Manufacturing of Aluminum Alloy Parts from Recycled Feedstock by PIG Die-Casting and Hot Stamping

Abstract

:1. Introduction

2. Materials and Methods

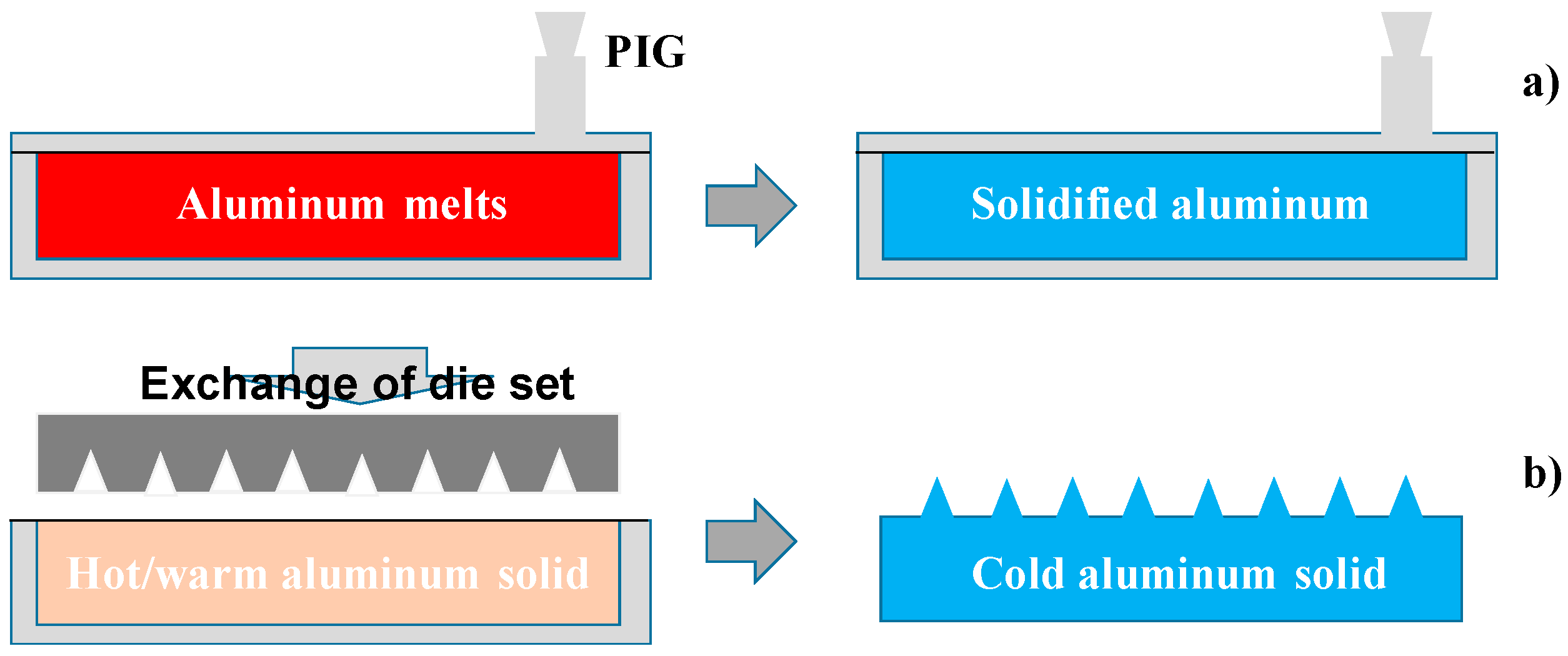

2.1. New Aluminum Manufacturing System by PIG Die-Casting and Hot Stamping

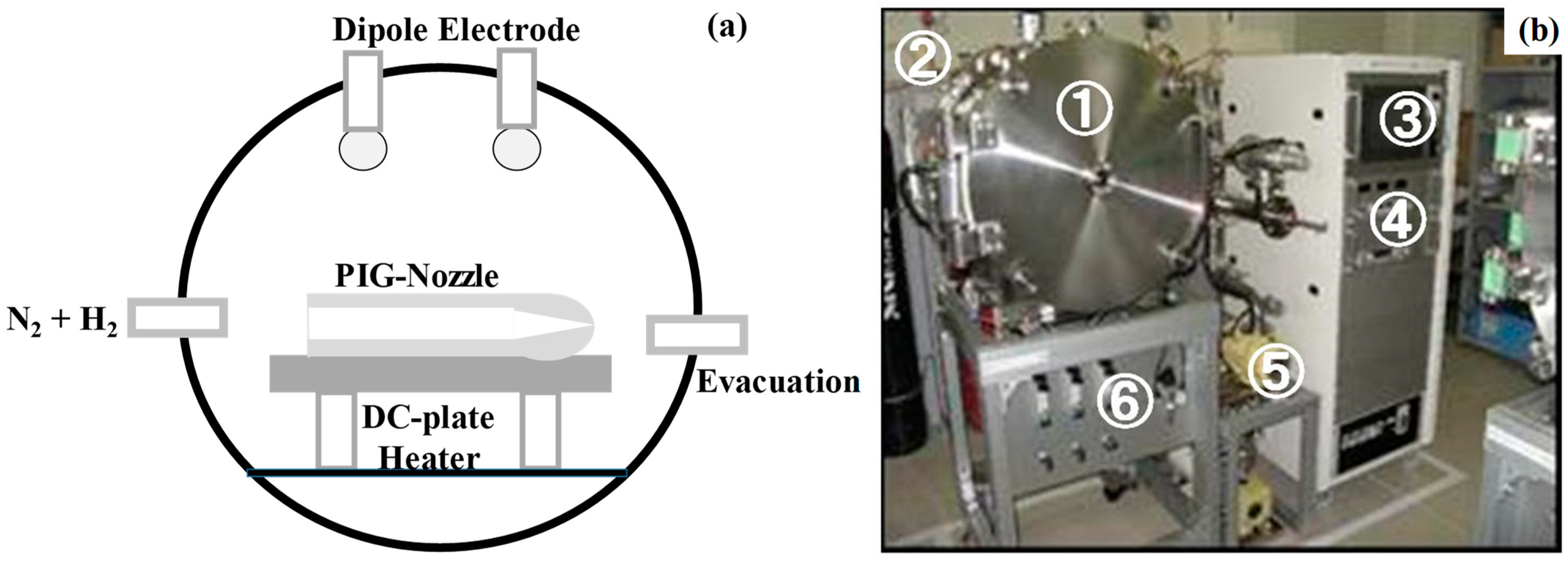

2.2. Tribological Treatment for PIG-Nozzles and Dies

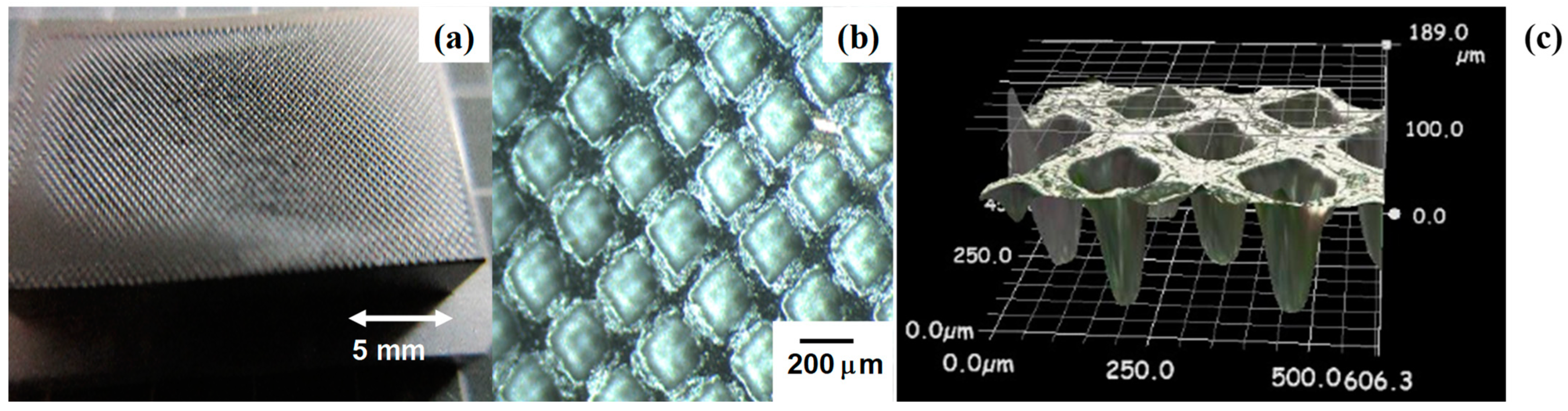

2.3. Warm and Hot Stamping Die for Microtexturing

2.4. Work Materials

2.5. Measurement and Characterization

3. Results

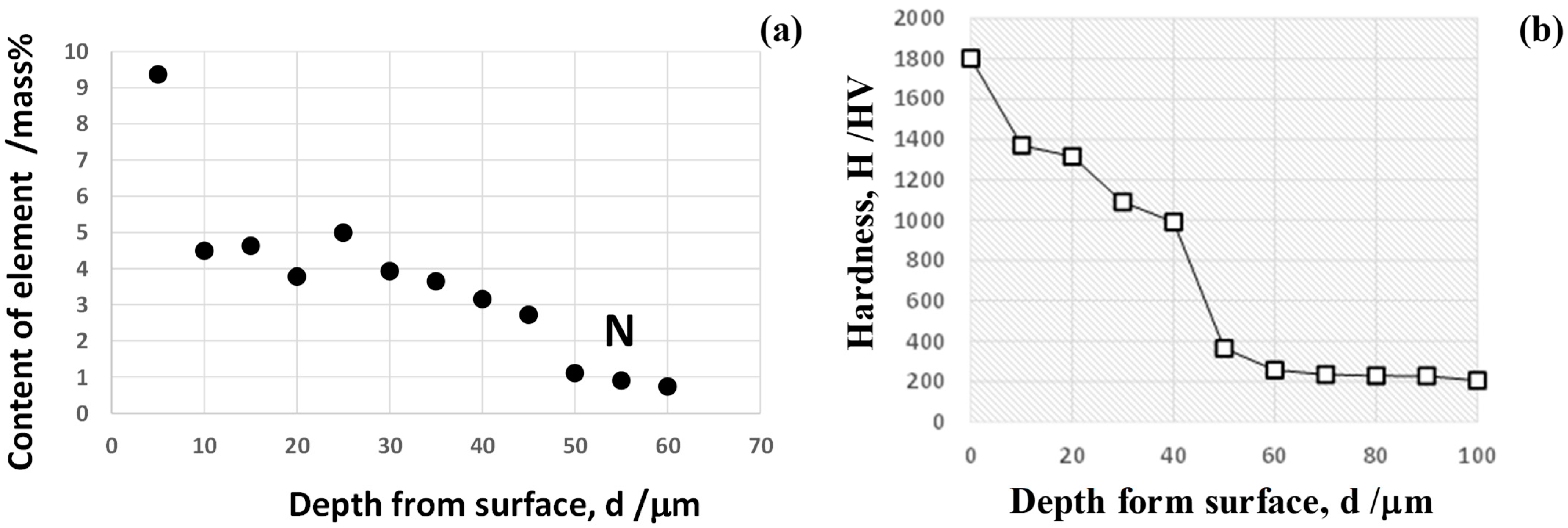

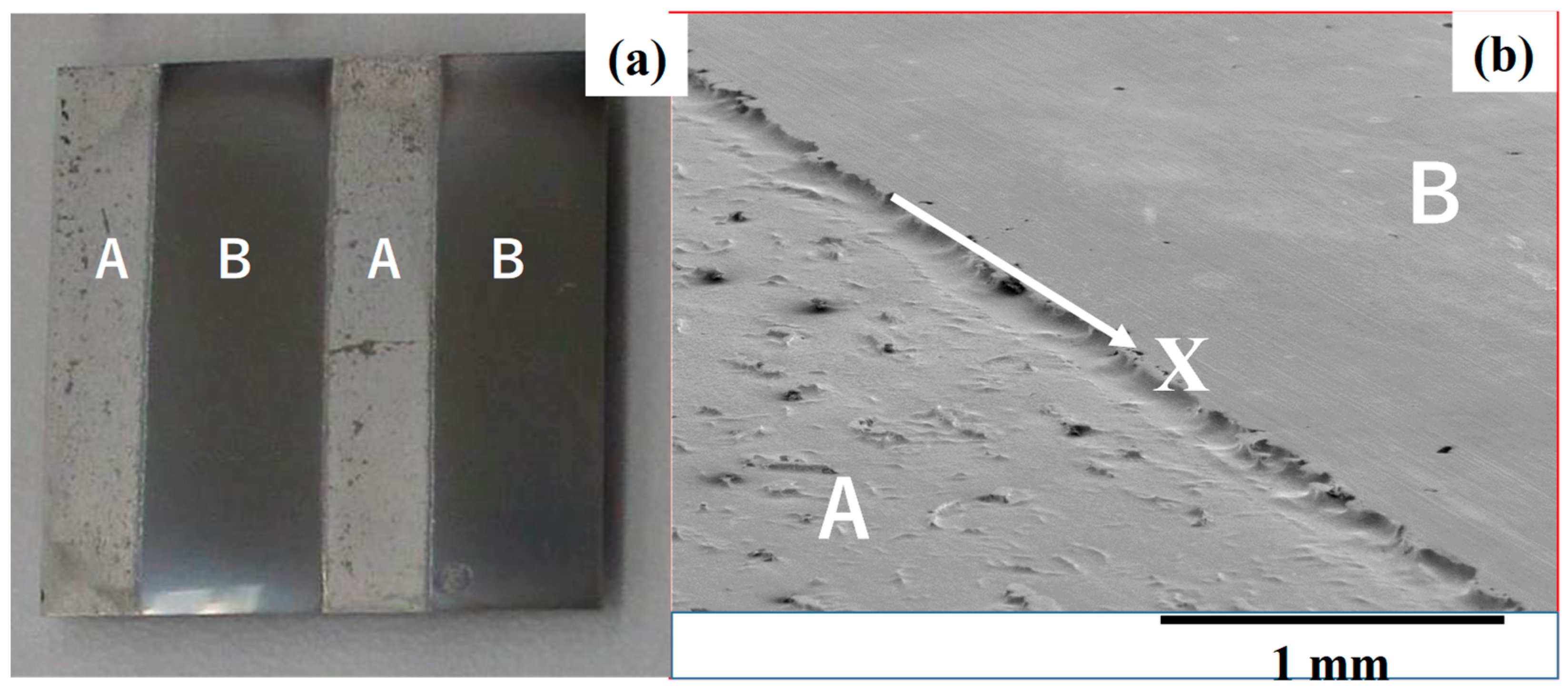

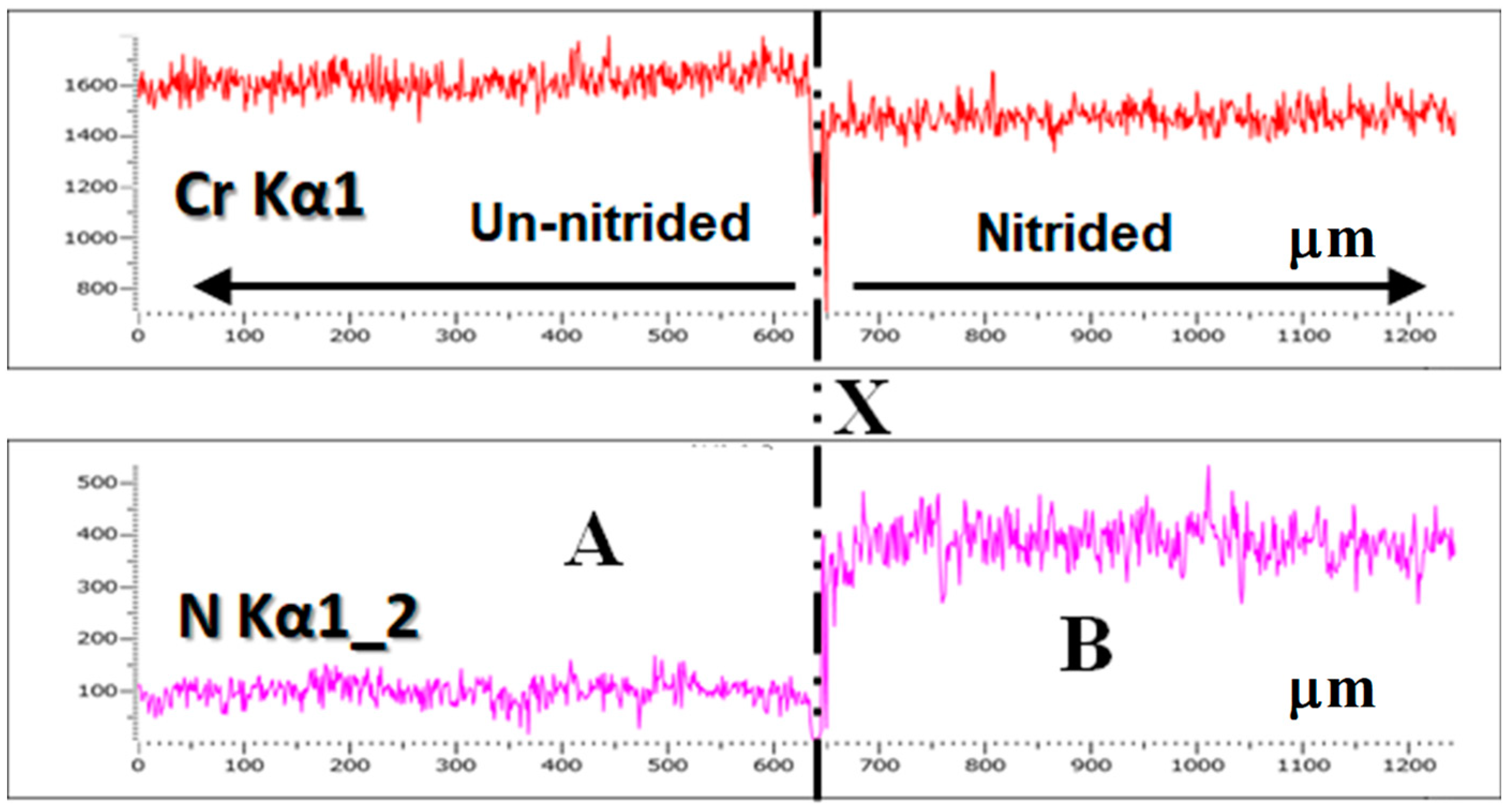

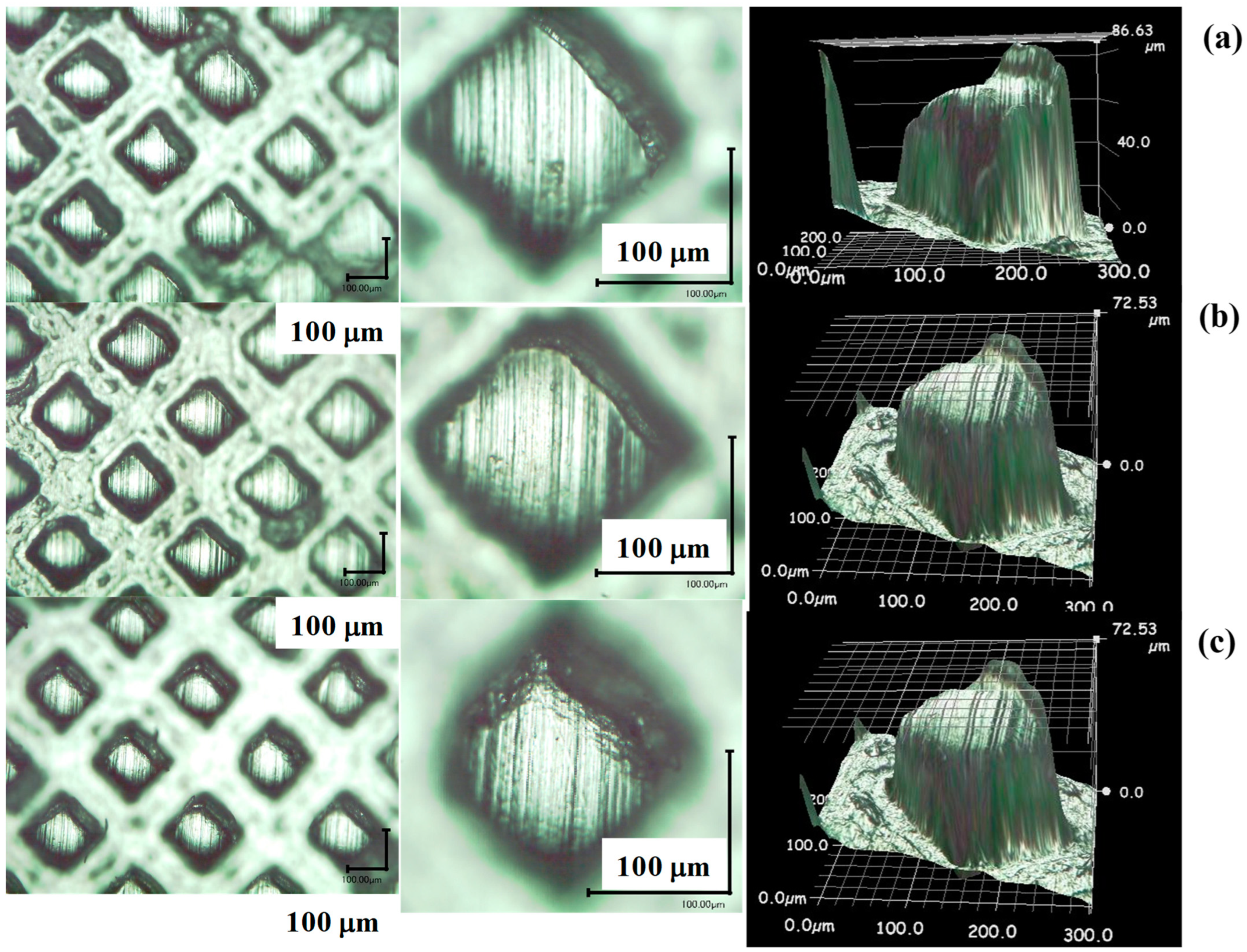

3.1. Tribological Characterization of Nitrided AISI420J2

3.2. Free Injection Behavior through a Single PIG-Nozzle Unit

3.3. Aluminum Flow into a Die Cavity

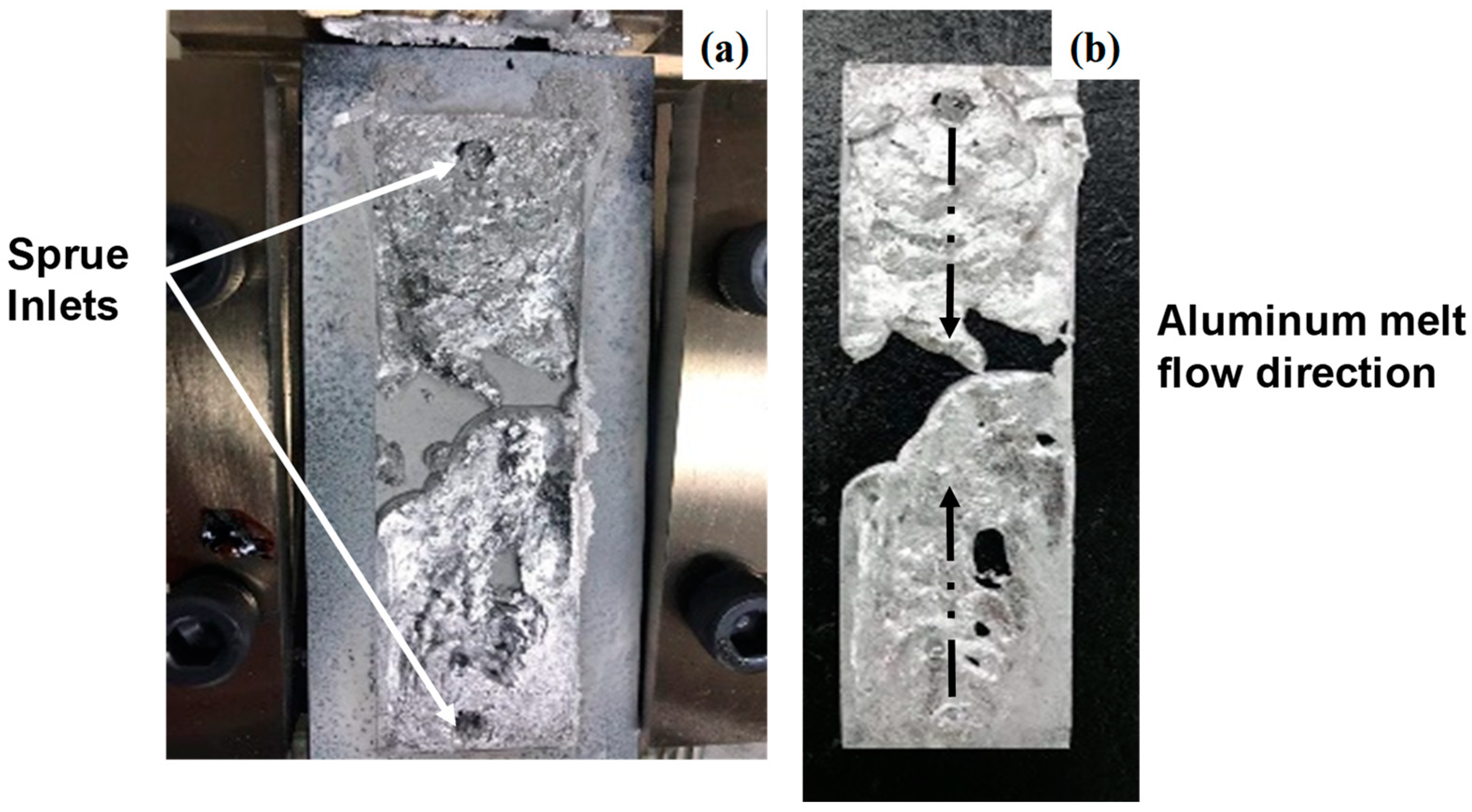

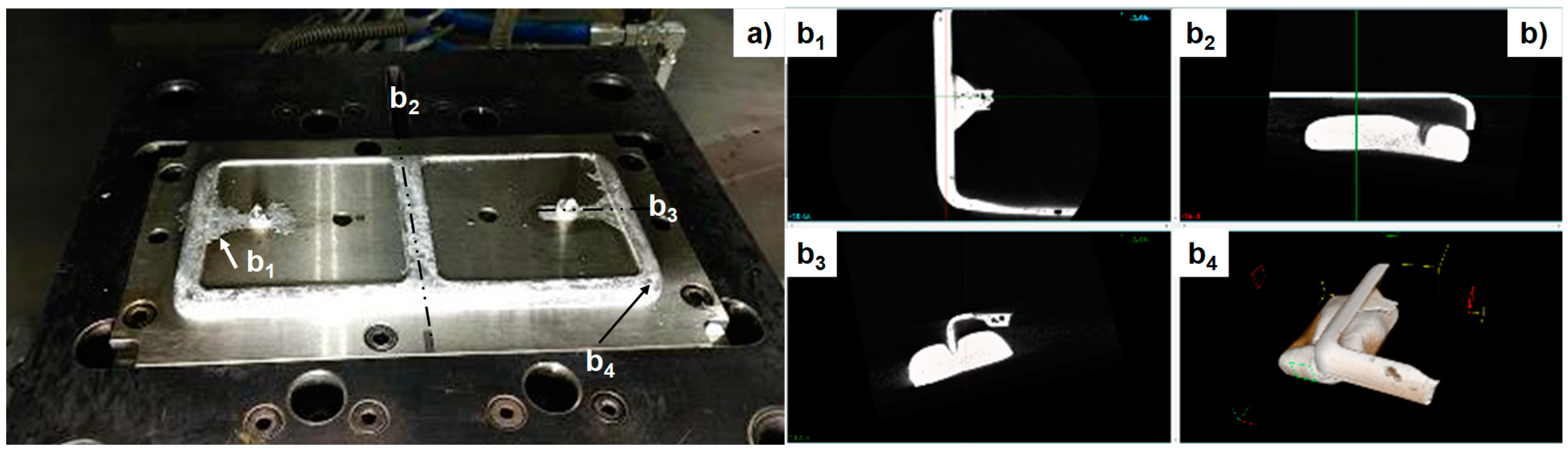

3.4. PIG Die-Casting of AA5052 Small Parts by Using a Single PIG-Nozzle Unit

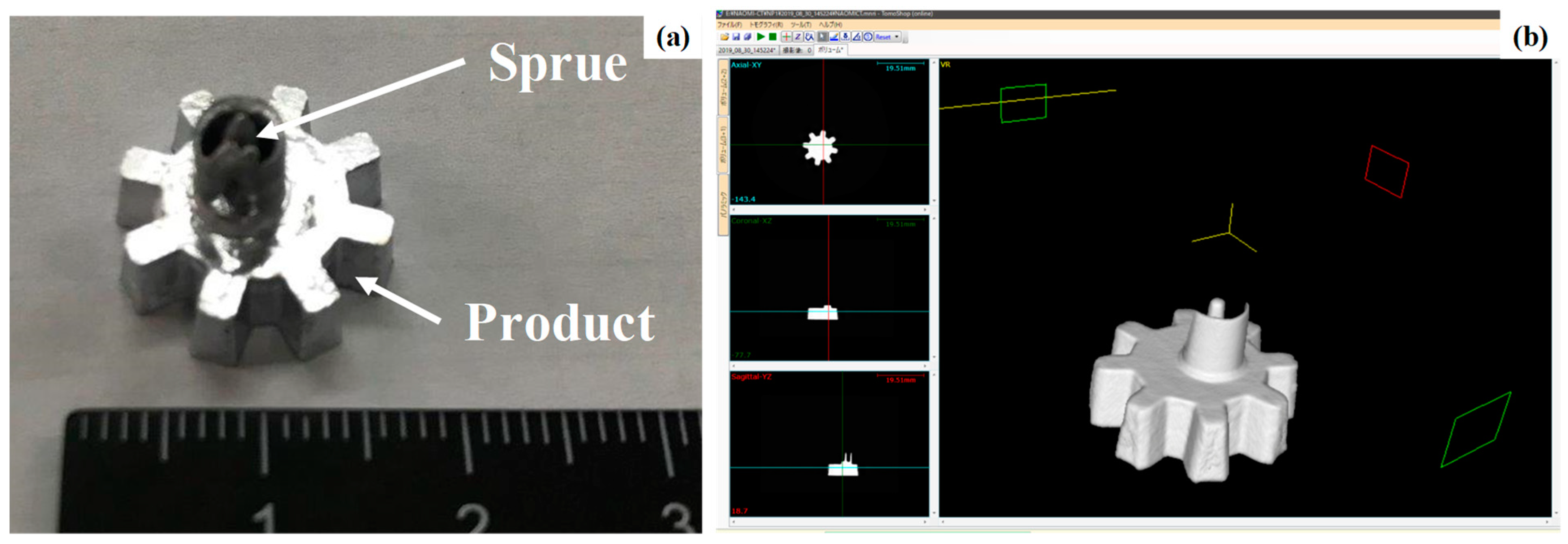

3.5. PIG Die-Casting of Aluminum Mobile Phone Case Using a Double PIG-Nozzle Unit

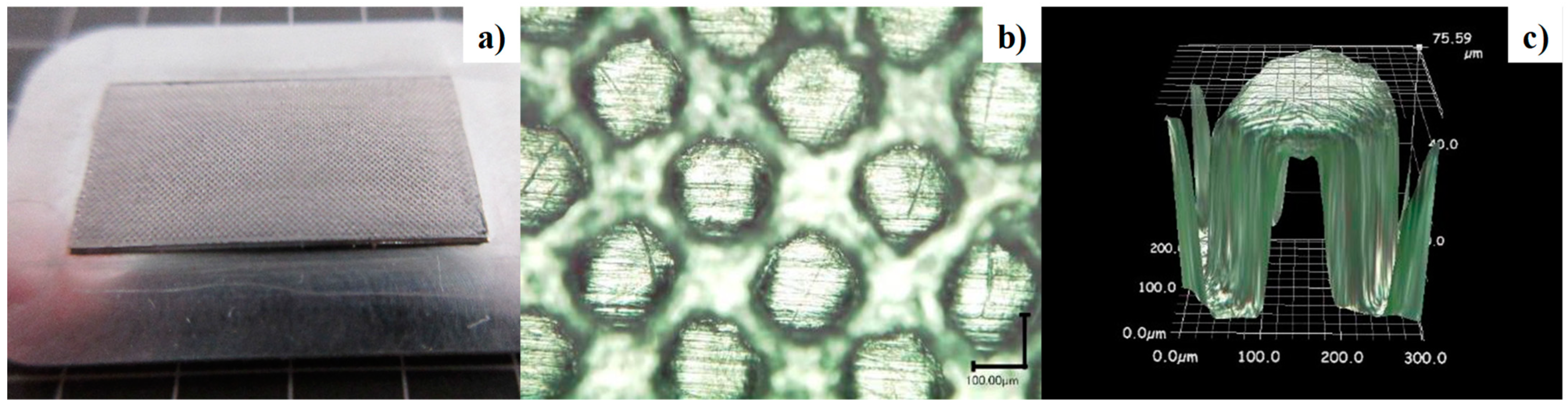

3.6. Warm and Hot Stamping of PIG Die-Cast Preform to Micro-Pillared Heatsink

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edwards, N. With green aluminum flowing, manufactures struggle to make product ESG top priority. Forbes, 22 July 2020. [Google Scholar]

- Aizawa, T.; Luangvaranunt, T.; Kondoh, K. Solid state recycling from green wastes to aluminum alloys with high material efficiency. J. JIM 2001, 65, 581–588. [Google Scholar]

- Jeong, M.-S.; Lee, S.-Y.; Lee, I.-K.; Lee, S.-K.; Kim, D.; Cho, Y.-J.; Ko, D.-C. Green alternative aluminum extrusion process through process convergence. Int. J. Prec. Eng. Manuf. 2014, 15, 1173–1177. [Google Scholar] [CrossRef]

- Hartlieb, M.; Anderson, K. Die casting. 2A. In Aluminum Science and Technology; ASM International: Almere, The Netherlands, 2018. [Google Scholar]

- Aizawa, T.; Yamaguchi, T.; Sakayori, H. JP-Patent 2019 with P19HS-001, 31 December 2019.

- Aizawa, T.; Yamaguchi, T.; Sakayori, H. Die Casting System and Manufacturing Procedure of Die Cast Products. JP-Patent 2021 with P21SL-001, 31 December 2021. [Google Scholar]

- Aizawa, T.; Yamaguchi, T.; Sakayori, H. Metal Forming System and Production Procedure. JP-Patent 2021 with P21SL-002, 31 December 2021. [Google Scholar]

- Aizawa, T.; Kurihara, T.; Yamaguchi, T.; Sakayori, H. Near-net shaping of aluminum alloy parts by pin-injection-gate die-casting. In Proceedings of the 13th AWMFT, Shanghai, China, 6 December 2021; pp. 253–262. [Google Scholar]

- Funazuka, T.; Dohda, K.; Takatsuji, N.; Hu, C.; Ngernbamrung, S. Effect of die coating on surface crack depth of hot extruded 7075 aluminum alloy. Friction 2022, 143, 21–32. [Google Scholar] [CrossRef]

- Aizawa, T. Low Temperature Plasma Nitriding of Austenitic Stainless Steels. Chapter 3 in Stainless Steels and Alloys; IntechOpen: London, UK, 2019; pp. 31–50. [Google Scholar]

- Aizawa, T.; Dohda, K.; Shiratori, T. Nano-structured tribo-coating for cold and hot stamping. In Proceedings of the 52nd ICFG Plenay Meeting, San Sebastian, Spain, 16 September 2019; pp. 116–123. [Google Scholar]

- Shiratori, T.; Aizawa, T.; Saito, Y.; Dohda, K. Fabrication of micro-punch array by plasma printing for micro-embossing into copper substrates. Materials 2019, 12, 2640. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shiratori, T.; Aizawa, T.; Saito, Y.; Wasa, K. Plasma printing of an AISI316 micro-meshing punch array for micro-embossing onto copper plates. Metals 2019, 9, 396. [Google Scholar] [CrossRef] [Green Version]

- Borgioli, F.; Galvanetto, E.; Bacco, T. Low temperature nitriding of AISI300 and 200 series austenitic stainless steels. Vacuum 2016, 12, 51–60. [Google Scholar] [CrossRef]

- Domain, C.; Becquart, C.S.; Foct, J. Ab initio study of foreign interstitial atom (C, N) interactions with intrinsic point defects in α-Fe. Phys. Rev. B 2004, 69, 144122. [Google Scholar] [CrossRef]

- ECO, Aluminum Die Casting. Available online: https://www.ecodiecasting.com/aluminum-die-casting/ (accessed on 3 June 2022).

- Xie, Z.; Jiao, J.; Yang, K. Theoretical and experimental study on the fluid-structure—Acoustic coupling dynamics of a new water lubricated bearing. Tribol. Int. 2023, 177, 107982. [Google Scholar] [CrossRef]

- Cleary, P.W.; Ha, J.; Prkash, M.; Nguyen, T. Short shots and industrial case studies: Understanding fluid flow and solidification in high pressure die casting. Appl. Math. Model. 2010, 34, 2018–2033. [Google Scholar] [CrossRef] [Green Version]

- Seow, L.W.; Lm, Y.C. Optimizing flow in plastic injection molding. J. Mater. Process. Technol. 1997, 72, 333–341. [Google Scholar] [CrossRef]

- JST, Aluminum Alloy Gear. Available online: http://www.precise-gear.com/aluminum-alloy-gear.html (accessed on 3 June 2022).

- Gangopadhyay, S.; Acharya, R.; Chattopadhyay, A.K.; Sargade, V.G. Effect of cutting speed and surface chemistry of cutting tools on the formation of bul or bue and surface quality of the generated surface in dry turning of AA6005 aluminum alloy. Mach. Sci. Technol. 2010, 14, 208–223. [Google Scholar] [CrossRef]

- Maeno, T.; Mori, K.-I.; Yachi, R. Hot stamping of high-strength aluminum alloy aircraft parts using quick heating. CIRP Ann. 2017, 66, 269–272. [Google Scholar] [CrossRef]

- Kumaraguruparan, G.; Sornakumar, T. Development of testing of aluminum micro channel heat sink. J. Therm. Sci. 2010, 19, 245–252. [Google Scholar] [CrossRef]

- Gong, M.F.; Li, Z.; Dong, J. Mechanics analysis of reinforcing rib structure in aluminum heating-plate automatic casting system. Adv. Mater. Res. 2012, 538–541, 1755–1761. [Google Scholar] [CrossRef]

- Ohashi, T.; Tabetabei, H.M.; Nishimura, T. Rib-structure on A5083 aluminum alloy sheet generated friction stir forming. Preced. Eng. 2017, 207, 1153–1158. [Google Scholar] [CrossRef]

- Ma, Z.; Ji, H.; Huang, X.; Xiao, W.; Tang, X. Research on high temperature stamping forming performance and process parameters optimization of 7075 aluminum alloy. Materials 2021, 14, 5435. [Google Scholar] [CrossRef]

- Chemical Resistance Reference Chart. Available online: https://www.calpaclab.com/content/chemical-charts/Aluminum.pdf (accessed on 6 November 2022).

- Kumar, S.; Maity, S.R.; Patnaik, L. Friction and tribological behavior of bare nitrided, TiAlN and AlCrN coated MDC-K hot work tool steel. Ceram. Int. 2020, 46, 17280–17294. [Google Scholar] [CrossRef]

- Tollmann, W.; Grisales, D.; Stangier, D.; Butzke, T. Tribomechanical behavior of TiAlN and CrAlN coatings deposited onto AISI H11 with different pre-treatments. Coatings 2019, 9, 519. [Google Scholar] [CrossRef]

- Dohda, K.; Aizawa, T.; Funazuka, T. Process tribology of PVD nitride coated dies in hot metal forming. Friction, 2022; in press. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aizawa, T.; Kurihara, T.; Sakayori, H. Manufacturing of Aluminum Alloy Parts from Recycled Feedstock by PIG Die-Casting and Hot Stamping. Lubricants 2023, 11, 13. https://doi.org/10.3390/lubricants11010013

Aizawa T, Kurihara T, Sakayori H. Manufacturing of Aluminum Alloy Parts from Recycled Feedstock by PIG Die-Casting and Hot Stamping. Lubricants. 2023; 11(1):13. https://doi.org/10.3390/lubricants11010013

Chicago/Turabian StyleAizawa, Tatsuhiko, Takeshi Kurihara, and Hiroki Sakayori. 2023. "Manufacturing of Aluminum Alloy Parts from Recycled Feedstock by PIG Die-Casting and Hot Stamping" Lubricants 11, no. 1: 13. https://doi.org/10.3390/lubricants11010013

APA StyleAizawa, T., Kurihara, T., & Sakayori, H. (2023). Manufacturing of Aluminum Alloy Parts from Recycled Feedstock by PIG Die-Casting and Hot Stamping. Lubricants, 11(1), 13. https://doi.org/10.3390/lubricants11010013