Development of an Intelligent Quality Management System for Micro Laser Welding: An Innovative Framework and Its Implementation Perspectives

Abstract

:1. Introduction

2. Industrial Standards and Laser Micro-Welding

2.1. Regulatory Environment

2.2. Welding Best Practices Adoption

3. Industry 4.0 and Quality Control for Laser Micro-Welding

4. Analysis of Laser Welding Quality On-line Monitoring

4.1. Defects in Laser Micro-Welding

4.2. Defects Capturing

4.2.1. Light Emissions

4.2.2. Acoustic Emissions

4.2.3. Image Processing

4.2.4. Thermal Signals

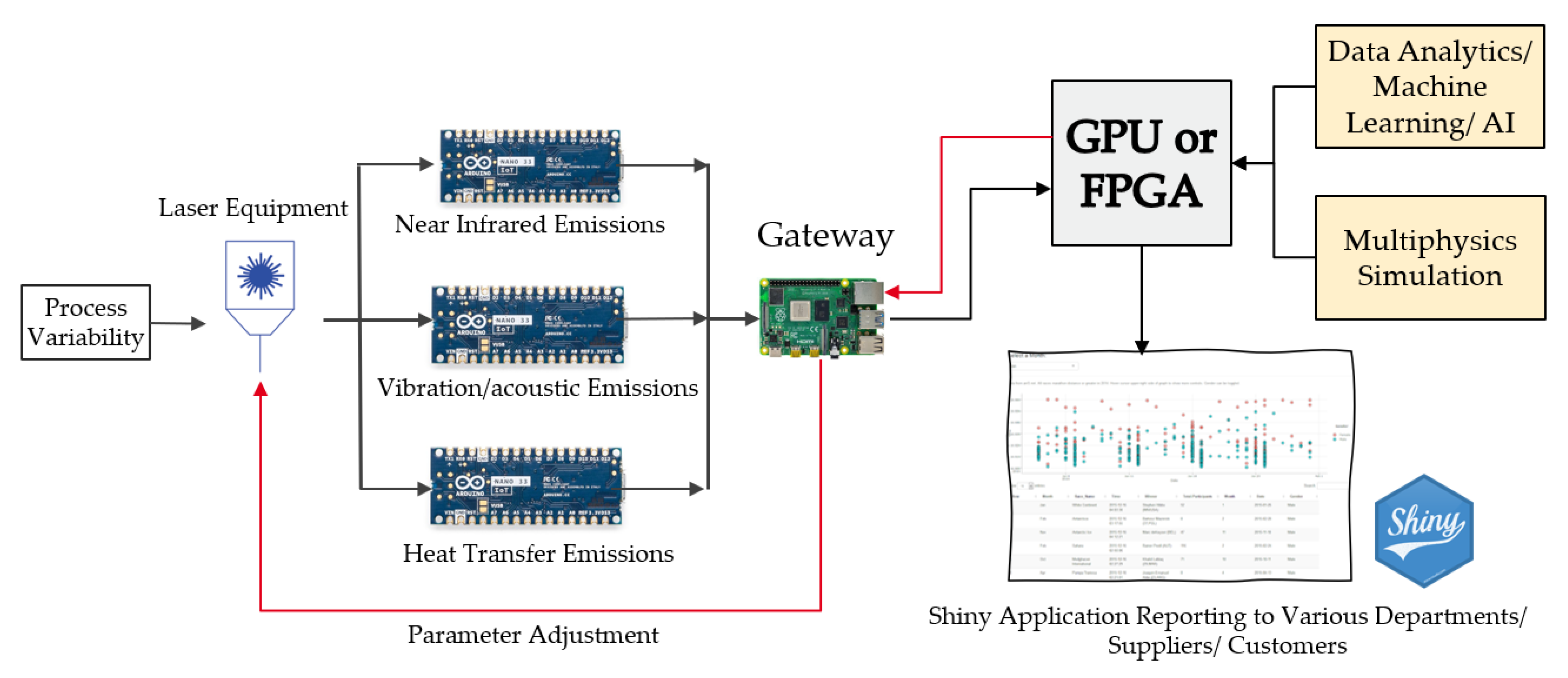

4.2.5. A Hybrid Data Collection

4.3. Defects Diagnosing

5. Framework of an Intelligent Laser Micro-Welding Quality Management System and Its Implementations

5.1. Vertical Integration

5.1.1. Welding Procedures and Welder Qualifications

5.1.2. Inspection and Testing of Laser Micro Welds

5.1.3. Equipment Maintenance, Calibration and Tooling for Laser Micro-Welding

5.2. Horizontal Integration

5.2.1. Requirements, Technical Challenges and Subcontracting

5.2.2. Production Control

5.2.3. Welding Coordination

5.3. End to End Integration: Co-Design, Servitization and Business Models Support

6. Future Research and Development

- Welding data and analytics: Quality of the information and data captured may constitute a concern and be perceived by some as a limitation to digitization. Further research should be directed to determine when and how welding data quality and the associated analytics are acceptable. The research should pinpoint if an aspect of welding quality should be dependent on data quality and the underlying analytical algorithms and analytics. The integration of Industry 4.0 is assembled on the reliability premise of welding quality. A methodology to measure welding data and ensure their quality should be researched likely through in-process measurement. Standardization of data is also an interesting research area. Incorporating these ideas above into the regular business activities may be the forfeiting of quality data. Traditional NDT reports and data, however, can be falsified, of which most welding professionals are often aware. Blockchain technology, so appropriate for this context, may increase the technology to do so, while limiting the incentive for fraud. NDT data integrity and veracity are areas that should be further researched. Research and development addressing digitization in quality management are further expected to identify all defects and their intricate correlations.

- Welding quality certification and documentation: Product personalization and/or customized product co-design multiply the need to qualify many additional WPS at every exchange with customers, as the design may be unique and involve no previous experience in those specific welds. A fascinating research theme could be the extrapolation of historical data to determine the process parameters for a new weld. Researching the results of allowing this practice in ISO 15611-4, qualification based on previous welding experience, should add substantial value. Updating the ISO 3834 family to reflect these new realities should be considered in research as well, particularly through integration with industry 4.0 principles and data automation.

- There is abundant literature on signal processing of laser welding thicker plates and butt welds on the most common materials used in industry, like steels and aluminum. The research appears to focus often on a generalized “one for all” solution. Further research is needed to find signal correlations to other materials and combinations, including dissimilar materials, weld preparations and joints and smaller thicknesses to establish causality between welding signal and specific defects.

- Business ecosystems for welding: Further research is required for a better understanding of welding process/value chains, their morphology, and strategies for capturing and providing added engineering value. Nowadays there is only incipient research available.

- A final interesting topic is to study the optimal ratio between vertical to horizontal integration for high-value welding companies.

7. Conclusions

- Industrial companies applying laser micro-welding often encounter difficulties assessing the quality of their small welds, particularly in a high-value manufacturing environment, in which defects are not allowed and can be detrimental to business. While appropriate for a lab setting, a mass production-oriented NDT protocol is costly and thus hard to apply on a production shop floor.

- Digitization of the welding processes brings along important consequences for both the production shop floor level and business level. For once, it facilitates the digitization of all activities involved in ISO-3834:2021, which inevitably results in an intelligent welding quality management system. An intelligent quality management system is dynamic and able to offer continuously a varying “snapshot” of the entire quality system, from suppliers or nodes of the network to the various vertical processes inside the company.

- The complexity and nonlinearity of the quality system can foster the required coarseness that cannot be captured in the traditional welding quality management philosophy. The intelligent welding quality management system is data-based and works in the industry 4.0 context, which provides the new framework for quality control and assurance in the laser micro-welding industry for high-pressure products/applications in particular.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ivanov, A.; Cheng, K. Non-Traditional and Hybrid Processes for Micro and Nano Manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 4481–4482. [Google Scholar]

- Naeem, M. 7-Developments in Laser Microwelding Technology. In Handbook of Laser Welding Technologies; Katayama, S., Ed.; Woodhead Publishing: Sawston, UK, 2013; pp. 163–211. [Google Scholar]

- Patschger, A.; Bliedtner, J.; Bergmann, J. Process-limiting Factors and Characteristics of Laser-based Micro Welding. Phys. Procedia 2014, 56, 740–749. [Google Scholar] [CrossRef] [Green Version]

- ISO. 3834-1:2021 Quality Requirements for Fusion Welding of Metallic Materials—Part 1: Criteria for the Selection of the Appropriate Level of Quality Requirements; ISO—International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- Carvalho, A.V.; Enrique, D.V.; Chouchene, A.; Charrua-Santos, F. Quality 4.0: An Overview. Procedia Comput. Sci. 2021, 181, 341–346. [Google Scholar] [CrossRef]

- Chiarini, A. Industry 4.0, Quality Management and TQM World. A Systematic Literature Review and a Proposed Agenda for Further Research. TQM J. 2020, 32, 603–616. [Google Scholar] [CrossRef]

- Albert, W.; Goekhan, A.; Teresa, W. Quality Management—History and Trends. TQM J. 2015, 27, 281–293. [Google Scholar]

- Pressure Equipment Directive (PED), 2014. Available online: https://www.euronorm.net/content/ce-marking/directives/en_36.pdf (accessed on 17 April 2021).

- EN. 13445—Unfired Pressure Vessels; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- EN. 13480—Metallic Industrial Piping; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Regulation (EC) No 1272/2008. 2008. Available online: http://data.europa.eu/eli/reg/2008/1272/oj (accessed on 22 May 2021).

- Council Directive 85/374/EEC, No L 210/29, 1985. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31985L0374&from=EN (accessed on 10 April 2021).

- ISO. 9001:2015 Quality Management Systems—Requirements; ISO—International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Ulewicz, R.; Nový, F. Quality Management Systems in Special Processes. Transp. Res. Procedia 2019, 40, 113–118. [Google Scholar] [CrossRef]

- Shackleton, D.N. Reducing Failure Risk in Welded. Weld. World 2006, 50, 92–97. [Google Scholar] [CrossRef]

- Duffy, G.L. The ASQ Quality Improvement Pocket Guide: Basic Components History, Concepts, Tools, and Relationships; Quality Press: Lincoln, NE, USA, 2013. [Google Scholar]

- ISO. 3834-5:2021 Quality Requirements for Fusion Welding of Metallic Materials—Part 5; ISO—International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- ISO. 3834-2:2021 Quality Requirements for Fusion Welding of Metallic Materials—Part 2: Comprehensive Quality Requirements; ISO—International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- ISO. 3834-3:2021 Quality Requirements for Fusion Welding of Metallic Materials—Part 3: Standard Quality Requirements; ISO—International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- ISO. 3834-4:2021 Quality Requirements for Fusion Welding of Metallic Materials—Part 4: Elementary Quality Requirements; ISO—International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- Fornasiero, R.; Carpanzano, E. Advances in Customer-Oriented Manufacturing and Value Chain Management. Int. J. Comput. Integr. Manuf. 2017, 30, 677–679. [Google Scholar] [CrossRef] [Green Version]

- Foidl, H.; Felderer, M. Research Challenges of Industry 4.0 for Quality Management. In Innovations in Enterprise Information Systems Management and Engineering, Proceedings of the 4th International Conference, ERP Future 2015—Research, Munich, Germany, 16–17 November 2015; Revised Papers; Felderer, M., Piazolo, F., Ortner, W., Brehm, L., Hof, H.-J., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 121–137. [Google Scholar]

- Zheng, T.; Ardolino, M.; Bacchetti, A.; Perona, M. The Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature Review. Int. J. Prod. Res. 2021, 59, 1922–1954. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Tran, N.-H.; Park, H.-S.; Nguyen, Q.-V.; Hoang, T.-D. Development of a Smart Cyber-Physical Manufacturing System in the Industry 4.0 Context. Appl. Sci. 2019, 9, 3325. [Google Scholar] [CrossRef] [Green Version]

- Otto, J.; Henning, S.; Niggemann, O. Why Cyber-Physical Production Systems Need a Descriptive Engineering Approach—A Case Study in Plug & Produce. Procedia Technol. 2014, 15, 295–302. [Google Scholar]

- Tilbury, D.M. Cyber-Physical Manufacturing Systems. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 427–443. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance. Free Press: London, NY, USA, 1985. [Google Scholar]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia Cirp 2013, 7, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Türkeș, M.C.; Oncioiu, I.; Aslam, H.D.; Marin-Pantelescu, A.; Topor, D.I.; Căpușneanu, S. Drivers and Barriers in Using Industry 4.0: A Perspective of SMEs in Romania. Processes 2019, 7, 153. [Google Scholar] [CrossRef] [Green Version]

- Toivanen, J.; Kah, P.; Martikainen, J. Quality Requirements and Conformity of Welded Products in the Manufacturing Chain in Welding Network. Int. J. Mech. Eng. Appl. 2015, 3, 109–119. [Google Scholar] [CrossRef] [Green Version]

- Simeone, A.; Caggiano, A.; Boun, L.; Deng, B. Intelligent Cloud Manufacturing Platform for Efficient Resource Sharing in Smart Manufacturing Networks. Procedia CIRP 2019, 79, 233–238. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y.; Toshev, R.; Boldosova, V. Cloud Manufacturing Ecosystem Analysis and Design. Robot. Comput.-Integr. Manuf. 2021, 67, 102050. [Google Scholar] [CrossRef]

- He, B.; Bai, K.-J. Digital Twin-Based Sustainable Intelligent Manufacturing: A Review. Adv. Manuf. 2020, 9, 1–21. [Google Scholar]

- Liu, Q.; Chen, J.; Liao, Y.; Mueller, E.; Jentsch, D.; Boerner, F.; She, M. An Application of Horizontal and Vertical Integration in Cyber-Physical Production Systems. In Proceedings of the International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery, Xi’an, China, 17–19 September 2015; pp. 110–113. [Google Scholar]

- Wen, D.; Sun, X.; Yan, D. The Quality Movement: Where Are We Going? Past, Present and Future. Total Qual. Manag. Bus. Excell. 2020, 1–21. [Google Scholar] [CrossRef]

- ISO. 6520-1:2007 Welding and Allied Processes—Classification of Geometric Imperfections in Metallic Materials—Part 1: Fusion Welding; ISO—International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- EN-ISO. 13919-1:2019 Electron and Laser-Beam Welded Joints—Requirements and Recommendations on Quality Levels for Imperfections—Part 1: Steels, Nickel, Titanium and Their Alloys; ISO—International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- ISO. 13919-2:2021 Electron and Laser-Beam Welded Joints—Requirements and Recommendations on Quality Levels for Imperfections—Part 2: Aluminium, Magnesium and Their Alloys and Pure Copper; ISO—International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- Lippold, J.C. Solidification Behavior and Cracking Susceptibility of Pulsed-Laser Welds in Austenitic Stainless-Steels. Weld. J. Incl. Weld. Res. Suppl. 1994, 73, S129–S139. [Google Scholar]

- Coroado, J.; Ganguly, S.; Suder, W.J.; Williams, S.; Meco, S.; Pardal, G. Selection of Processing Parameters in Laser Microwelding. Part 1: Continuous Wave (CW) Mode. Lasers Eng. 2020, 46, 265–284. [Google Scholar]

- Xu, J.; Rong, Y.; Huang, Y.; Wang, P.; Wang, C. Keyhole-Induced Porosity Formation During Laser Welding. J. Mater. Process. Technol. 2018, 252, 720–727. [Google Scholar] [CrossRef]

- Svenungsson, J.; Choquet, I.; Kaplan, A.F.H. Laser Welding Process—A Review of Keyhole Welding Modelling. Phys. Procedia 2015, 78, 182–191. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Gao, X.; You, D.; Ge, W. A Low-Cost Welding Status Monitoring Framework for High-Power Disk Laser Welding. IEEE Access 2019, 7, 17365–17376. [Google Scholar] [CrossRef]

- De Bono, P.; Allen, C.; D’Angelo, G.; Cisi, A. Investigation of Optical Sensor Approaches for Real-Time Monitoring during Fibre Laser Welding. J. Laser Appl. 2017, 29, 022417. [Google Scholar] [CrossRef] [Green Version]

- Sibillano, T.; Ancona, A.; Berardi, V.; Lugarà, M. A Real-Time Spectroscopic Sensor for Monitoring Laser Welding Processes. Sensors 2009, 9, 3376–3385. [Google Scholar] [CrossRef] [PubMed]

- Mrňa, L.; Šarbort, M.; Řeřucha, Š.; Jedlička, P. Correlation between the Keyhole Depth and the Frequency Characteristics of Light Emissions in Laser Welding. Phys. Procedia 2013, 41, 469–477. [Google Scholar] [CrossRef] [Green Version]

- Hollatz, S.; Hummel, M.; Jaklen, L.; Lipnicki, W.; Olowinsky, A.; Gillner, A. Processing of Keyhole Depth Measurement Data during Laser Beam Micro Welding. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 722–731. [Google Scholar]

- Luo, Y.; Zhu, L.; Han, J.; Xie, X.; Wan, R.; Zhu, Y. Study on the Acoustic Emission Effect of Plasma Plume in Pulsed Laser Welding. Mech. Syst. Signal Process. 2019, 124, 715–723. [Google Scholar] [CrossRef]

- Schmidt, L.; Römer, F.; Böttger, D.; Leinenbach, F.; Straß, B.; Wolter, B.; Schricker, K.; Seibold, M.; Bergmann, J.P.; Del Galdo, G. Acoustic Process Monitoring in Laser Beam Welding. Procedia CIRP 2020, 94, 763–768. [Google Scholar] [CrossRef]

- Kuo, B.-S.; Lu, M.-C. Analysis of a Sound Signal for Quality Monitoring in Laser Microlap Welding. Appl. Sci. 2020, 10, 1934. [Google Scholar] [CrossRef] [Green Version]

- Wasmer, K.; Le-Quang, T.; Meylan, B.; Vakili-Farahani, F.; Olbinado, M.P.; Rack, A.; Shevchik, S.A. Laser Processing Quality Monitoring by Combining Acoustic Emission and Machine Learning: A High-Speed X-ray Imaging Approach. Procedia CIRP 2018, 74, 654–658. [Google Scholar] [CrossRef]

- Shevchik, S.; Le, Q.T.; Meylan, B.; Wasmer, K. Acoustic Emission for in Situ Monitoring of Laser Processing. In Proceedings of the 33rd European Conference on Acoustic Emission Testing, Senlis, France, 12–14 September 2018. [Google Scholar]

- Cai, W.; Wang, J.; Zhou, Q.; Yang, Y.; Jiang, P. Equipment and Machine Learning in Welding Monitoring: A Short Review. In Proceedings of the 5th International Conference on mechatronics and robotics engineering, Rome, Italy, 16–19 February 2019; pp. 9–15. [Google Scholar]

- Zhang, B.; Hong, K.-M.; Shin, Y.C. Deep-Learning-Based Porosity Monitoring of Laser Welding Process. Manuf. Lett. 2020, 23, 62–66. [Google Scholar] [CrossRef]

- Fan, X.; Gao, X.; Liu, G.; Ma, N.; Zhang, Y. Research and Prospect of Welding Monitoring Technology Based on Machine Vision. Int. J. Adv. Manuf. Technol. 2021, 115, 3365–3391. [Google Scholar] [CrossRef]

- Chandrasekhar, N.; Vasudevan, M.; Bhaduri, A.K.; Jayakumar, T. Intelligent Modeling for Estimating Weld Bead Width and Depth of Penetration from Infra-Red Thermal Images of the Weld Pool. J. Intell. Manuf. 2015, 26, 59–71. [Google Scholar] [CrossRef]

- Weberpals, J.; Hermann, T.; Berger, P.; Singpiel, H. Utilisation of Thermal Radiation for Process Monitoring. Phys. Procedia 2011, 12, 704–711. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Gao, X. Detection of Weld Pool Width Using Infrared Imaging During High-Power Fiber Laser Welding of Type 304 Austenitic Stainless Steel. Int. J. Adv. Manuf. Technol. 2014, 74, 1247–1254. [Google Scholar] [CrossRef]

- Cai, W.; Wang, J.; Jiang, P.; Cao, L.; Mi, G.; Zhou, Q. Application of Sensing Techniques and Artificial Intelligence-Based Methods to Laser Welding Real-Time Monitoring: A Critical Review of Recent Literature. J. Manuf. Syst. 2020, 57, 1–18. [Google Scholar] [CrossRef]

- You, D.; Gao, X.; Katayama, S. Multiple-Optics Sensing of High-Brightness Disk Laser Welding Process. Ndt E. Int. 2013, 60, 32–39. [Google Scholar] [CrossRef]

- Benakis, M.; Du, C.; Patran, A.; French, R. Welding Process Monitoring Applications and Industry 4.0. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 1755–1760. [Google Scholar]

- Artinov, A.; Bakir, N.; Bachmann, M.; Gumenyuk, A.; Rethmeier, M. Weld Pool Shape Observation in High Power Laser Beam Welding. Procedia CIRP 2018, 74, 683–686. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, S.; Yang, L.; Zhao, S.; Liu, Y.; Shi, Y. Defect Detection During Laser Welding Using Electrical Signals and High-Speed Photography. J. Mater. Process. Technol. 2019, 271, 394–403. [Google Scholar] [CrossRef]

- Zhao, S.; Yang, L.; Huang, Y.; Zhao, D.; Xu, S. A Study on Welding Mode Transition by Electrical Detection of Laser-Induced Plasma at Varying Energy Levels. Int. J. Adv. Manuf. Technol. 2019, 104, 893–906. [Google Scholar] [CrossRef]

- Zhang, Y.; You, D.; Gao, X.; Zhang, N.; Gao, P.P. Welding Defects Detection Based on Deep Learning with Multiple Optical Sensors During Disk Laser Welding of Thick Plates. J. Manuf. Syst. 2019, 51, 87–94. [Google Scholar] [CrossRef]

- Ahmed, F.; Jannat, N.-E.; Schmidt, D.; Kim, K.-Y. Data-Driven Cyber-Physical System Framework for Connected Resistance Spot Welding Weldability Certification. Robot. Comput.-Integr. Manuf. 2021, 67, 102036. [Google Scholar] [CrossRef]

- Martinez, R.T.; Alfaro, S.C.A. Data Analysis and Modeling Techniques of Welding Processes: The State-of-the-Art. In Welding-Modern Topics; IntechOpen: London, UK, 2020. [Google Scholar]

- Xu, Z.; Dang, Y.; Munro, P. Knowledge-Driven Intelligent Quality Problem-Solving System in the Automotive Industry. Adv. Eng. Inform. 2018, 38, 441–457. [Google Scholar] [CrossRef]

- Svetashova, Y.; Zhou, B.; Pychynski, T.; Schmidt, S.; Sure-Vetter, Y.; Mikut, R.; Kharlamov, E. Ontology-Enhanced Machine Learning: A Bosch Use Case of Welding Quality Monitoring. In International Semantic Web Conference; Springer International Publishing: Cham, Switzerland, 2020; pp. 531–550. [Google Scholar]

- Cao, L.; Zhang, L.; Wu, Y. A Data-Driven Model for Weld Bead Monitoring During the Laser Welding Assisted by Magnetic Field. Int. J. Adv. Manuf. Technol. 2020, 107, 475–487. [Google Scholar] [CrossRef]

- Hinchy, E.; O’Dowd, N.; McCarthy, C.T. Using Open-Source Microcontrollers to Enable Digital Twin Communication for Smart Manufacturing. Procedia Manuf. 2019, 38, 1213–1219. [Google Scholar] [CrossRef]

- Costa, F.S.; Nassar, S.M.; Gusmeroli, S.; Schultz, R.; Conceição, A.G.; Xavier, M.; Hessel, F.; Dantas, M.A. FASTEN IIoT: An Open Real-Time Platform for Vertical, Horizontal and End-to-End Integration. Sensors 2020, 20, 5499. [Google Scholar] [CrossRef]

- Forcina, A.; Falcone, D. The Role of Industry 4.0 Enabling Technologies for Safety Management: A Systematic Literature Review. Procedia Comput. Sci. 2021, 180, 436–445. [Google Scholar] [CrossRef]

- Csalódi, R.; Süle, Z.; Jaskó, S.; Holczinger, T.; Abonyi, J. Industry 4.0-Driven Development of Optimization Algorithms: A Systematic Overview. Complexity 2021, 2021, 6621235. [Google Scholar] [CrossRef]

- ISO. 15607:2019 Specification and Qualification of Welding Procedures for Metallic Materials—General Rules; ISO—International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Pereira, A.B.; de Melo, F.J.M.Q. Quality Assessment and Process Management of Welded Joints in Metal Construction—A Review. Metals 2020, 10, 115. [Google Scholar] [CrossRef] [Green Version]

- Öberg, A.E.; Åstrand, E. Variation in Welding Procedure Specification Approach and Its Effect on Productivity. Procedia Manuf. 2018, 25, 412–417. [Google Scholar] [CrossRef]

- ISO. 14732:2013 Welding Personnel—Qualification Testing of Welding Operators and Weld Setters for Mechanized and Automatic Welding of Metallic Materials; ISO—International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. A Review of Data-Driven Decision-Making Methods for Industry 4.0 Maintenance Applications. Electronics 2021, 10, 828. [Google Scholar] [CrossRef]

- Qin, S.-F.; Cheng, K. Future Digital Design and Manufacturing: Embracing Industry 4.0 and Beyond. Chin. J. Mech. Eng. 2017, 30, 1047–1049. [Google Scholar] [CrossRef] [Green Version]

- Asif, M. Are QM Models Aligned with Industry 4.0? A Perspective on Current Practices. J. Clean. Prod. 2020, 258, 120820. [Google Scholar]

- Emblemsvåg, J. On Quality 4.0 in Project-Based Industries. TQM J. 2020, 32, 725–739. [Google Scholar] [CrossRef]

- ISO. 14731:2019 Welding Coordination—Tasks and Responsibilities; ISO—International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Jiao, R.; Commuri, S.; Panchal, J.; Milisavljevic-Syed, J.; Allen, J.K.; Mistree, F.; Schaefer, D. Design Engineering in the Age of Industry 4.0. J. Mech. Des. 2021, 143, 070801. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business Model Innovation through Industry 4.0: A Review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Opresnik, D.; Taisch, M. The Value of Big Data in Servitization. Int. J. Prod. Econ. 2015, 165, 174–184. [Google Scholar] [CrossRef]

- Bashir, M.; Verma, R. Why Business Model Innovation Is the New Competitive Advantage. IUP J. Bus. Strategy 2017, 14, 7–17. [Google Scholar]

- Magretta, J. Why Business Models Matter; Harvard Business School Online: Boston, MA, USA, 2002. [Google Scholar]

| Stages | Monitoring Signals | Objectives |

|---|---|---|

| Monitoring before welding | Optical signals | Seam tracking and gap measuring |

| Monitoring during welding | Acoustic signals Optical signals Electrical signals Thermal signals | Defects monitoring, feedback control and feature prediction |

| Monitoring after welding | Optical signal Acoustic signal | Defects classification and weld geometry |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velázquez de la Hoz, J.L.; Cheng, K. Development of an Intelligent Quality Management System for Micro Laser Welding: An Innovative Framework and Its Implementation Perspectives. Machines 2021, 9, 252. https://doi.org/10.3390/machines9110252

Velázquez de la Hoz JL, Cheng K. Development of an Intelligent Quality Management System for Micro Laser Welding: An Innovative Framework and Its Implementation Perspectives. Machines. 2021; 9(11):252. https://doi.org/10.3390/machines9110252

Chicago/Turabian StyleVelázquez de la Hoz, José Luis, and Kai Cheng. 2021. "Development of an Intelligent Quality Management System for Micro Laser Welding: An Innovative Framework and Its Implementation Perspectives" Machines 9, no. 11: 252. https://doi.org/10.3390/machines9110252