Design and Simulation of a New Near Zero-Wear Non-Contact Self-Impact Seal Based on the Tesla Valve Structure

Abstract

1. Introduction

2. Tesla Valve and Its Structural Improvements

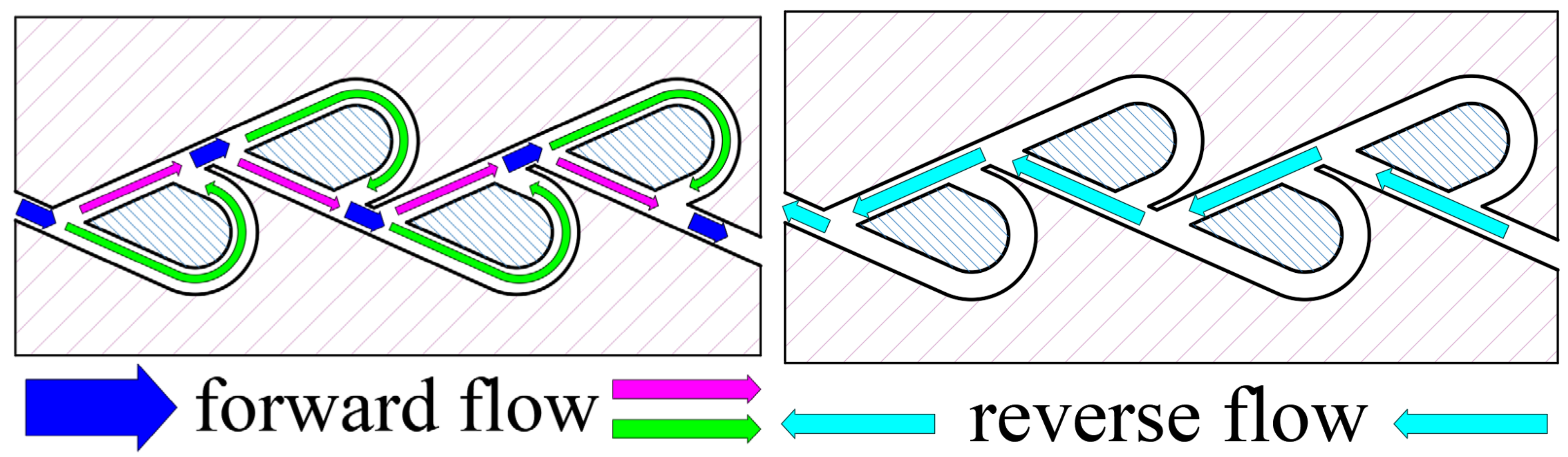

2.1. Tesla Valve Structure and Operating Principle

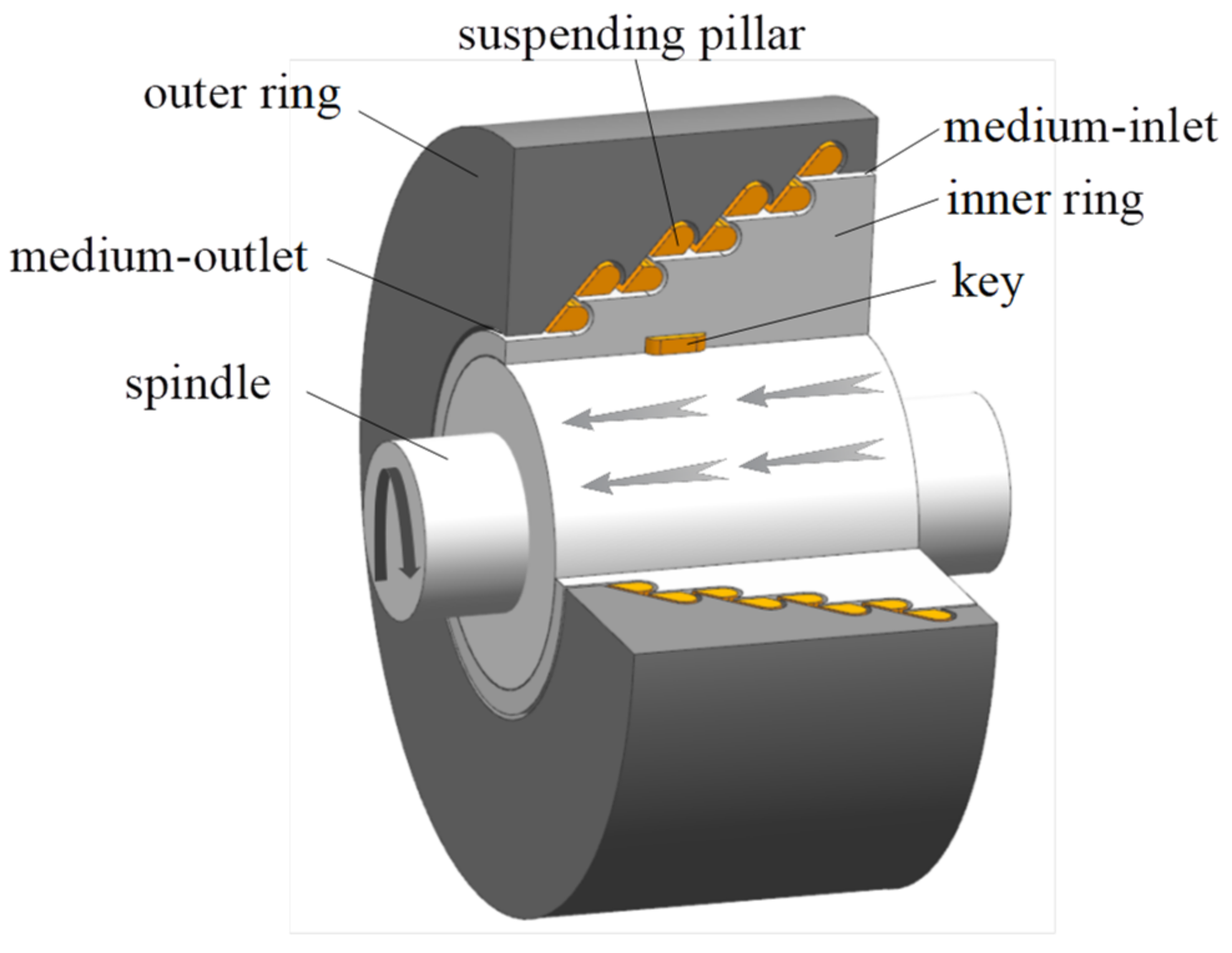

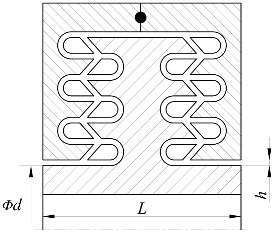

2.2. Proposed Near Zero-Wear Non-Contact Self-Impact Seal

2.3. Structure Optimization

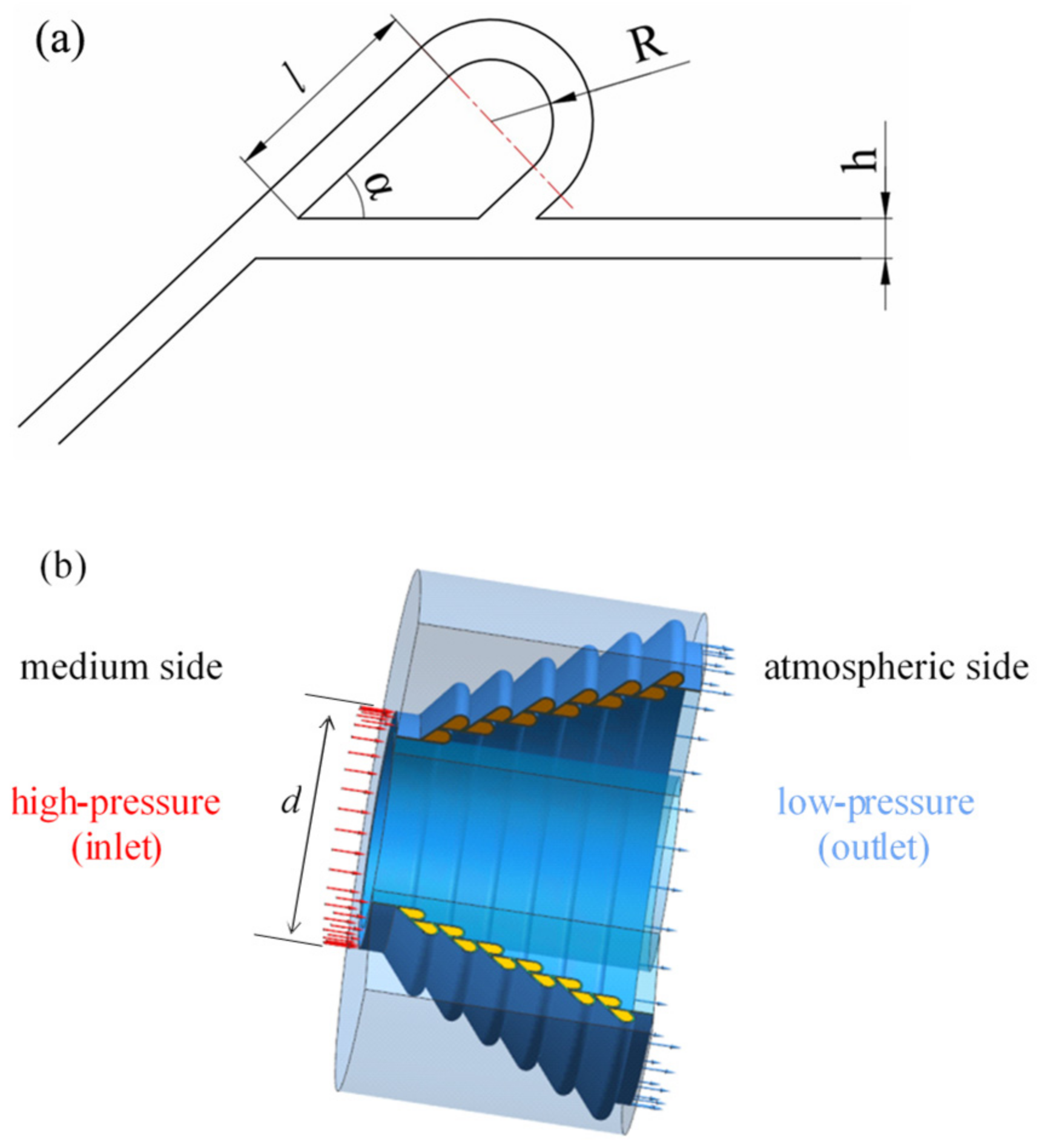

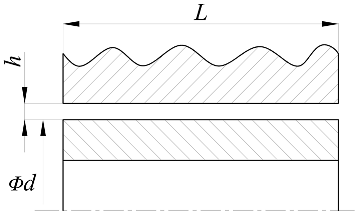

2.3.1. Geometric Model

2.3.2. Efficient Design

2.3.3. Stage Unit Design

3. Numerical Model

3.1. Calculation Parameters

3.2. Computational Analysis Model

3.2.1. Basic Assumptions

- (1)

- the medium between the three-dimensional tubular channels is a continuous medium flow [26];

- (2)

- the fluid behaviour in the Tesla valve structure belongs to the typical internal strong curvature separation flow [27], and the flow state of the self-impact sealing flow field is turbulent;

- (3)

- the temperature and viscosity of the fluid within the flow field remain constant [28];

- (4)

- the lubrication layer in the flow field is closely adsorbed to the pipe wall with no slip generated;

- (5)

- the effect of seal channel deformation on fluid flow is disregarded;

- (6)

- the effect of cavitation is disregarded;

- (7)

- the surface of the pipe is theoretically smooth.

3.2.2. Governing Equation

- ρ—medium density of the fluid

- u, v and w—axial, radial and tangential fluid flow velocities, respectively

- T—fluid temperature

- c—specific heat capacity

- U—heat transfer coefficient

- c—specific heat capacity

- ST—viscous dissipative item [29]

3.2.3. Boundary Conditions

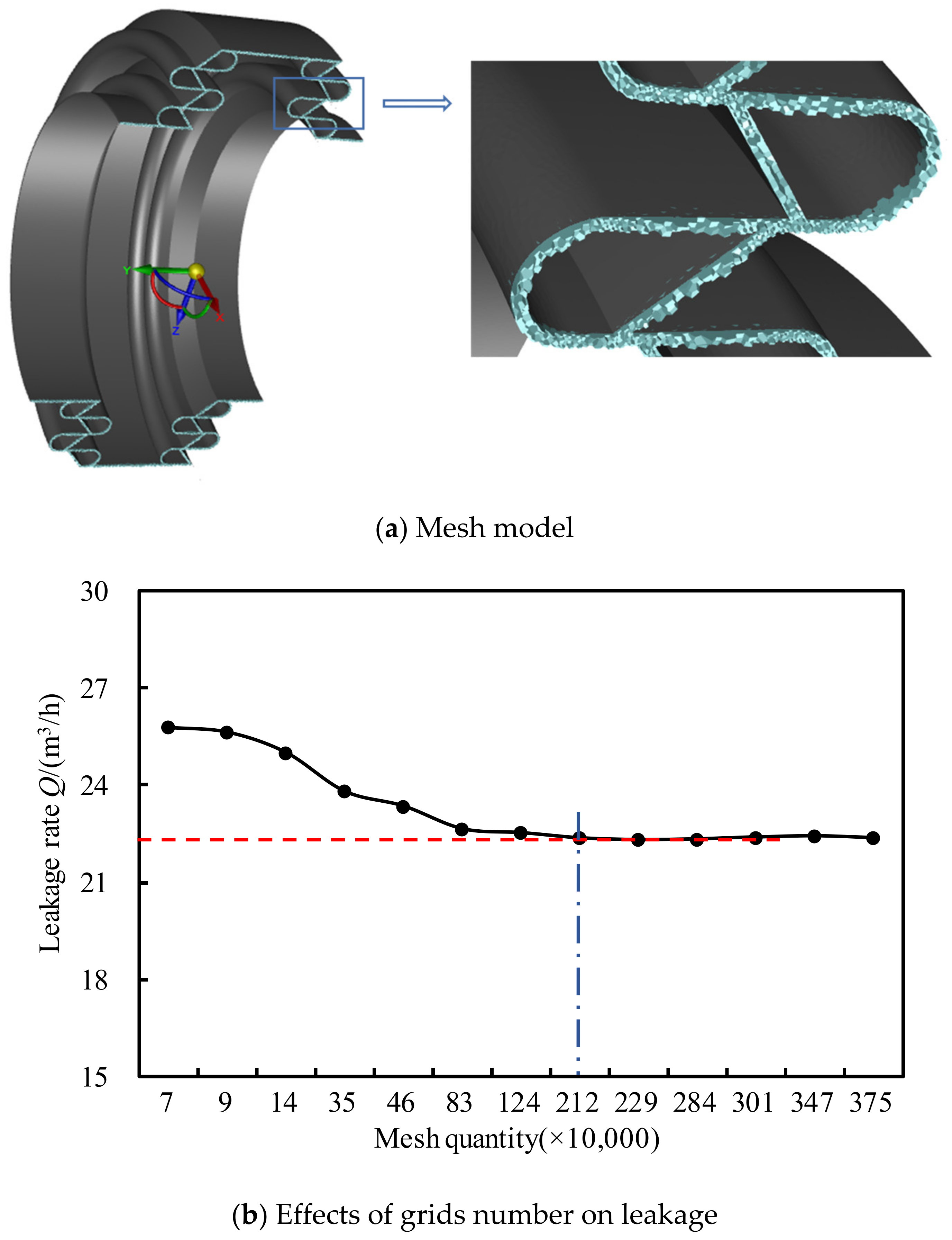

3.2.4. Mesh Division and Boundary Setting

4. Calculation Results and Analysis

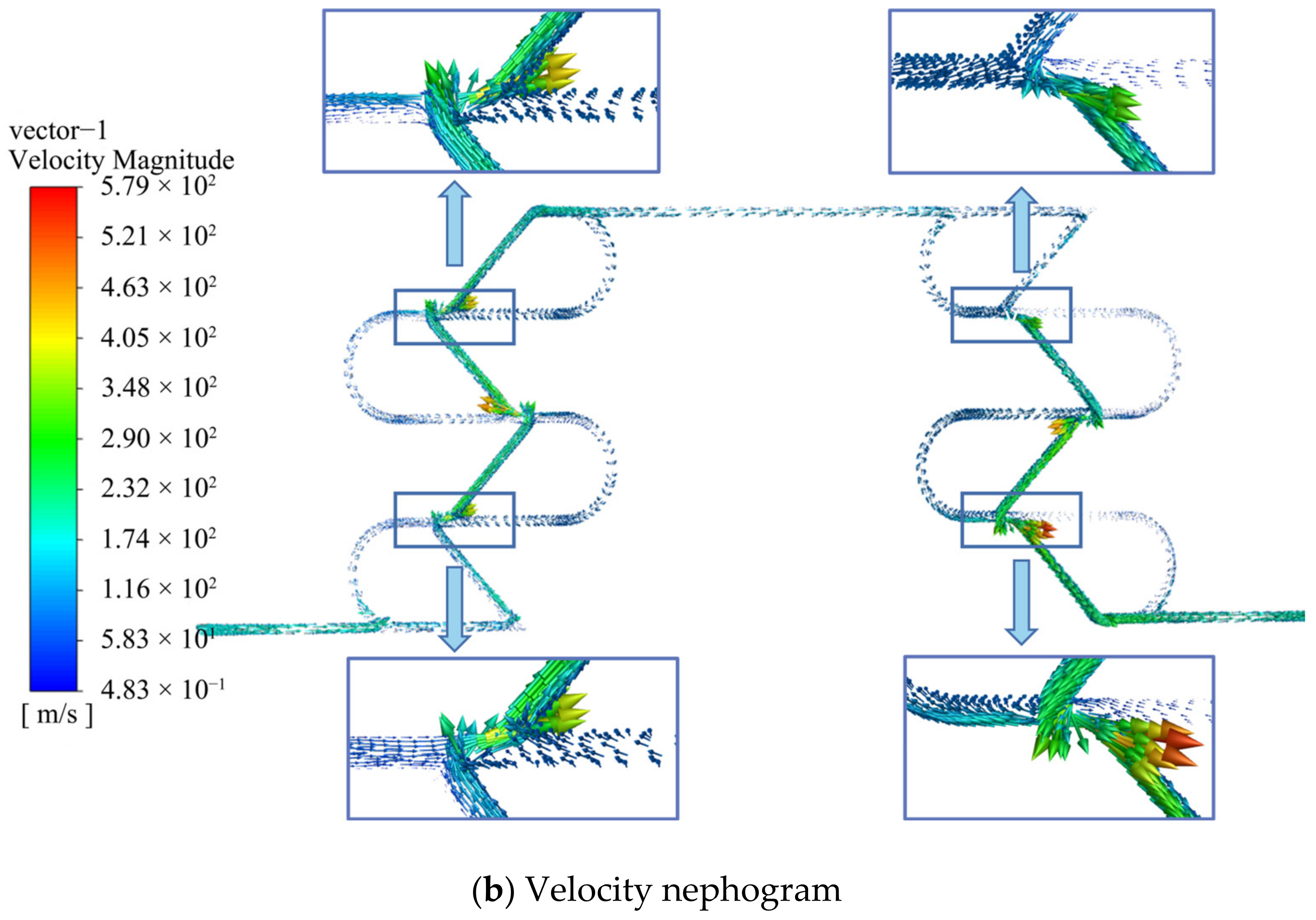

4.1. Flow Field Characteristics

4.2. Calculation of Optimal Design Parameters

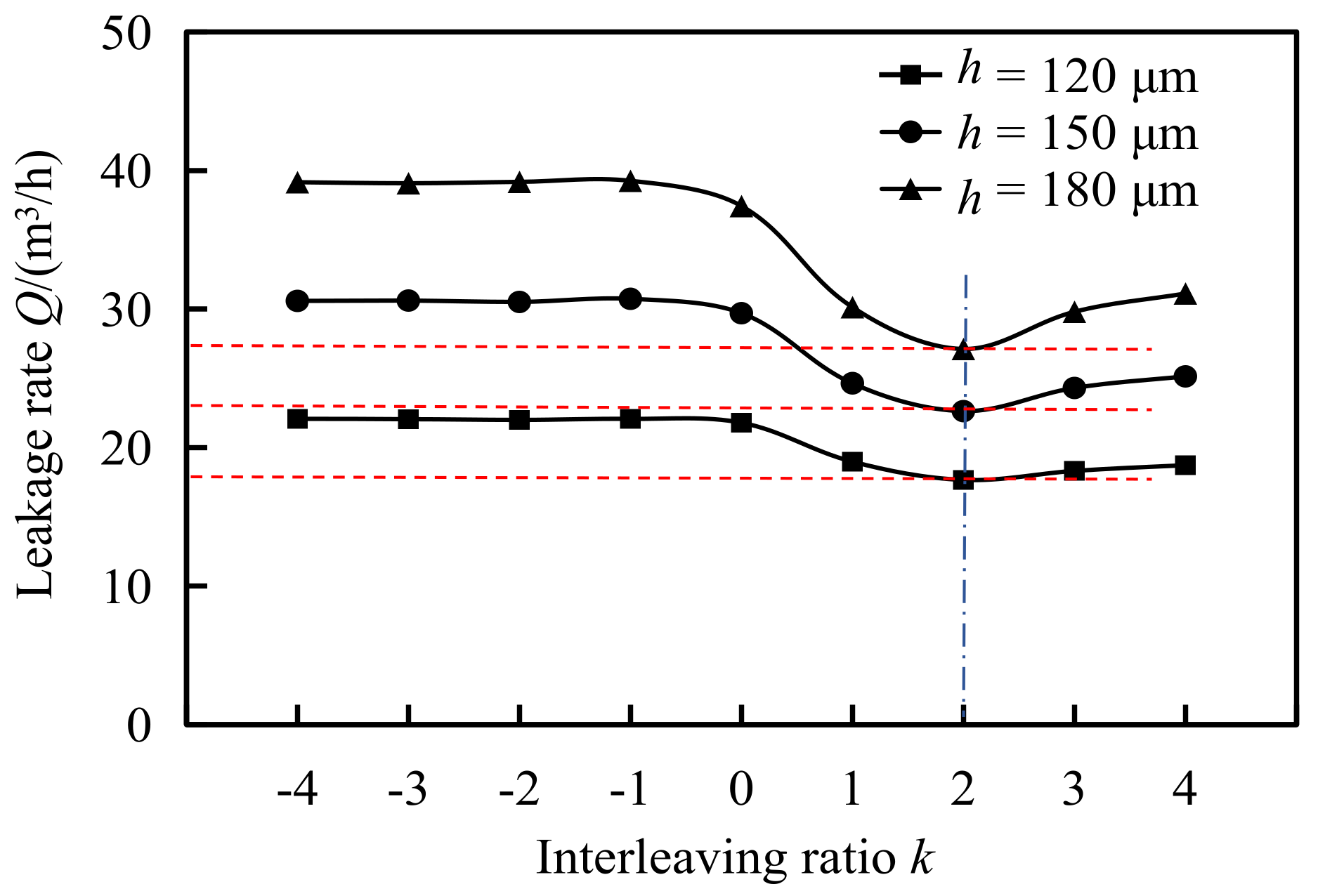

- (1)

- Optimal interleaving ratio

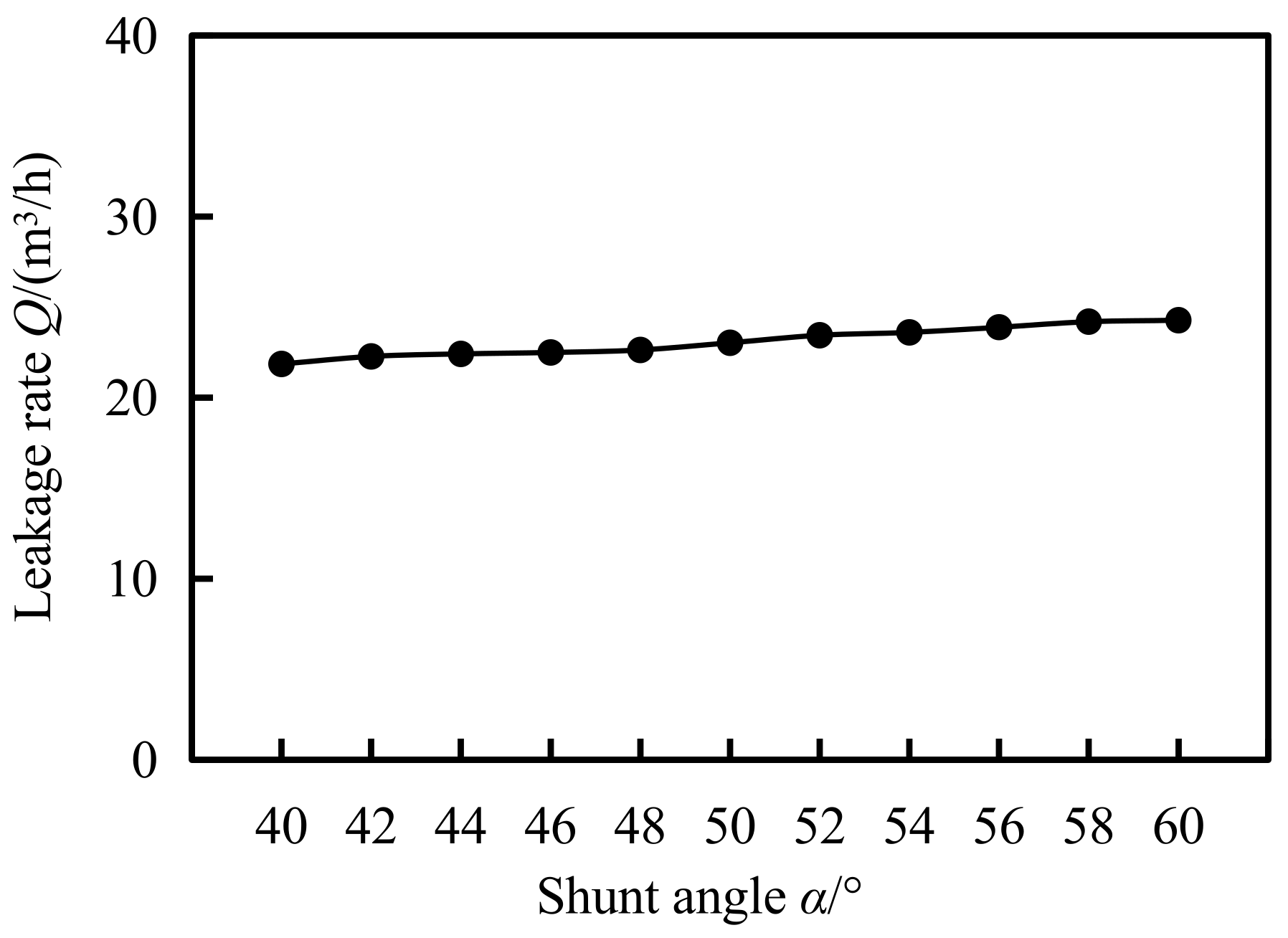

- (2)

- Optimal shunt angle

- (3)

- Optimal radius of suspending pillar

- (4)

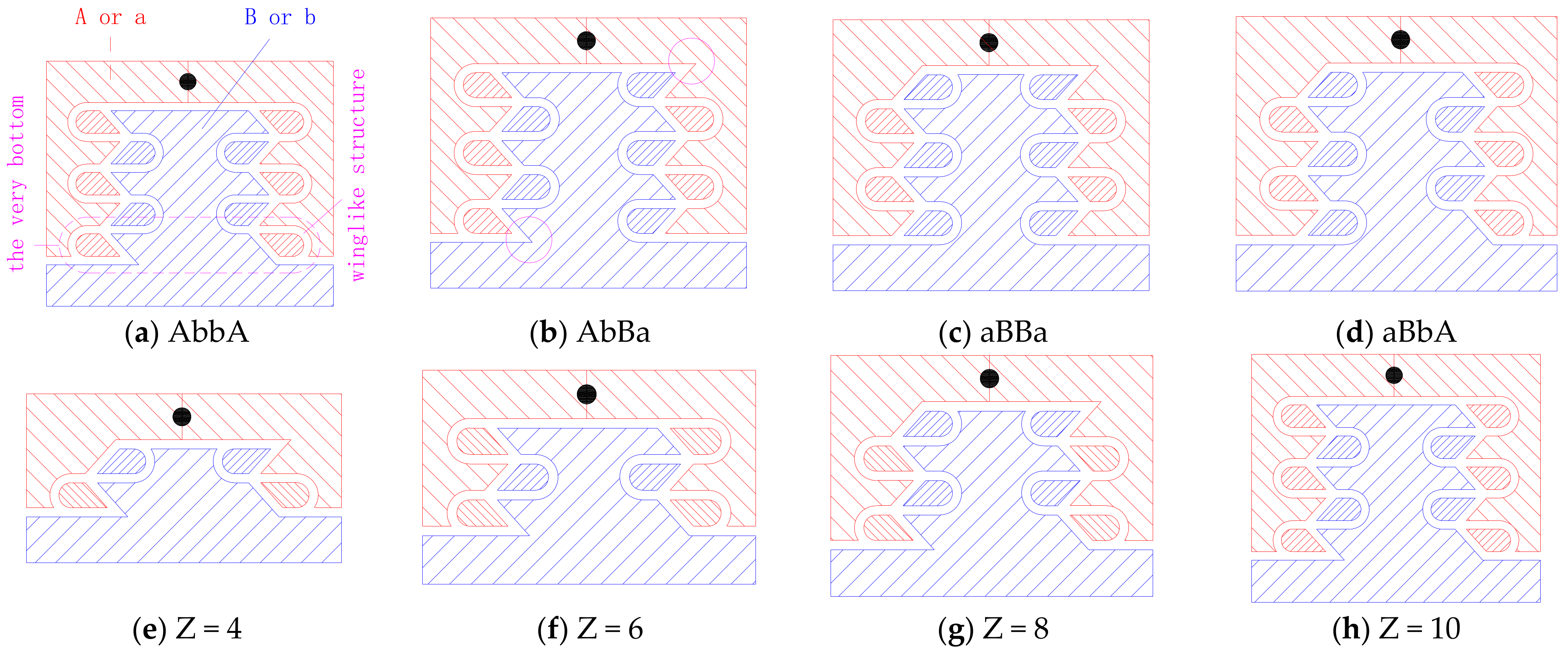

- Optimal structure scheme

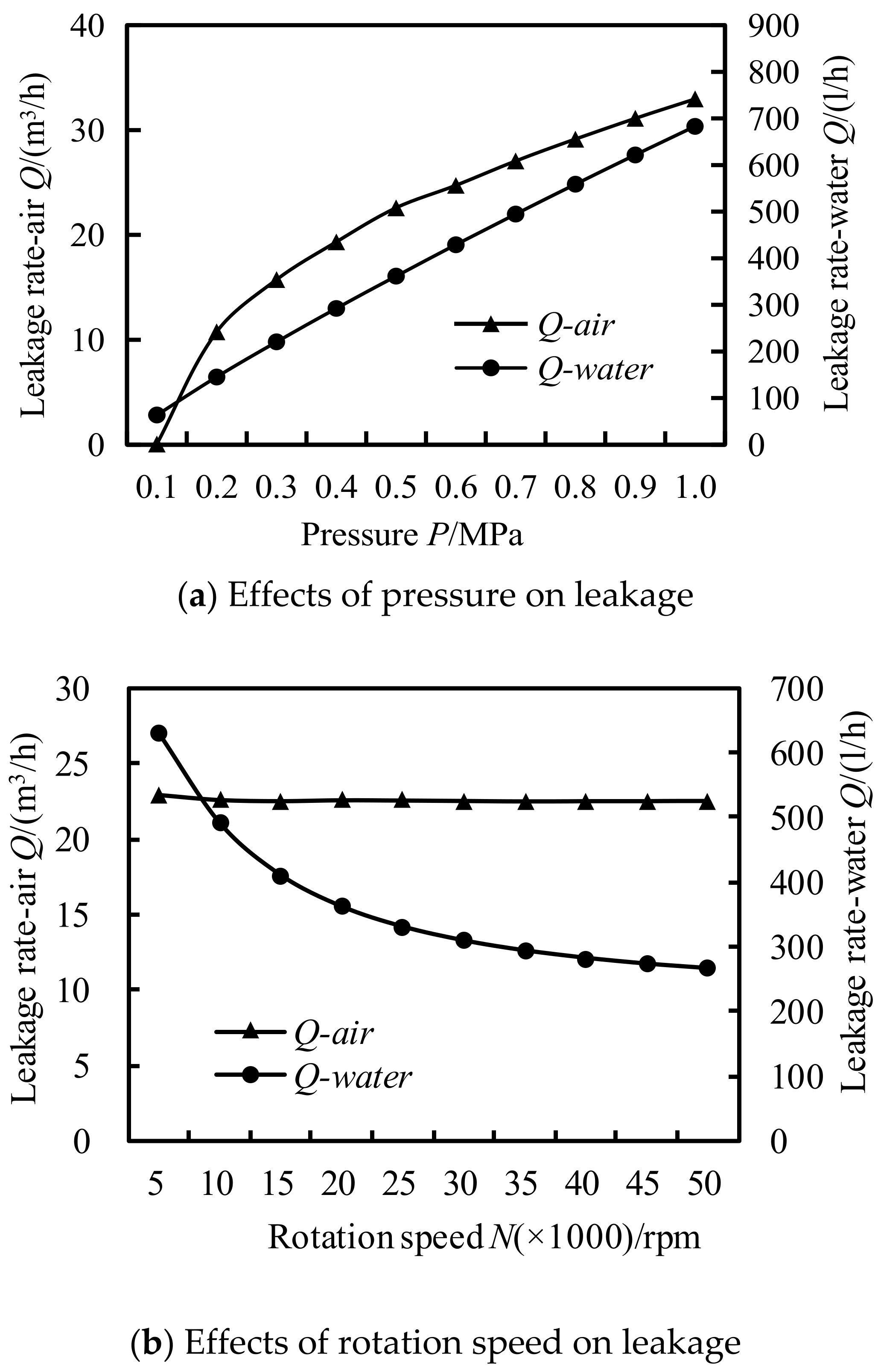

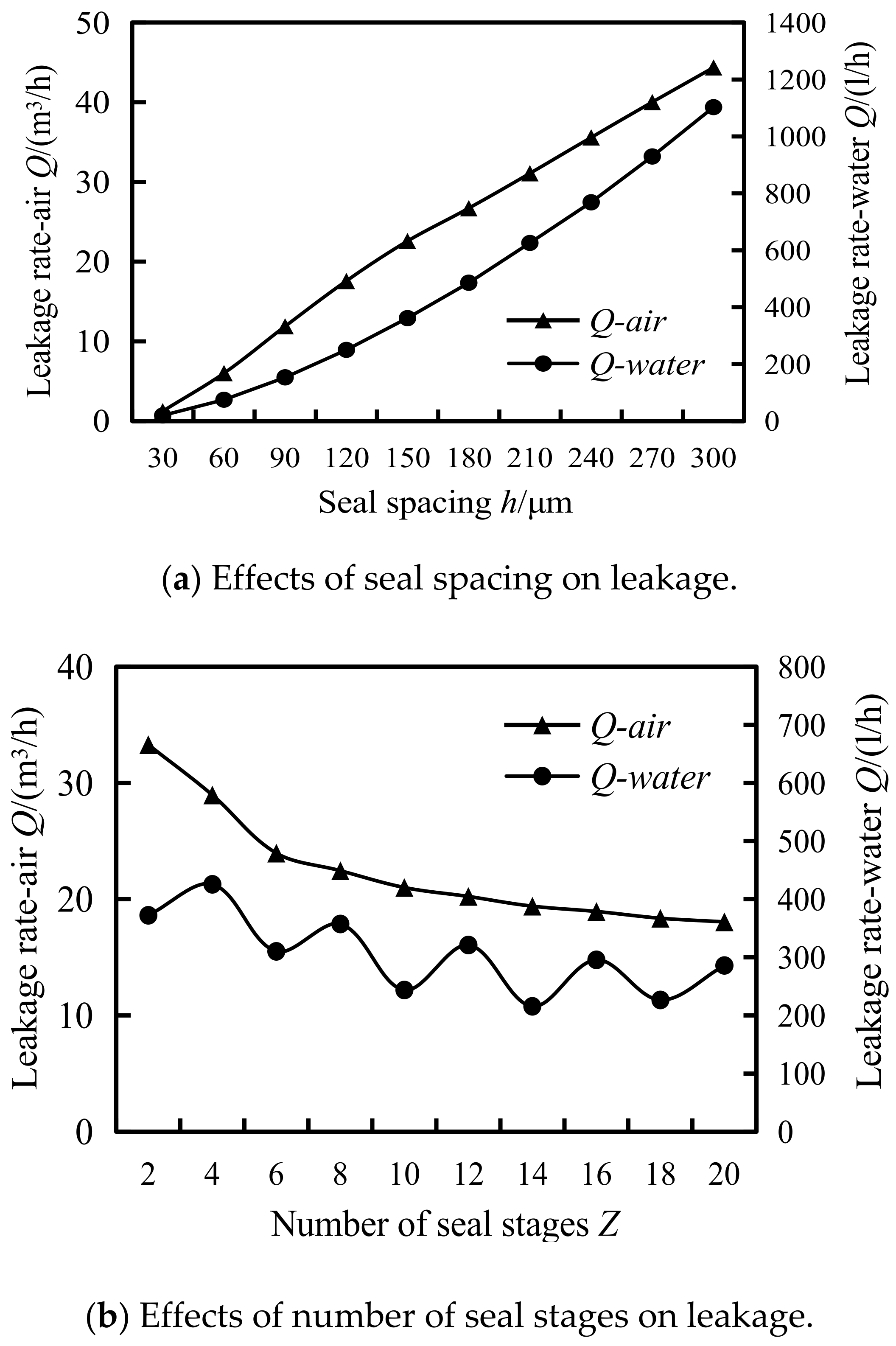

4.3. Leakage Characteristics

- (1)

- Effect of operating parameters

- (2)

- Effects of geometric parameters

4.4. Temperaturecharacteristic

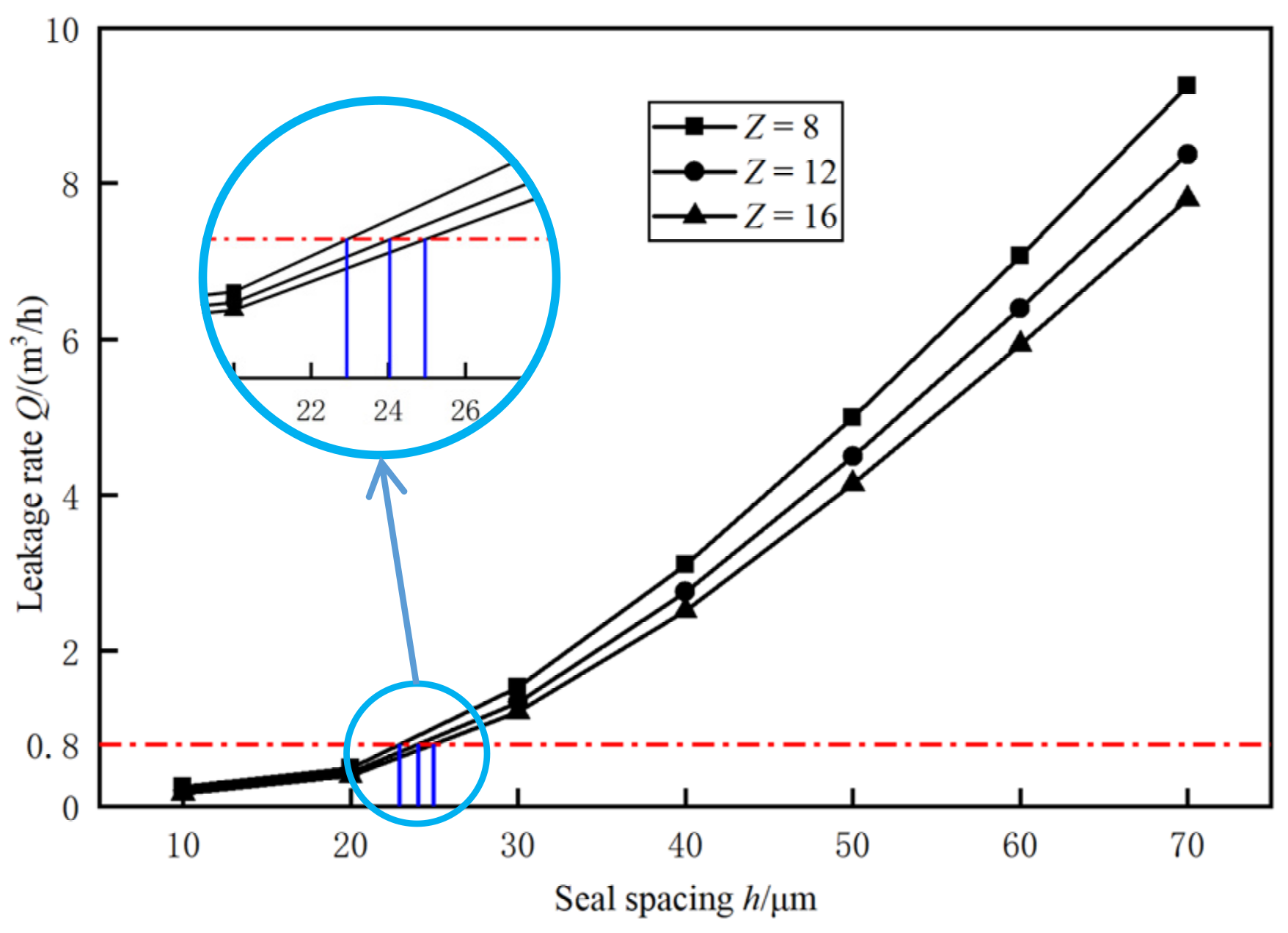

4.5. Leakage Characteristic

4.6. Comparative Analysis of Various Types of Non-Contact Seals under the Same Working Conditions

5. Conclusions

- The inner and outer rings of the proposed seal design can be rigidly fixed by relying on other components. Furthermore, the rings maintained a stable clearance to enable non-contact operation under the sealing function. Consequently, the ability of the sealing pair in resisting axial/radial vibrations improved significantly. Furthermore, the sealing condition was not limited by the rotation speed and no stopping of the auxiliary sealing device was required.

- Theoretically, the standard leakage or even zero leakage of the proposed seal can be achieved if the number of seal stages is sufficiently high. The proposed seal exhibited an improved leak suppression effect in low-pressure and high-viscosity media, with multiple seal stages and small seal spacings; furthermore, it was less affected by the rotation speed and media density. The reverse throttling effect was the most sensitive to pressure and seal spacing changes and it remained insensitive to the rotation speed and density.

- Under the same operating conditions, when the proposed seal achieved the same standard of leakage, the corresponding seal spacing was several or dozens of times that of the dry gas seal, which was conducive to reducing the direct contact risk of the sealing pair and significantly improved the operation stability of the non-contact seal.

- The proposed symmetrical seal structure is able to achieve the same cross-sectional area at the inlet and outlet interfaces; as such, leakage will not increase when the number of seal stages is increased, which improves the throttling effect. The segmented design of the outer ring is able to solve the assembly problem. This design idea can provide a theoretical reference for the further optimisation and engineering development of the proposed impact seal.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| R | Turning radius [mm] |

| l | Flow distance [mm] |

| α | Shunt angle [°] |

| d | Sealing shaft diameter [mm] |

| h | Seal spacing [μm] |

| m | Inlet distance [mm] |

| n | Outlet distance [mm] |

| e | Interleaving value [mm] |

| k(e/h) | Interleaving ratio |

| Pin | Medium pressure [MPa] |

| Z | Number of seal stages |

| N | Rotation speed [rpm] |

| ρ | Medium density of the fluid [kg/m3] |

| u | Axial fluid flow velocities [m/s] |

| v | Radial fluid flow velocities [m/s] |

| w | Tangential fluid flow velocities [m/s] |

| T | Fluid temperature [K] |

| U | Heat transfer coefficient |

| c | Specific heat capacity [J/kg·K] |

| ST | Viscous dissipative item |

| Q | Leakage rate [m3·h−1] |

| Qmin | Standard value for dynamic leakage of dry gas seals for compressors [m3·h−1] |

| P | Sealing gas pressure [MPa] |

| L | Seal axial width [mm] |

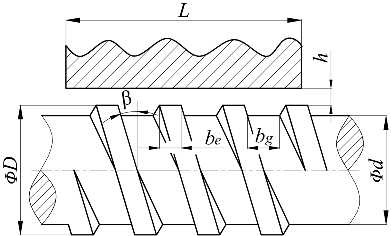

| D | Outer diameter of screw seal [mm] |

| be | Tooth top width of screw seal [mm] |

| bg | Groove width of screw seal [mm] |

| β | Helix angle [°] |

| i | Number of spiral heads |

| s1 | Seal pitch of labyrinth seal [mm] |

| s2 | Tooth thickness of labyrinth seal [mm] |

| c1 | Clearance of labyrinth seal [mm] |

| hl | Tooth height of labyrinth seal [mm] |

| θ | Inclination angle of labyrinth seal [°] |

| Zt | Tooth number of labyrinth seal |

References

- Dindorf, R.; Wos, P. A numerical solution of temperature distribution in the clearance and the sealing rings of the non-contact face seal. J. Phys. Conf. Ser. 2021, 1741, 012032. [Google Scholar] [CrossRef]

- Zaniewski, D.; Klimaszewski, P.; Klonowicz, P.; Lampart, P.; Witanowski, Ł.; Jędrzejewski, Ł.; Suchocki, T.; Antczak, Ł. Performance of the honeycomb type sealings in organic vapour microturbines. Energy 2021, 226, 120242. [Google Scholar] [CrossRef]

- Androsovich, I.V.; Siluyanova, M.V. Optimization of labyrinth seals in gas-turbine engines. Russ. Eng. Res. 2021, 41, 360–362. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, J.J.; Hu, Q.; Wang, D.; Zheng, X. Orientation effect of orderly roughness microstructure on spiral groove dry gas seal. Tribol. Int. 2018, 126, 97–105. [Google Scholar] [CrossRef]

- Bai, S.X.; Hao, J.L.; Yang, J.; Song, Y. Gas-liquid mass transfer behavior of upstream pumping mechanical face seals. Materials 2022, 15, 1482. [Google Scholar] [CrossRef]

- Zhang, W.W.; Chen, H.Z.; Jiang, W.K.; Liu, R.; Jiang, S. A Spiral Seal Method in the Lunar Regolith for Chang’E-5 Drill: Seal Design and Experiment. IEEE Access 2019, 7, 11378–11386. [Google Scholar] [CrossRef]

- Zhou, X.J.; Chen, C.L.; Li, J.H.; Wu, Y. Study on radial clearance sealing performance of graphite ring. J. Press. Vessel Technol. 2021, 143, 031703–031711. [Google Scholar] [CrossRef]

- Zhi, D.; Li, S.X.; Zhang, Q.X.; Cai, J.N. Experimental research on new type of the centrifugal seal for sealing gas. Fluid Mach. 2012, 40, 12–15. [Google Scholar] [CrossRef]

- Mitamura, Y.; Nishimura, I.; Yano, T. Thermal analysis of a miniature magnetic fluid seal installed in an implantable rotary pump. J. Magn. Magn. Mater. 2022, 548, 168977. [Google Scholar] [CrossRef]

- Nikola, T. Valvular Conduit. US1329559, 3 February 1920. [Google Scholar]

- Forster, F.K.; Bardell, R.L.; Afromowitz, M.A.; Sharma, N.R.; Blanchard, A. Design, fabrication and testing of fixed-valve micro-pumps. In Proceedings of the 1995 ASME International Mechanical Engineering Congress and Exposition, San Francisco, CA, USA, 12–17 November 1995. [Google Scholar]

- Mohammadzadeh, K.; Kolahdouz, M.E.; Shirani, E.; Shafii, M.B. Numerical investigation on the effect of the size and number of stages on the Tesla microvalve efficiency. J. Mech. 2013, 29, 527–534. [Google Scholar] [CrossRef]

- Truong, T.Q.; Nguyen, N.T. Simulation and optimization of Tesla valves. Nanotechnology 2003, 1, 178–181. [Google Scholar]

- Gamboa, A.R.; Morris, C.J.; Forster, F.K. Improvements in fixed-valve micropump performance through shape optimization of valves. J. Fluids Eng. 2005, 127, 339–346. [Google Scholar] [CrossRef]

- Thompson, S.M.; Ma, H.B.; Wilson, C. Investigation of a flat-plate oscillating heat pipe with Tesla-type check valves. Exp. Therm. Fluid 2011, 35, 1265–1273. [Google Scholar] [CrossRef]

- Thompson, S.M.; Paudel, B.J.; Jamal, T.; Walters, D.K. Numerical investigation of multistaged Tesla valves. J. Fluids Eng. 2014, 136, 081102. [Google Scholar] [CrossRef]

- Wang, C.T.; Chen, Y.M.; Hong, P.A.; Wang, Y.T. Tesla valves in micromixers. International Jouresign and operation of a Tesla-type valve for pulsating heat pipes. Sci. Int. J. Heat Mass Transf. 2017, 105, 1–11. [Google Scholar] [CrossRef]

- Vries, S.D.; Florea, D.; Homburg, F.; Frijns, A. Design and operation of a Tesla-type valve for pulsating heat pipes. Sci. J. Heat Mass Transf. 2017, 105, 1–11. [Google Scholar] [CrossRef]

- Jin, Z.J.; Gao, Z.X.; Chen, M.R.; Qian, J.-Y. Parametric study on Tesla valve with reverse flow for hydrogen decompression. Int. J. Hydrogen Energy 2018, 43, 8888–8896. [Google Scholar] [CrossRef]

- Qian, J.Y.; Chen, M.R.; Liu, X.L.; Jin, Z.-J. A numerical investigation of the flow of nanofluids through a micro Tesla valve. J. Zhejiang Univ. —Sci. A Appl. Phys. Eng. 2019, 29, 50–60. [Google Scholar] [CrossRef]

- Qian, J.Y.; Chen, M.R.; Gao, Z.X.; Jin, Z.-J. Mach number and energy loss analysis inside multi-stage Tesla valves for hydrogen decompression. Energy 2019, 179, 647–654. [Google Scholar] [CrossRef]

- Wahidi, T.; Chandavar, R.A.; Yadav, A.K. Stability enhancement of supercritical CO2 based natural circulation loop using a modified Tesla valve. J. Supercrit. Fluids 2020, 166, 105020. [Google Scholar] [CrossRef]

- Monika, K.; Chakraborty, C.; Roy, S.; Sujith, R.; Datta, S.P. A numerical analysis on multi-stage Tesla valve based cold plate for cooling of pouch type Li-ion batteries. Int. J. Heat Mass Transf. 2021, 177, 121560. [Google Scholar] [CrossRef]

- Shi, H.H.; Cao, Y.; Zeng, Y.N.; Zhou, Y.; Wen, W.; Zhang, C.; Zhao, Y.; Chen, Z. Wearable tesla valve-based sweat collection device for sweat colorimetric analysis. Talanta 2022, 240, 123208. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xie, X.F.; He, Y.M.; Huang, Z.X.; Xu, H.; Chai, D.Z.; Yang, H.S. Research on a new non-contact fluid seal technology based on Tesla Valve. Tribology 2022. [Google Scholar] [CrossRef]

- Yang, Z.; Xi, D.L.; Li, N.; Zhou, J. Numerical simulation and experimental channel performance evaluation of the microchannel structure. Chem. Prog. 2021, 40, 39–47. [Google Scholar] [CrossRef]

- Xu, J.L.; Ma, H.Y.; Huang, Y.N. Nonlinear turbulence model reflecting strong flow curvature effect. Appl. Math. Mech. 2008, 29, 27–37. [Google Scholar] [CrossRef]

- Weng, X.Y.; Yan, S.H.; Zhang, Y.; Liu, J.W.; Shen, J.F. Design, simulation and experimental study of a micromixer based on Tesla Valve structure. Chem. Prog. 2021, 40, 4173–4178. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Wiley: New York, NY, USA, 1995. [Google Scholar]

- Zhou, R.Z.; Qiao, Y.J.; Zhang, Y.X.; Dai, Z.B. Simulation study on the performance of Tesla valve. Phys. Exp. 2020, 40, 44–50. [Google Scholar] [CrossRef]

- JB/T 11289-2012; Specification for Dry Gas Seal. China Machine Press: Beijing, China, 2012.

- Sun, K.Y.; Hao, Z.J. Mechanical Seal Structure Legend and Application; Chemical Industrial Press: Beijing, China, 2019. [Google Scholar]

- Huo, C.; Sun, J.; Song, P.; Sun, W. Influence of tooth geometrical shape on the leakage and rotordynamic characteristics of labyrinth seals in a cryogenic liquid turbine expander. Int. J. Refrig. 2022, 145, 105–117. [Google Scholar] [CrossRef]

- Ren, Z.H.; Wei, J.T.; Li, Y.C.; Xv, Y. Sealing capability and parameter optimization of screw seal. J. Northeast. Univ. (Nat. Sci.) 2016, 37, 1755–1758. [Google Scholar] [CrossRef]

| Parameters | Specification | Relative Fixed Value |

|---|---|---|

| Sealing shaft diameter d [mm] | 76 | 76 |

| Seal spacing h [μm] | 30–300 | 150 |

| Turning radius R [mm] | 2.25 | 2.25 |

| Flow distance l [mm] | 5.50 | 5.50 |

| Medium pressure Pin [MPa] | 0.10–1 | 0.50 |

| Rotation speed N/rpm | 5000–50,000 | 20,000 |

| Number of seal stage Z | 2–20 | 8 |

| Shunt angle α/° | 40–60 | 48 |

| AbbA | AbBa | aBBa | aBbA | |

|---|---|---|---|---|

| Z = 4 | 24.63 | 23.69 | 24.88 | 26.23 |

| Z = 6 | 22.63 | 22.02 | 22.24 | 22.70 |

| Z = 8 | 21.24 | 20.65 | 20.98 | 21.56 |

| Z = 10 | 20.28 | 20.09 | 20.26 | 20.43 |

| Sealing Gas Pressure P/MPa | Rotation Speed N/rpm | Seal Diameter D/mm |

|---|---|---|

| 60 ≦ d ≦ 90 | ||

| 0.5 < P ≦ 1.0 | >1000~3000 | ≦0.45 |

| >3000~7000 | ≦0.5 | |

| >7000~13,000 | ≦0.7 | |

| >13,000~18,000 | ≦0.8 |

|  |

|---|---|

| (a) clearance seal [32] | (b) labyrinth seal [33] |

|  |

| (c) screw seal [34] | (d) self-impact seal |

| Calculation Parameters | |

| Sealing medium | Air |

| Seal axial width L/mm | 35 |

| Sealing shaft diameter d/mm | 76 |

| Seal spacing h/μm | 150 |

| Outer diameter of screw seal D/mm | 76.78 |

| Tooth top width of screw seal be/mm | 3.48 |

| Groove width of screw seal bg/mm | 3.48 |

| Helix angle β/° | 5 |

| Number of spiral heads i | 3 |

| Seal pitch of labyrinth seal s1/mm | 2 |

| Tooth thickness of labyrinth seal s2/mm | 0.3 |

| Clearance of labyrinth seal c1/mm | 0.1 |

| Tooth height of labyrinth seal hl /mm | 2.45 |

| Inclination angle of labyrinth seal θ/° | 12 |

| Tooth number of labyrinth seal Zt | 17 |

| Medium pressure Pin/MPa | 0.5 |

| Rotation speed N/rpm | 20,000 |

| Number of stages for self-impact seal Z | 16 |

| Shunt angle α/° | 48 |

| Turning radius R/mm | 2.25 |

| Flow distance l/mm | 5.50 |

| Seal Type | Air Leakage Rate (m3/h) | Relative Reduction Ratio |

|---|---|---|

| Labyrinth seal | 29.60 | 35.14% |

| Screw seal | 41.37 | 53.59% |

| Clearance seal | 46.25 | 58.49% |

| Self-impact seal | 19.20 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; He, Y.; Xie, X.; Huang, Z.; Xu, H.; Hu, Q.; Ma, C. Design and Simulation of a New Near Zero-Wear Non-Contact Self-Impact Seal Based on the Tesla Valve Structure. Lubricants 2023, 11, 102. https://doi.org/10.3390/lubricants11030102

Wang Y, He Y, Xie X, Huang Z, Xu H, Hu Q, Ma C. Design and Simulation of a New Near Zero-Wear Non-Contact Self-Impact Seal Based on the Tesla Valve Structure. Lubricants. 2023; 11(3):102. https://doi.org/10.3390/lubricants11030102

Chicago/Turabian StyleWang, Yan, Yiming He, Xuefei Xie, Zhouxin Huang, Hui Xu, Qiong Hu, and Chenbo Ma. 2023. "Design and Simulation of a New Near Zero-Wear Non-Contact Self-Impact Seal Based on the Tesla Valve Structure" Lubricants 11, no. 3: 102. https://doi.org/10.3390/lubricants11030102

APA StyleWang, Y., He, Y., Xie, X., Huang, Z., Xu, H., Hu, Q., & Ma, C. (2023). Design and Simulation of a New Near Zero-Wear Non-Contact Self-Impact Seal Based on the Tesla Valve Structure. Lubricants, 11(3), 102. https://doi.org/10.3390/lubricants11030102