Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

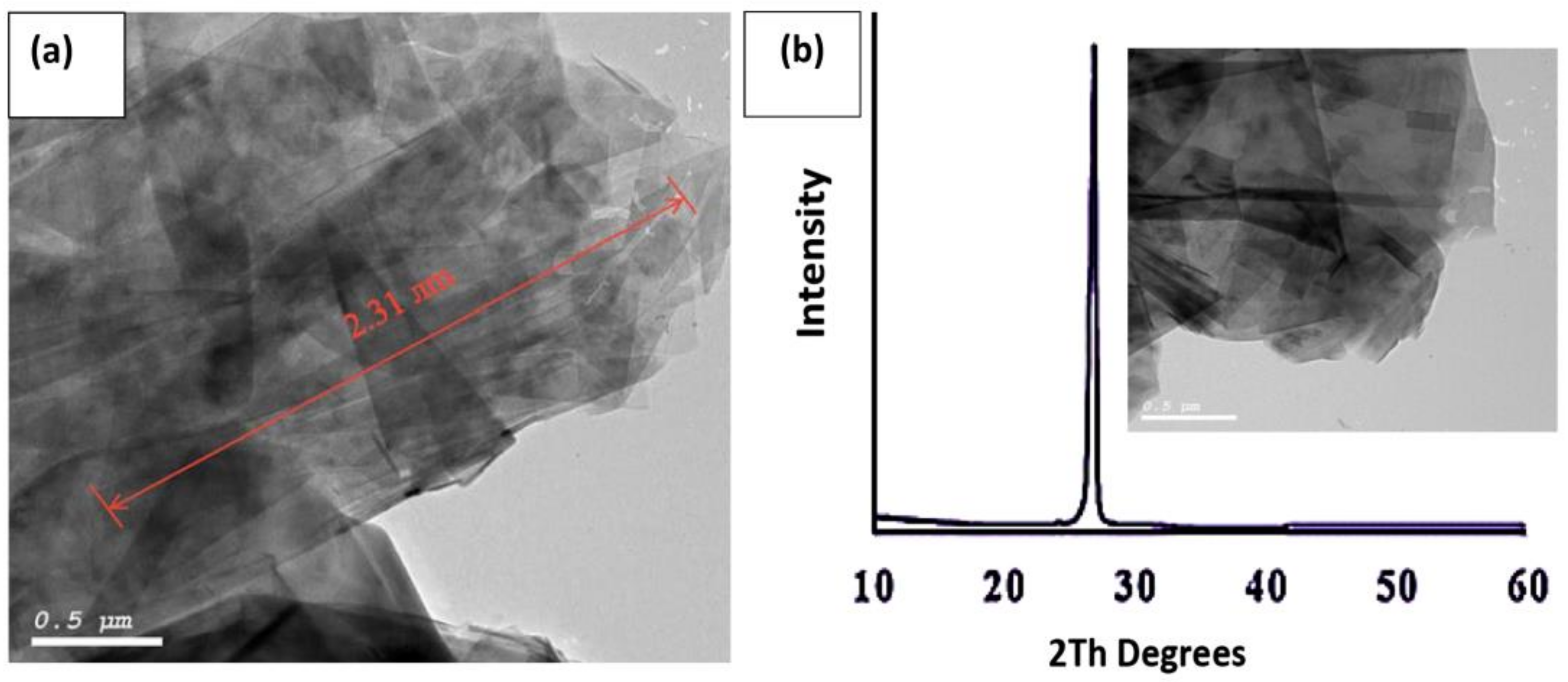

2.2. Characterization of the GNs

2.3. Nanolubricant Processing and Testing Equipment

2.4. Rheological and Tribological Examinations

2.5. Measurements Properties

2.6. Kinematic Viscosity Measurement

3. Results and Discussions

3.1. Characterization of GNs

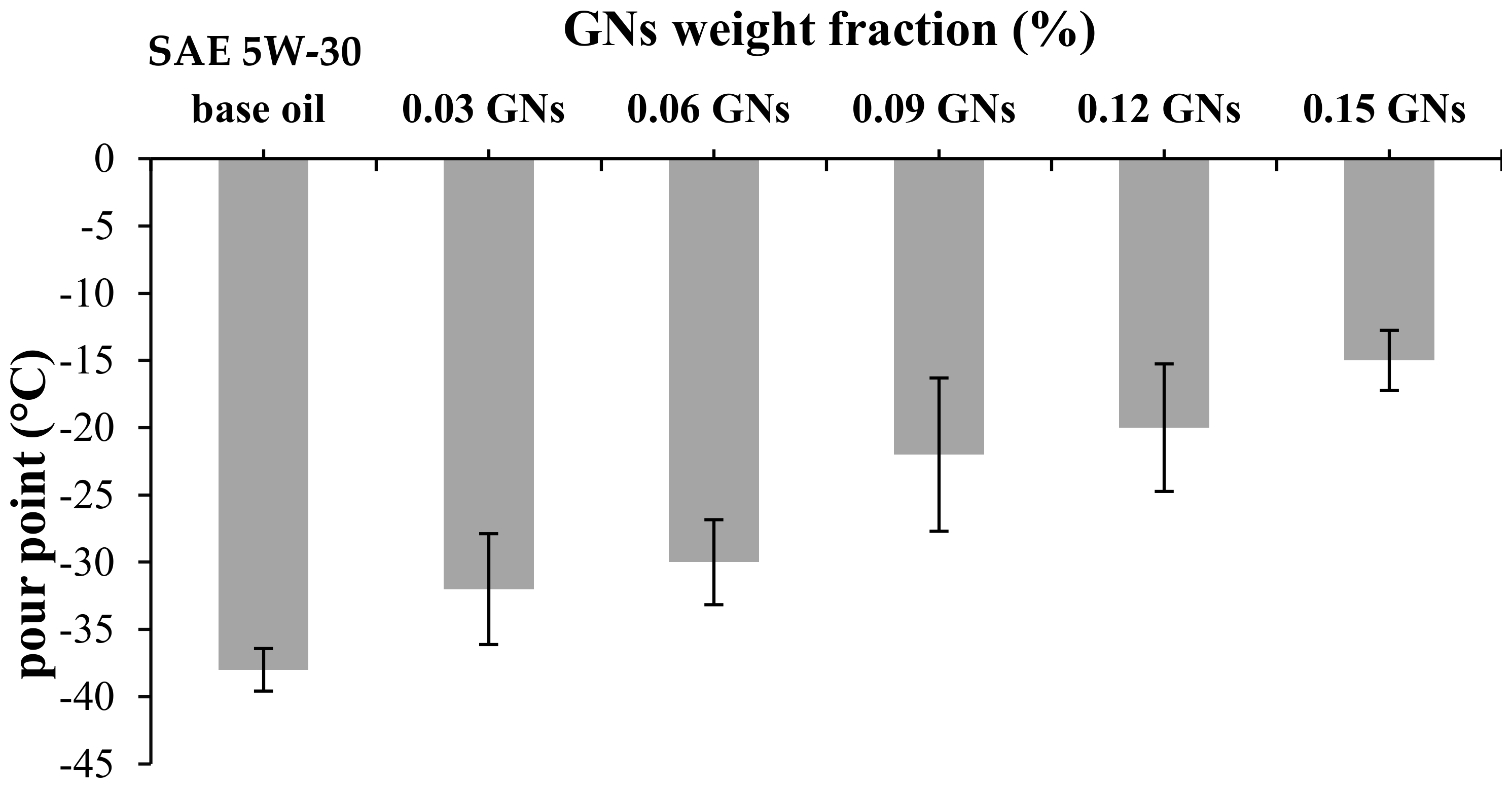

3.2. Pour Point and Flashpoint

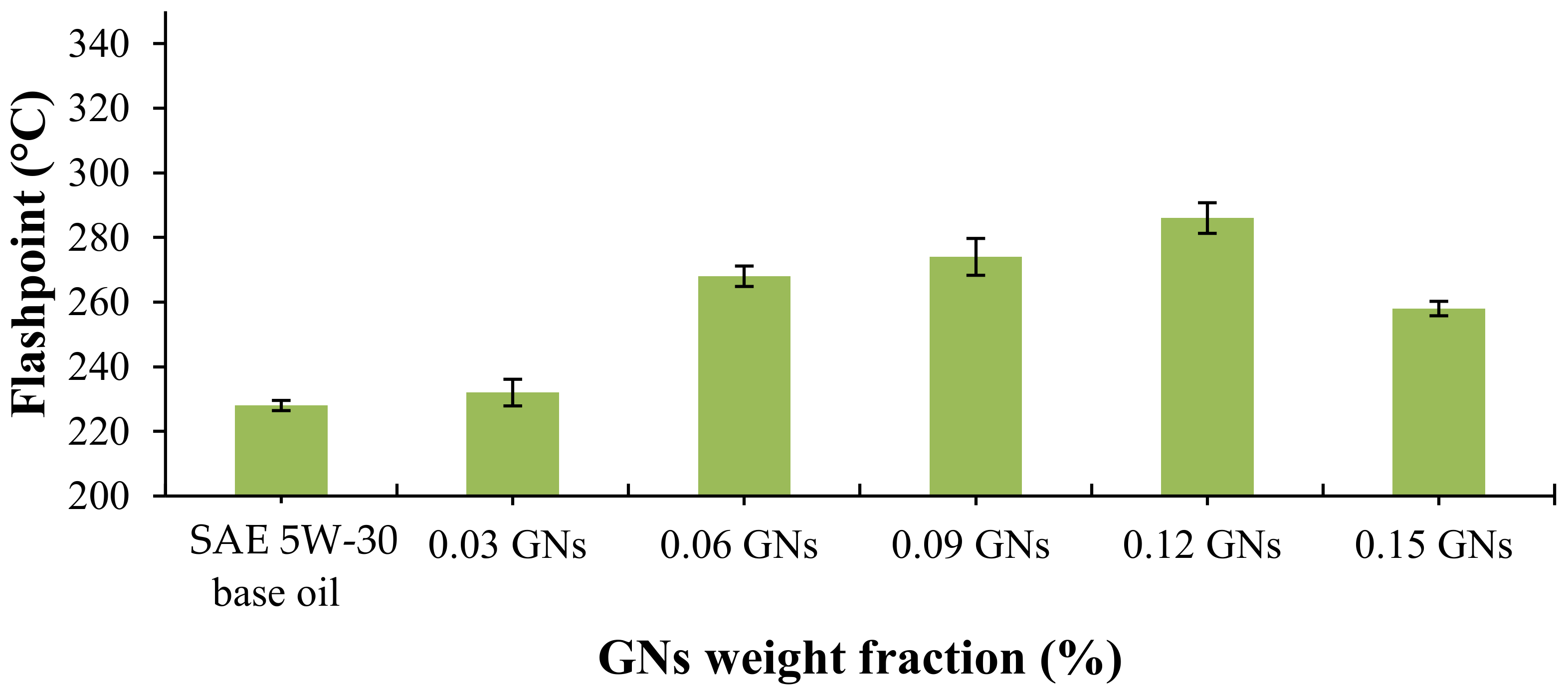

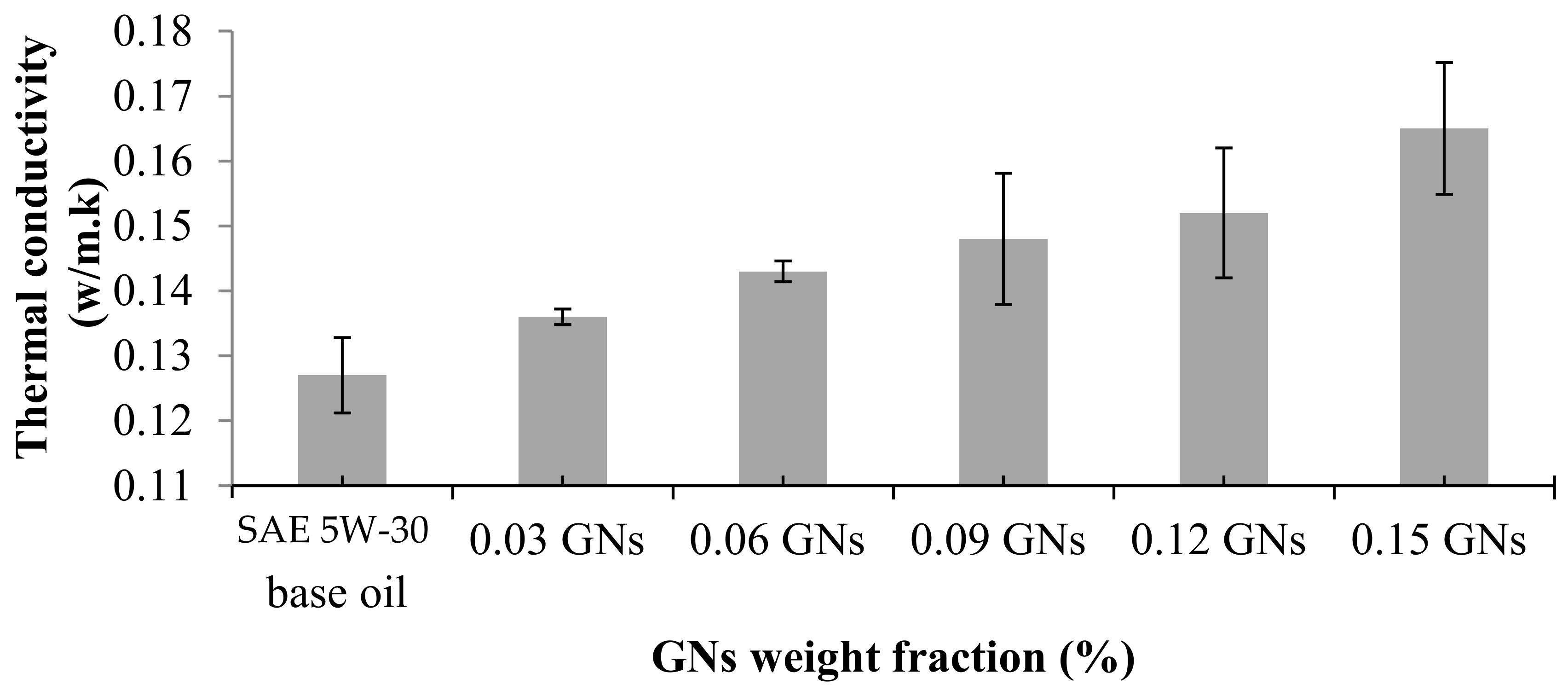

3.3. Thermal Conductivity

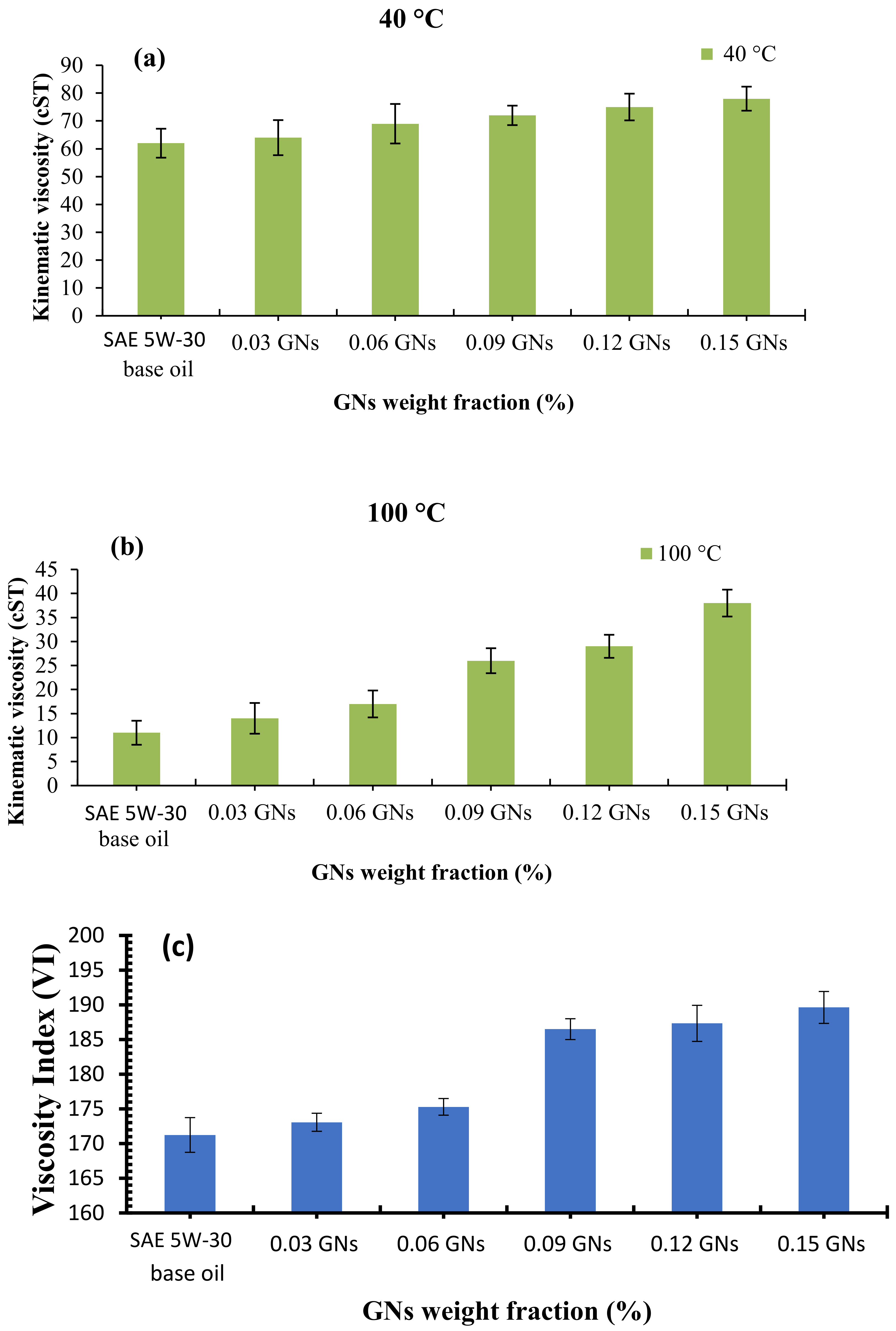

3.4. Kinematic Viscosity

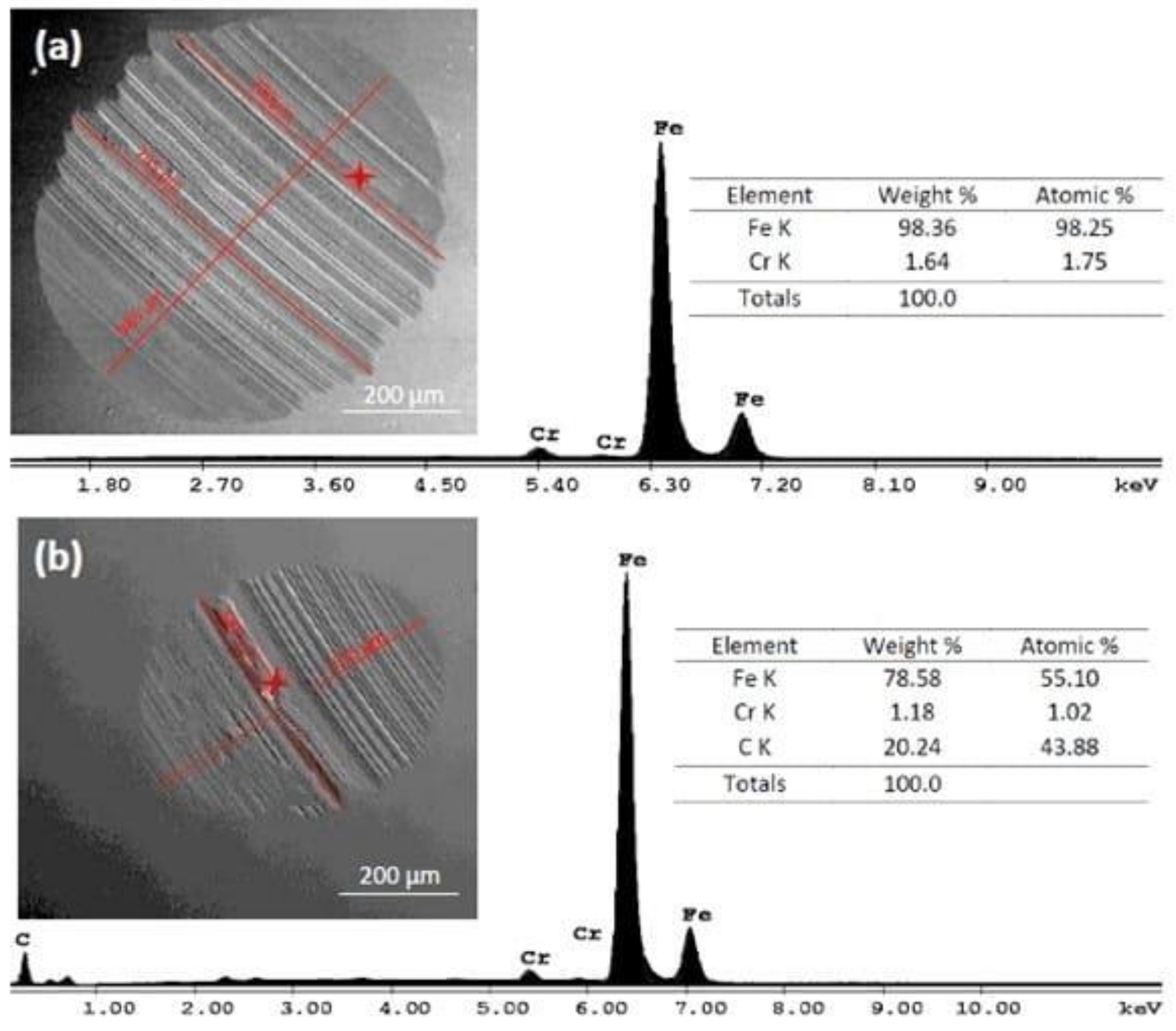

3.5. Tribological Properties

3.6. Comparison between Present Work and Previous Work

4. Conclusions

- increase in flashpoint by 25.4% when the percentage of GNs was increased;

- increase in thermal conductivity by increasing the content of additive nanoparticles of GNs;

- reduced wear rate at the concentration of 0.12 wt.% GNs;

- reduced friction by increasing the concentration of GNs below 0.12 wt.%;

- the viscosity index of SAE 5W-30 oil lubricant was increased by 8.5% using 0.09 wt.% GNs as an additive.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashour, M.; Mohamed, A.; Elshalakany, A.B.; Osman, T.; Khatab, A. Rheological behavior of lithium grease with CNTs/GNPs hybrid nanocomposite as an additive. Ind. Lubr. Tribol. 2018, 70, 331–338. [Google Scholar] [CrossRef]

- Kerni, L.; Raina, A.; Haq, M.I.U. Friction and wear performance of olive oil containing nanoparticles in boundary and mixed lubrication regimes. Wear 2019, 426–427, 819–827. [Google Scholar] [CrossRef]

- Cigno, E.; Magagnoli, C.; Pierce, M.S.; Iglesias, P. Lubricating ability of two phosphonium-based ionic liquids as additives of a bio-oil for use in wind turbines gearboxes. Wear 2017, 376–377, 756–765. [Google Scholar] [CrossRef]

- Ouyang, T.; Huang, H.; Zhang, N.; Mo, C.; Chen, N. A model to predict tribo-dynamic performance of a spur gear pair. Tribol. Int. 2017, 116, 449–459. [Google Scholar] [CrossRef]

- Pu, W.; Zhang, Q.; Zhang, W.; Ren, S.; Chen, Z.; Tian, T. Flash temperature and anti-wear tribofilm growth mechanisms by asperity contact in top-ring/liner conjunction of IC engines. Tribol. Int. 2020, 146, 106186. [Google Scholar] [CrossRef]

- Ouyang, T.; Huang, G.; Chen, J.; Gao, B.; Chen, N. Investigation of lubricating and dynamic performances for high-speed spur gear based on tribo-dynamic theory. Tribol. Int. 2019, 136, 421–431. [Google Scholar] [CrossRef]

- Bayat, R.; Lehtovaara, A. EHL/mixed transition of fully formulated environmentally acceptable gear oils. Tribol. Int. 2020, 146, 106158. [Google Scholar] [CrossRef]

- Yu, R.; Liu, J.; Zhou, Y. Experimental Study on Tribological Property of MoS2 Nanoparticle in Castor Oil. J. Tribol. 2019, 141, 102001. [Google Scholar] [CrossRef]

- Zhu, J.C.; Qi, J.; Guan, D.; Ma, L.; Dwyer-Joyce, R. Tribological behaviour of self-lubricating Mg matrix composites reinforced with silicon carbide and tungsten disulfide. Tribol. Int. 2020, 146, 106253. [Google Scholar] [CrossRef]

- Desai, J.A.; Bandyopadhyay, A.; Min, M.; Saenz, G.; Kaul, A.B. A photo-capacitive sensor operational from 6 K to 350 K with a solution printable, thermally-robust hexagonal boron nitride (h-BN) dielectric and conductive graphene electrodes. Appl. Mater. Today 2020, 20, 100660. [Google Scholar] [CrossRef]

- Liu, Y.F.; Ge, X.Y.; Li, J.J. Graphene lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

- D’Elia, E.; Ahmed, H.S.; Feilden, E.; Saiz, E. Electrically-responsive graphene-based shape-memory composites. Appl. Mater. Today 2019, 15, 185–191. [Google Scholar] [CrossRef]

- Fan, K.; Chen, X.Y.; Wang, X.; Liu, X.K.; Liu, Y.; Lai, W.C.; Liu, X.Y. Toward excellent tribological performance as oil-based lubricant additive: Particular tribological behavior of fluorinated graphene. ACS Appl. Mater. Interfaces 2018, 10, 28828–28838. [Google Scholar] [CrossRef]

- Ashour, M.E.; Osman, T.A.; Khattab, A.; Elshalakny, A.B. Novel Tribological Behavior of Hybrid MWCNTs/MLNGPs as an Additive on Lithium Grease. J. Tribol. 2017, 139, 041801. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Macroscale superlubricity enabled by graphene nanoscroll formation. Science 2015, 348, 1118–1122. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Su, F.; Chen, Y. Au/Graphene Oxide Nanocomposite Synthesized in Supercritical CO2 Fluid as Energy Efficient Lubricant Additive. ACS Appl. Mater. Interfaces 2017, 9, 39549–39559. [Google Scholar] [CrossRef]

- Verma, D.K.; Kumar, B.; Kavita; Rastogi, R.B. Zinc Oxide- and Magnesium-Doped Zinc Oxide-Decorated Nanocomposites of Reduced Graphene Oxide as Friction and Wear Modifiers. ACS Appl. Mater. Interfaces 2018, 11, 2418–2430. [Google Scholar] [CrossRef]

- Nehme, G.; Mourhatch, R.; Aswath, P. Effect of contact load and lubricant volume on the properties of tribofilms formed under boundary lubrication in a fully formulated oil under extreme load conditions. Wear 2010, 268, 1129–1147. [Google Scholar] [CrossRef]

- Nehme, G. The effect of FeF3/TiF3 catalysts on the thermal and tribological performance of plain oil ZDDP under extreme pressure loading. Wear 2012, 278–279, 9–17. [Google Scholar] [CrossRef]

- He, A.S.; Huang, S.Q.; Yun, J.H.; Jiang, Z.Y.; Stokes, J.; Jiao, S.H.; Wang, L.Z.; Huang, H. The pH-dependent structural and tribological behaviour of aqueous graphene oxide suspensions. Tribol. Int. 2017, 116, 460–469. [Google Scholar] [CrossRef] [Green Version]

- Zvereva, E.R.; Khabibullina, R.V.; Akhmetvalieva, G.R.; Makarova, A.O.; Zueva, O.S. Influence of Nanoadditives on Rheological Properties of Fuel Oil. In Proceedings of the International Conference “Actual Issues of Mechanical Engineering” 2017 (AIME 2017), Tomsk, Russia, 27–29 July 2017; Atlantis Press: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Dinesh, R.; Prasad, M.G.; Kumar, R.R.; Santharaj, N.J.; Santhip, J.; Raaj, A.A. Investigation of Tribological and Thermophysical Properties of Engine Oil Containing Nano additives. Mater. Today Proc. 2016, 3, 45–53. [Google Scholar] [CrossRef]

- Kamel, B.M.; El-Kashif, E.; Hoziefa, W.; Shiba, M.S.; Elshalakany, A.B. The effect of MWCNTs/GNs hybrid addition on the tribological and rheological properties of lubricating engine oil. J. Dispers. Sci. Technol. 2020, 42, 1811–1819. [Google Scholar] [CrossRef]

- Babu, D.; Anand, R. Influence of fuel injection timing and nozzle opening pressure on a CRDI assisted diesel engine fueled with biodiesel-diesel-alcohol fuel. In Eco-Fuels for a Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 353–390. [Google Scholar]

- Balakrishnan, J.; Pramila, J. A eminence value of hydrocarbon diesel oil with viscosity density flash point aniline point and distillation. Mater. Today Proc. 2020, 33, 4015–4019. [Google Scholar] [CrossRef]

- Braun, J.L.; Olson, D.H.; Gaskins, J.T.; Hopkins, P.E. A steady-state the reflectance method to measure thermal conductivity. Rev. Sci. Instrum. 2019, 90, 024905. [Google Scholar] [CrossRef] [Green Version]

- Hoffmann, J.F.; Henry, J.F.; Vaitilingom, G.; Olivès, R.; Chirtoc, M.; Caron, D.; Py, X. Temperature dependence of thermal conductivity of vegetable oils for use in concentrated solar power plants, measured by 3omega hot wire method. Int. J. Therm. Sci. 2016, 107, 105–110. [Google Scholar] [CrossRef]

- Guo, W.; Li, G.; Zheng, Y.; Dong, C. Measurement of the thermal conductivity of SiO2 nanofluids with an optimized transient hot wire method. Thermochim. Acta 2018, 661, 84–97. [Google Scholar] [CrossRef]

- Kommandur, S.; Yee, S. A suspended 3-omega technique to measure the anisotropic thermal conductivity of semiconducting polymers. Rev. Sci. Instrum. 2018, 89, 114905. [Google Scholar] [CrossRef]

- Sajith, V.; Mohiddeen, M.D.; Sajanish, M.B.; Sobhan, C.B. An investigation of the effect of addition of nanoparticles on the properties of lubricating oil. Heat Transf. Summer Conf. 2007, 42754, 329–335. [Google Scholar]

- Abdullah, M.A.; Saleman, S.A.; Tamaldin, N.; Suhaimi, M.S. Reducing wear and friction by means of lubricants mixtures. Procedia Eng. 2013, 68, 338–344. [Google Scholar] [CrossRef] [Green Version]

- Jakubek, B.; Barczewski, R. The influence of kinematic viscosity of a lubricant on broadband rolling bearing vibrations in amplitude terms. Diagnostyka 2019, 20, 93–102. [Google Scholar] [CrossRef]

- Syahrullail, S.; Ani, F.N.; Golshokouh, I. Wear Resistance Characteristic of Vegetable Oil. Adv. Mater. Res. 2013, 795, 42–46. [Google Scholar] [CrossRef]

- Do Valle, C.P.; Silva Rodrigues, J.; Fechine, L.M.U.D.; Cunha, A.P.; Queiroz Malveira, J.; Luna, F.M.T.; Ricardo, N.M.P.S. Chemical modification of Tilapia oil for biolubricant applications. J. Clean Prod. 2017, 191, 158–166. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, C.; Hwang, Y.; Park, M.; Lee, J.; Choi, C.; Jung, M. Tribological behavior of copper nanoparticles as additives in oil. Curr. Appl. Phys. 2009, 9, e124–e127. [Google Scholar] [CrossRef]

- Yu, H.-L.; Xu, Y.; Shi, P.J.; Xu, B.S.; Wang, X.L.; Liu, Q. Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant. Trans. Nonferrous Met. Soc. China 2008, 18, 636–641. [Google Scholar] [CrossRef]

- Kamel, B.M.; Tirth, V.; Algahtani, A.; Shiba, M.S.; Mobasher, A.; Abu Hashish, H.; Dabees, S. Optimization of the Rheological Properties and Tribological Performance of SAE 5w-30 Base Oil with Added MWCNTs. Lubricants 2021, 9, 94. [Google Scholar] [CrossRef]

- Singh, N.K.; Singh, Y.; Sharma, A.; Chinnasamy, V.; Palamanit, A. Rheological characteristics and tribological performance of neem biodiesel–based nano oil added with MWCNT. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Lubricant Grade | SAE 5W-30 |

| Kinematic Viscosity @ 40 °C mm2/s, ASTM D445 | 73.95 |

| Kinematic Viscosity @ 100 °C, mm2/s, ASTM D445 | 12.02 |

| Pour Point, °C, ASTM D97 | −48 |

| Density @ 15 °C, kg/m3, ASTM D4052 | 848 |

| Flash Point, Cleveland Open-Cup, _C, ASTM D92 | 220 |

| Nanoparticles | GNs |

|---|---|

| True density | ≤2.20 g/cm3 |

| Average lateral dimension (x and y) length | ≤5 µm |

| Average through-plane dimension (z) thickness | ~10–20 nm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqahtani, B.; Hoziefa, W.; Abdel Moneam, H.M.; Hamoud, M.; Salunkhe, S.; Elshalakany, A.B.; Abdel-Mottaleb, M.; Davim, J.P. Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants 2022, 10, 137. https://doi.org/10.3390/lubricants10070137

Alqahtani B, Hoziefa W, Abdel Moneam HM, Hamoud M, Salunkhe S, Elshalakany AB, Abdel-Mottaleb M, Davim JP. Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants. 2022; 10(7):137. https://doi.org/10.3390/lubricants10070137

Chicago/Turabian StyleAlqahtani, Bader, Wael Hoziefa, Hussein Mohammed Abdel Moneam, Mohamed Hamoud, Sachin Salunkhe, Abou Bakr Elshalakany, Mohamed Abdel-Mottaleb, and João Paulo Davim. 2022. "Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives" Lubricants 10, no. 7: 137. https://doi.org/10.3390/lubricants10070137

APA StyleAlqahtani, B., Hoziefa, W., Abdel Moneam, H. M., Hamoud, M., Salunkhe, S., Elshalakany, A. B., Abdel-Mottaleb, M., & Davim, J. P. (2022). Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants, 10(7), 137. https://doi.org/10.3390/lubricants10070137