Disturbance Simulation in the Packaging Process of Confectionary Using Virtual Commissioning

Abstract

:1. Introduction

- With what accuracy can VC software simulate process disturbances?

- Is the accuracy achieved sufficient to depict the effect of real operational machine behavior?

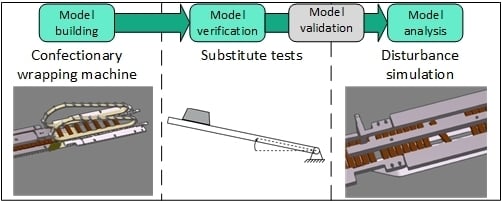

2. Materials and Methods

2.1. Preliminary Remark on the Applied Method

2.2. Model Building of the Feeding System of a Wrapping Machine

2.3. Verification of the Model

2.4. Disturbance Simulation

- Can the process and disturbance-relevant behavior of the object be represented as in the model of rigid bodies?

- Can the process be modeled with 3D-CAD tools?

- Can the sensors be represented within the VC software?

3. Results and Discussion

3.1. Results of the Model Building Process

3.2. Results of the Verification

3.3. Results of the Disturbance Simulation

4. Conclusions

- To what accuracy can VC software simulate process disturbances?

- Is the achieved accuracy sufficient at depicting the effect of real operational machine behavior?

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schult, A.; Beck, E.; Majschak, J.-P. Steigerung der Effizienz von Verarbeitungs- und Verpackungsanlagen durch Wirkungsgradanalysen. Pharma + Food 2015, 18, 66–68. [Google Scholar]

- Wandke, H. Assistance in human–machine interaction: A conceptual framework and a proposal for a taxonomy. Theor. Issues Ergon. Sci. 2005, 6, 129–155. [Google Scholar] [CrossRef]

- Allais, I.; Edoura-Gaena, R.-B.; Gros, J.-B.; Trystram, G. How human expertise at industrial scale and experiments can be combined to improve food process knowledge and control. Food Res. Int. 2007, 40, 585–602. [Google Scholar] [CrossRef]

- Perrot, N.; Agioux, L.; Ioannou, I.; Mauris, G.; Corrieu, G.; Trystram, G. Decision support system design using the operator skill to control cheese ripening––Application of the fuzzy symbolic approach. J. Food Eng. 2004, 64, 321–333. [Google Scholar] [CrossRef]

- Edoura-Gaena, R.B.; Allais, I.; Gros, J.B.; Trystram, G. A decision support system to control the aeration of sponge finger batters. Food Control 2006, 17, 585–596. [Google Scholar] [CrossRef]

- Kansou, K.; Chiron, H.; Della Valle, G.; Ndiaye, A.; Roussel, P. Predicting the quality of wheat flour dough at mixing using an expert system. Food Res. Int. 2014, 64, 772–782. [Google Scholar] [CrossRef] [PubMed]

- Klaeger, T.; Schult, A.; Majschak, J.-P. Lernfähige Bedienerassistenz für Verarbeitungsmaschinen. Ind. 4.0 Manag. 2017, 33, 25–28. [Google Scholar]

- Kong, L.; Peng, X.; Chen, Y.; Wang, P.; Xu, M. Multi-sensor measurement and data fusion technology for manufacturing process monitoring: A literature review. Int. J. Extrem. Manuf. 2020, 2, 1–27. [Google Scholar] [CrossRef]

- Domingos, P. A few useful things to know about machine learning. Commun. ACM 2012, 55, 78–87. [Google Scholar] [CrossRef] [Green Version]

- Müller, R.; Oehm, L. Process industries versus discrete processing: How system characteristics affect operator tasks. Cogn. Technol. Work 2018, 21, 1–20. [Google Scholar] [CrossRef]

- Klaeger, T.; Schult, A.; Oehm, L. Using anomaly detection to support classification of fast running packaging processes. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN’19), Helsinki-Espoo, Finland, 23–25 July 2019; Volume 1, pp. 343–348. [Google Scholar]

- Lu, J.; Liu, A.; Dong, F.; Gu, F.; Gama, J.; Zhang, G. Learning under Concept Drift: A Review. IEEE Trans. Knowl. Data Eng. 2019, 31, 2346–2363. [Google Scholar] [CrossRef] [Green Version]

- Reinhart, G.; Wünsch, G. Economic application of virtual commissioning to mechatronic production systems. Prod. Eng. Res. Dev. 2007, 1, 371–379. [Google Scholar] [CrossRef]

- Lechler, T.; Fischer, E.; Metzner, M.; Mayr, A.; Franke, J. Virtual Commissioning—Scientific review and exploratory use cases in advanced production systems. Procedia CIRP 2019, 81, 1125–1130. [Google Scholar] [CrossRef]

- Metzner, M.; Krieg, L.; Merhof, J.; Ködel, T.; Franke, J. Intuitive Interaction with Virtual Commissioning of Production Systems for Design Validation. Procedia CIRP 2019, 84, 892–895. [Google Scholar] [CrossRef]

- Scheifele, C.; Verl, A.; Riedel, O. Real-time co-simulation for the virtual commissioning of production systems. Procedia CIRP 2019, 79, 397–402. [Google Scholar] [CrossRef]

- Ayani, M.; Ganebäck, M.; Ng, A.H.C. Digital Twin: Applying emulation for machine reconditioning. Procedia CIRP 2018, 72, 243–248. [Google Scholar] [CrossRef]

- Wünsch, G. Methoden für die Virtuelle Inbetriebnahme Automatisierter Produktionssysteme. Ph.D. Thesis, Technische Universität München, München, Germany, 2008. [Google Scholar]

- Verein Deutscher Ingenieure. VDI/VDE 3693—Virtual Commissioning—Model Types and Glossary; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2016. [Google Scholar]

- Stich, P.; Krotil, S.; Reinhart, G. Interaktive simulationsgestützte Programmierung bei der Entwicklung mechatronischer Verpackungsanlagen. In Proceedings of the VVD 2015 Verarbeitungsmaschinen und Verpackungstechnik—8. Wissenschaftliche Fachtagung, Dresden, Germany, 12–13 March 2015; Majschak, J.-P., Ed.; Technische Universität Dresden: Radebeul, Germany, 2015. [Google Scholar]

- Spitzweg, M. Methode und Konzept für den Einsatz eines Physikbasierten Modells in der Entwicklung von Produktionsanlagen. Ph.D. Thesis, Technische Universität München, München, Germany, 2009. [Google Scholar]

- Boeing, A.; Bräunl, T. Evaluation of real-time physics simulation systems. In Proceedings of the 5th International Conference on Computer Graphics and Interactive Techniques in Australia and Southeast Asia—GRAPHITE ’07, New York, NY, USA, December 2007; ACM Press: Perth, Australia, 2007; pp. 281–288. [Google Scholar]

- Hummel, J.; Wolff, R.; Stein, T.; Gerndt, A.; Kuhlen, T. An Evaluation of Open Source Physics Engines for Use in Virtual Reality Assembly Simulations. In Advances in Visual Computing; Bebis, G., Boyle, R., Parvin, B., Koracin, D., Fowlkes, C., Wang, S., Choi, M.-H., Mantler, S., Schulze, J., Acevedo, D., et al., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7432, pp. 346–357. [Google Scholar]

- Lacour, F.-F. Modellbildung für die Physikbasierte Virtuelle Inbetriebnahme Materialflussintensiver Produktionsanlagen. Ph.D. Thesis, Technische Universität München, München, Germany, 2011. [Google Scholar]

- Coumans, E. Bullet 2.83 Physics SDK Manual 2015. Available online: https://github.com/bulletphysics/bullet3/blob/master/docs/Bullet_User_Manual.pdf (accessed on 23 January 2019).

- Drescher, B.; Stich, P.; Kiefer, J.; Strahilov, A.; Bär, T.; Reinhart, G. Physikbasierte Simulation im Anlagenentstehungsprozess—Einsatzpotentiale bei der Entwicklung automatisierter Montageanlagen im Automobilbau. In Proceedings of the Simulation in Produktion und Logistik 2013, Paderborn, Germany, 9–11 October 2013; Dangelmaier, W., Laroque, C., Klaas, A., Eds.; Heinz Nixdorf Institut (HNI): Paderborn, Germany, 2013; Volume 316, pp. 271–281. [Google Scholar]

- Stich, P. Interaktiver Simulationsgestützter Entwurf mechatronischer Verarbeitungssysteme. Ph.D. Thesis, Technische Universität München, München, Germany, 2017. [Google Scholar]

- Verein Deutscher Ingenieure. VDI 4465—Modellierung und Simulation: Modellbildungsprozess; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2016. [Google Scholar]

- Döring, M.; Majschak, J.-P. Berechnung von Bewegungsvorgaben unter Beachtung der Prozessdynamik am Beispiel des schnelllaufenden Transports von kleinstückigen Stückgütern. In Proceedings of the 10. Kolloquium Getriebetechnik—Berichte der Illmenauer Mechanismentechnik, Ilmenau, Germany, 11–13 September 2013; Universitätsverlag Illmenau: Ilmenau, Germany, 2013; Volume 2, pp. 187–200. [Google Scholar]

- Troll, C.; Schebitz, B.; Majschak, J.-P.; Döring, M.; Holowenko, O.; Ihlenfeldt, S. Commissioning new applications on processing machines: Part I—Process modelling. Adv. Mech. Eng. 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Hofman, D. Simulationsgestützte Auslegung von Ordnungsschikanen in Vibrationswendelförderern. Ph.D. Thesis, Technische Universität München, München, Germany, 2014. [Google Scholar]

| Class 1 | Class 2 | Class 3 | Class 4 | |

|---|---|---|---|---|

| Effect | Additional friction | Additional impact | Position change | Forcing sensor variable |

| Example | Products too high | Edge between conveyor belts | Broken products | Contaminated sensor |

| Simulated via | Changing product geometry | Changing machine geometry | Changing product geometry | Affecting switching characteristic |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolf, J.; Carsch, S.; Troll, C.; Majschak, J.-P. Disturbance Simulation in the Packaging Process of Confectionary Using Virtual Commissioning. Machines 2020, 8, 19. https://doi.org/10.3390/machines8020019

Wolf J, Carsch S, Troll C, Majschak J-P. Disturbance Simulation in the Packaging Process of Confectionary Using Virtual Commissioning. Machines. 2020; 8(2):19. https://doi.org/10.3390/machines8020019

Chicago/Turabian StyleWolf, Johanna, Sebastian Carsch, Clemens Troll, and Jens-Peter Majschak. 2020. "Disturbance Simulation in the Packaging Process of Confectionary Using Virtual Commissioning" Machines 8, no. 2: 19. https://doi.org/10.3390/machines8020019

APA StyleWolf, J., Carsch, S., Troll, C., & Majschak, J.-P. (2020). Disturbance Simulation in the Packaging Process of Confectionary Using Virtual Commissioning. Machines, 8(2), 19. https://doi.org/10.3390/machines8020019