Prediction of RUL of Lubricating Oil Based on Information Entropy and SVM

Abstract

:1. Introduction

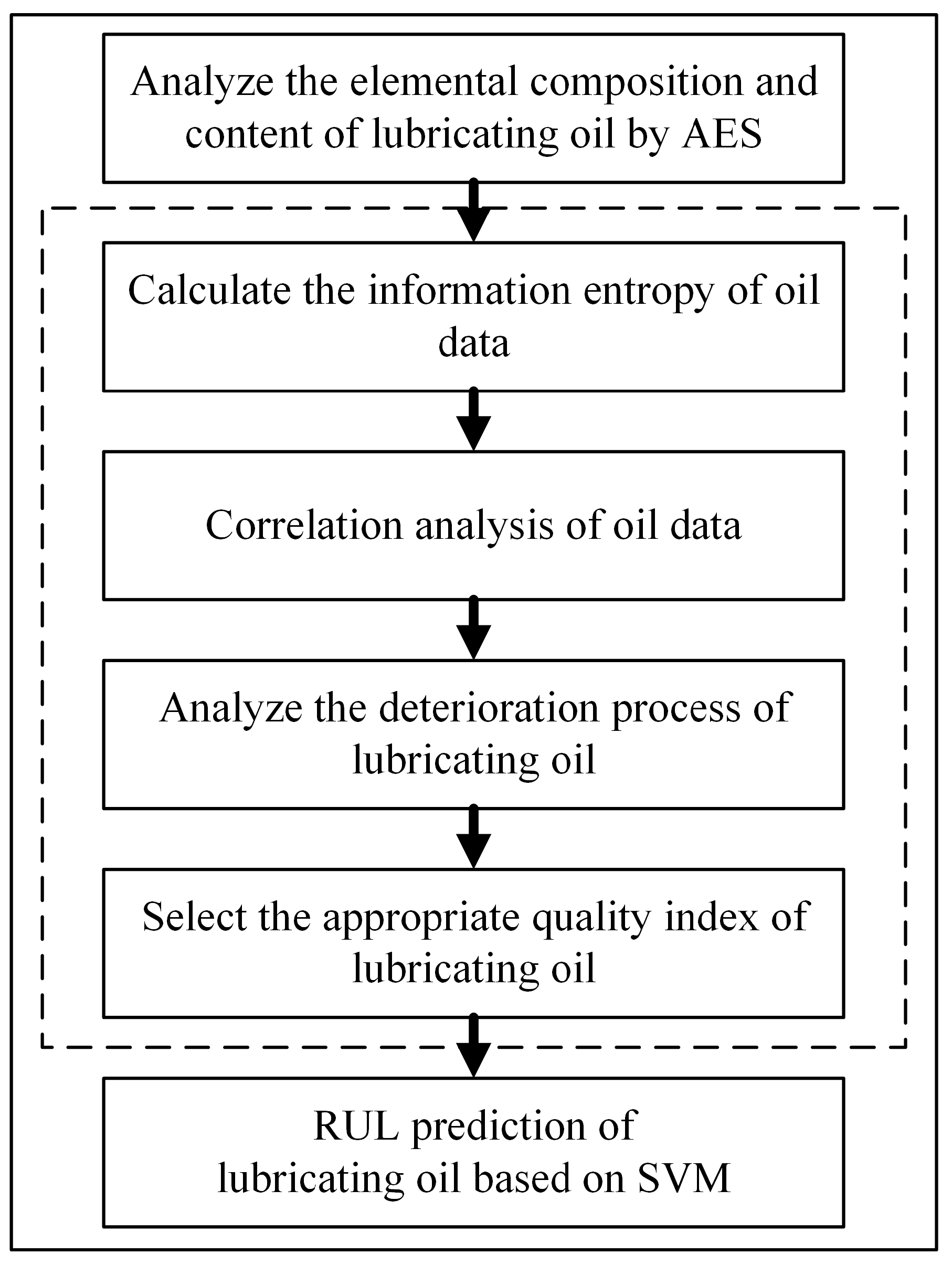

2. Materials and Methods

2.1. Oil Samples

2.2. AES Measurements

3. Parameter Selection

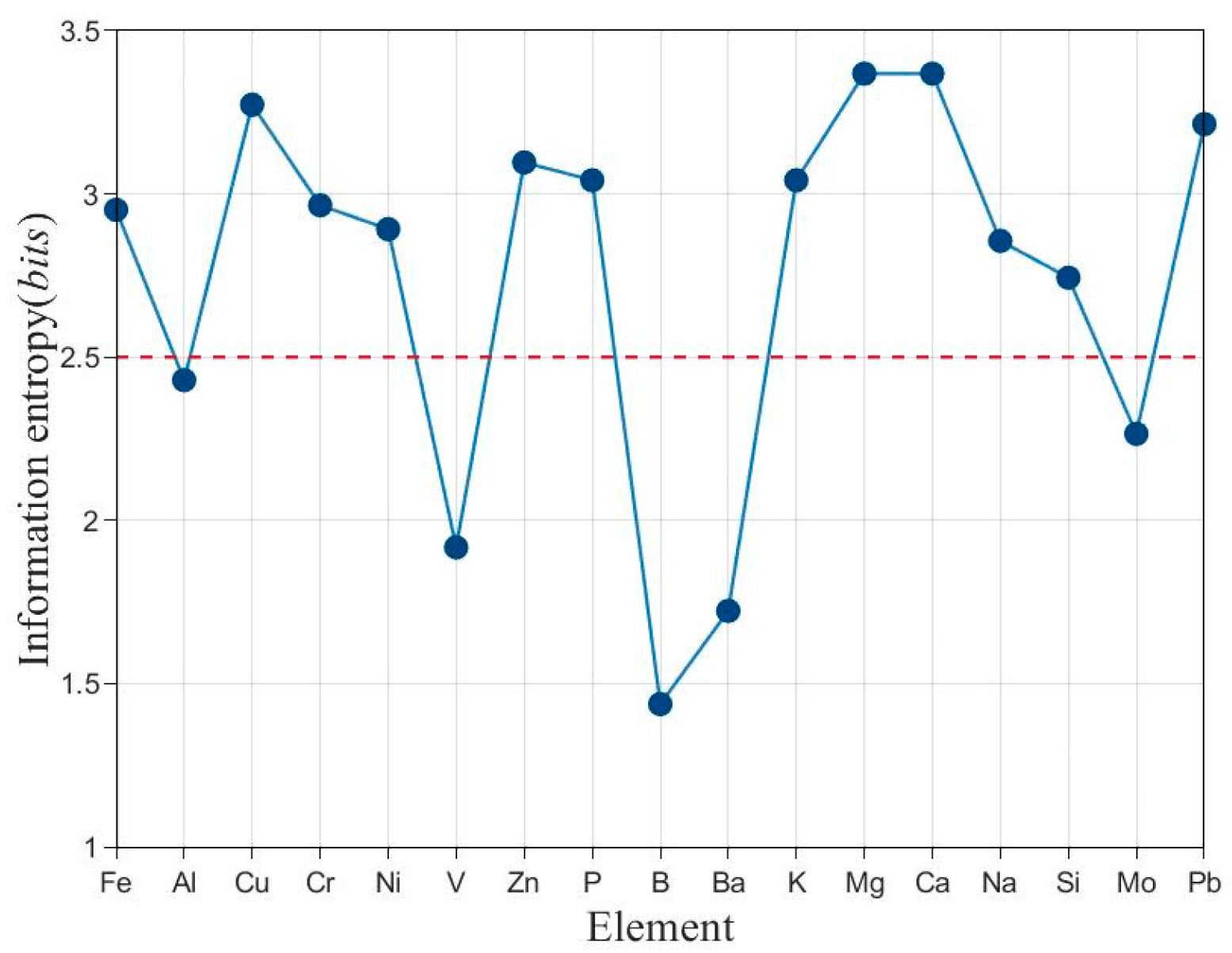

3.1. Information Entropy

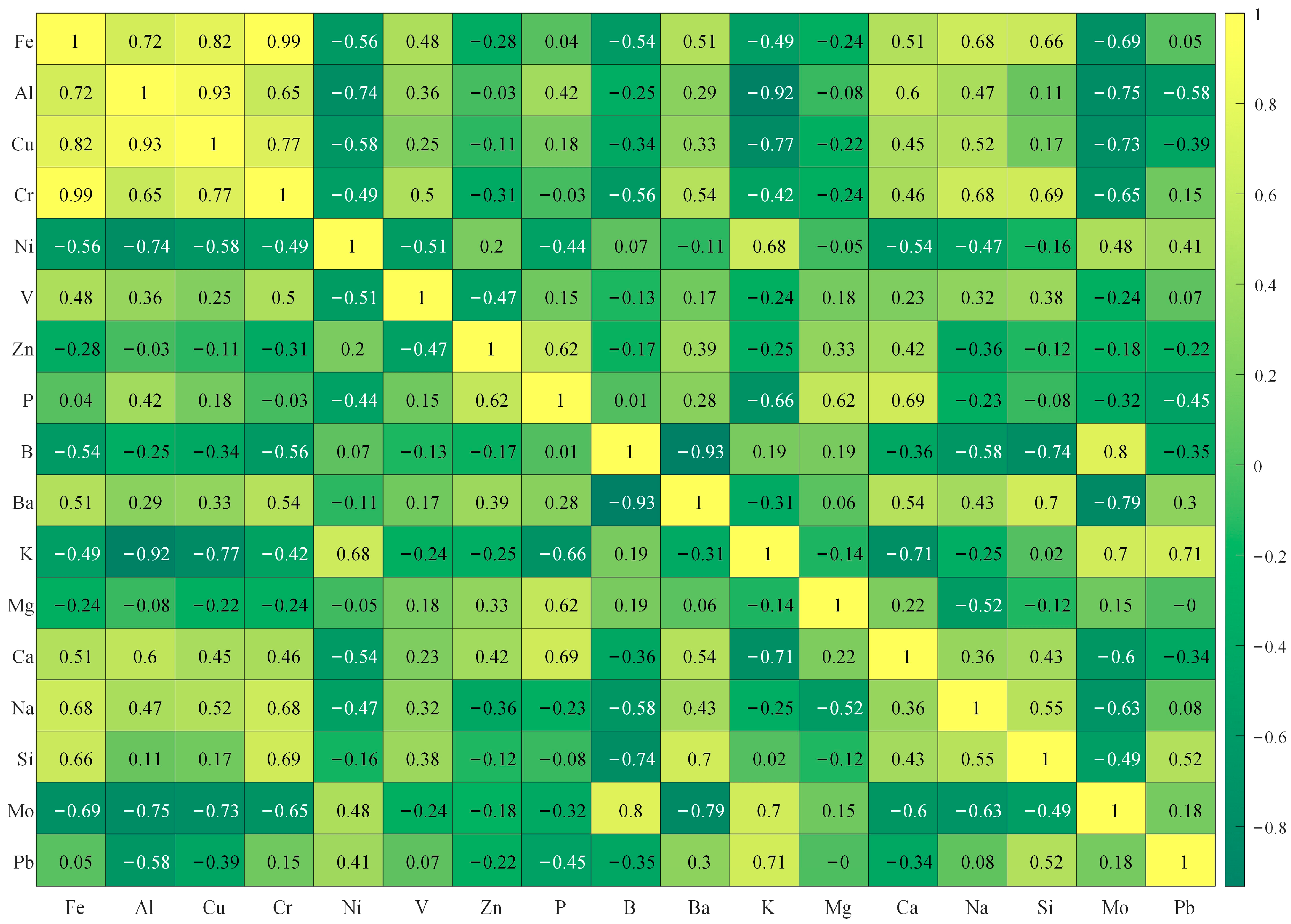

3.2. Correlation Analysis

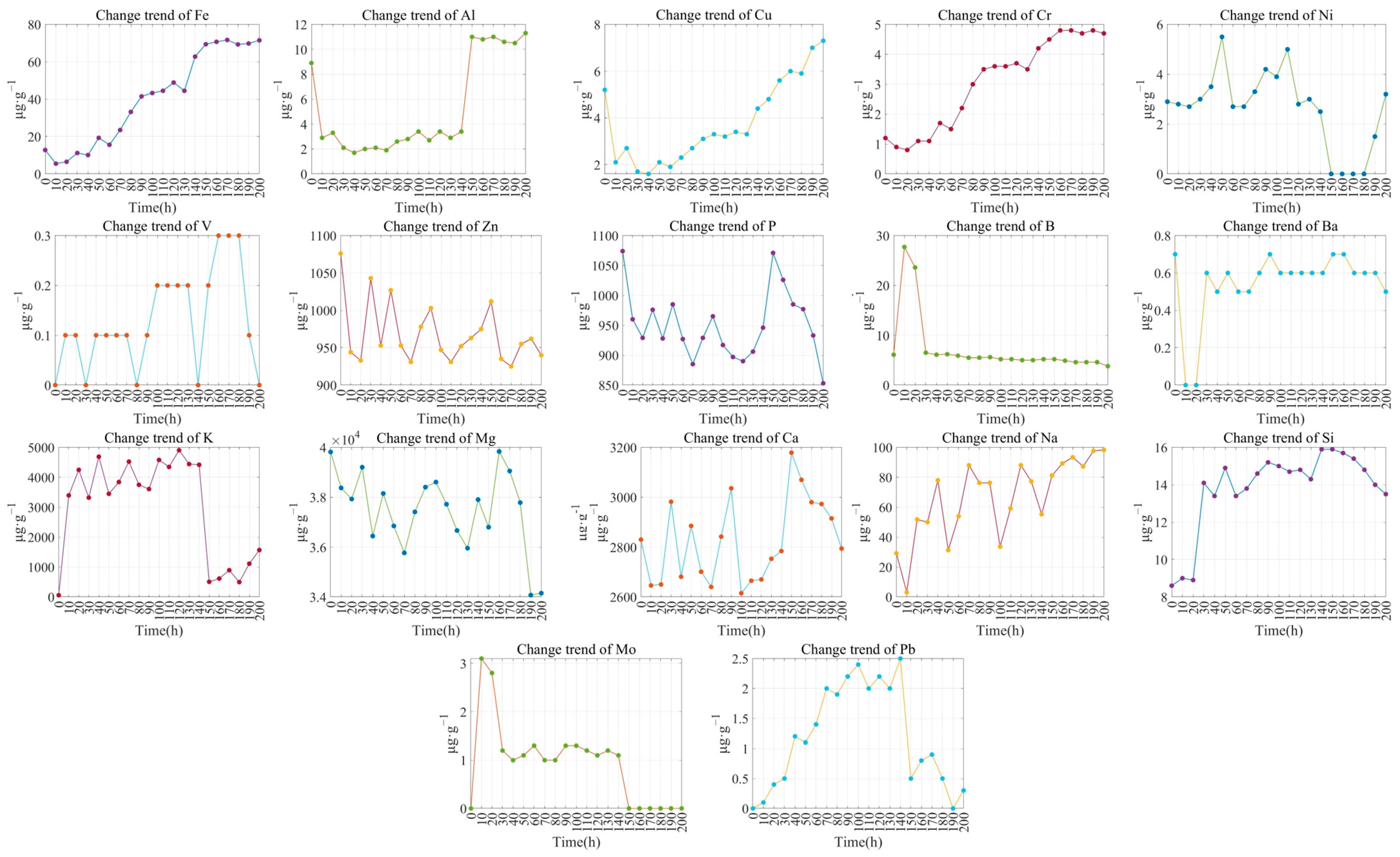

3.3. Potential Source of The Main Elements in Used Lubricating Oil

3.4. Feature Selection

- The average mass fraction of V and Ba elements is less than 1 μg·g−1, which has little effect on the quality change of lubricating oil;

- The information entropic value of oil spectrum data of five elements Al, V, B, Ba, and Mo is less than 2.5 bits, so these five elements cannot reflect the deterioration process of engine oil very well;

- The five elements Al, V, B, Ba, and Mo can be reflected by other elements with very strong correlation or strong correlation;

- The 12 elements Fe, Cu, Cr, Ni, Zn, P, K, Mg, Ca, Na, Si, and Pb can completely reflect the changes of wear particles, additives, and pollutants in lubricating oil.

4. RUL Prediction of Lubricating Oil Based on SVM

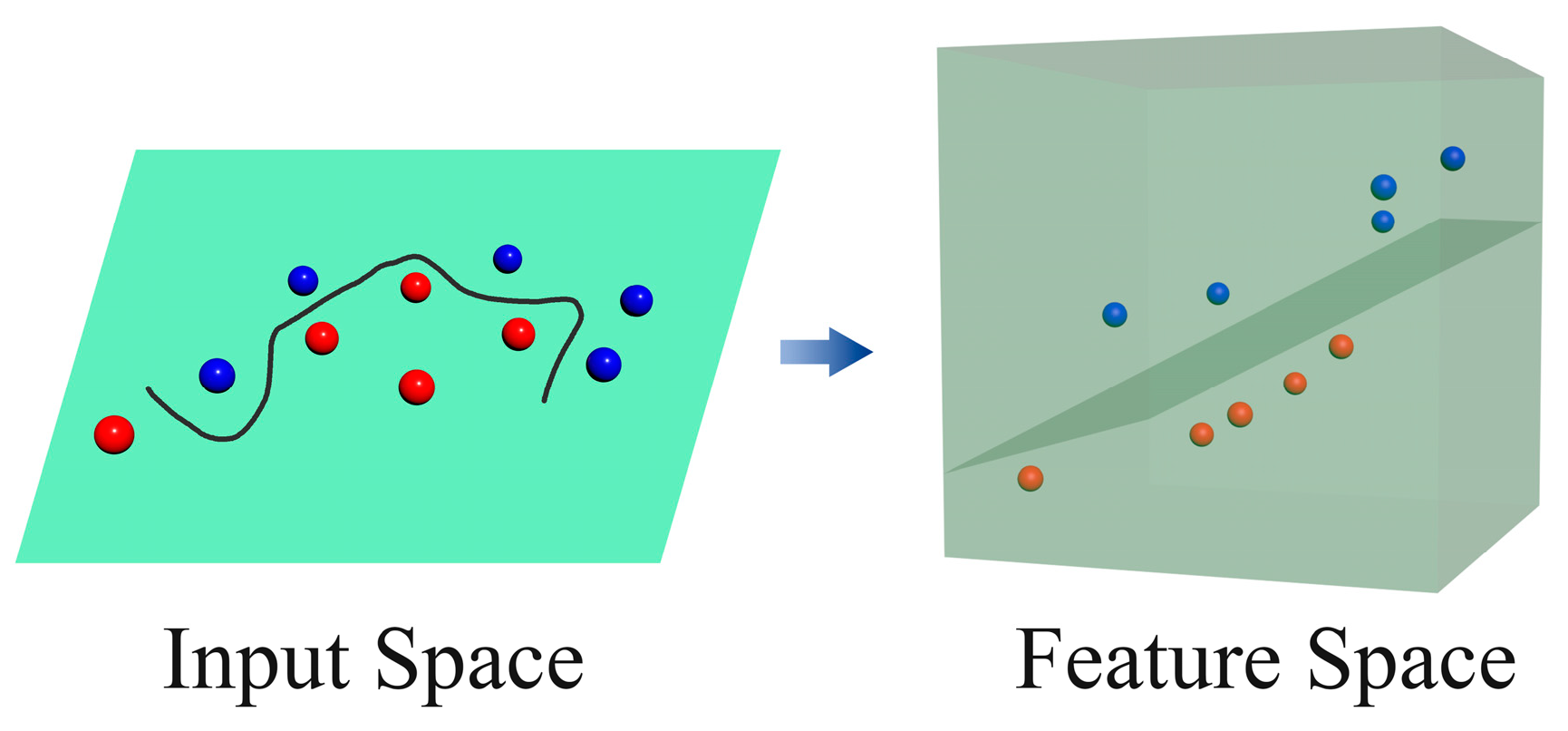

4.1. Principle of SVM

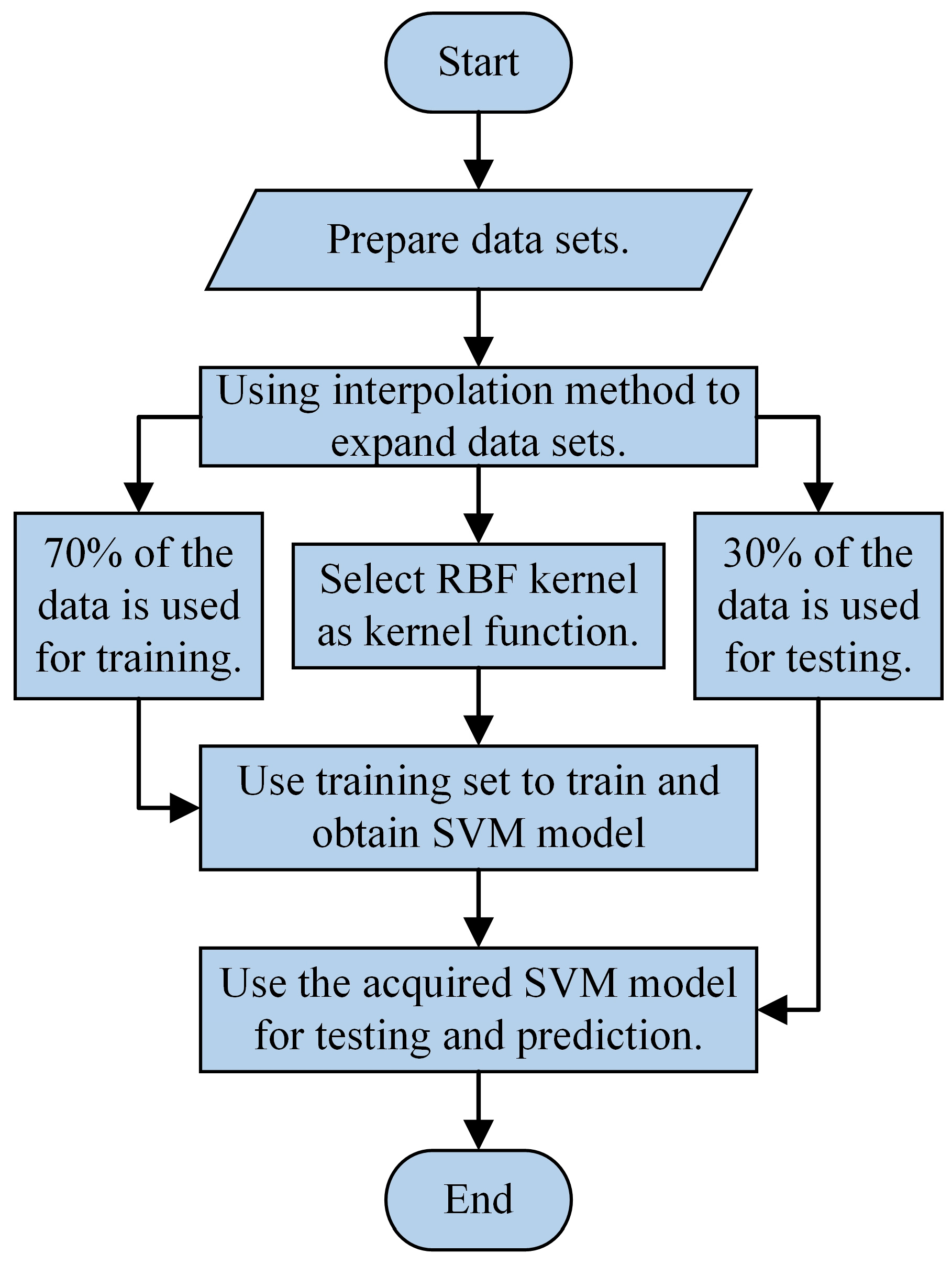

4.2. Lubricating Oil RUL Prediction Model

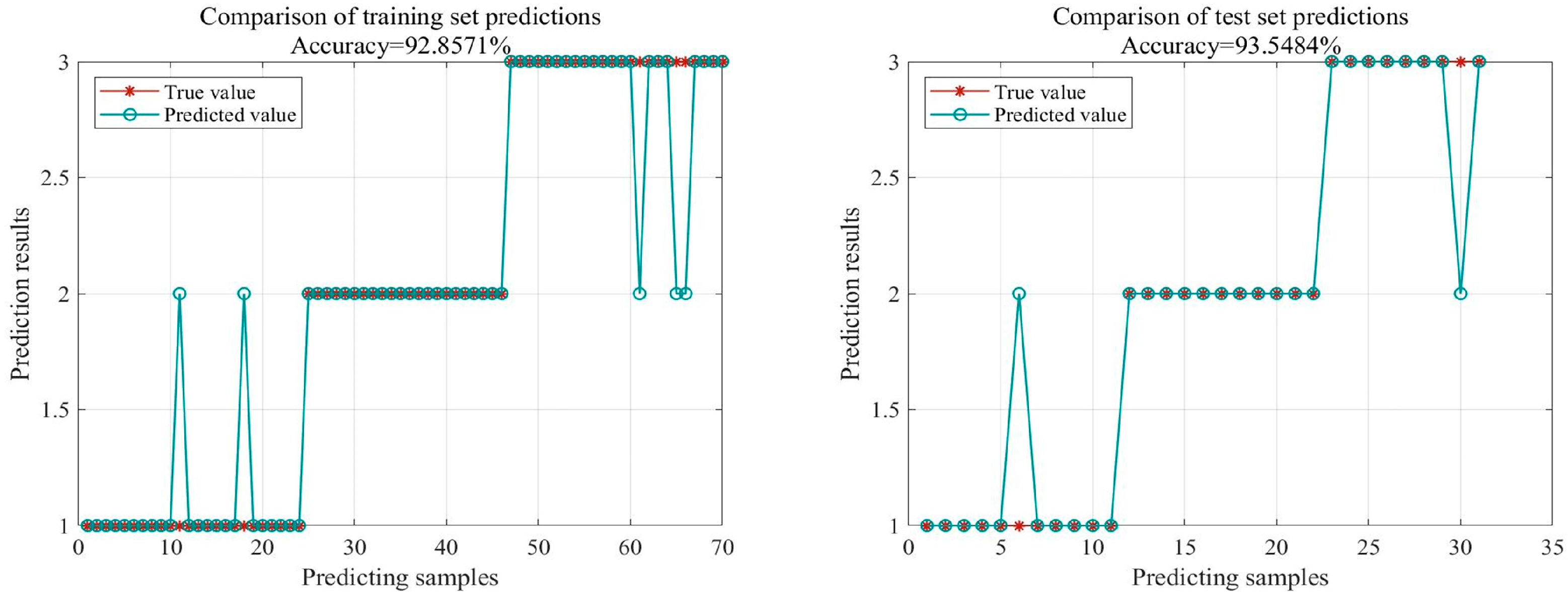

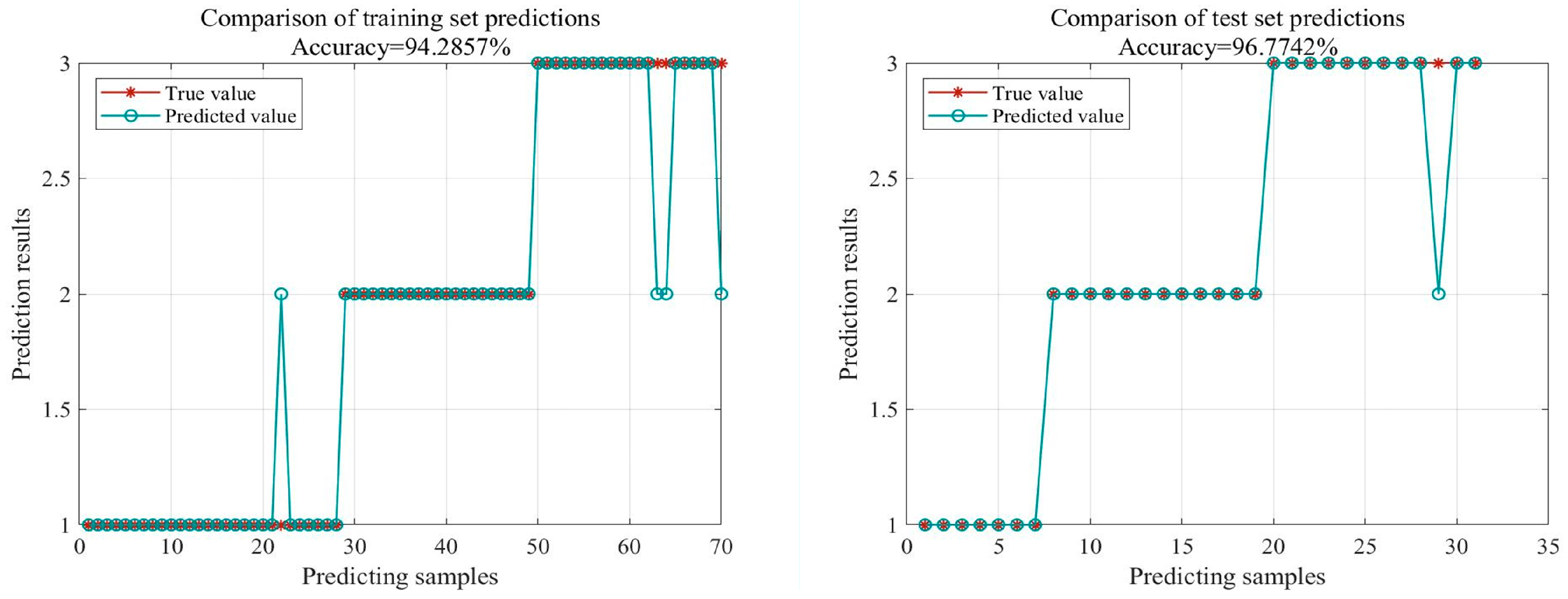

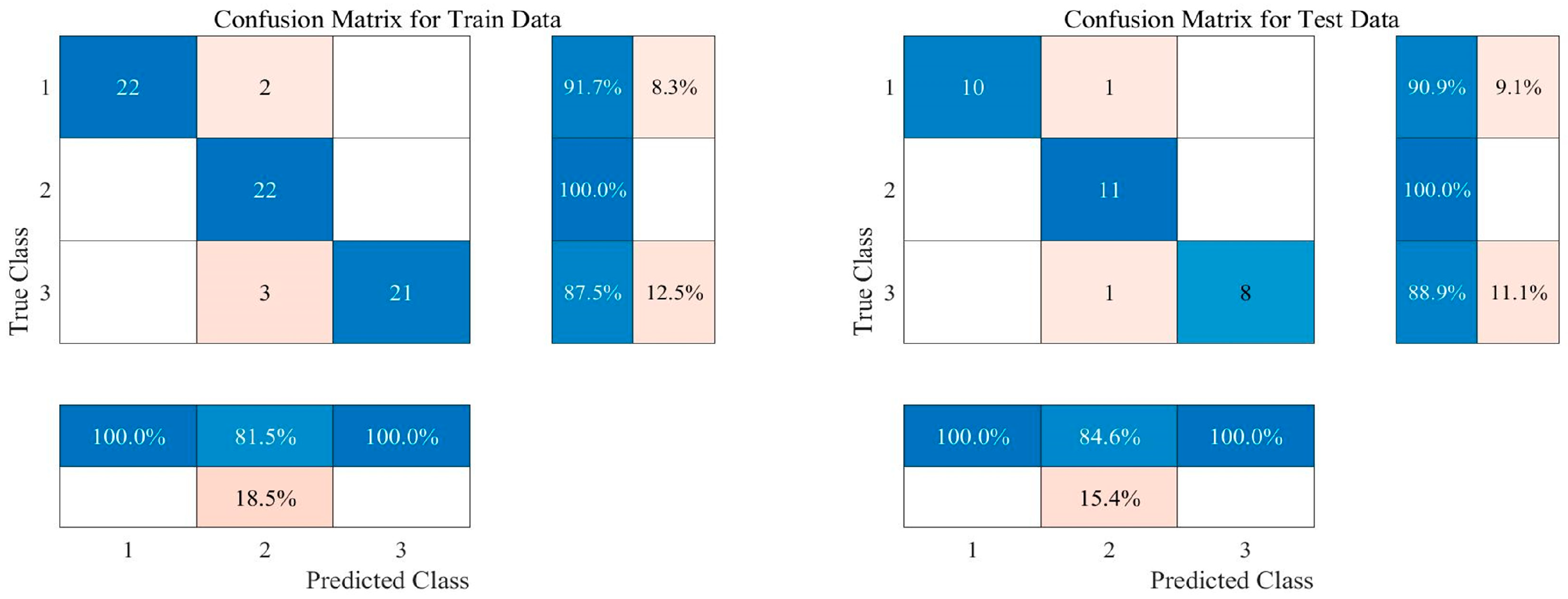

5. Results and Discussions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rodrigues, J.; Cost, I.; Farinha, J.T.; Mendes, M.; Margalho, L. Predicting motor oil condition using artificial neural networks and principal component analysis. Eksploat. Niezawodn.—Maint. Reliab. 2020, 22, 440–448. [Google Scholar] [CrossRef]

- de M. Bezerra, A.C.; de A. Coelho, N.M.; Bertelli, F.; Pacheco, M.T.T.; Silveira, L., Jr. Temperature-Induced Chemical Changes in Lubricant Automotive Oils Evaluated Using Raman Spectroscopy. Appl. Spectrosc. 2021, 75, 145–155. [Google Scholar] [CrossRef] [PubMed]

- Shu, G.; Dong, L.; Liang, X. A review of experimental studies on deposits in the combustion chambers of internal combustion engines. Int. J. Engine Res. 2012, 13, 357–369. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Fonseca, I.; Galar, D. Predicting condition based on oil analysis—A case study. Tribol. Int. 2019, 135, 65–74. [Google Scholar] [CrossRef]

- Du, Y.; Wu, T.; Makis, V. Parameter estimation and remaining useful life prediction of lubricating oil with HMM. Wear 2017, 376–377, 1227–1233. [Google Scholar] [CrossRef]

- Dörr, N.; Agocs, A.; Besser, C.; Ristić, A.; Frauscher, M. Engine Oils in the Field: A Comprehensive Chemical Assessment of Engine Oil Degradation in a Passenger Car. Tribol. Lett. 2019, 67, 68. [Google Scholar] [CrossRef]

- Passoni, D.d.J.; Pacheco, M.T.T.; Silveira, L. Raman spectroscopy for the identification of differences in the composition of automobile lubricant oils related to SAE specifications and additives. Instrum. Sci. Technol. 2020, 49, 164–181. [Google Scholar] [CrossRef]

- Kurre, S.K.; Garg, R.; Pandey, S. A review of biofuel generated contamination, engine oil degradation and engine wear. Biofuels 2016, 8, 273–280. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dörr, N. Comprehensive assessment of oil degradation patterns in petrol and diesel engines observed in a field test with passenger cars—Conventional oil analysis and fuel dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Heredia-Cancino, J.A.; Ramezani, M.; Álvarez-Ramos, M.E. Effect of degradation on tribological performance of engine lubricants at elevated temperatures. Tribol. Int. 2018, 124, 230–237. [Google Scholar] [CrossRef]

- Langfitt, Q.; Haselbach, L. Coupled oil analysis trending and life-cycle cost analysis for vessel oil-change interval decisions. J. Mar. Eng. Technol. 2016, 15, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Gajewski, J.; Vališ, D. The determination of combustion engine condition and reliability using oil analysis by MLP and RBF neural networks. Tribol. Int. 2017, 115, 557–572. [Google Scholar] [CrossRef]

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K. A review on lubricant condition monitoring information analysis for maintenance decision support. Mech. Syst. Signal Process. 2019, 118, 108–132. [Google Scholar] [CrossRef]

- Wakiru, J.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K.; Mburu, S. Towards an innovative lubricant condition monitoring strategy for maintenance of ageing multi-unit systems. Reliab. Eng. Syst. Saf. 2020, 204, 107200. [Google Scholar] [CrossRef]

- Fan, B.; Li, B.; Feng, S.; Mao, J.; Xie, Y.-B. Modeling and experimental investigations on the relationship between wear debris concentration and wear rate in lubrication systems. Tribol. Int. 2017, 109, 114–123. [Google Scholar] [CrossRef] [Green Version]

- Yan, S.; Ma, B.; Wang, X.; Chen, J.; Zheng, C. Maintenance policy for oil-lubricated systems with oil analysis data. Eksploat. Niezawodn.—Maint. Reliab. 2020, 22, 455–464. [Google Scholar] [CrossRef]

- Sejkorová, M.; Kučera, M.; Hurtová, I.; Voltr, O. Application of FTIR-ATR Spectrometry in Conjunction with Multivariate Regression Methods for Viscosity Prediction of Worn-Out Motor Oils. Appl. Sci. 2021, 11, 3842. [Google Scholar] [CrossRef]

- Zzeyani, S.; Mikou, M.; Naja, J.; Elachhab, A. Spectroscopic analysis of synthetic lubricating oil. Tribol. Int. 2017, 114, 27–32. [Google Scholar] [CrossRef]

- Zhou, F.; Yang, K.; Li, D.; Shi, X. Acid Number Prediction Model of Lubricating Oil Based on Mid-Infrared Spectroscopy. Lubricants 2022, 10, 205. [Google Scholar] [CrossRef]

- Evans, E.H.; Pisonero, J.; Smith, C.M.M.; Taylor, R.N. Atomic spectrometry update: Review of advances in atomic spectrometry and related techniques. J. Anal. At. Spectrom. 2020, 35, 830–851. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Wang, Q.; Xiong, X.; Luo, H.; Huang, K. Recent developments in chemical vapor generation atomic spectrometry for zinc detection. Microchem. J. 2019, 149, 104052. [Google Scholar] [CrossRef]

- D6595-17; Standard Test Method for Determination of Wear metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry. ASTM: West Conshohocken, PA, USA, 2017.

- Shannon, C.E. A Mathematical Theory of Communication. Bell System Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef] [Green Version]

- Xing, X. Physical entropy, information entropy and their evolution equations. Sci. China Ser. A Math. 2001, 44, 1331–1339. [Google Scholar] [CrossRef]

- Li, Z.; Qu, L.; Zhang, G.; Xie, N. Attribute selection for heterogeneous data based on information entropy. Int. J. Gen. Syst. 2021, 50, 548–566. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Qian, Y.; Xu, J.; Zhang, S. Feature selection using neighborhood entropy-based uncertainty measures for gene expression data classification. Inf. Sci. 2019, 502, 18–41. [Google Scholar] [CrossRef]

- Sejkorová, M.; Hurtová, I.; Jilek, P.; Novák, M.; Voltr, O. Study of the Effect of Physicochemical Degradation and Contamination of Motor Oils on Their Lubricity. Coatings 2021, 11, 60. [Google Scholar] [CrossRef]

- Ding, S.; Zhu, Z.; Zhang, X. An overview on semi-supervised support vector machine. Neural Comput. Appl. 2015, 28, 969–978. [Google Scholar] [CrossRef]

- Hajirahimi, Z.; Khashei, M. Hybridization of hybrid structures for time series forecasting: A review. Artif. Intell. Rev. 2023, 56, 1201–1261. [Google Scholar] [CrossRef]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Han, T.; Jiang, D.; Zhao, Q.; Wang, L.; Yin, K. Comparison of random forest, artificial neural networks and support vector machine for intelligent diagnosis of rotating machinery. Trans. Inst. Meas. Control 2017, 40, 2681–2693. [Google Scholar] [CrossRef]

| Parameter | Description/Value |

|---|---|

| Engine type | Diesel |

| Engine cylinder | V-8 |

| Engine cooling mode | Water-cooling |

| Element | 0 h | 10 h | … | 190 h | 200 h |

|---|---|---|---|---|---|

| Fe | 12.8 | 5.5 | … | 69.8 | 71.5 |

| Al | 8.9 | 2.9 | … | 10.5 | 11.3 |

| Cu | 5.2 | 2.1 | … | 7 | 7.3 |

| Cr | 1.2 | 0.9 | … | 4.8 | 4.7 |

| Ni | 2.9 | 2.8 | … | 1.5 | 3.2 |

| V | 0 | 0.1 | … | 0.1 | 0 |

| Zn | 1076 | 944 | … | 962 | 940 |

| P | 1074 | 960 | … | 933 | 853 |

| B | 6.1 | 27.7 | … | 4.6 | 3.8 |

| Ba | 0.7 | 0 | … | 0.6 | 0.5 |

| K | 57 | 3396 | … | 1111 | 1567 |

| Mg | 39,818 | 38,374 | … | 34,071 | 34,149 |

| Ca | 2830 | 2646 | … | 2915 | 2794 |

| Na | 29.2 | 3.1 | … | 97.7 | 98.3 |

| Si | 8.6 | 9 | … | 14 | 13.5 |

| Mo | 0 | 3.1 | … | 0 | 0 |

| Pb | 0 | 0.1 | … | 0 | 0.3 |

| Category | Element | Symbol | Potential Source of the Specified Element |

|---|---|---|---|

| Abrasive Metals | Iron | Fe | Wear and rust of almost all parts (pistons, bearings, gears, crankshafts, shafts, rings, valves, etc.) |

| Aluminum | Al | Wear of piston, bearing, and pump | |

| Copper | Cu | Wear of connecting rod bushing and camshaft bushing, corrosion of radiator piping | |

| Chrome | Cr | Wear of piston ring, cylinder sleeve, bearing, and the other alloy parts | |

| Nickel | Ni | Wear of bearing, shaft, and gear | |

| Vanadium | V | Wear of the alloy parts | |

| Additive Elements | Zinc | Zn | Zinc dialkyl dithiophosphate (ZDDP) |

| Phosphorus | P | Phosphate ester type base oil, antirust additive, load-carrying additives, friction modifier, and ZDDP | |

| Boron | B | Load-carrying additives, friction modifiers, and purification dispersants | |

| Barium | Ba | Purification dispersant, rust inhibitor, and demulsifying compound | |

| Comprehensive | Potassium | K | Water pollution and coolant contamination |

| Magnesium | Mg | Lubricant additives (purification dispersant, rust inhibitor), engine cylinder, water pollution, and coolant contamination | |

| Calcium | Ca | Lubricant additives (purification dispersant), water pollution, and coolant contamination | |

| Sodium | Na | Lubricant additives (rust inhibitor), water pollution, and coolant contamination | |

| Silicon | Si | Lubricant additives (antifoaming agent), dust intrusion (poor working air filter), and piston wear | |

| Molybdenum | Mo | Lubricant additives (load-carrying additives, friction modifier, and rust inhibitor) and ring wear | |

| Lead | Pb | Fuel intrusion and white alloy bearing wear |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wang, H.; Hao, M.; Wu, D. Prediction of RUL of Lubricating Oil Based on Information Entropy and SVM. Lubricants 2023, 11, 121. https://doi.org/10.3390/lubricants11030121

Liu Z, Wang H, Hao M, Wu D. Prediction of RUL of Lubricating Oil Based on Information Entropy and SVM. Lubricants. 2023; 11(3):121. https://doi.org/10.3390/lubricants11030121

Chicago/Turabian StyleLiu, Zhongxin, Huaiguang Wang, Mingxing Hao, and Dinghai Wu. 2023. "Prediction of RUL of Lubricating Oil Based on Information Entropy and SVM" Lubricants 11, no. 3: 121. https://doi.org/10.3390/lubricants11030121