Friction and Wear Characteristics of Aqueous ZrO2/GO Hybrid Nanolubricants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Formulation of Nanolubricants

2.2. Tribological Tests

3. Results and Discussion

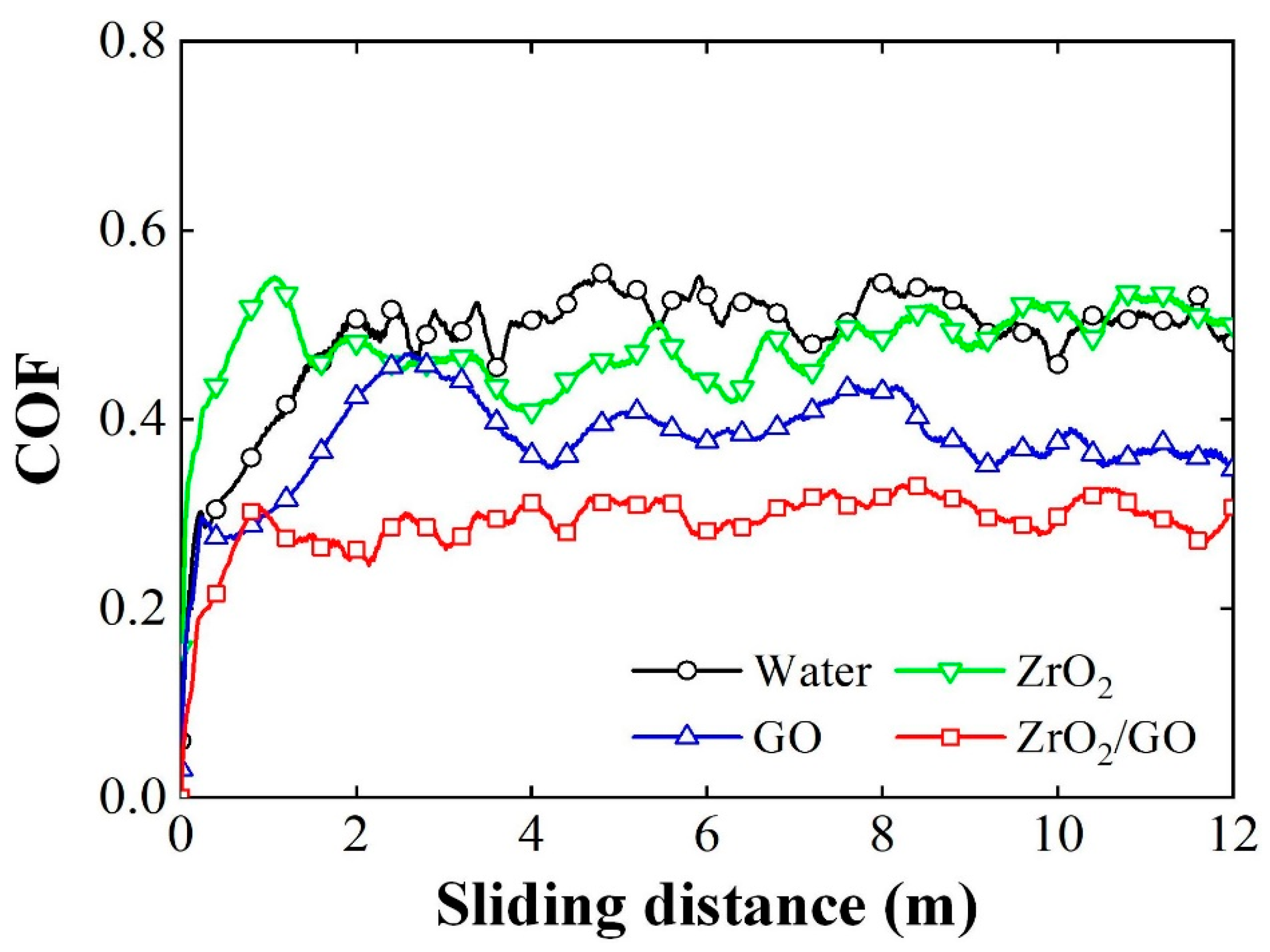

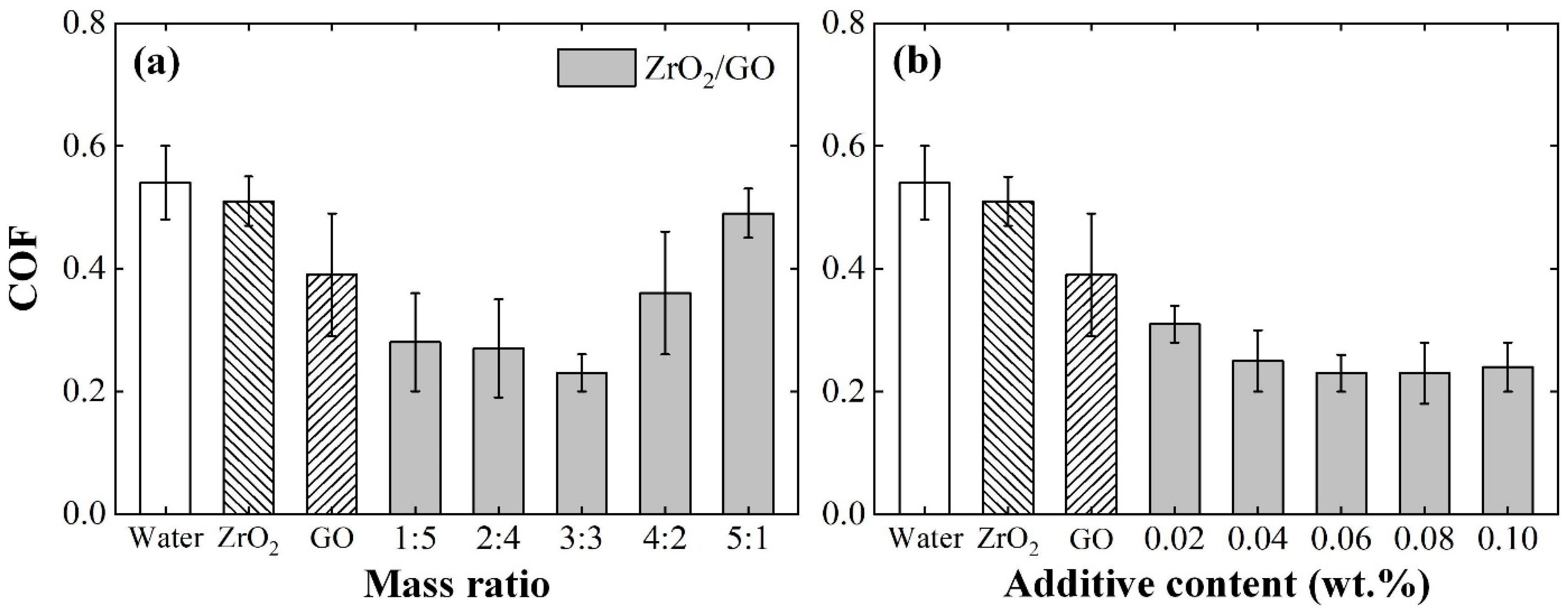

3.1. Friction and Wear Properties of Nanolubricants

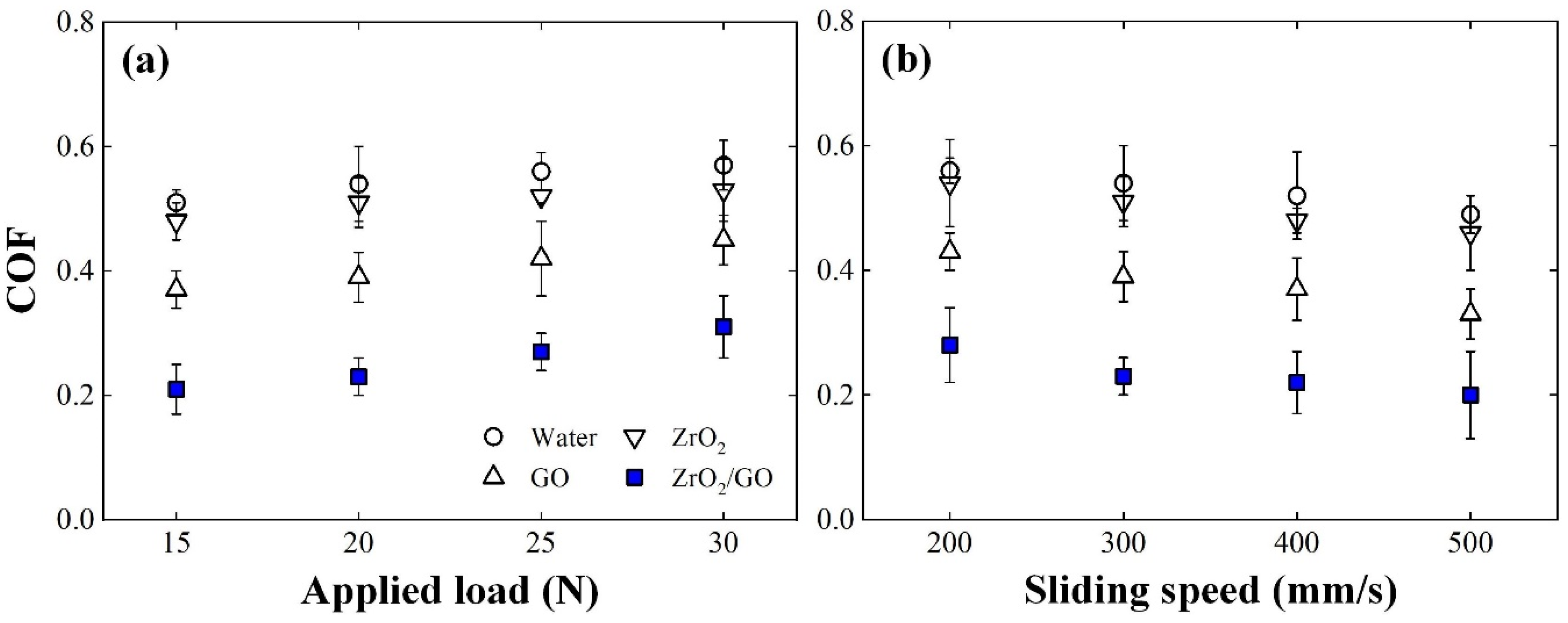

3.2. Effect of Testing Conditions on Friction-Reduction Performance

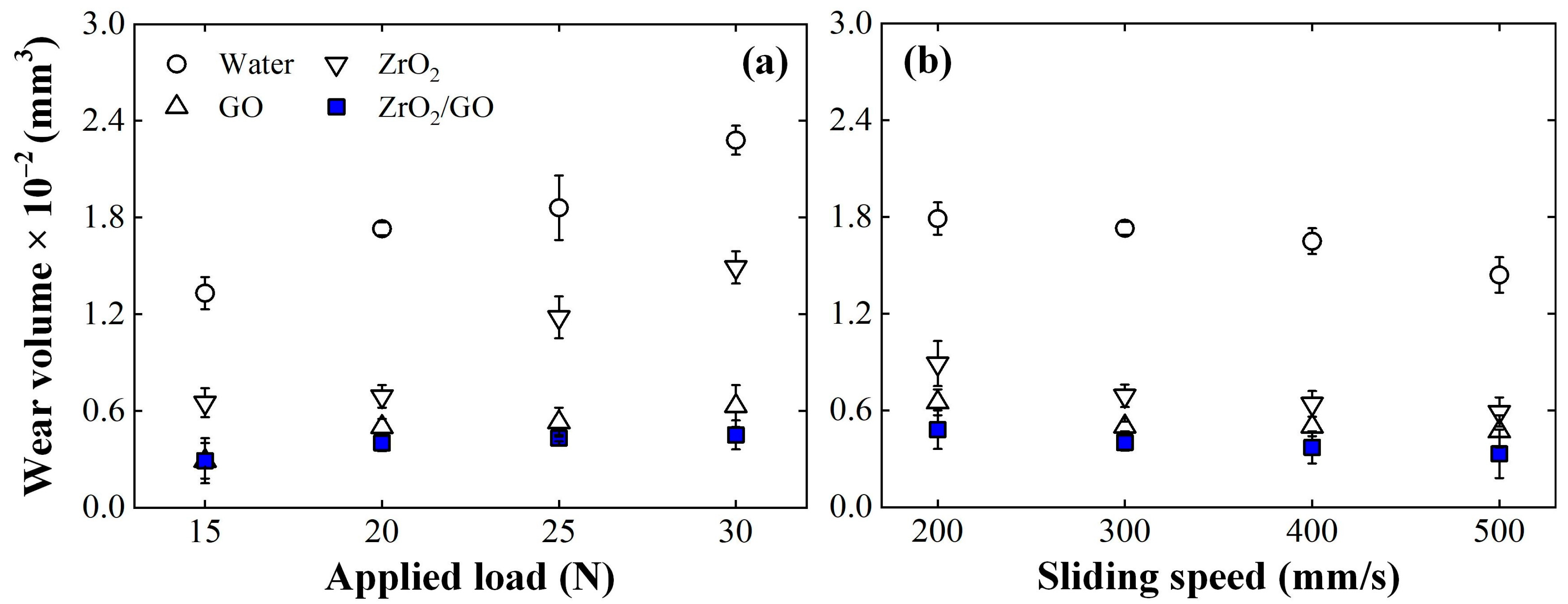

3.3. Effect of Testing Conditions on Anti-Wear Performance

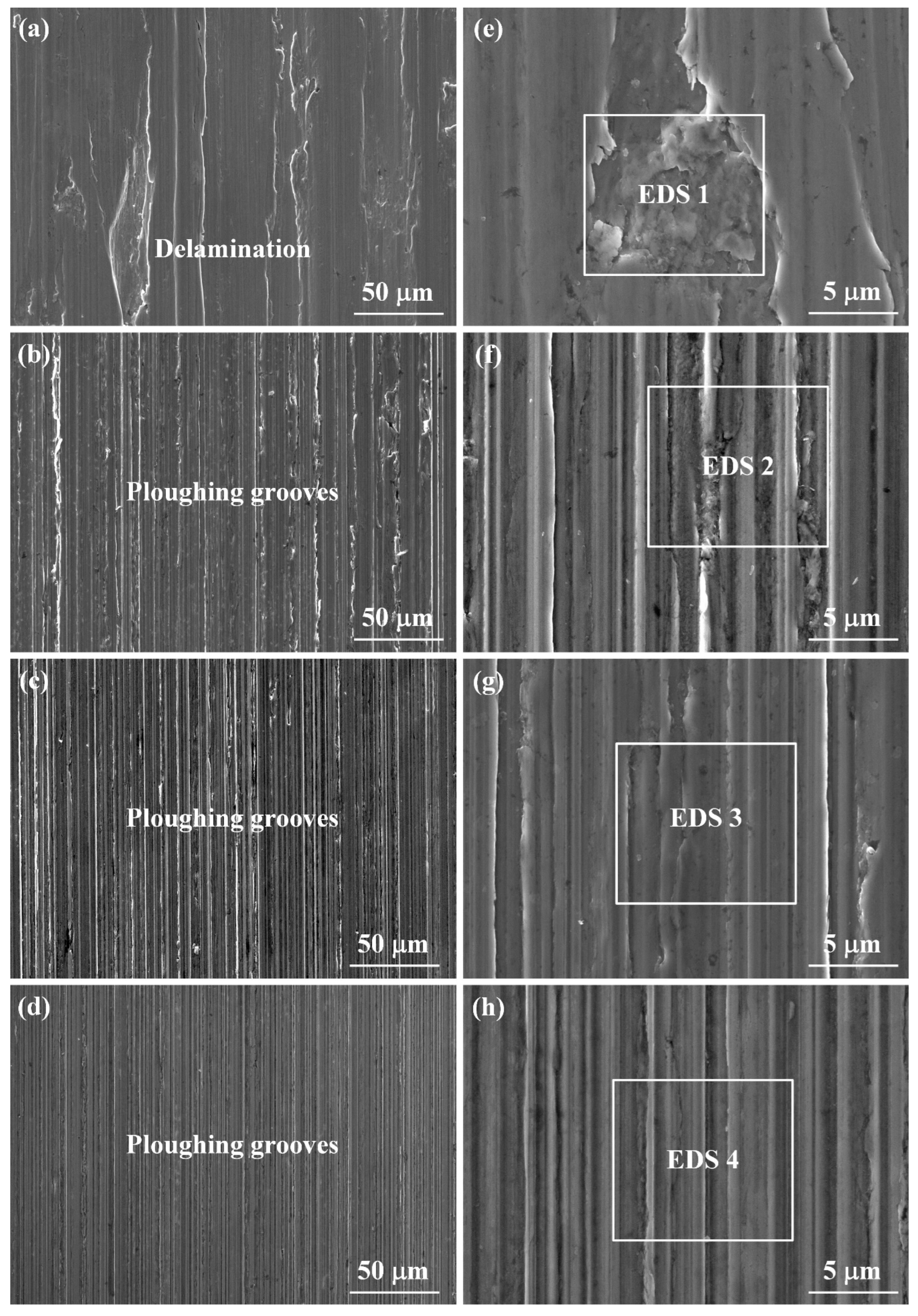

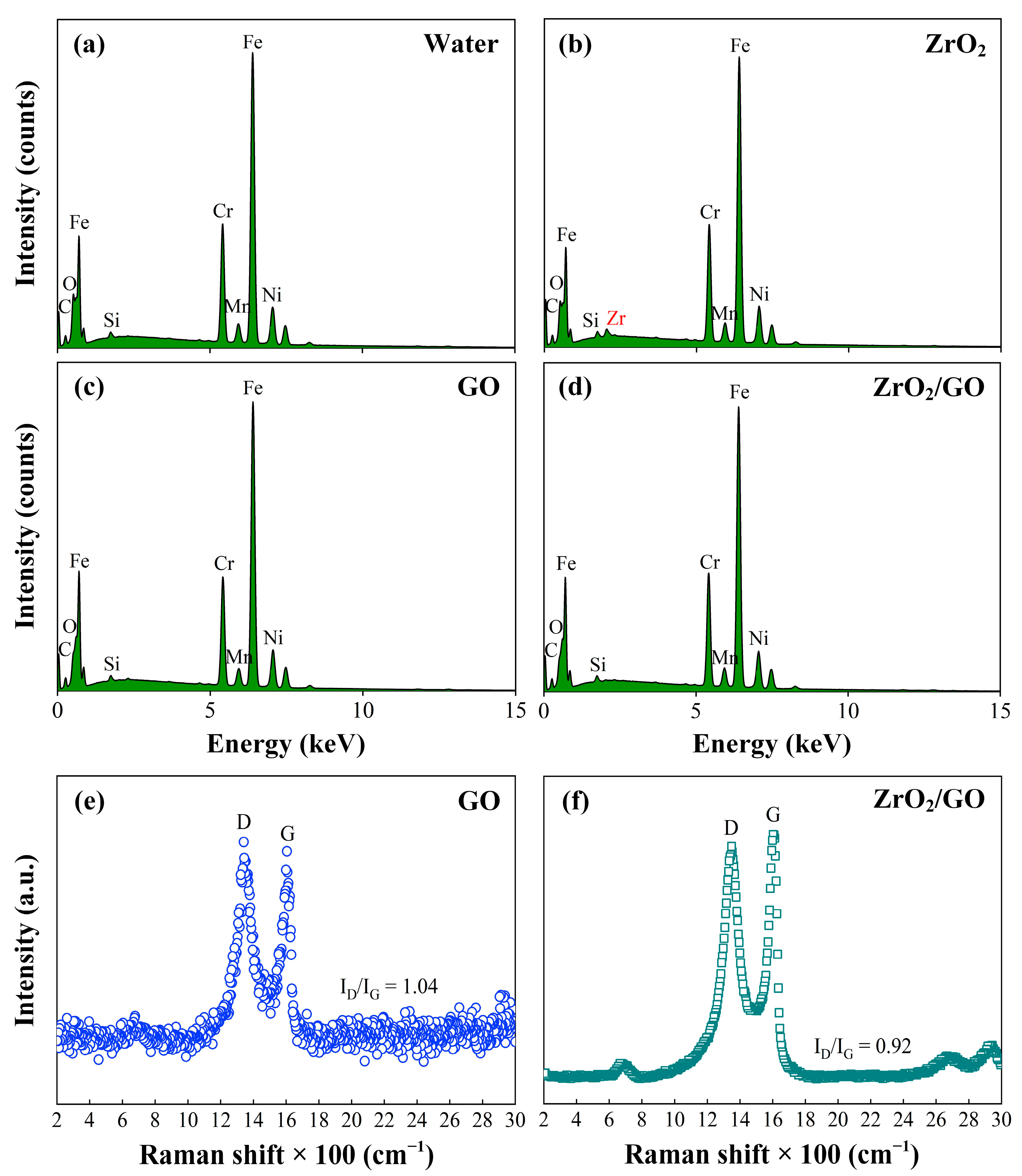

3.4. Worn Surface Characteristics

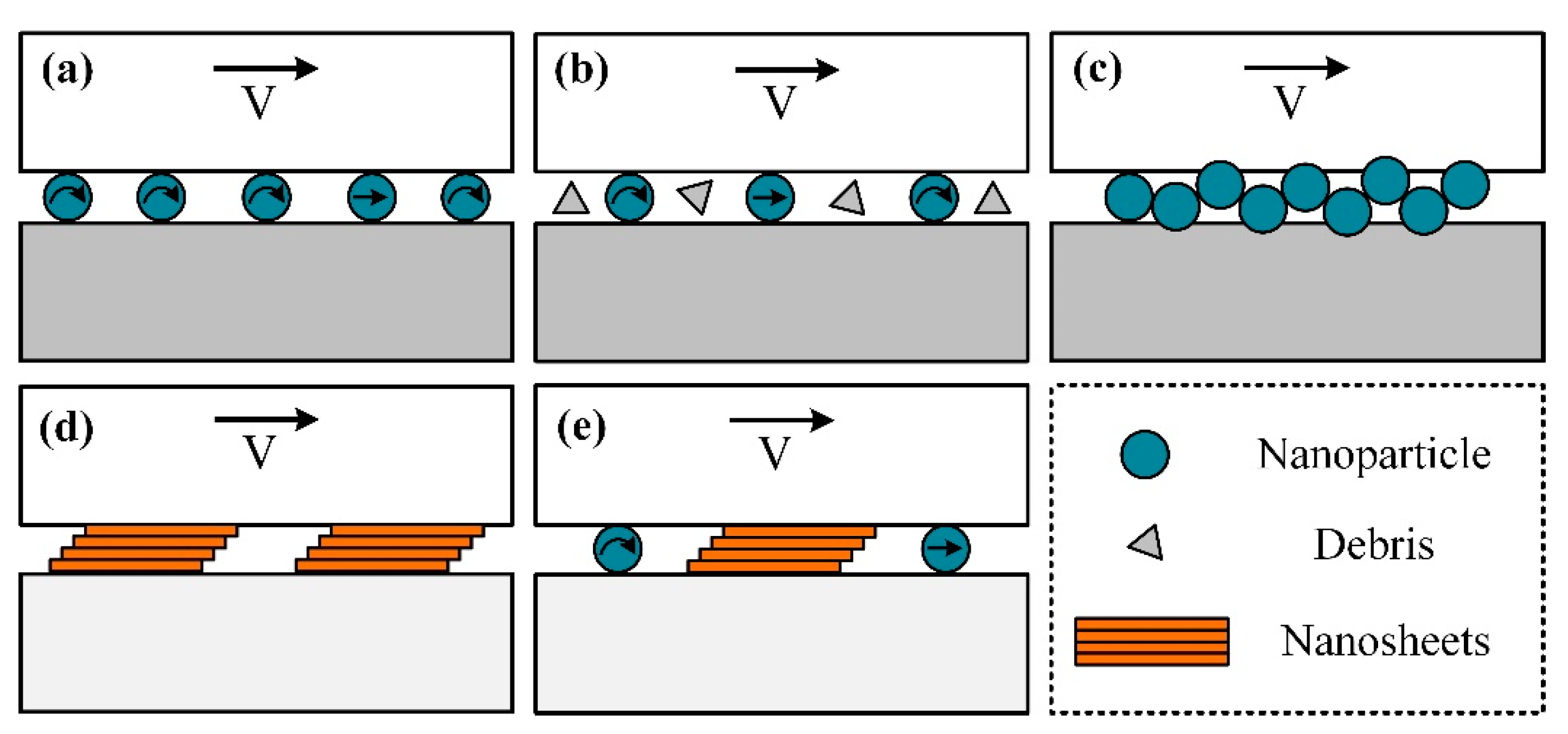

3.5. Lubrication Mechanism Analysis

4. Conclusions

- Dimensional integration is an effective approach to improve nanoparticle dispersion in water.

- Addition of nanoadditives to water can improve its tribological performance, and there is an optimal concentration and mass ratio of nanoadditives for the best lubrication performance.

- In water-based lubrication, 0D-ZrO2 nanoparticles are likely to generate a localised deposit layer on the rubbing area. This tribo-layer can help relieve asperity welding, i.e., adhesive wear, thus resulting in reduced friction and improved surface quality.

- In water-based lubrication, 2D-GO nanosheets tend to form a lubricating layer of low shear resistance on the sliding area. This self-lubricating layer can improve asperity contact and ploughing, thereby leading to reduced friction and wear.

- Hybrid nanoadditives of ZrO2 nanoparticles and GO nanosheets can produce a synergistic friction-reduction and anti-wear effect in water-based lubrication, reliving abrasive wear (i.e., asperity ploughing) and suppressing adhesive wear (i.e., asperity welding), which thus enables the achievement of both improved tribological performance and enhanced surface quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tool. Manu. 2012, 57, 83–101. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. Friction and wear behavior of environmentally friendly ionic liquids for sustainability of biolubricants. J. Tribol. 2019, 141, 051604. [Google Scholar] [CrossRef]

- Siddaiah, A.; Kasar, A.K.; Manoj, A.; Menezes, P.L. Influence of environmental friendly multiphase lubricants on the friction and transfer layer formation during sliding against textured surfaces. J. Clean. Prod. 2019, 209, 1245–1251. [Google Scholar] [CrossRef]

- Wu, H.; Jia, F.; Li, Z.; Lin, F.; Huo, M.; Huang, S.; Sayyar, S.; Jiao, S.; Huang, H.; Jiang, Z. Novel water-based nanolubricant with superior tribological performance in hot steel rolling. Int. J. Extreme Manuf. 2020, 2, 025002. [Google Scholar] [CrossRef]

- Morshed, A.; Wu, H.; Jiang, Z. A comprehensive review of water-based nanolubricants. Lubricants 2021, 9, 89. [Google Scholar] [CrossRef]

- Huang, S.; Wu, H.; Jiang, Z.; Huang, H. Water-based nanosuspensions: Formulation, tribological property, lubrication mechanism, and applications. J. Manuf. Process. 2021, 71, 625–644. [Google Scholar] [CrossRef]

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-based lubricants: Development, properties, and performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Wu, H.; Kamali, H.; Huo, M.; Lin, F.; Huang, S.; Huang, H.; Jiao, S.; Xing, Z.; Jiang, Z. Eco-friendly water-based nanolubricants for industrial-scale hot steel rolling. Lubricants 2020, 8, 96. [Google Scholar] [CrossRef]

- Sun, J.; Meng, Y.; Zhang, B. Tribological behaviors and lubrication mechanism of water-based MoO3 nanofluid during cold rolling process. J. Manuf. Process. 2021, 61, 518–526. [Google Scholar] [CrossRef]

- Meng, Y.; Sun, J.; He, J.; Yan, X.; Pei, Y. Recycling prospect and sustainable lubrication mechanism of water-based MoS2 nano-lubricant for steel cold rolling process. J. Clean. Prod. 2020, 277, 123991. [Google Scholar]

- Musavi, S.H.; Davoodi, B.; Niknam, S.A. Effects of reinforced nanoparticles with surfactant on surface quality and chip formation morphology in MQL-turning of superalloys. J. Manuf. Process. 2019, 40, 128–139. [Google Scholar] [CrossRef]

- Wu, H.; Jia, F.; Zhao, J.; Huang, S.; Wang, L.; Jiao, S.; Huang, H.; Jiang, Z. Effect of water-based nanolubricant containing nano-TiO2 on friction and wear behaviour of chrome steel at ambient and elevated temperatures. Wear 2019, 426, 792–804. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Luo, L.; Huang, S.; Wang, L.; Zhang, S.; Jiao, S.; Huang, H.; Jiang, Z. Performance evaluation and lubrication mechanism of water-based nanolubricants containing nano-TiO2 in hot steel rolling. Lubricants 2018, 6, 57. [Google Scholar] [CrossRef] [Green Version]

- He, A.; Huang, S.; Yun, J.-H.; Wu, H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. Tribological performance and lubrication mechanism of alumina nanoparticle water-based suspensions in ball-on-three-plate testing. Tribol. Lett. 2017, 65, 40. [Google Scholar] [CrossRef]

- Huang, S.; Lin, W.; Li, X.; Fan, Z.; Wu, H.; Jiang, Z.; Huang, H. Roughness-dependent tribological characteristics of water-based GO suspensions with ZrO2 and TiO2 nanoparticles as additives. Tribol. Int. 2021, 161, 107073. [Google Scholar] [CrossRef]

- He, A.; Huang, S.; Yun, J.-H.; Jiang, Z.; Stokes, J.R.; Jiao, S.; Wang, L.; Huang, H. Tribological characteristics of aqueous graphene oxide, graphitic carbon nitride, and their mixed suspensions. Tribol. Lett. 2018, 66, 42. [Google Scholar] [CrossRef]

- Kinoshita, H.; Nishina, Y.; Alias, A.A.; Fujii, M. Tribological properties of monolayer graphene oxide sheets as water-based lubricant additives. Carbon 2014, 66, 720–723. [Google Scholar] [CrossRef]

- Song, H.J.; Na, L. Frictional behavior of oxide graphene nanosheets as water-base lubricant additive. Appl. Phys. A 2011, 105, 827–832. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Zeng, Z.; Zhao, H.; Ge, X.; Wang, K.; Wang, L.; Xue, Q. PEGlated graphene as nanoadditive for enhancing the tribological properties of water-based lubricants. Carbon 2018, 137, 41–48. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Maldonado-Cortés, D.; Rodríguez-Villalobos, M.; Romero-Cantú, A.G.; Montemayor, O.E. Enhancing tool life, and reducing power consumption and surface roughness in milling processes by nanolubricants and laser surface texturing. J. Clean. Prod. 2020, 253, 119836. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Maldonado-Cortés, D.; Rodríguez-Villalobos, M.; Romero-Cantú, A.G.; Montemayor, O.E.; Herrera, M.; Trousselle, G.; González, J.; Hugler, W. Optimization of milling parameters of 1018 steel and nanoparticle additive concentration in cutting fluids for enhancing multi-response characteristics. Wear 2019, 426–427, 877–886. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lin, W.; Huang, S.; Edwards, G.; Lu, M.; Huang, H. Tribological performance of zeolite/sodium dodecylbenzenesulfonate hybrid water-based lubricants. Appl. Surf. Sci. 2022, 598, 153764. [Google Scholar] [CrossRef]

- Li, X.; Huang, S.; Wu, Y.; Huang, H. Performance evaluation of graphene oxide nanosheet water coolants in the grinding of semiconductor substrates. Precis. Eng. 2019, 60, 291–298. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Huang, S.; Li, L.; Zhang, F. Ultra-precision grinding of Gd3Ga5O12 crystals with graphene oxide coolant: Material deformation mechanism and performance evaluation. J. Manuf. Process. 2021, 61, 417–427. [Google Scholar] [CrossRef]

- Huang, H.; Li, X.; Mu, D.; Lawn, B.R. Science and art of ductile grinding of brittle solids. Int. J. Mach. Tool. Manu. 2021, 161, 103675. [Google Scholar] [CrossRef]

- Wu, Y.; Mu, D.; Huang, H. Deformation and removal of semiconductor and laser single crystals at extremely small scales. Int. J. Extreme Manuf. 2020, 2, 012006. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L. A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol. Int. 2017, 109, 398–408. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Xia, Y.; Song, H.; Chen, B.; Zhang, Z. Synthesis of the liquid-like graphene with excellent tribological properties. Tribol. Int. 2017, 105, 118–124. [Google Scholar] [CrossRef]

- He, A.; Huang, S.; Yun, J.-H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. The pH-dependent structural and tribological behaviour of aqueous graphene oxide suspensions. Tribol. Int. 2017, 116, 460–469. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L. Analysis of TiO2 nano-additive water-based lubricants in hot rolling of microalloyed steel. J. Manuf. Process. 2017, 27, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Das, A.; Pradhan, O.; Patel, S.K.; Das, S.R.; Biswal, B.B. Performance appraisal of various nanofluids during hard machining of AISI 4340 steel. J. Manuf. Process. 2019, 46, 248–270. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Rodríguez-Villalobos, M.; Maldonado-Cortés, D.; Guajardo, M.; Rico-Medina, C.S.; Elizondo, G.; Quintanilla, D.I. Study of hybrid nanofluids of TiO2 and montmorillonite clay nanoparticles for milling of AISI 4340 steel. Wear 2021, 477, 203805. [Google Scholar] [CrossRef]

- Huang, S.; He, A.; Yun, J.-H.; Xu, X.; Jiang, Z.; Jiao, S.; Huang, H. Synergistic tribological performance of a water based lubricant using graphene oxide and alumina hybrid nanoparticles as additives. Tribol. Int. 2019, 135, 170–180. [Google Scholar] [CrossRef]

- He, J.; Sun, J.; Meng, Y.; Pei, Y. Superior lubrication performance of MoS2-Al2O3 composite nanofluid in strips hot rolling. J. Manuf. Process. 2020, 57, 312–323. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Pan, G.; Luo, J. A comparative study between graphene oxide and diamond nanoparticles as water-based lubricating additives. Sci. China Technol. Sci. 2013, 56, 152–157. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Cheng, X.; Xia, W.; He, A.; Yun, J.-H.; Huang, S.; Wang, L.; Huang, H.; Jiao, S. Friction and wear characteristics of TiO2 nano-additive water-based lubricant on ferritic stainless steel. Tribol. Int. 2018, 117, 24–38. [Google Scholar] [CrossRef] [Green Version]

- Ji, P.; Mao, Z.; Wang, Z.; Xue, X.; Zhang, Y.; Lv, J.; Shi, X. Improved surface-enhanced raman scattering properties of ZrO2 Nanoparticles by Zn Doping. Nanomaterials 2019, 9, 983. [Google Scholar] [CrossRef] [Green Version]

| Analysed Area | Lubricant | C | O | Zr | Cr | Ni | Mn | Si | Fe |

|---|---|---|---|---|---|---|---|---|---|

| EDS 1 | Water | 1.6 | 0.5 | / | 14.7 | 5.6 | 0.9 | 0.6 | 76.1 |

| EDS 2 | ZrO2 | 1.8 | 1.7 | 0.9 | 17.0 | 7.3 | 1.2 | 0.4 | 69.7 |

| EDS 3 | GO | 4.4 | 3.5 | / | 14.7 | 6.5 | 0.9 | 0.6 | 69.4 |

| EDS 4 | ZrO2/GO | 3.6 | 2.8 | / | 14.8 | 5.9 | 0.9 | 0.6 | 71.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Wang, Z.; Xu, L.; Huang, C. Friction and Wear Characteristics of Aqueous ZrO2/GO Hybrid Nanolubricants. Lubricants 2022, 10, 109. https://doi.org/10.3390/lubricants10060109

Huang S, Wang Z, Xu L, Huang C. Friction and Wear Characteristics of Aqueous ZrO2/GO Hybrid Nanolubricants. Lubricants. 2022; 10(6):109. https://doi.org/10.3390/lubricants10060109

Chicago/Turabian StyleHuang, Shuiquan, Zhen Wang, Longhua Xu, and Chuanzhen Huang. 2022. "Friction and Wear Characteristics of Aqueous ZrO2/GO Hybrid Nanolubricants" Lubricants 10, no. 6: 109. https://doi.org/10.3390/lubricants10060109

APA StyleHuang, S., Wang, Z., Xu, L., & Huang, C. (2022). Friction and Wear Characteristics of Aqueous ZrO2/GO Hybrid Nanolubricants. Lubricants, 10(6), 109. https://doi.org/10.3390/lubricants10060109