Tribological and Micro-Mechanical Properties of Injected Polypropylene Modified by Electron Radiation

Abstract

:1. Introduction

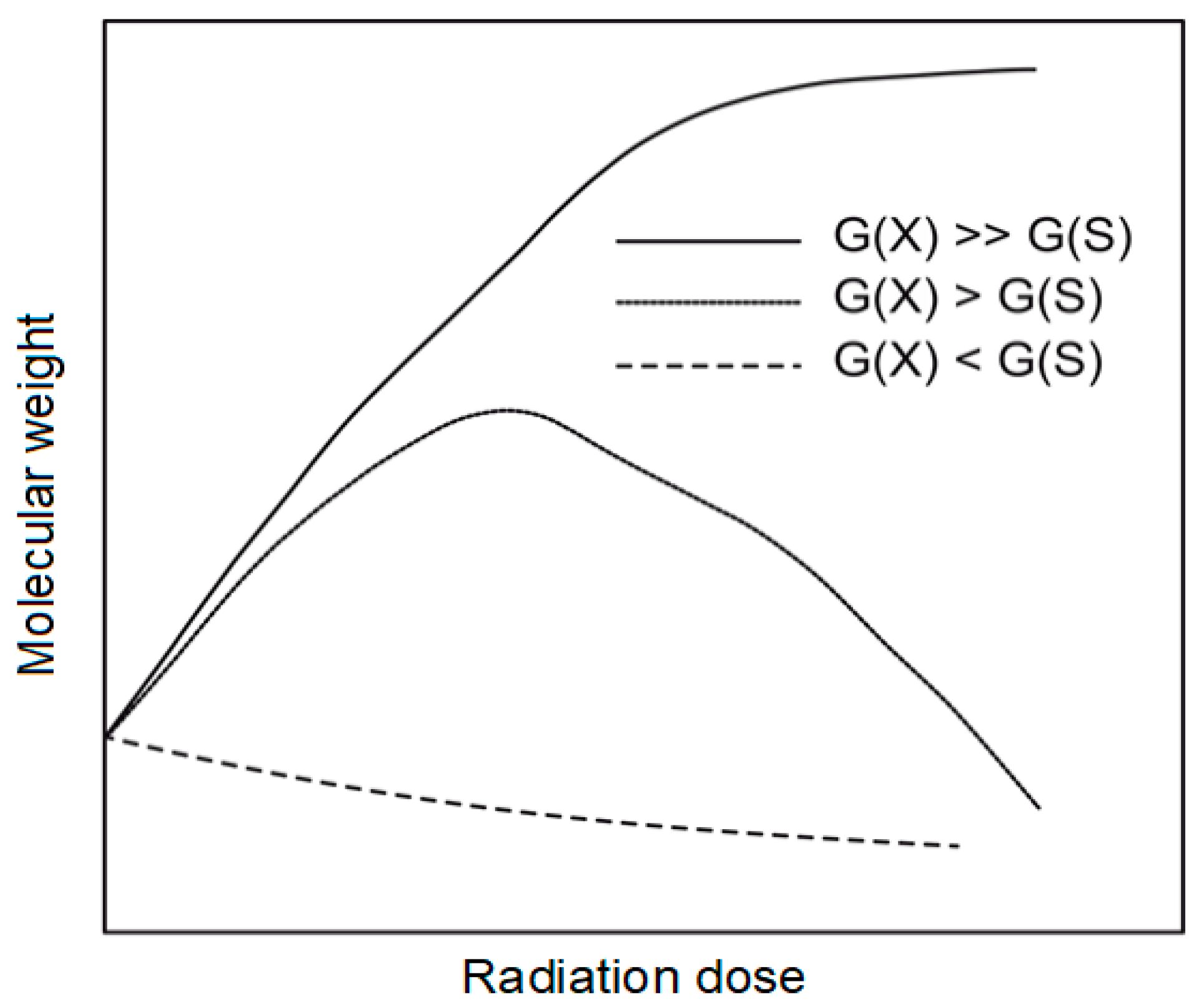

- Cross-linking, which is when polymer chains link together in to a network,

- Chain scission, which leads to lower molecular weight of polymer;

- Oxidation, when polymer molecules react with oxygen (oxidation and chain scission often times appear concurrently);

- Chain branching, which is when polymer chains link, but 3D network is not yet created;

2. Materials and Methods

2.1. Material

2.2. Preparation of Test Samples

2.3. Tribological Properties—Scratch Test

2.4. Micro-Mechanical Properties

2.5. Morphology

2.5.1. Gel Test

2.5.2. Wide-Angle X-ray Diffraction

2.5.3. Optical Microscopy—Microtome Cuts

2.5.4. Transmission Electron Microscope

3. Results

3.1. Tribological Properties

3.2. Micro-Mechanical Properties

3.3. Micro-Mechanical Properties—Section across Sample

3.4. Morphology—Change of Structure

3.4.1. Degree of Cross-Linking

3.4.2. Wide-Angle X-ray Diffraction

3.4.3. Microscope Images of Microtome Cuts

3.4.4. Transmission Electron Microscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Makuuchi, K.; Cheng, S. Radiation Processing of Polymer Materials and Its Industrial Applications; Wiley: Hoboken, NJ, USA, 2012; p. 415. [Google Scholar]

- Drobny, J.G. Ionizing Radiation and Polymers: Principles, Technology and Applications; Elsevier/William Andrew: Oxford, UK, 2013; p. 298. [Google Scholar]

- Gheysari, D.; Behjat, A.; Haji-Saeid, M. The effect of high-energy electron beam on mechanical and thermal properties of LDPE and HDPE. Eur. Polym. J. 2001, 37, 295–302. [Google Scholar] [CrossRef]

- Satapathy, S.; Chattopadhy, S.; Chakrabarty, K.K.; Nag, A.; Tiwari, K.N.; Tikku, V.K.; Nando, G.B. Studies on the effect of electron beam irradiation on waste polyethylene and its blends with virgin polyethylene. J. Appl. Polym. Sci. 2006, 101, 715–726. [Google Scholar] [CrossRef]

- Reichmanis, E.; Frank, F.; O’donnell, J.H. Irradiation of Polymeric Materials: Processes, Mechanisms, and Applications; American Chemical Society: Washington, DC, USA, 1993; p. 338. [Google Scholar]

- Clegg, D.; Collyer, A. Irradiation Effects on Polymers; Elsevier Applied Science: London, UK, 1991; p. 450. [Google Scholar]

- Gehring, J.; Zyball, A. Radiation crosslinking of polymers-status, current issues, trends and challenges. Radiat. Phys. Chem. 1995, 46, 931–936. [Google Scholar] [CrossRef]

- Clough, R.L.; Shalaby, W. Irradiation of Polymers: Fundamentals and Technological Applications; American Chemical Society: Washington, DC, USA, 1996; p. 433. [Google Scholar]

- Sirin, M.; Zeybek, M.S.; Sirin, K.; Abali, Y. Effect of gamma irradiation on the thermal and mechanical behaviour of polypropylene and polyethylene blends. Radiat. Phys. Chem. 2022, 194, 110034. [Google Scholar] [CrossRef]

- Yang, T.H.; Cheng, Y.C.; Wu, Y.P.; Yu, B.; Huang, T.; Yu, H.; Zhu, M.F. Enhanced crosslinking of polypropylene in gamma-irradiation via Copper (II) doping. Radiat. Phys. Chem. 2022, 194, 110042. [Google Scholar] [CrossRef]

- Naikwadi, A.T.; Sharma, B.K.; Bhatt, K.D.; Mahanwar, P.A. Gamma Radiation Processed Polymeric Materials for High Performance Applications: A Review. Front. Chem. 2022, 10, 837111. [Google Scholar] [CrossRef]

- Abraham, A.C.; Czayka, M.A.; Fisch, M.R. Electron beam irradiations of polypropylene syringe barrels and the resulting physical and chemical property changes. Radiat. Phys. Chem. 2010, 79, 83–92. [Google Scholar] [CrossRef]

- Ashfaq, A.; Clochard, M.C.; Coqueret, X.; Dispenza, C.; Driscoll, M.S.; Ulański, P.; Al-Sheikhly, M. Polymerization Reactions and Modifications of Polymers by Ionizing Radiation. Polymers 2020, 12, 2877. [Google Scholar] [CrossRef]

- Han, D.H.; Shin, S.H.; Petrov, S. Crosslinking and degradation of polypropylene by electron beam irradiation in the presence of trifunctional monomers. Radiat. Phys. Chem. 2004, 69, 239–244. [Google Scholar] [CrossRef]

- Wang, H.T.; Jiang, H.Q.; Shen, R.F.; Ding, X.J.; Zhang, C.; Li, L.F.; Li, J.Y. Electron-beam radiation effects on the structure and properties of polypropylene at low dose rates. Nucl. Sci. Tech. 2018, 29, 87. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, X.C.; Xie, J.H.; Liu, Y.; Sun, S.L. Enhanced dielectric and energy storage properties of polypropylene by high-energy electron beam irradiation. Polym. Eng. Sci. 2022, 62, 1756–1763. [Google Scholar] [CrossRef]

- Okuhara, M.; Nomura, R.; Nishi, Y. Improvements of Elasticity and tensile strength of Glass Fiber Reinforced Thermoplastic Polypropylene by Electron Beam Irradiation. J. Jpn. Inst. Met. Mater. 2016, 80, 360–364. [Google Scholar] [CrossRef]

- Rahman, M.S.; Shaislamov, U.; Yang, J.K.; Kim, J.K.; Yu, Y.H.; Choi, S.; Lee, H.J. Effects of electron beam irradiation on tribological and physico-chemical properties of Polyoxymethylene copolymer (POM-C). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 387, 54–62. [Google Scholar] [CrossRef]

- Yang, D.; Xie, G.; Cao, C. The effect of gamma irradiation on the tribological properties of UHMWPE composite filled with HDPE. J. Thermoplast. Compos. Mater. 2014, 27, 1045–1053. [Google Scholar]

- Liu, B.; Pei, X.; Wang, Q.; Sun, X.; Wang, T. Effects of proton and electron irradiation on the structural and tribological properties of MoS2/polyimide. Appl. Surf. Sci. 2011, 258, 1097–1102. [Google Scholar] [CrossRef]

- Wierzbicka, N.; Sterzyński, T.; Nowicki, M. The Friction of Structurally Modified Isotactic Polypropylene. Materials 2021, 14, 7462. [Google Scholar] [CrossRef]

- Manas, D.; Ovsik, M.; Mizera, A.; Manas, M.; Hylova, L.; Bednarik, M.; Stanek, M. The Effect of Irradiation on Mechanical and Thermal Properties of Selected Types of Polymers. Polymers 2018, 10, 158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drobny, J.G. Radiation Technology for Polymers; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Dadbin, S.; Frounchi, M.; Saeid, M.H.; Gangi, F. Molecular Structure and Physical Properties of EBeam Crosslinked Low-Density Polyethylene for Wire and Cable Insulation Applications. J. Appl. Polym. Sci. 2002, 86, 1959–1969. [Google Scholar] [CrossRef]

- Toselli, M.; Saccani, A.; Pilati, F. Thermo-oxidative resistance of crosslinked polyethylene (XLPE) coated by hybrid coatings containing grapheme oxide. Surf. Coat. Technol. 2014, 258, 503–508. [Google Scholar] [CrossRef]

- Qureshi, M.I.; Malik, N.H.; Al-Arainy, A.A. Impact of cations toward the water tree propensity in crosslinked polyethylene insulation. J. King Saud Univ.-Eng. Sci. 2011, 23, 43–48. [Google Scholar] [CrossRef] [Green Version]

- Kelley, K.M.; Stenson, A.C.; Dey, R.; Whelton, A.J. Release of drinking eater contaminants and odor impacts caused by green building cross-linked polyethylene (PEX) plumbing systems. Water Res. 2014, 67, 19–32. [Google Scholar] [CrossRef] [PubMed]

- Roumeli, E.; Markoulis, A.; Kyratsi, T.; Bikiaris, D.; Chrissafis, K. Carbon nanotube-reinforced crosslinked polyethylene pipes for geothermal applications: From synthesis to decomposition using analytical pyrolysis—GC/MS and thermogravimetric analysis. Polym. Degrad. Stab. 2014, 100, 42–53. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Ovsik, M.; Stanek, M.; Stanek, M.; Dockal, A.; Vanek, J.; Hylova, L. Influence of Cross-Linking Agent Concentration/Beta Radiation Surface Modification on the Micro-Mechanical Properties of Polyamide 6. Materials 2021, 14, 6407. [Google Scholar] [CrossRef] [PubMed]

| Technological Parameter | Unit | Value |

|---|---|---|

| Injection pressure | MPa | 80 |

| Injection speed | mm/s | 50 |

| Length of dose | mm | 40 |

| Temperature under hopper | °C | 50 |

| Cooling time | s | 40 |

| Holding pressure | MPa | 8 |

| Holding pressure duration | s | 5 |

| Heat zones settings | ||

| Zone n. 1 | °C | 210 |

| Zone n. 2 | °C | 220 |

| Zone n. 3 | °C | 230 |

| Zone n. 4 | °C | 240 |

| Measurement Parameter | Measurement 1 | Measurement 2 |

|---|---|---|

| Applied load (N) | 1 | 5 |

| Speed (mm/min) | 10 | 10 |

| Length (mm) | 5 | 5 |

| Acquisition Rate (Hz) | 30 | 30 |

| Measurement Parameters | |||

|---|---|---|---|

| Applied load (N) | 0.5 | 1 | 5 |

| Load hold duration (s) | 90 | 90 | 90 |

| Loading/de-loading speed (m/s) | 1 | 2 | 10 |

| Poisson number | 0.3 | 0.3 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ovsik, M.; Stanek, M.; Dockal, A. Tribological and Micro-Mechanical Properties of Injected Polypropylene Modified by Electron Radiation. Lubricants 2023, 11, 296. https://doi.org/10.3390/lubricants11070296

Ovsik M, Stanek M, Dockal A. Tribological and Micro-Mechanical Properties of Injected Polypropylene Modified by Electron Radiation. Lubricants. 2023; 11(7):296. https://doi.org/10.3390/lubricants11070296

Chicago/Turabian StyleOvsik, Martin, Michal Stanek, and Adam Dockal. 2023. "Tribological and Micro-Mechanical Properties of Injected Polypropylene Modified by Electron Radiation" Lubricants 11, no. 7: 296. https://doi.org/10.3390/lubricants11070296