A Review of In-Situ TEM Studies on the Mechanical and Tribological Behaviors of Carbon-Based Materials

Abstract

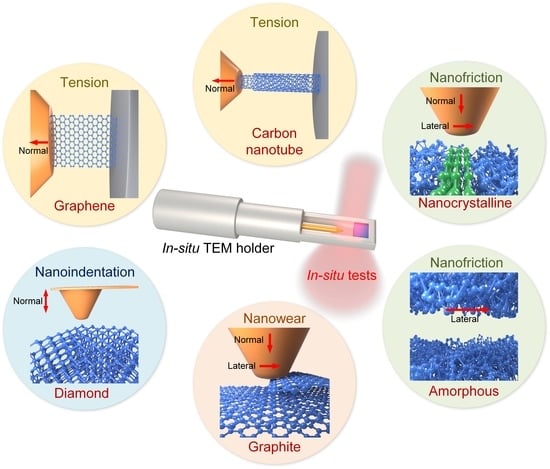

1. Introduction

2. Quantitative Actuation and Detection

2.1. Sample-Integrated MEMS

2.2. Sample-Separated MEMS

3. Mechanical Properties

3.1. Strength

3.2. Adhesion

4. Tribological Behaviors

4.1. Friction

4.2. Wear

5. Conclusions and Outlooks

5.1. Conclusions

- (1)

- MEMS devices used in in-situ TEM experiments consist of sample-integrated MEMS and sample-separated MEMS. The sample-integrated ones have been widely used in tensile tests to avoid positioning and alignment problems, while the sample-separated ones are more flexible and can be used in nanoindentation, nanoscratch, and nanowear tests.

- (2)

- The strength and adhesion of carbon-based materials exhibit strong relationships with the nanostructure. In-situ TEM tensile, compression, and nanoindentation tests were conducted to study the unusual strengths of simple nanostructures such as CNT and graphene, the reconstruction of complex nanostructures, the intrinsic works, and adhesion range of different carbon-based interfaces.

- (3)

- The nanostructure also significantly affects the friction and wear of carbon-based materials. In-situ observations of contact interfaces were used to investigate the superlubricity between CNT shells, the origin of stick–slip friction of different carbon films, the wear types of atom-by-atom removals, and the collective motion of atoms.

5.2. Outlooks

- (1)

- Conducting various in-situ TEM experiments to examine how defects and variations in nanostructures induced by factors such as electron and ion irradiation affect the mechanical and tribological behaviors of carbon-based materials. Furthermore, carbon-based materials composed of different nanostructures should also be included. This can lead to a clearer understanding of carbon-based materials.

- (2)

- Using in-situ TEM to elucidate the contact and deformation mechanism of carbon-based contact interfaces with modified nanostructures is encouraged, as this can benefit the development of self-lubricated materials.

- (3)

- Developing in-situ MEMS devices for multi-physical field experiments to conduct the in-situ TEM mechanical and tribological tests should also be prioritized. This is because carbon-based materials with different nanostructures exhibit different properties under different physical fields, and there is a lack of systematic experimental research on the nanocontact interface at multi-physical fields.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shirasu, K.; Kitayama, S.; Liu, F.; Yamamoto, G.; Hashida, T. Molecular dynamics simulations and theoretical model for engineering tensile properties of single-and multi-walled carbon nanotubes. Nanomaterials 2021, 11, 795. [Google Scholar] [CrossRef] [PubMed]

- Cao, K.; Feng, S.Z.; Han, Y.; Gao, L.B.; Ly, T.H.; Xu, Z.P.; Lu, Y. Elastic straining of free-standing monolayer graphene. Nat. Commun. 2020, 11, 284. [Google Scholar] [CrossRef] [PubMed]

- Zhan, H.; Chen, Y.W.; Shi, Q.Q.; Zhang, Y.; Mo, R.W.; Wang, J.N. Highly aligned and densified carbon nanotube films with superior thermal conductivity and mechanical strength. Carbon 2022, 186, 205–214. [Google Scholar] [CrossRef]

- Diao, D.F.; Wang, C.; Fan, X. Frictional behavior of nanostructured carbon films. Friction 2013, 1, 63–71. [Google Scholar] [CrossRef]

- Chen, C.; Xue, P.D.; Fan, X.; Wang, C.; Diao, D.F. Friction-induced rapid restructuring of graphene nanocrystallite cap layer at sliding surfaces: Short run-in period. Carbon 2018, 130, 215–221. [Google Scholar] [CrossRef]

- Hu, Z.L.; Fan, X.; Chen, C. Multiscale frictional behaviors of sp2 nanocrystallited carbon films with different ion irradiation densities. Friction 2021, 9, 1025–1037. [Google Scholar] [CrossRef]

- Huang, Z.Q.; Xue, P.D.; Chen, C.; Diao, D.F. Rapid fabrication of ultra-wear-resistant graphene nanocrystallite film by direct laser writing. Appl. Surf. Sci. 2022, 604, 154658. [Google Scholar] [CrossRef]

- Liu, M.; Su, W.L.; Qin, X.Z.; Cheng, K.; Ding, W.; Ma, L.; Cui, Z.; Chen, J.B.; Rao, J.J.; Ouyang, H.K.; et al. Mechanical/electrical characterization of ZnO nanomaterial based on AFM/nanomanipulator embedded in SEM. Micromachines 2021, 12, 248. [Google Scholar] [CrossRef]

- Choi, M.G.; Park, S.; Lee, H.; Kim, S. Correlating surface structures and nanoscale friction of CVD multi-layered graphene. Appl. Surf. Sci. 2022, 584, 152572. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, W.L.; Zhu, Z.W.; Zhu, L.M. Design, assessment, and trajectory control of a novel decoupled robotic nanomanipulator. IEEE-ASME Trans. Mechatron. 2022, 27, 3999–4010. [Google Scholar] [CrossRef]

- Yuan, S.; Wu, B.Y.; Wang, K.X.; Yu, P. Low-noise analysis and design for the sensing system of the nanomanipulation robot by AFM. In Proceedings of the 2022 IEEE International Conference on Robotics and Biomimetics (ROBIO), Jinghong, China, 5–9 December 2022; pp. 1491–1496. [Google Scholar]

- Sampath, V.; von Gratowski, S.; Irzhak, A.; Lega, P.; Song, Z.; Cotta, M.A.; Koledov, V. Mechanical bottom-up nanoassembling and nanomanipulation using shape memory alloy nanogripper. In Nanomaterials for Sensing and Optoelectronic Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 299–310. [Google Scholar]

- Jacobs, T.D.B.; Martini, A. Measuring and understanding contact area at the nanoscale: A review. Appl. Mech. Rev. 2017, 69, 060802. [Google Scholar] [CrossRef]

- Ellinas, K.; Gogolides, E. Ultra-low friction, superhydrophobic, plasma micro-nanotextured fluorinated ethylene propylene (FEP) surfaces. Micro. Nano. Eng. 2022, 14, 100104. [Google Scholar] [CrossRef]

- Falk, K.; Reichenbach, T.; Gkagkas, K.; Moseler, M.; Moras, G. Relating dry friction to interdigitation of surface passivation species: A molecular dynamics study on amorphous carbon. Materials 2022, 15, 3247. [Google Scholar] [CrossRef]

- Yin, S.C.; Wu, H.X.; Yi, X.B.; Huang, Z.Y.; Ye, C.P.; Li, P.F.; Zhang, Y.X.; Shi, J.Q.; Hua, K.; Wang, H.F. Enhanced graphene oxide adhesion on steel surface through boronizing functionalization treatment: Toward the robust ultralow friction. Carbon 2023, 206, 201–210. [Google Scholar] [CrossRef]

- Zeng, X.Z.; Peng, Y.T.; Yu, M.C.; Lang, H.J.; Cao, X.A.; Zou, K. Dynamic sliding enhancement on the friction and adhesion of graphene, graphene oxide, and fluorinated graphene. ACS Appl. Mater. Interfaces 2018, 10, 8214–8224. [Google Scholar] [CrossRef]

- Liu, S.W.; Wang, H.P.; Xu, Q.; Ma, T.B.; Yu, G.; Zhang, C.H.; Geng, D.C.; Yu, Z.W.; Zhang, S.G.; Wang, W.Z.; et al. Robust microscale superlubricity under high contact pressure enabled by graphene-coated microsphere. Nat. Commun. 2017, 8, 14029. [Google Scholar] [CrossRef]

- Goryacheva, I.G.; Paggi, M.; Popov, V.L. Contact mechanics perspective of tribology. Front. Mech. Eng. 2021, 7, 649792. [Google Scholar] [CrossRef]

- Dietzel, D.; Schwarz, U.D.; Schirmeisen, A. Nanotribological studies using nanoparticle manipulation: Principles and application to structural lubricity. Friction 2014, 2, 114–139. [Google Scholar] [CrossRef]

- Li, S.Z.; Li, Q.Y.; Carpick, R.W.; Gumbsch, P.; Liu, X.Z.; Ding, X.D.; Sun, J.; Li, J. The evolving quality of frictional contact with graphene. Nature 2016, 539, 541–545. [Google Scholar] [CrossRef]

- Liu, J.J.; Notbohm, J.K.; Carpick, R.W.; Turner, K.T. Method for characterizing nanoscale wear of atomic force microscope tips. ACS Nano 2010, 4, 3763–3772. [Google Scholar] [CrossRef]

- Yang, Z.T.; Hu, Z.L.; Fan, X.; Chen, C. Parallel electricity at friction interface induced fast superlow friction of amorphous carbon films. Appl. Surf. Sci. 2022, 577, 151962. [Google Scholar] [CrossRef]

- Chen, R.M.; Vishnubhotla, S.B.; Khanal, S.R.; Jacobs, T.D.B.; Martini, A. Quantifying the pressure-dependence of work of adhesion in silicon-diamond contacts. Appl. Phys. Lett. 2020, 116, 051602. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Yuan, D.D.; Zhang, H.; Xu, T.; Sun, L.T. Atomic-scale insights into the formation of 2D crystals from in situ transmission electron microscopy. Nano Res. 2021, 14, 1650–1658. [Google Scholar] [CrossRef]

- Ngo, D.T.; Kuhn, L.T. In situ transmission electron microscopy for magnetic nanostructures. Adv. Nat. Sci.-Nanosci. Nanotechnol. 2016, 7, 045001. [Google Scholar] [CrossRef]

- Tian, X.C.; Caruntu, G.; Kavey, B.; Tan, X.L. In situ TEM measurement of electrical properties of individual BaTiO3 nanocubes. Appl. Phys. Lett. 2021, 118, 192901. [Google Scholar] [CrossRef]

- Dong, H.; Xu, F.; Sun, Z.Q.; Wu, X.; Zhang, Q.B.; Zhai, Y.S.; Tan, X.D.; He, L.B.; Xu, T.; Zhang, Z.; et al. In situ interface engineering for probing the limit of quantum dot photovoltaic devices. Nat. Nanotechnol. 2019, 14, 950–956. [Google Scholar] [CrossRef]

- Espinosa, I.P.M.; Azadehranjbar, S.; Ding, R.K.; Baker, A.J.; Jacobs, T.D.B.; Martini, A. Platinum nanoparticle compression: Combining in situ TEM and atomistic modeling. Appl. Phys. Lett. 2022, 120, 013101. [Google Scholar] [CrossRef]

- Jensen, K.; Mickelson, W.; Kis, A.; Zettl, A. Buckling and kinking force measurements on individual multiwalled carbon nanotubes. Phys. Rev. B 2007, 76, 195436. [Google Scholar] [CrossRef]

- Li, P.F.; Cao, K.; Jiang, C.C.; Xu, S.; Gao, L.B.; Xiao, X.F.; Lu, Y. In situ tensile fracturing of multilayer graphene nanosheets for their in-plane mechanical properties. Nanotechnology 2019, 30, 475708. [Google Scholar] [CrossRef]

- Wang, D.S.; Chang, S.Y.; Huang, Y.C.; Wu, J.B.; Lai, H.J.; Leu, M.S. Nanoscopic observations of stress-induced formation of graphitic nanocrystallites at amorphous carbon surfaces. Carbon 2014, 74, 302–311. [Google Scholar] [CrossRef]

- Fan, X.; Diao, D.F. The adhesion behavior of carbon coating studied by re-indentation during in situ TEM nanoindentation. Appl. Surf. Sci. 2016, 362, 49–55. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Ryan, K.E.; Keating, P.L.; Grierson, D.S.; Lefever, J.A.; Turner, K.T.; Harrison, J.A.; Carpick, R.W. The effect of atomic-scale roughness on the adhesion of nanoscale asperities: A combined simulation and experimental investigation. Tribol. Lett. 2013, 50, 81–93. [Google Scholar] [CrossRef]

- Bernal, R.A.; Chen, P.; Schall, J.D.; Harrison, J.A.; Jeng, Y.R.; Carpick, R.W. Influence of chemical bonding on the variability of diamond-like carbon nanoscale adhesion. Carbon 2018, 128, 267–276. [Google Scholar] [CrossRef]

- Lin, L.T.; Cui, T.R.; Qin, L.C.; Washburn, S. Direct measurement of the friction between and shear moduli of shells of carbon nanotubes. Phys. Rev. Lett. 2011, 107, 206101. [Google Scholar] [CrossRef]

- Schweizer, P.; Dolle, C.; Dasler, D.; Abellan, G.; Hauke, F.; Hirsch, A.; Spiecker, E. Mechanical cleaning of graphene using in situ electron microscopy. Nat. Commun. 2020, 11, 1743. [Google Scholar] [CrossRef]

- Hu, Z.L.; Fan, X.; Diao, D.F. Facilitation of sp2 nanocrystallites on the formation of transfer films for stable low friction with in-situ TEM nanofriction study. Tribol. Int. 2022, 174, 107713. [Google Scholar] [CrossRef]

- Wang, J.J.; Lockwood, A.J.; Peng, Y.; Xu, X.; Bobji, M.S.; Inkson, B.J. The formation of carbon nanostructures by in situ TEM mechanical nanoscale fatigue and fracture of carbon thin films. Nanotechnology 2009, 20, 305703. [Google Scholar] [CrossRef]

- Casillas, G.; Liao, Y.; Jose-Yacaman, M.; Marks, L.D. Monolayer transfer layers during sliding at the atomic scale. Tribol. Lett. 2015, 59, 45. [Google Scholar] [CrossRef]

- Bernal, R.A.; Carpick, R.W. Visualization of nanoscale wear mechanisms in ultrananocrystalline diamond by in-situ TEM tribometry. Carbon 2019, 154, 132–139. [Google Scholar] [CrossRef]

- Kizuka, T.; Yamada, K.; Deguchi, S.; Naruse, M.; Tanaka, N. Cross-sectional time-resolved high-resolution transmission electron microscopy of atomic-scale contact and noncontact-type scannings on gold surfaces. Phys. Rev. B-Condens. Matter 1997, 55, 7398–7401. [Google Scholar] [CrossRef]

- Haque, M.A.; Saif, M.T.A. Application of MEMS force sensors for in situ mechanical characterization of nano-scale thin films in SEM and TEM. Sens. Actuator A-Phys. 2002, 97–98, 239–245. [Google Scholar] [CrossRef]

- Zhu, Y.; Corigliano, A.; Espinosa, H.D. A thermal actuator for nanoscale in situ microscopy testing: Design and characterization. J. Micromech. Microeng. 2006, 16, 242–253. [Google Scholar] [CrossRef]

- Sato, T.; Tochigi, E.; Mizoguchi, T.; Ikuhara, Y.; Fujita, H. An experimental system combined with a micromachine and double-tilt TEM holder. Microelectron. Eng. 2016, 164, 43–47. [Google Scholar] [CrossRef]

- Lu, H.H.; Wang, Z.J.; Yun, D.; Li, J.; Shan, Z.W. A new approach of using Lorentz force to study single-asperity friction inside TEM. J. Mater. Sci. Technol. 2021, 84, 43–48. [Google Scholar] [CrossRef]

- Sato, T.; Milne, Z.B.; Nomura, M.; Sasaki, N.; Carpick, R.W.; Fujita, H. Ultrahigh strength and shear-assisted separation of sliding nanocontacts studied in situ. Nat. Commun. 2022, 13, 2551. [Google Scholar] [CrossRef]

- He, Y.; She, D.S.; Liu, Z.Y.; Wang, X.; Zhong, L.; Wang, C.M.; Wang, G.F.; Mao, S.X. Atomistic observation on diffusion-mediated friction between single-asperity contacts. Nat. Mater. 2022, 21, 173–180. [Google Scholar] [CrossRef]

- Haque, M.A.; Saif, M.T.A. Investigation of micro-scale materials behavior with MEMS. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Nashville, TN, USA, 14–19 November 1999; Volume 16387, pp. 283–288. [Google Scholar]

- Haque, M.A.; Saif, M.T.A. Microscale materials testing using MEMS actuators. J. Microelectromech. Syst. 2001, 10, 146–152. [Google Scholar] [CrossRef]

- Haque, M.A.; Saif, M.T.A. In-situ tensile testing of nano-scale specimens in SEM and TEM. Exp. Mech. 2002, 42, 123–128. [Google Scholar] [CrossRef]

- Zhu, Y.; Espinosa, H.D. An electromechanical material testing system for in situ electron microscopy and applications. Proc. Natl. Acad. Sci. USA 2005, 102, 14503–14508. [Google Scholar] [CrossRef]

- Ishida, T.; Nakajima, Y.; Kakushima, K.; Mita, M.; Toshiyoshi, H.; Fujita, H. Design and fabrication of MEMS-controlled probes for studying the nano-interface under in situ TEM observation. J. Micromech. Microeng. 2010, 20, 075011. [Google Scholar] [CrossRef]

- Sato, T.; Ishida, T.; Jalabert, L.; Fujita, H. Real-time transmission electron microscope observation of nanofriction at a single Ag asperity. Nanotechnology 2012, 23, 505701. [Google Scholar] [CrossRef]

- Sato, T.; Jalabert, L.; Fujita, H. Development of MEMS integrated into TEM setup to monitor shear deformation, force and stress for nanotribology. Microelectron. Eng. 2013, 112, 269–272. [Google Scholar] [CrossRef]

- Ishida, T.; Sato, T.; Ishikawa, T.; Oguma, M.; Itamura, N.; Goda, K.; Sasaki, N.; Fujita, H. Time-lapse nanoscopy of friction in the non-Amontons and non-Coulomb regime. Nano Lett. 2015, 15, 1476–1480. [Google Scholar] [CrossRef]

- Zhang, D.F.; Breguet, J.M.; Clavel, R.; Sivakov, V.; Christiansen, S.; Michler, J. In situ electron microscopy mechanical testing of silicon nanowires using electrostatically actuated tensile stages. J. Microelectromech. Syst. 2010, 19, 663–674. [Google Scholar] [CrossRef]

- Wang, Y.L.; Li, T.; Zhang, X.; Zeng, H.J.; Jin, Q.H. In situ TEM/SEM electronic/mechanical characterization of nano material with MEMS chip. J. Semicond. 2014, 35, 081001. [Google Scholar] [CrossRef]

- Svensson, K.; Jompol, Y.; Olin, H.; Olsson, E. Compact design of a transmission electron microscope-scanning tunneling microscope holder with three-dimensional coarse motion. Rev. Sci. Instrum. 2003, 74, 4945–4947. [Google Scholar] [CrossRef]

- Lockwood, A.J.; Wedekind, J.; Gay, R.S.; Bobji, M.S.; Amavasai, B.; Howarth, M.; Mobus, G.; Inkson, B.J. Advanced transmission electron microscope triboprobe with automated closed-loop nanopositioning. Meas. Sci. Technol. 2010, 21, 075901. [Google Scholar] [CrossRef]

- Lobato-Dauzier, N.; Denoual, M.; Sato, T.; Tachikawa, S.; Jalabert, L.; Fujita, H. Current driven magnetic actuation of a MEMS silicon beam in a transmission electron microscope. Ultramicroscopy 2019, 197, 100–104. [Google Scholar] [CrossRef] [PubMed]

- Wall, M.A.; Dahmen, U. An in situ nanoindentation specimen holder for a high voltage transmission electron microscope. Microsc. Res. Tech. 1998, 42, 248–254. [Google Scholar] [CrossRef]

- Minor, A.M.; Morris, J.W.; Stach, E.A. Quantitative in situ nanoindentation in an electron microscope. Appl. Phys. Lett. 2001, 79, 1625–1627. [Google Scholar] [CrossRef]

- Bobji, M.S.; Ramanujan, C.S.; Pethica, J.B.; Inkson, B.J. A miniaturized TEM nanoindenter for studying material deformation in situ. Meas. Sci. Technol. 2006, 17, 1324–1329. [Google Scholar] [CrossRef]

- Desai, A.V.; Haque, M.A. A novel MEMS nano-tribometer for dynamic testing in-situ in SEM and TEM. Tribol. Lett. 2005, 18, 13–19. [Google Scholar] [CrossRef]

- Erts, D.; Lohmus, A.; Lohmus, R.; Olin, H. Instrumentation of STM and AFM combined with transmission electron microscope. Appl. Phys. A-Mater. Sci. Process. 2001, 72, 71–74. [Google Scholar] [CrossRef]

- Fujisawa, S.; Kizuka, T. Lateral displacement of an AFM tip observed by in-situ TEM/AFM combined microscopy: The effect of the friction in AFM. Tribol. Lett. 2003, 15, 163–168. [Google Scholar] [CrossRef]

- Anantheshwara, K.; Bobji, M.S. In situ transmission electron microscope study of single asperity sliding contacts. Tribol. Int. 2010, 43, 1099–1103. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.Y.; He, Y.; Tan, S.S.; Wang, G.F.; Mao, S.X. Atomic-scale friction between single-asperity contacts unveiled through in situ transmission electron microscopy. Nat. Nanotechnol. 2022, 17, 799. [Google Scholar] [CrossRef]

- Xue, P.D.; Chen, C.; Fan, X.; Diao, D.F. Current-carrying friction in carbon coated ball bearing. Friction 2023, 1–13. [Google Scholar] [CrossRef]

- Wang, X.Y.; Zhang, X.; Wang, C.; Lu, Y.; Hao, J.Y. High temperature tribology behavior of silicon and nitrogen doped hydrogenated diamond-like carbon (DLC) coatings. Tribol. Int. 2022, 175, 107845. [Google Scholar] [CrossRef]

- Vuchkov, T.; Evaristo, M.; Carvalho, A.; Cavaleiro, A. On the tribological performance of laser-treated self-lubricating thin films in contact with rubber. Tribol. Int. 2022, 174, 107758. [Google Scholar] [CrossRef]

- Alsem, D.H.; Sood, S.; Salmon, N.; Jacobs, T.D.B. In situ electrical testing of device-relevant nanocontacts in the transmission electron microscope. Microsc. Microanal. 2016, 22, 818–819. [Google Scholar] [CrossRef]

- Vishnubhotla, S.B.; Chen, R.M.; Khanal, S.R.; Li, J.; Stach, E.A.; Martini, A.; Jacobs, T.D.B. Quantitative measurement of contact area and electron transport across platinum nanocontacts for scanning probe microscopy and electrical nanodevices. Nanotechnology 2018, 30, 045705. [Google Scholar] [CrossRef] [PubMed]

- Minenkov, A.; Santic, N.; Truglas, T.; Aberl, J.; Vukusic, L.; Brehm, M.; Groiss, H. Advanced preparation of plan-view specimens on a MEMS chip for in situ TEM heating experiments. MRS Bull. 2022, 47, 359–370. [Google Scholar] [CrossRef] [PubMed]

- Zak, A.M. Light-induced in situ transmission electron microscopy-development, challenges, and perspectives. Nano Lett. 2022, 22, 9219–9226. [Google Scholar] [CrossRef] [PubMed]

- Tsai, P.C.; Jeng, Y.R.; Huang, Y.X.; Wu, K.T. Buckling characterizations of an individual multi-walled carbon nanotube: Insights from quantitative in situ transmission electron microscope nanoindentation and molecular dynamics. Appl. Phys. Lett. 2013, 103, 053119. [Google Scholar] [CrossRef]

- Tsai, P.C.; Jeng, Y.R. In-situ nanomechanical study on bending characteristics of individual multi-walled carbon nanotubes. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2016, 658, 389–392. [Google Scholar] [CrossRef]

- Zhao, J.; He, M.R.; Dai, S.; Huang, J.Q.; Wei, F.; Zhu, J. TEM observations of buckling and fracture modes for compressed thick multiwall carbon nanotubes. Carbon 2011, 49, 206–213. [Google Scholar] [CrossRef]

- Jang, B.; Kim, B.; Kim, J.H.; Lee, H.J.; Sumigawa, T.; Kitamura, T. Asynchronous cracking with dissimilar paths in multilayer graphene. Nanoscale 2017, 9, 17325–17333. [Google Scholar] [CrossRef]

- Wei, X.L.; Xiao, S.; Li, F.X.; Tang, D.M.; Chen, Q.; Bando, Y.; Golberg, D. Comparative fracture toughness of multilayer graphenes and boronitrenes. Nano Lett. 2015, 15, 689–694. [Google Scholar] [CrossRef]

- Wang, M.S.; Golberg, D.; Bando, Y. Tensile tests on individual single-walled carbon nanotubes: Linking nanotube strength with its defects. Adv. Mater. 2010, 22, 4071–4075. [Google Scholar] [CrossRef]

- Filleter, T.; Bernal, R.; Li, S.; Espinosa, H.D. Ultrahigh strength and stiffness in cross-linked hierarchical carbon nanotube bundles. Adv. Mater. 2011, 23, 2855–2860. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, X.; Gao, H.W.; Wang, J.M.; Luo, G.F.; Golberg, D.; Wang, M.S. Diameter, strength and resistance tuning of double-walled carbon nanotubes in a transmission electron microscope. Carbon 2020, 160, 98–106. [Google Scholar] [CrossRef]

- Cao, C.H.; Daly, M.; Chen, B.; Howe, J.Y.; Singh, C.V.; Filleter, T.; Sun, Y. Strengthening in graphene oxide nanosheets: Bridging the gap between interplanar and intraplanar fracture. Nano Lett. 2015, 15, 6528–6534. [Google Scholar] [CrossRef]

- Cao, C.H.; Mukherjee, S.; Howe, J.Y.; Perovic, D.D.; Sun, Y.; Singh, C.V.; Filleter, T. Nonlinear fracture toughness measurement and crack propagation resistance of functionalized graphene multilayers. Sci. Adv. 2018, 4, eaao7202. [Google Scholar] [CrossRef]

- Cao, C.H.; Howe, J.Y.; Perovic, D.; Filleter, T.; Sun, Y. In situ TEM tensile testing of carbon-linked graphene oxide nanosheets using a MEMS device. Nanotechnology 2016, 27, 28LT01. [Google Scholar] [CrossRef]

- Chen, C.; Xue, P.D.; Diao, D.F. Graphitization vs tribo-oxidation governing friction behaviors of doped graphene nanocrystalline carbon films. Carbon 2022, 197, 435–443. [Google Scholar] [CrossRef]

- Wan, N.; Pan, W.; Lin, T. Strain-induced growth of oriented graphene layers revealed by in situ transmission electron microscopy observation. Phys. Chem. Chem. Phys. 2016, 18, 16641–16646. [Google Scholar] [CrossRef]

- Beese, A.M.; Papkov, D.; Li, S.Y.; Dzenis, Y.; Espinosa, H.D. In situ transmission electron microscope tensile testing reveals structure-property relationships in carbon nanofibers. Carbon 2013, 60, 246–253. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Lefever, J.A.; Carpick, R.W. A technique for the experimental determination of the length and strength of adhesive interactions between effectively rigid materials. Tribol. Lett. 2015, 59, 1. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Lefever, J.A.; Carpick, R.W. Measurement of the length and strength of adhesive interactions in a nanoscale silicon-diamond interface. Adv. Mater. Interfaces 2015, 2, 1400547. [Google Scholar] [CrossRef]

- Carpick, R.W.; Bernal, R.A.; Chen, P.; Schall, J.D.; Harrison, J.A. Influence of chemical bonding on the variability of diamond-like carbon nanoscale adhesion: An in-situ TEM/nanoindentation and molecular dynamics study. Microsc. Microanal. 2018, 24, 1822–1823. [Google Scholar] [CrossRef]

- Milne, Z.B.; Schall, J.D.; Jacobs, T.D.B.; Harrison, J.A.; Carpick, R.W. Covalent bonding and atomic-level plasticity increase adhesion in silicon-diamond nanocontacts. ACS Appl. Mater. Interfaces 2019, 11, 40734–40748. [Google Scholar] [CrossRef] [PubMed]

- Vishnubhotla, S.B.; Chen, R.M.; Khanal, S.R.; Hu, X.L.; Martini, A.; Jacobs, T.D.B. Matching atomistic simulations and in situ experiments to investigate the mechanics of nanoscale contact. Tribol. Lett. 2019, 67, 97. [Google Scholar] [CrossRef]

- Milne, Z.B.; Bernal, R.A.; Carpick, R.W. Sliding history-dependent adhesion of nanoscale silicon contacts revealed by in situ transmission electron microscopy. Langmuir 2019, 35, 15628–15638. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.H.; Milne, Z.; Rouhani, M.; Lin, Y.P.; Bernal, R.A.; Sato, T.; Carpick, R.W.; Jeng, Y.R. Stress-dependent adhesion and sliding-induced nanoscale wear of diamond-like carbon studied using in situ TEM nanoindentation. Carbon 2022, 193, 230–241. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.R.; Grey, F.; Liu, J.Z.; Liu, Y.L.; Wang, Y.B.; Yang, Y.L.; Cheng, Y.; Zheng, Q.S. Observation of microscale superlubricity in graphite. Phys. Rev. Lett. 2012, 108, 205503. [Google Scholar] [CrossRef]

- Kis, A.; Jensen, K.; Aloni, S.; Mickelson, W.; Zettl, A. Interlayer forces and ultralow sliding friction in multiwalled carbon nanotubes. Phys. Rev. Lett. 2006, 97, 025501. [Google Scholar] [CrossRef]

- Fan, X.; Hu, Z.L.; Huang, W.C. In-situ TEM studies on stick-slip friction characters of sp2 nanocrystallited carbon films. Friction 2022, 10, 1635–1649. [Google Scholar] [CrossRef]

- Sato, T.; Nabeya, S.; Menon, V.; Ishida, T.; Kometani, R.; Fujita, H. Real-time observation of slipping and rolling events in DLC wear nanoparticles. Nanotechnology 2018, 29, 325707. [Google Scholar] [CrossRef]

- Hintsala, E.D.; Stauffer, D.D.; Oh, Y.; Asif, S.A.S. In situ TEM scratch testing of perpendicular magnetic recording multilayers with a novel MEMS tribometer. JOM 2017, 69, 51–56. [Google Scholar] [CrossRef]

- Liu, J.J.; Jiang, Y.J.; Grierson, D.S.; Sridharan, K.; Shao, Y.C.; Jacobs, T.D.B.; Falk, M.L.; Carpick, R.W.; Turner, K.T. Tribochemical wear of diamond-like carbon-coated atomic force microscope tips. ACS Appl. Mater. Interfaces 2017, 9, 35341–35348. [Google Scholar] [CrossRef]

- Merkle, A.P.; Erdemir, A.; Eryilmaz, O.L.; Johnson, J.A.; Marks, L.D. In situ TEM studies of tribo-induced bonding modifications in near-frictionless carbon films. Carbon 2010, 48, 587–591. [Google Scholar] [CrossRef]

- M’ndange-Pfupfu, A.; Eryilmaz, O.; Erdemir, A.; Marks, L.D. Quantification of sliding-induced phase transformation in N3FC diamond-like carbon films. Diam. Relat. Mat. 2011, 20, 1143–1148. [Google Scholar] [CrossRef]

- Johnson, J.A.; Holland, D.; Woodford, J.B.; Zinovev, A.; Gee, I.A.; Eryilmaz, O.L.; Erdemir, A. Top-surface characterization of a near frictionless carbon film. Diam. Relat. Mat. 2007, 16, 209–215. [Google Scholar] [CrossRef]

- M’ndange-Pfupfu, A.; Ciston, J.; Eryilmaz, O.; Erdemir, A.; Marks, L.D. Direct observation of tribochemically assisted wear on diamond-like carbon thin films. Tribol. Lett. 2013, 49, 351–356. [Google Scholar] [CrossRef]

- Eryilmaz, O.L.; Erdemir, A. Surface analytical investigation of nearly-frictionless carbon films after tests in dry and humid nitrogen. Surf. Coat. Technol. 2007, 201, 7401–7407. [Google Scholar] [CrossRef]

- Merkle, A.P.; Marks, L.D. Friction in full view. Appl. Phys. Lett. 2007, 90, 064101. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Fan, X.; Diao, D. A Review of In-Situ TEM Studies on the Mechanical and Tribological Behaviors of Carbon-Based Materials. Lubricants 2023, 11, 187. https://doi.org/10.3390/lubricants11050187

Hu Z, Fan X, Diao D. A Review of In-Situ TEM Studies on the Mechanical and Tribological Behaviors of Carbon-Based Materials. Lubricants. 2023; 11(5):187. https://doi.org/10.3390/lubricants11050187

Chicago/Turabian StyleHu, Zelong, Xue Fan, and Dongfeng Diao. 2023. "A Review of In-Situ TEM Studies on the Mechanical and Tribological Behaviors of Carbon-Based Materials" Lubricants 11, no. 5: 187. https://doi.org/10.3390/lubricants11050187

APA StyleHu, Z., Fan, X., & Diao, D. (2023). A Review of In-Situ TEM Studies on the Mechanical and Tribological Behaviors of Carbon-Based Materials. Lubricants, 11(5), 187. https://doi.org/10.3390/lubricants11050187