Dynamometric Investigation on Airborne Particulate Matter from Automobile Brake: Impact of Disc Materials on Brake Emission Factor

Abstract

:1. Introduction

2. Materials and Methods

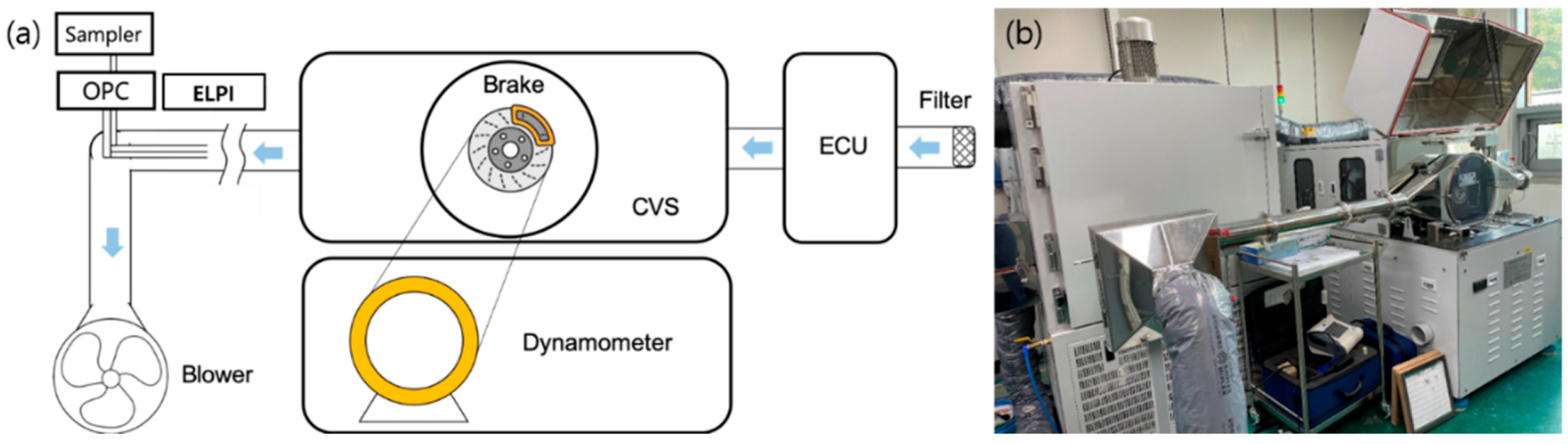

2.1. Brake Dynamometer

2.2. Particulate Matter Measurement

2.3. Friction Materials

2.4. Disc Rotor

2.5. Nitrocarburization

2.6. Superhard Ceramic Coating

3. Results and Discussion

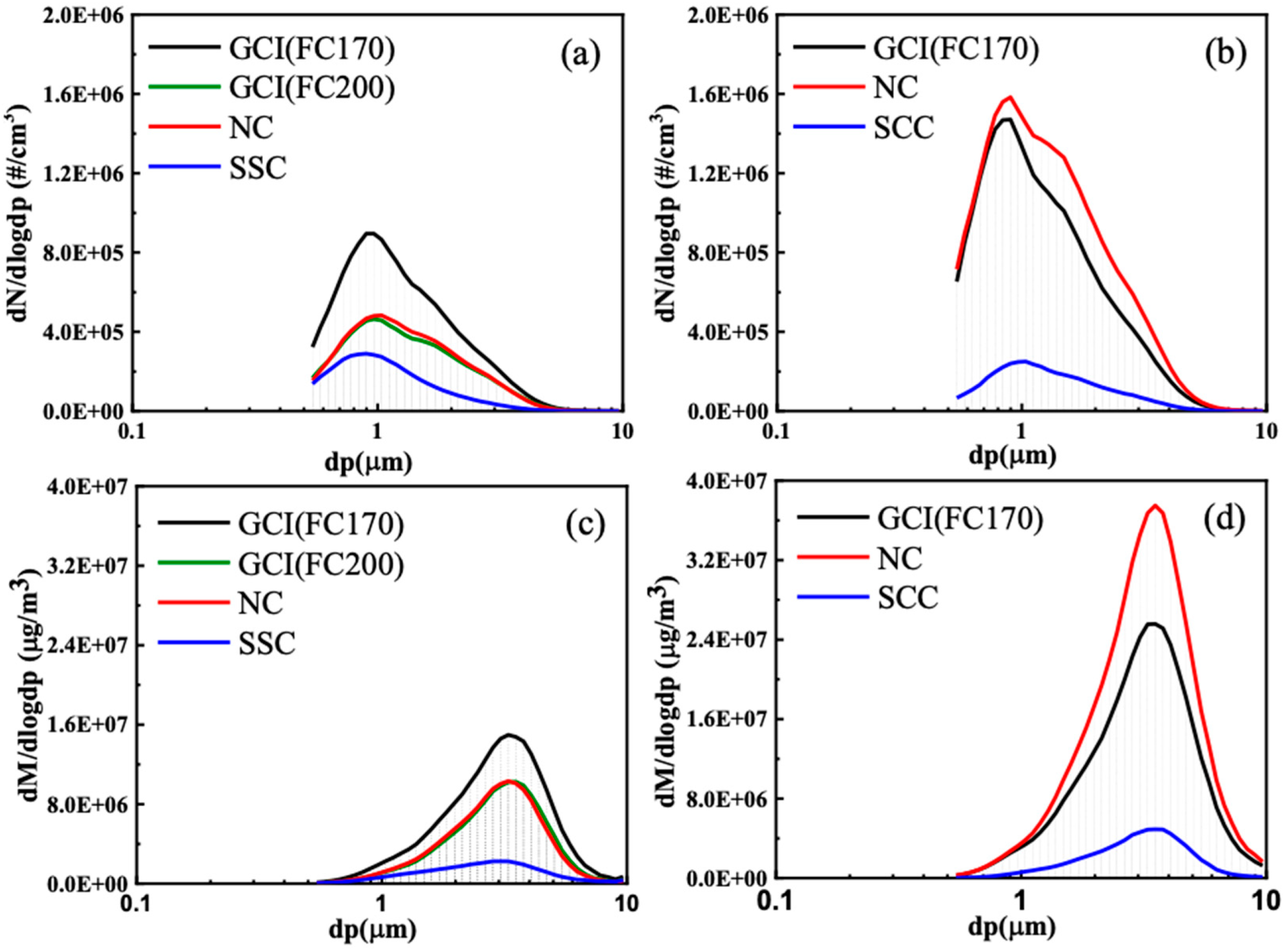

3.1. PM Emission vs. Hardening of Disc Materials

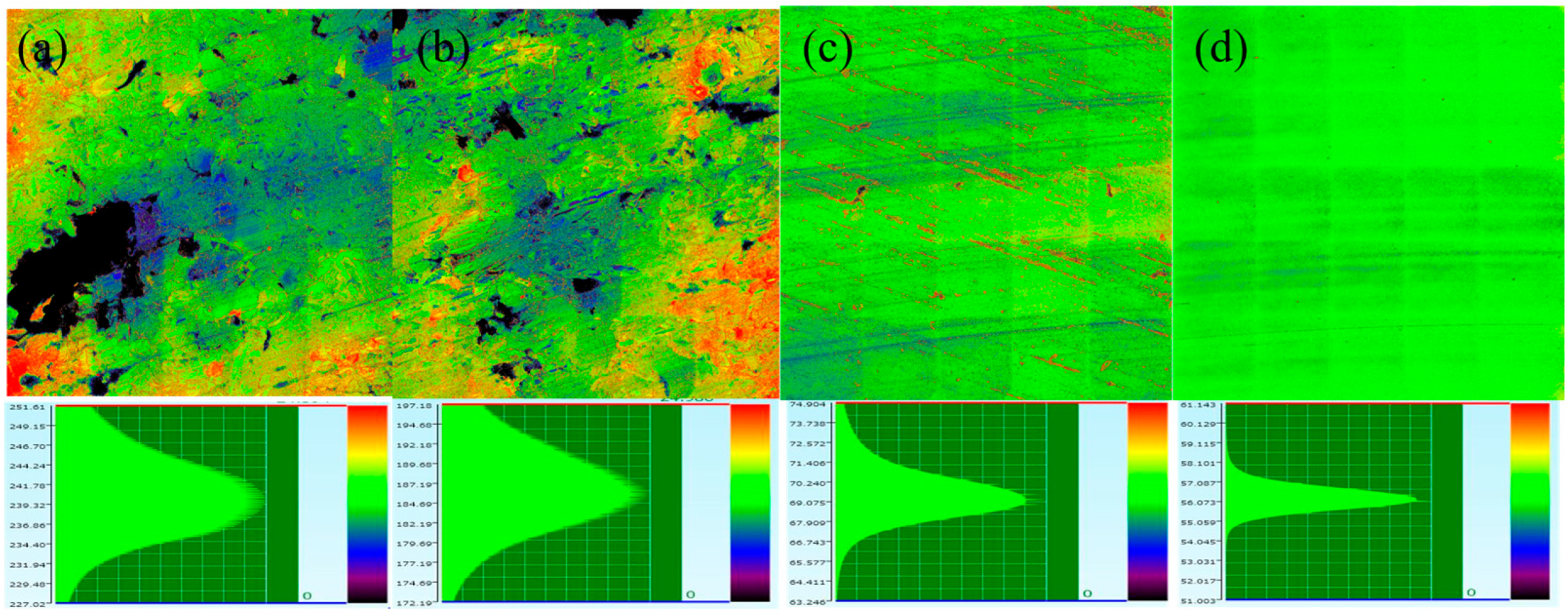

3.2. Surface Topological Analysis

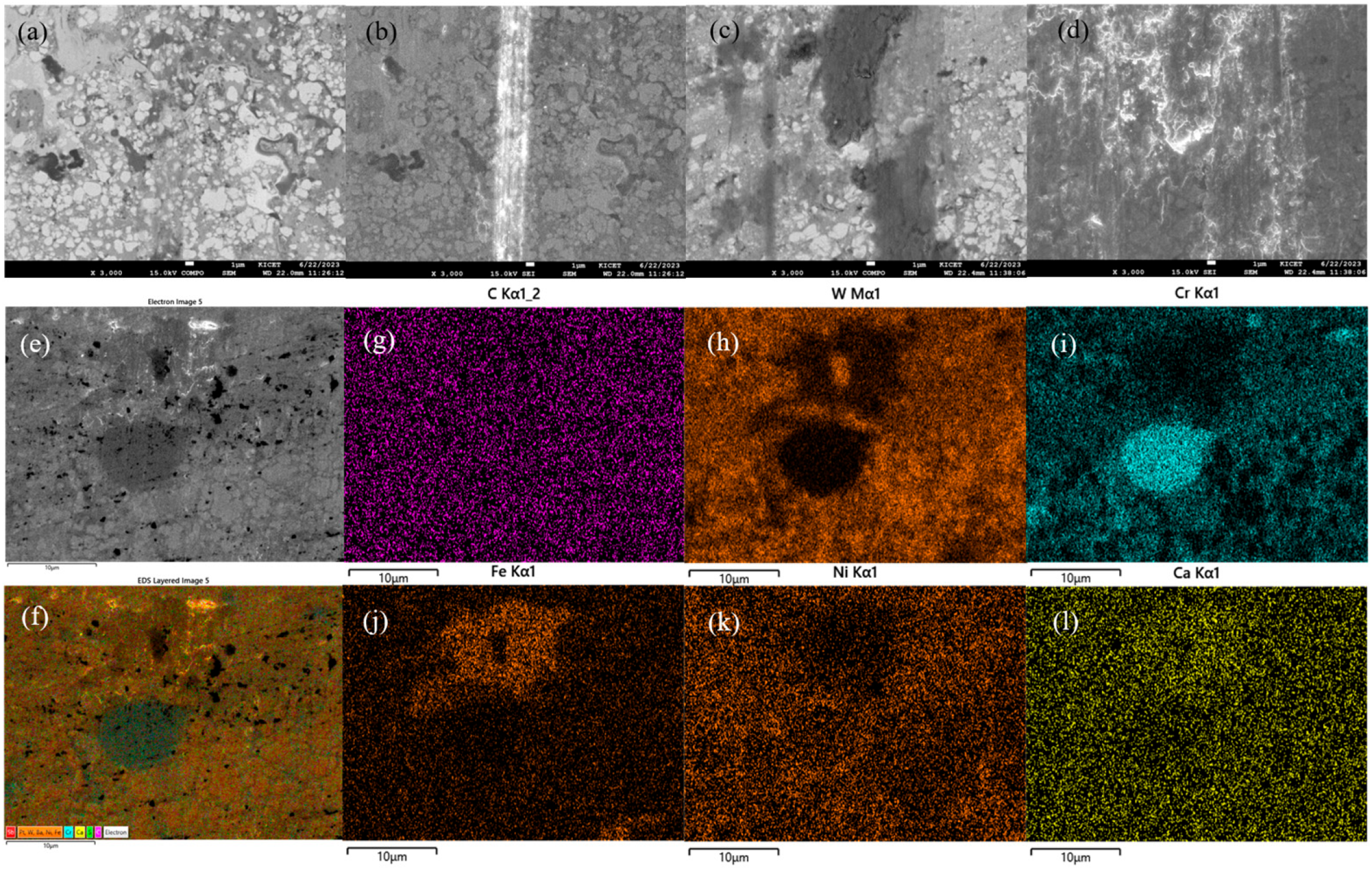

3.3. Microstructure Analysis

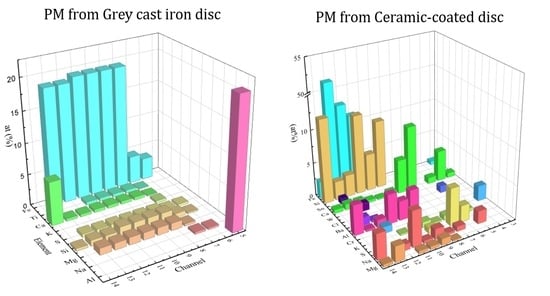

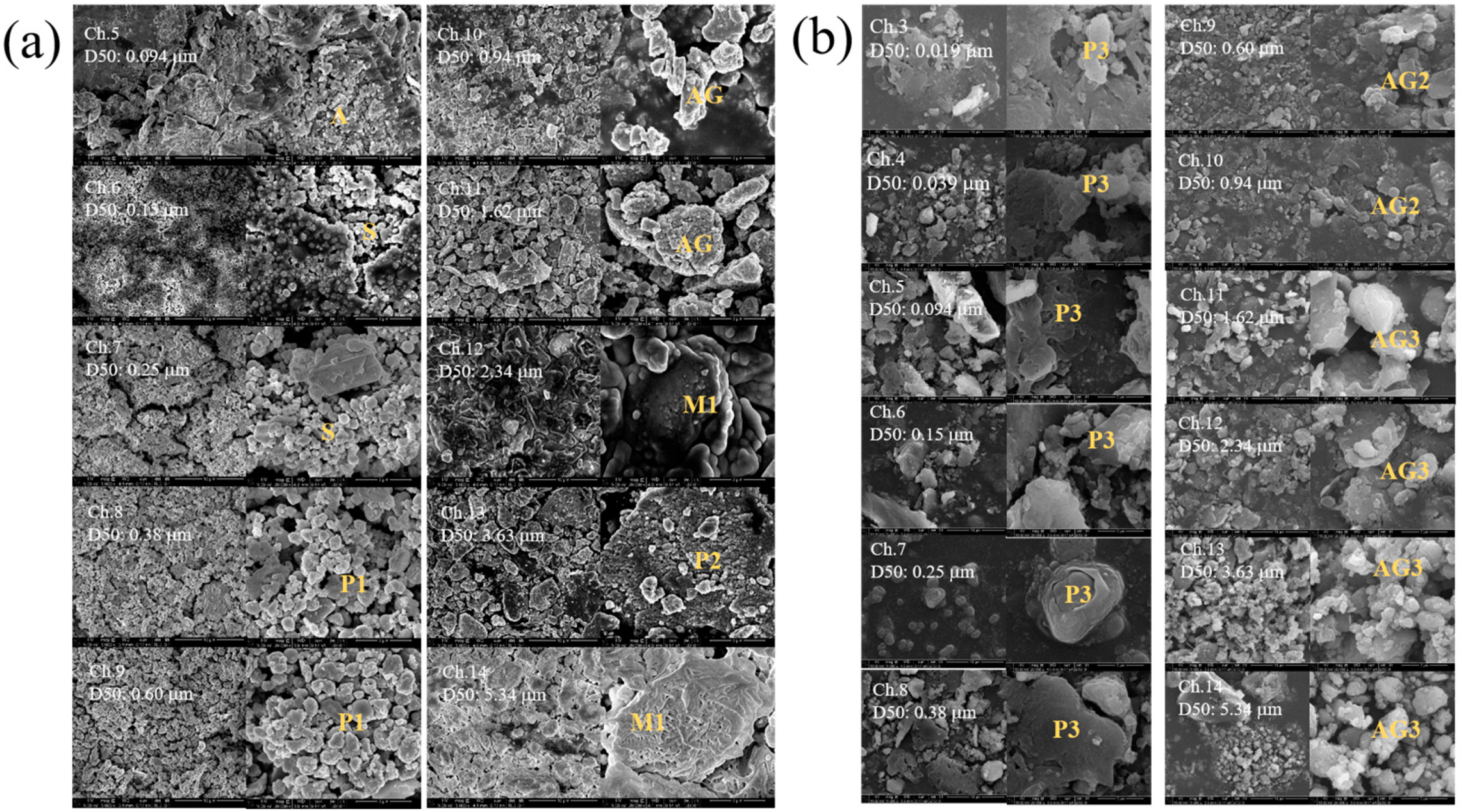

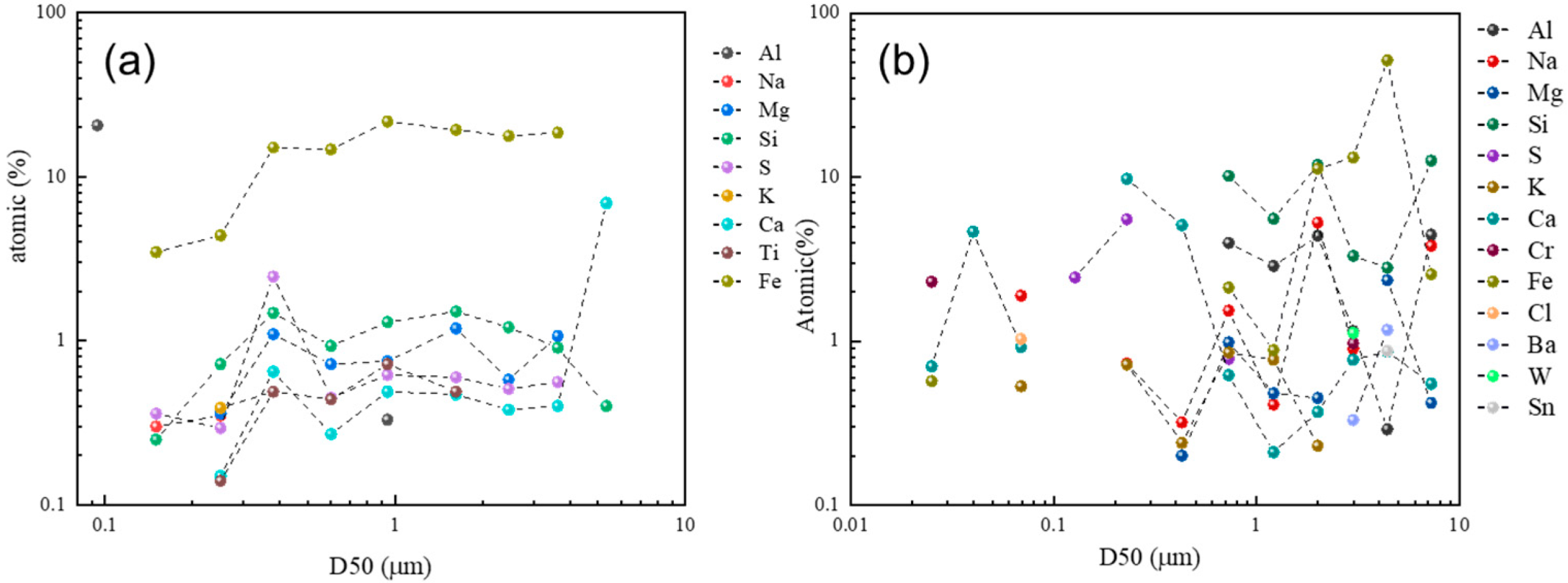

3.4. Wear Debris Analysis

4. Conclusions

- Dynamometric PM measurements based on the NOVEL cycle showed that the brake emission factor (BEF) for the SCC rotor was reduced by more than a factor of 1/5 compared with the GCI and NC, while the coefficient of friction (COF) of the SCC increased by >20% compared with the GCI and NC rotors.

- With increasing disc hardness in the order of FC170 → FC200 → NC → SCC, the BEF for the N/S materials was decreased from 2.73 to 0.5 mg/km/vehicle. On the other hand, the BEF value of the NC disc rotor (6.26 mg/km/vehicle) was higher than the GCI (4.85 mg/km/vehicle) and SCC rotors (0.64 mg/km/vehicle) because of more severe character of wear mechanism.

- According to surface profile analyses of the disc rotors and friction materials worn by dynamometric tests, severe wear was conspicuous for the NC rotor, especially with the L/S friction materials, in contrast to the SCC rotor. Microstructural analysis confirmed that severe wear, involving wear debris from cracks in the nitride layer, was present for the NC disc rotor with L/S materials.

- Results of FE-SEM and EDS analyses of the size-classified airborne PM indicated that micron-sized particles, which mainly originated from fragmented Fe lumps from the GCI disc rotor, were observed at D50 = 0.1–3.5 μm. Aggregates of steel fiber and friction materials were observed for the SCC rotor at D50 = 1.0–3.5 μm without Fe lumps from the disc rotor, which was responsible for the lower BEF due to the enhanced surface hardness of the SCC rotor.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rashid, A. Overview of disc brakes and related phenomena—A review. Int. J. Veh. Noise Vib. 2014, 10, 257–301. [Google Scholar] [CrossRef]

- Cueva, G.; Sinatora, A.; Guesser, W.L.; Tschiptschin, A.P. Wear resistance of cast irons used in brake disc rotors. Wear 2003, 255, 1256–1260. [Google Scholar] [CrossRef]

- Thornton, R.; Slatter, T.; Jones, A.H.; Lewis, R. The effects of cryogenic processing on the wear resistance of grey cast iron brake discs. Wear 2011, 271, 2386–2395. [Google Scholar] [CrossRef]

- Vasiljević, S.; Glišović, J.; Stojanović, B.; Vencl, A. Review of the coatings used for brake discs regarding their wear resistance and environmental effect. Proc. Inst. Mech. Eng. Part J J. Eng. Trib. 2022, 236, 1932–1949. [Google Scholar] [CrossRef]

- Garg, B.D.; Cadle, S.H.; Mulawa, P.A.; Groblicki, P.J.; Laroo, C.; Parr, G.A. Brake Wear Particulate Matter Emissions. Environ. Sci. Technol. 2000, 34, 4463–4469. [Google Scholar] [CrossRef]

- Kumar, P.; Pirjola, L.; Ketzel, M.; Harrison, R.M. Nanoparticle emissions from 11 non-vehicle exhaust sources—A review. Atmos. Environ. 2013, 67, 252–277. [Google Scholar] [CrossRef]

- Hagino, H.; Oyama, M.; Sasaki, S. Laboratory testing of airborne brake wear particle emissions using a dynamometer system under urban city driving cycles. Atmos. Environ. 2016, 131, 269–278. [Google Scholar] [CrossRef]

- Iijima, A.; Sato, K.; Yano, K.; Kato, M.; Tago, H.; Kato, M.; Kimura, H.; Furuta, N. Particle size and composition distribution analysis of automotive brake abrasion dusts for the evaluation of antimony sources of airborne particulate matter. Atmos. Environ. 2007, 41, 4908–4919. [Google Scholar] [CrossRef]

- Herman, H.; Sampath, S. Thermal spray coatings. In Metallurgical and Ceramic Protective Coatings; Springer: Dordrecht, The Netherlands, 1996; pp. 261–289. [Google Scholar]

- Mandich, N.V.; Snyder, D.L. Electrodeposition of chromium. In Modern Electroplating; Schlesinger, M., Paunovic, M., Eds.; Wiley: Hoboken, NJ, USA, 2010; pp. 205–241. [Google Scholar]

- Dunleavy, C.S.; Golosnoy, I.O.; Curran, J.A.; Clyne, T.W. Characterisation of discharge events during plasma electrolytic oxidation. Surf. Coat Technol. 2009, 203, 3410–3419. [Google Scholar] [CrossRef]

- Van Acker, K.; Vanhoyweghen, D.; Persoons, R.; Vangrunderbeek, J. Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings. Wear 2005, 258, 194–202. [Google Scholar] [CrossRef]

- Fernandes, F.; Cavaleiro, A.; Loureiro, A. Oxidation behavior of Ni-based coatings deposited by PTA on gray cast iron. Surf. Coat. Technol. 2012, 207, 196–203. [Google Scholar] [CrossRef]

- Cho, Y.W.; Won, J.H.; Woo, J.H.; Yu, S.H.; Cho, Y.R. Effect of oxy-nitrocarburizing on microstructure, nanohardness and corrosion properties for low carbon steel. Kor. J. Met. Mater. 2018, 56, 289–295. [Google Scholar]

- Sanders, P.G.; Xu, N.; Dalka, T.M.; Maricq, M.M. Airborne brake wear debris: Size distributions, composition, and a comparison of dynamometer and vehicle tests. Environ. Sci. Technol. 2003, 37, 4060–4069. [Google Scholar] [CrossRef]

- Wahlstrom, J.; Olander, L.; Olofsson, U. Size, shape, and elemental composition of airborne wear particles from disc brake materials. Tribol. Lett. 2010, 38, 15–24. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Brake wear particle emissions: A review. Environ. Sci. Pollut. Res. Int. 2015, 22, 2491–2504. [Google Scholar] [CrossRef] [PubMed]

- Perricone, G.; Alemani, M.; Metinöz, I.; Matějka, V.; Wahlström, J.; Olofsson, U. Towards the ranking of airborne particle emissions from car brakes–a system approach. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 781–797. [Google Scholar] [CrossRef]

- Perricone, G.; Matějka, V.; Alemani, M.; Valota, G.; Bonfanti, A.; Ciotti, A.; Olofsson, U.; Söderberg, A.; Wahlström, J.; Nosko, O.; et al. A concept for reducing PM10 emissions for car brakes by 50%. Wear 2018, 396, 135–145. [Google Scholar] [CrossRef]

- Krenkel, W.; Heidenreich, B.; Renz, R. C/C-SiC composites for advanced friction systems. Adv. Eng. Mater. 2002, 4, 427–436. [Google Scholar] [CrossRef]

- Kim, S.H.; Shim, W.; Kwon, S.U.; Lee, J.J.; Seo, M.; Kim, J.; Pee, J.; Kim, J. The impact of composition of non-steel and low-steel type friction materials on airborne brake wear particulate emission. Tribol. Lett. 2020, 68, 118. [Google Scholar] [CrossRef]

- Mathissen, M.; Grochowicz, J.; Schmidt, C.; Vogt, R.; Farwick zum Hagen, F.H.; Grabiec, T.; Steven, H.; Grigoratos, T.A. Novel real-world braking cycle for studying brake wear particle emissions. Wear 2018, 414–415, 219–226. [Google Scholar] [CrossRef]

- Seo, H.; Park, J.; Kim, Y.C.; Lee, J.J.; Jang, H. Effect of disc materials on brake emission during moderate-temperature braking. Tribol. Int. 2021, 163, 107185. [Google Scholar]

- Shen, M.; Li, H.; Du, J.; Ji, D.; Liu, S.; Xiao, Y. New insights into reducing airborne particle emissions from brake materials: Grooved textures on brake disc surface. Tribol. Int. 2022, 174, 107721. [Google Scholar] [CrossRef]

- Seo, H.; Lee, D.G.; Park, J.; Song, W.; Lee, J.J.; Sohn, S.S.; Jang, H. Quench hardening effect of gray iron brake discs on particulate matter emission. Wear 2023, 523, 204781. [Google Scholar] [CrossRef]

- Popov, V.L. Contact Mechanics and Friction; Springer: Berlin/Heidelberg, Germany, 2010; Chapter 3. [Google Scholar]

- Al-Samarai, R.A.; Haftirman; Ahmad, K.R.; Al-Douri, Y. The influence of roughness on the wear and friction coefficient under dry and lubricated sliding. Int. J. Sci. Eng. Res. 2012, 3, 1–6. [Google Scholar]

- Wang, A.; Plineni, V.K.; Stark, C.; Dumbleton, J.H. Effect of femoral head surface roughness on the wear of ulrahigh molecular weight polyethylene acetabular cups. J. Arthroplast. 1998, 13, 615–620. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Arnell, R.D. The effect of substrate surface roughness on the wear of DLC coatings. Wear 2000, 239, 1–9. [Google Scholar] [CrossRef]

- Park, J.; Joo, B.; Seo, H.; Song, W.; Lee, J.J.; Lee, W.K.; Jang, H. Analysis of wear induced particle emissions from brake pads during the worldwide harmonized light vehicles test procedure (WLTP). Wear 2021, 466–467, 203539. [Google Scholar] [CrossRef]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Effect of roughness on the wear behavior of HVOF coatings dry sliding against a friction material. Wear 2016, 368–369, 326–334. [Google Scholar] [CrossRef]

- Wahlstrom, J.; Lyu, Y.; Matjeka, V.; Soderberg, A. A pin-on-disc tribometer study on disc brake contact pairs with respect to wear and airborne particle emissions. Wear 2017, 384–385, 124–130. [Google Scholar] [CrossRef]

- Shinde, T.; Dhokey, N.B. Influence of carbide density on surface roughness and quasi-stable wear behaviour of H13 die steel. Surf. Eng. 2017, 33, 944–952. [Google Scholar] [CrossRef]

- Shinde, T. Influence of carbide particle size on the wear performance of cryogenically treated H13 die steel. Surf. Eng. 2020, 37, 1206–1214. [Google Scholar] [CrossRef]

- Kim, S.H.; Jeong, M.H.; Kim, J.; Shim, W.; Kwon, S.U.; Lee, J.J.; Huh, S.H.; Pee, J.H.; Kim, J.Y. Dynamometric Investigation on Airborne Particulate Matter (PM) from Friction Materials for Automobile: Impact of Abrasive and Lubricant on PM Emission Factor. Lubricants 2021, 9, 118. [Google Scholar] [CrossRef]

| N/S Friction Materials | GCI Disc (FC170) | GCI Disc (FC200) | NC Disc | SCC Disc |

|---|---|---|---|---|

| BEF (mg/km/vehicle) 1 | 2.73 | 1.76 | 1.74 | 0.50 |

| Pad wear (kg) | 32(3) × 10−6 | 16(2) × 10−6 | 16(2) × 10−6 | 8(1) × 10−6 |

| Disc wear (kg) | 60(6) × 10−6 | 10(1) × 10−6 | 20(2) × 10−6 | 10(1) × 10−6 |

| Avg. COF 2 | 0.42(2) | 0.40(2) | 0.37(2) | 0.47(2) |

| Hardness | 185 HB | 210 HB | 670 HV | 1150 HV |

| L/S Friction Materials | GCI Disc (FC170) | NC Disc | SCC Disc |

|---|---|---|---|

| BEF (mg/km/vehicle) 1 | 4.85 | 6.26 | 0.64 |

| Pad wear (kg) | 89(8) × 10−6 | 11(1) × 10−5 | 73(7) × 10−6 |

| Disc wear (kg) | 67(7) × 10−5 | 77(5) × 10−5 | 29(3) × 10−5 |

| Hardness | 185 HB | 670 HV | 1150 HV |

| Avg. COF 2 | 0.49(2) | 0.48(2) | 0.60(3) |

| N/S Friction Materials | L/S Friction Materials | ||||||

|---|---|---|---|---|---|---|---|

| Counterpart disc | GCI disc (FC170) | GCI disc (FC200) | NC disc | SSC disc | GCI disc (FC170) | NC disc | SCC disc |

| Ra (μm), before test | 1.8 (3) | 1.2 (2) | |||||

| Ra (μm), after test | 2.3 (5) | 2.2 (5) | 2.1 (3) | 1.5 (2) | 1.2 (4) | 1.8 (5) | 1.0 (2) |

| GCI Disc (FC170) | GCI Disc (FC200) | NC Disc | SCC Disc | GCI Disc (FC170) | NC Disc | SCC Disc | |

|---|---|---|---|---|---|---|---|

| Counterpart Disc (Friction Materials) | N/S Friction Materials | L/S Friction Materials | |||||

| Ra (μm), before test | 2.19 (6) | 2.30 (5) | 0.9 (2) | 0.12 (1) | 2.30 (6) | 0.88 (6) | 0.12 (1) |

| Ra (μm), after burnish | 0.25 (7) | 0.26 (6) | 0.17 (7) | 0.13 (1) | 0.25 (6) | 0.42 (5) | 0.14 (1) |

| Ra (μm), after test | 0.23 (6) | 0.23 (6) | 0.19 (6) | 0.12 (2) | 0.17 (6) | 0.37 (5) | 0.12 (2) |

| Hardness | 210 HB | 185 HB | 670 HV | 1150 HV | 185 HB | 670 HV | 1150 HV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, M.H.; Shin, W.C.; Oh, Y.-S.; Lee, J.; Huh, S.H.; Pee, J.-H.; Seo, H.; Jang, H.; Kim, J.-Y. Dynamometric Investigation on Airborne Particulate Matter from Automobile Brake: Impact of Disc Materials on Brake Emission Factor. Lubricants 2023, 11, 526. https://doi.org/10.3390/lubricants11120526

Jeong MH, Shin WC, Oh Y-S, Lee J, Huh SH, Pee J-H, Seo H, Jang H, Kim J-Y. Dynamometric Investigation on Airborne Particulate Matter from Automobile Brake: Impact of Disc Materials on Brake Emission Factor. Lubricants. 2023; 11(12):526. https://doi.org/10.3390/lubricants11120526

Chicago/Turabian StyleJeong, Mu Hyeok, Won Cheol Shin, Yoon-Suk Oh, Jungju Lee, Seung Hun Huh, Jae-Hwan Pee, Hyungjo Seo, Ho Jang, and Jong-Young Kim. 2023. "Dynamometric Investigation on Airborne Particulate Matter from Automobile Brake: Impact of Disc Materials on Brake Emission Factor" Lubricants 11, no. 12: 526. https://doi.org/10.3390/lubricants11120526

APA StyleJeong, M. H., Shin, W. C., Oh, Y.-S., Lee, J., Huh, S. H., Pee, J.-H., Seo, H., Jang, H., & Kim, J.-Y. (2023). Dynamometric Investigation on Airborne Particulate Matter from Automobile Brake: Impact of Disc Materials on Brake Emission Factor. Lubricants, 11(12), 526. https://doi.org/10.3390/lubricants11120526