Virtual Reality for Training in Assembly and Disassembly Tasks: A Systematic Literature Review

Abstract

:1. Background and Motivation

1.1. Challenges in Assembly and Disassembly Tasks

- –

- Complexity, variability, and uncertainty: The trend toward customized products and on-demand manufacturing increases the complexity of assembly tasks, requiring workers to cope with constantly changing work instructions without impacting production speed [14]. The complexity level of tasks is influenced by factors such as the structure of the task, input factors, process operation factors, and output factors [16]. These factors significantly affect the task complexity in an assembly line and contribute to the overall complexity level of the task [17]. Furthermore, in a mixed-model assembly line, the production process is designed to handle various product configurations, allowing for greater flexibility and efficiency and this entails a strong variability in the tasks that operators must perform. Task complexity also impacts the disassembly process, including interlocked components; the need for optimal disassembly sequences, often inefficient for large or complex products; and the need for parallel disassembly techniques that employ several manipulators (manual and/or automatic) to remove multiple components simultaneously. Disassembly tasks often involve uncertain parameters, such as disassembly time, which can impact the feasibility and cost of operations. The lack of tools to analyze and compare remanufacturing processes is a significant issue [15]. Additionally, uncertainties in product take-back contribute to the complexity of remanufacturing systems [18]. Furthermore, the complexity of assembly and, above all, disassembly tasks impacts on the incessant operators’ rotation for tasks in swift alternations between learning and forgetting periods. For this reason, these non-routine and complex tasks require a structured learning process based on employee and workplace assessments [19].

- –

- Cognitive load and motor skills involved: The low-volume/high-production-mix strategy of manufacturing companies increases the cognitive load on manual assembly and disassembly operators, highlighting the need for well-trained operators and efficient training programs [20]. The cognitive load on workers increases with the complexity of manual assembly, leading to more frequent errors and decreased productivity [21]. Assembly tasks primarily comprise cognitive tasks, and the assembly performance depends on the operators’ cognition skills [22]. Motor skills in manual assembly and disassembly are necessary to limit short- and long-term fatigue, and for this reason, the workstations must be designed to determine the best ergonomic layout of components for assembly and demonstrate the best assembly sequence to the operator [23].

- –

- Safety: Ensuring the safety of human workers in the disassembly environment is a critical challenge, particularly in collaborative human–robot settings.

- –

- Technologies to support assembly and disassembly tasks: Human–robot collaboration and augmented reality represent the technologies on which the academic and industrial world is focusing to increase the performance of operators and the system. The use of augmented reality technology is proposed to optimize disassembly processes for maintenance purposes, aiming to make it immediate for operators to efficiently carry out the repair process while learning in parallel what they need to do.

- –

- Strategies for managing complexity in task assembly/disassembly involve the development of efficient encoding and decoding strategies for the disassembly process, as well as the application of metaheuristic approaches such as genetic algorithms to solve the asynchronous parallel disassembly planning problem. The application of metaheuristic approaches, such as genetic algorithms, is effective in solving the asynchronous parallel disassembly planning problem and identifying faster disassembly processes, especially for large-scale problems.

- –

- Workforce training and operator learning [19]: Research shows that the architectural complexity of products significantly impacts operator learning, productivity, and quality performance in both assembly and disassembly tasks. Learning repetitions affect manual assembly/disassembly performance, with instructions playing a crucial role in learning and unequal temporal workloads among workers in larger groups, leading to decreased productivity. A planning method for structuring the learning process in manual assembly can improve the performance and support the appropriate human task allocation.

1.2. Training Strategies

1.3. Virtual Reality Technologies for Training

1.4. Main Contribution and Paper Structure

2. Materials and Methods

2.1. Systematic Literature Review

- Main bibliometric characteristics of papers whereby the articles were classified according to information about the authors, the year of publication, and the type of document.

- Content analysis, as better described in the next section.

2.2. Content Analysis

- Type of task and research environment: The case studies were classified concerning the assembly or disassembly activities and the type of environment in which they were carried out (laboratory/company plant).

- Technology used: The different technologies for the development of VR used in the selected cases were identified and classified. This was essential to be able to identify the level of immersion reproduced in the case study. Level of immersion is the ability to abstract the user from the real world, using projection screens or helmets. The advancement of information technologies today allows us to navigate photo-realistic environments in real time, interacting with the objects present in them. When talking about VR, it is good to immediately make a distinction between non-immersive VR and immersive VR: in the former, the user simply finds himself in front of a monitor, which acts as a window onto the three-dimensional world with which to interact through special joysticks. The resulting effect is different from that obtained with an immersive VR, in which the effects that the user perceives are much more engaging and capable of making the user live in a completely new reality.

- Sample experience with technology and tasks: Pre-learning processes were identified for each case study, which aimed to increase participants’ confidence in both the technology used for the study and the task to be performed.

- Learning strategy: For each article, the devices used, the methods of comparison, the number of tasks performed, and the number of attempts allowed were defined.

- Operator performance: Results on objective metrics such as training time; task completion time; and number of errors and subjective ones, such as perceived workload, usability, and other qualitative evaluations, were analyzed.

3. SLR Results

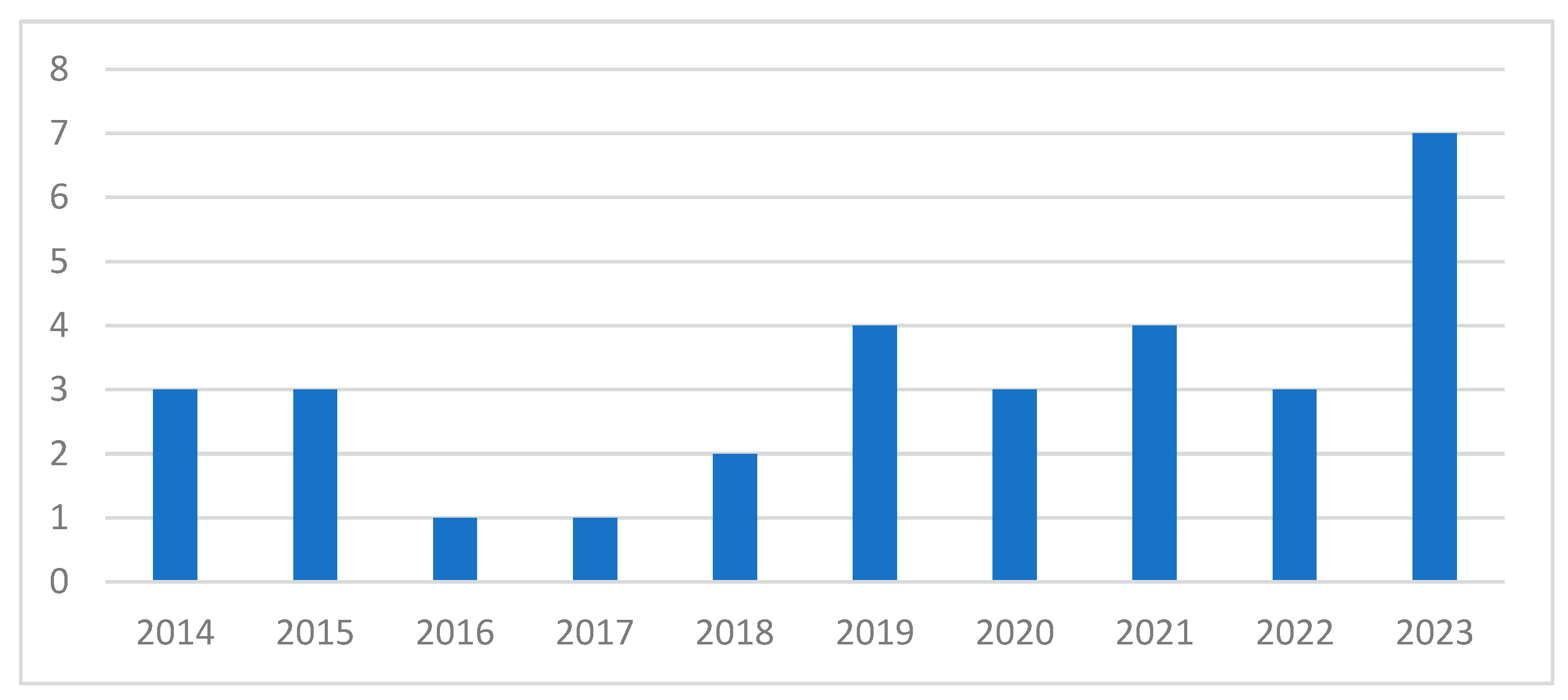

3.1. Selected Papers

3.2. Content Analysis

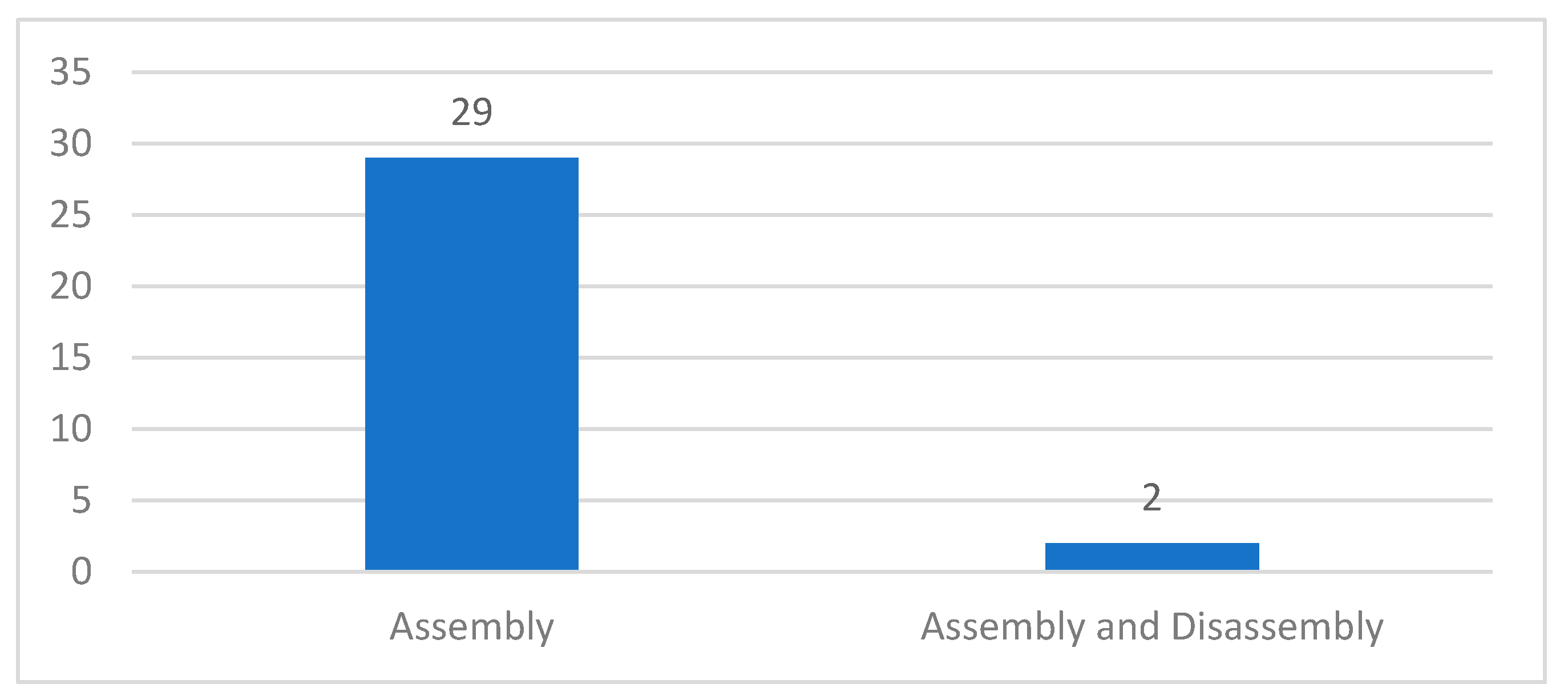

3.2.1. Type of Case Study

3.2.2. Level of Immersion

- High, characterized by the use of HMDs (Head Mounted Displays), wire gloves, as well as tracking devices for head and eye movements;

- Medium, characterized by the use of stereoscopic viewers and movement-tracking devices;

- Low, characterized by the use of a mouse, keyboard, 2D desktop PC, and headset.

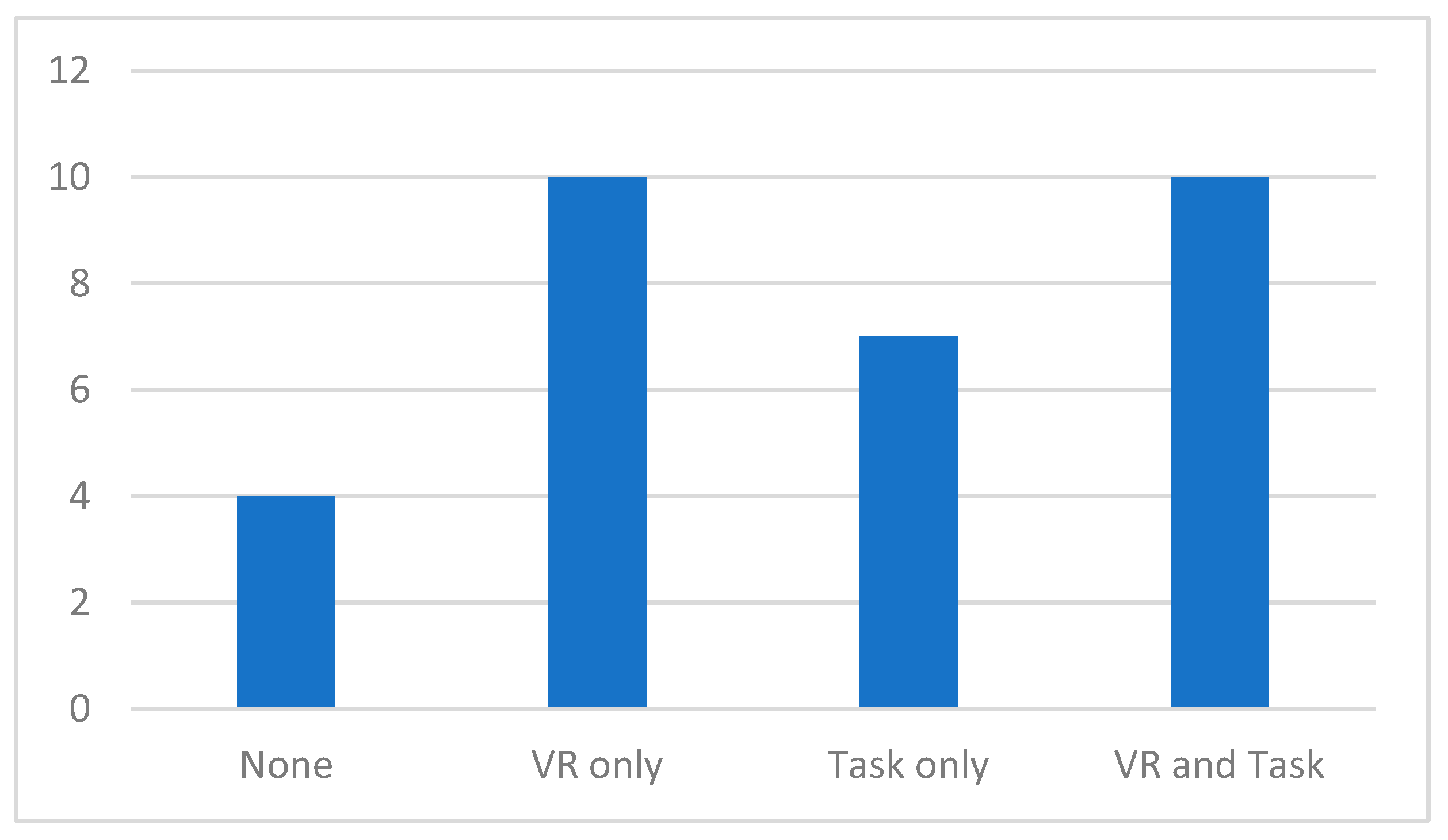

3.2.3. Previous Experience and Pre-Learning

- Experience with VR technology, which could influence the time to complete the training because the operator appears to be already comfortable with the new technology;

- Experience with the task, which could result in effects on both the number of errors and task completion time, because experienced operators, while undergoing traditional training processes, could achieve better performance even without the aid of VR technologies.

3.2.4. Evaluation of VR Impact

- time required for training;

- completion time of the assigned task(s);

- number of errors.

- perceived workload;

- usability;

- qualitative evaluation.

- audio recordings, describing the steps needed to assemble/disassemble the object [63];

3.3. Benefits and Limitations

- Reducing risks of accidents: VR makes it possible to simulate difficult working conditions, failures, or dangerous/emergency conditions that cannot be reproduced with real equipment, allowing the user to acquire skills and knowledge previously impossible. Through VR, every aspect of the components involved in complex operations can be explored, allowing an infinite number of repetitions. Furthermore, the use of VR can significantly reduce the risks associated with work-related injuries, quality defects, and financial losses [8]. VR-based systems may be more expensive, but they provide risk-free and injury-free environments for teaching and training [45].

- Improved learning and skill retention: Physical exploration of simulated space and time facilitates learning, knowledge, and memorization, while experimental practice helps to understand complex themes, concepts, and theories. According to Edgar Dale, in fact, a person remembers 10 per cent of what he or she learns when reading, 20 per cent when listening, and as much as 90 per cent when performing a determined action [65]. VR provides a platform for ‘learning by doing’, rather than learning by seeing, hearing, or observing, and this, therefore, explains how VR technologies allow to improve the effectiveness of training and extend knowledge retention time. VR supports active learning and the practice of repeated tasks because it offers the opportunity to examine all the details of the parts involved in a complex operation, and, above all, it offers the opportunity to perform the desired number of repetitions and applications without worrying about the damage that results from any mistakes as these have no consequences in real life. This can only have a positive effect on learning effectiveness, as also underlined in the case study [39].

- Increased staff motivation: As VR is still considered an innovative technology, immersive training is less frustrating and sometimes even more fun than a classic treatment. The possibility offered to the user to immerse and interact with a virtual world and the use of gaming techniques and features (such as the division into levels and the realization of intermediate drill games [39,44,46,48,56]) significantly improves the operator’s attention. Again, VR presents an intuitive approach because movement in a virtual environment resembles real-world actions. This makes it possible to enter the training scenario more quickly, keeping the user’s attention on the learning content. These aspects, therefore, increase the attention and motivation of the staff and improve the learning process which will be, as mentioned, effective and efficient.

- Enlarged availability: Because it has no physical limits, the virtual environment offers paradoxically unlimited spaces in which many individuals can participate in training activities simultaneously, thus stimulating collaboration and meeting the current needs of increasingly global organizations.

- Easier onboarding: The extended availability thus enables a mass training process at the same time, which in turn speeds up onboarding, i.e., the return on investment on new employees within a company. In addition, for companies that need to train employees who are geographically dispersed or who prefer to work remotely, this mode eliminates the need to organize in-person training.

- Reduced costs: The adoption of VR technologies for personnel training results in cost savings for the company due to several aspects. Firstly, the possibility of interacting with virtual equipment avoids the need to stop the production process to illustrate the structure and operation of the various machines and tools to workers, which represents a significant cost saving. Secondly, again thanks to virtual replicas, real parts are no longer required, avoiding the potential damage not only to expensive equipment due to the inexperience of the trainees, but also to the parts themselves.

- Tracking: It is essential for a quality VR experience to have stable and accurate tracking of the user’s body in virtual space. Tracking should be accurate to within 1 mm and without ‘jitter’. Common limitations include optical occlusions, limited space, and tracking accuracy.

- Simulation software: This introduces several sources of error in VR interactions, such as usability problems, rendering, scene lighting, and collision detection.

- Visualization: Devices such as HMDs have limitations in the field of view, low latency, and limited frame rate and resolution, which may affect the user experience.

- User factors: The user’s level of training and physiological limitations, such as tremor or vision problems, can affect the overall performance of the VR system.

4. Discussion and Conclusions

4.1. Preliminary Guidelines for Defining VR Training Strategies

4.2. Research Gaps and Future Research Agenda

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Ref. | Title | Year | Source Title | Type of Pre-Learning | Experience with VR | Experience with Task | Type of Comparison |

|---|---|---|---|---|---|---|---|

| [40] | Natural and hybrid bimanual interaction for virtual assembly tasks | 2014 | Virtual Reality | Task | No | Not specified | VR vs. VR |

| [42] | Virtual training of assembly tasks using virtual reality techniques and haptic systems | 2014 | ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE) | VR and Task | Not specified | Not specified | VR vs. traditional and VR vs. VR |

| [43] | The influence of interaction technology on the learning of assembly tasks using virtual reality | 2014 | Journal of Computing and Information Science in Engineering | VR and Task | No | Not specified | VR vs. traditional and VR vs. VR |

| [61] | Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks | 2015 | Interactive Learning Environments | VR and Task | No | Yes | VR vs. traditional and VR vs. VR |

| [37] | Training in VR: A preliminary study on learning assembly/disassembly sequences | 2015 | Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics) | VR and Task | Not specified | Not specified | VR vs. traditional |

| [46] | Serious Games and Virtual Simulator for Automotive Manufacturing Education & Training | 2015 | Procedia Computer Science | VR | Yes | No | VR vs. VR |

| [38] | Establishing the Usability of a Virtual Training System for Assembly Operations within the Automotive Industry | 2016 | Human Factors and Ergonomics In Manufacturing | VR and Task | Not specified | Not specified | VR vs. traditional |

| [20] | The evaluation of an elementary virtual training system for manual assembly | 2017 | International Journal of Production Research | None | Not specified | Not specified | VR vs. traditional |

| [56] | A comparison of virtual and physical training transfer of bimanual assembly tasks | 2018 | IEEE Transactions on Visualization and Computer Graphics | Task | Not specified | Yes | VR vs. traditional and VR vs. VR |

| [57] | Manual assembly training in virtual environments | 2018 | Proceedings—IEEE 18th International Conference on Advanced Learning Technologies, ICALT 2018 | None | Not specified | Not specified | VR vs. VR |

| [48] | Comparison of a gamified and non-gamified virtual reality training assembly task | 2019 | 2019 11th International Conference on Virtual Worlds and Games for Serious Applications, VS-Games 2019—Proceedings | VR | No | No | VR vs. VR |

| [55] | The effects of stereopsis and immersion on bimanual assembly tasks in a virtual reality system | 2019 | 26th IEEE Conference on Virtual Reality and 3D User Interfaces, VR 2019—Proceedings | VR | Not specified | No | VR vs. VR |

| [44] | Gamification of assembly planning in virtual environment | 2019 | Assembly Automation | Task | Yes | No | VR vs. VR |

| [62] | Assessment of virtual reality-based manufacturing assembly training system | 2019 | International Journal of Advanced Manufacturing Technology | VR | Not specified | No | VR vs. traditional and VR vs. VR |

| [41] | A smart factory in a smart city: Virtual and augmented reality in a smart assembly line | 2020 | IEEE Access | VR and Task | Not specified | Not specified | VR vs. traditional and VR vs. VR |

| [59] | Effectiveness of Virtual vs. Physical Training: The Case of Assembly Tasks, Trainer’s Verbal Assistance and Task Complexity | 2020 | IEEE Computer Graphics and Applications | Task | Not specified | Not specified | VR vs. traditional and VR vs. VR |

| [51] | Usability study of auditory feedback and visual feedback in an immersive virtual assembly system | 2020 | Proceedings—2020 International Conference on Intelligent Computing, Automation and Systems, ICICAS 2020 | Task | Not specified | Not specified | VR vs. traditional |

| [49] | Effect of Virtual Reality-Based Training on Complex Industrial Assembly Task Performance | 2021 | Arabian Journal for Science and Engineering | VR | No | No | VR vs. traditional |

| [47] | Effects of Level of Immersion on Virtual Training Transfer of Bimanual Assembly Tasks | 2021 | Frontiers in Virtual Reality | None | Yes | No | VR vs. traditional and VR vs. VR |

| [36] | Development of Virtual disassembly and assembly platform for marine air compressor | 2021 | Journal of Physics: Conference Series | Task | No | Not specified | VR vs. traditional |

| [52] | A System for Collaborative Assembly Simulation and User Performance Analysis | 2021 | Proceedings—2021 International Conference on Cyberworlds, CW 2021 | Task | Yes | Not specified | VR vs. VR |

| [50] | Virtual Reality For Training: A Computer Assembly Application | 2022 | ICGI 2022—International Conference on Graphics and Interaction, Proceedings | None | No | Not specified | Not specified |

| [39] | Gamification of virtual reality assembly training: Effects of a combined point and level system on motivation and training results | 2022 | International Journal of Human Computer Studies | VR | No | Not specified | VR vs. traditional and VR vs. VR |

| [63] | Virtual Reality Assembly of Physical Parts: The Impact of Interaction Interface Techniques on Usability and Performance | 2022 | Virtual, Augmented and mixed reality: applications in education, aviation and industry, pt II | VR | Yes | Not specified | VR vs. VR |

| [25] | Analyzing the potential of virtual reality-supported training for industrial assembly tasks | 2023 | Computers in Industry | VR | No | No | VR vs. traditional and VR vs. VR |

| [45] | Skill retention after desktop and head-mounted-display virtual reality training | 2023 | Experimental Results | VR | / | No | VR vs. VR |

| [58] | A Comparison of Two Interaction Paradigms for Training Low Cost Automation Assembly in Virtual Environments | 2023 | Information (Switzerland) | VR and Task | Yes | / | VR vs. VR |

| [60] | Low-cost VR system for interactive education of manual assembly procedure | 2023 | Interactive Learning Environments | VR & Task | / | / | VR vs. VR |

| [53] | Virtual Reality for Industrial Assembly Training: The Impact of Tool Interaction Realism on Learning Outcomes | 2023 | Proceedings—2023 IEEE International Symposium on Mixed and Augmented Reality Adjunct, ISMAR-Adjunct 2023 | VR | / | / | VR vs. traditional |

| [54] | Comparative Evaluation of Virtual Reality and In-Person Onboarding for Assembly Trainings in Manufacturing | 2023 | Proceedings—2023 IEEE International Symposium on Mixed and Augmented Reality Adjunct, ISMAR-Adjunct 2023 | VR and Task | No | No | VR vs. traditional |

| [64] | Assemble it like this!-Is AR- or VR-based training an effective alternative to video-based training in manual assembly? | 2023 | Applied Ergonomics | VR and Task | Yes | No | VR vs. traditional |

References

- El Maraghy, W.; El Mar, H. A new engineering design paradigm-The quadruple bottom line. Procedia CIRP 2014, 21, 18–26. [Google Scholar] [CrossRef]

- Falck, A.-C.; Örtengren, R.; Rosenqvist, M.; Söderberg, R. Proactive assessment of basic complexity in manual assembly: Development of a tool to predict and control operator-induced quality errors. Int. J. Prod. Res. 2017, 55, 4248–4260. [Google Scholar] [CrossRef]

- Oh, K.; Kim, D.; Hong, Y.S. Measurement of assembly system complexity based on the task differences induced from product variety. In Proceedings of the ASME Design Engineering Technical Conference, Boston, MA, USA, 2–5 August 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Latos, B.A.; Kalantar, P.; Burgert, F.; Arend, M.; Nitsch, V.; Przybysz, P.M.; Mütze-Niewöhner, S. Development, implementation and evaluation of a complexity measure for the work of assembly teams in one-piece-flow assembly systems employing simulation studies. In Proceedings of the 32nd Annual European Simulation and Modelling Conference 2018, ESM 2018, Ghent, Belgium, 24–26 October 2018; pp. 88–94. [Google Scholar]

- Alkan, B.; Vera, D.; Ahmad, M.; Ahmad, B.; Harrison, R. A Model for Complexity Assessment in Manual Assembly Operations Through Predetermined Motion Time Systems. Procedia CIRP 2016, 44, 429–434. [Google Scholar] [CrossRef]

- BS 8887-220:2010; Specifies Requirements for the Process of Remanufacture. European Standards: Plzen, Czech Republic, 2010.

- Available online: https://ec.europa.eu/clima/eu-action/european-green-deal/european-climate-law_en (accessed on 1 March 2024).

- Caterino, M.; Fera, M.; Macchiaroli, R.; Pham, D.T. Cloud remanufacturing: Remanufacturing enhanced through cloud technologies. J. Manuf. Syst 2022, 64, 133–148. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Pham, D.T.; Xu, W.; Ramirez, F.J.; Ji, C.; Liu, Q. Disassembly sequence planning: Recent developments and future trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 1450–1471. [Google Scholar] [CrossRef]

- Wang, Y.; Lan, F.; Liu, J.; Huang, J.; Su, S.; Ji, C.; Pham, D.T.; Xu, W.; Liu, Q.; Zhou, Z. Interlocking problems in disassembly sequence planning. Int. J. Prod. Res. 2021, 59, 4723–4735. [Google Scholar] [CrossRef]

- Xu, C.; Wei, H.; Guo, X.; Liu, S.; Qi, L.; Zhao, Z. Human-Robot Collaboration Multi-objective Disassembly Line Balancing Subject to Task Failure via Multi-objective Artificial Bee Colony Algorithm. IFAC-PapersOnLine 2020, 53, 1–6. [Google Scholar] [CrossRef]

- Xu, W.; Tang, Q.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. Disassembly sequence planning using discrete Bees algorithm for human-robot collaboration in remanufacturing. Robot. Comput. Manuf. 2020, 62, 101860. [Google Scholar] [CrossRef]

- Ramírez, F.J.; Aledo, J.A.; Gamez, J.A.; Pham, D.T. Economic modelling of robotic disassembly in end-of-life product recovery for remanufacturing. Comput. Ind. Eng 2020, 142, 106339. [Google Scholar] [CrossRef]

- Pimminger, S.; Kurschl, W.; Panholzer, L.; Schönböck, J. Exploring the Learnability of Assembly Tasks Using Digital Work Instructions in a Smart Factory. Procedia CIRP 2021, 104, 696–701. [Google Scholar] [CrossRef]

- Butzer, S.; Schötz, S.; Steinhilper, R. Remanufacturing Process Capability Maturity Model. Procedia Manuf. 2017, 8, 715–722. [Google Scholar] [CrossRef]

- Le, S.T.Q.; Huynh, V.N. An evaluation model for task complexity in production lines. Int. J. Product. Perform. Manag. 2023, 72, 3162–3183. [Google Scholar] [CrossRef]

- Falck, A.-C.; Tarrar, M.; Mattsson, S.; Andersson, L.; Rosenqvist, M.; Söderberg, R. Assessment of manual assembly complexity: A theoretical and empirical comparison of two methods. Int. J. Prod. Res 2017, 55, 7237–7250. [Google Scholar] [CrossRef]

- Gunasekara, H.; Gamage, J.; Punchihewa, H. Remanufacture for sustainability: Barriers and solutions to promote automotive remanufacturing. Procedia Manuf. 2020, 43, 606–613. [Google Scholar] [CrossRef]

- Maier, M.; Tropschuh, B.; Teubner, S.; Reinhart, G. Method for designing the training process in manual assembly. ZWF Z. Fuer Wirtsch. Fabr. 2020, 115, 682–686. [Google Scholar]

- Hoedt, S.; Claeys, A.; Van Landeghem, H.; Cottyn, J. The evaluation of an elementary virtual training system for manual assembly. Int. J. Prod. Res. 2017, 55, 7496–7508. [Google Scholar] [CrossRef]

- Cannas, V.G.; Pero, M.; Pozzi, R.; Rossi, T. Complexity reduction and kaizen events to balance manual assembly lines: An application in the field. Int. J. Prod. Res. 2018, 56, 3914–3931. [Google Scholar] [CrossRef]

- Duan, F.; Zhang, Z.; Gao, Q.; Arai, T. Verification of the effect of an assembly skill transfer method on cognition skills. IEEE Trans. Cogn. Dev. Syst. 2016, 8, 73–83. [Google Scholar] [CrossRef]

- Lim, J.T.A.; Hoffmann, E.R.; Hoffmann, E.R. Strategies in performing a manual assembly task. Int. J. Ind. Ergon. 2014, 50, 121–129. [Google Scholar] [CrossRef]

- Haber, J.; Xu, H.; Priya, K. Harnessing virtual reality for management training: A longitudinal study. Organ. Manag. J. 2023, 20, 93–106. [Google Scholar] [CrossRef]

- Wolfartsberger, J.; Zimmermann, R.; Obermeier, G.; Niedermayr, D. Analyzing the potential of virtual reality-supported training for industrial assembly tasks. Comput. Ind. 2023, 147, 103838. [Google Scholar] [CrossRef]

- Jenab, K.; Moslehpour, S.; Khoury, S. Virtual maintenance, reality, and systems: A review. Int. J. Electr. Comput. Eng. 2016, 6, 2698–2707. [Google Scholar] [CrossRef]

- Mak, S.L.; Tang, F.W.F.; Li, C.H.; Lee, G.T.W.; Chiu, W.H. A review on development and application of virtual reality (Vr) training platform for testing, inspection and certification industry. Int. J. Inf. Educ. Technol. 2020, 10, 926–931. [Google Scholar] [CrossRef]

- Akinola, Y.M.; Agbonifo, O.C.; Sarumi, O.A. Virtual Reality as a tool for learning: The past, present and the prospect. J. Appl. Learn. Teach. 2020, 3, 51–58. [Google Scholar] [CrossRef]

- Barkokebas, R.; Ritter, C.; Sirbu, V.; Li, X.; Al-Hussein, M. Application of virtual reality in task training in the construction manufacturing industry. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction, ISARC 2019, Banff, AB, Canada, 21–24 May 2019; pp. 796–803. [Google Scholar] [CrossRef]

- Pallavicini, F.; Toniazzi, N.; Argenton, L.; Aceti, L.; Mantovani, F. Developing effective virtual reality training for military forces and emergency operators: From technology to human factors. In Proceedings of the 14th International Conference on Modeling and Applied Simulation, MAS, Bergeggi, Italy, 21–23 September 2015; pp. 206–210. [Google Scholar]

- Watson, W.L.; House, S.; Hart, R.; Abbas, J.; Asthana, S.; Gaudl, S.E. A Case Study Using Virtual Reality to Prime Knowledge for Procedural Medical Training; Springer Nature: Cham, Switzerland, 2023; Volume 14145, pp. 189–208. [Google Scholar] [CrossRef]

- Ho, N.; Wong, P.-M.; Chua, M.; Chui, C.-K. Virtual reality training for assembly of hybrid medical devices. Multimed. Tools Appl. 2018, 77, 30651–30682. [Google Scholar] [CrossRef]

- Bayonne, E.; Marin-Garcia, J.A.; Alfalla-Luque, R. Partial least squares (PLS) in operations management research: Insights from a systematic literature review. J. Ind. Eng. Manag 2020, 13, 565–597. [Google Scholar] [CrossRef]

- Di Pasquale, V.; Miranda, S.; Neumann, W.P.; Setayesh, A. Human reliability in manual assembly systems: A Systematic Literature Review. IFAC-PapersOnLine 2018, 51, 675–680. [Google Scholar] [CrossRef]

- Boletsis, C.; Karahasanovic, A. Immersive technologies in retail: Practices of augmented and virtual reality. In Proceedings of the 4th International Conference on Computer-Human Interaction Research and Applications, INSTICC, Budapest, Hungary, 5–6 November 2020. [Google Scholar] [CrossRef]

- Wei, L. Development of Virtual disassembly and assembly platform for marine air compressor. J. Phys. Conf. Ser. 2021, 1884, 012011. [Google Scholar] [CrossRef]

- Sportillo, D.; Avveduto, G.; Tecchia, F.; Carrozzino, M. Training in VR: A preliminary study on learning assembly/disassembly sequences. In Proceedings of the Augmented and Virtual Reality: Second International Conference, AVR 2015, Lecce, Italy, 31 August–3 September 2015; Volume 9254, pp. 332–343. [Google Scholar] [CrossRef]

- Langley, A.; Lawson, G.; Hermawati, S.; D’Cruz, M.; Apold, J.; Arlt, F.; Mura, K. Establishing the Usability of a Virtual Training System for Assembly Operations within the Automotive Industry. Hum. Factors Ergon. Manuf. 2016, 26, 667–679. [Google Scholar] [CrossRef]

- Ulmer, J.; Braun, S.; Cheng, C.-T.; Dowey, S.; Wollert, J. Gamification of virtual reality assembly training: Effects of a combined point and level system on motivation and training results. Int. J. Hum.-Comput. Stud. 2021, 165, 102854. [Google Scholar] [CrossRef]

- Vélaz, Y.; Lozano-Rodero, A.; Suescun, A.; Gutiérrez, T. Natural and hybrid bimanual interaction for virtual assembly tasks. Virtual Real. 2014, 18, 161–171. [Google Scholar] [CrossRef]

- Horejsi, P.; Novikov, K.; Simon, M. A smart factory in a smart city: Virtual and augmented reality in a smart assembly line. IEEE Access 2020, 8, 94330–94340. [Google Scholar] [CrossRef]

- Gallegos-Nieto, E.; Medellín-Castillo, H.I.; González-Badillo, G.; Lim, T. Virtual training of assembly tasks using virtual reality techniques and haptic systems. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; Volume 46445, p. V02BT02A063. [Google Scholar] [CrossRef]

- Vélaz, Y.; Arce, J.R.; Gutiérrez, T.; Lozano-Rodero, A.; Suescun, A. The influence of interaction technology on the learning of assembly tasks using virtual reality. J. Comput. Inf. Sci. Eng. 2014, 14, 041007. [Google Scholar] [CrossRef]

- Garbaya, S.; Romano, D.M.; Hattar, G. Gamification of assembly planning in virtual environment. Assem. Autom. 2019, 39, 931–943. [Google Scholar] [CrossRef]

- Farr, A.; Pietschmann, L.; Zürcher, P.; Bohné, T. Skill retention after desktop and head-mounted-display virtual reality training. Exp. Results 2023, 4, e2. [Google Scholar] [CrossRef]

- Ordaz, N.; Romero, D.; Gorecky, D.; Siller, H.R. Serious Games and Virtual Simulator for Automotive Manufacturing Education & Training. Procedia Comput. Sci. 2015, 75, 267–274. [Google Scholar] [CrossRef]

- Shen, S.; Chen, H.-T.; Raffe, W.; Leong, T.W. Effects of Level of Immersion on Virtual Training Transfer of Bimanual Assembly Tasks. Front. Virtual Real. 2021, 2, 597487. [Google Scholar] [CrossRef]

- Palmas, F.; Labode, D.; Plecher, D.A.; Klinker, G. Comparison of a gamified and non-gamified virtual reality training assembly task. In Proceedings of the 2019 11th International Conference on Virtual Worlds and Games for Serious Applications (VS-Games), Vienna, Austria, 4–6 September 2019. [Google Scholar] [CrossRef]

- Kalkan, M.K.; Karabulut, E.; Höke, G. Effect of Virtual Reality-Based Training on Complex Industrial Assembly Task Performance. Arab. J. Sci. Eng. 2021, 46, 12697–12708. [Google Scholar] [CrossRef]

- Rodrigues, P.; Coelho, H.; Melo, M.; Bessa, M. Virtual Reality For Training: A Computer Assembly Application. In Proceedings of the 2022 International Conference on Graphics and Interaction (ICGI), Aveiro, Portugal, 3–4 November 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Han, Y.; Chen, L.; Zhang, Z.; Liu, H. Usability study of auditory feedback and visual feedback in an immersive virtual assembly system. In Proceedings of the 2020 International Conference on Intelligent Computing, Automation and Systems (ICICAS), Chongqing, China, 11–13 December 2020; pp. 395–399. [Google Scholar] [CrossRef]

- Kloiber, S.; Settgast, V.; Schinko, C.; Weinzerl, M.; Schreck, T.; Preiner, R. A System for Collaborative Assembly Simulation and User Performance Analysis. In Proceedings of the 2021 International Conference on Cyberworlds (CW), Caen, France, 28–30 September 2021; pp. 93–100. [Google Scholar] [CrossRef]

- Niedermayr, D.; Wolfartsberger, J.; Maurer, M. Virtual Reality for Industrial Assembly Training: The Impact of Tool Interaction Realism on Learning Outcomes. In Proceedings of the 2023 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct), Sydney, Australia, 16–20 October 2023; pp. 183–190. [Google Scholar] [CrossRef]

- Zigart, T.; Stürzl, F.; Niedermayr, D.; Wolfartsberger, J.; Sorko, S.R. Comparative Evaluation of Virtual Reality and In-Person Onboarding for Assembly Trainings in Manufacturing. In Proceedings of the 2023 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct), Sydney, Australia, 16–20 October 2023; pp. 167–174. [Google Scholar] [CrossRef]

- De Moura, D.Y.; Sadagic, A. The effects of stereopsis and immersion on bimanual assembly tasks in a virtual reality system. In Proceedings of the 26th IEEE Conference on Virtual Reality and 3D User Interfaces (VR), Osaka, Japan, 23–27 March 2019; pp. 286–294. [Google Scholar] [CrossRef]

- Murcia-Lopez, M.; Steed, A. A comparison of virtual and physical training transfer of bimanual assembly tasks. IEEE Trans. Vis. Comput. Graph. 2018, 24, 1574–1583. [Google Scholar] [CrossRef]

- Dwivedi, P.; Cline, D.; Joe, C.; Etemadpour, R. Manual assembly training in virtual environments. In Proceedings of the 18th International Conference on Advanced Learning Technologies (ICALT), Mumbai, India, 9–13 July 2018; pp. 395–399. [Google Scholar] [CrossRef]

- Manuri, F.; Decataldo, F.; Sanna, A.; Brizzi, P. A Comparison of Two Interaction Paradigms for Training Low Cost Automation Assembly in Virtual Environments. Information 2023, 14, 340. [Google Scholar] [CrossRef]

- Koumaditis, K.; Chinello, F.; Mitkidis, P.; Karg, S.T. Effectiveness of Virtual vs. Physical Training: The Case of Assembly Tasks, Trainer’s Verbal Assistance, and Task Complexity. IEEE Comput. Graph. Appl. 2020, 40, 41–56. [Google Scholar] [CrossRef] [PubMed]

- Grajewski, D.; Hamrol, A. Low-cost VR system for interactive education of manual assembly procedure. Interact. Learn. Environ. 2023, 31, 68–86. [Google Scholar] [CrossRef]

- Gavish, N.; Gutiérrez, T.; Webel, S.; Rodríguez, J.; Peveri, M.; Bockholt, U.; Tecchia, F. Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks. Interact. Learn. Environ. 2015, 23, 778–798. [Google Scholar] [CrossRef]

- Abidi, M.H.; Al-Ahmari, A.; Ahmad, A.; Ameen, W.; Alkhalefah, H. Assessment of virtual reality-based manufacturing assembly training system. Int. J. Adv. Manuf. Technol. 2019, 105, 3743–3759. [Google Scholar] [CrossRef]

- Vix Kemanji, K.; Mpwadina, R.; Meixner, G. Virtual Reality Assembly of Physical Parts: The Impact of Interaction Interface Techniques on Usability and Performance. In Proceedings of the Virtual, Augmented and Mixed Reality Applications in Education, Aviation and Industry—14th International Conference, VAMR 2022 Held as Part of the 24th HCI International Conference, HCII 2022, Virtual Event, 26 June–1 July 2022; Proceedings, Part II. Volume 13318. [Google Scholar] [CrossRef]

- Daling, L.M.; Tenbrock, M.; Isenhardt, I.; Schlittmeier, S.J. Assemble it like this!—Is AR- or VR-based training an effective alternative to video-based training in manual assembly? Appl. Ergon. 2023, 110, 104021. [Google Scholar] [CrossRef] [PubMed]

- Dwyer, F. Edgar Dale’s Cone of experience: A quasi-experimental analysis. Int. J. Instr. Media 2010, 37, 431–438. [Google Scholar]

- Numfu, M.; Riel, A.; Noel, F. Virtual reality based digital chain for maintenance training. Procedia CIRP 2019, 84, 1069–1074. [Google Scholar] [CrossRef]

- Kuipers, N.; Kolbeinsson, A.; Thorvald, P. Appropriate assembly instruction modes: Factors to consider. Adv. Transdiscipl. Eng. 2021, 15, 27–32. [Google Scholar] [CrossRef]

- Marraffino, M.D.; Johnson, C.I.; Garibaldi, A.E. Virtual Reality is Better Than Desktop for Training a Spatial Knowledge Task, but Not for Everyone. In Proceedings of the 14th International Conference, VAMR 2022, Held as Part of the 24th HCI International Conference, HCII 2022, Virtual Event, 26 June–1 July 2022; Proceedings, Part I. Volume 13317, pp. 212–223. [Google Scholar] [CrossRef]

- Li, C.; Yeom, S.; Dermoudy, J.; de Salas, K. Cognitive Load Measurement in the Impact of VR Intervention in Learning. In Proceedings of the 2022 International Conference on Advanced Learning Technologies (ICALT), Bucharest, Romania, 1–4 July 2022; pp. 325–329. [Google Scholar] [CrossRef]

- Young, K.; Dermoudy, J.; Lewis, I.; Young, K.; Dermoudy, J.; Lewis, I. A Digital Future in Virtual Reality—Insights for Training. 2020. Available online: https://aisel.aisnet.org/acis2020/26/ (accessed on 12 April 2023).

- Lee, C.-M.; Woo, W.-S.; Roh, Y.-H. Remanufacturing: Trends and issues. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 113–125. [Google Scholar] [CrossRef]

- Matsumoto, M.; Yang, S.; Martinsen, K.; Kainuma, Y. Trends and research challenges in remanufacturing. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 129–142. [Google Scholar] [CrossRef]

- Pollard, K.A.; Oiknine, A.H.; Files, B.T.; Sinatra, A.M.; Patton, D.; Ericson, M.; Thomas, J.; Khooshabeh, P. Level of immersion affects spatial learning in virtual environments: Results of a three-condition within-subjects study with long intersession intervals. Virtual Real. 2020, 24, 783–796. [Google Scholar] [CrossRef]

- de Back, T.T.; van Hoef, R.; Tinga, A.M.; Louwerse, M.M. Presence is Key: Unlocking Performance Benefits of Immersive Virtual Reality. In Proceedings of the 40th Annual Meeting of the Cognitive Science Society: Changing Minds, CogSci 2018, Madison, WI, USA, 25–28 July 2018; Volume 1, pp. 1602–1607. [Google Scholar]

- Martirosov, S.; Bureš, M.; Zítka, T. Cyber sickness in low-immersive, semi-immersive, and fully immersive virtual reality. Virtual Real. 2022, 26, 15–32. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez-Maldonado, J.; Andres-Pueyo, A.; Jarne, A.; Talarn, A.; Ferrer, M.; Achotegui, J. Virtual reality for training diagnostic skills in anorexia nervosa: A usability assessment. In Virtual, Augmented and Mixed Reality: Proceedings of the 9th International Conference, VAMR 2017, Held as Part of HCI International 2017, Vancouver, BC, Canada, 9–14 July 2017; Springer International Publishing: Cham, Switzerland, 2017; Volume 10280, pp. 239–247. [Google Scholar] [CrossRef]

| Group A | Group B | Group C |

|---|---|---|

| Virtual Reality (VR), VR, Virtual Environment, Immersive Technolog *, GamiFication, Synthetic Reality, Serious Game | Training, Learning | Disassembl *, Assembl *, Remanufactur * |

| Level of Immersion | Devices |

|---|---|

| LOW [40,41,42,43,44,45] | PC desktop 2D + Mouse + Keyboard |

| PC desktop 2D + Mouse + Keyboard | |

| PC desktop 2D + Mouse + Keyboard + Leap Motion Controller | |

| PC desktop 2D + Mouse | |

| PC desktop 2D + Mouse + Keyboard + Headphones | |

| Detection Response Task + HMD + Manual controllers | |

| Mouse + Haptic Phantom OmniVR + Markerless Motion Capture | |

| Multi-touch table | |

| MEDIUM [36,38,46,47,48,49] | HTC VIVE + Manual controllers |

| Microsoft Kinect + Controller Nintendo Wii Mote + HMD | |

| VR Glasses + Joystick | |

| Laptop + Microsoft Kinect + Wii Mote | |

| Headphones + HMD + Controllers | |

| Microsoft Hololens | |

| HMD + Joystick | |

| HIGH [20,25,37,39,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64] | HTC VIVE + HTC VIVE headset + HTC VIVE controllers + HTC VIVE base station + VIVE tracker |

| HTC VIVE 3 HMD + HTC VIVE controllers | |

| HTC Vive and accessories + IR camera | |

| HTC VIVE Pro + Leap Motion Controller | |

| HTC Vive Pro Head-Mounted Display + 6-DOF Motion Controller | |

| Keyboard + Mouse + Tactile devices + HTC VIVE | |

| Oculus Quest (or Oculus Rift) + Controllers | |

| Oculus Rift + IR camera + Leap Motion Controller | |

| Optical marker + HMD Oculus Rift DK2 + 3D camera + CAVE system | |

| HMD + Tactile devices | |

| 3D screen + Tactile devices + Stereoscopic glasses | |

| 3D monitor + Stereoscopic glasses + Wire glove + Hand and head tracking systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Pasquale, V.; Cutolo, P.; Esposito, C.; Franco, B.; Iannone, R.; Miranda, S. Virtual Reality for Training in Assembly and Disassembly Tasks: A Systematic Literature Review. Machines 2024, 12, 528. https://doi.org/10.3390/machines12080528

Di Pasquale V, Cutolo P, Esposito C, Franco B, Iannone R, Miranda S. Virtual Reality for Training in Assembly and Disassembly Tasks: A Systematic Literature Review. Machines. 2024; 12(8):528. https://doi.org/10.3390/machines12080528

Chicago/Turabian StyleDi Pasquale, Valentina, Paolo Cutolo, Carmen Esposito, Benedetta Franco, Raffaele Iannone, and Salvatore Miranda. 2024. "Virtual Reality for Training in Assembly and Disassembly Tasks: A Systematic Literature Review" Machines 12, no. 8: 528. https://doi.org/10.3390/machines12080528