Innovative Urban Transportation Means Developed by Integrating Design Methods

Abstract

:1. Introduction

1.1. The Paper

1.2. Background

- Air pollution and greenhouse gas emissions

- Noise pollution

- Road congestion

- Accident rate

- Deterioration of urban areas (caused by the space occupied by cars to the detriment of pedestrians)

- Land consumption (caused by the construction of roads and infrastructures)

- -

- Public transport: Public transport is a form of organized and mass transport with lower environmental impact than private means of transport. It is the first form of intervention on sustainable mobility for urban or local transport that consists of buses, subways, trolleybuses and trams, as well as national/international transport.

- -

- Preferential lanes: Preferential lanes are high-speed roads exclusively used by public transport or emergency vehicles. They help avoid traffic congestion and offer a further advantage to those using public transport instead of private vehicles.

- -

- Cycle paths: cycle paths are lanes exclusively dedicated to bicycles. If the territory is flat or with low gradients, bicycle lanes encourage people to use bikes for short urban journeys, instead of cars or scooters. They evidently imply an environmental advantage.

1.3. Small Urban Vehicles

1.4. Objective

- -

- Used by as many people as possible

- -

- Exploited in more situations compared to the simple kick scooter or the simple hoverboard

- -

- Compact and easily transportable

- -

- A good alternative to bikes and public transport

- -

- A means of sustainable mobility

- Kick scooter mode: when the hoverboard part and the kick scooter part are connected, the vehicle can be used as a kick scooter.

- Hoverboard mode: when the two parts are disconnected, the hoverboard part can be individually used.

2. Design Methods and Tools

- 1.

- Analysis of the environment

- 2.

- Task evaluation

- 3.

- Six questions

- 4.

- Lists of quality requirements

- 5.

- Analysis with evaluation matrixes (interrelation matrixes)

- 6.

- Requirements from relative importance matrix

- 7.

- Requirements from relative independence matrix

- 8.

- What/how matrix

- -

- The customer is the first priority of the company, so one needs to understand exactly what he wants

- -

- The company must be proactive in guiding and suggesting to the client how to satisfy his needs

- -

- The involvement of all staff ensures the internalization and assumption of responsibilities towards the customer

- -

- A correct methodology helps working together and pursuing common goals.

- Transferring and turning the requests of the external customer into the requests of the internal customers of the company

- Improving communication between the different business areas

- Setting priorities in product improvement

- -

- Defined on complex geometries, and this represents the heart and power of FEM methods

- -

- Related to a wide variety of engineering problems

- -

- With complex constraint conditions

- -

- With complex loading conditions.

- -

- The impossibility of generating a solution in a closed and parameterizable form of the problem

- -

- In the approximations of the solution related to the finite element approach used.

3. Case Study

- (1) Who: who uses the Innovative City Transportation Means (ICTM)? who produced the ICTM? The ICTM is used by people going to their jobs; moving about in the city centre and in traffic; avoiding several barriers; going to the shops.Requirements obtained after discussion: use immediacy, agility, mobility, dexterity, access to the restricted traffic zone (A-ZTL), flexibility of use, accessibility to close spaces (ACS), accessibility to pedestrian spaces (APS).

- (2) What: what is the use of the ICTM? The ICTM needs to transport people; is faster than on foot; to move about the city centre; to move about in strict spaces; to be used for leisure; to reach workplaces.Requirements (after discussion): capacity of transportation for drivers and other people, superior speed than pedestrians, dynamicity, flexibility, fun, availability.

- (3) Where: where is the ICTM used? It is used in the city centre, close spaces, traffic, pedestrian areas.Requirements (after discussion): agility, mobility, access to the restricted traffic zone (A-ZTL), flexibility of use, accessibility to close spaces (ACS), accessibility to pedestrian spaces (APS).

- (4) When: when is the ICTM used? It is used in the morning to reach workplaces; during the weekend for leisure; for shopping; as an alternative to walking.Requirements (after discussion): reliability, accessibility (A-ZTL, ACS, APS), flexibility of use, speed.

- (5) Why: why is the ICTM used? It is faster than walking; enables people to go farther than they would on foot; makes life easy; helps people reach destinations on time; have a good time; to not pollute the environment.Requirements (after discussion): comfort, speed, use immediacy, fun, ecology, duration of use, autonomy, dynamicity.

- (6) How: how is the ICTM used? It can be used as a transport means; as a service device; in a secure way (it can hardly be stolen, being transportable); in a flexible way (it can be used to access close spaces, for example, supermarkets); can be transported and moved.Requirements (after discussion): functionality, flexibility, self-transportability, not stealability.

| Value | Opinion |

|---|---|

| 0 | Poor |

| 2 | Inadequate |

| 4 | Insufficient |

| 6 | Sufficient |

| 8 | Optimum |

| 10 | Excellent |

- (1)

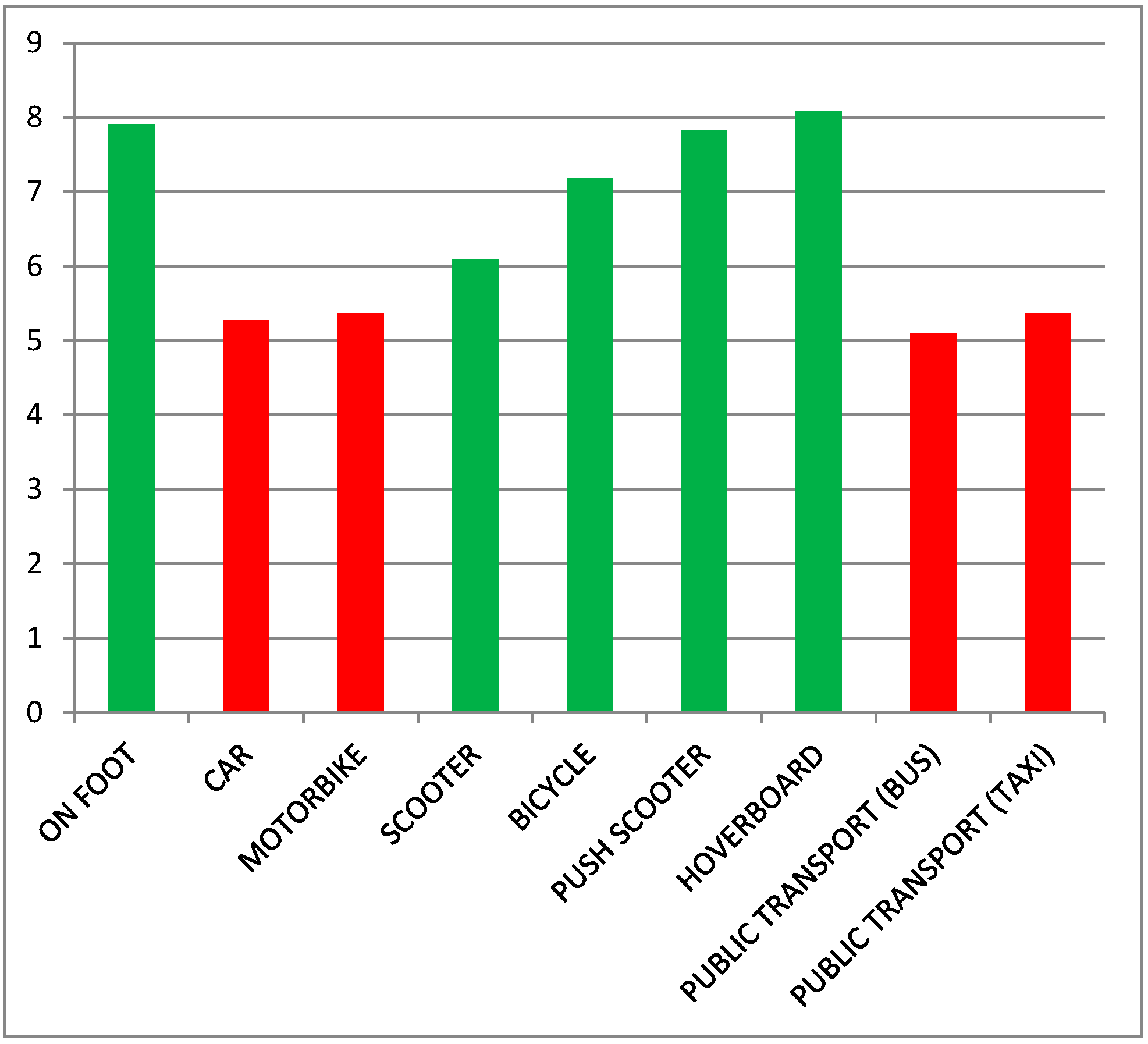

- Four means are not enough for transportation in the city. Car, motorbike, bus and taxi didn’t get sufficient vote to be considered as a competitive means: in particular, car →5,3; motorbike → 5,4; bus → 5,1; taxi → 5,4. Parameters linked to mobility, immediate use, flexibility, price, and alike were taken into consideration to arrive at these results.

- (2)

- Five means are suitable for transportation in the city, but only four (excluding scooter, voted 6,1) can be considered very good (vote over 7): foot, bicycle, push scooter and hoverboard. Only hoverboard is excellent (over 8).

- -

- Who (who uses the product)

- -

- What (what the product should have)

- -

- Where (where the product is used)

- -

- When (when the product is used)

- -

- Why (why the product is used)

- -

- How (how the product is used)

- -

- 10 usually travel by bus

- -

- 10 usually move on foot

- -

- 10 usually move by bicycle

- -

- 15 were women

- -

- 15 were men

- -

- 15 were students, including 10 undergraduate and 5 high school students

- -

- 15 were workers

- 1.

- Is it important for the kick scooter to reach a high speed? (>38 km/h from the benchmark)

- 2.

- Is it important for the kick scooter to have a high level of autonomy?

- 3.

- Is it important for the kick scooter to be rechargeable in a short time?

- 4.

- Is it important for the kick scooter to have a seat?

- 5.

- Is it important for the kick scooter to have an information display and position lights?

- 6.

- Is it important that the kick scooter is light?

- 7.

- Is it important that the kick scooter is foldable?

- 8.

- How much are you willing to spend on this item? (< €400, which is the average price of the kick scooters taken into account for the benchmark).

- 1.

- High autonomy

- 2.

- Quick charge

- 3.

- Lights and displays

- 4.

- Small size

- 5.

- Reduced weight

- 6.

- Price lower than €400

- 7.

- Appealing design

- 8.

- Lack of noise

- 1: When the element of the row is not so much affected by the column element

- 3: When the element of the row is moderately influenced by the column element

- 9: When the element of the row is severely influenced by the column element

- 0: Most important row of the column

- 1: Equally important line to the column

- 2: Less important row of the column

- 1: Weak link

- 3: Average link

- 9: Strong link

- -

- Maximum speed of 25 km/h (7 m/s) as the average speed of the other “urban” electric scooters

- -

- Autonomy > 30 Km

- -

- Maximum weight supported of 130 kg

- -

- Quick charge

- -

- Object weight ≤ 10 kg

- -

- Small size

- -

- 8-inch wheels (d = 200 mm).

- Yield limit Rp0,2: (265–324) Mpa

- Tensile strength Rm: (304–362) Mpa

- Elongation E: (5–13)%

- Hardness (HB): (90–105) HB

- Yield limit Rp0,2: 295 Mpa

- Tensile strength Rm: 310 Mpa

- Elongation E: 14%

- Hardness (HB): 85 HB

- -

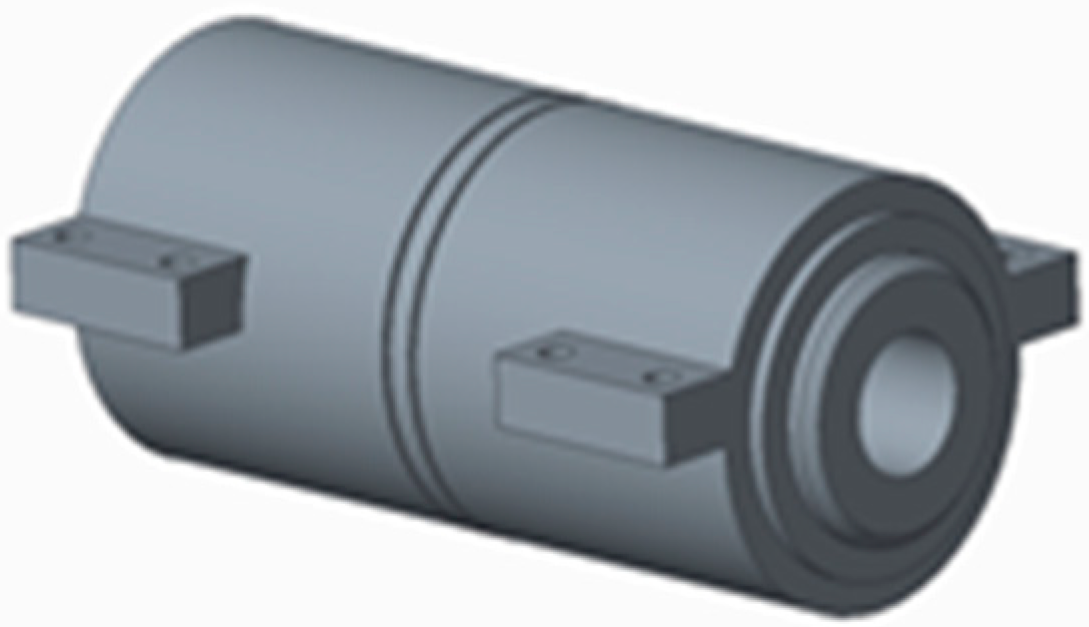

- Mechanical: when the two parts are connected, they must be built-in and therefore represent a single vehicle in the running phase. When the kick scooter part is disconnected from the hoverboard, the latter can be used as a common hoverboard.

- -

- Electric: when the two parts are connected, an electrical connection must be established between them so that, during the running phase, the kick scooter battery, along with that of the hoverboard, transfers energy to the hoverboard motors. When the two parts are disconnected, the electrical connection is obviously interrupted.

- Yield Strength Rp0,2: 138 MPa

- Tensile strength Rm: 207 MPa

- Elongation A: 3%

4. Conclusions and Final Result (Rendering)

Author Contributions

Funding

Conflicts of Interest

References

- Frizziero, L. Conceptual design of an innovative electric transportation means with QFD, Benchmarking, TOP-FLOP Analysis. Far East J. Electron. Commun. 2018, 18, 189–205. [Google Scholar] [CrossRef]

- Meuli, M.; Raghunath, M. Tops and flops using cultured epithelial autografts in children. Pediatr. Surg. Int. 1997, 12, 471–477. [Google Scholar] [CrossRef] [PubMed]

- Akao, Y. Quality Function Deployment: Integrating Customer Requirements into Product Design; Productivity Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Bathe, K.J. Finite Element Procedures, 2nd ed.; Klaus-Jürgen Bathe: Watertown, MA, USA, 2014. [Google Scholar]

- Frizziero, L.; Donnici, G.; Francia, D.; Liverani, A.; Caligiana, G.; Cantarelli, S. Powered CAD design of a green transportation means obtained by QFD and TRIZ. In Advances in Computer Science and Engineering; Pushpa Publishing House: Allahabad, India, 2018; Volume 17, Number 2; pp. 55–74. [Google Scholar]

- Gaddoni, A. Studio di design di un mezzo di trasporto urbano innovativo. Ph.D. Thesis, Alma Mater Studiorum University of Bologna, Bologna, Italy, 2017. [Google Scholar]

- Dimitri, M. Causes, Impacts and Solutions of the Problem Generated by Traffic in Towns (In Italian, “Cause, impatti e soluzioni dei problemi generati dal traffico nelle città”). Available online: www.marcodemitri.it (accessed on 12 November 2014).

- Lorien Consulting. Forum QualeMobilità; Lorien Consulting: Milano, Italy, 2017. [Google Scholar]

- Hubka, V.; Eder, W.E. Engineering Design; Heurista: Zürich, Switzerland, 1992. [Google Scholar]

- Fargnoli, M.; Sakao, T.; Notarnicola, S. A procedure to identify effective redesign options in ecodesign. In Proceedings of the International Conference on Engineering Design ICED 05, Melbourne, Australia, 15–18 August 2005. [Google Scholar]

- Freddi, A. Imparare a progettare, Principi e metodi del progetto concettuale per lo sviluppo della creatività industriale; Pitagora: Bologna, Italy, 2005; ISBN 88-371-1512-1. [Google Scholar]

- Pahl, G.; Beitz, W.; Feldhusen, J.; et al. Engineering Design a Systematic Approach; Springer: London, UK, 2007; ISBN 978-1-84628-319-2. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar]

- Lam, J.S.L.; Lai, K.-H. Developing environmental sustainability by ANP-QFD approach: The case of shipping operations. J. Clean. Prod. 2015, 105, 275–284. [Google Scholar] [CrossRef]

- Brauer, J. Finite Element Analysis; Marcel Dekker: New York, NY, USA, 1988. [Google Scholar]

- Cesari, F. Introduzione al metodo degli elementi finiti; Pitagora Editrice: Bologna, Italy, 2002. [Google Scholar]

- Renzi, C.; Leali, F. A Multicriteria Decision-Making Application to the Conceptual Design of Mechanical Components. J. Multi-Criteria Decis. Anal. 2016, 23, 87–111. [Google Scholar] [CrossRef]

- Sadok Cherif, M.; Aouni, B.; Chabchoub, H. An imprecise goal programming approach for modeling design team’s preferences in quality function deployment planning process. J. Multi-Criteria Decis. Anal. 2010, 17, 137–154. [Google Scholar] [CrossRef]

- Hauser, J.R.; Clausing, D.P. The House of Quality. Harv. Bus. Rev. 1988, 66, 63–73. [Google Scholar]

- Chan, L.K.; Wu, M.L. Prioritizing the technical measures in quality function deployment. Qual. Eng. 1998, 10, 467–479. [Google Scholar] [CrossRef]

- Wu, H.-H.; Liao, A.Y.H.; Wang, P.-C. Using grey theory in quality function deployment to analyse dynamic customer requirements. Int. J. Adv. Manuf. Technol. 2005, 25, 1241–1247. [Google Scholar] [CrossRef]

- Wu, H.-H. Applying grey model to prioritise technical measures in quality function deployment. Int. J. Adv. Manuf. Technol. 2006, 29, 1278–1283. [Google Scholar] [CrossRef]

- Wu, H.-H.; Shieh, J.-I. Applying repertory grids technique for knowledge elicitation in quality function deployment. Qual. Quant. 2010, 44, 1139–1149. [Google Scholar] [CrossRef]

- Cristiano, J.J.; Liker, J.K.; White, C.C. Key Factors in the Successful Application of Quality Function Deployment (QFD). IEEE Trans. Eng. Manang. 2001, 48, 81–95. [Google Scholar] [CrossRef]

- Zeithaml, V.A.; Berry, L.L.; Parasuraman, A. The behavioral consequences of service quality. J. Mark. 1996, 60, 31–46. [Google Scholar] [CrossRef]

- Gherardini, F.; Renzi, C.; Leali, F. A Systematic User-Centred Framework for Engineering Product Design in Small and Medium-sized Enterprises (SMEs). Int. J. Adv. Manuf. Technol. 2017, 91, 1723–1746. [Google Scholar] [CrossRef]

- Turner, M.J.; Clough, R.W.; Martin, H.C.; Topp, L.J. Stiffness and Deflection Analysis of Complex Structures. J. Aeronaut. Sci. 1956, 23, 805–823. [Google Scholar] [CrossRef]

- Hrennikoff, A. Solution of problems of elasticity by the framework method. J. Appl. Mech. 1941, 8, 169–175. [Google Scholar]

- Strang, G.; Fix, G. An Analysis of the Finite Element Method; Prentice Hall: Upper Saddle River, NJ, USA, 1973. [Google Scholar]

- Clough, R.W. The Finite Element Method, in Plane Stress Analysis. In Proceedings of the 2nd ASCE Conference on Electronic Computation, Pittsburgh, PA, USA, 8–9 September 1960. [Google Scholar]

- Frizziero, L.; Francia, D.; Donnici, G.; Caligiana, G.; Liverani, L. Sustainable design of open molds with QFD and TRIZ combination. J. Ind. Prod. Eng. 2018, 35, 21–31. [Google Scholar]

- Francia, D.; Caligiana, G.; Liverani, A.; Frizziero, L.; Donnici, G. PrinterCAD: A QFD and TRIZ integrated design solution for large size open moulding manufacturing. Int. J. Interact. Des. Manuf. 2018, 12, 81–94. [Google Scholar] [CrossRef]

- Ghezzo, F.; Giannini, G.; Cesari, F.; Caligiana, G. Numerical and experimental analysis of the interaction between two notches in carbon fibre laminates. Compos. Sci. Technol. 2008, 68, 1057–1072. [Google Scholar] [CrossRef]

- Caligiana, G.; Liverani, A.; Francia, D.; Frizziero, L.; Donnici, G. Integrating QFD and TRIZ for innovative design. J. Adv. Mech. Des. Syst. Manuf. 2017, 11. [Google Scholar] [CrossRef] [Green Version]

- Argyris, J.H.; Balmer, H.; Doltsinis, J.S.; Dunne, P.C.; Haase, M.; Kleiber, M.; Malejannakis, G.A.; Mlejnek, H.-P.; Müller, M.; Scharpf, D.W. Finite element method—The natural approach. Comput. Methods Appl. Mech. Eng. 1979, 1, 17–18. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.-H. Engineering Design, a Systematic Approach; Springer: London, UK, 1977. [Google Scholar]

| Analysis of the Best Innovative Renewable Energy City Transportation Means | On foot | Car | Motorbike | Scooter | Bicycle | Push Scooter | Hoverboard | Public Transport (bus) | Public Transport (taxi) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Use immediacy | 10 | 2 | 4 | 6 | 8 | 10 | 10 | 2 | 2 |

| 2 | Agility, mobility | 10 | 2 | 4 | 6 | 8 | 8 | 10 | 2 | 2 |

| 3 | Dexterity | 10 | 2 | 4 | 6 | 8 | 10 | 10 | 2 | 2 |

| 4 | Access to the restricted traffic zone (a-ztl) | 10 | 4 | 6 | 8 | 10 | 10 | 10 | 10 | 10 |

| 5 | Accessibility to close (acs) and to pedestrain spaces (aps) | 10 | 0 | 0 | 0 | 4 | 10 | 10 | 2 | 2 |

| 6 | Reliability | 10 | 8 | 8 | 6 | 8 | 10 | 8 | 2 | 6 |

| 7 | Flexibility | 10 | 2 | 4 | 6 | 8 | 10 | 10 | 2 | 2 |

| 8 | Speed in traffic | 2 | 2 | 4 | 6 | 10 | 6 | 8 | 2 | 2 |

| 9 | Speed | 0 | 10 | 10 | 8 | 6 | 2 | 4 | 6 | 8 |

| 10 | Duration of use, autonomy | 8 | 10 | 10 | 10 | 10 | 10 | 4 | 10 | 10 |

| 11 | Functionality | 10 | 8 | 8 | 8 | 8 | 6 | 8 | 6 | 6 |

| 12 | Not stealability | 10 | 8 | 4 | 4 | 2 | 10 | 10 | 10 | 10 |

| 13 | Self-transportability | 10 | 0 | 0 | 0 | 4 | 10 | 10 | 6 | 6 |

| 14 | Capacity of transportation for driver | 10 | 10 | 8 | 8 | 8 | 8 | 8 | 10 | 10 |

| 15 | Capacity of transportation for other people | 4 | 10 | 6 | 6 | 2 | 0 | 0 | 10 | 10 |

| 16 | Faster than pedestrians | 0 | 10 | 10 | 10 | 8 | 4 | 6 | 8 | 10 |

| 17 | Dinamicity | 8 | 4 | 6 | 8 | 10 | 10 | 10 | 8 | 6 |

| 18 | Fun | 8 | 6 | 8 | 8 | 8 | 6 | 8 | 0 | 0 |

| 19 | Availibility | 10 | 6 | 4 | 4 | 6 | 10 | 10 | 4 | 4 |

| 20 | Comfort | 4 | 10 | 6 | 8 | 6 | 2 | 4 | 2 | 6 |

| 21 | Ecology | 10 | 2 | 2 | 4 | 10 | 10 | 10 | 4 | 2 |

| 22 | Price/cost | 10 | 0 | 2 | 4 | 6 | 10 | 10 | 4 | 2 |

| Total | 174 | 116 | 118 | 134 | 158 | 172 | 178 | 112 | 118 | |

| Vote in */10 | 7.9 | 5.3 | 5.4 | 6.1 | 7.2 | 7.8 | 8.1 | 5.1 | 5.4 | |

|  |  |  |  |  |  |  |  |  | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Brand and model | Beeper FX3 | Electronic star V8 | Electronic star V12 | Nilox doc air | Nilox doc eco | Razor E300S | Smartgyro viper urban | SXT 1000 turbo | Takira tank 1000 | Xiaomi M365 | |

| Speed (Km/h) | 25 | 16 | 38 | 25 | 15 | 24 | 18 | 32 | 32 | 25 | >=38 |

| Autonomy (Km) | 19 | 16 | nd | 25 | 12 | nd | 12 | 25 | 20 | 30 | >=30 |

| Recharge time (hours) | 4 | 8 | 8 | 2 | 8 | nd | 2 | nd | 8 | 6 | <=2 |

| Maximum weight supported (Kg) | 120 | 80 | 80 | 120 | 100 | 100 | 100 | nd | 125 | 100 | >=125 |

| Weight (Kg) | 7.9 | 9.5 | 38 | 10 | 14.8 | 23.5 | 9 | 28 | 48.5 | 12.5 | <=7.9 |

| Height (mm) | 920 | 800 | 1100 | 840 | 1000 | 1060 | 1000 | 1100 | 1470 | 1140 | <=800 |

| Length (mm) | 1200 | 1180 | nd | 1180 | 1180 | 1200 | 1400 | 1220 | 1200 | 1200 | <=1180 |

| Width (mm) | 405 | 390 | 620 | 420 | 450 | 431 | 320 | 400 | 600 | 430 | <=320 |

| Maximum power (Watt) | 250 | 120 | 500 | 250 | 250 | nd | 250 | 1000 | 1000 | 250 | >=1000 |

| Brakes number | 2 | 2 | 2 | 2 | nd | 1 | 1 | 2 | 2 | 2 | 2 |

| Adjustable handlebar | no | yes | no | yes | yes | no | no | nd | no | yes | yes |

| Material | nd | steel | steel | nd | plastic | plastic | nd | steel | steel | yes | steel |

| Display | yes | no | no | no | no | no | yes | no | no | no | yes |

| Led light | yes | no | no | no | no | no | no | yes | no | yes | yes |

| Folding | yes | si | yes | yes | yes | no | yes | yes | yes | yes | yes |

| Removable battery | nd | nd | nd | yes | nd | nd | nd | nd | nd | yes | yes |

| Saddle | no | yes | no | no | no | yes | no | no | yes | no | yes |

| Price (Euros) | 282 | 179 | 449.99 | 399 | 279 | 320 | 320 | 599 | 599.99 | 579 | <=179 |

| Top | 5 | 8 | 4 | 6 | 3 | 1 | 4 | 5 | 6 | 7 | |

| Flop | 2 | 5 | 7 | 3 | 7 | 6 | 6 | 2 | 6 | 2 | |

| ∆ | 3 | 3 | −3 | 3 | −4 | −5 | −2 | 3 | 0 | 5 | >=5 |

| Who | What | Where | When | Why | How |

|---|---|---|---|---|---|

| Students | Aesthetically appealing | City | Free time | Sustainable mobility | Control on the handlebar |

| Workers | Conceptually functional | To go to work | Simplicity of use | Breaks | |

| Adolescents | Easily usable | To do a little shopping | Practicality of use | Display on the means | |

| Men/Women | To move fast |

| Foot | Bicycle | Bus | Total | |||||

|---|---|---|---|---|---|---|---|---|

| Yes | No | Yes | No | Yes | No | Yes | No | |

| High speed | 2 | 8 | 3 | 7 | 1 | 9 | 6 | 24 |

| High autonomy | 9 | 1 | 10 | 0 | 10 | 0 | 29 | 1 |

| Rechargeable | 6 | 4 | 8 | 2 | 5 | 5 | 19 | 11 |

| Seat | 3 | 7 | 6 | 4 | 2 | 8 | 11 | 19 |

| Display/lights | 8 | 2 | 8 | 2 | 9 | 1 | 25 | 5 |

| Lightweight | 9 | 1 | 8 | 2 | 10 | 0 | 27 | 3 |

| Foldable | 10 | 0 | 9 | 1 | 10 | 0 | 29 | 1 |

| Price | <400 | >400 | <400 | >400 | <400 | >400 | 24 | 6 |

| 8 | 2 | 7 | 3 | 9 | 1 | |||

| High Autonomy | Quick Charge | Lights/Display | Small Size | Low weight | Price | Nice Design | Lack of Noise | Total | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 1 | 3 | 7 | |||||

| 2 | 0 | ||||||||

| 3 | 3 | 1 | 1 | 5 | |||||

| 4 | 9 | 3 | 1 | 13 | |||||

| 5 | 9 | 3 | 12 | ||||||

| 6 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 21 | |

| 7 | 1 | 1 | 3 | 5 | |||||

| 8 | 0 | ||||||||

| TOT | 6 | 3 | 7 | 14 | 15 | 10 | 5 | 3 | 63 |

| High Autonomy | Quick Charge | Lights/ Display | Small Size | Low Weight | Price | Nice Design | Lack of Noise | |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| 2 | 2 | 1 | 2 | 2 | 2 | 2 | 0 | 0 |

| 3 | 2 | 0 | 1 | 2 | 2 | 0 | 0 | 1 |

| 4 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| 5 | 2 | 0 | 0 | 2 | 1 | 0 | 0 | 0 |

| 6 | 2 | 0 | 2 | 0 | 0 | 1 | 1 | 0 |

| 7 | 2 | 1 | 1 | 2 | 2 | 1 | 1 | 1 |

| 8 | 2 | 2 | 2 | 2 | 2 | 2 | 1 | 1 |

| Total | 14 | 4 | 8 | 12 | 9 | 6 | 4 | 3 |

| Importance | Light Materials | Shape and Color | Easily Obtainable | Easy to Produce | Correct Dimension | Easy Assembly | Quality Elements | Techical Assistance | Tot | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 10 | x | 9 | 9 | 3 | ||||||

| 2 | 4 | x | 9 | ||||||||

| 3 | 8 | x | 3 | 3 | 3 | 9 | |||||

| 4 | 10 | x | 9 | 1 | 3 | ||||||

| 5 | 9 | x | 9 | 9 | 1 | 9 | 9 | ||||

| 6 | 6 | x | 3 | 3 | 9 | 9 | 9 | 9 | 9 | ||

| 7 | 4 | x | 1 | 9 | 9 | 9 | 3 | 9 | |||

| 8 | 3 | x | 1 | 3 | 3 | 3 | 9 | ||||

| Technical Imp. | Absolute Relative | 196 15.3% | 78 6.1% | 78 6.1% | 90 7% | 384 30% | 94 7.3% | 348 27.2% | 9 0.7% | 1277 |

|  |  |  |  |  |  |  |  |  | Innovation parameters |  | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Brand and Model | Beeper FX3 | Electronic Star V8 | Electronic Star V12 | Nilox Doc Air | Nilox Doc Eco | Razor E300S | Smartgyro Viper Urban | SXT 1000 Turbo | Takira Tank 1000 | Xiaomi M365 | NEW ONE DESIGNED | |

| Speed (Km/h) | 25 | 16 | 38 | 25 | 15 | 24 | 18 | 32 | 32 | 25 | >=38 | 25 |

| Autonomy (Km) | 19 | 16 | nd | 25 | 12 | nd | 12 | 25 | 20 | 30 | >=30 | 35 |

| Recharge Time (hours) | 4 | 8 | 8 | 2 | 8 | nd | 2 | nd | 8 | 6 | <=2 | 6 |

| Maximum weight supported (Kg) | 120 | 80 | 80 | 120 | 100 | 100 | 100 | nd | 125 | 100 | >=125 | 130 |

| Weight (Kg) | 7.9 | 9.5 | 38 | 10 | 14.8 | 23.5 | 9 | 28 | 48.5 | 12.5 | <=7.9 | >=7,9 |

| Height (mm) | 920 | 800 | 1100 | 840 | 1000 | 1060 | 1000 | 1100 | 1470 | 1140 | <=800 | 1181 |

| Lenght (mm) | 1200 | 1180 | nd | 1180 | 1180 | 1200 | 1400 | 1220 | 1200 | 1200 | <=1180 | 1176 |

| Width (mm) | 405 | 390 | 620 | 420 | 450 | 431 | 320 | 400 | 600 | 430 | <=320 | 324 |

| Maximum power (Watt) | 250 | 120 | 500 | 250 | 250 | nd | 250 | 1000 | 1000 | 250 | >=1000 | 250 |

| Brakes number | 2 | 2 | 2 | 2 | nd | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| Adjustable handlebar | no | yes | no | yes | yes | no | no | nd | no | yes | yes | yes |

| Material | nd | steel | steel | nd | plastic | plastic | nd | steel | steel | yes | steel | alluminium |

| Display | yes | no | no | no | no | no | yes | no | no | no | yes | yes |

| Led light | yes | no | no | no | no | no | no | yes | no | yes | yes | yes |

| Folding | yes | si | yes | yes | yes | no | yes | yes | yes | yes | yes | yes |

| Removable battery | nd | nd | nd | yes | nd | nd | nd | nd | nd | yes | yes | yes |

| Saddle | no | yes | no | no | no | yes | no | no | yes | no | yes | no |

| Price (Euros) | 282 | 179 | 449.99 | 399 | 279 | 320 | 320 | 599 | 599.99 | 579 | <=179 | >500 |

| Top | 5 | 8 | 4 | 6 | 3 | 1 | 4 | 5 | 6 | 7 | 11 | |

| Flop | 2 | 5 | 7 | 3 | 7 | 6 | 6 | 2 | 6 | 2 | 3 | |

| ∆ | 3 | 3 | −3 | 3 | −4 | −5 | −2 | 3 | 0 | 5 | >=5 | 8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frizziero, L.; Donnici, G.; Francia, D.; Liverani, A.; Caligiana, G.; Di Bucchianico, F. Innovative Urban Transportation Means Developed by Integrating Design Methods. Machines 2018, 6, 60. https://doi.org/10.3390/machines6040060

Frizziero L, Donnici G, Francia D, Liverani A, Caligiana G, Di Bucchianico F. Innovative Urban Transportation Means Developed by Integrating Design Methods. Machines. 2018; 6(4):60. https://doi.org/10.3390/machines6040060

Chicago/Turabian StyleFrizziero, Leonardo, Giampiero Donnici, Daniela Francia, Alfredo Liverani, Gianni Caligiana, and Francesco Di Bucchianico. 2018. "Innovative Urban Transportation Means Developed by Integrating Design Methods" Machines 6, no. 4: 60. https://doi.org/10.3390/machines6040060

APA StyleFrizziero, L., Donnici, G., Francia, D., Liverani, A., Caligiana, G., & Di Bucchianico, F. (2018). Innovative Urban Transportation Means Developed by Integrating Design Methods. Machines, 6(4), 60. https://doi.org/10.3390/machines6040060