1. Introduction

Understanding the machining interface’s tribological behavior is crucial for modeling material removal processes using a defined geometry tool. To date, no model adequately describes the friction in the cutting areas [

1]. Therefore, advances in understanding the contact conditions, the plastic deformation behavior, and the cutting temperatures describe this chaotic tribosystem [

2,

3]. Among the various factors that affect the friction coefficient at the cutting interface, the type of work and tool materials, tool geometry, tool wear, and lubricating conditions can be highlighted. These factors are responsible for changes in the machining forces and heat generated in the cutting zones, and as such, they continuously change the tribosystem’s behavior [

4].

Tribological tests can help simulate the machining tribosystem, thus helping understand the friction coefficient behavior and tool wear [

5,

6]. Through these methods, it is possible to investigate the relationship of different types of coatings with the workpiece materials, load capacity of the tribo-films formed with fluids, or even a combination of coating, tribo-films, and geometry when using a real cutting tool as counterbody [

7]. However, conventional tribometers can reproduce the friction coefficient at the cutting interface but with reservations because of the low relative velocities, contact pressures, and temperatures between the workpiece and the counterbody compared to the machining conditions [

8,

9], resulting in poor quantitative predictions [

3]. Furthermore, there are no accurate predictive models that generally predict the coefficient of friction at the workpiece-tool interface, disregarding the shear effect of material inherent to the machining process. This difficulty is demonstrated by the fact that the Coulomb friction model [

10] and models derived from the Merchant diagram [

4,

11] are still widely used in simulations, even though efforts to create more complex models considering the mechanical and adhesive effects of friction are already increasingly common [

12,

13].

One alternative for better simulation is to adapt machine centers as open tribometers [

3,

14]. This type of tribometer is often presented as an alternative to a more detailed investigation of the tribological aspects of machining [

15], thus allowing for the use of test parameters closer to those used in actual machining conditions [

2,

16,

17].

Salur et al. [

18] compared MQL and dry machining in the AISI 1040 carbon steel milling process. The authors reported that the MQL outperformed dry cutting regarding cutting temperature (37%), power consumption (94%), and tool wear (74%). Sen et al. [

19] studied mixtures of castor-palm oil (1:0.5–1:3) applied using the MQL delivery system in hard milling. The authors reported that the mixture with a 1:2 proportion resulted in lower surface roughness (8.262 and 16.146%), specific cutting energy (5.459% and 7.971%), and tool wear (2.445% and 3.155%). Mia et al. [

20] compared dry, MQL, and solid lubricants applied with compressed air as machining environments in the hardened AISI 1060 steel turning process. According to the Pugh matrix environmental approach, the authors reported that the MQL system is the most environmentally friendly among the evaluated conditions.

Cutting fluid is typically used to reduce friction and heat generation during machining. The lubricating efficiency depends on the fluids’ ability to penetrate and form a lubricant film at the workpiece–tool–chip contact regions to reduce friction and decrease material adhesion on the tool [

21,

22]. In the case of fluids with lubricating nanoparticles, the particles cause different tribological effects between the two surfaces: they can highlight the effect of rolling, film formation, filling, and polishing [

23,

24]. The nanoparticles act as spacers between the tribological pairs, cause the scrolling effect, fill the surface gaps, and shear at high machining pressures, promoting the filling of cavities and cutting the peaks existing on the surface during machining; consequently, this process promotes polishing of the workpiece [

24]. Tribofilm formation reduces friction between contact surfaces, reducing heat generation and wear [

25]. In addition, increasing the nanofluid concentration and the degree of chemical interaction between the particles and the newly formed surface increases the protective film between the tribological pairs; therefore, the surface quality is increased, and the COF is reduced [

26].

The literature is scarce regarding the tribological effects of graphene sheets in the cutting fluid on the machining process [

27]. However, graphene presents excellent mechanical properties because of the atoms’ covalent bonds [

28] and can act as an extreme pressure self-lubricating system that justifies its tribological application [

29]. Furthermore, graphene increases the cutting fluids’ wettability [

30] and reduces the machining temperature regardless of the fluid flow applied [

31]. Past studies indicate that the use of graphene combined with other particles, such as aluminum oxide (Al

2O

3) [

32] and silver (Ag) [

33], can further enhance their tribological behavior in the machining process.

Abbas et al. [

34] studied the effects of nanofluid MQL in the turning process of the AISI 1045 steel regarding the surface roughness and power consumption. The authors compared the results with dry and flood cooling and reported that the nanofluid MQL presented the highest sustainability index of all tested machining atmospheres. Dubey et al. [

35] studied different multicriteria decision-making approaches to optimize the turning process of AISI 304 steel using nano MQL (alumina-graphene) as a machining environment. The authors reported that the use of the nano MQL reduced the cutting forces (13%), surface roughness (31%), and machining temperature (14%) when compared to the nano MQL with only alumina particles. Çamlı et al. [

36] compared MQL and Nano-MQL lubrication in the machining process of high-strength steel destined to train wheel manufacturing. The authors reported that MQL and nano MQL reduced surface roughness (24% and 34%) and tool wear (34.1% and 37.6%) compared to dry machining.

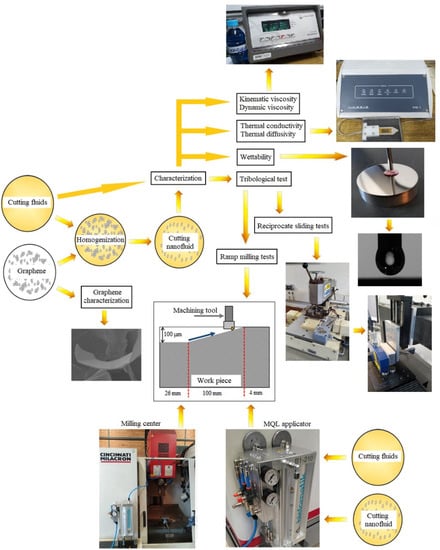

This work investigates the influence on thermophysical and tribological properties of concentrations of 0.05 wt% and 0.1 wt% of graphene sheets in one mineral-based and two vegetable-based cutting fluids.

2. Materials and Methods

This section specifies the steel, graphene sheets, cutting fluids, equipment, and tools used in the experiments.

2.1. Workpiece Materials

In this study, AISI 1045 steel was used as the workpiece material, having the conventional microstructure composed predominantly of coarse perlite grains and ferrite, according to

Figure 1. According to the ASTM E8/E8M [

37] standard, the material was characterized by its stress-strain behavior resulting in an average ultimate tensile strength of 869 MPa and 13.60% strain, and its hardness, according to (ASTM E92-17 [

38] standard, resulting in an average hardness of 262 ± 11.35 HV1.

2.2. Cutting Fluids

Three different cutting fluids were evaluated, two of which are manufactured by SpecialMix Industrial Ltd.a, Pinhais, Paraná, (MQL14 and MQL15) and manufactured by ITW Chemical Products Ltd.a, Embu das Artes, Brazil, (LB1000). MQL15 and LB1000 are vegetable-based, and the MQL 14 is mineral-based, with the main characteristics of the fluids summarized in

Table 1. The three oils were tested pure and with graphene additions in two concentrations, 0.05 wt% and 0.1 wt%. These concentrations were selected based on a literature review [

39,

40,

41]. For the homogenization of graphene sheets in the oil samples, initially, they were manually stirred up for 10 min and then sonicated for 60 min. Volumetric concentrations and synthesis processes were the same for all fluids. In this case, there was no chemical treatment or addition of surfactant in the mixtures for the dispersion of graphene to avoid any interference chemical effects that these elements may have on the properties of nanofluids.

The graphene used in the research was produced at the Federal University of Triângulo Mineiro, Uberaba, Brazil, through the exfoliation of graphite supplied by Nacional de Grafite LTDA, Itapecerica-MG, Brazil (with flakes from 1 to 20 µm in length and 1 to 30 nm in width) as described by [

45].

An image of the graphene sheets taken within the scanning electron microscope (SEM) model TESCAN VEGA3 LMU is shown in

Figure 2. Graphene’s morphology resembles a folded sheet composed of multilayers and irregular edges due to mechanical exfoliation [

46]. These edge defects originate from breaking carbon in the planes, causing structural disorder at these points [

47]. A sequence of 10 measurements of the dimensions of the layers of graphene atoms was made, indicating an average thickness of 36.83 ± 3.22 nm after mixing with the cutting oils.

Graphene sheets were also analyzed using a transmission electron microscope (TEM) JEOL JEM 1200EX-II (TEM).

Figure 3a presents an image of a graphene particle with multiple layers (or sheets) identified by electron diffraction (

Figure 3b), where the external hexagonal (arrangement of the carbon atoms) has an intensity equal to or greater than the internal hexagonal. These results are consistent with the studies [

48,

49,

50,

51] and prove that the graphene particles added to the fluids are composed of mono and multilayers.

The dynamic and kinematic viscosities and the specific mass are essential for evaluating and monitoring the cutting oils. These parameters were measured on an Anton Paar viscometer, model SVMTM 3000. The experiments were carried out at a controlled temperature of 40 °C. The viscometer is accurate to the range described in ASTM D445-18 [

52], and the measurement method was according to ASTM D2270-10 [

53].

The tests for measuring specific heat, diffusivity, and thermal conductivity were performed on the Transient Hot Bridge equipment, model Linseis, with a measurement range for specific heat from 100 to 5000 kJ/(m3K), diffusivity from 0.05 to 10 mm2/s, and thermal conductivity from 0.01 to 1 W/(mK). The experiments were carried out at a controlled temperature of 40 °C, where 2.5 mL of cutting oil was deposited on the equipment, using 5 mL sterile syringes. Oils with graphene mixtures were homogenized before testing.

The wettability represents the contact conditions between a solid surface and a liquid through cohesion and adhesion forces, forming a contact angle, where the lower the angle, the greater the wettability of the liquid [

54]. With the wettability test, the characteristic adhesion and spreading of the fluids on a solid surface with low surface roughness are measured. For the wettability tests, the Krüss easy drop goniometer was used. The test consisted of depositing a drop of 10 μL of cutting oil on an AISI 1045 steel sample with average surface roughness less than 0.050 μm, with the dynamic angle measurement being carried out at intervals of 0.2 s at a controlled temperature of 23 °C.

2.3. Progressive Load Reciprocate Sliding Tests

The evaluation of the friction coefficient (COF) and electrical contact potential (POT) of the tribological pair (6 mm carbide ball and flat surface in AISI 1045 steel with an average roughness of 0.050 μm) was carried out using progressive load reciprocate sliding tests at a frequency of 2 Hz, amplitude of 10 mm, and incremental loading of 6.867 N at 10-min intervals. A droplet of 0.5 µL was placed in the contact region between the substrate at every load increase. The workpiece surface had an average roughness of less than 0.050 µm, and a carbide sphere of 5 mm in diameter was used as a counterbody. The tests were completed 5 min after the lubricant film broke, so the test time and applied load varied for each condition.

The tests were developed according to the standard method for linearly reciprocating ball-on-flat sliding wear [

55]. A Universal Plint

® Tribometer model TE67 was used, manufactured by Plint & Partners LTD (

Figure 4). This equipment has a load cell similar to that described in reference [

56] for monitoring tangential and normal forces. A linear variable differential transformer (LVDT) sensor, model RS 646-511, was used to measure the position of the counterbody during the tests. The LVDT and load cell data were collected at an acquisition rate of 4 kHz. To ensure reliability, three repetitions were performed for all tests. The wear tracks were analyzed by scanning electron microscopy using secondary electrons (SEM-SE) and laser interferometry scanning (

Figure 4c).

2.4. Milling Experiments

The results obtained from the tribological tests were compared with the ramp milling test results. A CNC machining center was used in these tests manufactured by Cincinnati Milacron, model Arrow 500, with 5.5 kW of power and a maximum rotation speed of 6000 rpm. This machining center was adapted as an open tribometer and equipped with a table dynamometer manufactured by Kistler Instruments AG, model 9272, to measure machining forces in ramp milling, as shown in

Figure 5a.

The machining conditions used in the test are summarized in

Table 2. TiAlN coated cemented carbide inserts with AOMT123608PEER-M VP15TF specifications from Mitsubishi Materials manufacturer (

Figure 5c) were used as counter bodies. These inserts have a cutting edge length of 12 mm, a cutting radius of 0.8 mm, and a rake angle of 11°. These tools feature M-type chip breaker geometry and are intended for machining carbon steels in general (Class P), with recommended cutting speed from 110 to 200 m/min, cutting depth of up to 4 mm, and feed per tooth of 0.15 mm/tooth, when using an ae greater than 75% of the diameter of the tool holder shank. The inserts were attached to a 25 mm diameter tool holder, with a 90° approach angle, with an ISO 13,399 designation or Mitsubishi Materials description APX3000R253SA25SA (

Figure 5c). The tool holder had a capacity for three inserts; however, only one was used during the tests, a common practice in experimental comparisons, which does not compromise the final results [

57], as all experiments were carried out under these conditions.

In

Figure 5a, the positioning of the two nozzles of the MQL spray system is illustrated, one on the entrance of the tool in the workpiece and the other at 90° from the first. The two nozzles are approximately 15 mm apart from the cutting edge. To simulate the progressive load reduction in the milling trials, a path on a flat surface for 26 mm with a depth of 100 µm was used to ramp for an additional 100 mm to zero depth, as illustrated in

Figure 5b [

14]. The workpiece surface was planned before each ramp milling to guarantee the same initial conditions for each test.

Ethanol was used to clean the workpiece before each test and the fluid delivery system when changing lubricants to avoid contamination. Three repetitions were performed for each cutting condition to guarantee the test results’ reliability, with the tool being changed at the end of the repetitions for any indication of wear.

Table 2 shows the general conditions of the test, which were planned with factorial planning.

The surface roughness was measured with a portable Time Group Inc profiler, model TR220, with a resolution of 0.01 µm. In addition, the absolute average roughness parameter (R

a) was measured according to NBR ISO 4288-2008 [

58] guidelines on the ramp surfaces. Four measurements were also performed on the initial 26 mm of the workpiece, where the tool traveled horizontally (

Figure 5b). Variance (ANOVA) and Tukey test were analyzed to compare the differences between fluids and graphene concentrations for all data.