Characterization of the Compressive Load on a Lithium-Ion Battery for Electric Vehicle Application

Abstract

1. Introduction

2. Overview of Mechanical Stresses on Lithium-Ion Batteries

3. The Novelties of This Work

4. Experimental Procedure

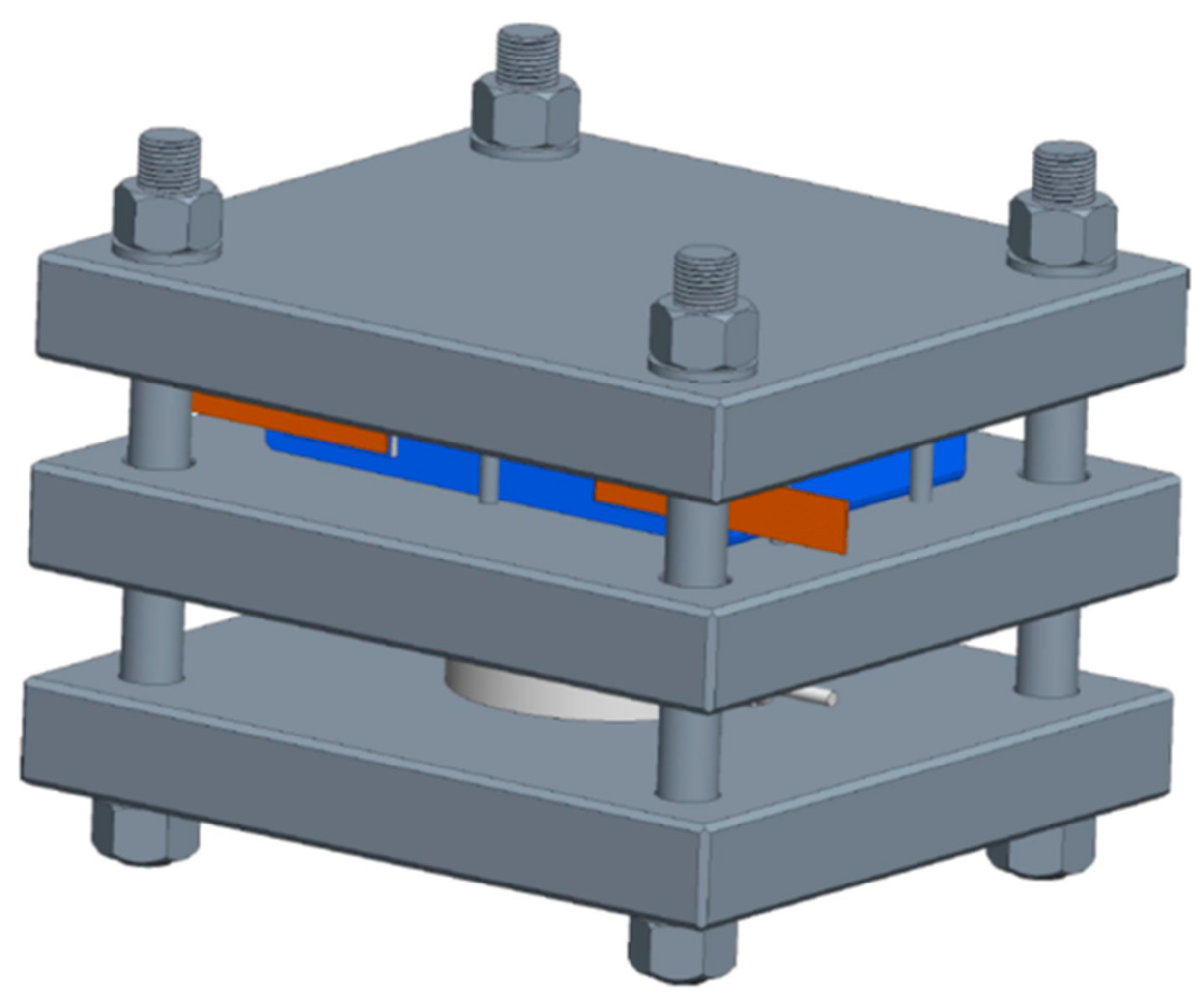

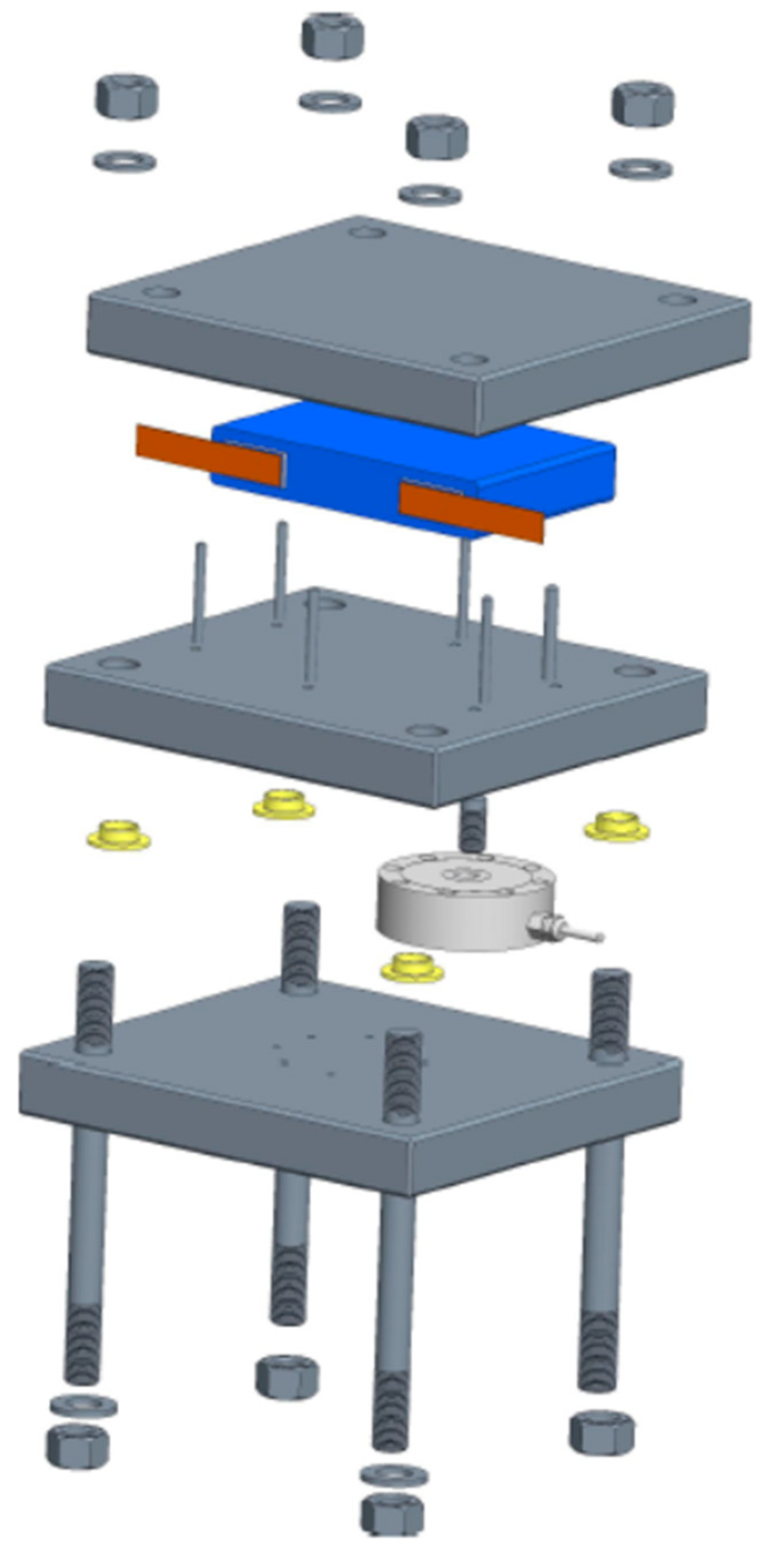

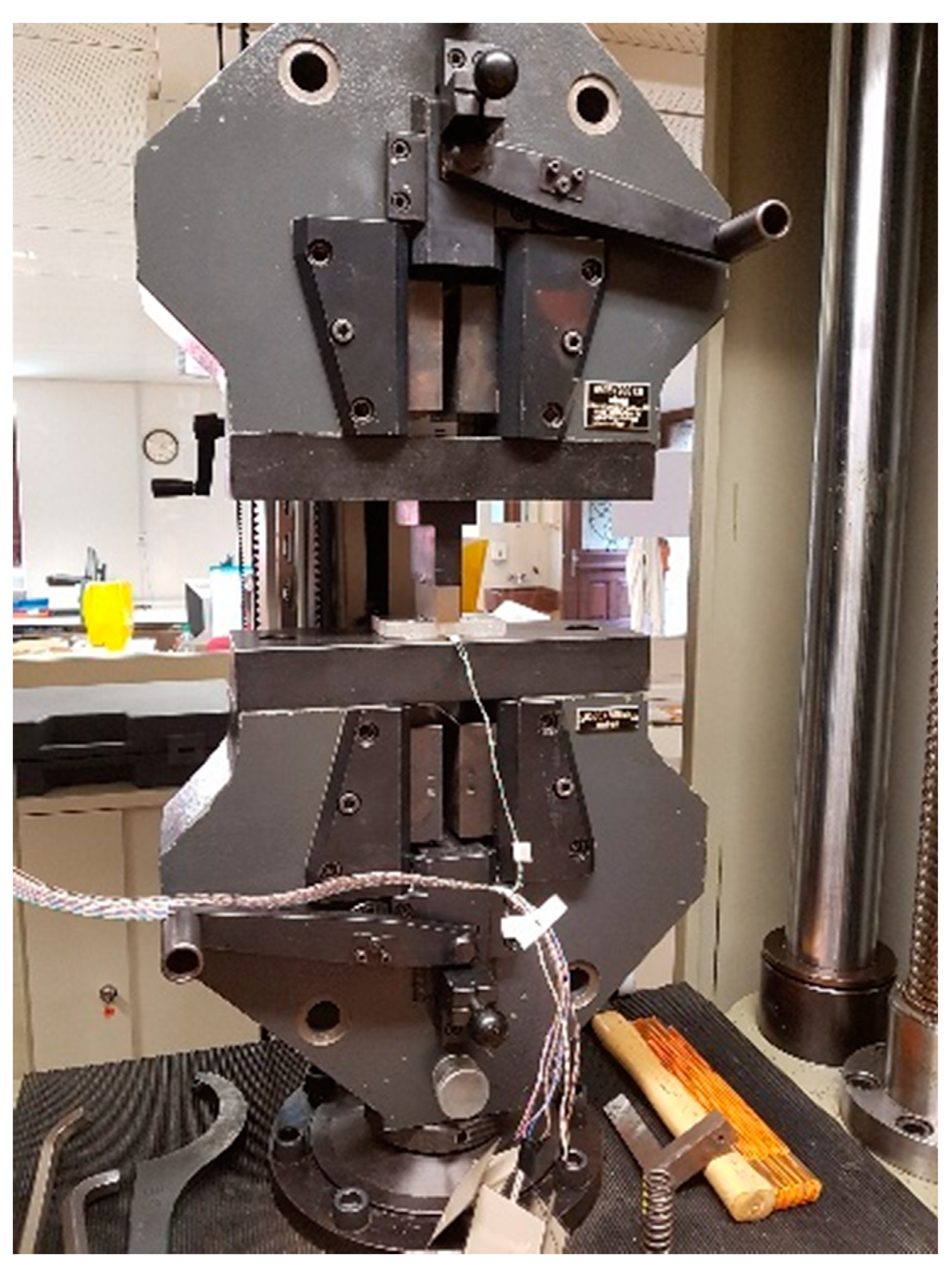

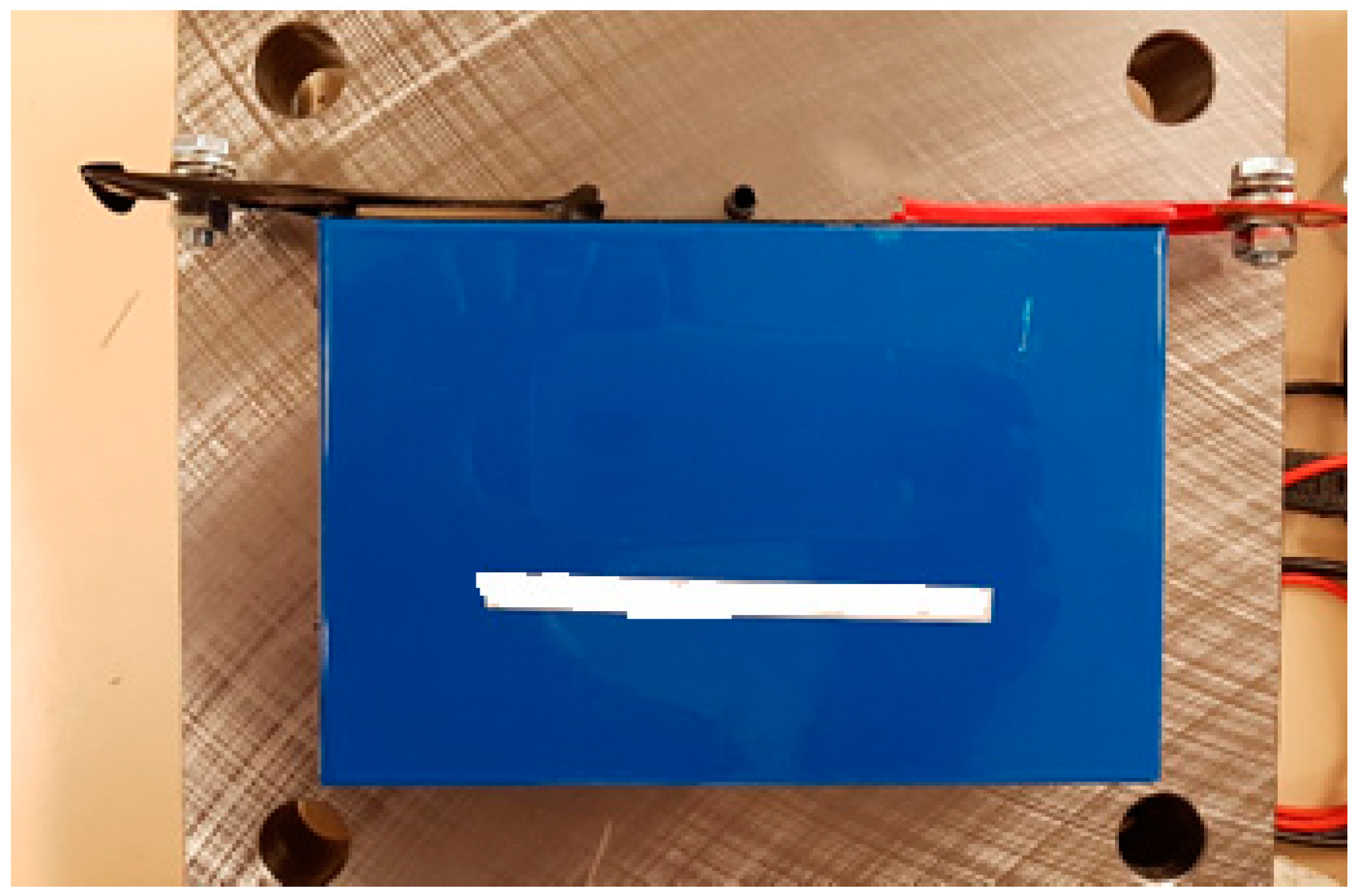

4.1. Pressure Setup

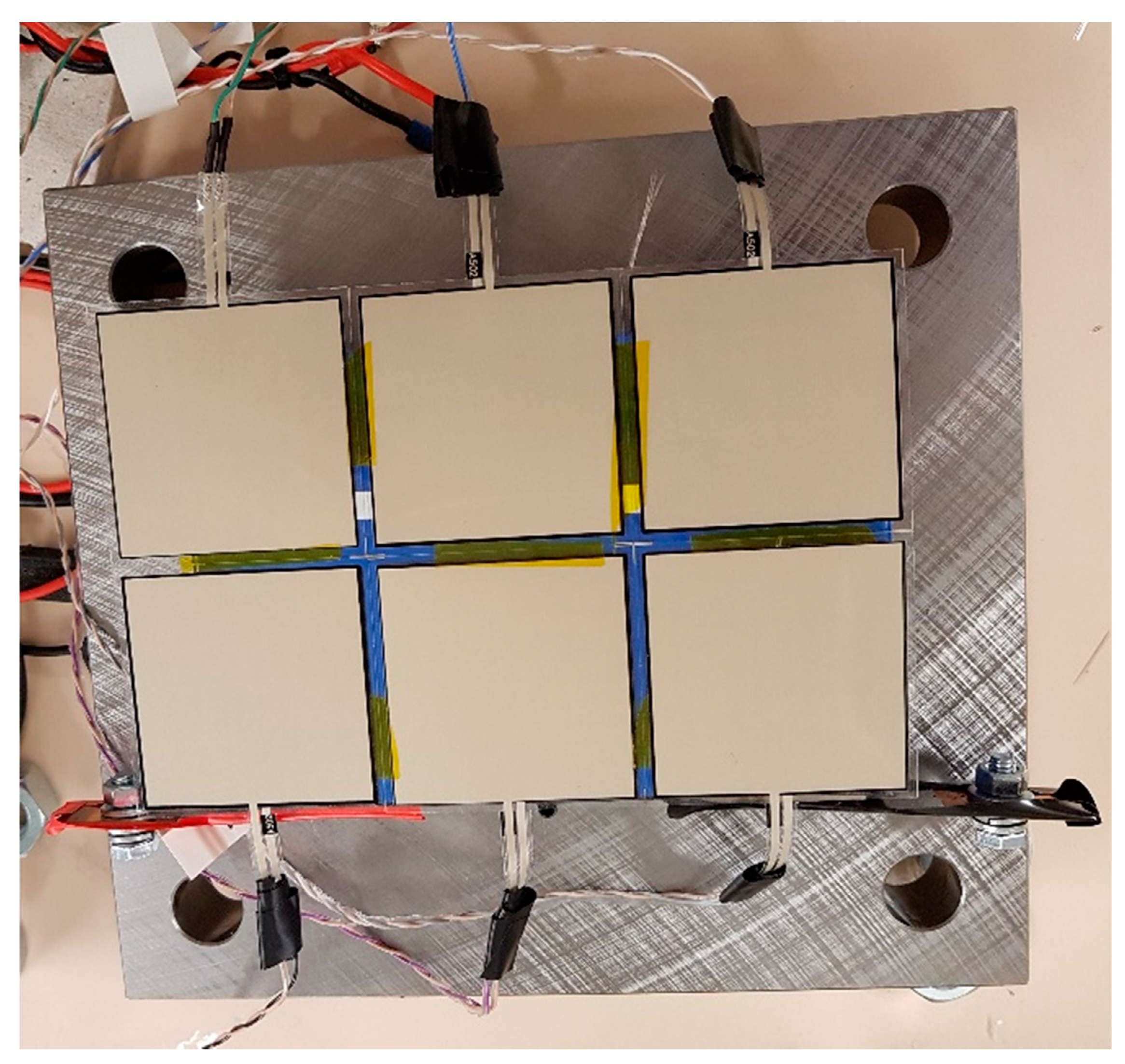

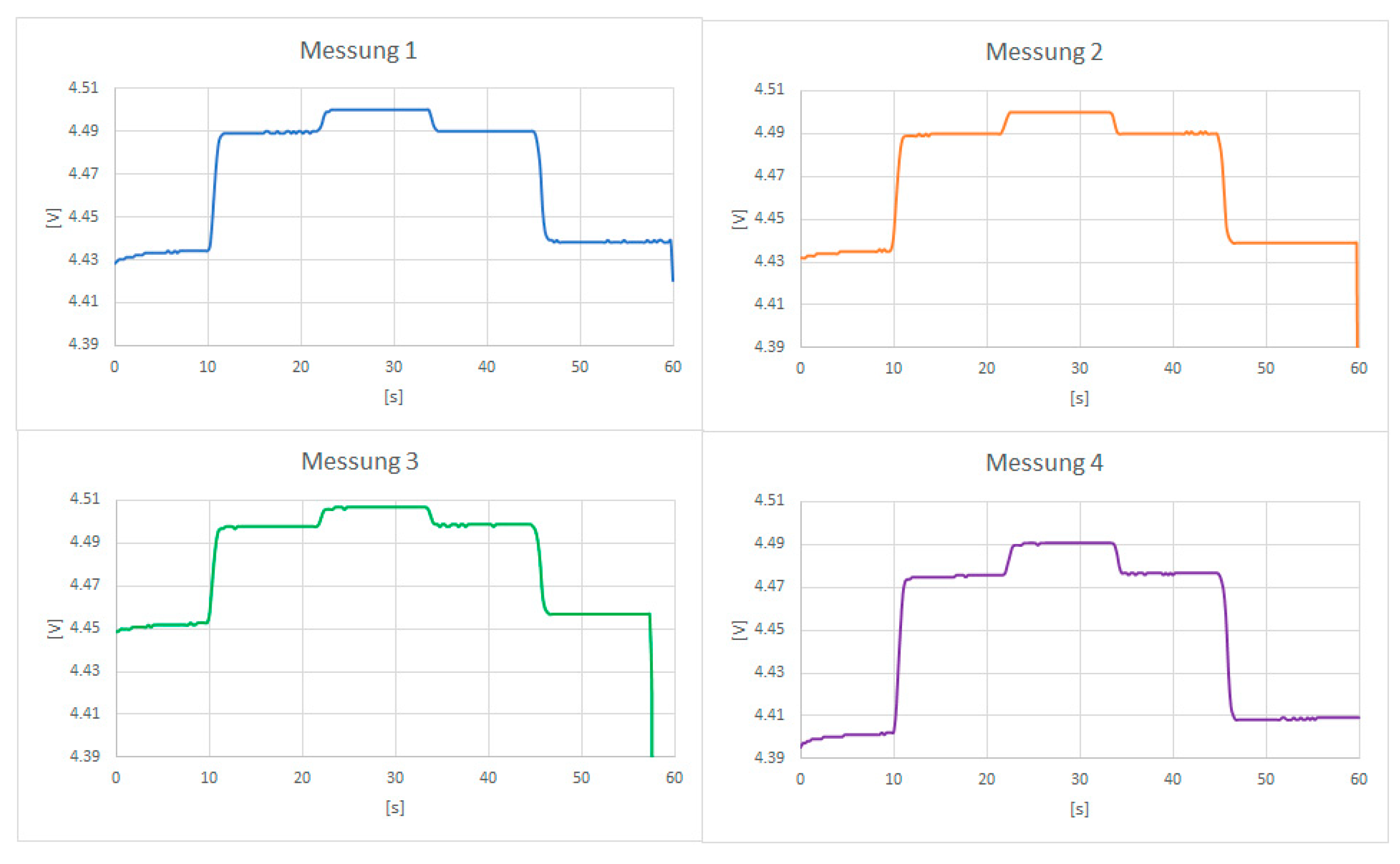

4.2. Flexiforce Pressure Sensor

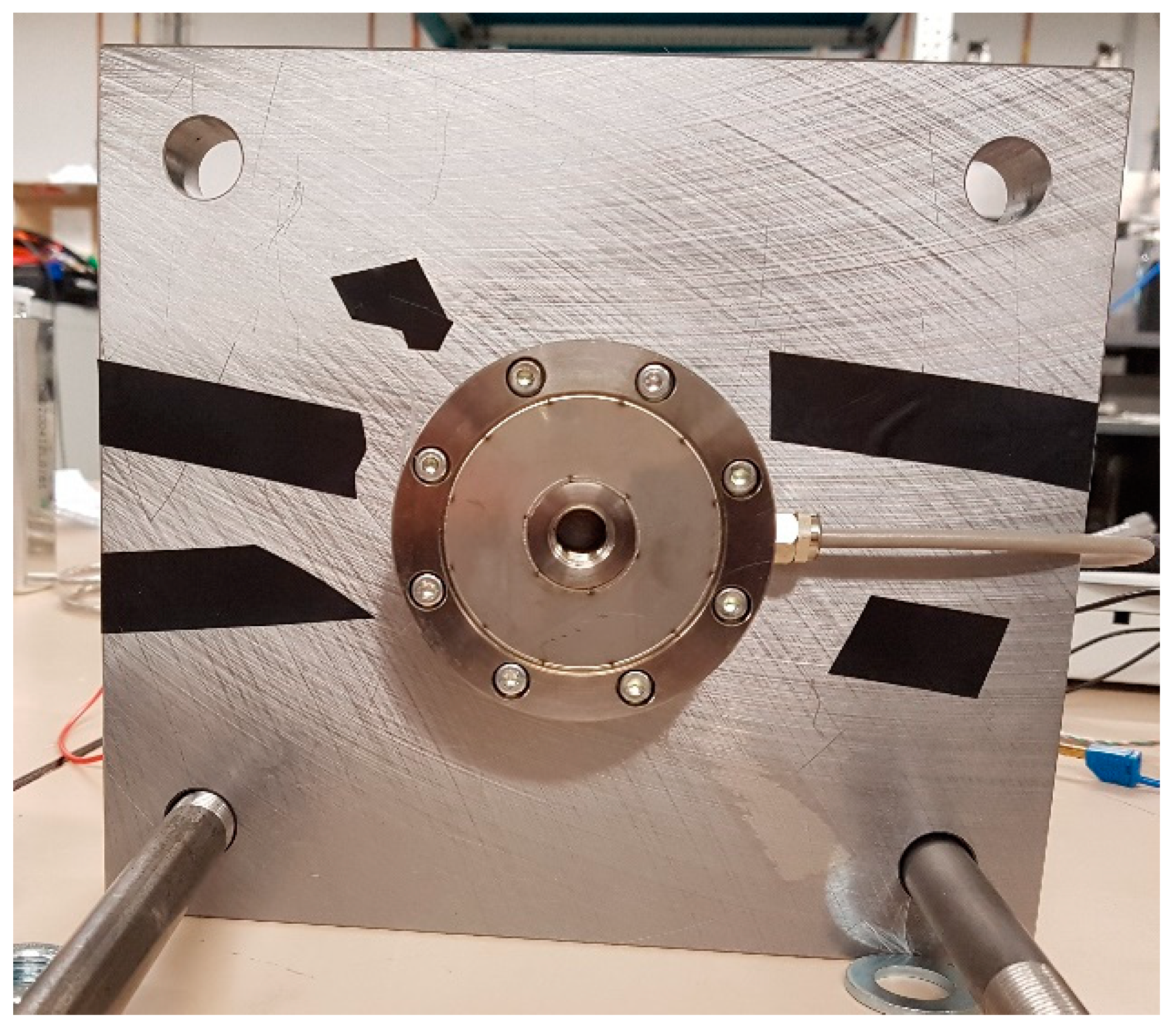

4.3. Strain Gage Load Cell (Type 4576A)

4.4. Calibration

5. Result and Discussion

5.1. Test Matrix

- Electrochemical impedance spectroscopy at actual state of charge (50%)

- Charge until state of charge 100%

- Electrochemical impedance spectroscopy at state of charge 100%

- Discharge of the battery cell at 10% steps (electrochemical impedance spectroscopy at each state of charge, from 100% to 20%)

- Charge the cell to 50%

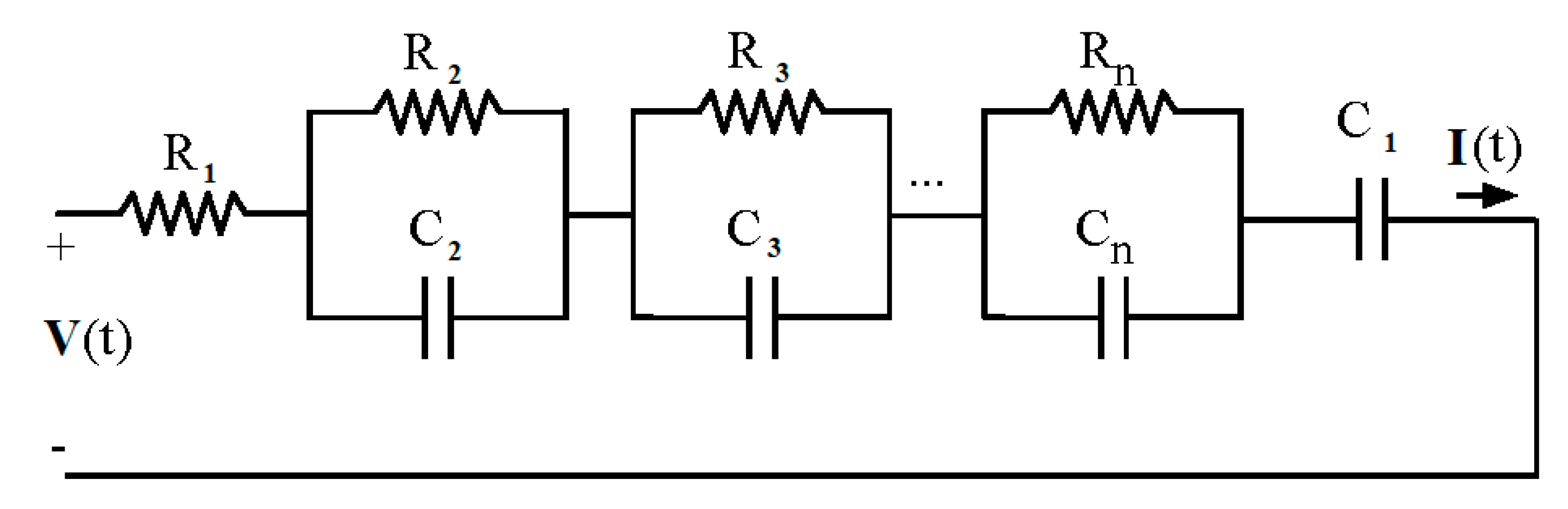

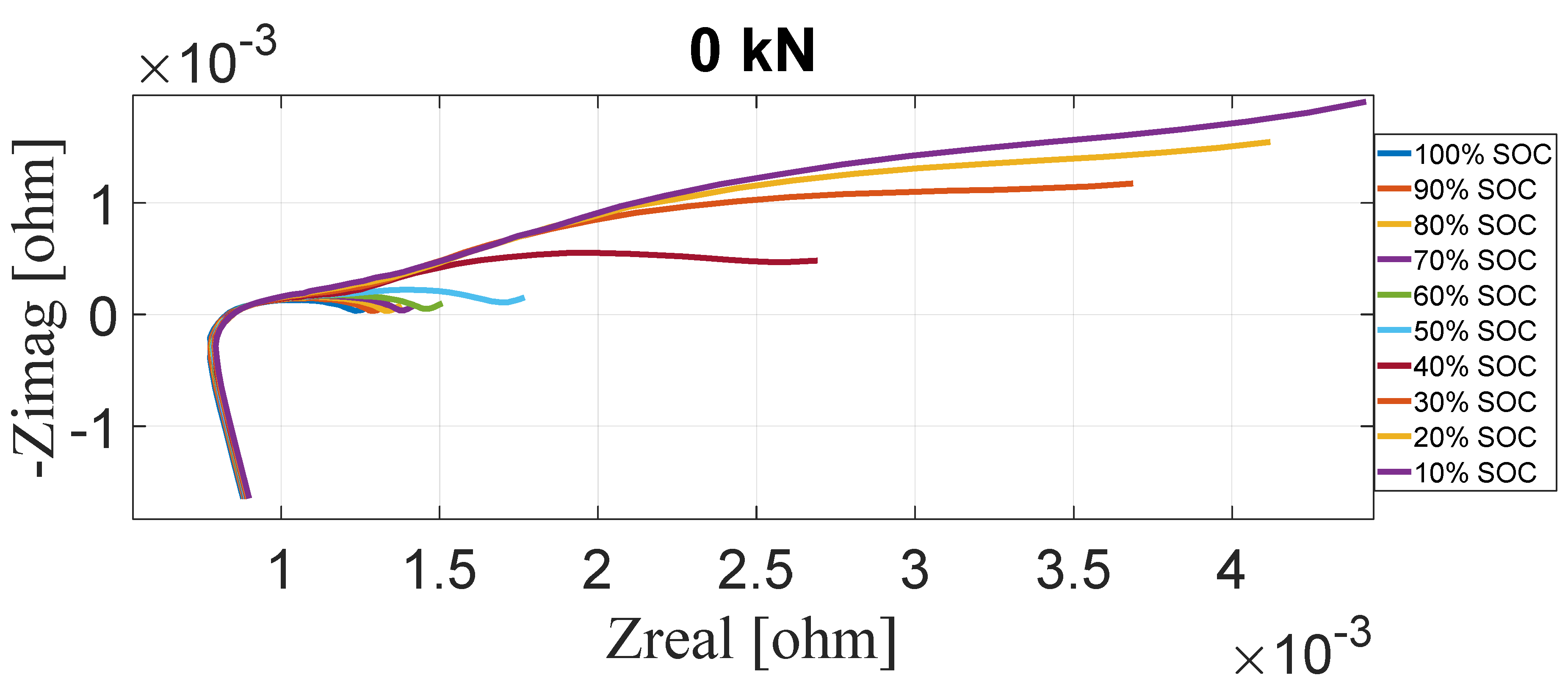

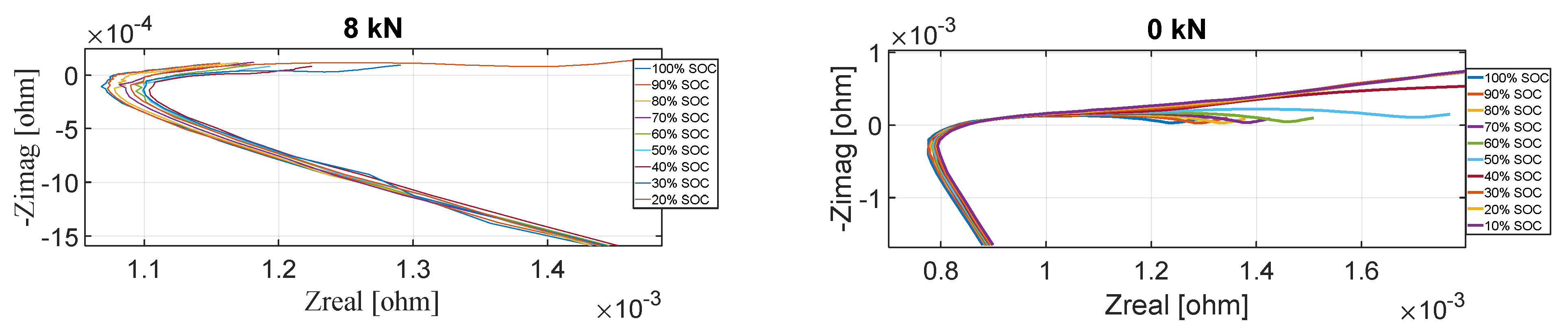

5.2. Electrochemical Impedance Spectroscopy Measurement

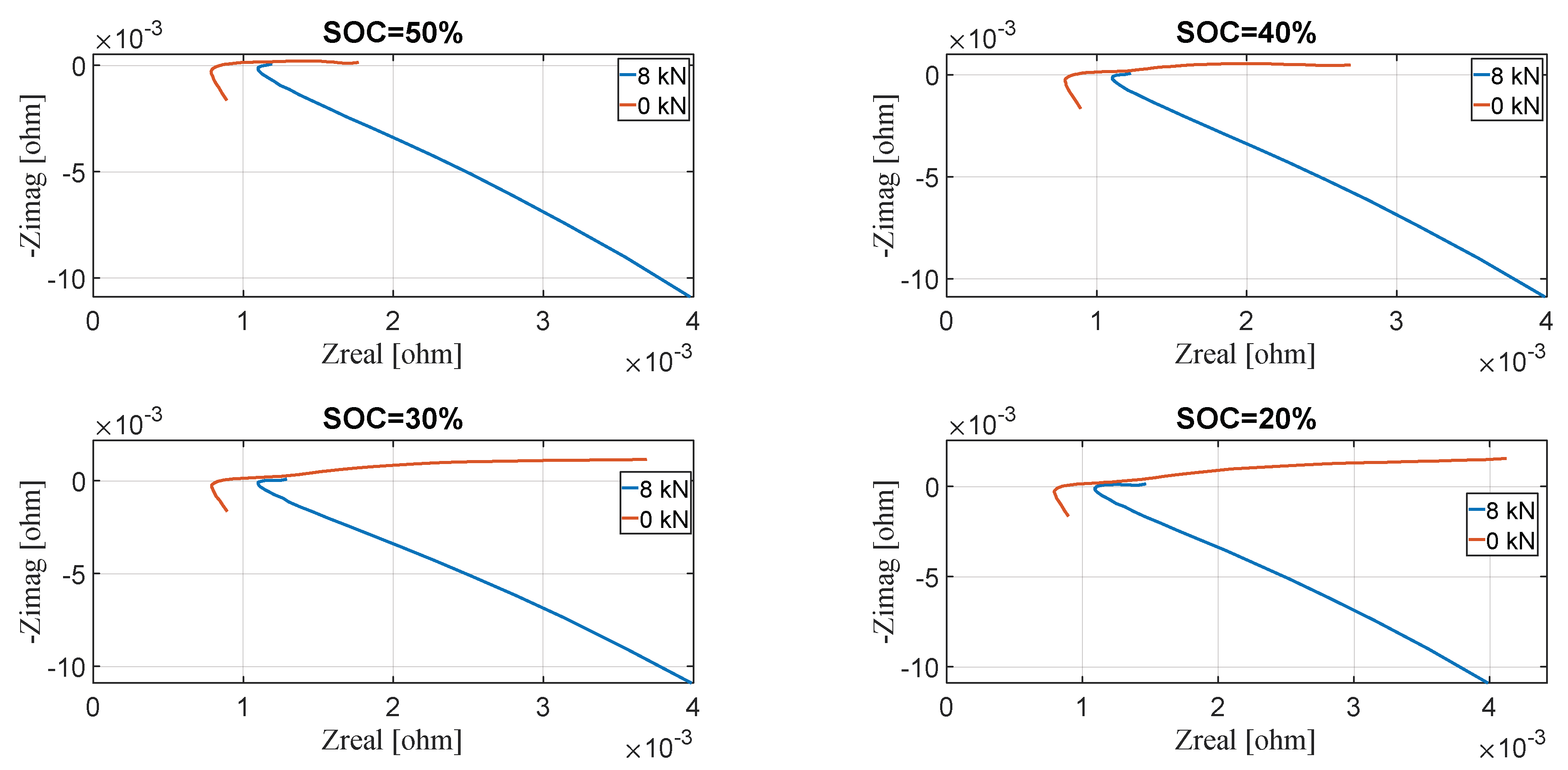

5.3. Impact of External Pressure on Performance

5.4. Influence of State of Charge

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Behrou, R.; Maute, K.; Smith, K. Numerical Simulation of Pressure Management Strategies for Lithium-Ion Pouch Cells. 2014. Available online: https://scholar.colorado.edu/concern/conference_proceedings/r494vk876 (accessed on 24 March 2021).

- Gnanaraj, J.; Cohen, Y.S.; Levi, M.; Aurbach, D. The effect of pressure on the electroanalytical response of graphite anodes and LiCoO2 cathodes for Li-ion batteries. J. Electroanal. Chem. 2001, 516, 89–102. [Google Scholar] [CrossRef]

- Nadimpalli, S.P.V.; Sethuraman, V.A.; Abraham, D.P.; Bower, A.F.; Guduru, P.R. Stress Evolution in Lithium-Ion Composite Electrodes during Electrochemical Cycling and Resulting Internal Pressures on the Cell Casing. J. Electrochem. Soc. 2015, 162, A2656–A2663. [Google Scholar] [CrossRef]

- Bach, T.C.; Schuster, S.F.; Fleder, E.; Müller, J.; Brand, M.J.; Lorrmann, H.; Jossen, A.; Sextl, G. Nonlinear aging of cylindrical lithium-ion cells linked to heterogeneous compression. J. Energy Storage 2016, 5, 212–223. [Google Scholar] [CrossRef]

- Rieger, B.; Schlueter, S.; Erhard, S.V.; Schmalz, J.; Reinhart, G.; Jossen, A. Multi-scale investigation of thickness chang-es in a commercial pouch type lithium-ion battery. J. Energy Storage 2016, 6, 213–221. [Google Scholar] [CrossRef]

- De Sutter, L.; Berckmans, G.; Marinaro, M.; Smekens, J.; Firouz, Y.; Wohlfahrt-Mehrens, M.; Van Mierlo, J.; Omar, N. Comprehensive Aging Analysis of Volumetric Constrained Lithium-Ion Pouch Cells with High Concentration Silicon-Alloy Anodes. Energies 2018, 11, 2948. [Google Scholar] [CrossRef]

- Mussa, A.S.; Klett, M.; Lindbergh, G.; Lindström, R.W. Effects of external pressure on the performance and ageing of single-layer lithium-ion pouch cells. J. Power Source 2018, 385, 18–26. [Google Scholar] [CrossRef]

- Barai, A.; Guo, Y.; McGordon, A.; Jennings, P. A study of the effects of external pressure on the electrical performance of a lithium-ion pouch cell. In Proceedings of the 2013 International Conference on Connected Vehicles and Expo (ICCVE), Las Vegas, NV, USA, 2–6 December 2013; pp. 295–299. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Briat, O.; Delétage, J.-Y.; Martin, C.; Gager, G.; Vinassa, J.-M. Characterization of external pressure effects on lithium-ion pouch cell. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018; pp. 2055–2059. [Google Scholar] [CrossRef]

- Cannarella, J.; Arnold, C.B. Stress evolution and capacity fade in constrained lithium-ion pouch cells. J. Power Source 2014, 245, 745–751. [Google Scholar] [CrossRef]

- Barai, A.; Tangirala, R.; Uddin, K.; Chevalier, J.; Guo, Y.; McGordon, A.; Jennings, P. The effect of external compressive loads on the cycle lifetime of lithium-ion pouch cells. J. Energy Storage 2017, 13, 211–219. [Google Scholar] [CrossRef]

- Lee, J.; Yeo, J.; Jang, M.; Yoon, J.; Kang, D.M. Mechanical durability and electrical durability of an alumini-um-laminated lithium-ion polymer battery pack for a hybrid electric vehicle. J. Automob. Eng. 2010, 224, 765–773. [Google Scholar] [CrossRef]

- Michael, J.; Marco, J. Characterising the in-vehicle vibration inputs to the high voltage battery of an electric vehi-cle. J. Power Source 2014, 245, 510–519. [Google Scholar]

- Hooper, J.M.; Marco, J. Experimental modal analysis of lithium-ion pouch cells. J. Power Source 2015, 285, 247–259. [Google Scholar] [CrossRef]

- Wang, H.; Tao, Z.; Fu, Y.; Li, W.; Cai, Y. Analysis on Vibration of Li-ion Battery Module Used for Electric Vehicle. DEStech Trans. Mater. Sci. Eng. 2017, 3–5. [Google Scholar] [CrossRef]

- Hong, S.-K.; Epureanu, B.I.; Castanier, M.P. Parametric reduced-order models of battery pack vibration including structural variation and prestress effects. J. Power Source 2014, 261, 101–111. [Google Scholar] [CrossRef]

- Brand, M.J.; Schuster, S.F.; Bach, T.; Fleder, E.; Stelz, M.; Gläser, S.; Müller, J.; Sextl, G.; Jossen, A. Effects of vibrations and shocks on lithium-ion cells. J. Power Source 2015, 288, 62–69. [Google Scholar] [CrossRef]

- Choi, Y.; Jung, D.; Ham, K.; Bae, S. A study on the accelerated vibration endurance tests for battery fixing bracket in electrically driven vehicles. Procedia Eng. 2011, 10, 851–856. [Google Scholar] [CrossRef]

- Somerville, L.; Hooper, J.M.; Marco, J.; McGordon, A.; Lyness, C.; Walker, M.; Jennings, P. Impact of vibration on the surface film of lithium-ion cells. Energies 2017, 10, 741. [Google Scholar] [CrossRef]

- Pham, H.L.; Adams, D.E.; Dietz, J.E.; Sharp, N.D. Lithium-Ion Battery Cell Health Monitoring Using Vibration Diagnostic Test, IMECE2013-63962. 2013; pp. 1–10. Available online: https://www.osti.gov/servlets/purl/1107247 (accessed on 24 March 2021).

- Zhang, L. Applied sciences Effects of Vibration on the Electrical Performance of Lithium-Ion Cells Based on Mathemat-ical Statistics. Appl. Sci. 2017, 7, 802. [Google Scholar] [CrossRef]

- Hooper, J.M.; Marco, J. EVS29 Symposium Defining a Representative Vibration Durability Test for Electric Vehicle (EV) Rechargeable Energy Storage Systems (RESS). World Electr. Veh. J. 2016, 8, 327–338. [Google Scholar] [CrossRef]

- Shevtsov, S.; Chang, S.H. Modeling of vibration energy harvesting system with power PZT stack loaded on Li-Ion battery. Int. J. Hydrogen Energy 2016, 41, 2618–12625. [Google Scholar] [CrossRef]

- Gao, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Ma, Z.; Jiang, Y. Lithium-ion battery aging mechanisms and life model under different charging stresses. J. Power Source 2017, 356, 103–114. [Google Scholar] [CrossRef]

- Hooper, J.M.; Marco, J.; Chouchelamane, G.H.; Lyness, C. Vibration Durability Testing of Nickel Manganese Cobalt Oxide (NMC) Lithium-Ion 18,650 Battery Cells. Energies 2016, 9, 52. [Google Scholar] [CrossRef]

- Bruen, T.; Hooper, J.M.; Marco, J.; Gama, M.; Chouchelamane, G.H. Analysis of a Battery Management System (BMS) Control Strategy for Vibration Aged Nickel Manganese Cobalt Oxide (NMC) Lithium-Ion 18650 Battery Cells. Energies 2016, 9, 255. [Google Scholar] [CrossRef]

- Popp, H.; Glanz, G.; Alten, K.; Gocheva, I.; Berghold, W.; Bergmann, A. Mechanical Frequency Response Analysis of Lithium-Ion Batteries to Disclose Operational Parameters. Energies 2018, 11, 541. [Google Scholar] [CrossRef]

- Lang, J.F.; Kjell, G. Comparing vibration measurements in an electric vehicle with standard vibration requirements for Li-ion batteries using power spectral density analysis. Int. J. Electr. Hybrid Veh. 2015, 7, 272–286. [Google Scholar] [CrossRef]

- Gonçalves, H.; Meireles, J.; Martins, J. Vibration analysis of integrated systems to electric vehicles. In Proceedings of the 5th International Operational Modal Analysis Conference, Guimarães, Portugal, 13–15 May 2013. [Google Scholar]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Bossche, P.V.D.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.; Veit, C.; Möller, K.-C.; Besenhard, J.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Source 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Andre, D.; Meiler, M.; Steiner, K.; Wimmer, C.; Soczka-Guth, T.; Sauer, D.U. Characterization of high-power lithi-um-ion batteries by electrochemical impedance spectroscopy. I. Experimental investigation. J. Power Source 2011, 196, 5334–5341. [Google Scholar] [CrossRef]

- Waag, W.; Käbitz, S.; Sauer, D.U. Experimental investigation of the lithium-ion battery impedance characteristic at various conditions and aging states and its influence on the application. Appl. Energy 2013, 102, 885–897. [Google Scholar] [CrossRef]

- Fu, R.; Xiao, M.; Choe, S.-Y. Modeling, validation and analysis of mechanical stress generation and dimension changes of a pouch type high power Li-ion battery. J. Power Source 2013, 224, 211–224. [Google Scholar] [CrossRef]

- Cannarella, J.; Arnold, C.B. Ion transport restriction in mechanically strained separator membranes. J. Power Source 2013, 226, 149–155. [Google Scholar] [CrossRef]

- Barreras, J.V. Practical Methods in Li-Ion Batteries: For Simplified Modeling, Battery Electric Vehicle Design, Battery Management System Testing and Balancing System Control. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2017. [Google Scholar]

- Marcinek, M.; Syzdek, J.; Marczewski, M.; Piszcz, M.; Niedzicki, L.; Kalita, M.; Plewa-Marczewska, A.; Bitner, A.; Wieczorek, P.; Trzeciak, T.; et al. Electrolytes for Li-ion transport—Review. Solid State Ion. 2015, 276, 107–126. [Google Scholar] [CrossRef]

| Test | T (°C) | External Pressure | Investigated Parameters | Effect on Voltage | Effect on Internal Impedance | Effect on Power | Effect on Capacity |

|---|---|---|---|---|---|---|---|

| Pulse power/Discharging | 45 | 0, 0.2, 0.4, 0.8 | Increasing pressure | Decreasing | Increasing | Decreasing | Decreasing |

| 25 | 0, 0.4, 0.8 | Increasing pressure | Decreasing | Increasing | Decreasing | Decreasing | |

| 0.2 | Increasing pressure | Increasing | |||||

| Pulse power/Charging | 45 | 0, 0.2, 0.4, 0.8 | Increasing pressure | Increasing | Increasing | ||

| 25 | 0, 0.4, 0.8 | Increasing pressure | Increasing | Increasing | |||

| 0.2 | Increasing pressure | Decreasing | |||||

| Capacity | 45 | 0, 0.2, 0.4, 0.8 | Increasing pressure | Mixed | Decreasing | ||

| 25 | 0, 0.2, 0.4, 0.8 | Increasing pressure | Mixed | Decreasing | |||

| 0 | 0, 0.2, 0.4, 0.8 | Increasing pressure | Mixed | Decreasing | |||

| Electrochemical impedance spectroscopy | 25 | 0, 0.2, 0.4, 0.8 | Increasing pressure | ||||

| 25 | 0, 0.2, 0.4, 0.8 | Increasing pressure | |||||

| 25 | 0, 0.2, 0.4, 0.8 | Increasing pressure |

| Test | Electrochemical Impedance Spectroscopy |

|---|---|

| Temperature (°C) | 25 |

| Pressure (kN) | 0, 3.675, 7.35, 14.7, 22.05, 29.4 |

| Investigated parameters | Increasing pressure |

| Effect on electrolyte | Negligible impact |

| Effect on separator | Negligible impact |

| Effect on current collector | Negligible impact |

| Effect on cabling properties | Negligible impact |

| Effect on ion diffusion in electrode | Increasing |

| Effect on ohmic contributions | Negligible impact |

| Attempt | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Force (KN) | Voltage (V) | ||||

| Load cell | 1.5 | 0.4759 | 0.7404 | 0.7505 | 0.7525 |

| 5 | 1.568 | 1.904 | 1.906 | 1.905 | |

| 8 | 2.452 | 2.785 | 2.784 | 2.783 | |

| 5 | 1.592 | 1.918 | 1.916 | 1.915 | |

| 1.5 | 0.494 | 0.7428 | 0.7449 | 0.7448 | |

| Sensor 1 | 1.5 | 4.89 | 4.9 | 4.909 | |

| 5 | 4.96 | 4.968 | 4.969 | ||

| 8 | 4.98 | 4.979 | 4.98 | ||

| 5 | 4.96 | 4.969 | 4.97 | ||

| 1.5 | 4.91 | 4.912 | 4.913 | ||

| Sensor 2 | 1.5 | 4.909 | 4.912 | 4.913 | |

| 5 | 4.971 | 4.971 | 4.972 | ||

| 8 | 4.981 | 4.982 | 4.982 | ||

| 5 | 4.972 | 4.973 | |||

| 1.5 | 4.916 | 4.916 | 4.921 | ||

| Sensor 3 | 1.5 | 4.924 | 4.931 | 4.933 | |

| 5 | 4.974 | 4.975 | 4.976 | ||

| 8 | 4.983 | 4.989 | 4.984 | ||

| 5 | 4.976 | 4.976 | 4.977 | ||

| 1.5 | 4.933 | 4.936 | 4.937 | ||

| Sensor 4 | 1.5 | 4.898 | 4.908 | 4.91 | |

| 5 | 4.967 | 4.968 | 4.969 | ||

| 8 | 4.979 | 4.98 | 4.98 | ||

| 5 | 4.69 | 4.97 | 4.97 | ||

| 1.5 | 4.911 | 4.914 | 4.915 | ||

| Sensor 5 | 1.5 | 4.938 | 4.944 | 4.946 | |

| 5 | 4.979 | 4.98 | 4.981 | ||

| 8 | 4.987 | 4.987 | 4.987 | ||

| 5 | 4.981 | 4.981 | 4.981 | ||

| 1.5 | 4.946 | 4.948 | 4.949 | ||

| Sensor 6 | 1.5 | 4.926 | 4.933 | 4.934 | |

| 5 | 4.974 | 4.975 | 4.975 | ||

| 8 | 4.983 | 4.983 | 4.983 | ||

| 5 | 4.976 | 4.976 | 4.976 | ||

| 1.5 | 4.935 | 4.937 | 4.938 | ||

| 2 RC | 3 RC | 4 RC | 5 RC | 6 RC | 7 RC | |

|---|---|---|---|---|---|---|

| R1 (ohm) | 2.06 × 10−2 | 2.05 × 10−2 | 2.05 × 10−2 | 2.05 × 10−2 | 2.05 × 10−2 | 8.87 × 10−4 |

| R2 (ohm) | 3.90 × 10−3 | 1.83 × 10−3 | 6.43 × 10−3 | 1.71 × 10−3 | 7.76 × 10−3 | 1.04 × 10−3 |

| R3 (ohm) | 9.03 × 10−3 | 7.97 × 10−3 | 7.60 × 10−3 | 3.03 × 10−3 | 1.08 × 10−3 | 8.50 × 10−5 |

| R4 (ohm) | 0 | 4.67 × 10−3 | 1.85 × 10−3 | 9.08 × 10−4 | 1.20 × 10−3 | 8.77 × 10−3 |

| R5 (ohm) | 0 | 0 | 1.21 × 10−3 | 1.34 × 10−1 | 5.43 × 10−4 | 1.12 × 10−4 |

| R6 (ohm) | 0 | 0 | 0 | 7.76 × 10−3 | 4.98 × 10−3 | 3.76 × 10−4 |

| R7 (ohm) | 0 | 0 | 0 | 0 | 1.95 × 10−3 | 3.09 × 10−4 |

| R8 (ohm) | 0 | 0 | 0 | 0 | 0 | 5.91 × 10−5 |

| C1 (F) | 212.2 | 8.655 | 539.5 | 5.948 | 1.55 × 10−1 | 2.91 × 10+4 |

| C2 (F) | 1.63 × 10−1 | 1.55 × 10−1 | 1.55 × 10−1 | 582.8 | 224 | 1.68 × 10+3 |

| C3 (F) | 0 | 340.7 | 4.915 | 199.9 | 9.212 | 1.55 × 10+5 |

| C4 (F) | 0 | 0 | 203.4 | 1.71 × 10+3 | 16.44 | 1.86 × 10+4 |

| C5 (F) | 0 | 0 | 0 | 1.55 × 10−1 | 596.8 | 56.67 |

| C6 (F) | 0 | 0 | 0 | 0 | 4.10 × 10+3 | 7.248 |

| C7 (F) | 0 | 0 | 0 | 0 | 0 | 37.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madani, S.S.; Schaltz, E.; Kær, S.K. Characterization of the Compressive Load on a Lithium-Ion Battery for Electric Vehicle Application. Machines 2021, 9, 71. https://doi.org/10.3390/machines9040071

Madani SS, Schaltz E, Kær SK. Characterization of the Compressive Load on a Lithium-Ion Battery for Electric Vehicle Application. Machines. 2021; 9(4):71. https://doi.org/10.3390/machines9040071

Chicago/Turabian StyleMadani, Seyed Saeed, Erik Schaltz, and Søren Knudsen Kær. 2021. "Characterization of the Compressive Load on a Lithium-Ion Battery for Electric Vehicle Application" Machines 9, no. 4: 71. https://doi.org/10.3390/machines9040071

APA StyleMadani, S. S., Schaltz, E., & Kær, S. K. (2021). Characterization of the Compressive Load on a Lithium-Ion Battery for Electric Vehicle Application. Machines, 9(4), 71. https://doi.org/10.3390/machines9040071