Self-Lubricating Effect of WC/Y–TZP–Al2O3 Hybrid Ceramic–Matrix Composites with Dispersed Hadfield Steel Particles during High-Speed Sliding against an HSS Disk

Abstract

:1. Introduction

2. Materials and Methods

3. Results

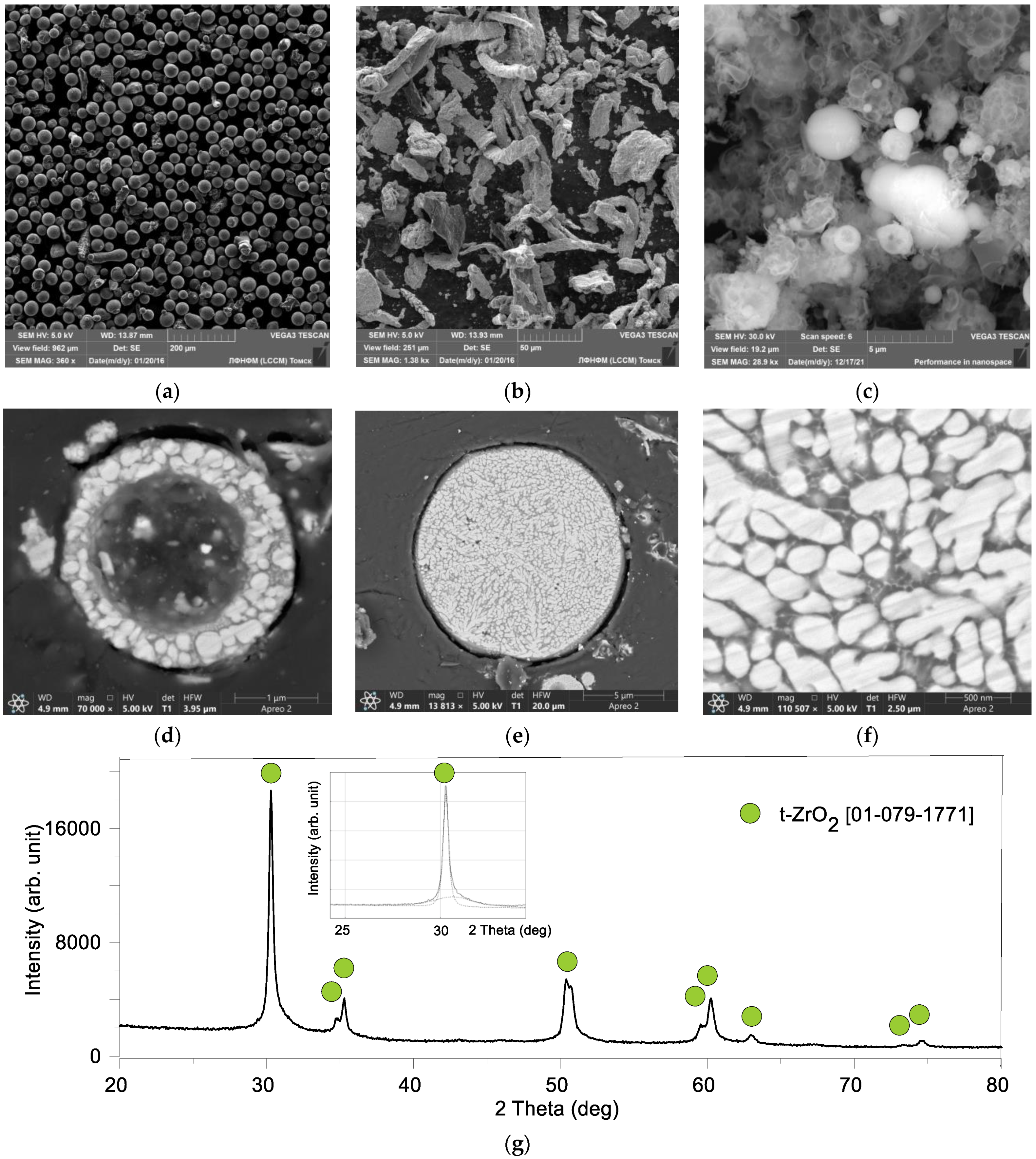

3.1. Microstructures and Phases in the As-Sintered Composites

3.2. Hardness, Fracture Toughness and Crack Propagation

3.3. Coefficient of Friction and Wear Rate

3.4. Microstructures and EDS of Worn Surfaces

3.5. Tribological Layer Microstructures and Phases

4. Discussion

4.1. Structure of As-Sintered Composites. Fracture Toughening Mechanism of WC/Y–TZP–Al2O3 Hybrid Ceramic–Matrix Composite with Dispersed Hadfield Steel Particles

4.2. Coefficient of Friction and Normalized Wear Rate of WC/Y–TZP–Al2O3 Hybrid Ceramic–matrix Composites with Dispersed Hadfield Steel Particles. Comparison to Other Composites

4.3. Subsurface Multi-Layer Tribooxidation Structure of WC/Y–TZP–Al2O3 Hybrid Ceramic–matrix Composite with Dispersed Hadfield Steel Particles That Provided the Self-Lubricating Effect and Self-Healing Effect in High-Speed Sliding

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, R.; Antonov, M. Self-lubricating materials for extreme temperature tribo-applications. Mater. Today Proc. 2020, 44, 4583–4589. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef] [PubMed]

- Torres, H.; Ripoll, M.R.; Prakash, B. Tribological behaviour of self-lubricating materials at high temperatures. Int. Mater. Rev. 2017, 63, 309–340. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, J.; Qiao, Z.; Yang, J. High temperature solid-lubricating materials: A review. Tribol. Int. 2019, 133, 206–223. [Google Scholar] [CrossRef]

- Kumar, R.; Hussainova, I.; Rahmani, R.; Antonov, M. Solid Lubrication at High-Temperatures—A Review. Materials 2022, 15, 1695. [Google Scholar] [CrossRef] [PubMed]

- Voevodin, A.A.; Muratore, C.; Aouadi, S.M. Hard coatings with high temperature adaptive lubrication and contact thermal management: Review. Surf. Coat. Technol. 2014, 257, 247–265. [Google Scholar] [CrossRef]

- Savchenko, N.; Sevostyanova, I.; Tarasov, S. Self-Lubricating Effect of FeWO4 Tribologically Synthesized from WC-(Fe-Mn-C) Composite during High-Speed Sliding against a HSS Disk. Lubricants 2022, 10, 86. [Google Scholar] [CrossRef]

- Savchenko, N.L.; Mirovoy, Y.A.; Buyakov, A.S.; Burlachenko, A.G.; Rudmin, M.A.; Sevostyanova, I.N.; Buyakova, S.P.; Tarasov, S.Y. Adaptation and self-healing effect of tribo-oxidizing in high-speed sliding friction on ZrB2-SiC ceramic composite. Wear 2020, 446–447, 203204. [Google Scholar] [CrossRef]

- Savchenko, N.L.; Mirovoy, Y.A.; Burlachenko, A.G.; Sevostyanova, I.N.; Buyakov, A.S.; Rudmin, M.A.; Vorontsov, A.V.; Buyakova, S.P.; Tarasov, S.Y. Subsurface multilayer evolution of ZrB2-SiC ceramics in high-speed sliding and adhesion transfer conditions. Wear 2021, 482–483, 203956. [Google Scholar] [CrossRef]

- Savchenko, N.L.; Gnyusov, S.F.; Kul’kov, S.N. Features of High-Speed Wear of WC–Steel 11G13 Material in Contact with Cast Tool Steel. J. Frict. Wear 2009, 30, 46–52. [Google Scholar] [CrossRef]

- Savchenko, N.L.; Kul’kov, S.N. Friction and wear of Y-TZP and Y-TZP-Al2O3 ceramics in high-speed sliding on steel. J. Frict. Wear. 2009, 30, 444–448. [Google Scholar] [CrossRef]

- Savchenko, N.L.; Sevostyanova, I.N.; Utyaganova, V.R.; Gnyusov, S.F. High speed sliding of a WC/Hadfield steel composite against steel. AIP Conf. Proc. 2018, 2053. [Google Scholar] [CrossRef]

- Ravikiran, A.; Nagarajan, V.S.; Biswas, S.K.; Bai, B.N.P. Effect of speed and pressure on dry sliding interactions of alumina against steel. J. Am. Ceram. Soc. 1995, 78, 356–364. [Google Scholar] [CrossRef]

- Ravikiran, A.; Subbanna, G.R.; Bai, B.N.P. Effect of interface layers formed during dry sliding of zirconia toughened alumina (ZTA) and monolithic alumina against steel. Wear 1996, 192, 56–65. [Google Scholar] [CrossRef]

- Ravikiran, A.; Bai, B.N.P. Influence of speed on the tribochemical reaction products and the associated transitions for the dry sliding of silicon nitride against steel. J. Am. Ceram. Soc. 1995, 78, 3025–3032. [Google Scholar] [CrossRef]

- Gogotsi, Y.G.; Koval’chenko, A.M.; Kossko, I.A. Tribochemical Interactions of Boron Carbides against Steel. Wear 1992, 154, 133–140. [Google Scholar] [CrossRef]

- Koval’chuk, V.; Yuga, A.; Timchenko, R.; Grigor’ev, O.; Panin, V.; Kostenko, A. Examination of the physicomechanical and tribological properties of heterophase materials of the SiC-MeB2 system. Powder Metall. Met. Ceram. 1992, 31, 183–187. [Google Scholar] [CrossRef]

- Podchernyaeva, I.A.; Grigor’ev, O.N.; Subbotin, V.I.; Kostenko, A.D.; Isaeva, L.P.; Artemenko, E.A. Wear-resistant layered electrospark coatings based on ZrB2. Powder Metall. Met. Ceram. 2004, 43, 391–395. [Google Scholar] [CrossRef]

- Qian, Y.; Zhang, W.; Ge, M.; Wei, X. Frictional response of a novel C/C-ZrB2-ZrC-SiC composite under simulated braking. J. Adv. Ceram. 2013, 2, 157–161. [Google Scholar] [CrossRef] [Green Version]

- Cai, L.; Huang, Z.; Hu, W.; Lei, C.; Zhai, H.; Zhou, Y. Dry sliding behaviors and friction surface characterization of Ti3Al0.8Si0.2Sn0.2C2 solid solution against S45C steel. Ceram. Int. 2019, 45, 2103–2110. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, H.; Zhai, H.; Wang, Y.; Zhou, Y. Strengthening and tribological surface self-adaptability of Ti3AlC2 by incorporation of Sn to form Ti3Al(Sn)C2 solid solutions. Ceram. Int. 2015, 41, 3701–3709. [Google Scholar] [CrossRef]

- Pędzich, Z. Tungsten Carbide as an Reinforcement in Structural Oxide-Matrix Composites. In Tungsten Carbide—Processing and Applications; IntechOpen: London, UK, 2012; Available online: https://www.intechopen.com/chapters/41528 (accessed on 19 December 2012). [CrossRef] [Green Version]

- Xia, X.; Li, X.; Li, J.; Zheng, D. Microstructure and characterization of WC-2.8 wt% Al2O3-6.8 wt% ZrO2 composites produced by spark plasma sintering. Ceram. Int. 2016, 42, 14182–14188. [Google Scholar] [CrossRef]

- Bai, T.; Xie, T. Fabriëcation and mechanical properties of WC-Al2O3 cemented carbide reinforced by CNTs. Mater. Chem. Phys. 2017, 201, 113–119. [Google Scholar] [CrossRef]

- Pedzich, Z.; Haberko, K. Toughening mechanisms in the TZP-WC particulate composites. Key Eng. Mater. 1997, 132–136, 2076–2079. [Google Scholar] [CrossRef]

- Jiang, D.; Van der Biest, O.; Vleugels, J. ZrO2–WC nanocomposites with superior properties. J. Eur. Ceram. Soc. 2007, 27, 1247–1251. [Google Scholar] [CrossRef]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia containing ceramics. J. Am. Ceram. Soc. 2004, 83, 461–487. [Google Scholar] [CrossRef]

- Sayir, A.; Farmer, S.C. The effect of the microstructure on mechanical properties of directionally solidified Al2O3/ZrO2(Y2O3) eutectic. Acta Mater. 2000, 48, 4691. [Google Scholar] [CrossRef] [Green Version]

- Balasubramanian, S.; Keshavan, H.; Cannon, W.R. Sinter forging of rapidly quenched eutectic Al2O3–ZrO2(Y2O3)-glass powders. J. Eur. Ceram. Soc. 2005, 25, 1359–1364. [Google Scholar] [CrossRef]

- Waku, Y.; Nakagawa, N.; Wakamoto, T. A ductile ceramic eutectic composite with high strength at 1873 K. Nature 1997, 389, 49–52. [Google Scholar] [CrossRef]

- Fu, L.; Fu, X.; Chen, G.; Han, W.; Zhou, W. Tailoring the morphology in Y2O3 doped melt–grown Al2O3/ZrO2 eutectic ceramic. Scr. Mater. 2017, 129, 20–24. [Google Scholar] [CrossRef]

- Claussen, N.; Lindemann, G.; Petzow, G. Rapid solidification in the Al2O3–ZrO2 system. Ceram. Int. 1983, 9, 83. [Google Scholar] [CrossRef]

- Freim, J.; McKittrick, J. Modeling and fabrication of fine-grain alumina-zirconia composites produced from nanocrystalline precursors. J. Am. Ceram. Soc. 1998, 81, 1773–1780. [Google Scholar] [CrossRef]

- Mah, T.I.; Parthasarathy, T.A.; Kerans, R.J. Processing, microstructure, and strength of alumina–YAG Eutectic Polycrystals. J. Am. Ceram. Soc. 2000, 83, 2088–2090. [Google Scholar] [CrossRef]

- Liu, D.; Gao, Y.; Liu, J.; Liu, F.; Li, K.; Su, H.; Wang, Y.; An, L. Preparation of Al2O3–Y3Al5O12–ZrO2 eutectic ceramic by flash sintering. Scr. Mater. 2016, 114, 108–111. [Google Scholar] [CrossRef]

- Humphry-Baker, S.A.; Vandeperre, L.J.M. Creep deformation of WC hardmetals with Fe-based binders. Int. J. Refract. Met. Hard Mater. 2021, 95, 105462. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R. Cemented carbide phase diagrams: A review. Int. J. Refract. Met. Hard Mater. 2011, 29, 405–418. [Google Scholar] [CrossRef]

- Biesuz, M.; Grasso, S.; Sglavo, V.M. What’s new in ceramics sintering? A short report on the latest trends and future prospects. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100868. [Google Scholar] [CrossRef]

- Owen, D.M.; Choksh, I.A.H. Final Stage Free Sintering and Sinter Forging Behaviour of a Yttria-Stabilized Tetragonal Zirconia. Acta Mater. 1998, 46, 719–729. [Google Scholar] [CrossRef]

- Venkatachari, K.R.; Raj, R. Enhancement of strength through Sinter-Forging. J. Am. Ceram. Soc. 1987, 70, 514–520. [Google Scholar] [CrossRef]

- Kulkov, S.N.; Buyakova, S.; Gömze, L.A. Zirconia-Based Powders Produced by Plasma-Spray Pyrolisys and Properties of Sintered Ceramics. IOP Conf. Ser. J. Phys. Conf. Series. 2017, 790, 012015. [Google Scholar] [CrossRef]

- Niihara, K.; Morena, R.; Hasselman, D.P.H. Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1982, 1, 13–16. [Google Scholar] [CrossRef]

- Hsieh, C.L.; Tuan, W.H. Elastic Properties of Ceramic-Metal Particulate Composites. Mater. Sci. Eng. A 2005, 393, 133–139. [Google Scholar] [CrossRef]

- Liu, Y.; Erdemir, A.; Meletis, E.I. A study of the wear mechanism of diamond like carbon films. Surf. Coating. Technol. 1996, 82, 48–56. [Google Scholar] [CrossRef]

- Tai, W.-P.; Watanabe, T. Fabrication and Mechanical Properties of Al2O3-WC-Co Composites by Vacuum Hot Pressing. J. Am. Ceram. Soc. 1998, 81, 1673–1676. [Google Scholar] [CrossRef]

- Huang, S.; Vanmeensel, K.; Van Der Biest, O.; Vleugels, J. Sintering, thermal stability and mechanical properties of ZrO2-WC composites obtained by pulsed electric current sintering. Front. Mater. Sci. 2011, 5, 50–56. [Google Scholar] [CrossRef]

- Gren, M.; Wahnström, G. Wetting of surfaces and grain boundaries in cemented carbides and the effect from local chemistry. Materialia 2019, 8, 100470. [Google Scholar] [CrossRef]

- Ueki, M.; Naka, M.; Okamoto, I. Wettability of Some Metals Against Zirconia Ceramics. J. Mater. Sci. Lett. 1986, 5, 1261–1262. [Google Scholar] [CrossRef]

- Xuan, C.; Shibata, H.; Sukenaga, S.; Jönsson, P.G.; Nakajima, K. Wettability of Al2O3, MgO and Ti2O3 by liquid iron and steel. ISIJ Int. 2015, 55, 1882–1890. [Google Scholar] [CrossRef] [Green Version]

- Ravikiran, A. Wear quantification. J. Tribol. 2000, 122, 650–656. [Google Scholar] [CrossRef]

- Basu, S.N.; Sarin, V.K. Oxidation behavior of WC-Co. Mater. Sci. Eng. A 1996, 209, 206–212. [Google Scholar] [CrossRef]

- Yang, G.; Liu, X.; Sun, X.; Liang, E.; Zhang, W. Synthesis process control of low-thermal-expansion Fe2W3O12 by suppressing the intermediate phase Fe2WO6. Ceram. Int. 2018, 44, 22032–22035. [Google Scholar] [CrossRef]

- Sharma, S.K.; Kumar, B.V.M.; Kim, Y.-W. Tribology of WC reinforced SiC ceramics: Influence of counterbody. Friction 2019, 7, 129–142. [Google Scholar] [CrossRef]

| Composition | WC, Vol.% | Y-TZP-Al2O3, Vol.% | Hadfield Steel Powder, Vol.% |

|---|---|---|---|

| 65 W | 65 | 25 | 10 |

| 45 W | 45 | 45 | 10 |

| 25 W | 25 | 65 | 10 |

| Sliding Speed m/s | Composites | |||||

|---|---|---|---|---|---|---|

| 25 W | 45 W | 65 W | ||||

| Tpyr, °C | Tcalc, °C | Tpyr, °C | Tcalc, °C | Tpyr, °C | Tcalc, °C | |

| 7 | 570 | 1280 | 490 | 966 | 400 | 589 |

| 10 | 550 | 1220 | 500 | 1040 | 380 | 561 |

| 20 | 650 | 1630 | 550 | 1240 | 380 | 561 |

| 37 | 700 | 2110 | 640 | 1280 | 450 | 726 |

| Area | Element, wt.% (at.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | O | Al | V | Cr | Mn | Fe | Zr | W | |

| 1 | 16.7 (48.8) | 5.2 (11.4) | 0.7 (0.9) | 1.8 (1.2) | 0.9 (0.6) | 0.3 (0.2) | 51.6 (32.4) | 0.7 (0.3) | 22.2 (4.2) |

| 2 | 19.2 (54.2) | 4.0 (8.4) | 0.6 (0.8) | 1.6 (1.1) | 0.7 (0.5) | 0.2 (0.1) | 50.4 (30.5) | 0.7 (0.3) | 22.5 (4.1) |

| 3 | 5.3 (17.9) | 9.9 (25.1) | 2.0 (2.9) | 11.5 (9.1) | 6.2 (4.8) | 2.9 (2.2) | 47.5 (34.4) | 1.5 (0.7) | 13.1 (2.9) |

| 4 | 8.1 (24.8) | 12.1 (28.0) | 2.3 (3.1) | 9.4 (6.8) | 4.4 (3.1) | 2.0 (1.3) | 43.7 (28.9) | 1.7 (0.7) | 16.4 (3.3) |

| 5 | 6.5 (19.8) | 12.6 (28.7) | 7.4 (10) | 11.4 (8.1) | 5.1 (3.5) | 2.8 (1.9) | 33.3 (21.7) | 10.4 (4.1) | 10.5 (2.1) |

| 6 | 13.4 (45.2) | 1.4 (3.6) | 0.3 (0.5) | 1.9 (1.5) | 1.1 (0.9) | 1.4 (1.0) | 54.4 (39.4) | 9.9 (4.4) | 16.2 (3.6) |

| 7 | 13.5 (46.4) | 2.0 (5.2) | 0.4 (0.6) | 1.5 (1.2) | 1.0 (0.8) | 0.4 (0.3) | 49.8 (36.8) | 7.5 (3.4) | 24.0 (5.4) |

| 8 | 11.2 (39.8) | 2.4 (6.3) | 0.4 (0.6) | 1.3 (1.1) | 1.0 (0.8) | 0.8 (0.6) | 55.6 (42.5) | 7.6 (3.6) | 19.8 (4.6) |

| 9 | 12.2 (61.0) | 0.5 (1.8) | 0.6 (1.4) | 0.6 (0.7) | 0.5 (0.6) | 0.6 (0.6) | 1.8 (2.0) | 14.3 (9.4) | 68.8 (22.5) |

| 10 | 11.2 (38.1) | 11.5 (29.2) | 0.6 (1.0) | 0.2 (0.2) | 0.2 (0.2) | 0.4 (0.3) | 1.0 (0.7) | 60.8 (27.2) | 14.1 (3.1) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savchenko, N.; Sevostyanova, I.; Grigoriev, M.; Sablina, T.; Buyakov, A.; Rudmin, M.; Vorontsov, A.; Moskvichev, E.; Rubtsov, V.; Tarasov, S. Self-Lubricating Effect of WC/Y–TZP–Al2O3 Hybrid Ceramic–Matrix Composites with Dispersed Hadfield Steel Particles during High-Speed Sliding against an HSS Disk. Lubricants 2022, 10, 140. https://doi.org/10.3390/lubricants10070140

Savchenko N, Sevostyanova I, Grigoriev M, Sablina T, Buyakov A, Rudmin M, Vorontsov A, Moskvichev E, Rubtsov V, Tarasov S. Self-Lubricating Effect of WC/Y–TZP–Al2O3 Hybrid Ceramic–Matrix Composites with Dispersed Hadfield Steel Particles during High-Speed Sliding against an HSS Disk. Lubricants. 2022; 10(7):140. https://doi.org/10.3390/lubricants10070140

Chicago/Turabian StyleSavchenko, Nickolai, Irina Sevostyanova, Mikhail Grigoriev, Tatiana Sablina, Ales Buyakov, Maxim Rudmin, Andrey Vorontsov, Evgeny Moskvichev, Valery Rubtsov, and Sergei Tarasov. 2022. "Self-Lubricating Effect of WC/Y–TZP–Al2O3 Hybrid Ceramic–Matrix Composites with Dispersed Hadfield Steel Particles during High-Speed Sliding against an HSS Disk" Lubricants 10, no. 7: 140. https://doi.org/10.3390/lubricants10070140

APA StyleSavchenko, N., Sevostyanova, I., Grigoriev, M., Sablina, T., Buyakov, A., Rudmin, M., Vorontsov, A., Moskvichev, E., Rubtsov, V., & Tarasov, S. (2022). Self-Lubricating Effect of WC/Y–TZP–Al2O3 Hybrid Ceramic–Matrix Composites with Dispersed Hadfield Steel Particles during High-Speed Sliding against an HSS Disk. Lubricants, 10(7), 140. https://doi.org/10.3390/lubricants10070140