Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective, Part I—Digital Triad Concept and Its Application as a System Reference Model

Abstract

:1. Introduction

- (1)

- It is found that the existing works on SM show the limitations of at two aspects, i.e., (a) the highly diversified understandings of the functionalities and expectations of SM that may result in overlapped, missed, or non-systematic research efforts in advancing the theory and methodologies in the field of SM; (b) few works have been published that propose a generic design methodology for the design of smart manufacturing systems in practice.

- (2)

- The definition of SM is simplified to unify the diversified expectations. A newly developed concept, digital triad (DT-II), is adopted to define a reference model for SM; it reflects all of the main characteristics of digital solutions at the different levels and domains of system operations.

- (3)

- The common features of various smart manufacturing systems are identified; particularly, the concept of IoDTT is proposed as a reference model to represent the need for system reconfiguration in the event of uncertainties and changes in business environments.

- (4)

- The generality and specialty in designing and implementing various smart manufacturing systems are discussed, to illustrate the need for developing a general design methodology to guide the design of a smart manufacturing system from a practical perspective.

2. Overview of Smart Manufacturing (SM)

2.1. Original Definition and Variations

2.2. Main Characteristics

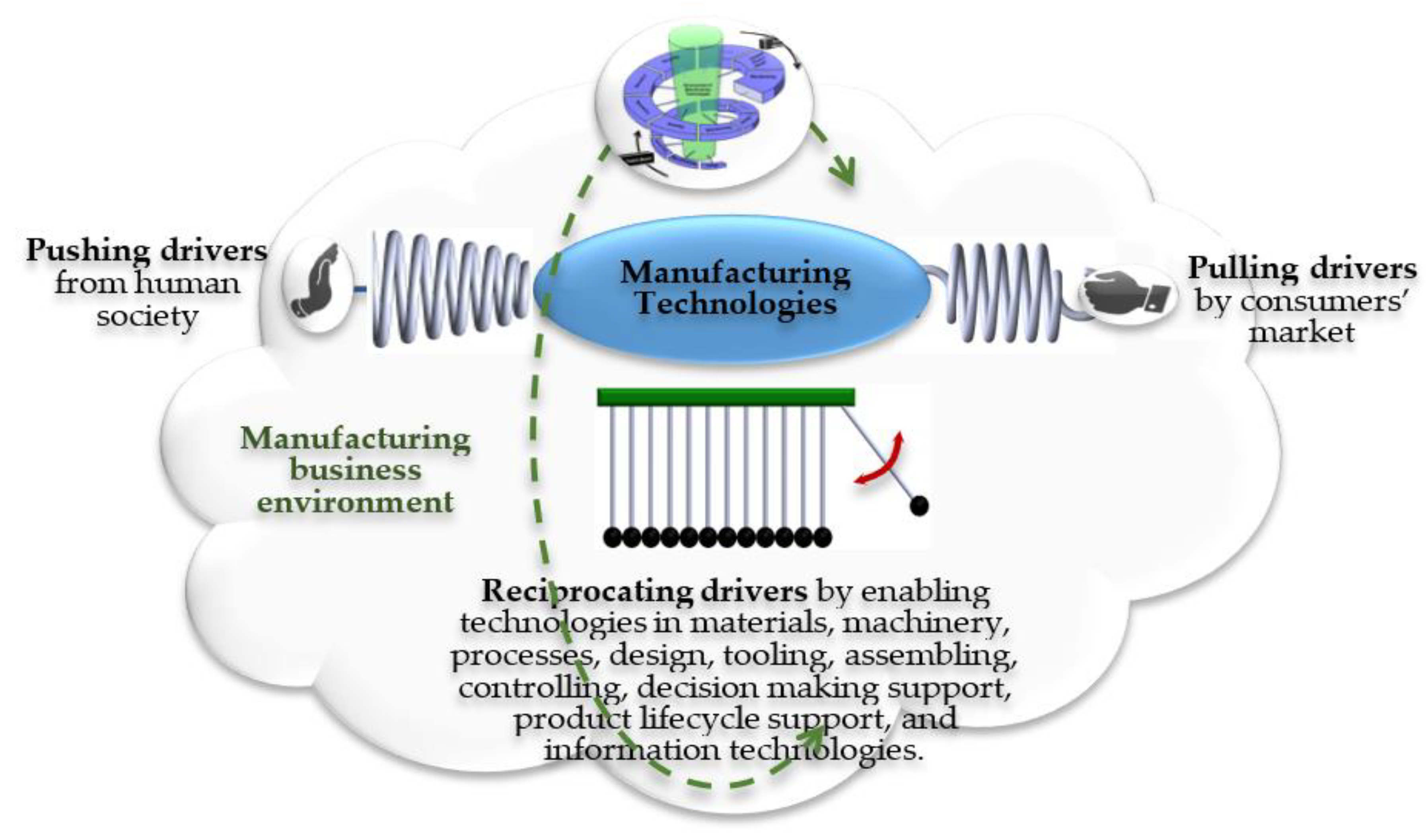

2.3. Technological Drivers

2.4. Applications

2.5. Limitations of Existing Works

3. Proposed Definition of SM

3.1. New Definition of SM

3.2. Functional Requirements (FRs) of SM

3.3. Generic Model of System Elements—Digital Triad (DT-II)

3.4. Internet of Digital Triad Things (IoDTT) as a Reference Model

4. Discussion on Generality and Specialty in Designing and Implementing Custom Smart Manufacturing Systems

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| 5V: | Variety, Volume, Velocity, Veracity, and Value |

| ADT: | Axiomatic Design Theory |

| AI: | Artificial Intelligence |

| AM: | Agile Manufacturing |

| AM: | Additive Manufacturing |

| AR: | Augmented Reality |

| BCT: | Blockchain Technology |

| BDA: | Big Data Analytics |

| BPM: | Business Process Management |

| CAD: | Computer Aided Design |

| CADM: | computer Aided dDesign and Manufacturing |

| CAE: | Computer Aided Engineering |

| CAM: | Computer Aided Manufacturing |

| CC: | Cloud Computing |

| CESMII | Clean Energy Smart Manufacturing Innovation Institute |

| CI: | Continuous Improvement |

| CIM: | Computer Integrated Manufacturing |

| CNC: | Computer Numerical Control |

| DM: | Digital Manufacturing |

| DSs: | Design Solutions |

| ERP: | Enterprise Resource Planning |

| ES: | Enterprise Systems |

| GT: | Group Technologies |

| HCPS: | Human-Cyber Physical Systems |

| HRI: | Human-Robot Interactions |

| IDM: | Intelligent Digital Mesh |

| IEEE: | Institute of Electrical and Electronics Engineers |

| IIoT: | Industrial Internet of Things |

| IIRA: | Industrial Internet Reference Architecture |

| IM: | Intelligent Manufacturing |

| IOS: | International Organization for Standardization |

| ITU; | International Telecommunication Union |

| KPIs: | Key Performance Indicators |

| LP: | Lean Production |

| ML: | Machine Learning |

| MRP: | Material Resource Planning |

| NC: | Numerical Controls |

| NIST: | National Institute of Standards and Technology |

| NSF: | National Science Foundation |

| PDM: | Product Data Management |

| PLM: | Product Lifecycle Management |

| QC: | Quality Controls |

| RAMI: | Reference Architectural Model Industrie |

| RFID: | Radio Frequency IDentification |

| SMEs: | Small to Midsize Enterprises |

| SoA: | Service-oriented Architecture |

| SoS: | System of Systems |

| TQM: | Total Quality Management |

References

- Bi, Z.M. Embracing Internet of things (IoT) and big data for industrial informatics. Enterp. Inf. Syst. 2017, 11, 949–951. [Google Scholar] [CrossRef]

- Bi, Z.M. Revisiting system paradigms from the viewpoint of manufacturing sustainability. Sustainability 2011, 3, 1323–1340. [Google Scholar] [CrossRef] [Green Version]

- Bi, Z.M.; Zhang, W.J. Chapter 1: Human Civilization, Products, and Manufacturing. Practical Guide to Digital Manufacturing—First-Time-Right from Digital Twin to Physical Twin; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-70303-5. [Google Scholar]

- Bi, Z.M.; Zhang, W.J. Chapter 2: Computer-Aided Design. In Practical Guide to Digital Manufacturing—First-Time-Right from Digital Twin to Physical Twin; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-70303-5. [Google Scholar]

- Blomeke, S.; Richert, J.; Mennenga, M.; Thiede, S.; Spengler, T.S.; Herrmann, C. Recycling 4.0—mapping smart manufacturing solutions to remanufacturing and recycling operations. Procedia CIRP 2020, 90, 600–605. [Google Scholar] [CrossRef]

- Baroroh, D.K.; Chu, C.H.; Wang, L. Systematic literature review on augmented reality in smart manufacturing: Collaboration between human and computational intelligence. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Bi, Z.M.; Lang, S.Y.T.; Shen, W.M. Reconfigurable manufacturing systems: The state of the art. Int. J. Prod. Res. 2008, 46, 967–992. [Google Scholar] [CrossRef] [Green Version]

- Bi, Z.M.; Xu, L.D.; Wang, C. Internet of things for enterprise systems of modern manufacturing. IEEE Trans. Industr. Inform. 2014, 10, 1537–1546. [Google Scholar]

- Guchhait, R.; Pareek, S.; Sarkar, B. How does a radio frequency identification optimize the profit in an unreliable supply chain management? Mathematics 2019, 7, 490. [Google Scholar] [CrossRef] [Green Version]

- Sardar, S.K.; Sarkar, B.; Kim, B. Integrating machine learning, radio frequency identification, and consignment policy for reducing unreliability in smart supply chain management. Processes 2021, 9, 247. [Google Scholar] [CrossRef]

- Ullah, M.; Sarkar, B. Recovery-channel selection in a hybrid manufacturing-remanufacturing production model with RFID and production quality. Int. J. Prod. Econ. 2020, 219, 360–374. [Google Scholar] [CrossRef]

- Dey, B.K.; Pareek, S.; Tayyab, M.; Sarkar, B. Autonomation policy to control work-in-process inventory in a smart production system. Int. J. Prod. Res. 2020, 59, 1258–1280. [Google Scholar] [CrossRef]

- Dey, B.K.; Bhuniys, S.; Sarkar, B. Involvement of controllable lead time and variable demand for a smart manufacturing under a supply chain management. Expert Syst. Appl. 2021, 184, 115464. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Ching, N.T. Adopting of digital technologies of smart manufacturing in SMEs. J. Ind. Inf. Integr. 2019, 16, 100107. [Google Scholar]

- Meindl, B.; Ayala, N.F.; Mendonca, J.; Frank, A.G. The four smarts of Industry 4.0: Evolution of ten years of research future perspectives. Technol. Forecast. Soc. Change 2021, 168, 120784. [Google Scholar] [CrossRef]

- Deloitte. The Smart Factory: Responsive, Adaptive, Connected Manufacturing. 2021. Available online: https://www2.deloitte.com/content/dam/insights/us/articles/4051_The-smart-factory/DUP_The-smart-factory.pdf (accessed on 22 September 2021).

- Li, Q.; Tang, Q.; Chan, I.; Wei, H.; Pu, Y.; Jiang, H.; Li, J.; Zhou, J. Smart manufacturing standardization: Architectures, reference models and standards framework. Comput. Ind. 2018, 101, 91–106. [Google Scholar] [CrossRef]

- Manufacturing Operations Management. A Brief History of Smart Manufacturing. 2021. Available online: https://www.manufacturing-operations-management.com/manufacturing/smart-manufacturing/ (accessed on 22 September 2021).

- Lu, Y.; Morris, K.C.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems, NIST Interagency/Internal Report (NISTIR); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016. [CrossRef]

- Lu, Y.; Witherell, P.; Jones, A. Standard connections for IIoT empowered smart manufacturing. Manuf. Lett. 2020, 26, 17–20. [Google Scholar] [CrossRef] [PubMed]

- SMLC. Implementing 21st Century Smart Manufacturing—Workshop Summary Report. 2011. Available online: https://www.controlglobal.com/assets/11wppdf/110621_smlc-smart-manufacturing.pdf (accessed on 22 September 2021).

- dek/din. The German Standardization Roadmap Smart City. 2014. Available online: https://www.dke.de/resource/blob/778248/d2afdaf62551586a54b3270ef78d2632/the-german-standardization-roadmap-smart-city-version-1-0-data.pdf (accessed on 22 September 2021).

- US Government. Made in China 2025 and the Future of American Industry: Hearing before the Committee on Small Business and Entrepreneurship United States Senate. 2019. Available online: https://www.govinfo.gov/content/pkg/CHRG-116shrg35699/pdf/CHRG-116shrg35699.pdf (accessed on 22 September 2021).

- Davis, J.F.; Edgar, T.F.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for industry 4.0 and smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Romero, M.; Guedria, W.; Tanetto, H.; Barafort, B. Towards a characterization of smart systems: A systematic literature review. Comput. Ind. 2018, 120, 103234. [Google Scholar]

- Lenz, J.; MacDonald, E.; Harik, R.; Wuest, T. Optimizing smart manufacturing systems by extending the smart products paradigm to beginning of life. J. Manuf. Syst. 2020, 57, 274–286. [Google Scholar] [CrossRef]

- Filleti, R.A.P.; Silva, D.A.L.; da Silva, E.J.; Ometto, A.R. Productive and environmental performance indicators analysis by a combined LCA hybrid model and real-time manufacturing process monitoring: A grinding unit process application. J. Clean. Prod. 2017, 161, 510–523. [Google Scholar] [CrossRef]

- Maggi, F.; Balduzzi, M.; Vosseler, R.; Rosler, M.; Quadrini, W.; Tavola, G.; Pogliani, M.; Quarta, D.; Zanero, S. Smart factory security: A case study on a modular smart manufacturing system. Procedia Comput. Sci. 2021, 180, 665–675. [Google Scholar] [CrossRef]

- Viriyasitava, W.; Xu, L.; Bi, Z.M. Specification patterns of service-based applications using blockchain technology. IEEE Trans. Comput. Soc. Syst. 2020, 7, 886–896. [Google Scholar] [CrossRef]

- Viriyasitava, W.; Xu, L.; Bi, Z.M. Sapsomboon, A. Blockchain-based business process management (BPM) framework for service composition in Industry 4.0. J. Intell. Manuf. 2020, 31, 1737–1748. [Google Scholar] [CrossRef]

- Viriyasitava, W.; Xu, L.; Bi, Z.M.; Hoonsopon, D. Blockchain technology for applications in Internet of Things—mapping from system design perspective. IEEE Internet Things J. 2019, 6, 8155–8168. [Google Scholar] [CrossRef]

- Viriyasitava, W.; Xu, L.; Bi, Z.M. Blockchain and Internet of Things for modern business process in digital economy—the state of the art. IEEE Trans. Comput. Soc. Syst. 2019, 6, 1420–1432. [Google Scholar] [CrossRef]

- Viriyasitava, W.; Xu, L.; Bi, Z.M.; Hoonsopon, D.; Charoenruk, N. Managing QoS of Internet-of-Thing services using blockchain. IEEE Trans. Comput. Soc. Syst. 2019, 6, 1357–1368. [Google Scholar] [CrossRef]

- Felice, F.; Petrillo, A.; Zomparelli, F. A bibliometric multicriteria model on smart manufacturing from 2011 to 2018. IFAC PapersOnLine 2018, 51–11, 1643–1648. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing& Industry 4.0 maturity models: Implication for smart and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Building blocks for adopting smart manufacturing. Procedia Manuf. 2019, 34, 978–985. [Google Scholar] [CrossRef]

- Kusiak, A. Fundamentals of smart manufacturing: A multi-thread perspective. Annu. Rev. Control 2019, 47, 214–220. [Google Scholar] [CrossRef]

- Byrne, G.; Damm, O.; Monostori, L.; Teti, R.; van Houten, F.; Wegener, K.; Wertheim, R.; Sammler, F. Towards high performance living manufacturing systems—A new convergence between biology and engineering. CIRP J. Manuf. Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Friheit, T. Smart manufacturing and intelligence manufacturing: A comparative review. Engineering 2020, 7, 738–757. [Google Scholar] [CrossRef]

- Kulvatunyou, B.; Oh, H.; Ivezic, N.; Nieman, S.T. Standards-based semantic integration of manufacturing information: Past, present and future. J Manuf Syst. 2020, 52, 184–197. [Google Scholar] [CrossRef] [PubMed]

- Bi, Z.M. On adaptive robot system for manufacturing applications. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2002. [Google Scholar]

- Brad, S.; Murar, M. Employing smart units and servitization towards reconfigurability of manufacturing processes. Procedia CIRP 2015, 30, 498–503. [Google Scholar] [CrossRef] [Green Version]

- Feldner, B.; Herber, P. A qualitative evolution of IPv6 for the industrial Internet of things. Procedia Comput. Sci. 2018, 134, 377–384. [Google Scholar] [CrossRef]

- Kumar, A. Methods and materials for smart manufacturing: Additive manufacturing, Internet of things, flexible sensors and soft robotics. Manuf. Lett. 2018, 15, 122–125. [Google Scholar] [CrossRef]

- Barletta, I.; Despeisse, M.; Johansson, B. The proposal of an environmental break-event point as assessment method of product-service systems for circular economy. Procedia CIRP 2018, 72, 720–725. [Google Scholar] [CrossRef]

- Jaspert, D.; Ebel, M.; Eckardt, A.; Poeppelbuss, J. Smart retrofitting in manufacturing: A systematic review. J. Clean. Prod. 2021, 312, 127555. [Google Scholar] [CrossRef]

- Zenisek, J.; Wild, N.; Wolffartsberger, J. Investigating the potential of smart manufacturing technologies. Procedia Comput. Sci. 2021, 180, 507–516. [Google Scholar] [CrossRef]

- Rodger, J.M.; Bey, N.; Alting, L.; Hauschild, M.Z. Life cycle targets applied in highly automated car body manufacturing—method and algorithm. J. Clean. Prod. 2018, 194, 786–799. [Google Scholar] [CrossRef] [Green Version]

- Siiskonen, M.; Malmqvist, J.; Folestad, S. Integrated product and manufacturing system platforms supporting the design of personalized medicines. J. Manuf. Syst. 2020, 56, 281–295. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Ghadge, A.; Raut, R. A performance measurement system for industry 4.0 enabled smart manufacturing system in SMMEs—a review and empirical investigation. Int. J. Prod. Econ. 2020, 229, 107853. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Bista, R. Challenges, opportunities and future directions of smart manufacturing: A state of art review. Sustain. Future 2020, 2, 100023. [Google Scholar] [CrossRef]

- Uysal, M.P.; Mergen, A.E. Smart manufacturing in intelligent digital mesh: Integration of enterprise architecture and software product line engineering. J. Ind. Inf. Integr. 2021, 22, 100202. [Google Scholar]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Xia, Q.; Jiang, C.; Yang, C.; Zheng, X.; Pan, X.; Shuai, Y.; Yuan, S. A method towards smart manufacturing capabilities and performance measurement. Procedia Manuf. 2019, 39, 851–858. [Google Scholar] [CrossRef]

- Helu, M.; Morris, K.; Jung, K.; Lyons, K.; Leong, S. Identifying performance assurance challenges for smart manufacturing. Manuf. Lett. 2015, 6, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Ramos, A.R.; Ferreira, J.C.E.; Kumar, V.; Garza-Reves, L.A.; Cherrafi, A. A lean and cleaner production benchmarking method for sustainability assessment: A study of manufacturing companies in Brazil. J. Clean. Prod. 2018, 177, 218–231. [Google Scholar] [CrossRef]

- Manoharan, S.; Haapala, K.R. A grey box software framework for sustainability assessment of composed manufacturing processes: A hybrid manufacturing case. Procedia CIRP 2019, 80, 440–445. [Google Scholar] [CrossRef]

- Mahmood, K.; Otto, T.; Golova, J.; Kangru, T.; Kuts, V. An approach to analyze the performance of advanced manufacturing environment. Procedia CIRP 2020, 93, 628–633. [Google Scholar] [CrossRef]

- Mahmoud, A.M.; Grace, J. A generic evaluation framework of smart manufacturing systems. Procedia Comput. Sci. 2019, 161, 1292–1299. [Google Scholar] [CrossRef]

- Arden, N.S.; Fisher, A.C.; Tyner, K.; Yu, L.X.; Lee, S.I.; Kpacha, M. Industry 4.0 for pharmaceutical manufacturing: Preparing for the smart factories o the future. Int. J. Pharm. 2020, 602, 120554. [Google Scholar] [CrossRef] [PubMed]

- Vernadat, F. Enterprise modelling: Research review and outlook. Comput. Ind. 2020, 122, 103265. [Google Scholar] [CrossRef]

- Essakly, A.; Wichmann, M.; Spengler, T.S. A reference framework for the holistic evaluation of industry 4.0 solutions for small and medium-sized enterprises. IFAC PaperOnLine 2019, 52–13, 427–432. [Google Scholar] [CrossRef]

- Moghaddam, M.; Cadavid, M.N.; Kenley, C.R.; Deshmukh, A.V. Reference architectures for smart manufacturing: A critical review. J. Manuf. Syst. 2018, 49, 215–225. [Google Scholar] [CrossRef]

- Yang, S.; Navarathna, P.; Ghosh, S.; Bequette, B.W. Hybrid modeling in the era of smart manufacturing. Comput. Chem. Eng. 2020, 140, 106874. [Google Scholar] [CrossRef]

- Part, H.S.; Febriani, R.A. Modeling a platform for smart manufacturing system. Procedia Manuf. 2019, 38, 1660–1667. [Google Scholar]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot Comput. Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Bi, Z.M.; Lang, S.Y.T.; Zhang, D.; Orban, P.E.; Verner, M. Integrated design toolbox for tripod based parallel kinematic machines. ASME J. Mech. Design 2007, 129, 799–807. [Google Scholar] [CrossRef]

- Bi, A.M.; Lang, S.Y.T. Kinematic and dynamic models of a tripod system with a passive leg. IEEE ASME Trans. Mechatron. 2006, 11, 108–111. [Google Scholar] [CrossRef]

- Bi, Z.M.; Jin, Y.; Maropoulos, P.; Zhang, W.J.; Wang, L.H. Internet of things (IOT) and big data analytics for digital manufacturing (DM). Int. J. Prod. Res. 2021. [Google Scholar] [CrossRef]

- Bi, Z.M.; Wang, G.; Thompson, J.; Ruiz, D.; Rosswurm, J.; Roof, S.; Guandique, C. System framework of adopting additive manufacturing in mass production line. Enterp. Inf. Syst. 2021, 1–24. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, Z.; Zhang, W.-J.; Wu, C.; Luo, C.; Xu, L. Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective, Part I—Digital Triad Concept and Its Application as a System Reference Model. Machines 2021, 9, 207. https://doi.org/10.3390/machines9100207

Bi Z, Zhang W-J, Wu C, Luo C, Xu L. Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective, Part I—Digital Triad Concept and Its Application as a System Reference Model. Machines. 2021; 9(10):207. https://doi.org/10.3390/machines9100207

Chicago/Turabian StyleBi, Zhuming, Wen-Jun Zhang, Chong Wu, Chaomin Luo, and Lida Xu. 2021. "Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective, Part I—Digital Triad Concept and Its Application as a System Reference Model" Machines 9, no. 10: 207. https://doi.org/10.3390/machines9100207

APA StyleBi, Z., Zhang, W.-J., Wu, C., Luo, C., & Xu, L. (2021). Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective, Part I—Digital Triad Concept and Its Application as a System Reference Model. Machines, 9(10), 207. https://doi.org/10.3390/machines9100207