Application of an Oleophobic Coating to Improve Formability in the Deep-Drawing Process

Abstract

:1. Introduction

2. Experimental and FEM Simulation Procedures

2.1. Experimental Procedures

2.1.1. Tribology Tests

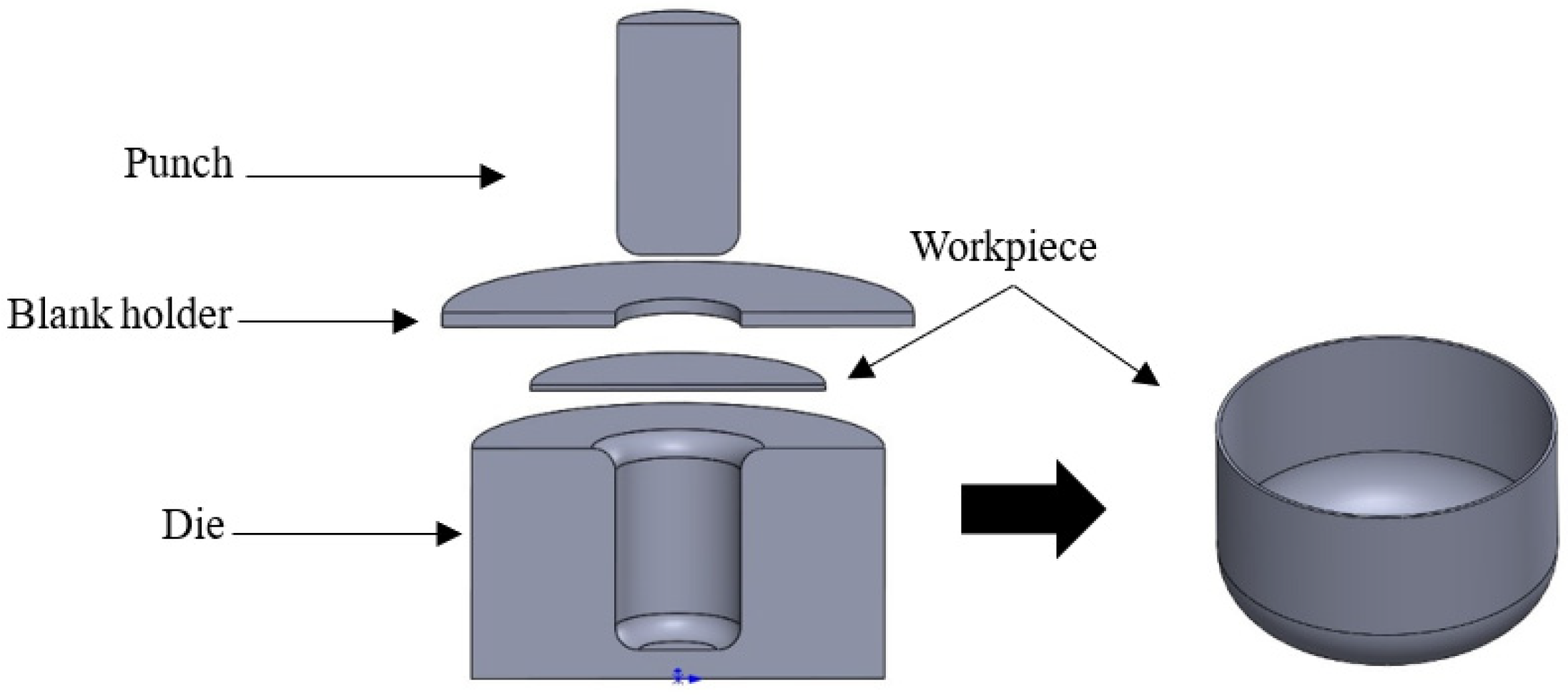

2.1.2. Deep-Drawing Experiments

2.2. FEM Simulation Procedures

3. Results and Discussion

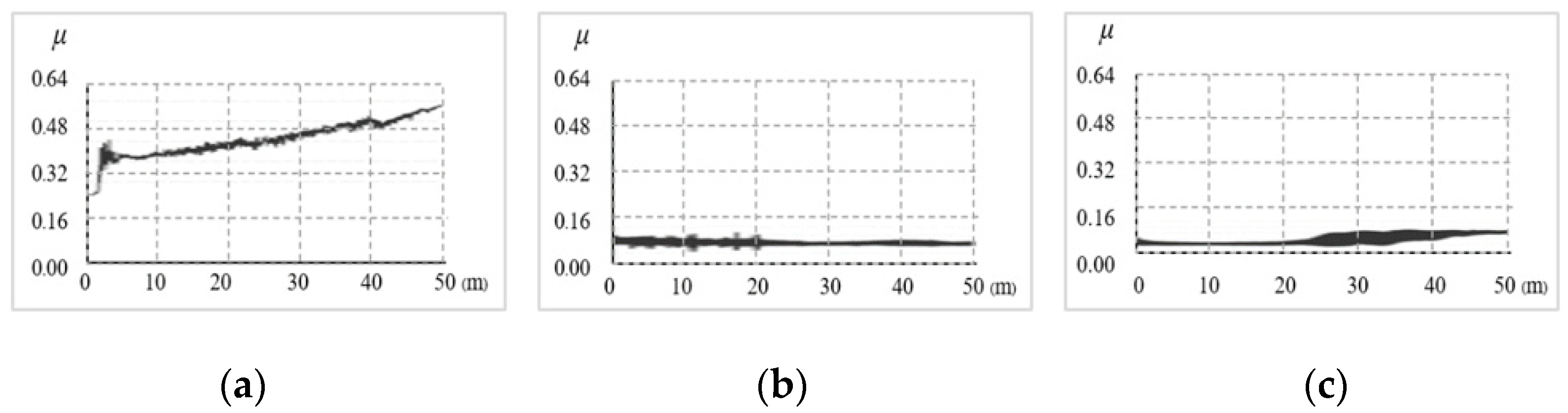

3.1. Friction Coefficient Examinations

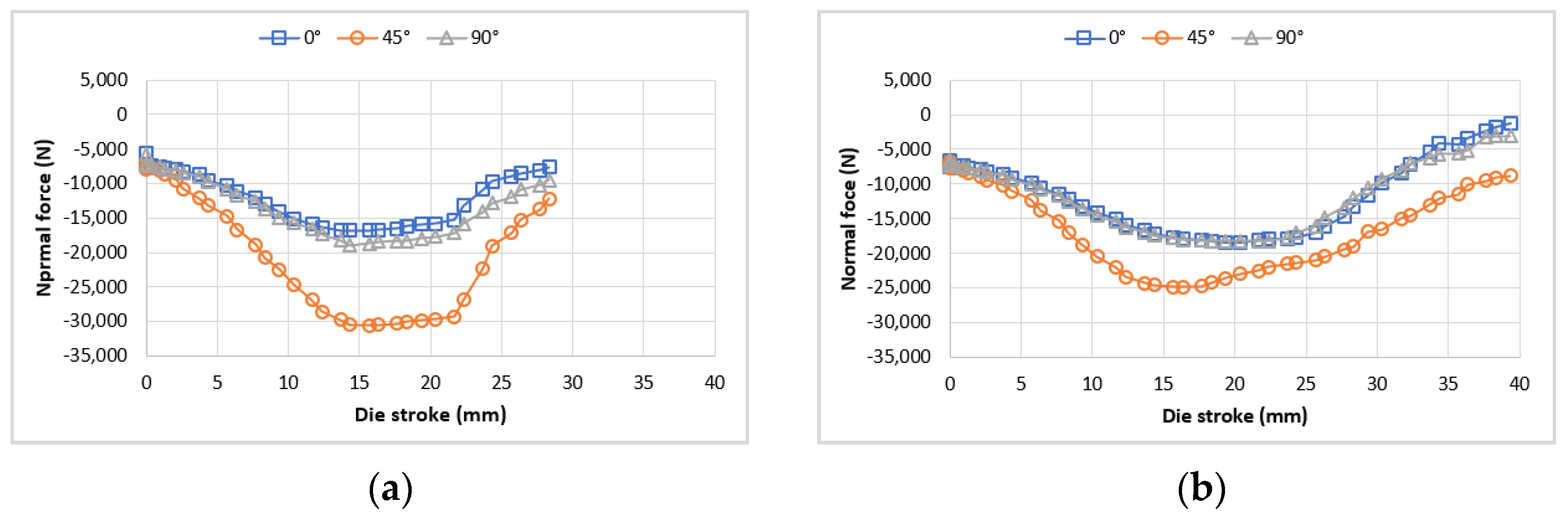

3.2. Analysis of Normal Force and Friction Force on Flange Portion during the Deep-Drawing Phase with Respect to Various Types of Lubricants

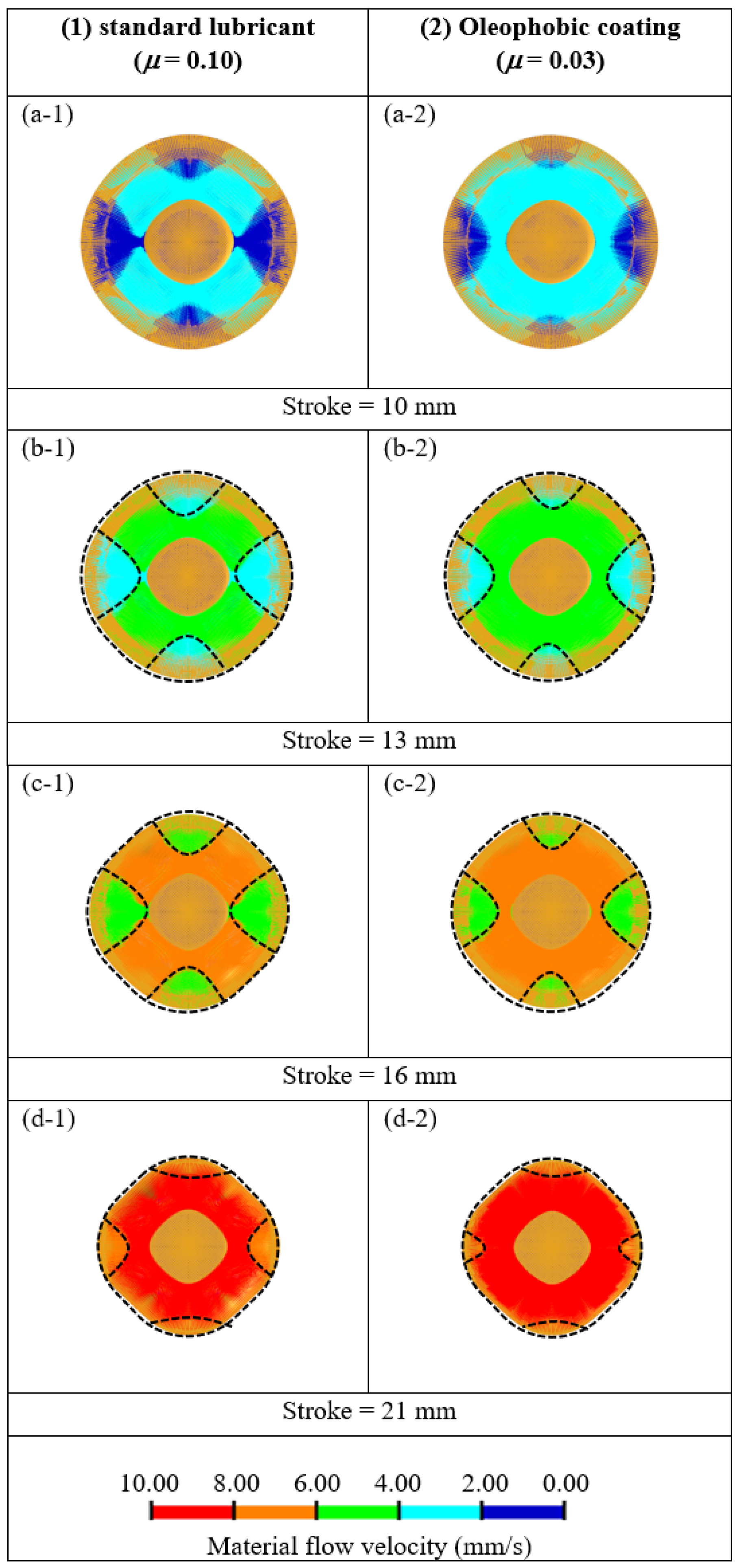

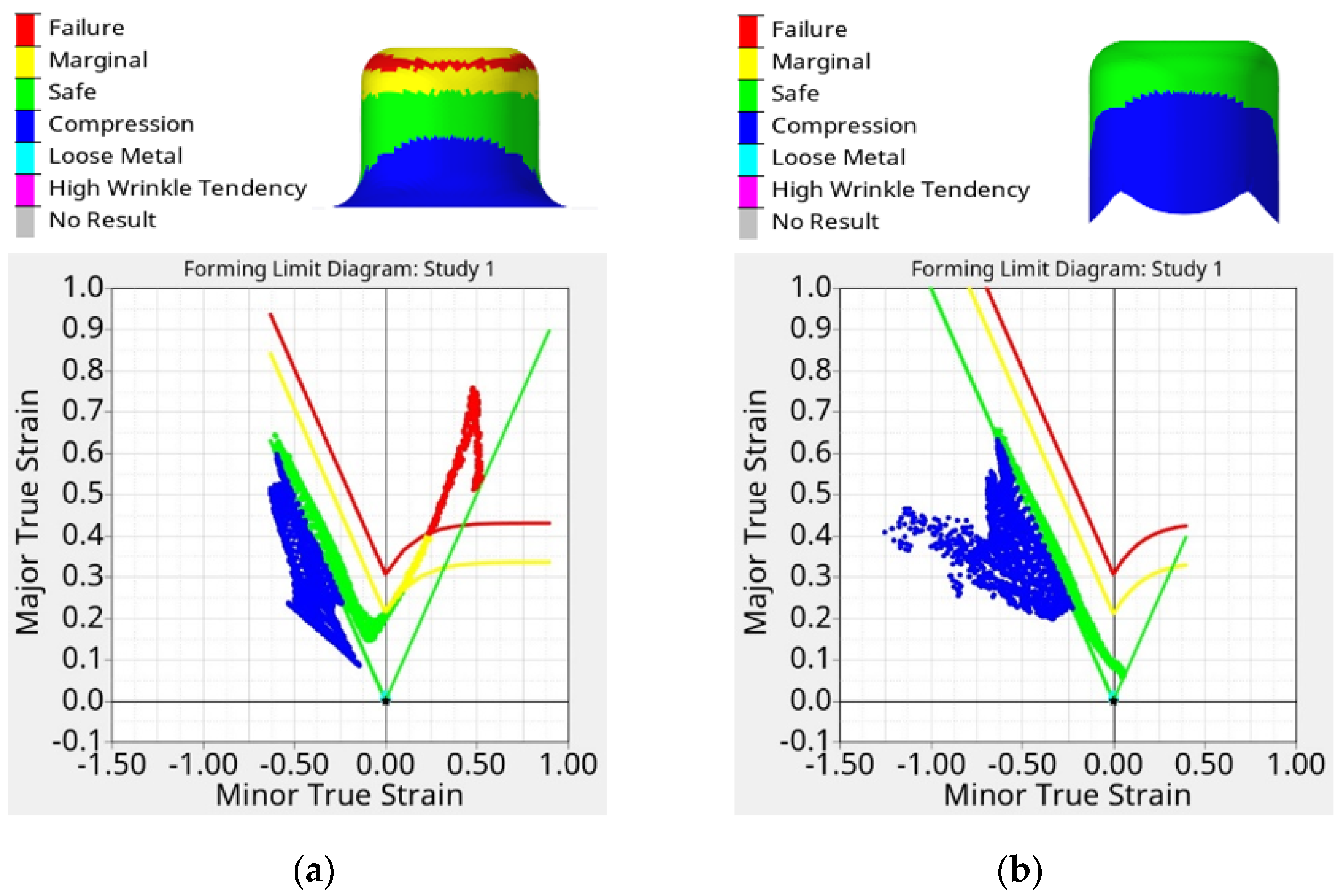

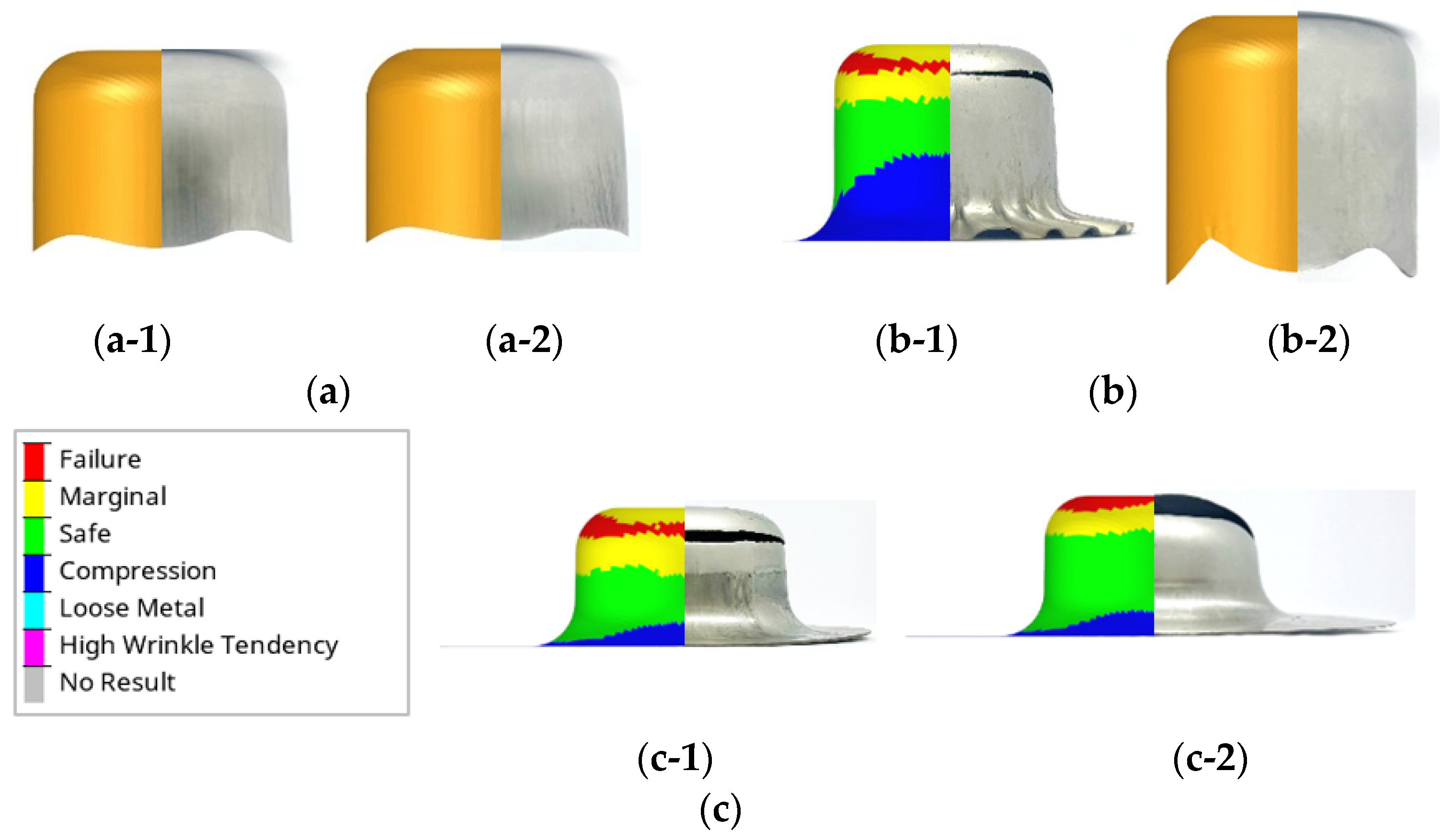

3.3. Comparison of Material Flow Analysis between a Standard Lubricant and Oleophobic Coating Applications

3.4. Examination of Material Flow Analysis with Respect to Drawing Ratios

3.5. Confirmation of FEM Simulation Use and Oleophobic Coating Applications

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leu, D.K. A simplified approach for distinguishing between spring-back and spring-go in free U-die bending process of SPFC 440 sheets. Mater. Des. 2016, 94, 314–321. [Google Scholar] [CrossRef]

- Thipprakmas, S.; Komolruji, P. Analysis of bending mechanism and spring-back characteristics in the offset Z-bending process. Int. J. Adv. Manuf. Technol. 2016, 85, 2589–2596. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, Z.; Du, Z.; Yu, H.; Qiu, D.; Cheng, Y.; Xiao, X. Inverse bending and springback-control using magnetic pulse forming. J. Mater. Process. Technol. 2020, 275, 116374. [Google Scholar] [CrossRef]

- Meng, Q.; Zhao, J.; Mu, Z.; Zhai, R.; Yu, G. Springback prediction of multiple reciprocating bending based on different hardening models. J. Manuf. Process. 2022, 76, 251–263. [Google Scholar] [CrossRef]

- Luoa, C.; Chena, Z.; Zhoua, K.; Yanga, X.; Zhang, X. A novel method to significantly decrease the die roll during fine-blanking process with verification by simulation and experiments. J. Mater. Process. Technol. 2022, 250, 254–260. [Google Scholar] [CrossRef]

- Ao, D.; Chu, X.; Yang, Y.; Lin, S.; Gao, J. Effect of electropulsing on springback during V-bending of Ti-6Al-4V titanium alloy sheet. Int. J. Adv. Manuf. Technol. 2018, 96, 3197–3207. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, L.; Lai, X. Influence of the electric pulse on springback during stretch U-bending of Ti6Al4V titanium alloy sheets. J. Mater. Process. Technol. 2018, 261, 12–23. [Google Scholar] [CrossRef]

- Gustafsson, E.; Oldenburg, M.; Jansson, A. Experimental study on the effects of clearance and clamping in steel sheet metal shearing. J. Mater. Process. Technol. 2016, 229, 172–180. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Tang, B.; Hua, L.; Mao, H. Investigation of a novel modified die design for fi-ne-blanking process to reduce the die-roll size. J. Mater. Process. Technol. 2018, 260, 30–37. [Google Scholar] [CrossRef]

- Zheng, Q.; Zhuang, X.; Hu, J.; Zhao, Z. Formability of the heat-assisted fine-blanking process for 304 stainless steel plates. Mater. Charact. 2020, 166, 110452. [Google Scholar] [CrossRef]

- Diewwanit, O.; Keawchaum, P.; Keawchaum, T.; Petchhan, W.; Thipprakmas, S. Microstructural evolution and fracture mechanism for scar defect formation on advanced high strength steel during a shearing process. J. Manuf. Sci. Eng. 2021, 143, 061008. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, T.; Hua, L.; Mao, H. Research on the effect of ultrasonic vibration on the roll-over during the fine blanking process. J. Mech. Sci. Technol. 2017, 31, 835–843. [Google Scholar] [CrossRef]

- Sahli1, M.; Roizard, X.; Assoul, M.; Colas, G.; Giampiccolo, S.; Barb, J.P. Finite element simulation and experimental investigation of the effect of clearance on the forming quality in the fine blanking process. Microsyst. Technol. 2021, 27, 871–881. [Google Scholar] [CrossRef]

- Mao, H.; Chen, H.; Liu, Y.; Ji, K. A novel force variation fine-blanking process for the high-strength and low-plasticity material. Metals 2022, 12, 458. [Google Scholar] [CrossRef]

- Balla, V.K.; Coox, L.; Deckers, E.; Greco, F.; Pluymers, B.; Desmet, W. A study of vibro-acoustic behaviour variation of thin sheet metal components manufactured through deep drawing process. Appl. Acoust. 2019, 153, 110–126. [Google Scholar] [CrossRef]

- Yuan, S.; Cheng, W.; Liu, W.; Xu, Y. A novel deep drawing process for aluminum alloy sheets at cryogenic temperatures. J. Mater. Process. Technol. 2020, 284, 116743. [Google Scholar] [CrossRef]

- Rivas-Menchi, A.; Medellin-Castillo, H.I.; De lnge, D.F.; Garcia-Zugasti, P.D.J. Performance evaluation of analytical expressions for cylindrical and rectangular deep drawing force estimation. J. Manuf. Process. 2018, 36, 340–350. [Google Scholar] [CrossRef]

- Prasad, K.S.; Panda, S.K.; Kar, S.K.; Murty, S.V.S.N.; Sharma, S.C. Prediction of fracture and deep drawing behavior of solution treated Inconel- 718 sheets: Numerical modeling and experimental validation. Mater. Sci. Eng. A 2018, 733, 393–407. [Google Scholar] [CrossRef]

- Phanitwong, W.; Thipprakmas, S. Multi draw radius die design for increases in limiting drawing ratio. Metals 2020, 10, 870. [Google Scholar] [CrossRef]

- Manabe, K.; Soeda, K.; Shibata, A. Effects of variable punch speed and blank holder force in warm superplastic deep drawing process. Metals 2021, 11, 493. [Google Scholar] [CrossRef]

- Jankree, R.; Thipprakmas, S. Achievements of nearly zero earing defects on SPCC cylindrical drawn cup using multi draw radius die. Metals 2020, 10, 1204. [Google Scholar] [CrossRef]

- Tran, M.T.; Shan, Z.; Lee, H.W.; Kim, D.K. Earing reduction by varying blank holding force in deep drawing with deep neural network. Metals 2021, 11, 395. [Google Scholar] [CrossRef]

- Wang, Z.; Dong, W.; Lin, Q.; Bu, G. On the earing in cup-drawing with non-uniform die clearance: Analytical, numerical and experimental approaches. J. Adv. Mech. Des. Syst. Manuf. 2021, 15, JAMDSM0029. [Google Scholar] [CrossRef]

- Park, T.; Abu-Farha, F.; Pourboghrat, F. An evolutionary yield function model based on plastic work and non-associated flow rule. Metals 2019, 9, 611. [Google Scholar] [CrossRef] [Green Version]

- Benke, M.; Schweitzer, B.; Hlavacs, A.; Mertinger, V. Prediction of earing of cross-rolled Al sheets from {h00} pole figures. Metals 2020, 10, 192. [Google Scholar] [CrossRef] [Green Version]

- Bouchaala, K.; Ghanameh, M.F.; Faqir, M.; Mada, M.; Essadiqi, E. Numerical investigation of the effect of punch corner radius and die shoulder radius on the flange earrings for AA1050 and AA1100 aluminum alloys in cylindrical deep drawing process. Heliyon 2021, 7, e06662. [Google Scholar] [CrossRef]

- Wang, C.; Li, D.; Meng, B.; Wan, M. Effect of anisotropic yield functions on prediction of critical process window and deformation behavior for hydrodynamic deep drawing of aluminum alloys. Metals 2020, 10, 492. [Google Scholar] [CrossRef] [Green Version]

- Hlavacs, A.; Szucs, M.; Mertinger, V.; Benke, M. Prediction of earing of hot-rolled Al sheets from pole figures. Metals 2021, 11, 99. [Google Scholar] [CrossRef]

- Sen, M.; Kurgan, N. Improving deep drawability of HC300LA sheet metal by warm forming. Int. J. Adv. Manuf. Technol. 2016, 82, 985–995. [Google Scholar] [CrossRef]

- Phanitwong, W.; Sriborwornmongkol, J.; Thipprakmas, S. Zoning lubricant die application for improving formability of box-shaped deep drawn parts. Metals 2021, 11, 1015. [Google Scholar] [CrossRef]

- Lange, K. Handbook of Metal Forming; McGraw-Hill Inc.: New York, NY, USA, 1985; pp. 20.10–20.69. [Google Scholar]

- Liewald, M.; Worz, C.; Riedmuller, K.R. Characterization of a novel aerostatic lubrication system for deep drawing processes. CIRP Ann.—Manuf. Technol. 2021, 70, 239–242. [Google Scholar] [CrossRef]

- Szewczyk, M.; Szwajka, K.; Trzepiecinski, T. Frictional characteristics of deep-drawing quality steel sheets in the flat die strip drawing test. Materials 2022, 15, 5236. [Google Scholar] [CrossRef]

- Zein, H.; Irfan, O.M. Optimization and mapping of the deep drawing force considering friction combination. Appl. Sci. 2021, 11, 9235. [Google Scholar] [CrossRef]

- Trzepiecinski, T.; Szewczyk, M.; Szwajka, K. The use of non-edible green oils to lubricate DC04 steel sheets in sheet metal forming process. Lubricants 2022, 10, 210. [Google Scholar] [CrossRef]

- Pieter, S. Active barrier coating for packaging paper with controlled release of sunflower oils. Molecules 2021, 26, 3561. [Google Scholar]

- Zhang, Y.; Qing, C.; Lin, Y.; Guan, Y.; Dai, W.; Yang, Y.; Deng, G.; Guan, L. The fabrication of oleophobic coating and its application in particulates filtration. Coatings 2022, 12, 905. [Google Scholar] [CrossRef]

- Cirisano, F.; Ferrari, M. Sustainable materials for liquid repellent coatings. Coatings 2021, 11, 1508. [Google Scholar] [CrossRef]

- Ross, H.; Nguyen, H.; Nguyen, B.; Foster, A.; Salud, L.; Patino, M.; Gan, Y.X.; Li, M. Filter modified with hydrophilic and oleophobic coating for efficient and affordable oil/water separation. Separations 2022, 9, 269. [Google Scholar] [CrossRef]

- Ikhsan, S.N.W.; Yusof, N.; Aziz, F.; Ismail, A.F.; Shamsuddin, N.; Jaafar, J.; Salleh, W.N.; Goh, P.S.; Lau, W.J.; Misdan, N. Synthesis and optimization of superhydrophilic-superoleophobic chitosan–silica/HNT nanocomposite coating for oil–water separation using response surface methodology. Nanomaterials 2022, 12, 3673. [Google Scholar] [CrossRef]

- Wilson, W.R.D. Friction and lubrication in bulk metal forming processes. J. Appl. Metalwork. 1979, 1, 7–19. [Google Scholar] [CrossRef]

- Wilson, W.R.D.; Sheu, S. Real area of contact and boundary friction in metal forming. Int. J. Mech. Sci. 1988, 30, 475–489. [Google Scholar] [CrossRef]

- Sheu, S.; Wilson, W.R.D. Flattening of workpiece surface asperities in metal forming. In Proceedings of the N.A.M.R.C. XI, Society of Manufacturing Engineers (SME), Madison, WI, USA, 24–26 May 1983; pp. 172–178. [Google Scholar]

- Waoheim, T.; Bay, N. A model for friction in metal forming processes. Ann. CIRP 1978, 27, 189–194. [Google Scholar]

- Trzepiecinski, T.; Fejkiel, R. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

| Tool geometry | Punch: Punch diameter 41.4 mm, Punch radius 8.0 mm Die: Die diameter 42.5 mm, Die radius 8.0 mm Clearance: 0.55 mm | |

| Rougthness of tool (Punch, Die, Blank holder) | Ra | 0.35 µm |

| Rsk | −1.584 | |

| Punch speed | 30 mm/min | |

| Blank holder force | 7.0 kN | |

| Initial blank size | 80, 90 and 100 mm in diameter | |

| Thickness (t) | 0.5 mm | |

| Sheet material: Stainless steel (SUS304) | Ultimate tensile Strength | 672.08 MPa |

| Yield strength | 283.8 MPa | |

| Elongation | 47.2% | |

| Young’s modulus | 190 GPa | |

| Possion strain ratio | 0.34 | |

| Constititive equation | ||

| Plastic strain ratio | 0°: 0.985 45°: 1.209 90°: 1.055 | |

| Lubricant and friction coefficient (μ) | Dry lubricant: μ = 0.40 | |

| Conventional Lubricant (Ilofom, TDN81): μ = 0.10 | ||

| Oleophobic coating (Ultra-Ever Dry): μ = 0.03 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thipprakmas, S.; Sriborwornmongkol, J.; Jankree, R.; Phanitwong, W. Application of an Oleophobic Coating to Improve Formability in the Deep-Drawing Process. Lubricants 2023, 11, 104. https://doi.org/10.3390/lubricants11030104

Thipprakmas S, Sriborwornmongkol J, Jankree R, Phanitwong W. Application of an Oleophobic Coating to Improve Formability in the Deep-Drawing Process. Lubricants. 2023; 11(3):104. https://doi.org/10.3390/lubricants11030104

Chicago/Turabian StyleThipprakmas, Sutasn, Juksawat Sriborwornmongkol, Rudeemas Jankree, and Wiriyakorn Phanitwong. 2023. "Application of an Oleophobic Coating to Improve Formability in the Deep-Drawing Process" Lubricants 11, no. 3: 104. https://doi.org/10.3390/lubricants11030104