Numerical Investigation of Bump Foil Configurations Effect on Gas Foil Thrust Bearing Performance Based on a Thermos-Elastic-Hydrodynamic Model

Abstract

:1. Introduction

2. Numerical Method and Experimental Validation

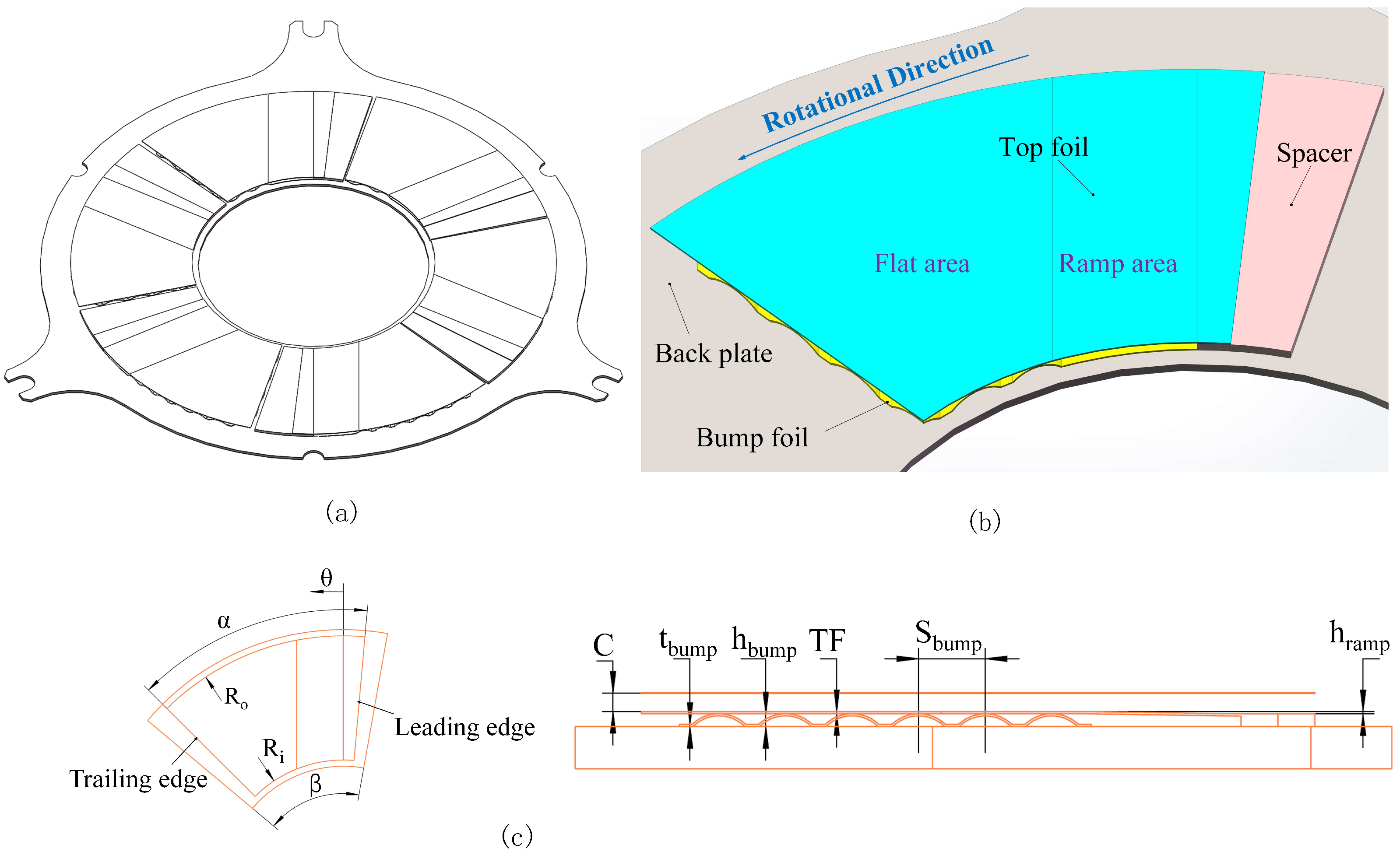

2.1. Description of GFTB and Bump Foil Configurations

2.2. Computational Mode and Boundary Conditions

2.3. Experimental Validation

3. Results and Discussion

3.1. Load Capacity

3.2. Thermal Characteristic

4. Conclusions

- (1)

- The 3D THED model of GFTB based on the FTSI approach is valid for the GFTB performance prediction.

- (2)

- Fixing the bump foil at the trailing edge improves the load capacity.

- (3)

- The influence of independent bump foil strips on load depends on the position where the bump foil is fixed. When the bump foil is fixed at the trailing edge, splitting it into several strips only slightly enhances the load capacity.

- (4)

- To reduce power loss and minimize the risk of bearing thermal failure, it is recommended to fix the bump foil at the trailing edge and split it into multiple strips.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, K.; Kaneko, S. Analytical Model of Bump-Type Foil Bearings Using a Link-Spring Structure and a Finite-Element Shell Model. J. Tribol. 2010, 132, 021706. [Google Scholar] [CrossRef]

- DellaCorte, C.; Bruckner, R.J. Remaining Technical Challenges and Future Plans for Oil-Free Turbomachinery. J. Eng. Gas Turbines Power 2011, 133, 042502. [Google Scholar] [CrossRef]

- Somaya, K.; Yamashita, T.; Yoshimoto, S. Experimental and Numerical Investigation of the High-Speed Instability of Aerodynamic Foil Journal Bearings for Micro Turbomachinery. In Proceedings of the ASME/STLE 2012 International Joint Tribology Conference, Denver, CO, USA, 7–10 October 2012. [Google Scholar]

- Agrawal, G.L. Foil Air/Gas Bearing Technology—An Overview. In Proceedings of the ASME 1997 International Gas Turbine and Aeroengine Congress and Exhibition, Orlando, FL, USA, 2–5 June 1997. [Google Scholar]

- Kim, T.H.; Lee, Y.-B.; Kim, T.Y.; Jeong, K.H. Rotordynamic Performance of an Oil-Free Turbo Blower Focusing on Load Capacity of Gas Foil Thrust Bearings. J. Eng. Gas Turbines Power 2011, 134, 022501. [Google Scholar] [CrossRef]

- Samanta, P.; Murmu, N.C.; Khonsari, M.M. The evolution of foil bearing technology. Tribol. Int. 2019, 135, 305–323. [Google Scholar] [CrossRef]

- Walton, J.F., II; Tomaszewski, M.J.; Heshmat, H. The Role of High Performance Foil Bearings in Advanced, Oil-Free, High-Speed Motor Driven Compressors. In Proceedings of the ASME 2003 1st International Conference on Fuel Cell Science, Engineering and Technology, Rochester, NY, USA, 21–23 April 2003. [Google Scholar]

- Fu, G.; Untaroiu, A.; Swanson, E. Effect of Foil Geometry on the Static Performance of Thrust Foil Bearings. J. Eng. Gas Turbines Power 2018, 140, 082502. [Google Scholar] [CrossRef]

- Heshmat, H.; Walowit, J.A.; Pinkus, O. Analysis of Gas Lubricated Compliant Thrust Bearings. J. Lubr. Technol. 1983, 105, 638–646. [Google Scholar] [CrossRef]

- Iordanoff, I. Analysis of an Aerodynamic Compliant Foil Thrust Bearing: Method for a Rapid Design. J. Tribol. 1999, 121, 816–822. [Google Scholar] [CrossRef]

- Heshmat, C.A.; Xu, D.S.; Heshmat, H. Analysis of Gas Lubricated Foil Thrust Bearings Using Coupled Finite Element and Finite Difference Methods. J. Tribol. 1999, 122, 199–204. [Google Scholar] [CrossRef]

- Park, D.-J.; Kim, C.-H.; Jang, G.-H.; Lee, Y.-B. Theoretical considerations of static and dynamic characteristics of air foil thrust bearing with tilt and slip flow. Tribol. Int. 2008, 41, 282–295. [Google Scholar] [CrossRef]

- Gad, A.M.; Kaneko, S. A New Structural Stiffness Model for Bump-Type Foil Bearings: Application to Generation II Gas Lubricated Foil Thrust Bearing. J. Tribol. 2014, 136, 041701. [Google Scholar] [CrossRef]

- Xu, F.; Kim, D.; Zamanian Yazdi, B. Theoretical Study of Top Foil Sagging Effect on the Performance of Air Thrust Foil Bearing. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016. [Google Scholar]

- Xu, Z.; Li, C.; Du, J.; Li, J.; Wang, Y. Load-carrying characteristics of bump-type gas foil thrust bearings. Int. J. Mech. Sci. 2023, 244, 108080. [Google Scholar] [CrossRef]

- Bruckner, R.J. Simulation and Modeling of the Hydrodynamic, Thermal, and Structural Behavior of Foil Thrust Bearings. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 2004. [Google Scholar]

- Lee, D.; Kim, D. Three-Dimensional Thermohydrodynamic Analyses of Rayleigh Step Air Foil Thrust Bearing with Radially Arranged Bump Foils. Tribol. Trans. 2011, 54, 432–448. [Google Scholar] [CrossRef]

- Gad, A.M.; Kaneko, S. Fluid Flow and Thermal Features of Gas Foil Thrust Bearings at Moderate Operating Temperatures. In Proceedings of the 9th IFToMM International Conference on Rotor Dynamics, Cham, Switzerland, 22–25 September 2015; pp. 1223–1233. [Google Scholar]

- Xu, F.; Kim, D. Three-Dimensional Turbulent Thermo-Elastohydrodynamic Analyses of Hybrid Thrust Foil Bearings Using Real Gas Model. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016. [Google Scholar]

- Lehn, A.; Mahner, M.; Schweizer, B. A thermo-elasto-hydrodynamic model for air foil thrust bearings including self-induced convective cooling of the rotor disk and thermal runaway. Tribol. Int. 2018, 119, 281–298. [Google Scholar] [CrossRef]

- Liu, X.; Li, C.; Du, J. The Fluid-Structure-Thermal Performance Analysis of Gas Foil Thrust Bearing by Using Computational Fluid Dynamics. Lubricants 2022, 10, 294. [Google Scholar] [CrossRef]

- Xiong, C.; Xu, B.; Yu, H.; Huang, Z.; Chen, Z. A thermo-elastic-hydrodynamic model for air foil thrust bearings considering thermal seizure and failure analyses. Tribol. Int. 2023, 183, 108373. [Google Scholar] [CrossRef]

- DellaCorte, C.; Radil, K.C.; Bruckner, R.J.; Howard, S.A. Design, Fabrication, and Performance of Open Source Generation I and II Compliant Hydrodynamic Gas Foil Bearings. Tribol. Trans. 2008, 51, 254–264. [Google Scholar] [CrossRef]

- Qin, K.; Li, D.; Huang, C.; Luo, K. Comparative analysis of turbulence models for gas bearings flowfield simulations. Fluid Dyn. Res. 2019, 51, 045505. [Google Scholar] [CrossRef]

- Hoffmann, R.; Liebich, R. Experimental and numerical analysis of the dynamic behaviour of a foil bearing structure affected by metal shims. Tribol. Int. 2017, 115, 378–388. [Google Scholar] [CrossRef]

- Zywica, G.; Baginski, P.; Bogulicz, M.; Martowicz, A.; Roemer, J.; Kantor, S. Numerical identification of the dynamic characteristics of a nonlinear foil bearing structure: Effect of the excitation force amplitude and the assembly preload. J. Sound Vib. 2022, 520, 116663. [Google Scholar] [CrossRef]

- San Andrés, L.; Ryu, K.; Diemer, P. Prediction of Gas Thrust Foil Bearing Performance for Oil-Free Automotive Turbochargers. J. Eng. Gas Turbines Power 2014, 137, 032502. [Google Scholar] [CrossRef]

- Dykas, B. Factors Influencing the Performance of Foil Gas Thrust Bearings for Oil-Free Turbomachinery Applications. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 2006. [Google Scholar]

- Conboy, T.M. Real-Gas Effects in Foil Thrust Bearings Operating in the Turbulent Regime. J. Tribol. 2013, 135, 031703. [Google Scholar] [CrossRef]

- Gad, A.M.; Kaneko, S. Tailoring of the bearing stiffness to enhance the performance of gas-lubricated bump-type foil thrust bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 541–560. [Google Scholar] [CrossRef]

- Dickman, J.R. An investigation of gas foil thrust bearing performance and its influencing factors. Master’s Thesis, Case Western Reserve University, Cleveland, OH, USA, 2010. [Google Scholar]

- Rieken, M.; Mahner, M.; Schweizer, B. Thermal Optimization of Air Foil Thrust Bearings Using Different Foil Materials. J. Turbomach. 2020, 142, 101003. [Google Scholar] [CrossRef]

| GFTB Parameters | Value |

|---|---|

| GFTB outer radium (mm), Ro | 40 |

| GFTB inner radium (mm), Ri | 20 |

| Pad angle (deg), α | 60 |

| Foil angle (deg), β | 45 |

| Ramp height (mm), hRamp | 0.11 |

| Ramp area ratio | 0.32 |

| Top foil thickness(mm), TF | 0.10 |

| Bump foil thickness (mm), tBump | 0.10 |

| Bump foil pitch (mm), SBump | 3.17 |

| Bump foil height (mm), hBump | 0.51 |

| Foil Poisson’s ratio, ν | 0.29 |

| Foil Young’s modulus, E | 209 GPa |

| Boundary Type | Part | Boundary Condition |

|---|---|---|

| Opening | Inner and outer diameter surfaces of the fluid domain | Ambient temperature , ambient press |

| Moving no-slip wall | Thrust disk | Rotational speed , forced thermal convection coefficient |

| Rotational periodicity | Both ends of the fluid and structure domain sector | |

| Fluid–solid interface | Top foil surface Top side of back plate | Transfer pressure, displacement, temperature and flux |

| Solid–solid interface | Top foil and bump foil bump foil and back plate | Contact and friction, solid thermal conductivity coefficient |

| Fixed | Fixed edges of top foil and bump foil | Fixed, solid thermal conductivity coefficient |

| Free wall | Underside of top foil bump foil | Unconstrained, natural thermal convection coefficient , ambient temperature , ambient press |

| Fixed wall | Back plate Spacer | Fixed, rigid body, natural thermal convection coefficient , ambient temperature , ambient press |

| Bearing Number | Maximum Load Capacity (N) | Difference from Bearing 1 | Difference from Bearing 4 |

|---|---|---|---|

| Bearing 1 | 70.0 | −26.7% | |

| Bearing 2 | 93.5 | 33.5% | −2.1% |

| Bearing 3 | 84.6 | 20.8% | −11.4% |

| Bearing 4 | 95.5 | 36.4% |

| Bearing Number | Maximum Temperature of Top Foil (°C) | Average Temperature of Top Foil (°C) | Power Loss (W) | Leakage (mg/s) |

|---|---|---|---|---|

| Bearing 1 | 167.16 | 153.87 | 56.99 | 57.59 |

| Bearing 2 | 185.37 | 168.26 | 60.15 | 59.01 |

| Bearing 3 | 186.42 | 170.34 | 63.33 | 57.69 |

| Bearing 4 | 166.14 | 160.14 | 59.04 | 59.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, B.; Hou, A.; Deng, R.; Wang, R.; Wu, Z.; Ni, Q.; Li, Z. Numerical Investigation of Bump Foil Configurations Effect on Gas Foil Thrust Bearing Performance Based on a Thermos-Elastic-Hydrodynamic Model. Lubricants 2023, 11, 417. https://doi.org/10.3390/lubricants11100417

Hu B, Hou A, Deng R, Wang R, Wu Z, Ni Q, Li Z. Numerical Investigation of Bump Foil Configurations Effect on Gas Foil Thrust Bearing Performance Based on a Thermos-Elastic-Hydrodynamic Model. Lubricants. 2023; 11(10):417. https://doi.org/10.3390/lubricants11100417

Chicago/Turabian StyleHu, Bin, Anping Hou, Rui Deng, Rui Wang, Zhiyong Wu, Qifeng Ni, and Zhong Li. 2023. "Numerical Investigation of Bump Foil Configurations Effect on Gas Foil Thrust Bearing Performance Based on a Thermos-Elastic-Hydrodynamic Model" Lubricants 11, no. 10: 417. https://doi.org/10.3390/lubricants11100417