Development and Balancing Control of Control Moment Gyroscope (CMG) Unicycle–Legged Robot

Abstract

1. Introduction

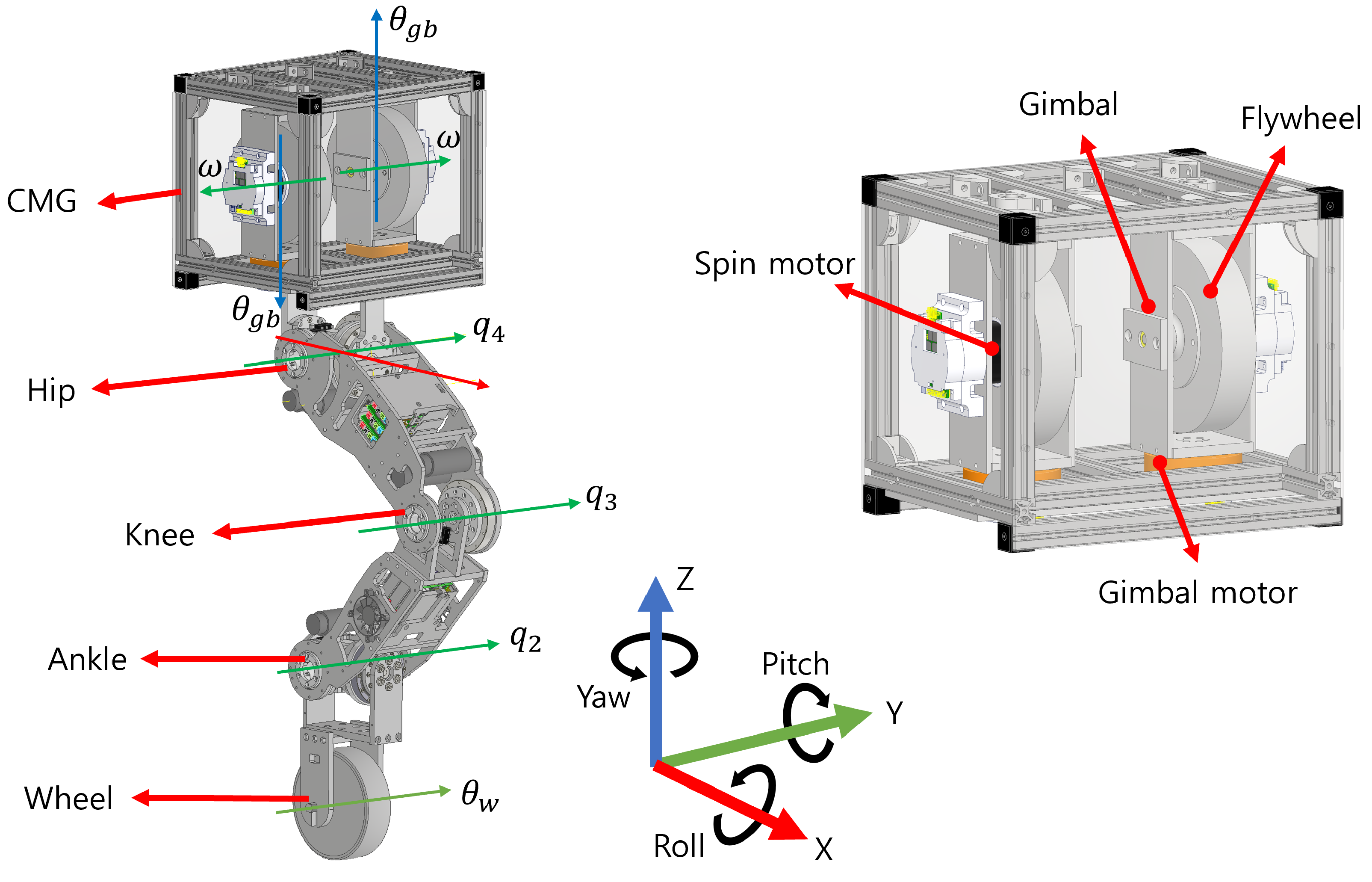

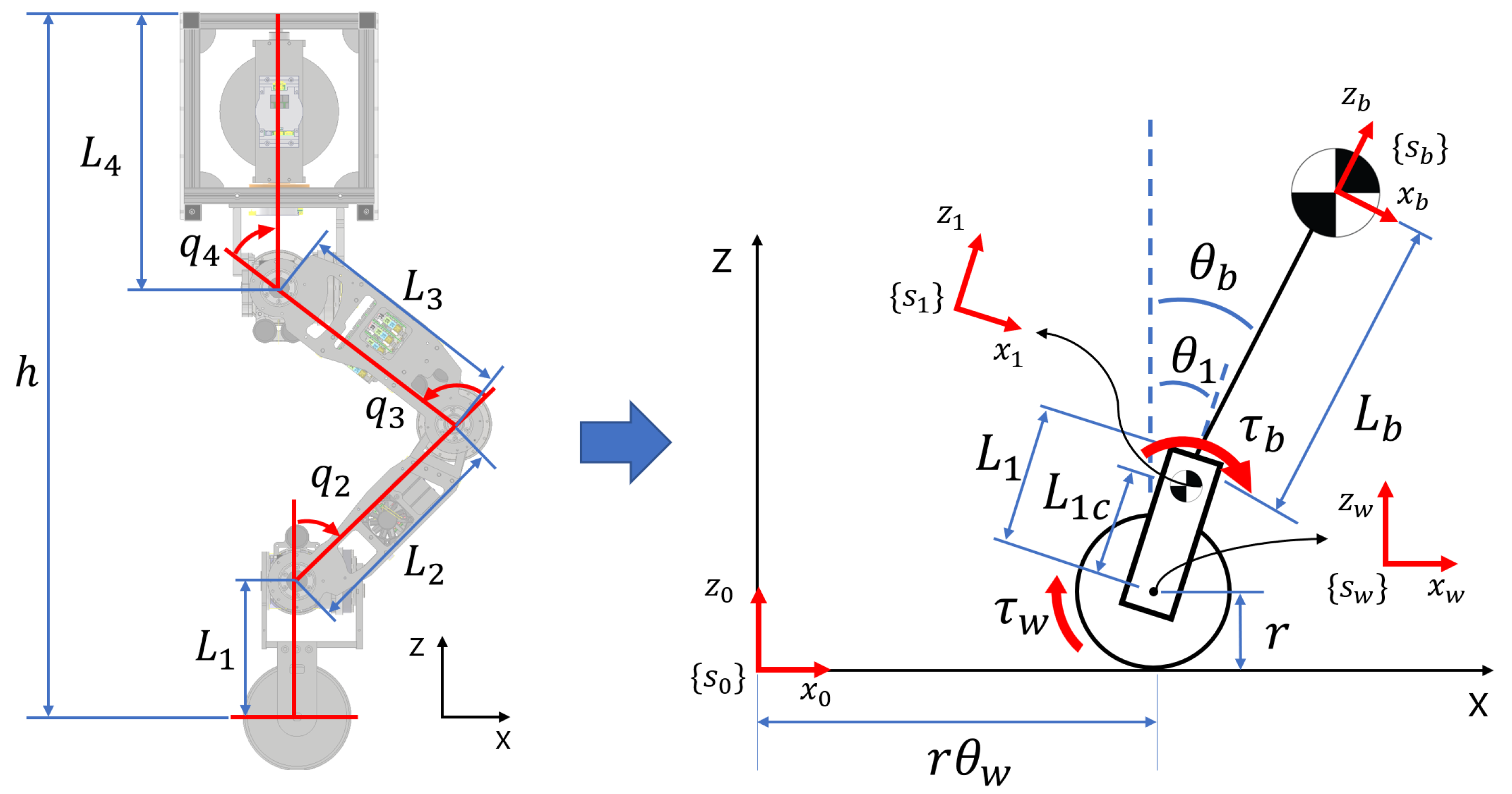

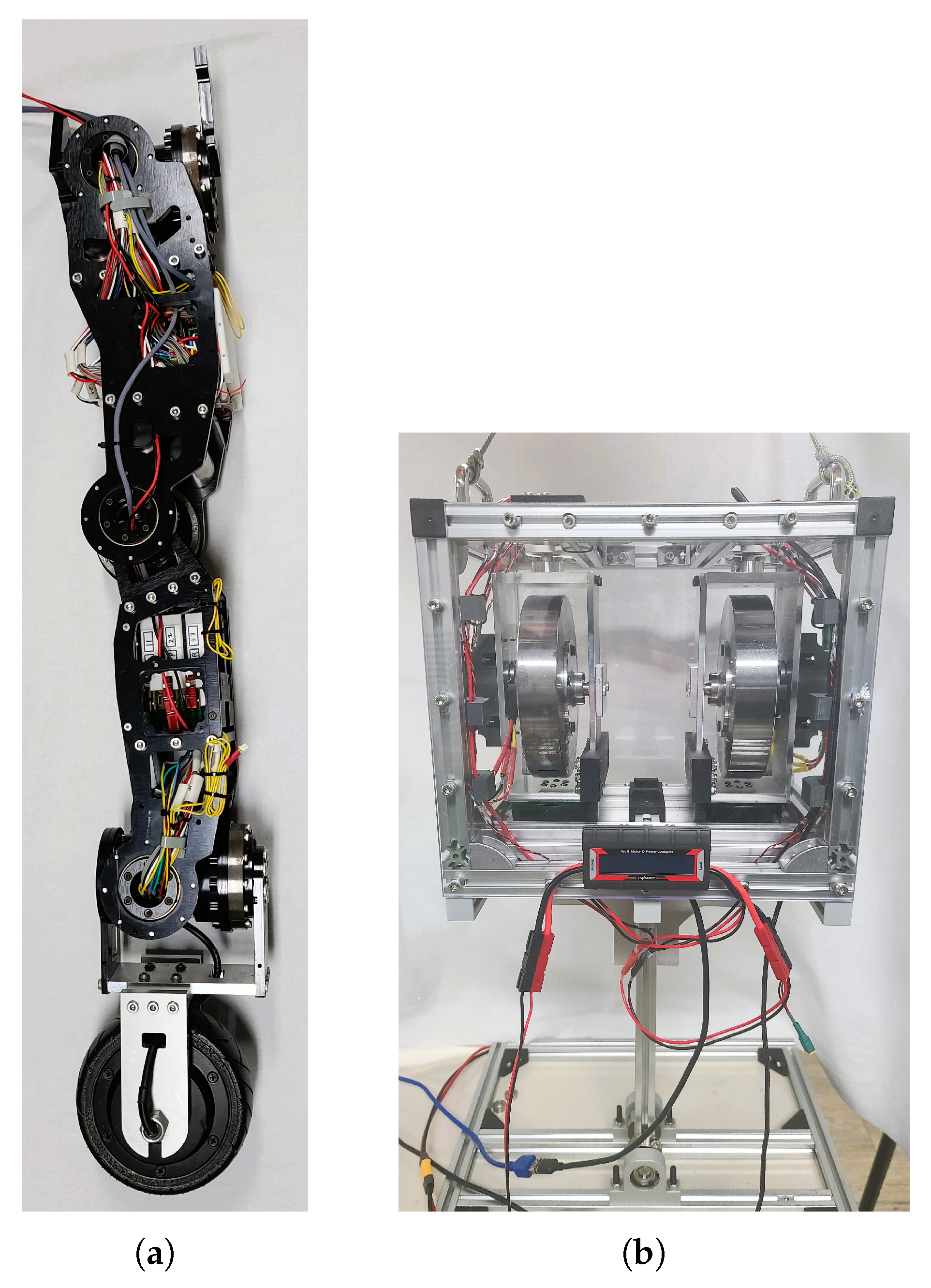

2. Mechanical Design

2.1. Hardware

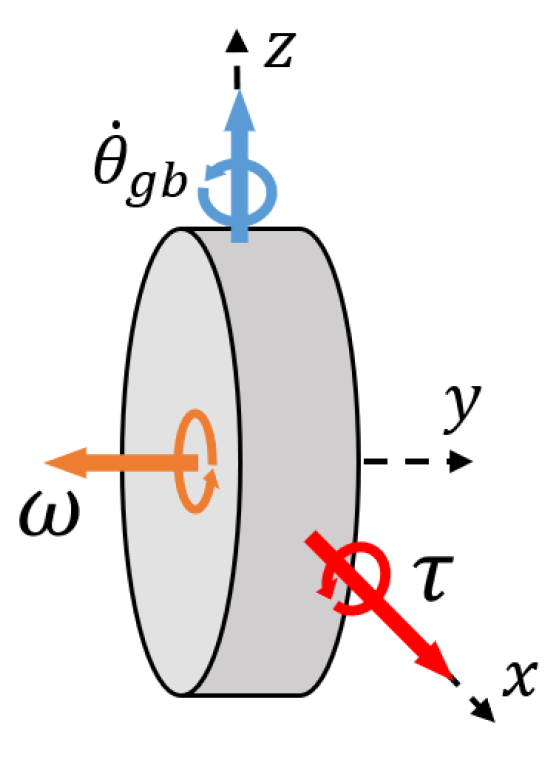

2.2. CMG (Control Moment Gyroscope)

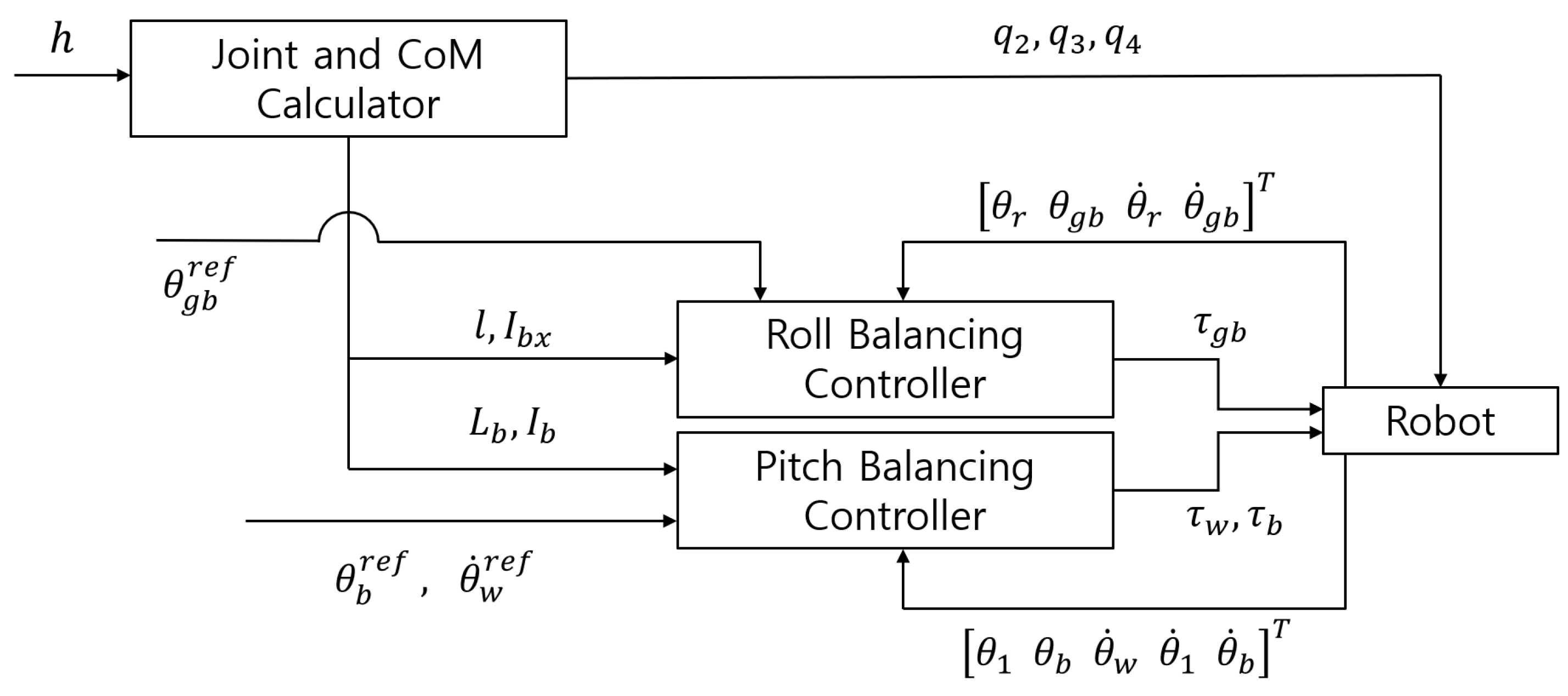

3. Dynamics and Controller Design

3.1. Notation and Assumptions

- No slip at the wheel–ground contact and a rigid, planar ground.

- Rigid links and CMG assembly; gearbox backlash and structural compliance are neglected.

- Small-angle operation about the upright, enabling first-order linearization .

- Roll–pitch decoupling near the operating region due to the scissored-pair CMG: pitch-direction torque components are canceled by symmetry and roll authority scales such as ; the residual coupling terms in the linearized model remain below the sensor noise within the stated range.

- Wheel actuation affects the pitch plane (forward/backward motion); roll torque is generated by the CMG; and yaw is actuated via gimbal motion (no external yaw moments).

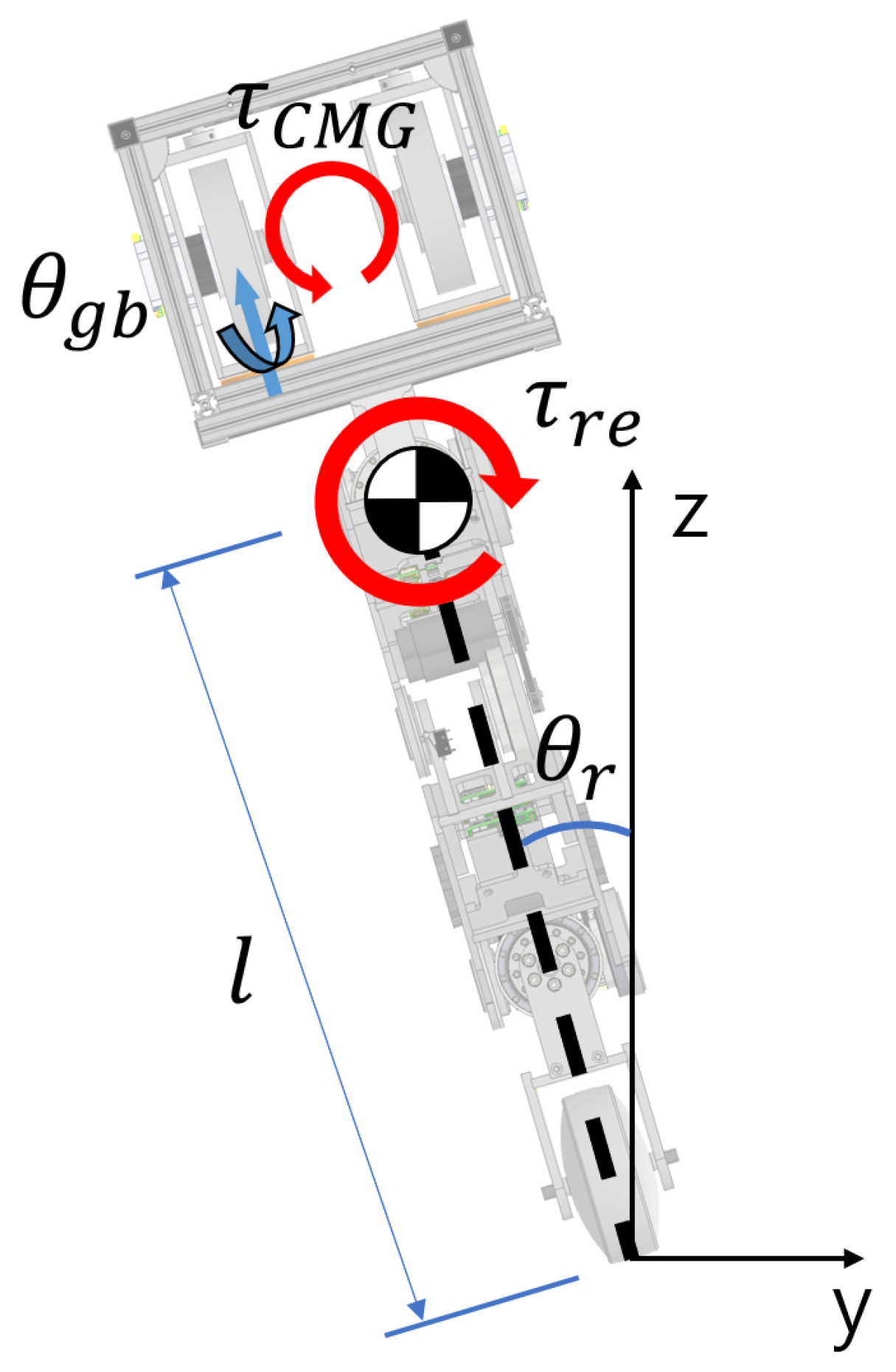

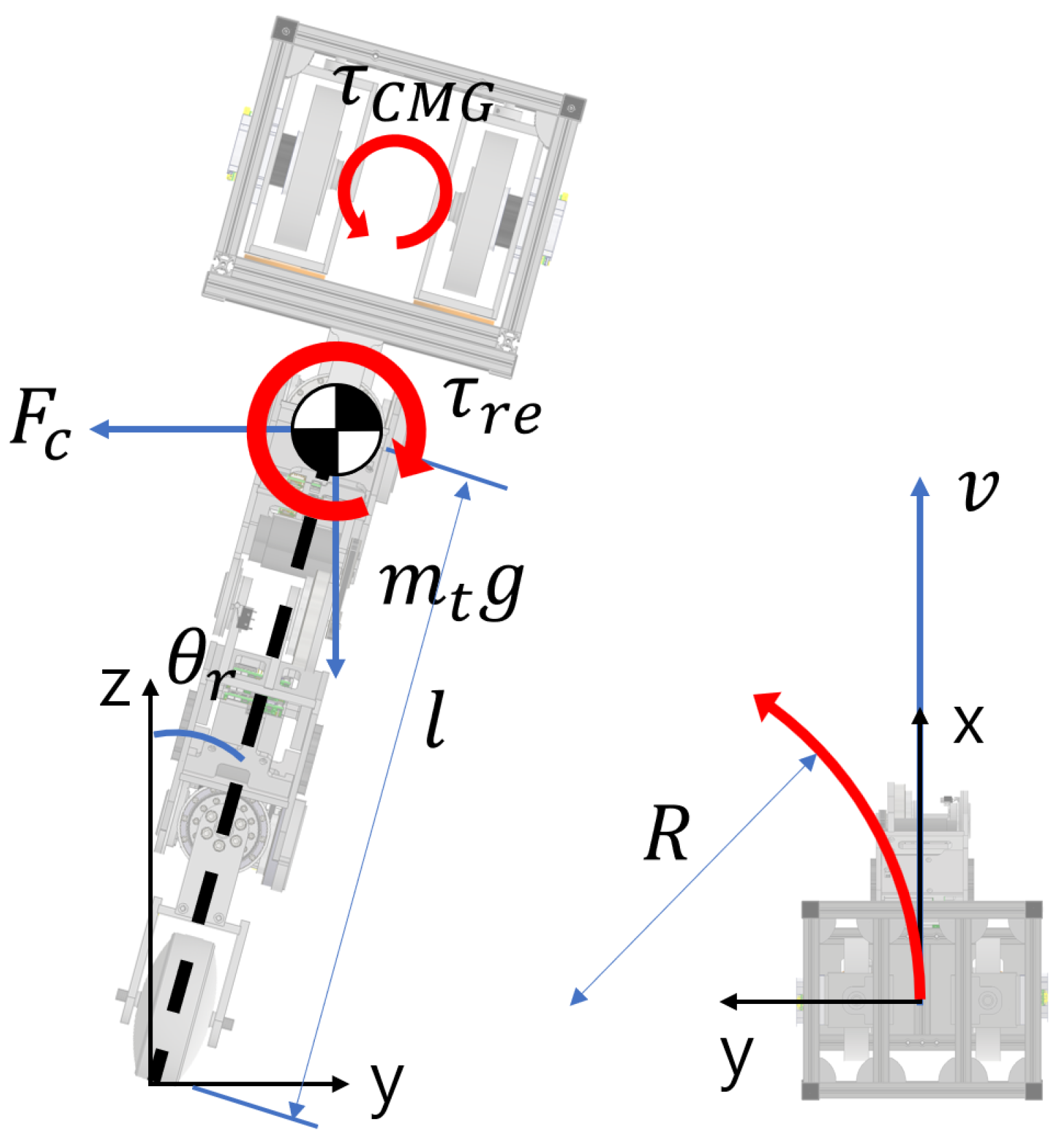

3.2. Roll Dynamics and Balancing Controller

3.3. Pitch Dynamics and Balancing Controller

3.4. Rotation Control in the Yaw Direction

4. Simulation

4.1. Self-Balancing Simulation

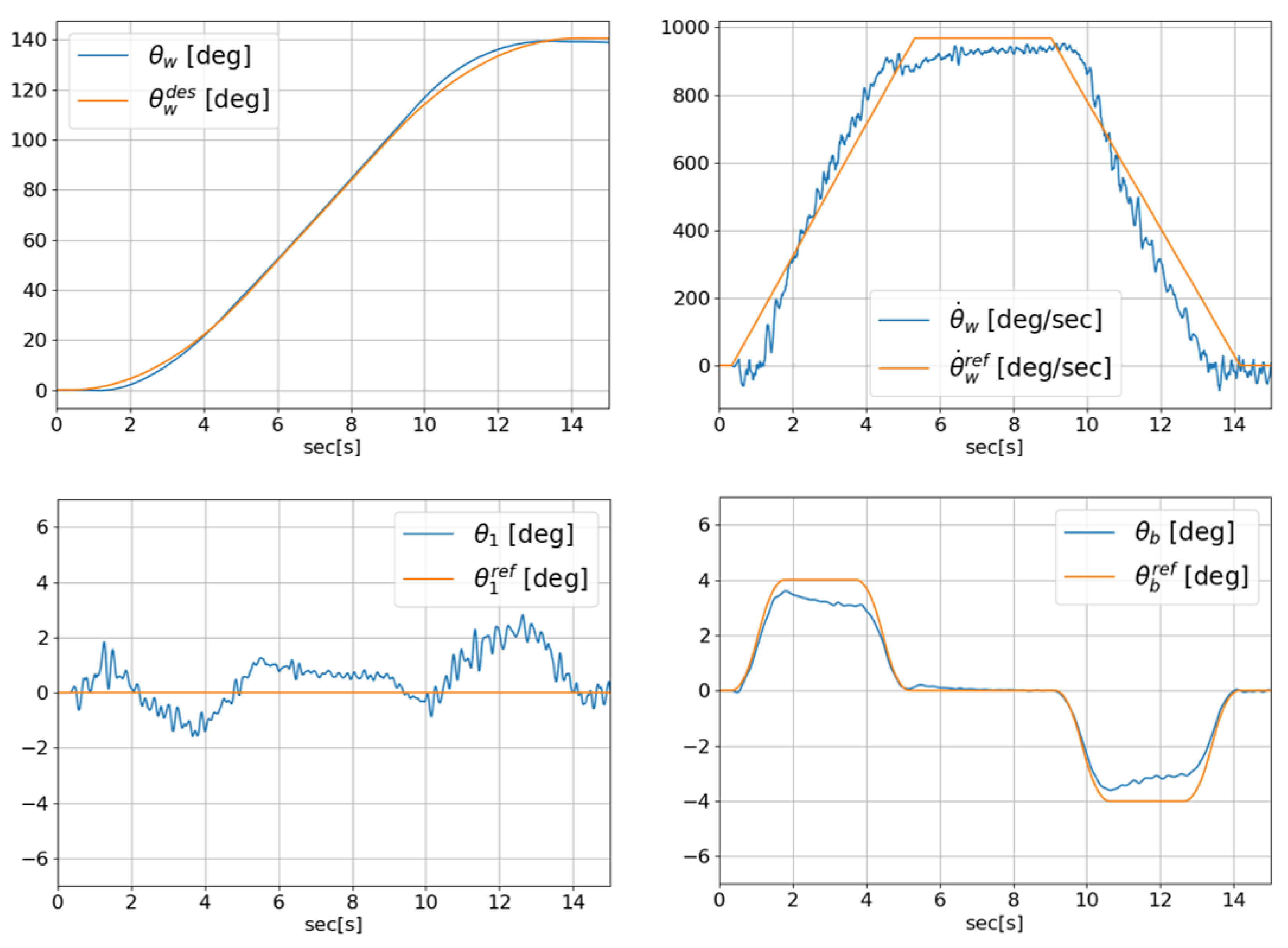

4.2. Driving Control Simulation in the X Direction

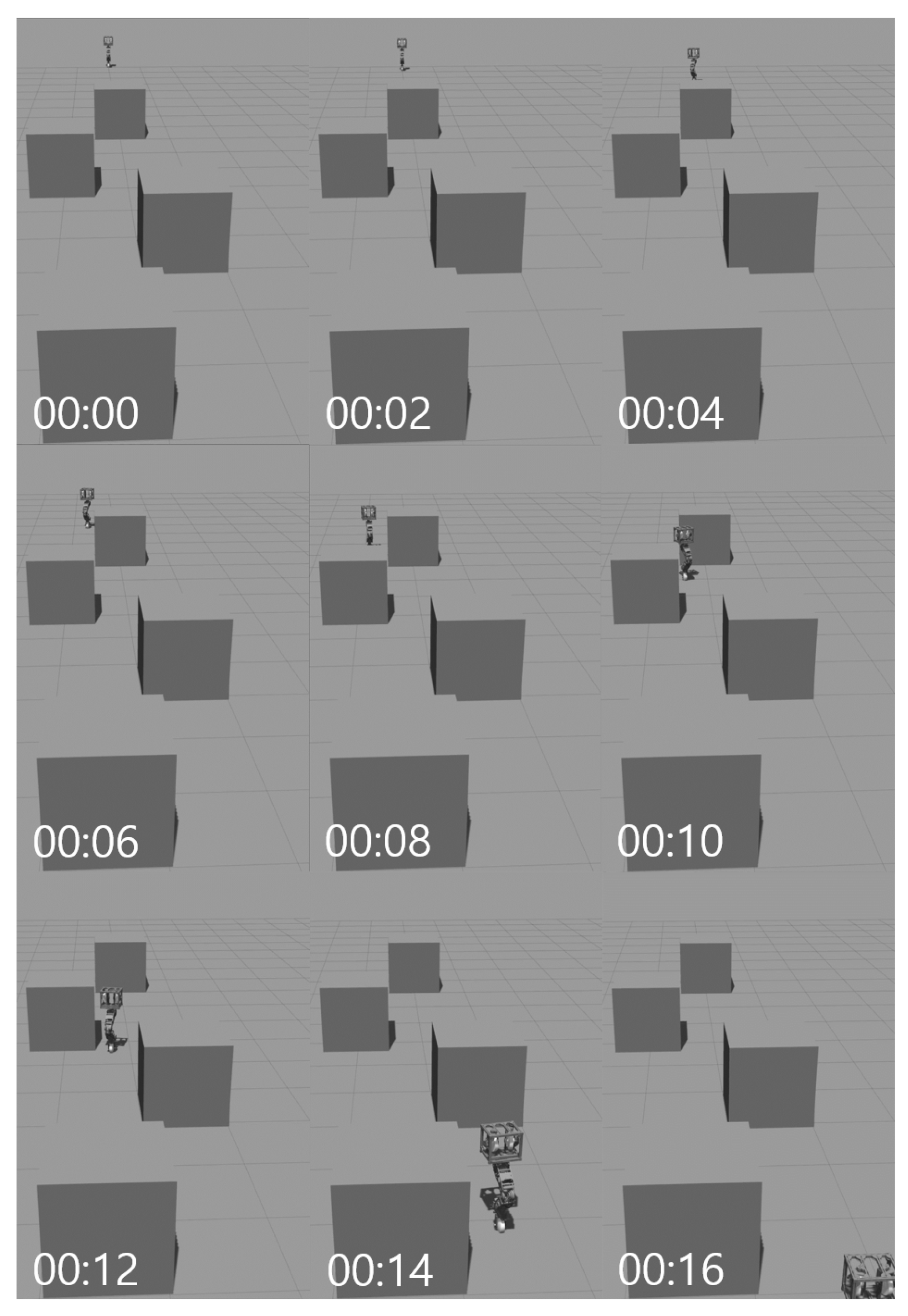

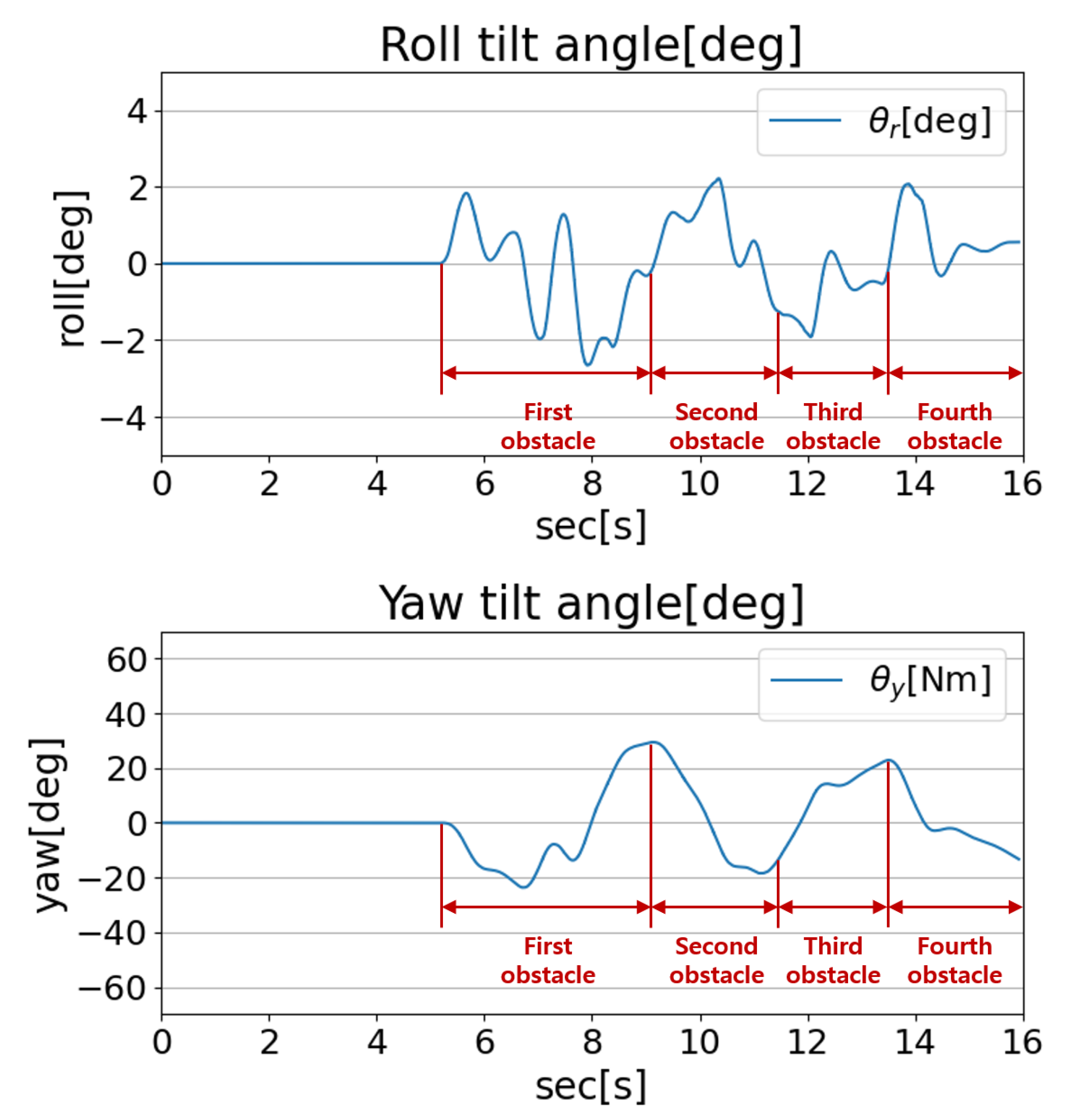

4.3. Obstacle Avoidance Simulation

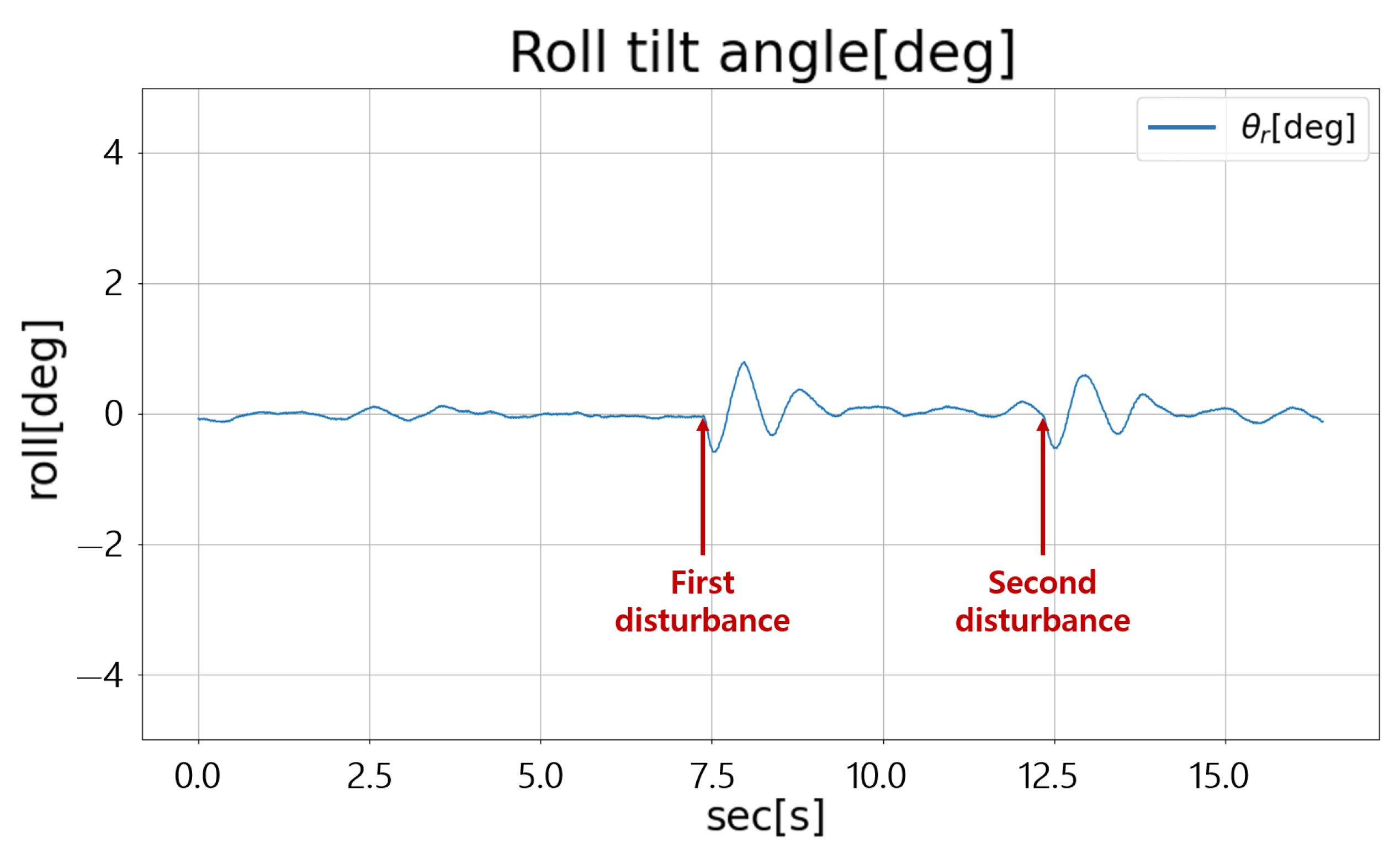

5. Experiment

6. Limitations and Practical Considerations

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CMG | Control Moment Gyroscope |

| LQR | Linear Quadratic Regulator |

| MPC | Model Predictive Control |

| DMPC | Discrete Model Predictive Control |

| W-SLIP | Wheeled–Spring-Loaded Inverted Pendulum |

| CULR | CMG Unicycle–Legged Robot |

| COM | Center of Mass |

| EMF | Electromotive Force |

References

- Schwarz, M.; Rodehutskors, T.; Droeschel, D.; Behnke, S. Hybrid driving–stepping locomotion with the wheeled-legged robot Momaro. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 5589–5596. [Google Scholar]

- Schwarz, M.; Rodehutskors, T.; Droeschel, D.; Behnke, S. NimbRo Rescue: Solving disaster-response tasks through mobile manipulation robot Momaro. J. Field Robot. 2018, 35, 400–425. [Google Scholar] [CrossRef]

- Bjelonic, M.; Bellicoso, C.D.; Jenelten, F.; Hutter, M. Design principles for wheeled-legged robots. IEEE Robot. Autom. Lett. 2019, 4, 315–322. [Google Scholar]

- Bjelonic, M.; Jenelten, F.; Bellicoso, C.D.; Hutter, M. Whole-body MPC and online gait sequence generation for wheeled-legged robots. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–1 October 2021; pp. 7080–7087. [Google Scholar]

- Cordes, F.; Dettmann, A.; Kirchner, F. Locomotion modes for a hybrid wheeled-leg planetary rover. In Proceedings of the 2011 IEEE International Conference on Robotics and Biomimetics (ROBIO), Phuket, Thailand, 7–11 December 2011; pp. 2581–2586. [Google Scholar]

- Cordes, F.; Kirchner, F.; Babu, A. Design and field testing of a rover with an actively articulated suspension system (SherpaTT). J. Field Robot. 2018, 35, 1101–1124. [Google Scholar] [CrossRef]

- Xin, S.; Vijayakumar, S. Online dynamic motion planning and control for wheeled biped robots. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 3892–3899. [Google Scholar]

- Chen, J.; Gao, F.; Huang, C.; Zhao, J. Whole-body motion planning for a six-legged robot walking on rugged terrain. Appl. Sci. 2019, 9, 5284. [Google Scholar] [CrossRef]

- Chen, H.; Wang, B.; Hong, Z.; Shen, C.; Wensing, P.M.; Zhang, W. Underactuated motion planning and control for jumping with wheeled-bipedal robots. IEEE Robot. Autom. Lett. 2021, 6, 747–754. [Google Scholar] [CrossRef]

- Semini, C.; Focchi, M.; Featherstone, R.; Caldwell, D.G. Quadrupedal locomotion over rough terrain: Models and experiments. Int. J. Robot. Res. 2017, 36, 170–187. [Google Scholar]

- Sheng, Z.; Yamafuji, K. Postural stability of a human riding a unicycle and its emulation by a robot. IEEE Trans. Robot. Autom. 1997, 13, 709–720. [Google Scholar] [CrossRef]

- Han, S.I.; Lee, J.M. Balancing and velocity control of a unicycle robot based on the dynamic model. IEEE Trans. Ind. Electron. 2015, 62, 405–413. [Google Scholar] [CrossRef]

- Lee, J.-O.; Han, S.-I.; Lee, J.-M. Decoupled dynamic control for pitch and roll axes of the unicycle robot. IEEE Trans. Ind. Electron. 2013, 60, 3814–3822. [Google Scholar] [CrossRef]

- Shim, Y.K.; Ha, M.S.; Jung, S. Roll control of a novel single line play robot by controlling air pressure of ducted fans. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics (ISIE), Hangzhou, China, 28–31 May 2012; pp. 937–942. [Google Scholar]

- Kawak, B.J. Development of a low-cost, low micro-vibration CMG for small agile satellite applications. Acta Astronaut. 2017, 131, 113–122. [Google Scholar] [CrossRef]

- Kojima, H.; Nakamura, R.; Keshtkar, S. Steering control law for double-gimbal scissored-pair CMG. Adv. Space Res. 2020, 66, 771–784. [Google Scholar] [CrossRef]

- Park, S.H.; Yi, S.Y. Active balancing control for unmanned bicycle using scissored-pair control moment gyroscope. Int. J. Control Autom. Syst. 2020, 18, 217–224. [Google Scholar] [CrossRef]

- Jin, H.; Wang, T.; Yu, F.; Zhu, Y.; Zhao, J.; Lee, J. Unicycle robot stabilized by the effect of gyroscopic precession and its control realization based on centrifugal force compensation. IEEE/ASME Trans. Mechatron. 2016, 21, 2737–2745. [Google Scholar] [CrossRef]

- Park, I.W.; Kim, J.Y.; Lee, J.; Oh, J.H. Mechanical design of the humanoid robot platform, HUBO. Adv. Robot. 2007, 21, 1305–1322. [Google Scholar] [CrossRef]

- Lim, J.; Lee, I.; Sim, O.; Joe, H.; Kim, I.; Lee, J.; Oh, J.H. Robot system of DRC-HUBO+ and control strategy of Team KAIST in DARPA Robotics Challenge Finals. J. Field Robot. 2017, 34, 1359–1382. [Google Scholar] [CrossRef]

- Choi, D.; Oh, J.H. Active suspension for a rapid mobile robot using Cartesian computed torque control. J. Intell. Robot. Syst. 2015, 79, 221–235. [Google Scholar] [CrossRef]

- Choi, D. Model predictive control of autonomous delivery robot with non-minimum phase characteristic. Int. J. Precis. Eng. Manuf. 2020, 21, 883–894. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, T.; Song, S.; Meng, M.Q.H. System design and balance control of a bipedal leg-wheeled robot. In Proceedings of the 2019 IEEE International Conference on Robotics and Biomimetics (ROBIO), Dali, China, 6–8 December 2019; pp. 1869–1874. [Google Scholar]

- Wertz, J.R. (Ed.) Spacecraft Attitude Determination and Control; Astrophysics and Space Science Library; Springer: Dordrecht, The Netherlands, 2012; Volume 73. [Google Scholar]

- Yang, Y.; Kim, S.; Lee, K.; Leeghim, H. Disturbance robust attitude stabilization of multirotors with control moment gyros. Sensors 2024, 24, 8212. [Google Scholar] [CrossRef] [PubMed]

- Choi, D. VESCular6: An Open-Source Motor Controller Framework for Robotics (Documentation). GitBook. Available online: https://dongilc.gitbook.io/ (accessed on 19 September 2025).

- Choi, D. Development of open-source motor controller framework for robotic applications. IEEE Access 2020, 8, 14134–14145. [Google Scholar] [CrossRef]

| Degrees of Freedom | CMG | 4 DOF |

| Hip | 2 DOF | |

| Knee | 1 DOF | |

| Ankle | 2 DOF | |

| Wheel | 1 DOF | |

| Total | 10 DOF | |

| Platform Size | 290 mm × 250 mm × 1146 mm (Maximum height) | |

| Wheel Size | 5.5 Inch | |

| Weight | 25.007 kg | |

| Flywheel Mass | 3.73 kg | |

| Height | 0.889∼1.146 m | |

| Symbol | Unit | |

|---|---|---|

| roll angle | ||

| pitch angle | ||

| yaw angle | ||

| gimbal angle | ||

| wheel angle | ||

| relative angle of the ith link | ||

| flywheel angular momentum (vector) | ||

| H | magnitude of | |

| gimbal angular velocity (vector) | ||

| CMG torque about body | ||

| V | motor drive voltage (gimbal) | |

| n | motor gear ratio | – |

| total mass of the robot | ||

| mass of the ith link | ||

| motor rotor inertia | ||

| body moment of inertia about the x-axis | ||

| wheel moment of inertia about the y-axis | ||

| flywheel moments of inertia about y and z axes | ||

| gimbal moment of inertia about the z-axis | ||

| length of the ith link | ||

| distance from joint of link i to its COM | ||

| link vector of length (base frame 0) | ||

| r | wheel radius | |

| l | distance from ground to COM | |

| distance from wheel center to COM along x/z axes | ||

| motor torque constant | ||

| motor back-EMF constant | ||

| motor winding resistance | ||

| motor viscous damping coefficient |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, S.; Choi, M.; Ahn, S.; Hur, S.; Kim, D.; Choi, D. Development and Balancing Control of Control Moment Gyroscope (CMG) Unicycle–Legged Robot. Machines 2025, 13, 937. https://doi.org/10.3390/machines13100937

Shin S, Choi M, Ahn S, Hur S, Kim D, Choi D. Development and Balancing Control of Control Moment Gyroscope (CMG) Unicycle–Legged Robot. Machines. 2025; 13(10):937. https://doi.org/10.3390/machines13100937

Chicago/Turabian StyleShin, Seungchul, Minjun Choi, Seongmin Ahn, Seongyong Hur, David Kim, and Dongil Choi. 2025. "Development and Balancing Control of Control Moment Gyroscope (CMG) Unicycle–Legged Robot" Machines 13, no. 10: 937. https://doi.org/10.3390/machines13100937

APA StyleShin, S., Choi, M., Ahn, S., Hur, S., Kim, D., & Choi, D. (2025). Development and Balancing Control of Control Moment Gyroscope (CMG) Unicycle–Legged Robot. Machines, 13(10), 937. https://doi.org/10.3390/machines13100937