2.2. Newtonian Mechanics Experiment

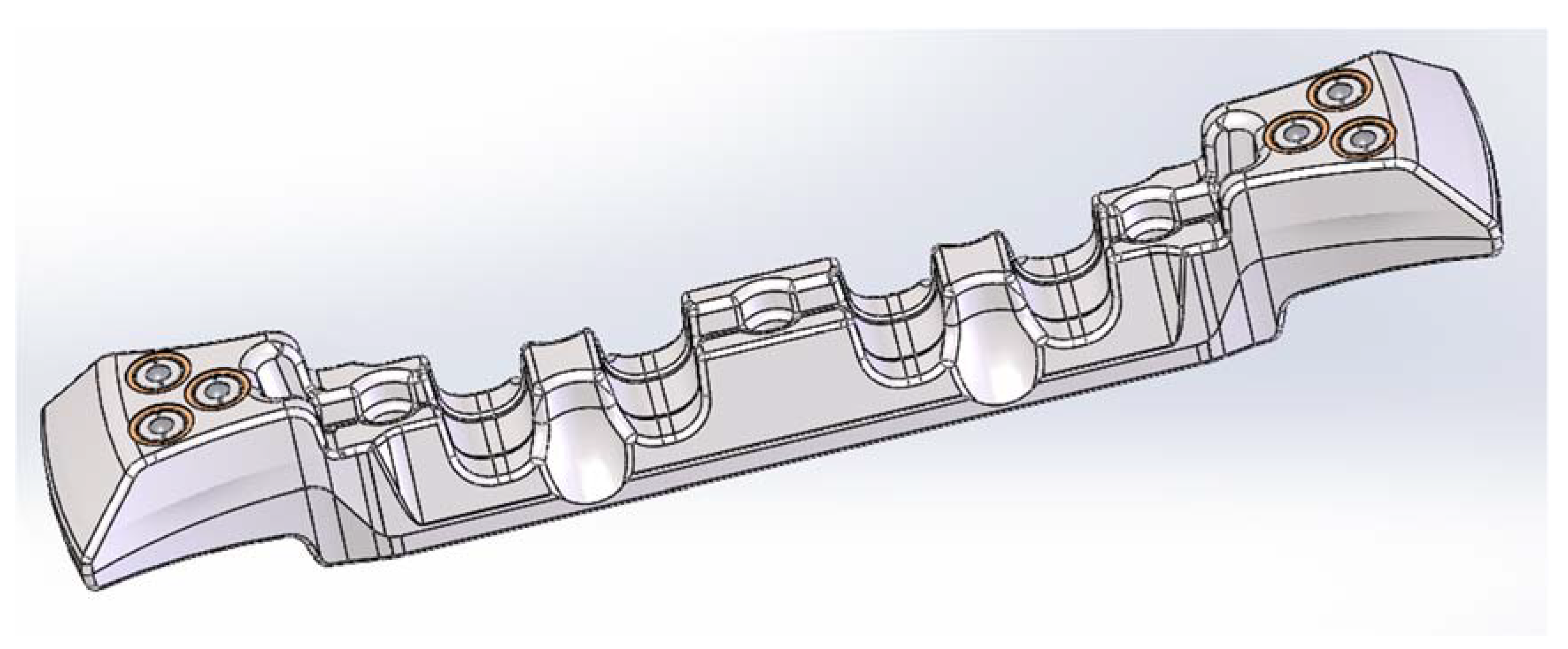

To quantitatively prove the advantages of the new scraper, the pulling force of the physical models of the new scraper in

Figure 5a and the traditional scraper in

Figure 5b are numerically measured before the measurement results are compared.

The Zhiqu DS2 series digital push–pull gauge(Dongguan Zhiqu Precision Instrument Co., Ltd., Dongguan, China), which is shown in

Figure 5c, is a multipurpose high-accuracy push–pull load tester designed for the push–pull load testing, insertion–withdrawal force testing, and destructive force experiment of various products [

29]. The DS2 series features high accuracy, long service life, small volume, long standby time, and easy operation. Armed with professional software and a USB data cable, these gauges can connect with instruments or computer to observe the test data and results [

30,

31,

32].

In real application, the new scraper is jointly driven by the push rod and the chain. In the numerical pulling force measurement, the pushing force of the push rod and the pulling force of the chain are integrated into the pulling force of the pull gauge on the physical model of the scraper. Plastic tape is used to simulate the scraper chain.

On the comprehensive mining face, there are coal debris, water, and other substances on the transport groove, and the coal distribution on the transport groove is uneven. These factors affect the moving speed of the scraper and cause it to not move at a constant speed. To simulate the effect of these factors, we moved the scraper by pulling the measuring sensor.

Pulling force is gradually applied to the physical model. The software system 3.0 of the Zhiqu DS2 series push–pull gauge is used to record pulling force development. The experiment process is shown in

Figure 6. On real coal mining faces, as the conveyor trough is not an absolute plane and due to presence of coal debris, the pulling and pushing forces on the scraper are not a constant value. In the simulation experiment, the pulling force on the scraper during stable operation is unstable, too. Therefore, in the simulation experiment, the pull gauge is set to “Peak”. The first peak pulling force obtained can be regarded as the instantaneous driving force received by the scraper [

33,

34]. When the pulling force peaks, the reading of maximum pulling force can be regarded as the driving force received by the new scraper during stable operation. After that, the readings can be taken again while the scraper works stably. However, as the readings at that time are unstable, the average can be used as the ideal stress condition.

The specific tension measurement scheme is as follows:

- (1)

Prepare the experimental equipment. The required experimental equipment includes: the new scraper, traditional scraper, digital force gauge (with a range of 500 N), lever, plastic tape, and camera.

- (2)

Place the new scraper horizontally on the test bench, and use plastic tape to simulate the chain. Tie (stick) it to the new scraper. The other end of the plastic tape should be connected to the lever. The folding binding method is used for the plastic tape, which, together with the lever, ensures that the new scraper is subjected to balanced and evenly distributed tension.

- (3)

Stick tape in the middle of the lever and connect the force gauge. Adjust the mode of the force gauge to peak mode, slowly pull the force gauge, and observe the changes in tension. When the first peak tension value is reached, that is, when the scraper starts to move, the number displayed on the force gauge no longer changes; record the tension data at this time.

2.3. Static Stress Analysis Scheme

SolidWorks (SolidWorks 2020, Dassault Systemes, Massachusetts, USA) is a 3D CAD software developed by Dassault Systemes and widely used in mechanical design, engineering analysis and other fields. It provides comprehensive functions for modeling, assembly, drawing, etc., which can help users efficiently complete product design and testing while performing numerical analysis and simulation. In this study, to conduct finite element analysis of the new and traditional scrapers, we used SolidWorks (version 2020) for static stress analysis and fatigue analysis.

- (1)

Material properties

Before starting static stress and fatigue analysis, it is necessary to define the material properties of five parts, including the modified base body, support body, rolling bearing, rolling ball, and auxiliary balls.

The modified base body is a traditional alloy steel scraper forged from 27SiMn. The material properties of the modified base body are provided in

Table 3 [

35].

The support body is made from high molecule polyurethane material, as shown in

Figure 7. This is designed to separate the rolling bearing from the modified base body to limit direct contact and reduce wear. It can also serve as a buffer that reduces the impact on the scraper. The material properties of the support body are provided in

Table 4.

The rolling bearing is forged from conventional stainless steel (1Cr18Ni9Ti). It is used to support the rolling ball and auxiliary balls. The material properties of the rolling bearing are provided in

Table 5.

The rolling ball and auxiliary balls are used to reduce friction and turn sliding friction into rolling friction. These balls are made from roughly the same material. Both can be YG8 carbide balls, as shown in

Figure 8. Composed mainly of ceramic (silicon nitride, Si

3N

4) with high hardness and wearability as well as good impact and vibration resistance, they are suitable for fabricating parts subject to high impact and vibration [

36,

37]. The material properties of the rolling ball and auxiliary balls are provided in

Table 6.

- (2)

Constraint

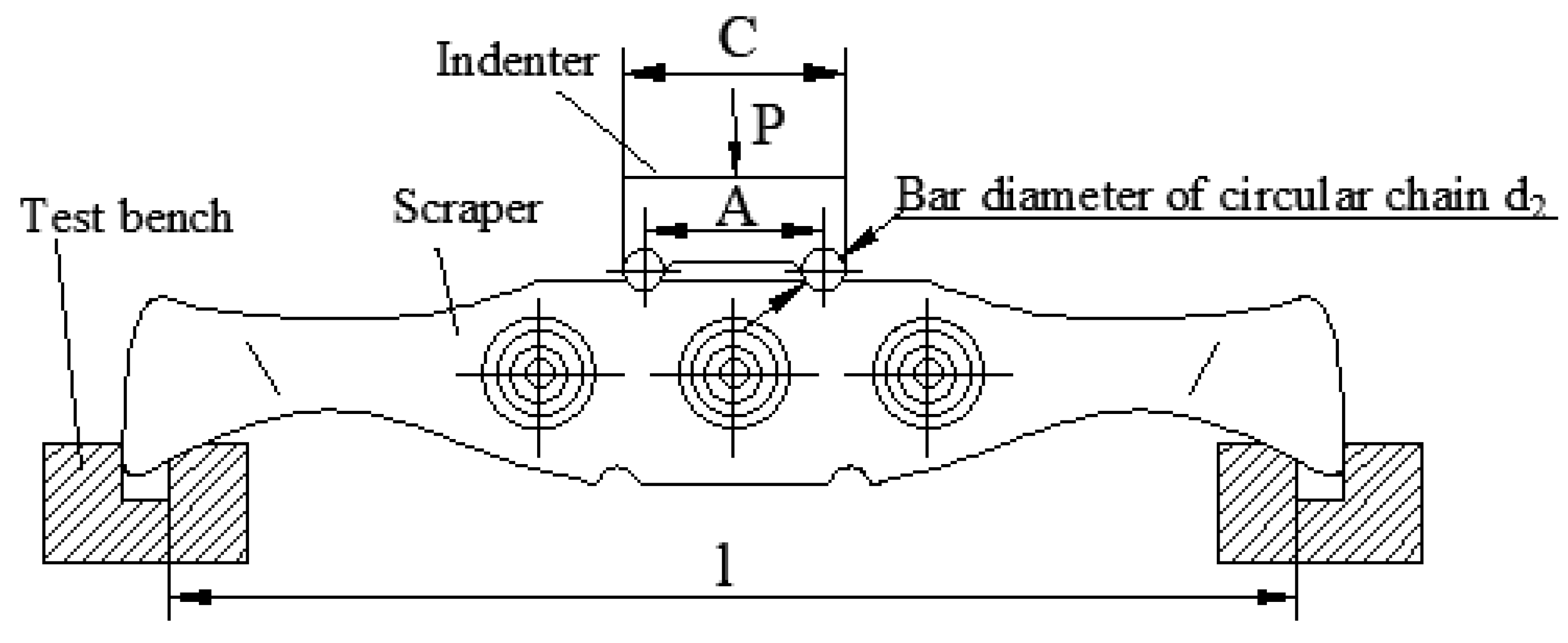

When performing finite element analysis, it is necessary to simulate the boundary conditions (displacement constraint) defined by the particular working environment (fully mechanized mining face) for the assembly (new scraper). According to national standard MT323-2005, Flight bar for twin inboard chain face conveyor, the load application type for the force–deflection test of the scraper is as shown in

Figure 9.

In the Figure,

C—width of the test indenter, mm;

A—chain center distance, mm;

d2—diameter of the circular chain bar, mm;

l—experimental span, mm;

P—load, kN.

Typically, the working environment of the scraper is harsh, and it often experiences loads beyond the capacity of the material and structure, leading to fatigue, fracture, distortion, or other failures. Therefore, in the national standard MT323-2005, Flight bar for twin inboard chain face conveyor, a force–deflection test for scrapers as shown in

Figure 9 is provided to check the quality and performance of scrapers.

The test procedures are as follows: (1) The test fixture should be fixed on the working surface of the testing machine, and the scraper should be placed on the test fixture. (2) The loading direction and position should follow the requirements shown in

Figure 9. (3) The testing machine should be started so that the press head contacts the scraper and applies the load. (4) The load P should be increased uniformly to the specified value at a loading rate not exceeding 20 N/mm

2 per second.

This test is a destructive test that requires a specified force to be applied to the scraper (with different requirements for different types of scrapers), which is large enough to cause bending displacement of the scraper. Due to practical constraints, we can only simulate this test using SolidWorks.

In finite element analysis, the test bench support can be regarded as the plane containing the constraint. The surface of the scraper in contact with this surface serves as the boundary condition, and its constraint form is a fixed geometry, as shown in

Figure 10 [

39]. The modified base body of the new scraper consists of a type II scraper with chain center distance = 280 ± 1.0 mm and length L = 1184 mm. According to the provisions of the national standard for scraper for double-chain scraper conveyor in MT323-2005, the experimental span l of a type II scraper with a length L of 1184 mm is 1104 mm, and the rated strength value, that is, the load P, is 560 kN, with the direction being normal, i.e., perpendicular to the force-bearing surface. Therefore, the experimental span of the new scraper is 1104 mm, which includes the five stressed faces in the model. The load is 560 kN and its direction is perpendicular to the five stressed faces in the model. The model under constraint is shown in

Figure 10.

- (3)

Load

The real load environment has to be defined on the finite element model [

40,

41]. Ideally, during coal mining, the coal fallen on the conveyor trough is evenly distributed. In finite element analysis, the load P applied by the test indenter is evenly spread on the side of the new scraper, as shown in

Figure 11. According to national standard MT323-2005, Flight bar for twin inboard chain face conveyor, for a scraper with length

L = 1184 mm, the experimental span should be

l = 1104 mm, namely the five stressed faces in the model. The rated strength, namely load, is

P = 560 kN. The direction is normal, namely perpendicular to the stressed face [

42].

- (4)

Model meshing

When meshing the model, it is important to choose the right mesh type and parameters according to the particular model structure and environment in question [

43]. On the one hand, as the modified base body is structurally complete and represents the main stressed area, plus the structure of the rolling bearing area is important, the model can be directly meshed. This way, the mesh density will be good and the mesh parameters will be curvature based meshes. On the other hand, as twisted cells exist in the balls and the number of balls is large, it is necessary to process the balls in batch separately. This way the mesh density will be good and the mesh parameters will be curvature based meshes. The overall size for the two is 9.522 mm with a tolerance of 0.476 mm. The model meshing result is shown in

Figure 12.

After completing the above steps, the prerequisite for static stress simulation is met. After simulating with SolidWorks, the displacement, stress, and strain nephogram of the new scraper can be obtained. the same procedure and analysis process are used to see what happens to the traditional scraper.

2.4. Fatigue Analysis Scheme

The forging material for the scraper is 27SiMn. 27SiMn steel is a low-carbon microalloyed steel with high strength, toughness, and fatigue life. It is a type of steel with good mechanical properties that is widely used in engineering machinery, oil pipelines, and metallurgy fields.

The fatigue characteristics of this material refer to indicators such as fatigue life and fatigue limit under repeated loads. The fatigue characteristics of this material are mainly determined by its microstructure, chemical composition, and processing hardening. Fatigue tests can be used to obtain information on the fatigue characteristics of this type of steel. Common methods for fatigue analysis include the limit state method, fatigue margin method, and stress intensity factor method. The limit state method evaluates based on the comparison of actual loads and the ultimate bearing capacity of the structure; the fatigue margin method calculates the reliability of the component based on its fatigue strength, actual load, and safety factor; and the stress intensity factor method studies and analyzes the relationship between fatigue residual life and stress intensity factors using linear elastic fracture mechanics theory.

In this study, we evaluated the fatigue life of the scraper using the fatigue margin method and described the experimental steps and parameter settings in detail. Specifically, we first established fatigue specimens according to the standard. Fatigue test results show that the fatigue limit of 27SiMn steel is usually around 400 MPa, and its hysteresis curve is similar to the S–N curve. Then, we performed finite element analysis of the scraper in SolidWorks and calculated the stress state of different parts of the scraper. Finally, we calculated the fatigue reliability of the scraper under actual working conditions using the fatigue margin calculation method. This type of fatigue analysis method can accurately assess the fatigue life of the scraper and provide reference basis for optimizing the design.

- (1)

Material properties

Prior to conducting fatigue analysis, it is necessary to define the material properties of the five components, including the modified substrate, support body, rolling bearing seat, ball bearings, and auxiliary ball bearings. The material properties of these components have already been provided in the static stress analysis and will not be reiterated here.

- (2)

Constraint

The constraints for fatigue analysis are the same as those for static stress analysis.

- (3)

Load

According to the safety rules, a scraper should be placed along the conveyor trough of a scraper conveyor every 0.98 m [

44]. The chain speed of the scraper conveyor used in a mine is 1.3 m/s. A 335 m long conveyor trough has been installed and requires 342 scrapers. The load P increases evenly to 560 kN at the rate of 2 N/mm

2 per second (the cross-sectional area is the total sectional area of the ring chain used), then it is unloaded to the initial load. The ring chain size is 48 × 152 mm; the cross-sectional area is 1808.64 mm

2; the total sectional area is 3617.28 mm

2. Accordingly, the peak loading of the load is 154.81 N/mm

2; the loading time is 7.74 s; the duration of a cycle is 523.12 s. The load variation in each cycle is calculated by

Static stress analysis is the prerequisite for fatigue analysis. The material properties, load, constraint, and connection form of the new scraper model have been determined [

45,

46,

47]. Fatigue analysis is performed using historical data with variable high and low amplitudes.

The new scraper is made of various materials including 27SiMn, stainless steel (1Cr18Ni9Ti), and high-molecule polyurethane, whose fatigue curves are not identical. To avoid lengthy and repetitive explanations while also observing confidentiality, we only present the fatigue curve of the base material (27SiMn) for the new scraper. The number of rain flow counting boxes is 25; the metric for calculating alternating stress is stress intensity (P1–P3); the average stress is corrected to Gerber. Considering that the production environment of the fully mechanized mining face is very complex, the fatigue strength reduction factor (kf) is set to 1. An S–N curve is derived from the material elastic modulus based on the ASME carbon steel curve [

48,

49,

50]. The interpolation of the fatigue S–N curve is double log; the stress ratio is 0. Finally, the resulting fatigue data are applied to all the parts. The load curve of the material in the added event is shown in

Figure 13.

The meaning of

Figure 13 is as follows: at the beginning of the test, the initial load on the new scraper is 0 N. From time t = 0 s, the load is uniformly applied to the five sides of the new scraper at a rate of 20 N/mm

2 per second, simulating the contact between the new scraper and coal. At time t = 7.74 s, the load on the new scraper reaches 560 kN and no longer continues to apply the load, simulating that the new scraper has carried enough coal. In the next 249.59 s, the scraper is subjected to a constant load of 560 kN, simulating the displacement of the new scraper carrying coal from the input end of the transport chute to the output end. At time t = 257.69 s, the load is uniformly unloaded at a rate of 20 N/mm

2 per second, simulating the unloading of the coal by the new scraper after reaching the output end of the transport chute. Again, after 7.74 s, at time t = 265.43 s, the load on the scraper is reduced to 0 N, simulating the completion of coal unloading by the new scraper. In the next 257.69 s, the new scraper undergoes displacement without carrying any load, simulating the movement of the new scraper from the output end of the transport chute to the input end and starting the next cycle [

51,

52].

- (4)

Model meshing

The model meshing for fatigue analysis is the same as that for static stress analysis.

After completing the above steps, the prerequisite for fatigue simulation is met. By simulating with SolidWorks, the damage percentage nephogram and total life nephogram of the new scraper can be obtained. The same procedure and analysis process are used to see what happens to the traditional scraper.