Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil

Abstract

:1. Introduction

1.1. Background

1.2. Literature Analysis

1.3. Research Objective

2. Materials and Methods

2.1. Materials

2.2. Fuel Characterization Test Method

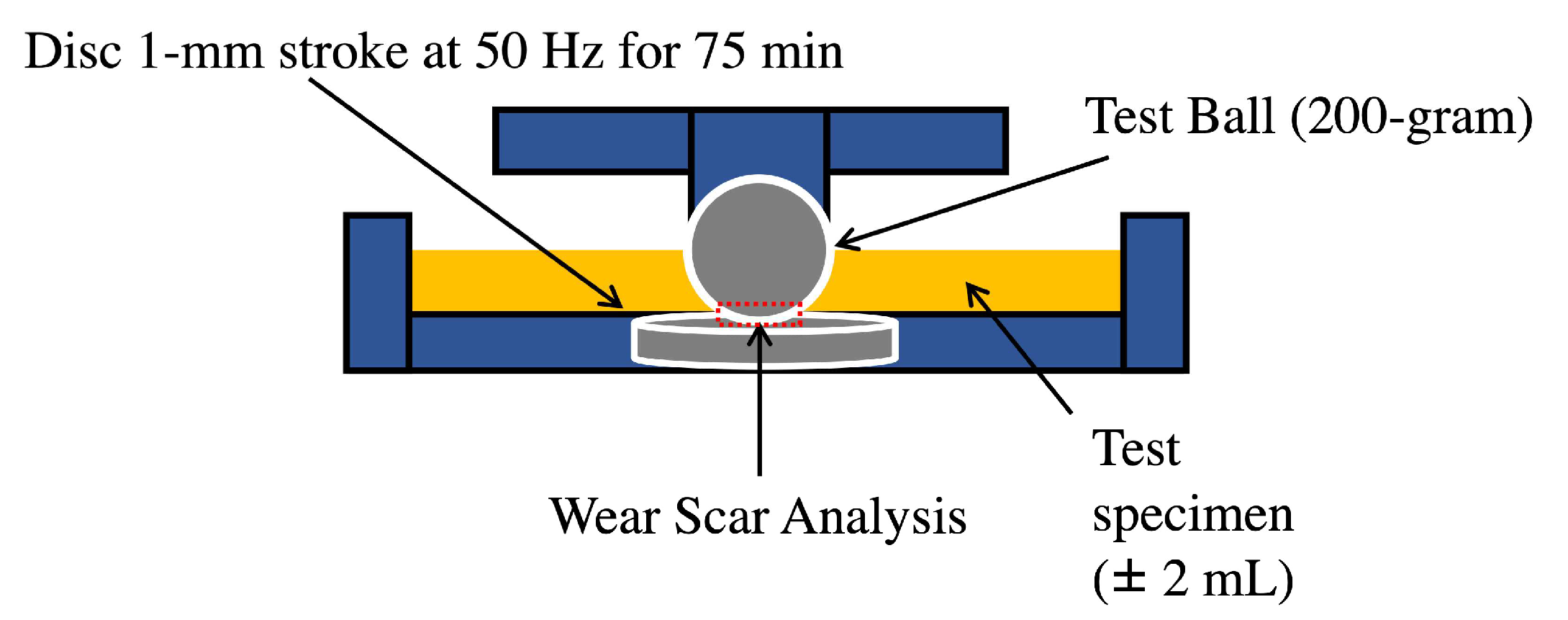

2.3. HFRR Test Method

3. Results and Discussions

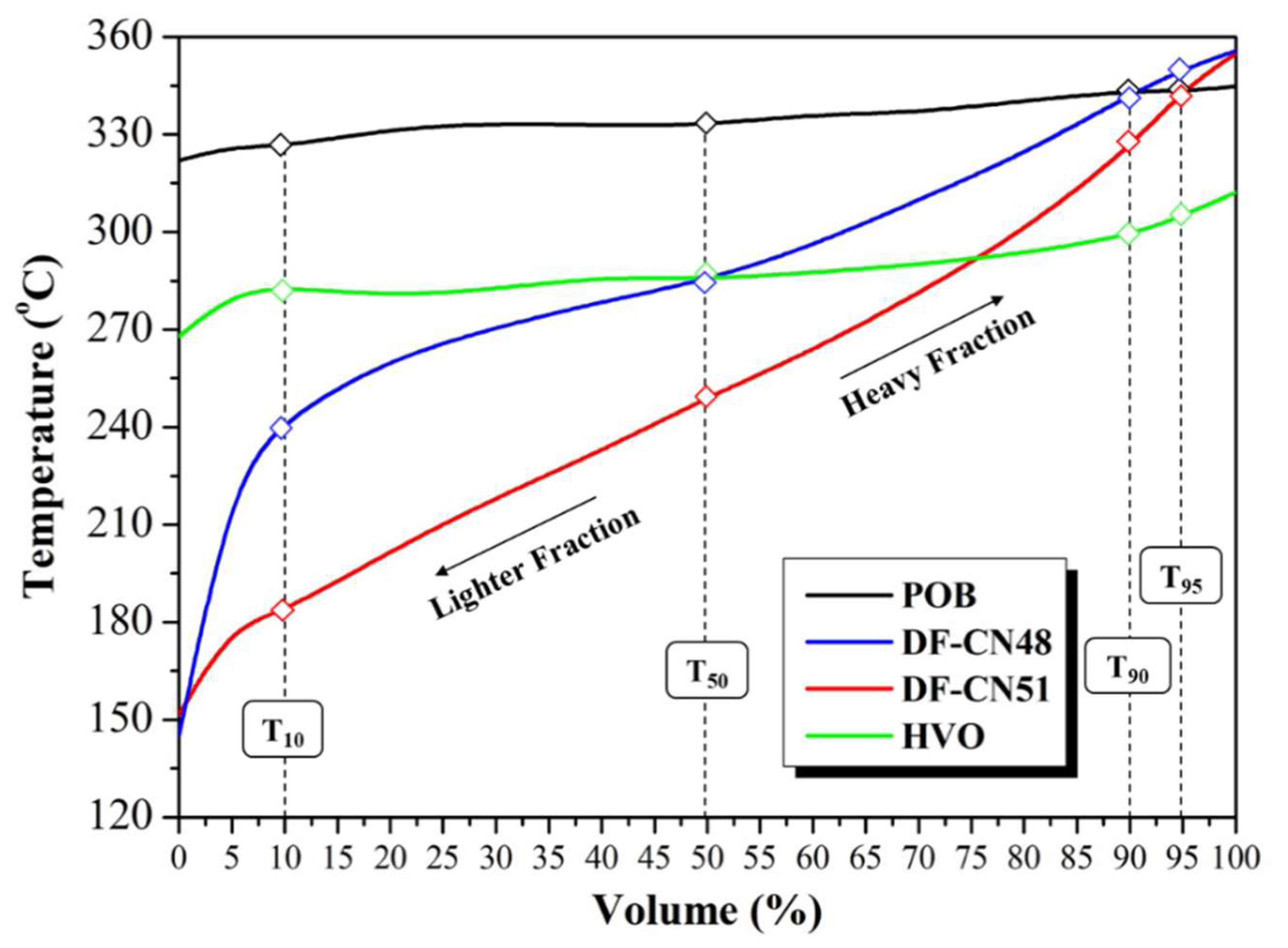

3.1. Physiochemical Properties of the Fuel

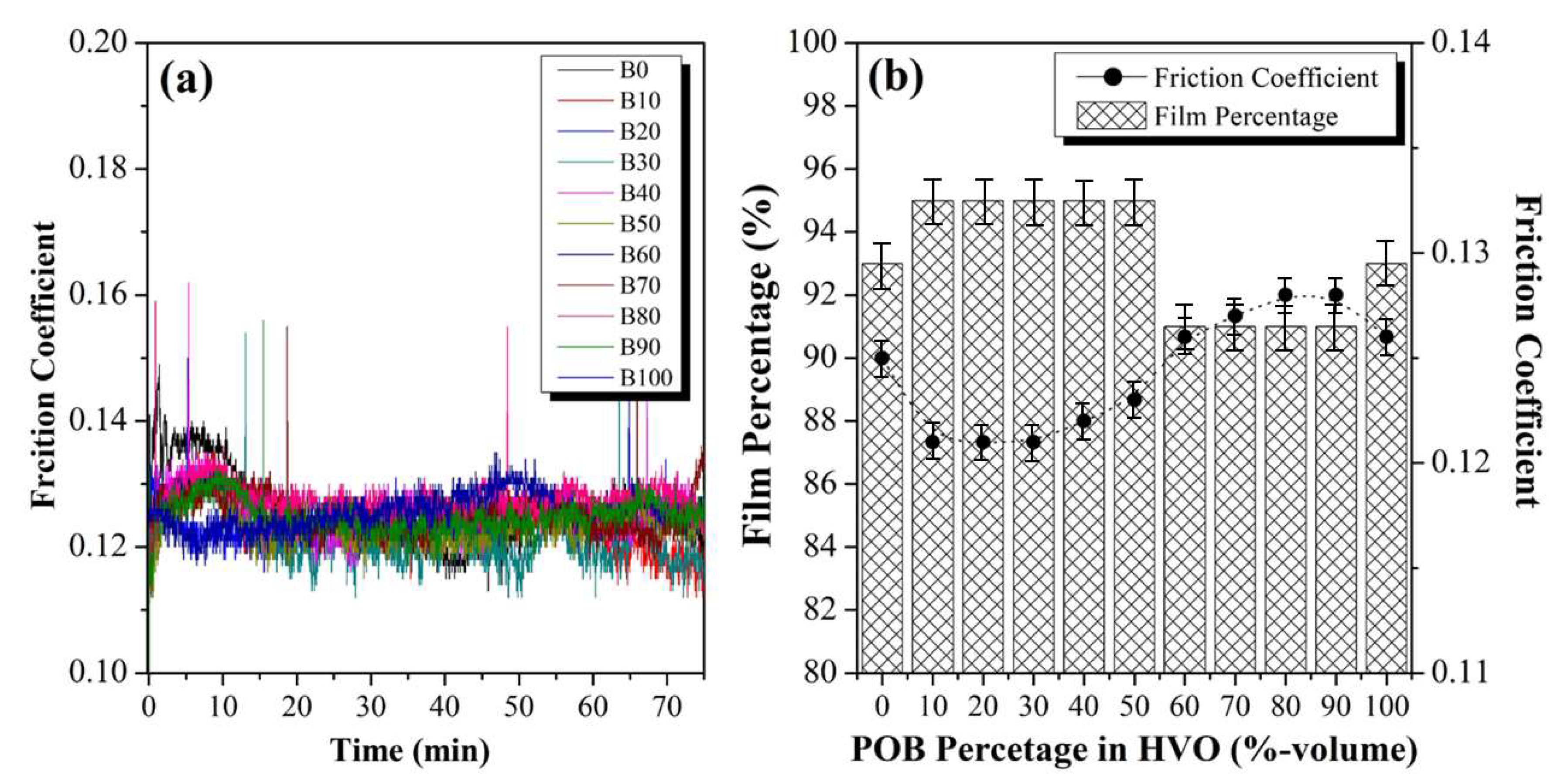

3.2. Friction Behavior Analysis

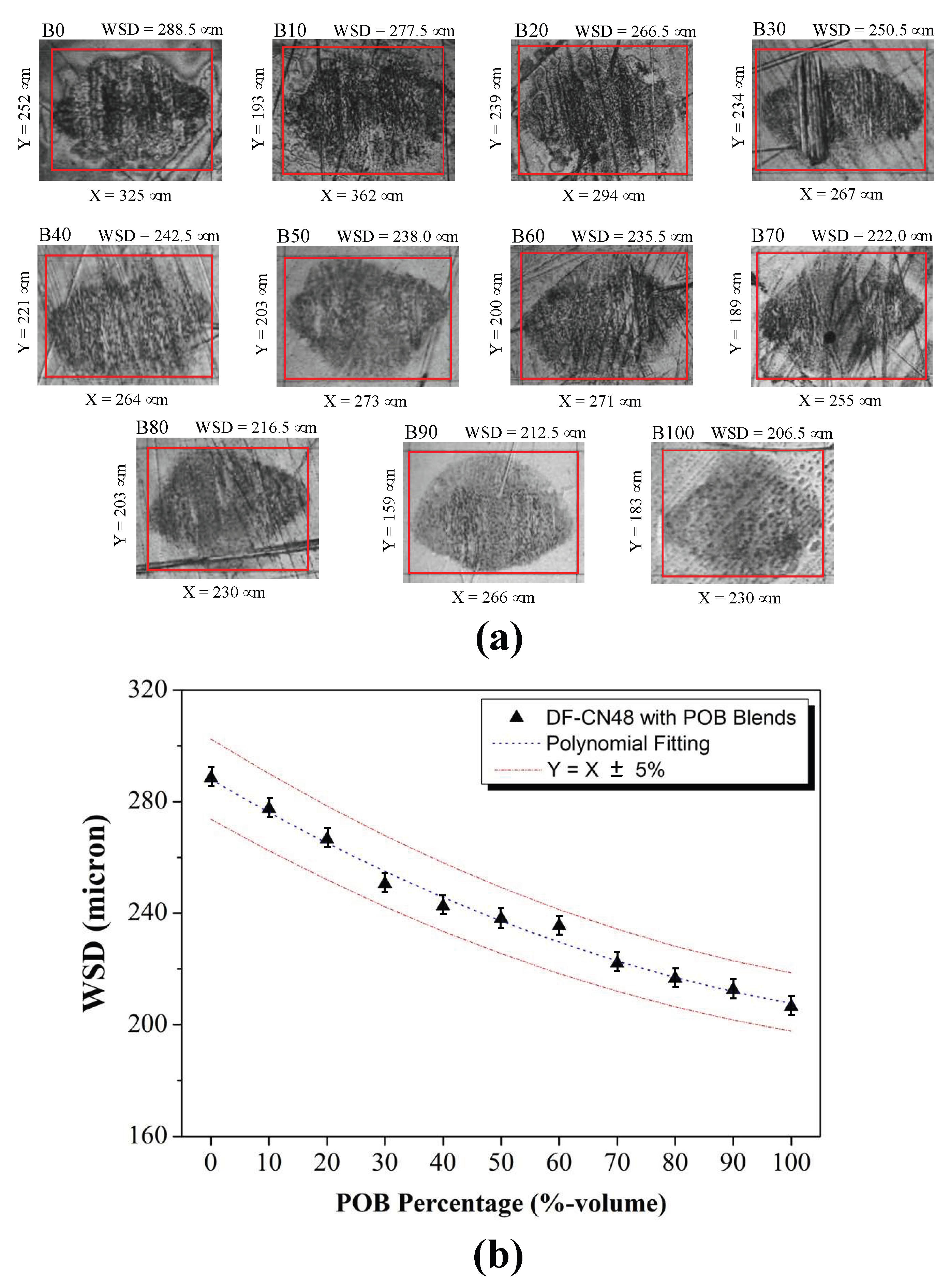

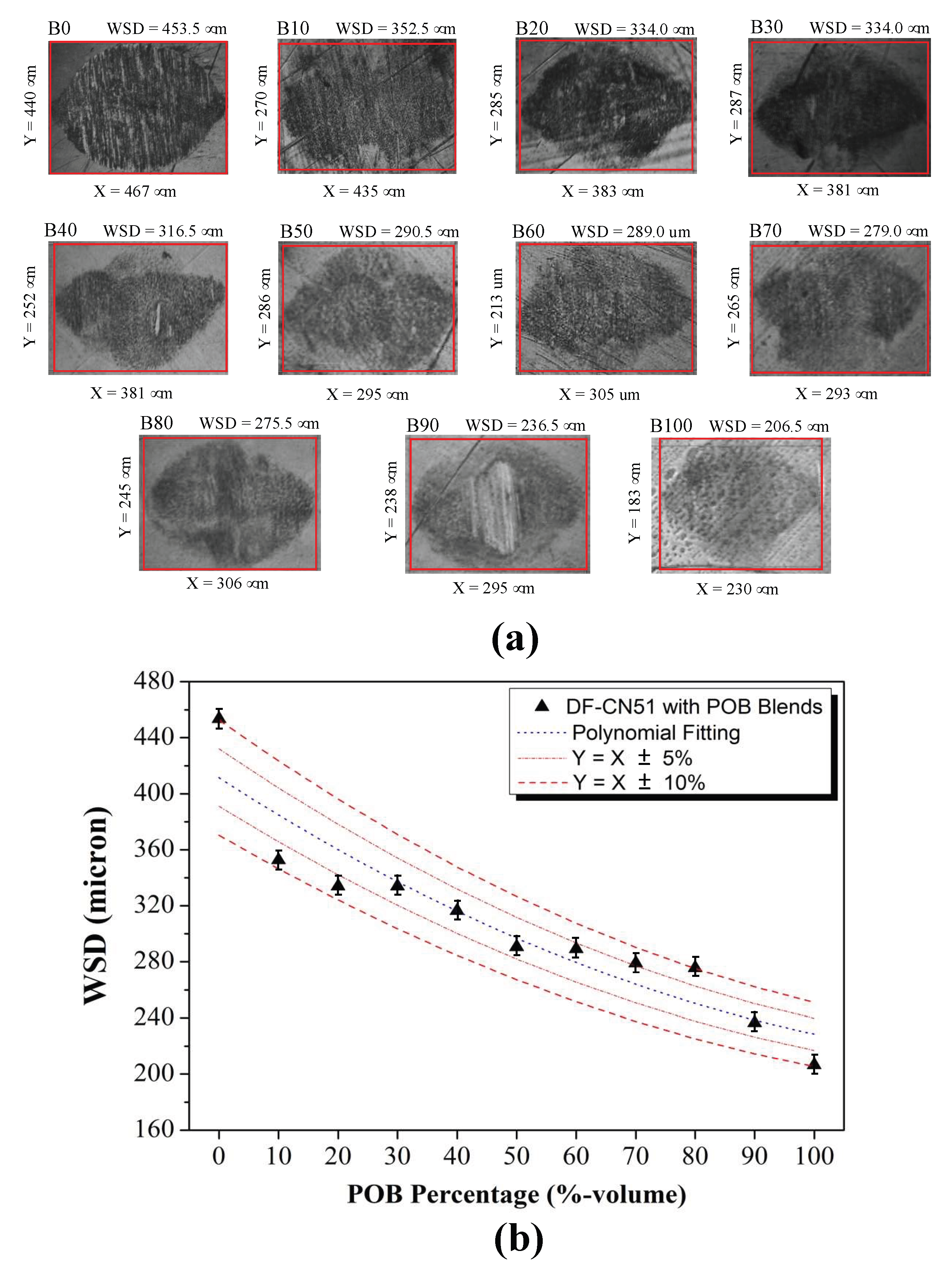

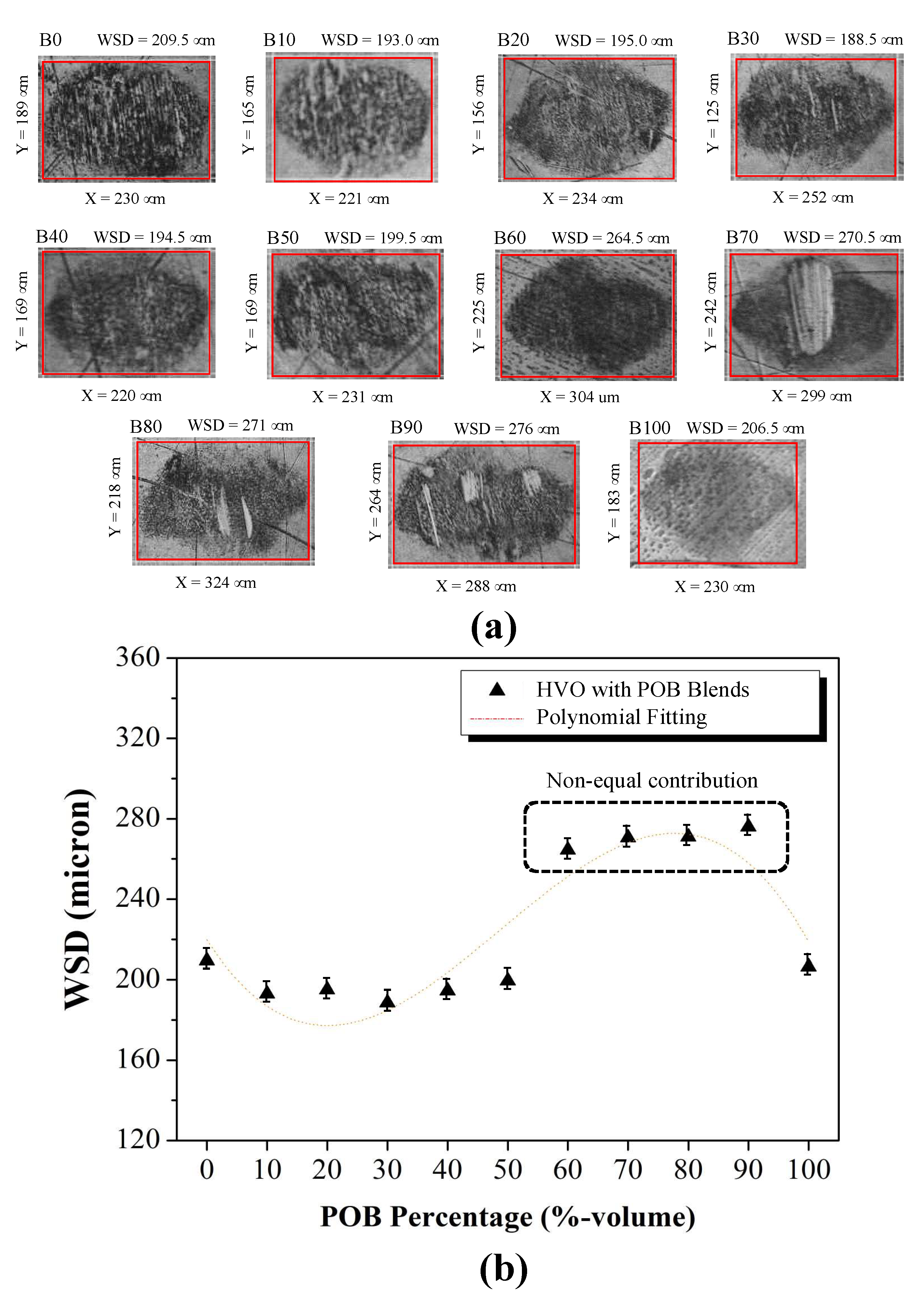

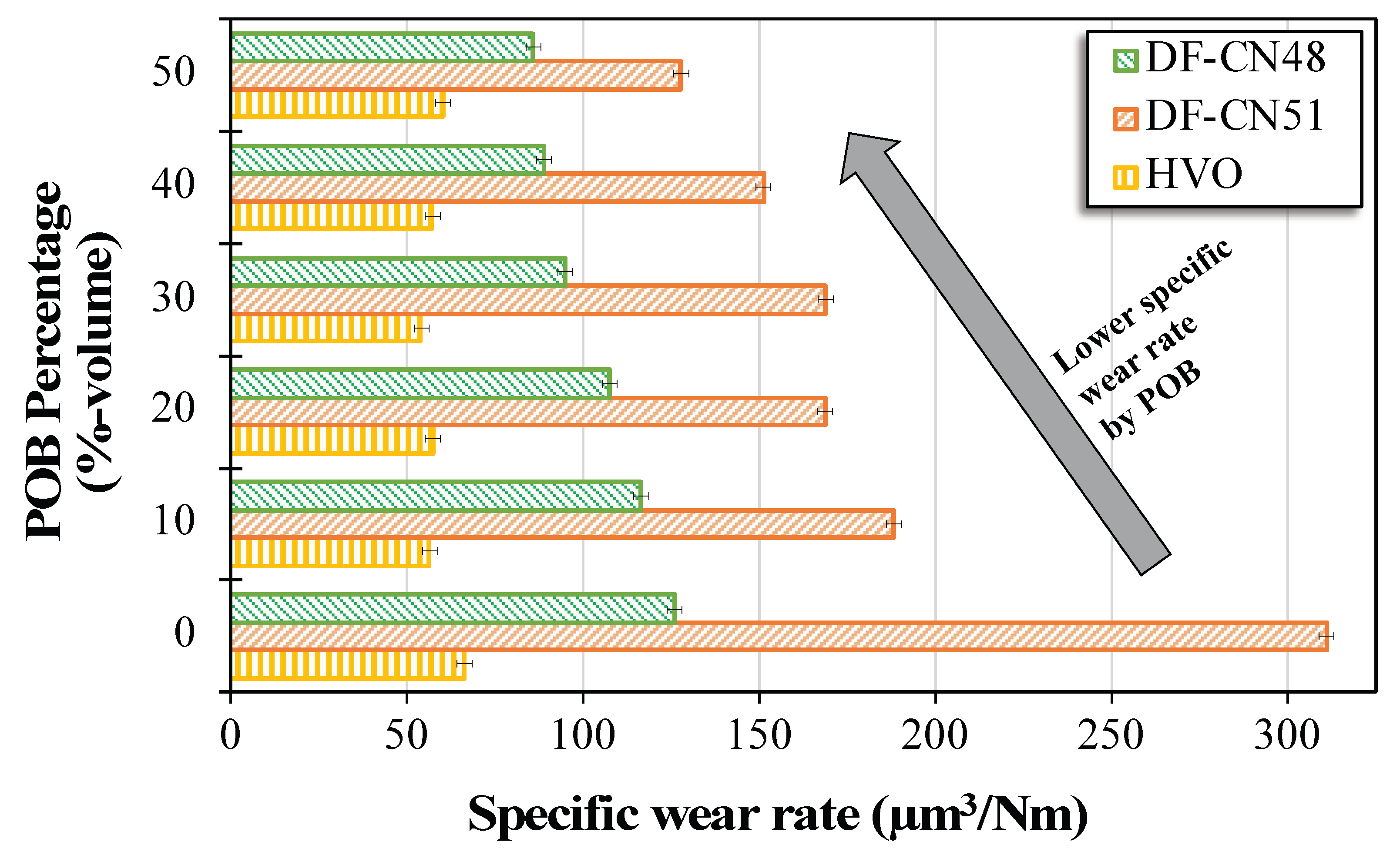

3.3. Wear Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Bxx | Biodiesel blends (xx %-volume) |

| DF-CN48 | Diesel fuel with cetane number 48 |

| DF-CN51 | Diesel fuel with cetane number 51 |

| HFRR | High-frequency reciprocating rig |

| HVO | Hydrogenated vegetable oil |

| POB | Palm oil biodiesel |

| WSD | Wear scar diameter |

| WWFC | Worldwide Fuel Chapter |

References

- Aghbashlo, M.; Peng, W.; Tabatabaei, M.; Kalogirou, S.A.; Soltanian, S.; Hosseinzadeh-Bandbafha, H.; Mahian, O.; Lam, S.S. Machine learning technology in biodiesel research: A review. Prog. Energy Combust. Sci. 2021, 85, 100904. [Google Scholar] [CrossRef]

- Canakci, M.; Sanli, H. Biodiesel production from various feedstocks and their effects on the fuel properties. J. Ind. Microbiol. Biotechnol. 2008, 35, 431–441. [Google Scholar] [CrossRef] [PubMed]

- Monirul, I.M.; Masjuki, H.H.; Kalam, A.; Zulkifli, N.W.M.; Rashedul, H.K.; Rashed, M.M.; Imdadul, H.K.; Mosarof, M.H. A comprehensive review on biodiesel cold flow properties and oxidation stability along with their improvement processes. RSC Adv. 2015, 5, 86631–86655. [Google Scholar] [CrossRef]

- Mukherjee, I.; Sovacool, B.K. Palm oil-based biofuels and sustainability in southeast Asia: A review of Indonesia, Malaysia, and Thailand. Renew. Sustain. Energy Rev. 2014. [CrossRef]

- Farobie, O.; Hartulistiyoso, E. Palm Oil Biodiesel as a Renewable Energy Resource in Indonesia: Current Status and Challenges. Bioenergy Res. 2022, 15, 93–111. [Google Scholar] [CrossRef]

- Fathurrahman, N.A.; Wibowo, C.S.; Bethari, S.A.; Anggarani, R.; Aisyah, L.; Maymuchar. Fuel Properties of Two Types High-Speed Diesel Blending with Palm Oil Biodiesel in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2021, 749, 012030. [Google Scholar] [CrossRef]

- Muñoz, M.; Moreno, F.; Monné, C.; Morea, J.; Terradillos, J. Biodiesel improves lubricity of new low sulphur diesel fuels. Renew. Energy 2011, 36, 2918–2924. [Google Scholar] [CrossRef]

- Hsieh, P.Y.; Bruno, T.J. A perspective on the origin of lubricity in petroleum distillate motor fuels. Fuel Process. Technol. 2015, 129, 52–60. [Google Scholar] [CrossRef]

- Kuronen, M.; Mikkonen, S.; Aakko, P.; Murtonen, T. Hydrotreated Vegetable Oil as Fuel for Heavy Duty Diesel Engines; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Ababneh, H.; Mohammad, N.; Choudhury, H.A.; Zhang, L.; Gani, R.; McKay, G.; Elbashir, N. Enhancing the lubricity of gas-to-liquid (GTL) paraffinic kerosene: Impact of the additives on the physicochemical properties. BMC Chem. Eng. 2020, 2, 1–16. [Google Scholar] [CrossRef]

- Hong, F.T.; Singh, E.; Sarathy, S.M. On the origins of lubricity and surface cleanliness in ethanol-diesel fuel blends. Fuel 2021, 302, 121135. [Google Scholar] [CrossRef]

- Dodos, G.S.; Vassileiou, F.; Karonis, D. Lubricity of Diesel Fuel Hydrocarbons and Surrogate Fuels; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, L.; Li, Y. Investigation of tall oil fatty acid as antiwear agent to improve the lubricity of ultra-low sulfur diesels. Tribol. Int. 2017, 114, 57–64. [Google Scholar] [CrossRef]

- Nikanjam, M.; Rutherford, J. Improving the Precision of the HFRR Lubricity Test; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Azad, A.K.; Rasul, M.G.; Sharma, S.C.; Khan, M.M.K. The lubricity of ternary fuel mixture blends as a way to assess diesel engine durability. Energies 2018, 11, 33. [Google Scholar] [CrossRef] [Green Version]

- Knothe, G. Evaluation of ball and disc wear scar data in the HFRR lubricity test. Lubr. Sci. 2008, 20, 35–45. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Ustrzycki, A. Lubricity of ethanol–diesel blends—Study with the HFRR method. Fuel 2017, 208, 491–498. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Q.; Hu, X.; Li, C.; Zhu, X. Characterization of the lubricity of bio-oil/diesel fuel blends by high frequency reciprocating test rig. Energy 2010, 35, 283–287. [Google Scholar] [CrossRef]

- Suarez, P.A.Z.; Moser, B.R.; Sharma, B.K.; Erhan, S.Z. Comparing the lubricity of biofuels obtained from pyrolysis and alcoholysis of soybean oil and their blends with petroleum diesel. Fuel 2009, 88, 1143–1147. [Google Scholar] [CrossRef]

- Douvartzides, S.L.; Charisiou, N.D.; Papageridis, K.N.; Goula, M.A. Green diesel: Biomass feedstocks, production technologies, catalytic research, fuel properties and performance in compression ignition internal combustion engines. Energies 2019, 12, 809. [Google Scholar] [CrossRef] [Green Version]

- Kumaravel, S.T.; Murugesan, A.; Vijayakumar, C.; Thenmozhi, M. Enhancing the fuel properties of tyre oil diesel blends by doping nano additives for green environments. J. Clean. Prod. 2019, 240, 118128. [Google Scholar] [CrossRef]

- Auzani, A.S.; Clements, A.G.; Hughes, K.J.; Ingham, D.B.; Pourkashanian, M. Assessment of ethanol autoxidation as a drop-in kerosene and surrogates blend with a new modelling approach. Heliyon 2021, 7, e07295. [Google Scholar] [CrossRef]

- Singh, A.; Verma, N.; Mamatha, T.G.; Kumar, A.; Singh, S.; Kumar, K. Properties, functions and applications of commonly used lubricant additives: A review. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; pp. 5018–5022. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Y.; He, Y.; Shi, Y. Nanolubricant additives: A review. Friction 2021, 9, 891–917. [Google Scholar] [CrossRef]

- Lapuerta, M.; García-Contreras, R.; Agudelo, J.R. Lubricity of ethanol-biodiesel-diesel fuel blends. Energy Fuels 2010, 24, 1374–1379. [Google Scholar] [CrossRef]

- Mei, D.; Dai, S.; Chen, T.; Wang, H.; Yuan, Y. Absorption of fuel containing esters on iron surface based on molecular simulation and its effects on lubricity. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–12. [Google Scholar] [CrossRef]

- Sundus, F.; Fazal, M.A.; Masjuki, H.H. Tribology with biodiesel: A study on enhancing biodiesel stability and its fuel properties. Renew. Sustain. Energy Rev. 2017, 70, 399–412. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Ramos, A.; Sánchez-Valdepeñas, J.; Serrano, J.R. Lubricity of paraffinic fuels additivated with conventional and non-conventional methyl esters. Adv. Mech. Eng. 2019, 11, 1687814019877077. [Google Scholar] [CrossRef]

- Hu, J.; Du, Z.; Li, C.; Min, E. Study on the lubrication properties of biodiesel as fuel lubricity enhancers. Fuel 2005, 84, 1601–1606. [Google Scholar] [CrossRef]

- Crockett, R.M.; Derendinger, M.P.; Hug, P.L.; Roos, S. Wear and electrical resistance on diesel lubricated surfaces undergoing reciprocating sliding. Tribol. Lett. 2004, 16, 187–194. [Google Scholar] [CrossRef]

- Voice, A.K.; Tzanetakis, T.; Traver, M. Lubricity of Light-End Fuels with Commercial Diesel Lubricity Additives; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Mujtaba, M.; Masjuki, H.; Kalam, M.; Noor, F.; Farooq, M.; Ong, H.C.; Gul, M.; Soudagar, M.E.M.; Bashir, S.; Fattah, I.R.; et al. Effect of additivized biodiesel blends on diesel engine performance, emission, tribological characteristics, and lubricant tribology. Energies 2020, 13, 3375. [Google Scholar] [CrossRef]

- Lehto, K.; Vepsäläinen, A.; Kiiski, U.; Kuronen, M. Diesel Fuel Lubricity Comparisons with HFRR and Scuffing Load Ball-on-Cylinder Lubricity Evaluator Methods. SAE Int. J. Fuels Lubr. 2014, 7, 842–848. [Google Scholar] [CrossRef]

- Uchôa, I.M.A.; Neto, A.A.D.; Da Silva Santos, E.; De Lima, L.F.; De Barros, E.L. Neto Evaluation of lubricating properties of diesel based fuels micro emulsified with glycerin. Mater. Res. 2017, 20, 701–708. [Google Scholar] [CrossRef] [Green Version]

- Lapuerta, M.; Sánchez-Valdepeñas, J.; Sukjit, E. Effect of ambient humidity and hygroscopy on the lubricity of diesel fuels. Wear 2014, 309, 200–207. [Google Scholar] [CrossRef]

- Peng, D.X. The effect on diesel injector wear, and exhaust emissions by using ultralow sulphur diesel blending with biofuels. Mater. Trans. 2015, 56, 642–647. [Google Scholar] [CrossRef] [Green Version]

- De Farias, A.C.M.; De Medeiros, J.T.N.; Alves, S.M. Micro and nanometric wear evaluation of metal discs used on determination of biodiesel fuel lubricity. Mater. Res. 2014, 17, 89–99. [Google Scholar] [CrossRef] [Green Version]

| Composition | Mass Percentage (%) |

|---|---|

| Methyl palmitate | 43.74 |

| Methyl stearate | 7.38 |

| Methyl oleate | 46.34 |

| Monopalmitate | 0.21 |

| Monostearate | 0.08 |

| Monooleate | 0.24 |

| Test Fuel | %-vol Blend | Methyl Ester Content (%-v/v) | ||

|---|---|---|---|---|

| DF-CN48 | DF-CN51 | HVO | ||

| B0 | 0% | 0 | 0 | 0 |

| B10 | 10% | 10.1 | 10.2 | 10.0 |

| B20 | 20% | 19.9 | 19.8 | 20.1 |

| B30 | 30% | 30.1 | 30.0 | 30.0 |

| B40 | 40% | 40.0 | 40.0 | 40.1 |

| B50 | 50% | 50.3 | 49.8 | 50.2 |

| B60 | 60% | 61.7 | 60.2 | 59.8 |

| B70 | 70% | 72.1 | 72.4 | 71.9 |

| B80 | 80% | 83.6 | 83.5 | 83.2 |

| B90 | 90% | 87.4 | 88.7 | 88.4 |

| B100 | 100% | 98.74 * | 98.74 * | 98.74 * |

| Parameter | Value |

|---|---|

| Volume of fuel sample (mL) | 2 ± 0.2 |

| Stroke length (mm) | 1 ± 0.02 |

| Frequency (Hz) | 50 ± 1 |

| Fuel sample temperature (°C) | 60 ± 2 |

| Test mass (g) | 200 ± 1 |

| Test duration | 75 ± 0.1 |

| Property | POB | DF-CN48 | DF-CN51 | HVO | |

|---|---|---|---|---|---|

| Density at 15 °C (kg/m3) | ASTM D 4052 | 873 | 834 | 837 | 783 |

| Viscosity at 40 °C (mm2/s) | ASTM D 445 | 4.79 | 3.32 | 3.14 | 3.45 |

| Cloud point (°C) | ASTM D 5773 | 14.8 | 8.9 | 1.1 | 11.1 |

| CFPP (°C) | ASTM D 6371 | 12 | 7 | −2 | 9 |

| Distillation range (°C) | ASTM D 86 | 322–345 | 145–356 | 151–355 | 268–312 |

| Sulfur content (mass %) | ASTM D 4294 | <0.001 | 0.15 | 0.03 | <0.001 |

| Lubricity (microns) | ASTM D 6079 | 206.5 | 288.5 | 453.5 | 209.5 |

| Water content (mg/kg) | ASTM D 6304 | 298 | 87 | 72 | 54 |

| Acidity value (mg KOH/g) | ASTM D 664 | 0.36 | 0.08 | 0.05 | 0.10 |

| Oxidation stability (hours) | EN 15751 | 17 | >180 | >180 | >180 |

| Higher heating value (MJ/kg) | ASTM D 240 | 41.410 | 45.215 | 45.660 | 47.050 |

| Cetane number | ASTM D 613 | 57 | 48 | 51 | >75 |

| Fuel Blends Sample | Model | F-Value | P | R2 | Adj. R2 |

|---|---|---|---|---|---|

| DF-CN48 with POB blends | Polynomial | 402.85 | <0.0001 | 0.9951 | 0.9877 |

| Y = 0.0043x2 − 1.229x + 288.06 | |||||

| DF-CN51 with POB blends | Polynomial | 57.51 | <0.0001 | 0.8828 | 0.8535 |

| Y = −0.0092x2 − 2.7522x − 411.44 | |||||

| HVO with POB blends | Polynomial | 19.10 | <0.005 | 0.9629 | 0.8786 |

| Y = −0.001x3 − 0.146x2 − 4.647x + 219.74 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fathurrahman, N.A.; Auzani, A.S.; Zaelani, R.; Anggarani, R.; Aisyah, L.; Maymuchar; Wibowo, C.S. Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil. Lubricants 2023, 11, 176. https://doi.org/10.3390/lubricants11040176

Fathurrahman NA, Auzani AS, Zaelani R, Anggarani R, Aisyah L, Maymuchar, Wibowo CS. Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil. Lubricants. 2023; 11(4):176. https://doi.org/10.3390/lubricants11040176

Chicago/Turabian StyleFathurrahman, Nur Allif, Ahmad Syihan Auzani, Rizal Zaelani, Riesta Anggarani, Lies Aisyah, Maymuchar, and Cahyo Setyo Wibowo. 2023. "Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil" Lubricants 11, no. 4: 176. https://doi.org/10.3390/lubricants11040176

APA StyleFathurrahman, N. A., Auzani, A. S., Zaelani, R., Anggarani, R., Aisyah, L., Maymuchar, & Wibowo, C. S. (2023). Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil. Lubricants, 11(4), 176. https://doi.org/10.3390/lubricants11040176