Current Trends in Monitoring and Analysis of Tool Wear and Delamination in Wood-Based Panels Drilling

Abstract

1. Introduction

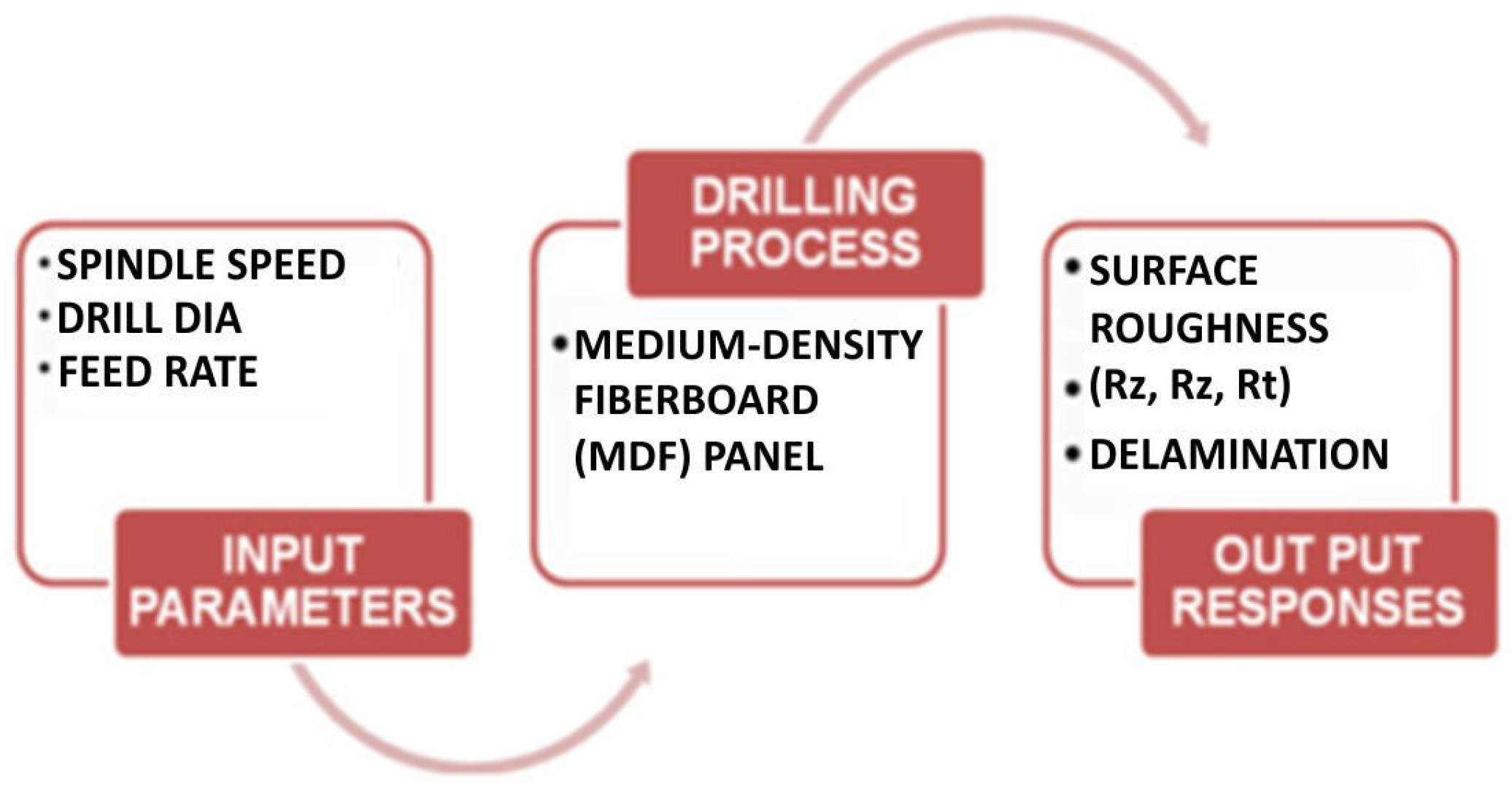

2. Particleboard Drilling

3. Medium-Density Fiberboard Drilling

4. Oriented Strand Board Drilling

5. Discussion

6. Conclusions

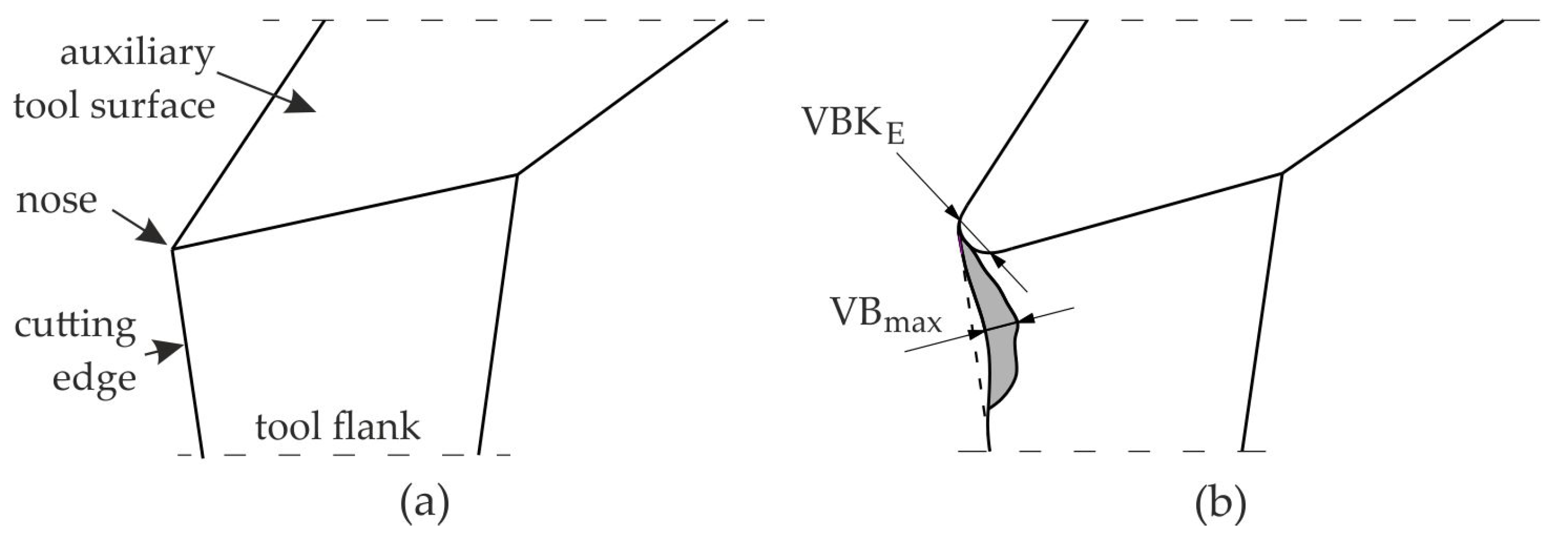

- Selecting the right drills, along with the appropriate material and coatings, for wood-like board processing is crucial to achieving high-quality holes and precision drilling. The delamination of the hole edges is greatest for the spur drill bit and increases with an increasing feed rate. The best machining quality is provided by the twist drill. Twist drills also provide better surface quality after machining compared to flat drills.

- The optimization of drilling parameters is a key factor influencing the quality and efficiency of the machining process. The influence of individual machining parameters, the type of drill and its geometry is not unambiguous. The research results presented in the literature link the influence of individual machining parameters with the type, density and physicochemical properties of wood-based panels, the coolants used, the type of drill material and the stiffness of the machine–holder–tool system. However, the key parameters mentioned by most authors include the spindle speed and feed rate, whereby increasing the rotational speed of the drill and reducing the feed rate lead to an improvement in the quality of holes drilled in wood-based panels.

- Spindle speed is one of the most important drilling parameters. Too high a speed can cause the tool to overheat and damage the material. Too low a speed causes too high a cutting force, which can lead to vibration and damage to the tool. The feed directly affects the value of thrust force, the damage to the surface of the holes and the processing time.

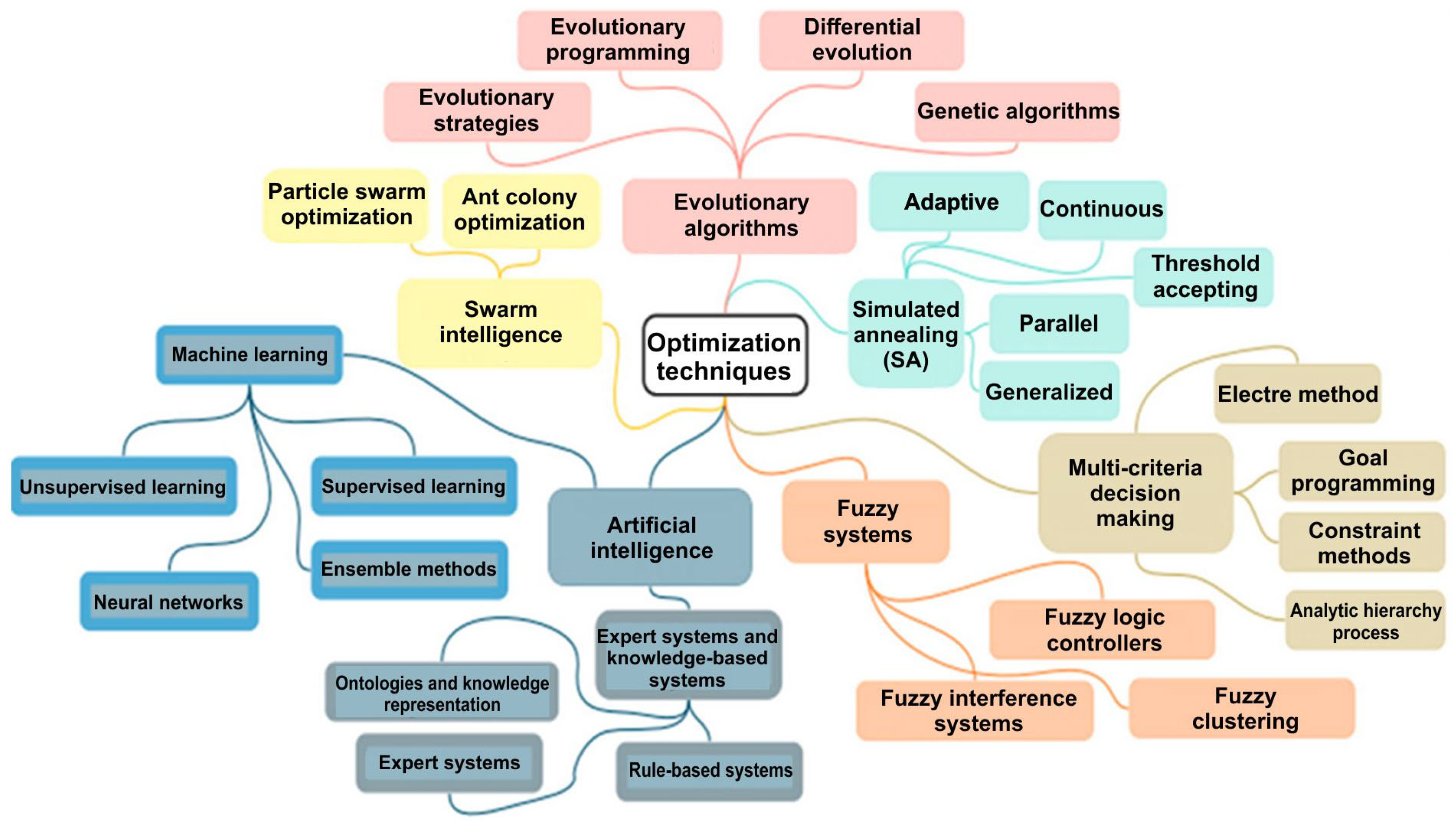

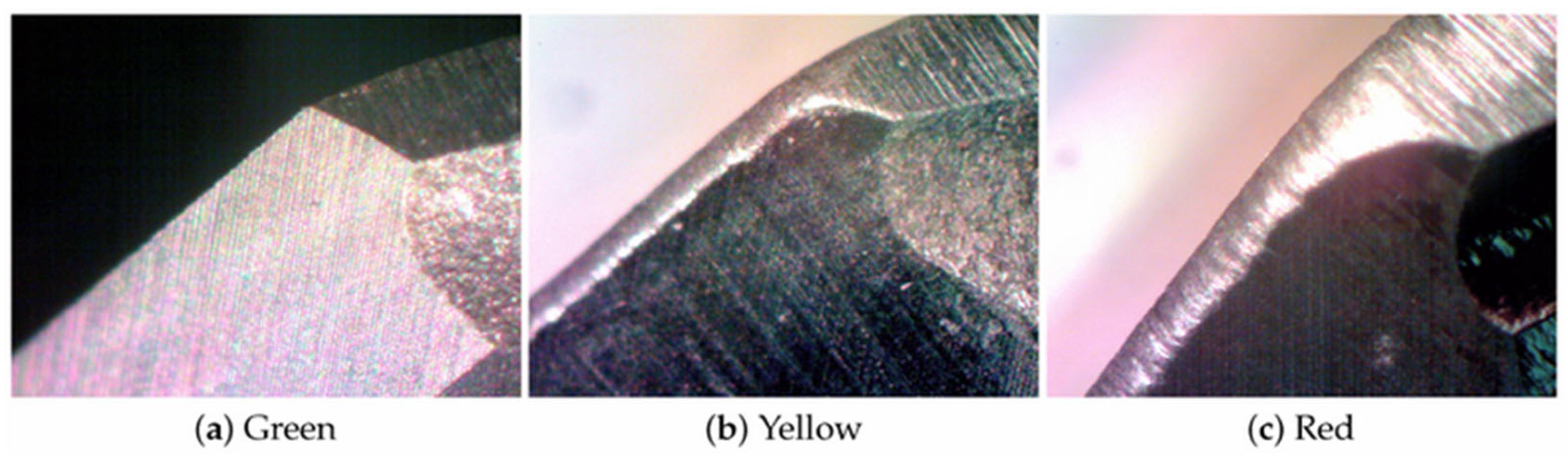

- Monitoring the condition of drills during machining involves many strategies, using the signal from sensors to measure machining force parameters, vibration, noise and acoustic emission. This requires the use of advanced algorithms to filter the signals and determine the features potentially related to the identification of changing tool wear. Currently, feature extraction solutions based on artificial intelligence techniques, including ANNs and machine learning, dominate.

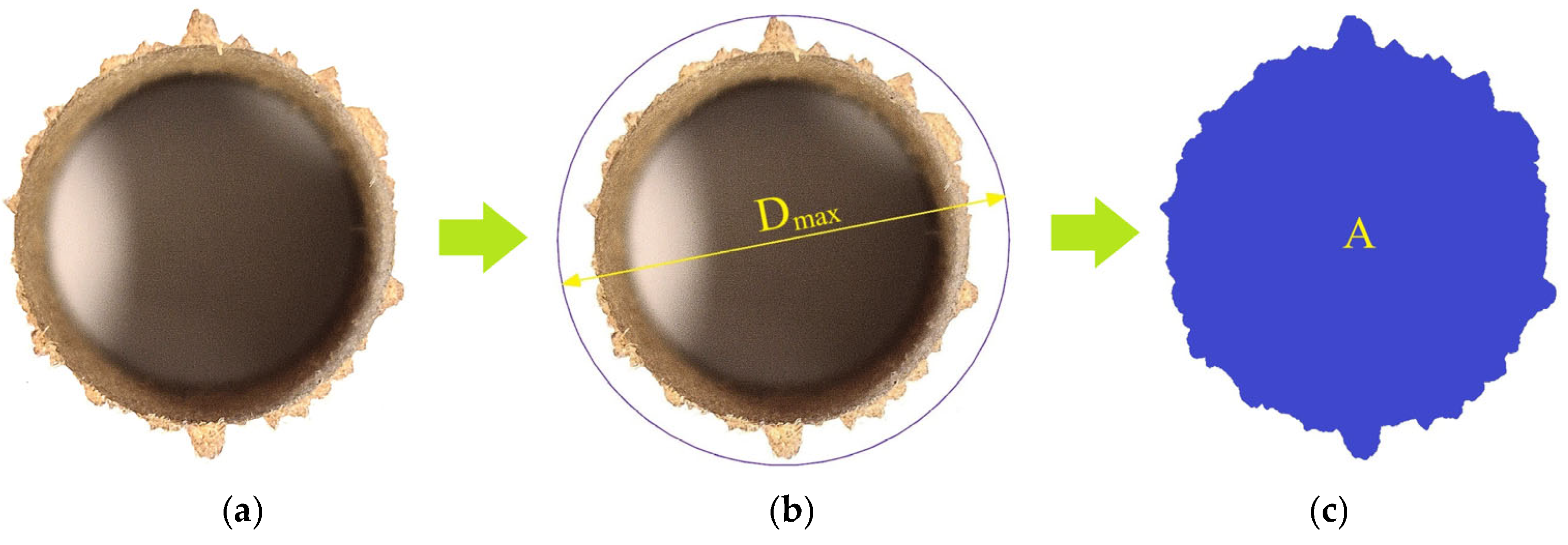

- There are solutions available to assess tool wear status based on the analysis of hole edge images as a direct link between tool damage and drill tip wear. Hole images are used as datasets for machine learning, digital image correlation techniques and drill wear prediction. These approaches are further enhanced by data augmentation and the selection of appropriate classifiers. Literature analysis indicates the need to develop a systematic methodology to select the most convincing feature extraction methods adapted to the type of boards and drills.

- When drilling multi-layered, wood-based panels with non-uniform structures, the quality of the drilled surface influences not only aesthetic features but also affects the potential stress localization in the vicinity of the hole edges. The optimal selection of drilling parameters and the monitoring of the tool condition can minimize or even prevent such defects.

Author Contributions

Funding

Conflicts of Interest

References

- Costa, D.; Serra, J.; Quinteiro, P.; Dias, A.C. Life cycle assessment of wood-based panels: A review. J. Clean. Prod. 2024, 444, 140955. [Google Scholar] [CrossRef]

- Kristak, L.; Kubovský, I.; Réh, R. New Challenges in Wood and Wood-Based Materials. Polymers 2021, 13, 2538. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; El-Zeadani, M.; Lee, Y.H.; Lee, Y.Y.; Murali, G.; Feduik, R. Design innovation, efficiency and applications of structural insulated panels: A review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Zhuang, B.; Cloutier, A.; Koubaa, A. Physical and Mechanical Properties of Oriented Strand Board Made from Eastern Canadian Softwood Species. Forests 2022, 13, 523. [Google Scholar] [CrossRef]

- Borysiuk, P.; Wilkowski, J. Selected properties and applications of particleboards. Biul. Inf. 2015, 1–2, 17–41. [Google Scholar]

- Ayrilmis, N.; Buyuksari, U.; As, N. Bending strength and modulus of elasticity of wood-based panels at cold and moderate temperatures. Cold Reg. Sci. Technol. 2010, 63, 40–43. [Google Scholar] [CrossRef]

- Sydor, M.; Waszkiewicz, K.; Potok, Z. Influence of Drill Bit Wear on Screw Withdrawal Resistance in Pinewood. Materials 2024, 17, 5729. [Google Scholar] [CrossRef]

- Motyka, M. Titanium Alloys and Titanium-Based Matrix Composites. Metals 2021, 11, 1463. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Najm, S.M.; Lemu, H.G. Current Concepts for Cutting Metal-Based and Polymer-Based Composite Materials. J. Compos. Sci. 2022, 6, 150. [Google Scholar] [CrossRef]

- Gisip, J.; Lemaster, R.; Saloni, D. Enhancing tool life through innovative process control in wood-based machining. Wood Mater. Sci. Eng. 2024, 19, 1–11. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J. The lifetime of cemented carbide blades during wood-based panels milling. Biul. Inf. OB-RPPD 2018, 3–4, 118–128. [Google Scholar] [CrossRef]

- Silva, R.G.; Baker, K.J.; Wilcox, S.J.; Reuben, R.L. The adaptability of a tool wear monitoring system under changing cutting conditions. Mech. Syst. Signal Process. 2000, 14, 287–298. [Google Scholar] [CrossRef]

- Jemielniak, K.; Urbański, T.; Kossakowska, J.; Bombiński, S. Tool condition monitoring based on numerous signal features. Int. J. Adv. Manuf. Technol. 2012, 59, 73–81. [Google Scholar] [CrossRef]

- Wilkowski, J.; Wieloch, G. Durability of tool blades during wood processing—The concept of durability, durability period testing, factors influencing durability. Biul. Inf. 2015, 1–2, 63–78. [Google Scholar]

- Prakash, S.; Mercy, J.L.; Salugu, M.K.; Vineeth, K.S.M. Optimization of Drilling Characteristics using Grey Relational Analysis (GRA) in Medium Density Fiber Board (MDF). Mater. Today Proc. 2015, 2, 1541–1551. [Google Scholar] [CrossRef]

- Jaworski, J.; Trzepieciński, T. Research on durability of turning tools made of low-alloy high-speed steels. Kov. Mater. –Met. Mater. 2016, 54, 17–25. [Google Scholar] [CrossRef]

- Chladil, J.; Sedlák, J.; Rybářová, E.R.; Kučera, M.; Dado, M. Cutting conditions and tool wear when machining wood-based materials. BioRes 2019, 14, 3495–3505. [Google Scholar] [CrossRef]

- Trzepieciński, T. Approaches for Preventing Tool Wear in Sheet Metal Forming Processes. Machines 2023, 11, 616. [Google Scholar] [CrossRef]

- Sujová, E.; Vysloužilová, D.; Koleda, P.; Gajdzik, B. Research on the evaluation of the efficiency of production processes through the implementation of key performance indicators. Manag. Syst. Prod. Eng. 2023, 31, 404–410. [Google Scholar] [CrossRef]

- Czarniak, P.; Szymanowski, K.; Kucharska, B.; Krawczyńska, A.; Sobiecki, J.R.; Kubacki, J.; Panjan, P. Modification of tools for wood based materials machining with TiAlN/a-CN coating. Mater. Sci. Eng. B 2020, 257, 114540. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kolesnikov, V.O.; Eliasz, J. Study of the wear resistance of high-nitrogen steels under dry sliding friction. Mater. Sci. 2013, 48, 642–646. [Google Scholar] [CrossRef]

- Szwajka, K.; Trzepieciński, T. Effect of tool material on tool wear and delamination during machining of particleboard. J. Wood Sci. 2016, 62, 305–315. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Trzepiecinski, T. Experimental Study on Drilling MDF with Tools Coated with TiAlN and ZrN. Materials 2019, 12, 386. [Google Scholar] [CrossRef] [PubMed]

- Demir, A.; Cakiroglu, E.O.; Aydin, I. Effects of CNC Processing Parameters on Surface Quality of Wood-Based Panels Used in Furniture Industry. Drv. Ind. 2022, 73, 363–371. [Google Scholar] [CrossRef]

- Gurau, L. Testing the Processing-Induced Roughness of Sanded Wood Surfaces Separated from Wood Anatomical Structure. Forests 2022, 13, 331. [Google Scholar] [CrossRef]

- Novák, V.; Rousek, M.; Kopecký, Z. Assessment of wood surface quality obtained during high speed milling by use of non-contact method. Drv. Ind. 2011, 62, 103–115. [Google Scholar] [CrossRef]

- Barcík, Š.; Gašparík, M. Effect of tool and milling parameters on the size distribution of splinters of planed native and thermally modified beech wood. BioResources 2014, 9, 1346–1360. [Google Scholar] [CrossRef]

- Sydor, M.; Zasuwik, A. Effect of Wood-based Material Type on Drilled Hole Diameter. Drewno. Prace Naukowe. Doniesienia. Komun. 2024, 67, 00038. [Google Scholar] [CrossRef]

- Górski, J. The Review of New Scientific Developments in Drilling in Wood-Based Panels with Particular Emphasis on the Latest Research Trends in Drill Condition Monitoring. Forests 2022, 13, 242. [Google Scholar] [CrossRef]

- Kurek, J.; Antoniuk, I.; Świderski, B.; Jegorowa, A.; Bukowski, M. Application of Siamese Networks to the Recognition of the Drill Wear State Based on Images of Drilled Holes. Sensors 2020, 20, 6978. [Google Scholar] [CrossRef]

- Bukowski, M.; Kurek, J.; Antoniuk, I.; Jegorowa, A. Decision Confidence Assessment in Multi-Class Classification. Sensors 2021, 21, 3834. [Google Scholar] [CrossRef] [PubMed]

- Świderski, B.; Antoniuk, I.; Kurek, J.; Bukowski, M.; Górski, J.; Jegorowa, A. Tool condition monitoring for the chipboard drilling process using automatic, signal-based tool state evaluation. BioResources 2022, 17, 5349–5371. [Google Scholar] [CrossRef]

- Lemaster, R.; Lu, L.; Jackson, S. The use of process monitoring techniques on a CNC wood router. Part 1. Sensor selection. For. Prod. J. 2000, 50, 31–64. [Google Scholar]

- Bedelean, B.; Ispas, M.; Răcășan, S. Optimizing Wood Composite Drilling with Artificial Neural Network and Response Surface Methodology. Forests 2024, 15, 1600. [Google Scholar] [CrossRef]

- Tiryaki, S.; Malkoçoğlu, A.; Özşahin, Ş. Artificial Neural Network Modeling to Predict Optimum Power Consumption in Wood Machining. Wood Res. Pap. Rep. Announc. 2015, 58, 109–125. [Google Scholar] [CrossRef]

- Jegorowa, A.; Kurek, J.; Antoniuk, I.; Krupa, A.; Wieczorek, G.; Świderski, B.; Bukowski, M.; Kruk, M. Automatic Estimation of Drill Wear Based on Images of Holes Drilled in Melamine Faced Chipboard with Machine Learning Algorithms. Forests 2023, 14, 205. [Google Scholar] [CrossRef]

- Özşahin, Ş.; Singer, H. Prediction of noise emission in the machining of wood materials by means of an artificial neural network. New Zealand J. For. Sci. 2022, 52, 1–10. [Google Scholar] [CrossRef]

- Panda, S.S.; Singh, A.K.; Chakraborty, D.D.; Pal, S.K. Drill wear monitoring using back propagation neural network. J. Mater. Process. Technol. 2006, 172, 283–290. [Google Scholar] [CrossRef]

- Sydor, M.; Potok, Z.; Pędzik, M.; Hitka, M.; Rogoziński, T. The influence of feed rate during pilot hole drilling on screw withdrawal resistance in particleboard. Eur. J. Wood Wood Prod. 2024, 82, 5–13. [Google Scholar] [CrossRef]

- Duntschew, J.; Eschelbacher, S.; Schluchter, I.; Möhring, H.C. Discrete wavelet transformation as a tool for analysing the borehole quality when drilling carbon fibre reinforced plastic aluminium stack material. J. Mach. Eng. 2021, 21, 78–88. [Google Scholar] [CrossRef]

- Marcineková, K.; Janáková Sujová, A. Multi-Objective Optimization of Manufacturing Process Using Artificial Neural Networks. Systems 2024, 12, 569. [Google Scholar] [CrossRef]

- Jegorowa, A.; Kurek, J.; Antoniuk, I.; Dołowa, W.; Bukowski, M.; Czarniak, P. Deep learning methods for drill wear classification based on images of holes drilled in melamine faced chipboard. Wood Sci. Technol. 2021, 55, 271–293. [Google Scholar] [CrossRef]

- Kurek, J.; Kruk, M.; Osowski, S.; Hoser, P.; Wieczorek, G.; Jegorowa, A.; Górski, J.; Wilkowski, J.; Śmietańska, K.; Kossakowska, J. Developing automatic recognition system of drill wear in standard laminated chipboard drilling process. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 64, 633–640. [Google Scholar] [CrossRef][Green Version]

- Jegorowa, A.; Górski, J.; Kurek, J.; Kruk, M. Initial study on the use of support vector machine (SVM) in tool condition monitoring in chipboard drilling. Eur. J. Wood Prod. 2019, 77, 957–959. [Google Scholar] [CrossRef]

- Kurek, J.; Antoniuk, I.; Górski, J.; Jegorowa, A.; Swiderski, B.; Kruk, M.; Wieczorek, G.; Pach, J.; Orłowski, A.; Aleksiejuk-Gawron, J. Data Augmentation Techniques for Transfer Learning Improvement in Drill Wear Classification Using Convolutional Neural Network. Mach. Graph. Vis. 2019, 28, 3–12. [Google Scholar] [CrossRef]

- Russakovsky, O.; Deng, J.; Su, H.; Krause, J.; Satheesh, S.; Ma, S.; Huang, Z.; Karpathy, A.; Khosla, A.; Bernstein, M.; et al. Imagenet large scale visual recognition challenge. Int. J. Comput. Vis. 2015, 115, 211–252. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. Imagenet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Kurek, J.; Antoniuk, I.; Górski, J.; Jegorowa, A.; Swiderski, B.; Kruk, M.; Wieczorek, G.; Pach, J.; Orłowski, A.; Aleksiejuk-Gawron, J. Classifiers ensemble of transfer learning for improved drill wear classification using convolutional neural network. Mach. Graph. Vis. 2019, 28, 13–23. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1–9. [Google Scholar] [CrossRef]

- BVLC AlexNet Model. Available online: https://github.com/BVLC/caffe/tree/master/models/bvlc_alexnet (accessed on 9 February 2025).

- Kurek, J.; Swiderski, B.; Jegorowa, A.; Kruk, M.; Osowski, S. Deep learning in assessment of drill condition on the basis of images of drilled holes. In Proceedings of the Eighth International Conference on Graphic and Image Processing (ICGIP 2016), Tokyo, Japan, 8 February 2017; Volume 10225, pp. 375–381. [Google Scholar]

- Swiderski, B.; Kurek, J.; Osowski, S.; Kruk, M.; Jegorowa, A. Diagnostic System of Drill Condition in Laminated Chipboard Drilling Process. MATEC Web Conf. 2017, 125, 6. [Google Scholar] [CrossRef]

- Jegorowa, A.; Górski, J.; Kurek, J.; Kurek, J. Use of nearest neighbors (K-NN) algorithm in tool condition identification in the case of drilling in melamine faced particleboard. Maderas. Cienc. Tecnol. 2020, 22, 189–196. [Google Scholar] [CrossRef]

- Ispas, M.; Gurău, L.; Răcăşan, S. The influence of the tool point angle and feed rate on the delamination at drilling of pre-laminated particleboard. Pro Ligno 2015, 11, 494–500. [Google Scholar]

- Szwajka, K.; Trzepieciński, T. An examination of the tool life and surface quality during drilling melamine faced chipboard. Wood Res. 2017, 62, 307–318. [Google Scholar]

- Antoniuk, I.; Kurek, J.; Krupa, A.; Wieczorek, G.; Bukowski, M.; Kruk, M.; Jegorowa, A. Advanced Feature Extraction Methods from Images of Drillings in Melamine Faced Chipboard for Automatic Diagnosis of Drill Wear. Sensors 2023, 23, 1109. [Google Scholar] [CrossRef]

- Czarniak, P.; Szymanowski, K.; Panjan, P.; Górski, J. Initial Study of the Effect of Some PVD Coatings (“TiN/AlTiN” and “TiAlN/a-C:N”) on the Wear Resistance of Wood Drilling Tools. Forests 2022, 13, 286. [Google Scholar] [CrossRef]

- Kucharska, B.; Sobiecki, J.R.; Czarniak, P.; Szymanowski, K.; Cymerman, K.; Moszczyńska, D.; Panjan, P. Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials. Materials 2021, 14, 2740. [Google Scholar] [CrossRef]

- Czarniak, P.; Szymanowski, K.; Panjan, P. Characteristic of the wear of a tool coating based on amorphous carbon during chipboard milling. Ann. Wars. Univ. Life Sci. For. Wood Technol. 2020, 111, 53–59. [Google Scholar] [CrossRef]

- Nadolny, K.; Kapłonek, W.; Sutowska, M.; Sutowski, P.; Myśliński, P.; Gilewicz, A.; Warcholiński, B. Experimental tests of PVD AlCrN-coated planer knives on planing Scots pine (Pinus sylvestris L.) under industrial conditions. Eur. J. Wood Wood Prod. 2021, 79, 645–665. [Google Scholar] [CrossRef]

- Aamir, M.; Davis, A.; Keeble, W.; Koklu, U.; Giasin, K.; Vafadar, A.; Tolouei-Rad, M. The Effect of TiN-, TiCN-, TiAlN-, and TiSiN Coated Tools on the Surface Defects and Geometric Tolerances of Holes in Multi-Spindle Drilling of Al2024 Alloy. Metals 2021, 11, 1103. [Google Scholar] [CrossRef]

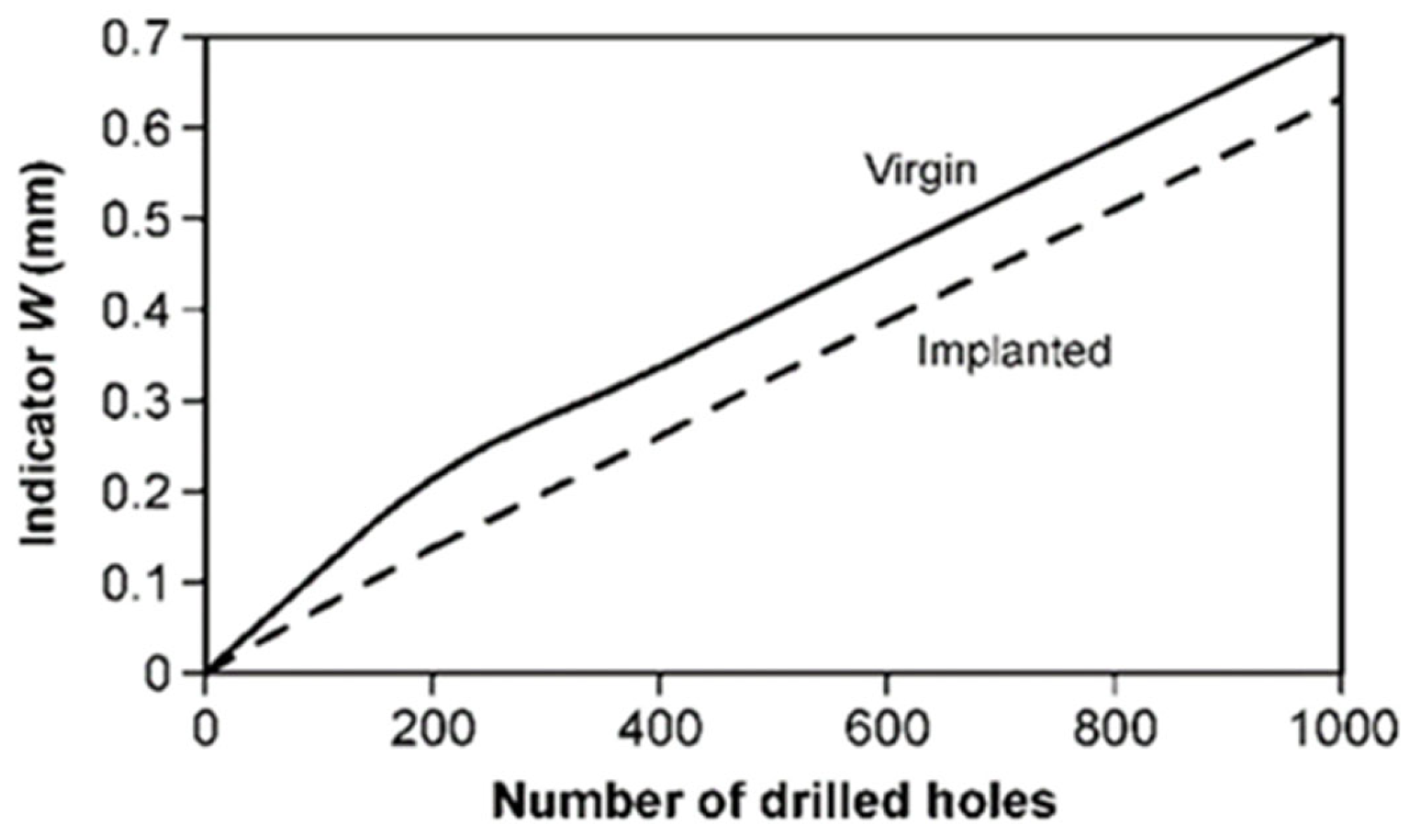

- Barlak, M.; Wilkowski, J.; Szymanowski, K.; Czarniak, P.; Podziewski, P.; Werner, Z.; Zagórski, J.; Staszkiewicz, B. Influence of the ion implantation of nitrogen and selected metals on the lifetime of WC-Co indexable knives during MDF machining. Ann. WULS -SGGW For. Wood Technol. 2019, 108, 45–52. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J. Effect of noble gases ion implantation on the life time of WC-Co tools used in wood-based material machining. Ann. WULS -SGGW For. Wood Technol. 2023, 124, 77–84. [Google Scholar] [CrossRef]

- Wilkowski, J.; Jegorowa, A.; Barlak, M.; Werner, Z.; Zagórski, J.; Staszkiewicz, B.; Kurek, J.; Kruk, M. Effect of Nitrogen Ion Implantation on the Tool Life Used in Particleboard CNC Drilling. Materials 2022, 15, 3420. [Google Scholar] [CrossRef] [PubMed]

- Barlak, M.; Chmielewski, M.; Werner, Z.; Pietrzak, K. Changes of tribological properties of Inconel 600 after ion implantation process. Bull. Pol. Acad. Sci. Tech. Sci. 2014, 62, 827–833. [Google Scholar] [CrossRef]

- Sieradzki, A.; Bednarek, J.; Jegorowa, A.; Kurek, J. Explainable AI (XAI) Techniques for Convolutional Neural Network-Based Classification of Drilled Holes in Melamine Faced Chipboard. Appl. Sci. 2024, 14, 7462. [Google Scholar] [CrossRef]

- Arrighi, L.; Barbon Junior, S.; Pellegrino, F.A.; Simonato, M.; Zullich, M. Explainable Automated Anomaly Recognition in Failure Analysis: Is Deep Learning Doing it Correctly? In World Conference on Explainable Artificial Intelligence; Communications in Computer and Information Science; Springer: Cham, Switzerland, 2023; Volume 1902, pp. 420–432. [Google Scholar]

- Afonso, C.; Matta, A.; Matos, L.M.; Gomes, M.B.; Santos, A.; Pilastri, A.; Cortez, P. Machine Learning for Predicting Production Disruptions in the Wood-Based Panels Industry: A Demonstration Case. In Artificial Intelligence Applications and Innovations; Maglogiannis, I., Iliadis, L., MacIntyre, J., Dominguez, M., Eds.; AIAI 2023. IFIP Advances in Information and Communication Technology; Springer: Cham, Swizterland, 2023; Volume 676. [Google Scholar] [CrossRef]

- Kurek, J.; Krupa, A.; Antoniuk, I.; Akhmet, A.; Abdiomar, U.; Bukowski, M.; Szymanowski, K. Improved Drill State Recognition during Milling Process Using Artificial Intelligence. Sensors 2023, 23, 448. [Google Scholar] [CrossRef]

- Bedelean, B.; Ispas, M.; Răcășan, S.; Baba, M.N. Optimization of Wood Particleboard Drilling Operating Parameters by Means of the Artificial Neural Network Modeling Technique and Response Surface Methodology. Forests 2022, 13, 1045. [Google Scholar] [CrossRef]

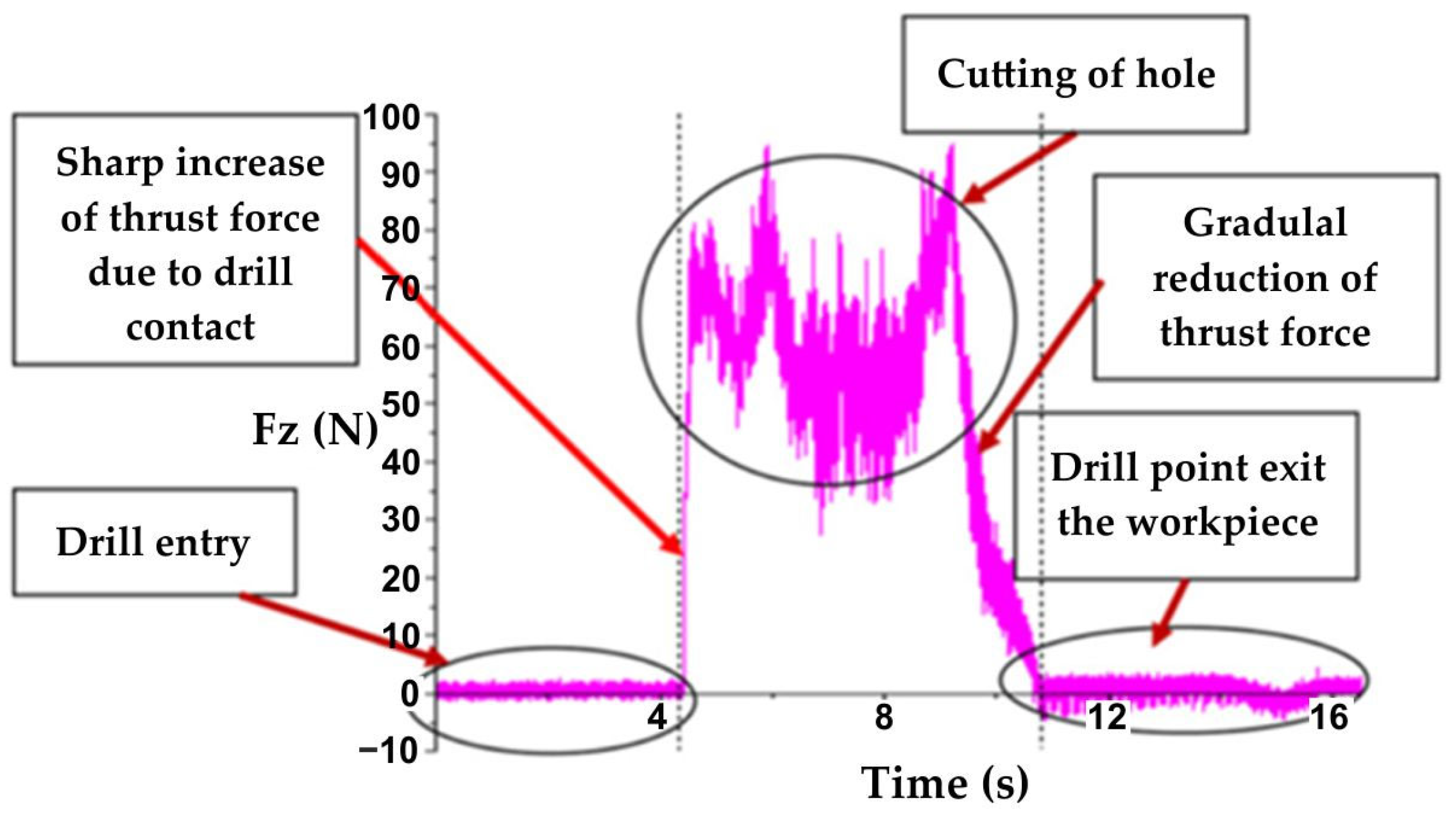

- Ispas, M.; Gurău, L.; Răcăşan, S. Study regarding the variation of the thrust force, drilling torque and surface delamination with the feed per tooth and drill tip angle at drilling pre-laminated particleboard. Pro Ligno 2014, 10, 40–52. [Google Scholar]

- Ispas, M.; Răcăşan, S. The influence of the tool point angle and feed rate on the dynamic parameters at drilling coated particleboard. Pro Ligno 2015, 11, 457–463. [Google Scholar]

- Kumar, A.M.; Jayakumar, K. Drilling studies on Particle Board composite using HSS twist drill and spade drill. Mater. Today Proc. 2018, 5, 16346–16351. [Google Scholar] [CrossRef]

- Bukowski, M.; Kurek, J.; Świderski, B.; Jegorowa, A. Custom Loss Functions in XGBoost Algorithm for Enhanced Critical Error Mitigation in Drill-Wear Analysis of Melamine-Faced Chipboard. Sensors 2024, 24, 1092. [Google Scholar] [CrossRef]

- Valarmathi, T.N.; Palanikumar, K.; Latha, B. Measurement and analysis of thrust force in drilling of particle board (PB) composite panels. Measurement 2013, 46, 1220–1230. [Google Scholar] [CrossRef]

- Auchet, S.; Pelaingre, C.; Barlier, C.; Méausoone, P.J. Influence of cutting and tool parameters on thrust force in drilling of different formaldehyde emission rate particleboards. Pro Ligno 2018, 14, 3–12. [Google Scholar]

- Kumar, A.M.; Jayakumar, K. Drilling studies on particle board composite using HSS twist drill and spade drill. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012029. [Google Scholar] [CrossRef]

- Ispas, M.; Răcășan, S. Study regarding the influence of the tool geometry and feed rate on the drilling quality of MDF panels. Pro Ligno 2017, 13, 174–180. [Google Scholar]

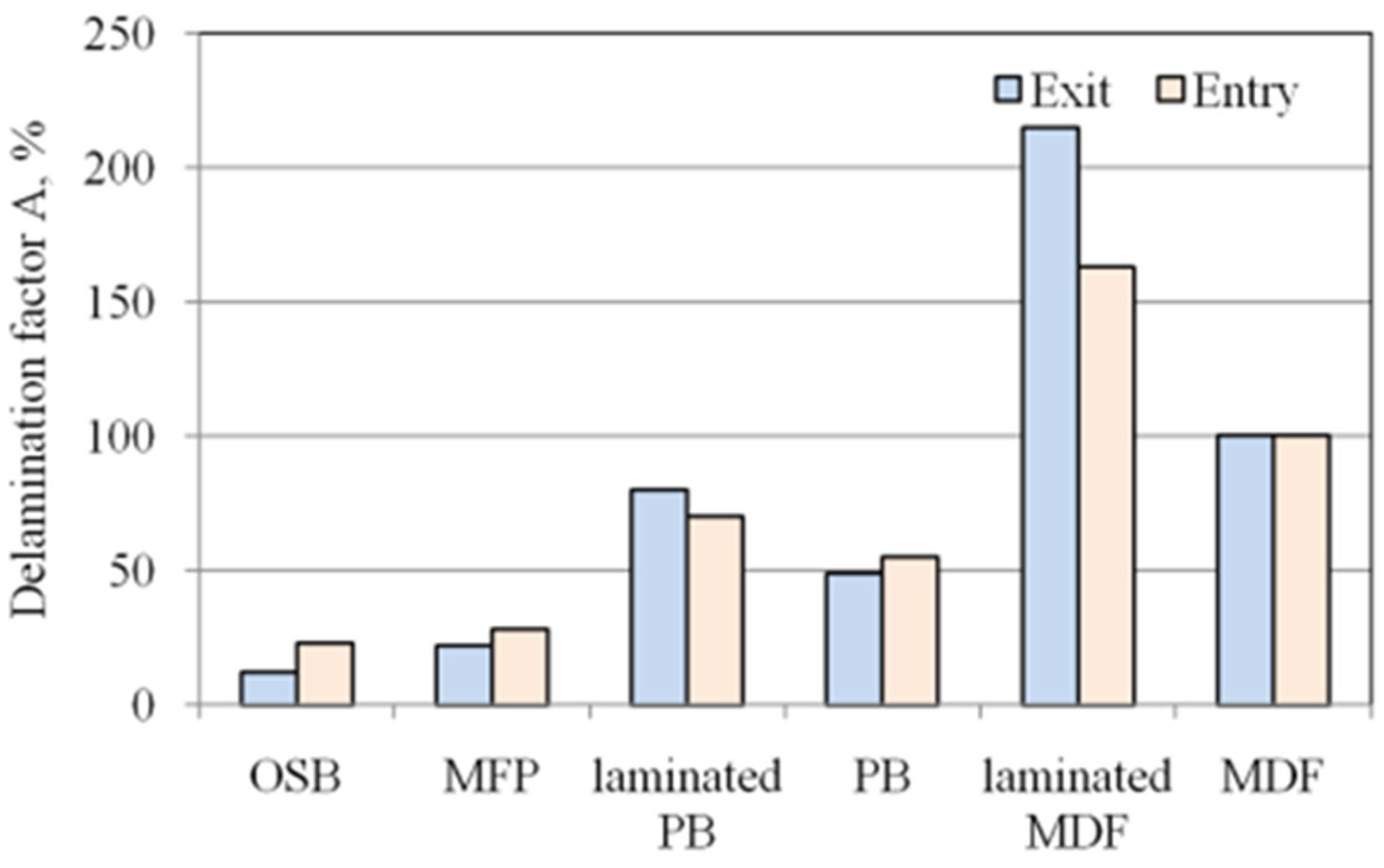

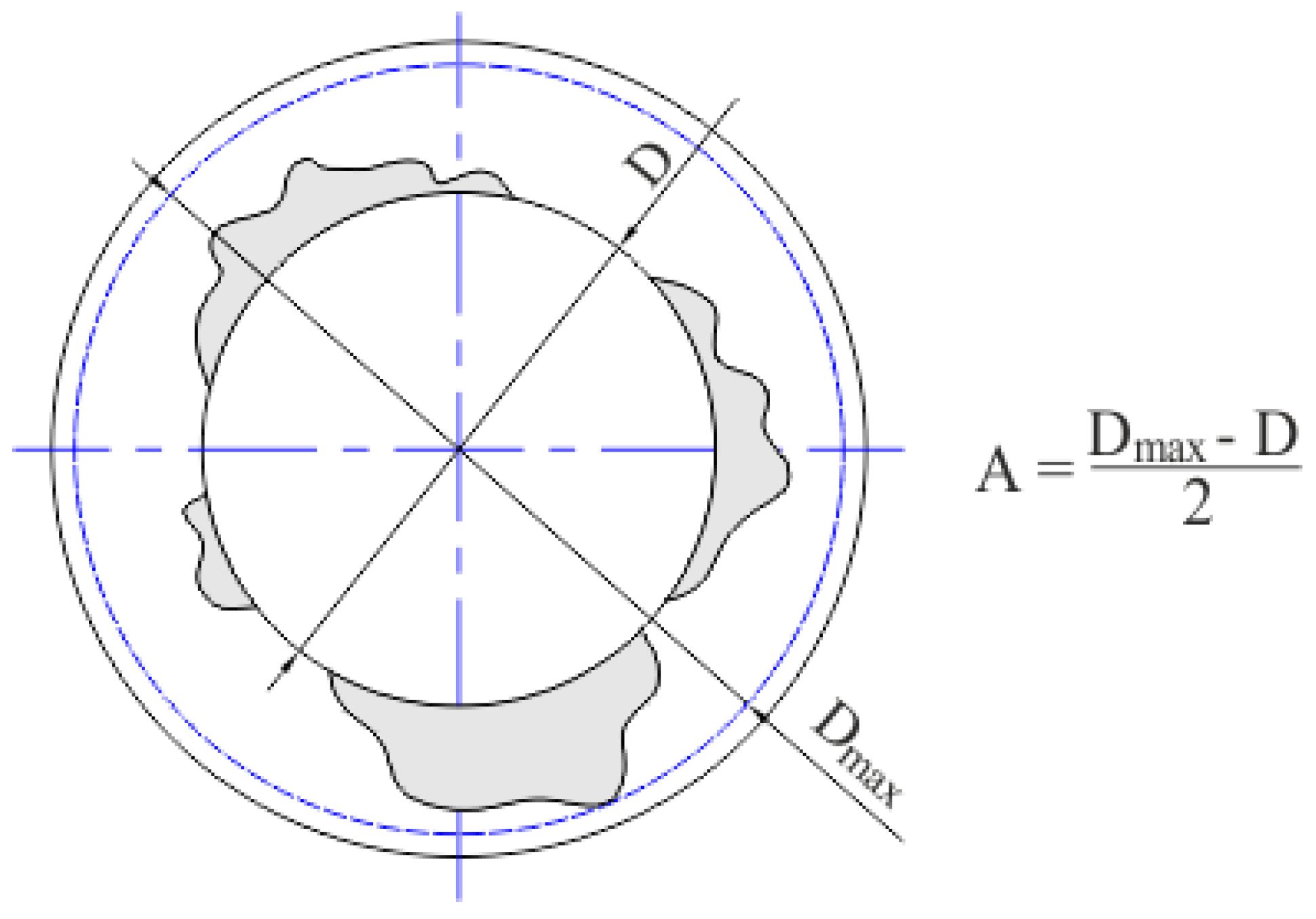

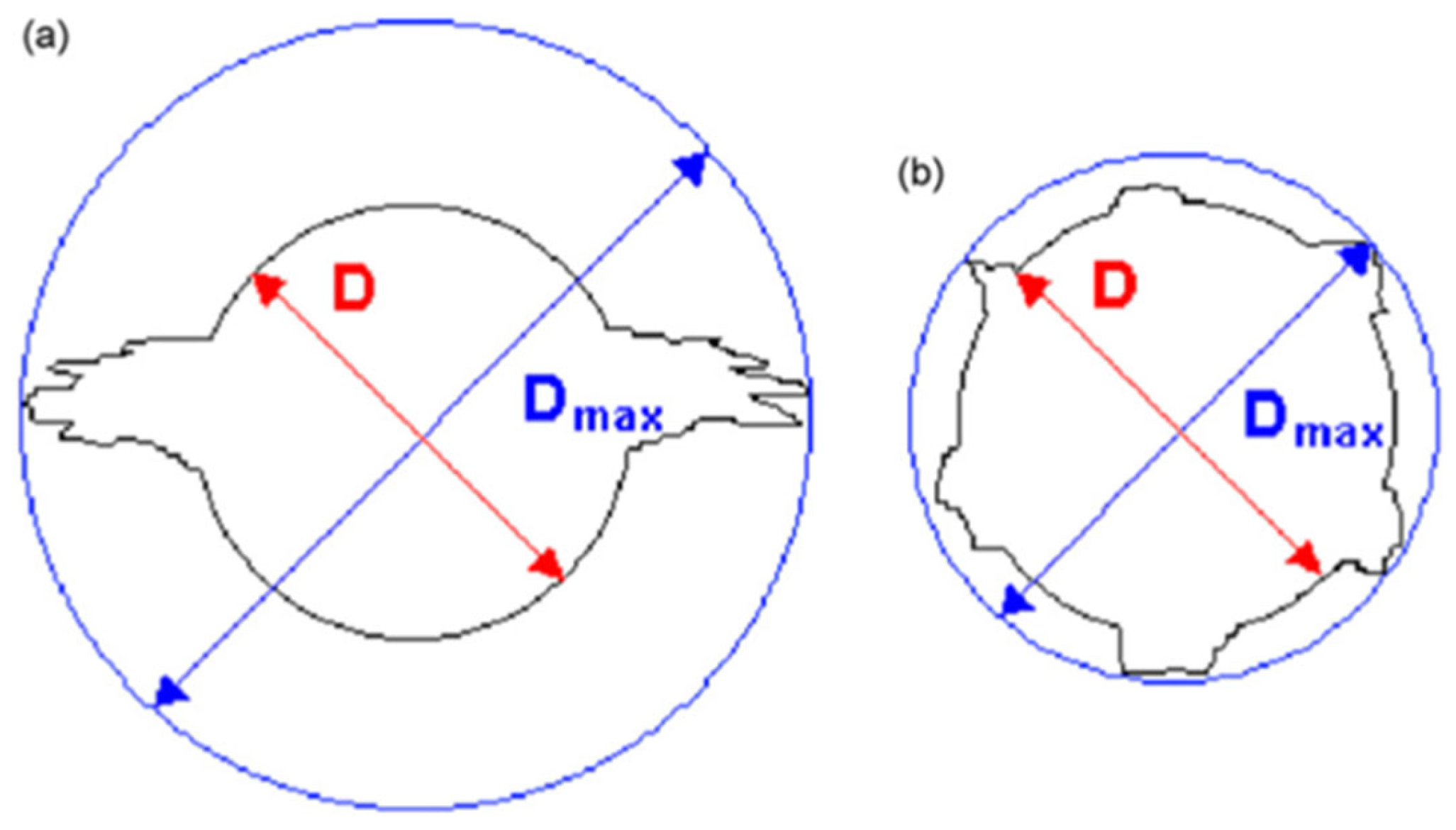

- Palanikumar, K.; Prakash, S.; Manoharan, N. Experimental Investigation and Analysis on Delamination in Drilling of Wood Composite Medium Density Fiber Boards. Mater. Manuf. Process. 2009, 24, 1341–1348. [Google Scholar] [CrossRef]

- Prakash, S.; Palanikumar, K.; Manoharan, N. Optimization of delamination factor in drilling medium-density fiberboards (MDF) using desirability-based approach. Int. J. Adv. Manuf. Technol. 2009, 45, 370–381. [Google Scholar] [CrossRef]

- Valarmathi, T.N.; Palanikumar, K.; Sekar, S. Parametric analysis on delamination in drilling of wood composite panels. Indian J. Sci. Technol. 2013, 6, 1–10. [Google Scholar]

- Gaitonde, V.N.; Karnik, S.R.; Davim, J.P. Taguchi multiple-performance characteristics optimization in drilling of medium density fibreboard (MDF) to minimize delamination using utility concept. J. Mater. Process. Technol. 2008, 196, 73–78. [Google Scholar] [CrossRef]

- Prakash, S.; Palanikumar, K. Modeling for prediction of surface roughness in drilling MDF panels using response surface methodology. J. Compos. Mater. 2010, 45, 1639–1646. [Google Scholar] [CrossRef]

- Ayyildiz, E.A.; Ayyildiz, M.; Kara, F. Optimization of Surface Roughness in Drilling Medium-Density Fiberboard with a Parallel Robot. Adv. Mater. Sci. Eng. 2021, 2021, 6658968. [Google Scholar] [CrossRef]

- Bedelean, B.; Ispas, M.; Răcășan, S. Combining Artificial Neural Network and Response Surface Methodology to Optimize the Drilling Operating Parameters of MDF Panels. Forests 2023, 14, 2254. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. Characterization, optimization, and acoustic emission monitoring of airborne dust emission during wood sawing. Int. J. Adv. Manuf. Technol. 2020, 109, 2365–2375. [Google Scholar] [CrossRef]

- Rabiei, F.; Yaghoubi, S. A comprehensive investigation on the influences of optimal CNC wood machining variables on surface quality and process time using GMDH neural network and bees optimization algorithm. Mater. Today Commun. 2023, 36, 106482. [Google Scholar] [CrossRef]

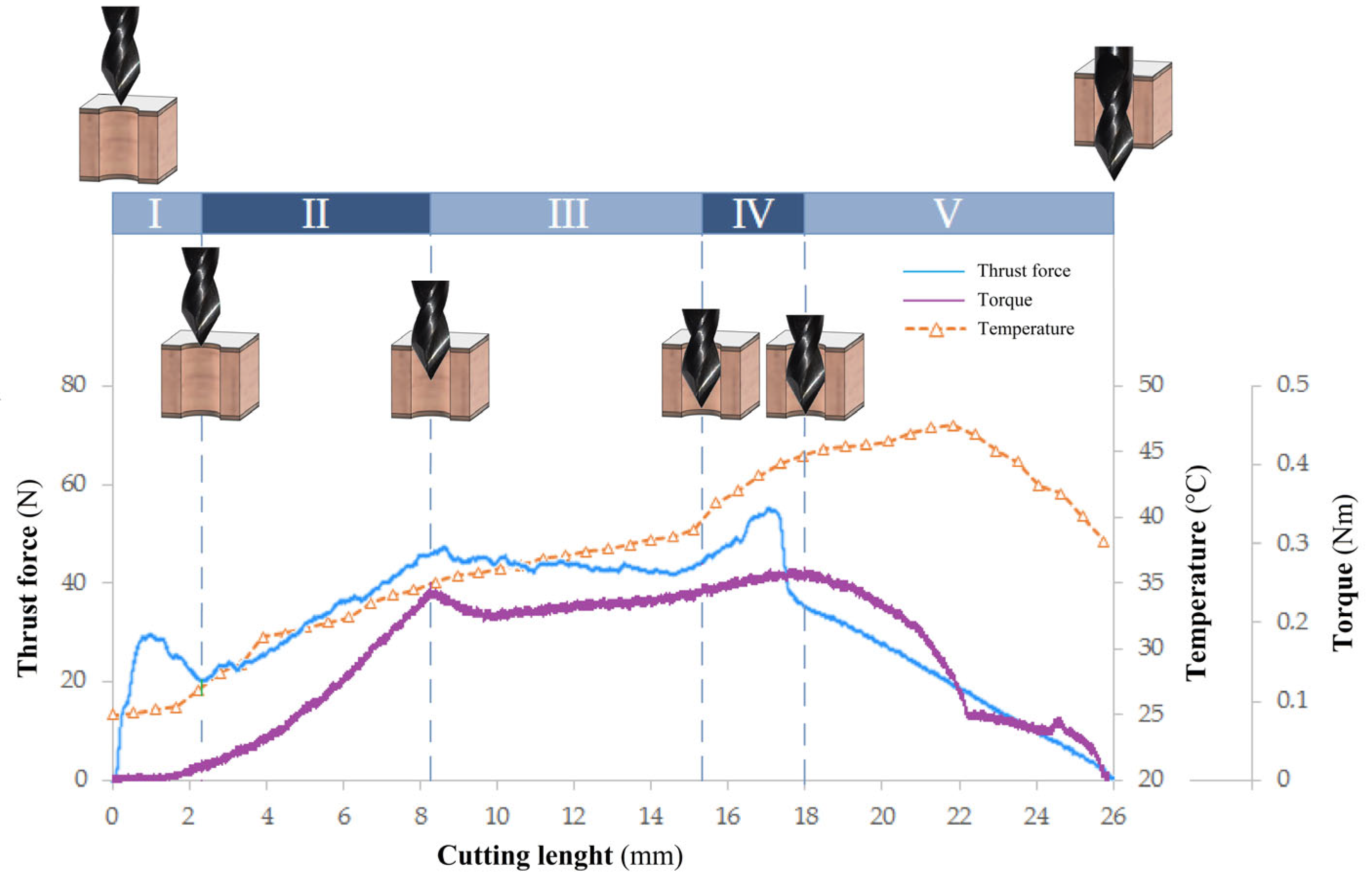

- Davim, J.P.; Clemente, V.C.; Silva, S. Drilling investigation of MDF (medium density fibreboard). J. Mater. Process. Technol. 2008, 203, 537–541. [Google Scholar] [CrossRef]

- Davim, J.P.; Gaitonde, V.N.; Karnik, S.R. An investigative study of delamination in drilling of medium density fibreboard (MDF) using response surface models. Int. J. Adv. Manuf. Technol. 2008, 37, 49–57. [Google Scholar] [CrossRef]

- Davim, J.P.; Clemente, V.C.; Silva, S. Evaluation of Delamination in Drilling Medium Density Fibre Board. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2007, 221, 655–658. [Google Scholar] [CrossRef]

- Davim, J.P.; Campos Rubio, J.; Abrao, A. Delamination assessment after drilling medium-density fibreboard (MDF) by digital image analysis. Holzforschung 2007, 61, 294–300. [Google Scholar] [CrossRef]

- Zhao, H.; Ehmann, K.F. Development and performance analysis of new spade bit designs. Int. J. Mach. Tools Manuf. 2002, 42, 1403–1414. [Google Scholar] [CrossRef]

- Zielińska-Szwajka, J.; Szwajka, K. Thrust force and torque in the drilling process laminated chipboard. Ann. Wars. Univ. Life Sci. 2014, 88, 248–254. [Google Scholar]

- Djouadi, A.; Nouveau, C.; Beer, P.; Lambertin, M. CrxNy hard coatings deposited with PVD method on tools for wood machining. Sur. Coat. Technol. 2000, 133–134, 478–483. [Google Scholar] [CrossRef]

- Lin, R.; van Houts, J.; Bhattacharyya, D. Machinability investigation of medium-density fibreboard. Holzforschung 2006, 60, 71–77. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Trzepieciński, T. Experimental Analysis of Smart Drilling for the Furniture Industry in the Era of Industry 4.0. Materials 2024, 17, 2033. [Google Scholar] [CrossRef] [PubMed]

- Szwajka, K.; Trzepiecinski, T. On the machinability of medium density fiberboard by drilling. BioRes 2018, 13, 8263–8278. [Google Scholar]

- Shirzaei, S.; Payam, S.R.F.; Shamsian, M.; Rahdar, H.A.; Ghalehno, M.D. Evaluation of delamination defect in drilling process of wood sandwich panels. Iran. J. Wood Pap. Ind. 2024, 15, 299–312. [Google Scholar]

- Balyts’kyi, O.I.; Kolesnikov, V.O. Investigation of wear products of high-nitrogen manganese steels. Mater. Sci. 2009, 45, 576–581. [Google Scholar] [CrossRef]

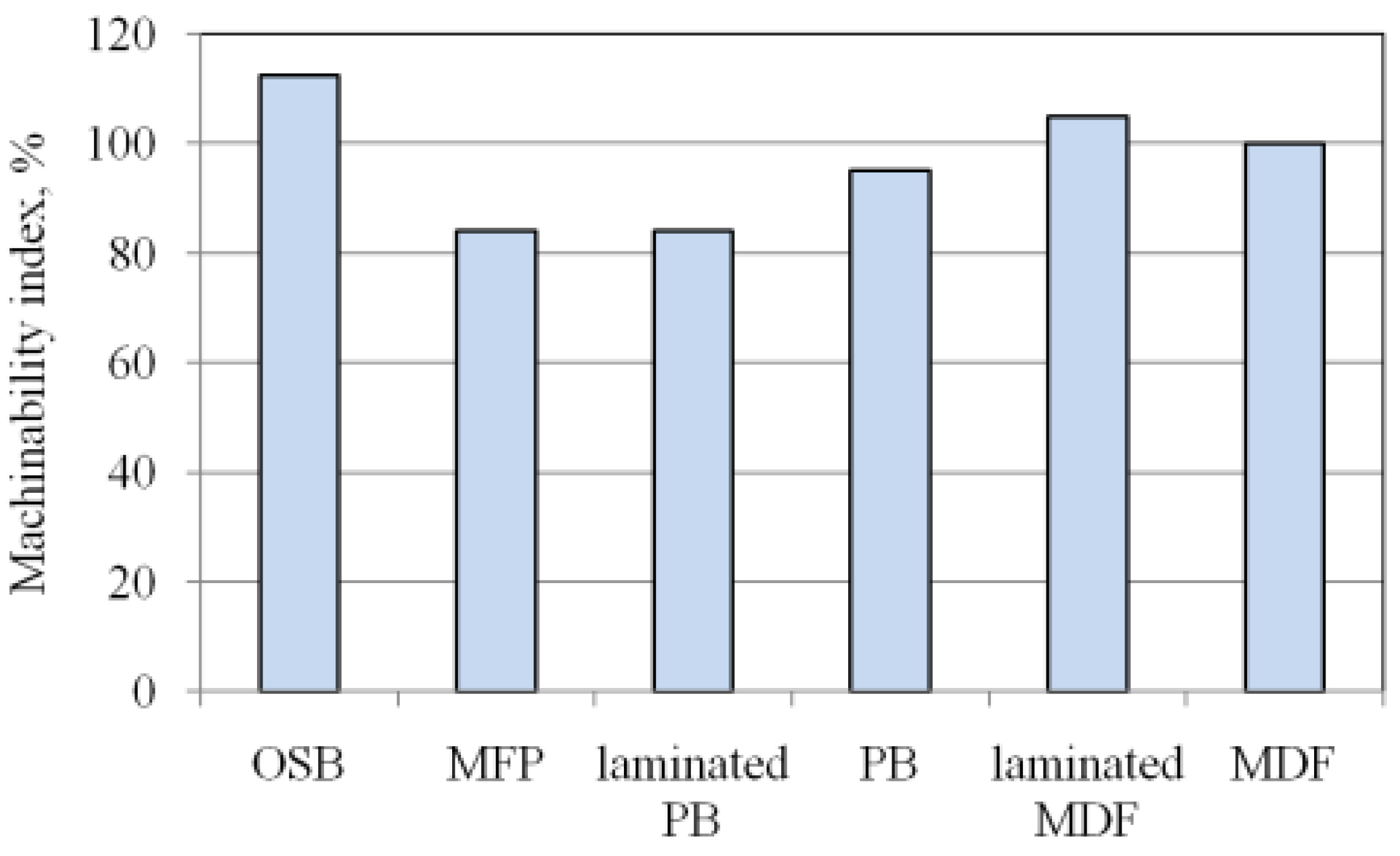

- Górski, J.; Podziewski, P.; Borysiuk, P. The Machinability of Flat-Pressed, Single-Layer Wood-Plastic Particleboards while Drilling—Experimental Study of the Impact of the Type of Plastic Used. Forests 2022, 13, 584. [Google Scholar] [CrossRef]

- Chen, S.; Liu, X.; Fang, L.; Wellwood, R. Digital X-ray analysis of density distribution characteristics of wood-based panels. Wood Sci. Technol. 2010, 44, 85–93. [Google Scholar] [CrossRef]

- Chen, S.; Wellwood, R. Nondestructive evaluation of oriented strand board. In Proceedings of the 13th International Symposium on Nondestructive Testing of Wood, Berkeley, CA, USA, 19–21 August 2002; University of California: Berkeley, CA, USA, 2002. [Google Scholar]

- Brochmann, J.; Edwardson, C.; Shmulsky, R. Influence of resin type and flake thickness on properties of OSB. For. Prod. J. 2004, 54, 51–55. [Google Scholar]

- Podziewski, P.; Górski, J.; Morek, R.; Szymanowski, K.; Czarniak, P.; Wilkowski, J. Effect of feed rate on cutting forces during drilling raw particleboard, laminated particleboard, MFP and OSB. Ann. Wars. Univ. Life Sci. 2015, 90, 146–149. [Google Scholar]

- Reddy, C.K.K.; Doss, S.; Pamulaparty, L.; Lippert, K.; Doshi, R. Industry 6.0. Technology, Practices, Challenges, and Applications; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzepieciński, T.; Szwajka, K.; Zielińska-Szwajka, J.; Szewczyk, M. Current Trends in Monitoring and Analysis of Tool Wear and Delamination in Wood-Based Panels Drilling. Machines 2025, 13, 249. https://doi.org/10.3390/machines13030249

Trzepieciński T, Szwajka K, Zielińska-Szwajka J, Szewczyk M. Current Trends in Monitoring and Analysis of Tool Wear and Delamination in Wood-Based Panels Drilling. Machines. 2025; 13(3):249. https://doi.org/10.3390/machines13030249

Chicago/Turabian StyleTrzepieciński, Tomasz, Krzysztof Szwajka, Joanna Zielińska-Szwajka, and Marek Szewczyk. 2025. "Current Trends in Monitoring and Analysis of Tool Wear and Delamination in Wood-Based Panels Drilling" Machines 13, no. 3: 249. https://doi.org/10.3390/machines13030249

APA StyleTrzepieciński, T., Szwajka, K., Zielińska-Szwajka, J., & Szewczyk, M. (2025). Current Trends in Monitoring and Analysis of Tool Wear and Delamination in Wood-Based Panels Drilling. Machines, 13(3), 249. https://doi.org/10.3390/machines13030249