Donaire, A.J.; Vallellano, C. On the Use of Maximum Force Criteria to Predict Localised Necking in Metal Sheets under Stretch-Bending. Metals 2017, 7, 469. [Google Scholar] [CrossRef]

- Schilp, H.; Suh, J.; Hoffmann, H. Reduction of Springback Using Simultaneous Stretch-Bending Processes. Int. J. Mater. Form. 2012, 5, 175–180. [Google Scholar] [CrossRef]

- Kim, T.J.; Yang, D.Y. Improvement of Formability for the Incremental Sheet Metal Forming Process. Int. J. Mech. Sci. 2000, 42, 1271–1286. [Google Scholar] [CrossRef]

- Gupta, P.; Szekeres, A.; Jeswiet, J. Manufacture of an Aerospace Component with Hybrid Incremental Forming Methodology. Int. J. Mater. Form. 2021, 14, 293–308. [Google Scholar] [CrossRef]

- Akrichi, S.; Abbassi, A.; Abid, S.; Ben Yahia, N. Roundness and Positioning Deviation Prediction in Single Point Incremental Forming Using Deep Learning Approaches. Adv. Mech. Eng. 2019, 11, 1687814019864465. [Google Scholar] [CrossRef]

- Cui, X.; Mo, J.; Li, J.; Xiao, X.; Zhou, B.; Fang, J. Large-Scale Sheet Deformation Process by Electromagnetic Incremental Forming Combined with Stretch Forming. J. Mater. Process Technol. 2016, 237, 139–154. [Google Scholar] [CrossRef]

- Abosaf, M.; Essa, K.; Alghawail, A.; Tolipov, A.; Su, S.; Pham, D. Optimisation of Multi-Point Forming Process Parameters. Int. J. Adv. Manuf. Technol. 2017, 92, 1849–1859. [Google Scholar] [CrossRef]

- Peng, H.; Li, M.; Liu, C.; Cao, J. Study of Multi-Point Forming for Polycarbonate Sheet. Int. J. Adv. Manuf. Technol. 2013, 67, 2811–2817. [Google Scholar] [CrossRef]

- Cherukupally, S.; Konka, P.; Venkata Reddy, N. Enhancement of Accuracy in Multi-Point Stretch Forming: Cushion Stretching. Manuf. Lett. 2022, 33, 205–213. [Google Scholar] [CrossRef]

- Cai, Z.-Y.; Wang, S.-H.; Xu, X.-D.; Li, M.-Z. Numerical Simulation for the Multi-Point Stretch Forming Process of Sheet Metal. J. Mater. Process Technol. 2009, 209, 396–407. [Google Scholar] [CrossRef]

- Hardt, D.E.; Norfleet, W.A.; Valentin, V.M.; Parris, A. In Process Control of Strain in a Stretch Forming Process. J. Eng. Mater. Technol. 2000, 123, 496–503. [Google Scholar] [CrossRef]

- Jones, J.; Mears, L. A Process Comparison of Simple Stretch Forming Using Both Conventional and Electrically-Assisted Forming Techniques. In Proceedings of the International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2010. [Google Scholar]

- Wang, N.-M.; Wenner, M.L. Elastic-Viscoplastic Analyses of Simple Stretch Forming Problems. In Mechanics of Sheet Metal Forming: Material Behavior and Deformation Analysis; Koistinen, D.P., Wang, N.-M., Eds.; Springer: Boston, MA, USA, 1978; pp. 367–402. ISBN 978-1-4613-2880-3. [Google Scholar]

- Hirt, G.; Bambach, M.; Bleck, W.; Prahl, U.; Stollenwerk, J. The Development of Incremental Sheet Forming from Flexible Forming to Fully Integrated Production of Sheet Metal Parts. In Advances in Production Technology; Brecher, C., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 117–129. [Google Scholar]

- Wang, S.; Cai, Z.; Li, M.; Lan, Y. Numerical Simulation on the Local Stress and Local Deformation in Multi-Point Stretch Forming Process. Int. J. Adv. Manuf. Technol. 2012, 60, 901–911. [Google Scholar] [CrossRef]

- Odenberger, E.-L.; Schill, M.; Oldenburg, M. Thermo-Mechanical Sheet Metal Forming of Aero Engine Components in Ti-6Al-4V—PART 2: Constitutive Modelling and Validation. Int. J. Mater. Form. 2013, 6, 403–416. [Google Scholar] [CrossRef]

- Park, J.-W.; Kim, Y.-B.; Kim, J.; Kang, B.-S. Study on Multiple Die Stretch Forming for Curved Surface of Sheet Metal. Int. J. Precis. Eng. Manuf. 2014, 15, 2429–2436. [Google Scholar] [CrossRef]

- Shim, D.-S.; Baek, G.-Y.; Shin, G.-Y.; Yoon, H.-S.; Lee, K.-Y.; Kim, K.-H. Investigation of Tension Force in Stretch Forming of Doubly Curved Aluminum Alloy (Al5083) Sheet. Int. J. Precis. Eng. Manuf. 2016, 17, 433–444. [Google Scholar] [CrossRef]

- Feng, J.-W.; Zhan, L.-H.; Yang, Y.-G. The Establishment of Surface Roughness as Failure Criterion of Al–Li Alloy Stretch-Forming Process. Metals 2016, 6, 13. [Google Scholar] [CrossRef]

- Ablat, M.A.; Qattawi, A. Numerical Simulation of Sheet Metal Forming: A Review. Int. J. Adv. Manuf. Technol. 2017, 89, 1235–1250. [Google Scholar] [CrossRef]

- Tufail, S.; Riggs, H.; Tariq, M.; Sarwat, A.I. Advancements and Challenges in Machine Learning: A Comprehensive Review of Models, Libraries, Applications, and Algorithms. Electronics 2023, 12, 1789. [Google Scholar] [CrossRef]

- Chamola, V.; Vineet, A.; Nayyar, A.; Hossain, E. Brain-Computer Interface-Based Humanoid Control: A Review. Sensors 2020, 20, 3620. [Google Scholar] [CrossRef] [PubMed]

- Di Boon, Y.; Joshi, S.C.; Bhudolia, S.K.; Gohel, G. Recent Advances on the Design Automation for Performance-Optimized Fiber Reinforced Polymer Composite Components. J. Compos. Sci. 2020, 4, 61. [Google Scholar] [CrossRef]

- Dumakor-Dupey, N.K.; Arya, S. Machine Learning—A Review of Applications in Mineral Resource Estimation. Energies 2021, 14, 4079. [Google Scholar] [CrossRef]

- Raza, A.; Benrabah, A.; Alquthami, T.; Akmal, M. A Review of Fault Diagnosing Methods in Power Transmission Systems. Appl. Sci. 2020, 10, 1312. [Google Scholar] [CrossRef]

- Peres, F.; Castelli, M. Combinatorial Optimization Problems and Metaheuristics: Review, Challenges, Design, and Development. Appl. Sci. 2021, 11, 6449. [Google Scholar] [CrossRef]

- Shen, C.-H.; Hsu, T.-J. Research on Vehicle Trajectory Prediction and Warning Based on Mixed Neural Networks. Appl. Sci. 2021, 11, 7. [Google Scholar] [CrossRef]

- Budzan, S.; Wyżgolik, R.; Kciuk, M.; Kulik, K.; Masłowski, R.; Ptasiński, W.; Szkurłat, O.; Szwedka, M.; Woźniak, Ł. Using Gesture Recognition for AGV Control: Preliminary Research. Sensors 2023, 23, 3109. [Google Scholar] [CrossRef]

- Munawar, H.S.; Hammad, A.W.A.; Haddad, A.; Soares, C.A.P.; Waller, S.T. Image-Based Crack Detection Methods: A Review. Infrastructures 2021, 6, 115. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, Y.; Zhao, F.; Zhang, E.; Wu, Z.; Shao, L. Surface Defect Detection Methods for Industrial Products: A Review. Appl. Sci. 2021, 11, 7657. [Google Scholar] [CrossRef]

- Matsuzaka, Y.; Yashiro, R. AI-Based Computer Vision Techniques and Expert Systems. AI 2023, 4, 289–302. [Google Scholar] [CrossRef]

- Kokol, P. Software Quality: How Much Does It Matter? Electronics 2022, 11, 2485. [Google Scholar] [CrossRef]

- Barbierato, E.; Gatti, A. The Challenges of Machine Learning: A Critical Review. Electronics 2024, 13, 416. [Google Scholar] [CrossRef]

- Mukhamediev, R.I.; Popova, Y.; Kuchin, Y.; Zaitseva, E.; Kalimoldayev, A.; Symagulov, A.; Levashenko, V.; Abdoldina, F.; Gopejenko, V.; Yakunin, K.; et al. Review of Artificial Intelligence and Machine Learning Technologies: Classification, Restrictions, Opportunities and Challenges. Mathematics 2022, 10, 2552. [Google Scholar] [CrossRef]

- Bressan, J.D.; Wang, Q.; Simonetto, E.; Ghiotti, A.; Bruschi, S. Formability Prediction of Ti6Al4V Titanium Alloy Sheet Deformed at Room Temperature and 600 °C. Int. J. Mater. Form. 2021, 14, 391–405. [Google Scholar] [CrossRef]

- Lu, K.; Zou, T.; Luo, J.; Li, D.; Peng, Y. Stretch Bending Process Design by Machine Learning. Int. J. Adv. Manuf. Technol. 2022, 120, 781–799. [Google Scholar] [CrossRef]

- Hmede, R.; Chapelle, F.; Lapusta, Y. Review of Neural Network Modeling of Shape Memory Alloys. Sensors 2022, 22, 5610. [Google Scholar] [CrossRef] [PubMed]

- Wen, X.; Shan, J.; He, Y.; Song, K. Steel Surface Defect Recognition: A Survey. Coatings 2023, 13, 17. [Google Scholar] [CrossRef]

- Ginerica, C.; Zaha, M.; Floroian, L.; Cojocaru, D.; Grigorescu, S. A Vision Dynamics Learning Approach to Robotic Navigation in Unstructured Environments. Robotics 2024, 13, 15. [Google Scholar] [CrossRef]

- Xu, K.; Li, Y.; Liu, C.; Liu, X.; Hao, X.; Gao, J.; Maropoulos, P.G. Advanced Data Collection and Analysis in Data-Driven Manufacturing Process. Chin. J. Mech. Eng. 2020, 33, 43. [Google Scholar] [CrossRef]

- Luiz, V.D.; de Matos Rodrigues, P.C. Failure Analysis of AISI 430 Stainless Steel Sheet under Stretching and Bending Conditions. Int. J. Adv. Manuf. Technol. 2022, 121, 2759–2772. [Google Scholar] [CrossRef]

| Machine Learning Algorithms | Purpose | Applicability | |

|---|---|---|---|

| Supervised Learning (uses labeled datasets to train algorithms to classify and predict outcomes [103]) | linear regression [104] | finds a linear relationship between one or more predictor(s) | traditional method for evaluating trends and making predictions |

| logistic regression [105] | analysis and classification of binary and proportional response data sets | widely used in data mining | |

| decision tree [106] | repeatedly performing tests on the input x, where the outcome of each test determines the next test until f(x) is known with certainty | mostly used in statistics and data mining | |

| Naïve Bayes [107] | finds the probability of an event occurring considering the probability of another that occurred | mostly used for text classification, spam filtering | |

| support vector machines (SVM) [108] | classification strategy minimizes the classification errors of the training data and obtains a better generalization ability | mostly used for data mining, pattern recognition | |

| k-nearest neighbors (kNN) [109] | classify unlabeled observations by assigning them to the class of the most similar labeled examples | mostly used for intrusion detection, financial market prediction | |

| ensemble learning techniques [110] | generated by multiple datasets by bootstrapping the training data and then developing models based on the individual datasets and making predictions using these models | mostly used for predicting crop yield, mapping natural hazards, or land surface temperature | |

| Semi-supervised Learning (uses both unlabeled and labeled data [111]) | pseudo labeling [112] | applying pseudo-labels to samples in the unlabeled set by using a model trained on the combination of the labeled samples and any previously pseudo-labeled samples and iteratively repeating this process in a self-training cycle | mostly used for image classification |

| semi-supervised generative adversarial network (SGAN) [113] | extract useful information from the unlabeled process data | used in interpreting unfiltered, noise data | |

| Unsupervised Learning (analyses and clusters unlabeled data to discover hidden patterns or data grouping without human intervention [114]) | K-means clustering [115] | categorized as a partitional clustering algorithm; partitioning given datasets into clusters involves finding the minimum squared error between the various data points in the data set and the mean of a cluster and then assigning each data point to the cluster center nearest to it | used in medical science, manufacturing, robotics, the financial sector, privacy protection, artificial intelligence, urban development, aviation, industries, sales, marketing |

| hierarchical agglomerative clustering (HAC) [116] | can yield impressive and rather easily readable results concerning clustering and classification of general building information/dataset | business intelligence, image pattern recognition, web search, biology, and security | |

| Density-Based Spatial Clustering of Applications with Noise (DBSCAN) [117] | performs clustering by finding different density regions that depart from each other | used in data analysis and pattern recognition | |

| principal component analysis [118] | versatile statistical method for reducing a cases-by-variables data table to its essential features, called principal components | population genetics, market research, quantitative finance | |

| Reinforcement Learning (sequential decision-making problems that are typically under uncertainty, mimicking how we, as humans, learn [119]) | Q-learning [120] | a simple way for agents to learn how to act optimally in controlled Markovian domains | used in news recommendations, online web system auto-configuration, traffic control signal |

| state–action– reward–state– action (SARSA) [121] | has faster convergence characteristics but not lower final performance than Q-learning | robotics, artificial intelligence, and mechatronics control | |

| Deep Q-Network (DQN) [122] | combines reinforcement learning with deep neural networks | used for algorithmic trading | |

| Deep Deterministic Policy Gradient (DDPG) [123] | explores the environment and makes action decisions | intelligent robotics | |

| Subsystems | Global Component | Particular Component | |

|---|---|---|---|

| Electrotechnical components | Mechanically powered subsystems | linear movement | pneumatic/hydraulic cylinders |

| rotational movement | air/hydraulic motors, combustion/steam engines | ||

| motion machine parts | rolling-element bearings (ball, roller, needle linear bearings), plain bearings, ball joints, leadscrew, ball screw, cams, gears, belts, pulleys, chains, sprockets, springs, | ||

| Electrically powered subsystems | linear movement | electric actuators, solenoids, shape memory alloys | |

| rotational movement | servo/stepper motors | ||

| sensors | proximity, photoelectric, temperature, pressure sensors, limit switch, rotary encoders, machine vision | ||

| Control subsystems | control hardware | switches, relays, PLCs, power management hardware (PMH) | |

| control software | human–machine interface | ||

| End effector | parallel mechanisms, unfolding mechanisms, and series-parallel mechanisms | ||

| Stretch-Forming Process Types | Particularities |

|---|---|

| Tangential stretch forming [72] | the gripping jaws and forming block/die can move |

| the sheet is pre-strained, after which it is stretched | |

| it is considered a two-step biaxial process | |

| Multi-point stretch forming/ flexible die stretch forming [101,165] | it uses reconfigurable dies and elastic cushions to manufacture 3D sheet metal parts |

| it is considered a flexible manufacturing process | |

| stress and strain are distributed more uniformly, as the elastic cushions help to a certain degree | |

| Incremental stretch forming (incremental sheet forming) [150,154,165] | it offers flexibility and increased formability, resulting in complex 3D shapes |

| it is a hybrid manufacturing process, combining classical stretch forming with incremental sheet forming | |

| the sheet experiments only localized plastic deformation | |

| Simple stretch forming [162,163,164] | the gripping jaws are stationary; only the forming block/die moves it has a large contact area; only tensile load has to be largely considered it can be used in large parts, such as airplane fuselage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoras, C.C.; Zichil, V.; Ciubotariu, V.A.; Cosa, S.M. Machine Learning, Mechatronics, and Stretch Forming: A History of Innovation in Manufacturing Engineering. Machines 2024, 12, 180. https://doi.org/10.3390/machines12030180

Grigoras CC, Zichil V, Ciubotariu VA, Cosa SM. Machine Learning, Mechatronics, and Stretch Forming: A History of Innovation in Manufacturing Engineering. Machines. 2024; 12(3):180. https://doi.org/10.3390/machines12030180

Chicago/Turabian StyleGrigoras, Cosmin Constantin, Valentin Zichil, Vlad Andrei Ciubotariu, and Stefan Marius Cosa. 2024. "Machine Learning, Mechatronics, and Stretch Forming: A History of Innovation in Manufacturing Engineering" Machines 12, no. 3: 180. https://doi.org/10.3390/machines12030180

APA StyleGrigoras, C. C., Zichil, V., Ciubotariu, V. A., & Cosa, S. M. (2024). Machine Learning, Mechatronics, and Stretch Forming: A History of Innovation in Manufacturing Engineering. Machines, 12(3), 180. https://doi.org/10.3390/machines12030180