An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy

Abstract

:1. Introduction

2. Experimental Procedure

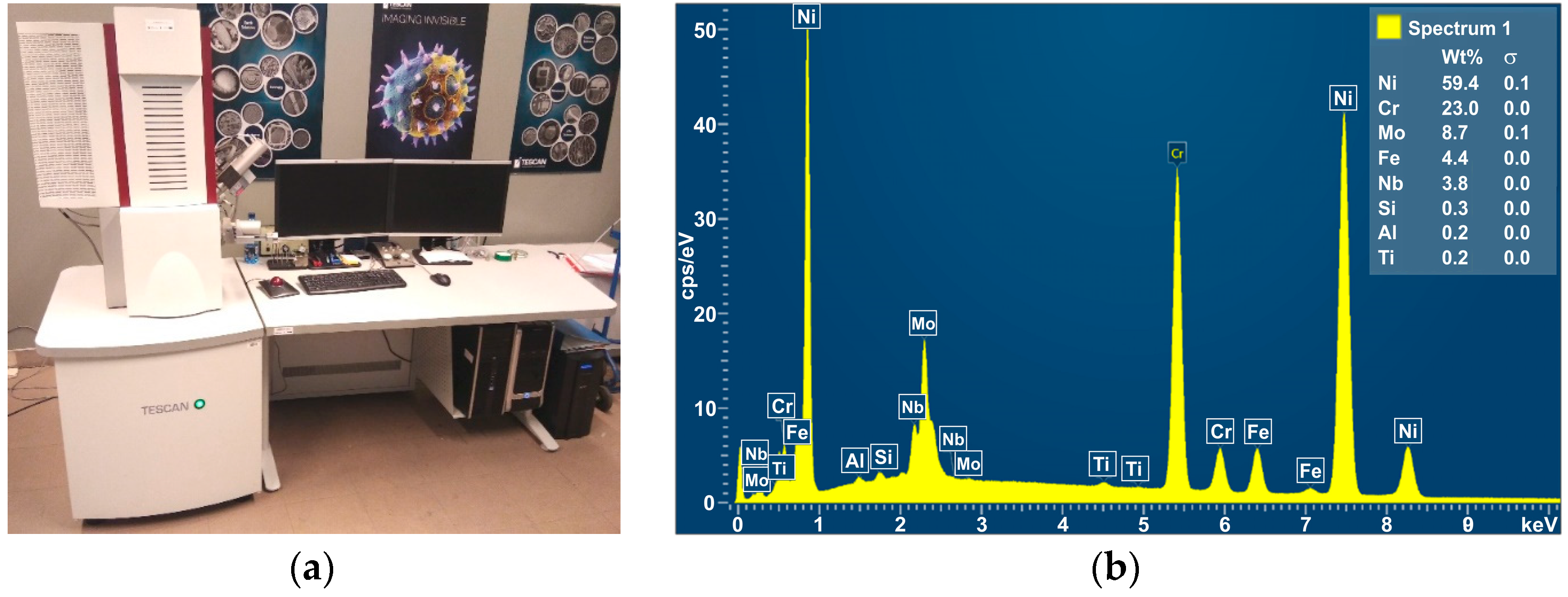

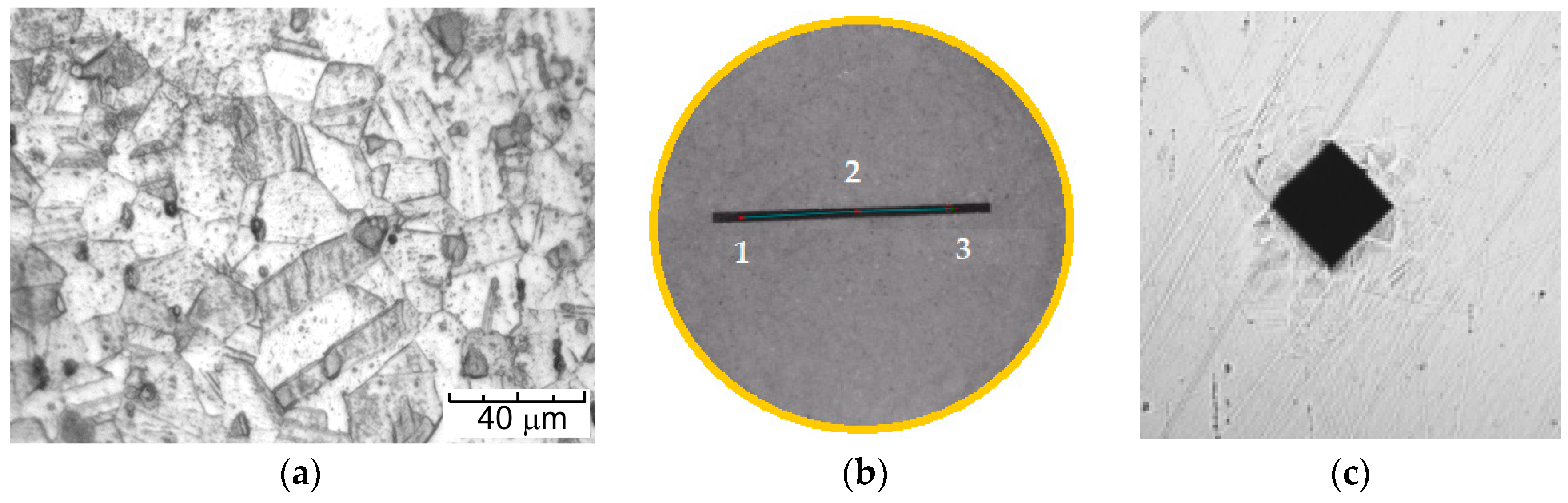

2.1. Material and Tool

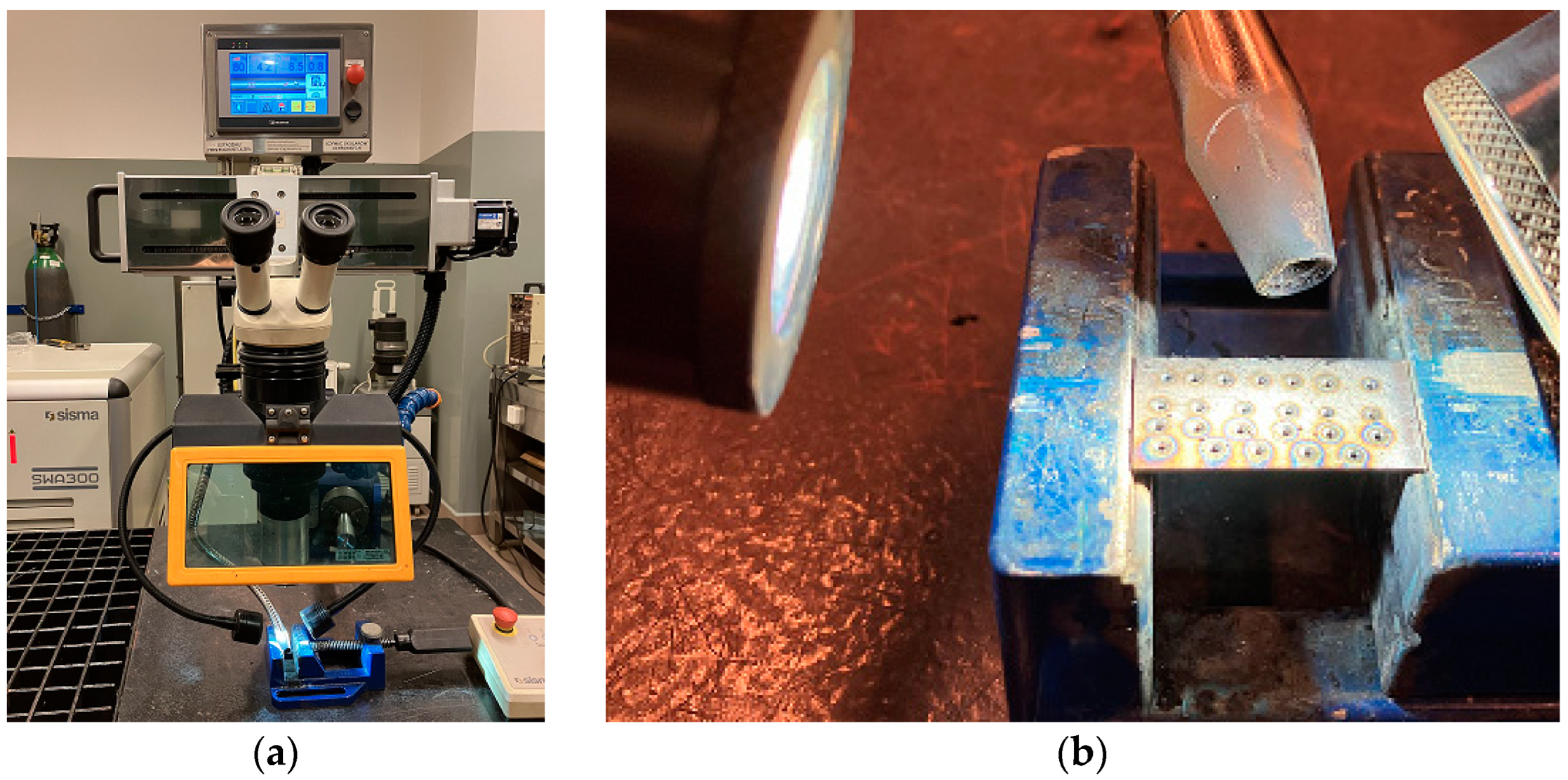

2.2. Experimental Setup

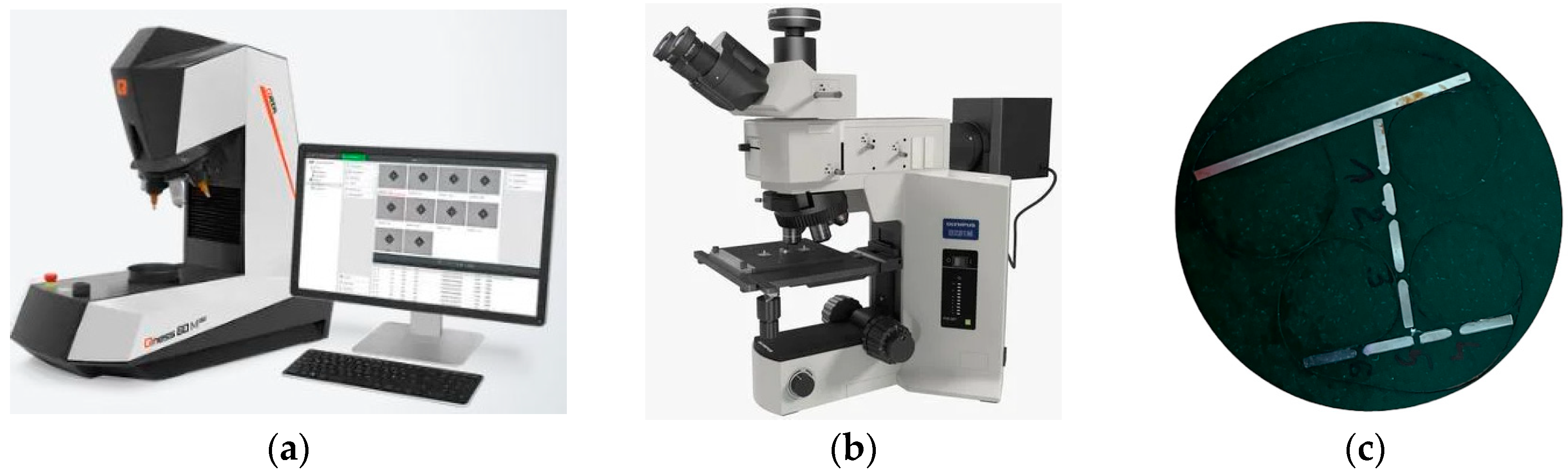

2.3. Measurement

3. Results and Discussion

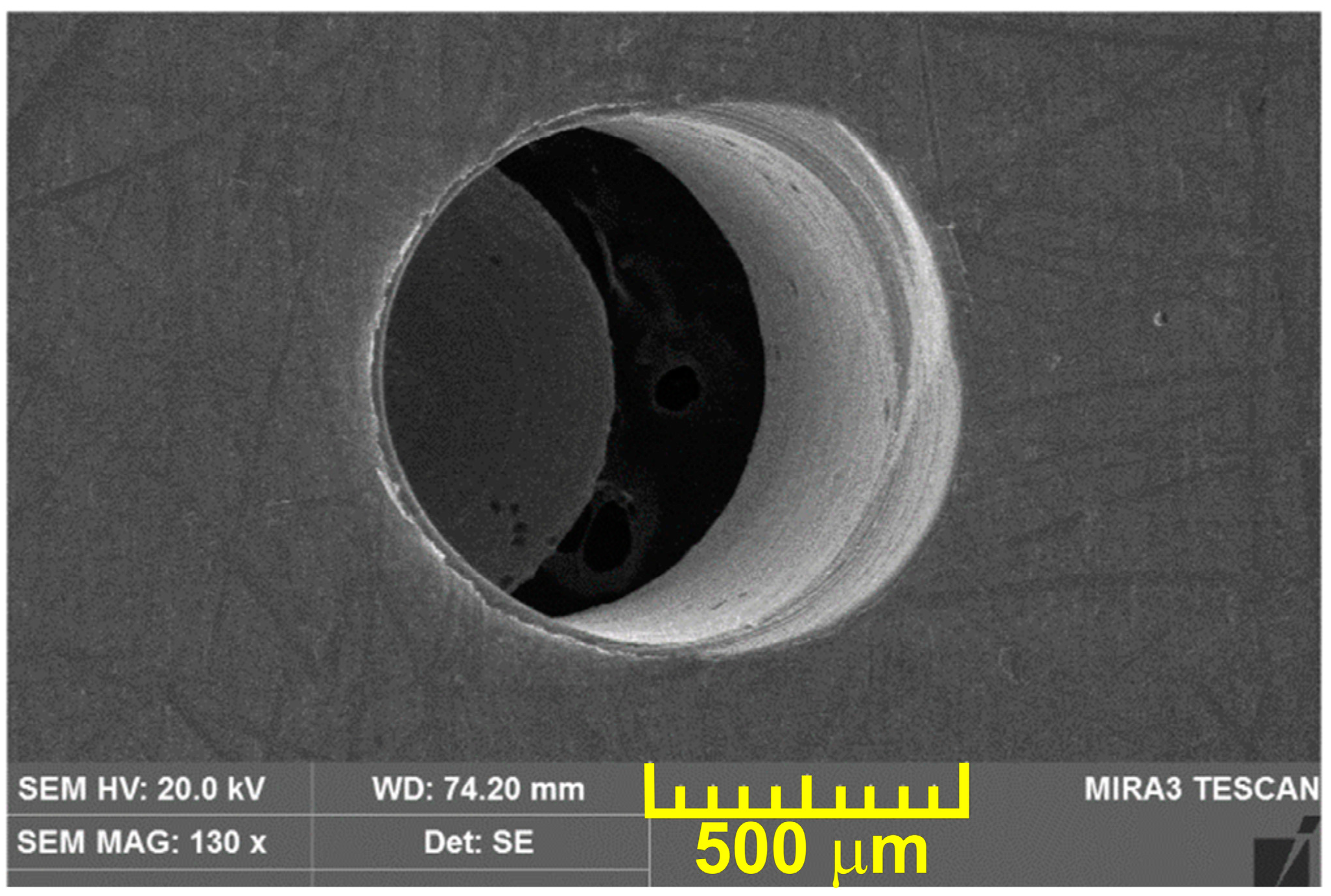

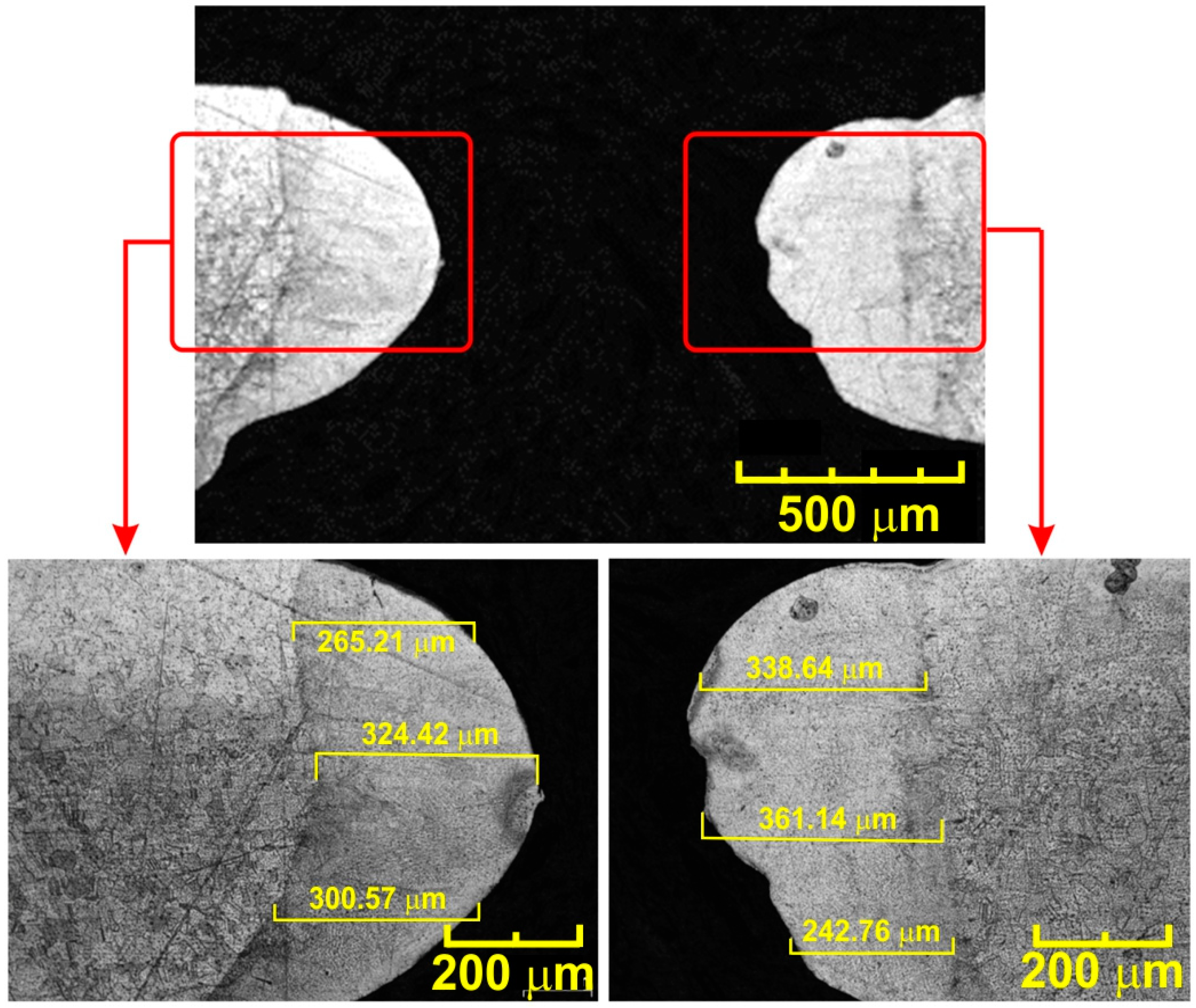

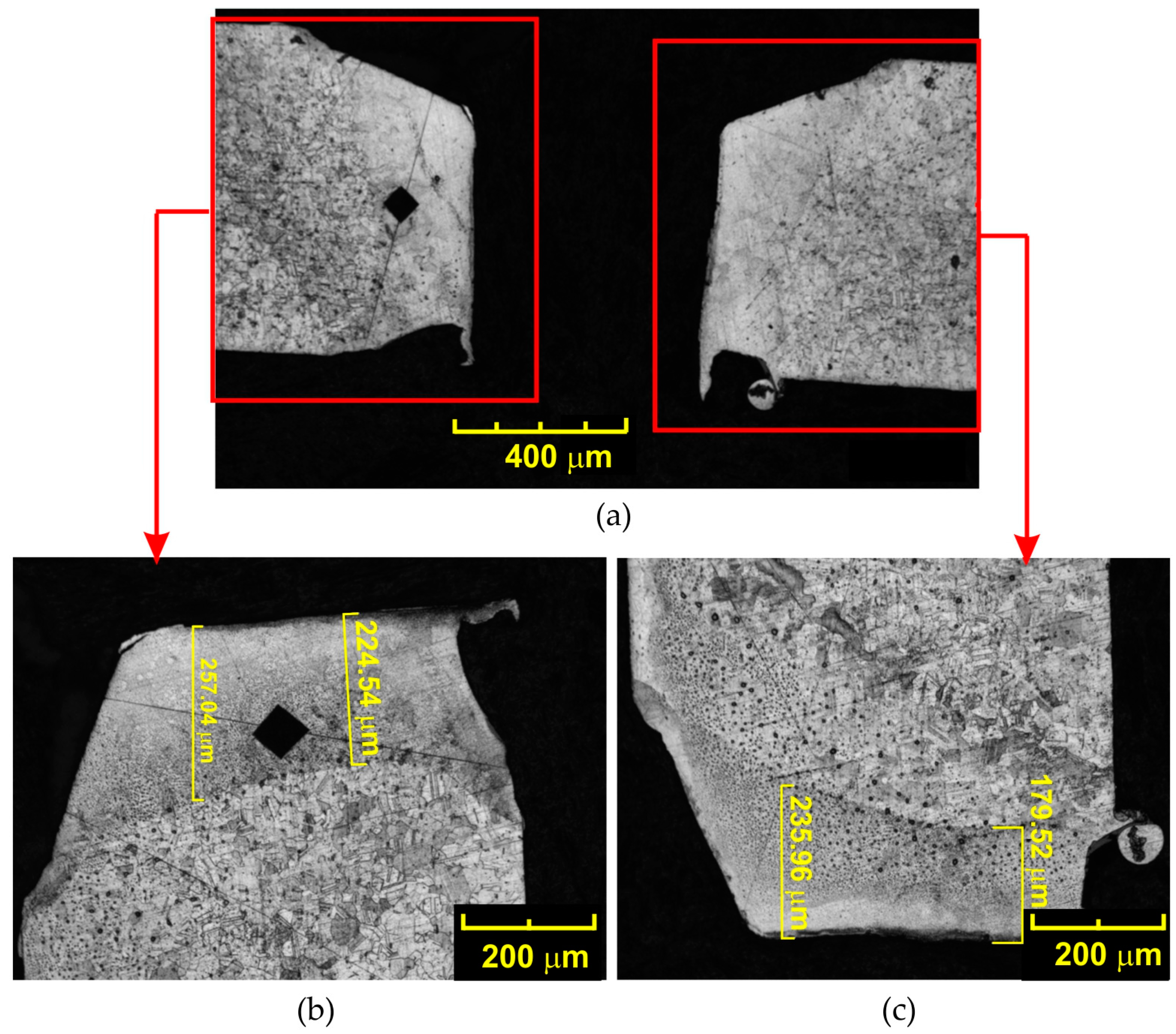

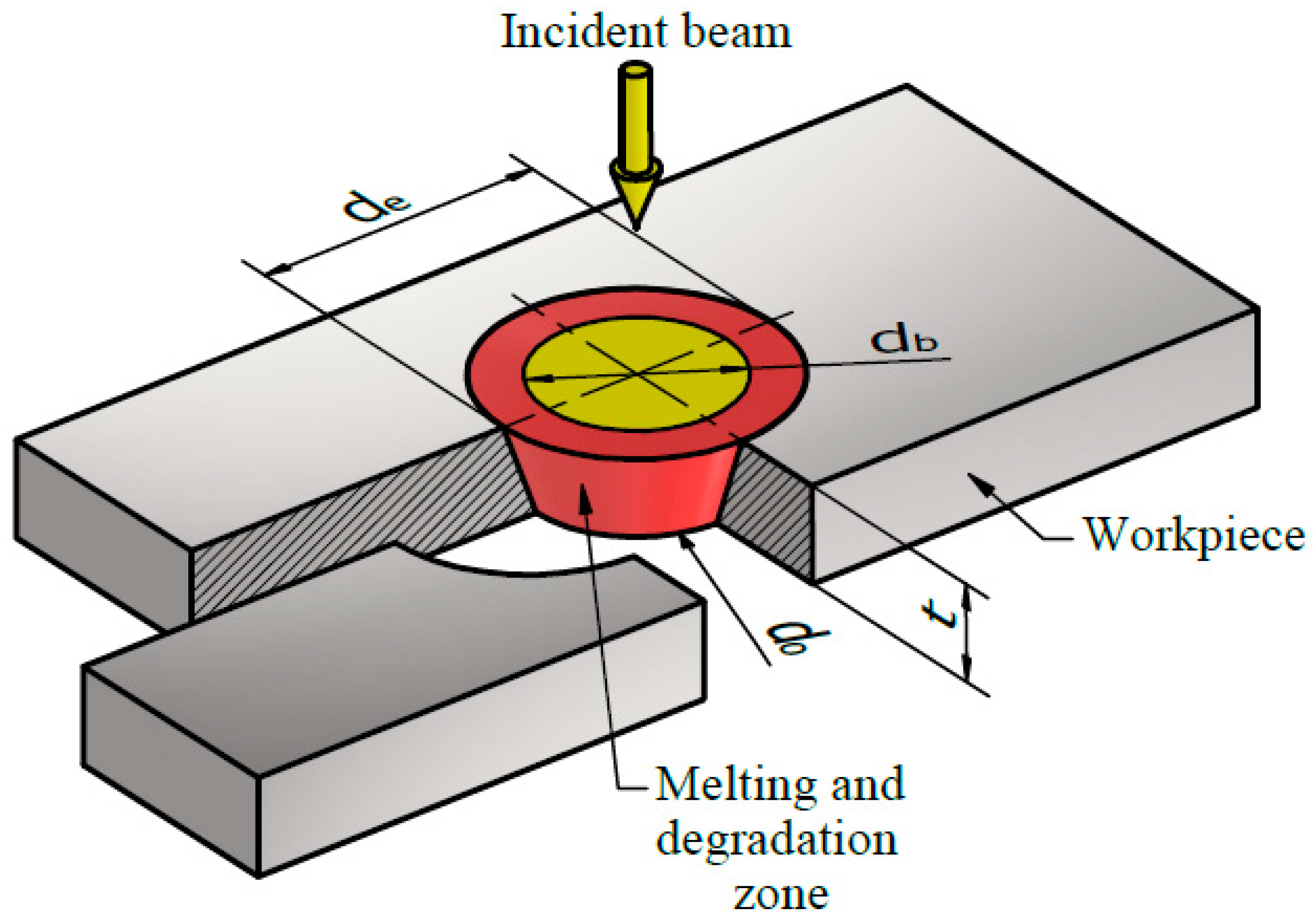

3.1. Shape and Structure of Holes Made with a Laser

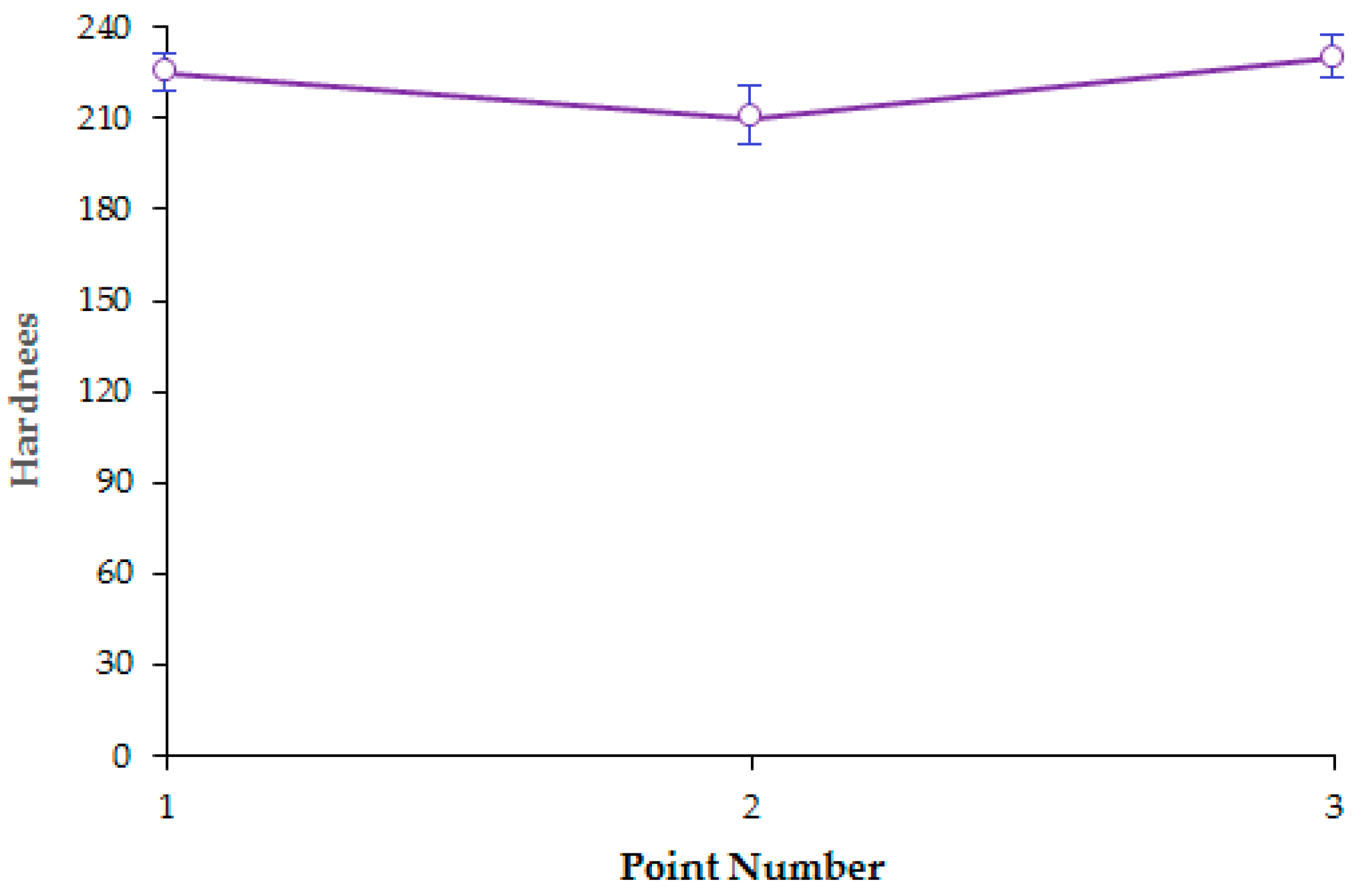

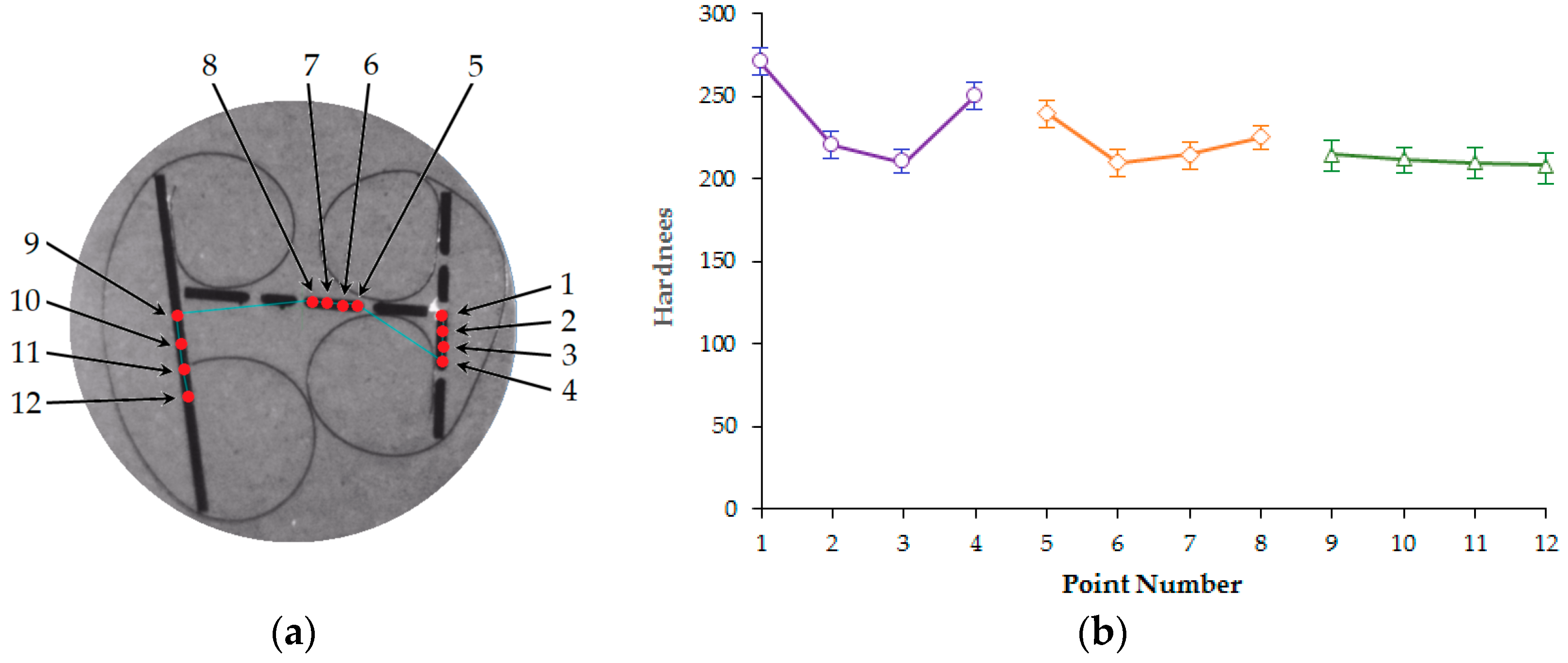

3.2. Hardness of the Surfaces of Holes Made with a Laser

3.3. Material Removal Rate and Volumetric Efficiency in Laser Drilling

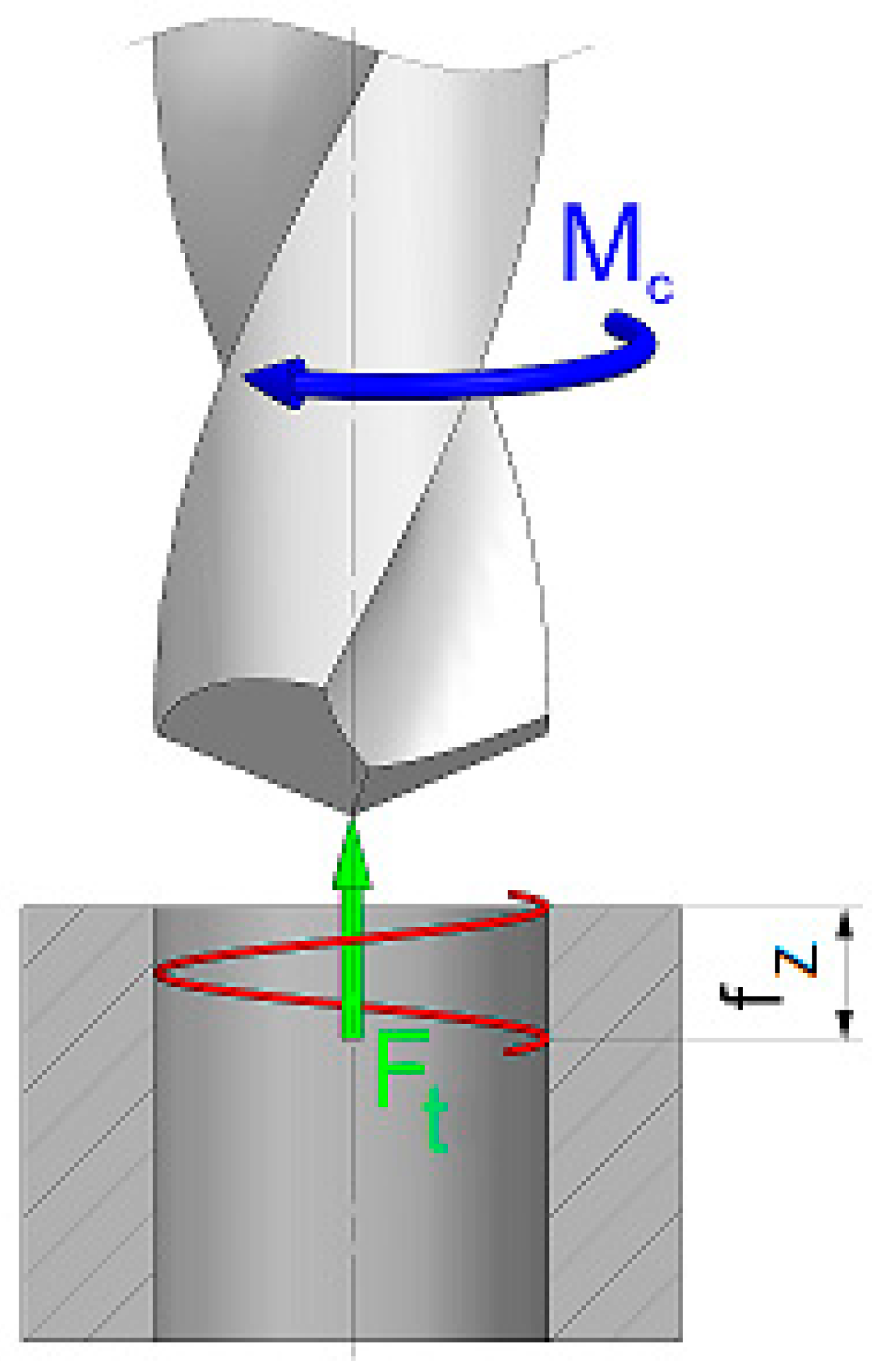

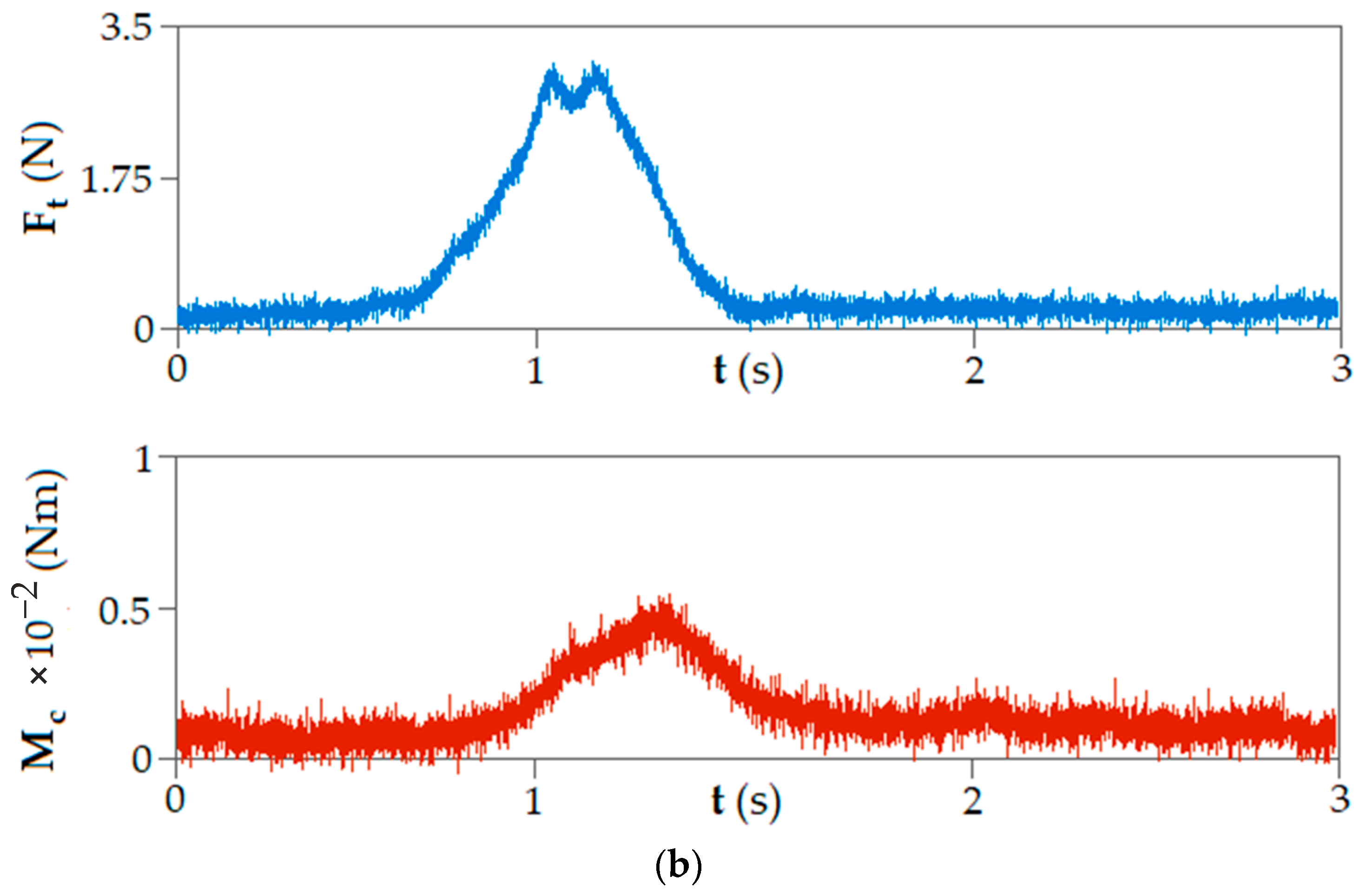

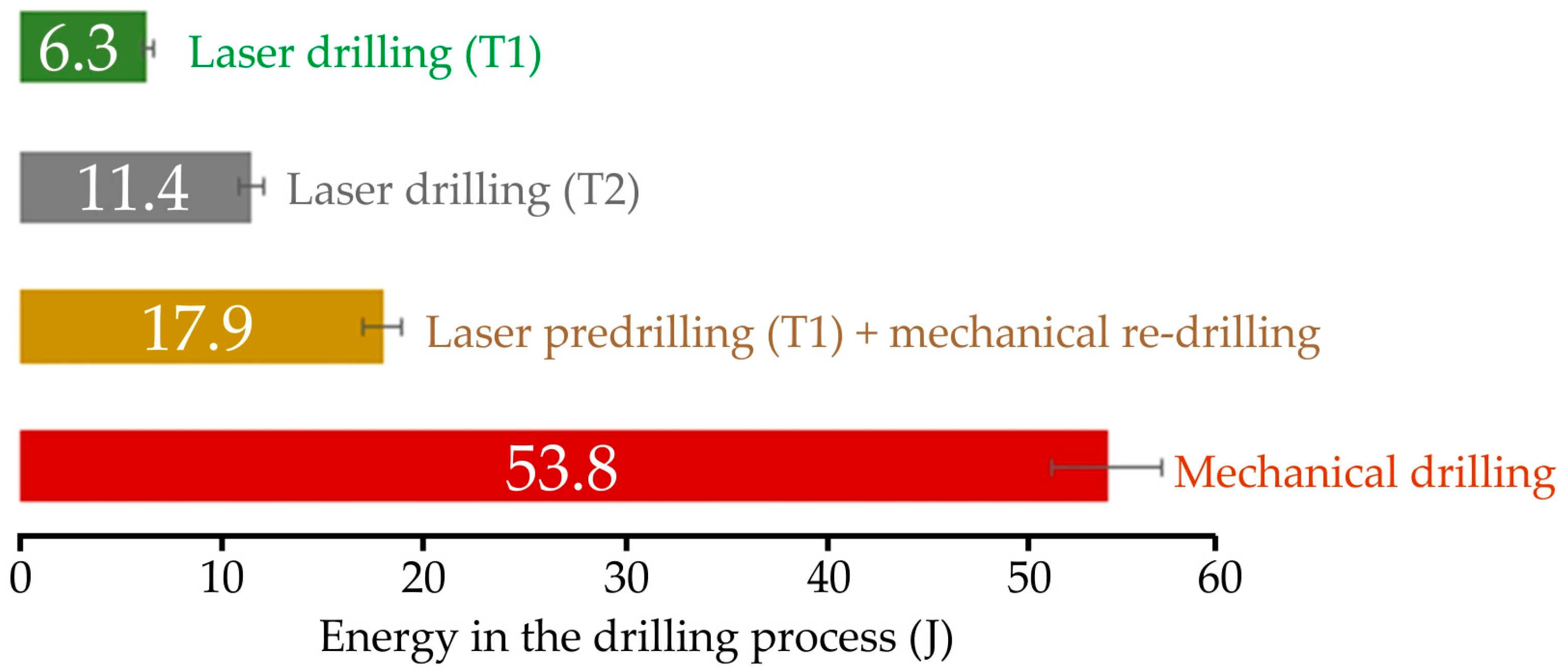

3.4. Energy in the Mechanical Drilling Process

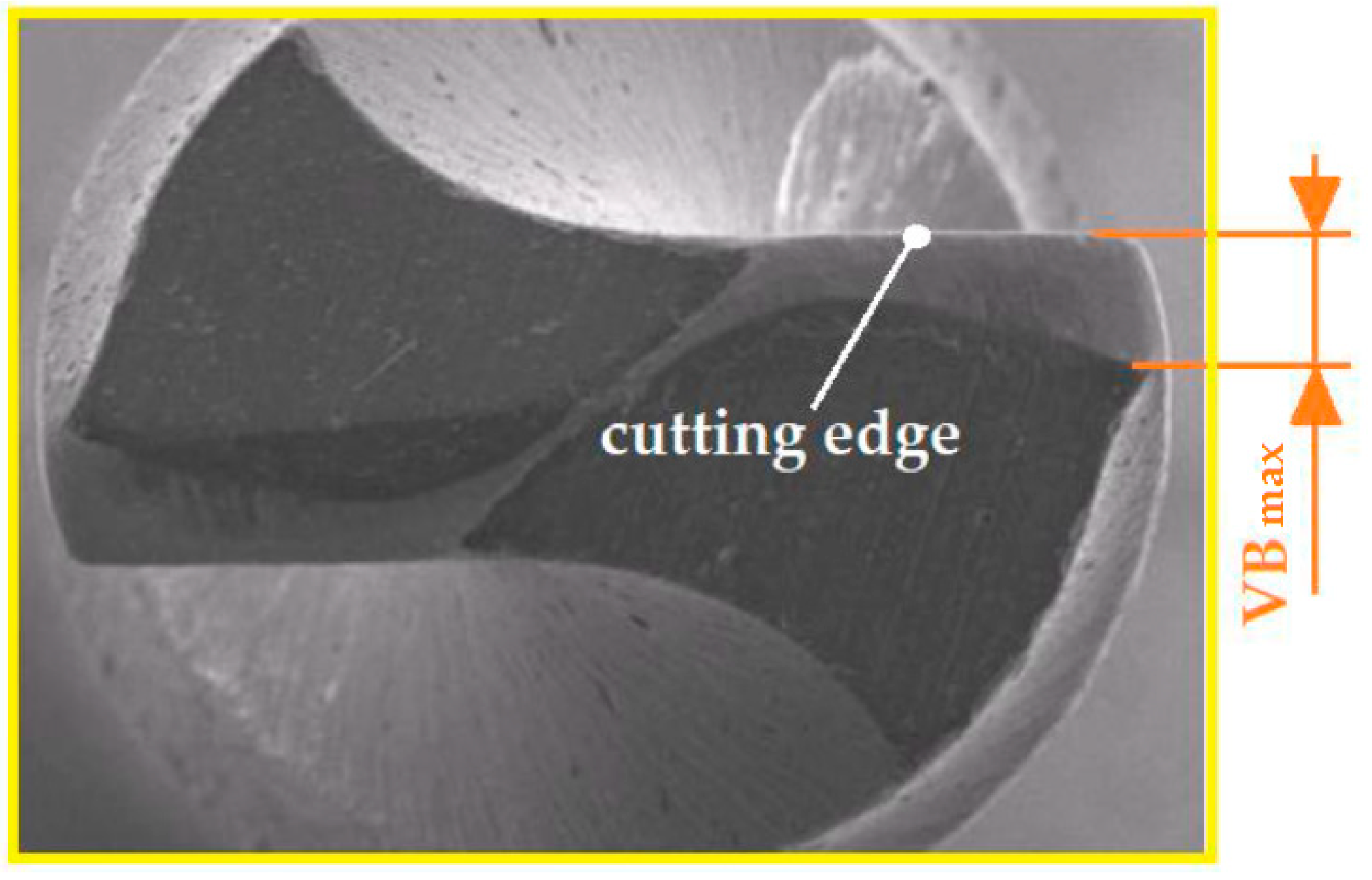

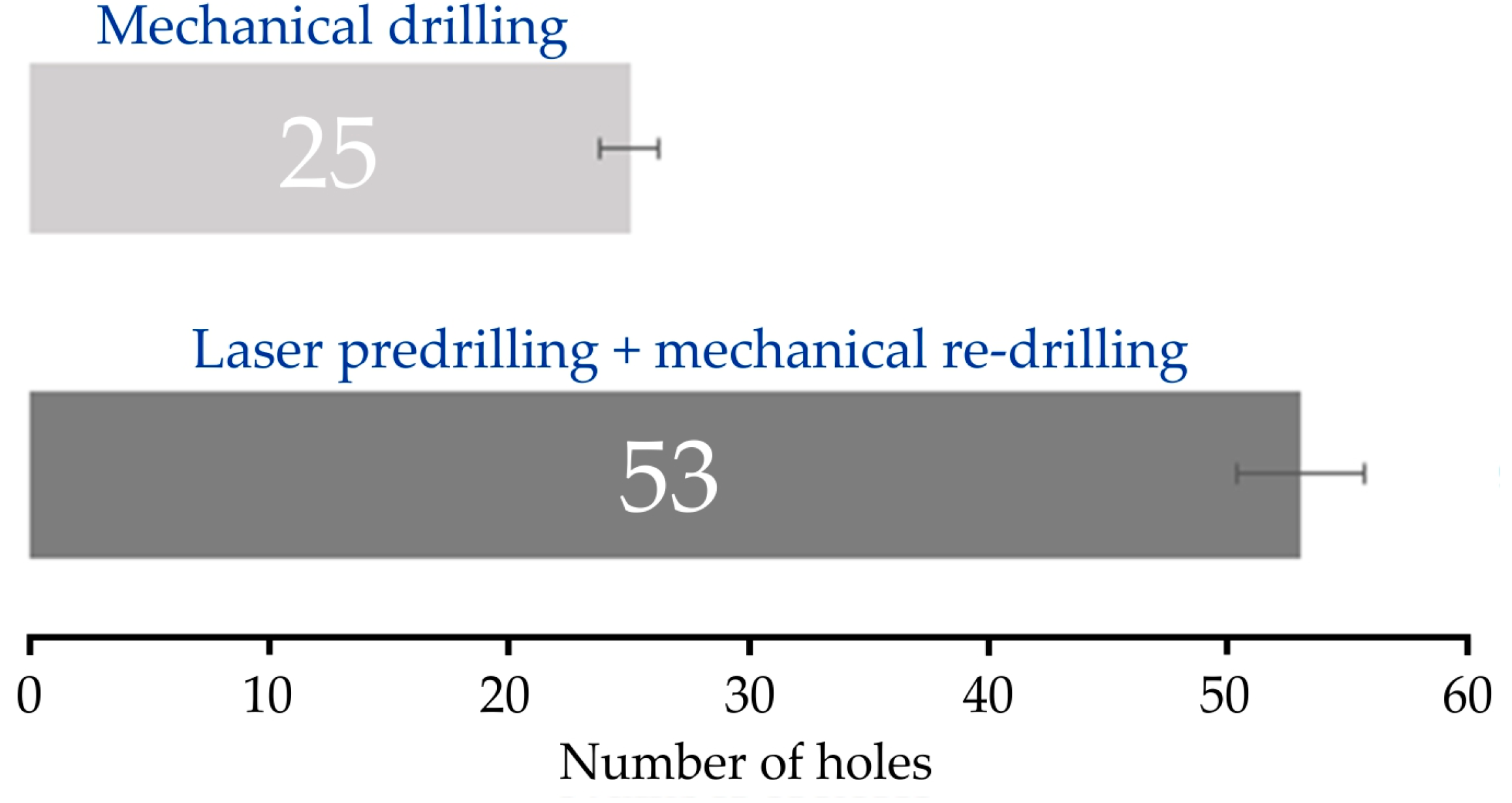

3.5. Tool Wear

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- D’Addona, D.M.; Raykar, S.J.; Narke, M.M. High Speed Machining of Inconel 718: Tool Wear and Surface Roughness Analysis. Procedia CIRP 2017, 62, 269–274. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- Rathi, N.; Kumar, P.; Khatkar, S.K.; Gupta, A. Non-conventional machining of nickel based superalloys: A review. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Selbmann, E.; Preiẞ, M.; Achour, A.B.; Teicher, U.; Hänel, A.; Ihlenfeldt, S. Investigation of bio-based cooling lubricants for the machining of aircraft stainless steels. Procedia CIRP 2022, 110, 47–52. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. State of art for sustainable machining of nickel-based alloys using coated and uncoated tools and machining of high strength materials using surface modified cutting tools. Tribol. Int. 2022, 170, 107517. [Google Scholar] [CrossRef]

- Salvi, H.; Vesuwala, H.; Raval, P.; Badheka, V.; Khanna, N. Sustainability analysis of additive + subtractive manufacturing processes for Inconel 625. Sustain. Mater. Technol. 2023, 35, e00580. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Newman, S.T.; Shokrani, A. High-speed milling Inconel 718 using Electrostatic Minimum Quantity Lubrication (EMQL). Procedia CIRP 2021, 101, 354–357. [Google Scholar] [CrossRef]

- Dureja, J.S.; Singh, R.; Singh, T.; Singh, P.; Dogra, M.; Bhatti, M.S. Performance evaluation of coated tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 123–129. [Google Scholar] [CrossRef]

- Jovicic, G.; Milosevic, A.; Kanovic, Z.; Sokac, M.; Simunovic, G.; Savkovic, B.; Vukelic, D. Optimization of Dry Turning of Inconel 601 Alloy Based on Surface Roughness, Tool Wear, and Material Removal Rate. Metals 2023, 13, 1068. [Google Scholar] [CrossRef]

- Lai, Z.; Wang, C.; Zheng, L.; Huang, W.; Yang, J.; Guo, G.; Xiong, W. Adaptability of AlTiN-based coated tools with green cutting technologies in sustainable machining of 316 L stainless steel. Tribol. Int. 2020, 148, 106300. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Zawada, P.; Hegab, H.; Deaib, I.; Kishawy, H. Coolant strategy influence on tool life and surface roughness when machining ADI. Int. J. Adv. Manuf. Technol. 2018, 94, 3875–3887. [Google Scholar] [CrossRef]

- Barbucha, R. Mikroobróbka laserowa metali. STAL Met. Nowe Technol. 2020, 3–4, 69–71. [Google Scholar]

- Muzykiewicz, W.; Łach, A. Analiza możliwości wykonania gęstych perforacji blach niekonwencjonalnymi technikami wysokoenergetycznymi. Obróbka Plast. Met. 2007, 18, 13–21. [Google Scholar]

- Pattanayak, S.; Panda, S. Laser Beam Micro Drilling—A Review. Lasers Manuf. Mater. Process. 2018, 5, 366–394. [Google Scholar] [CrossRef]

- Raj, D.; Reddy, B.V.R.; Maity, S.R.; Pandey, K.M. Laser Beam Micromachining of Metals: A Review. Mater. Today Proc. 2019, 18, 98–103. [Google Scholar] [CrossRef]

- Ay, M.; Çaydaş, U.; Hasçalık, A. Optimization of micro-EDM drilling of Inconel 718 super alloy. Int. J. Adv. Manuf. Technol. 2013, 66, 1015–1023. [Google Scholar] [CrossRef]

- Chen, Y.C.; Liao, Y.S. Study on wear mechanisms in drilling of Inconel 718 superalloy. J. Mater. Process. Technol. 2003, 140, 269–273. [Google Scholar] [CrossRef]

- Venkatesan, T.; Jerald, J.; Pillingrin, J.C.; Asokan, P. Experimental investigation on micro drilling of Inconel 718 super alloy. Int. J. Mach. Mach. Mater. 2018, 20, 48–63. [Google Scholar] [CrossRef]

- Kivak, T.; Habali, K.; Şeker, U. The effect of cutting parameters on the hole quality and tool wear during the drilling of Inconel 718. Gazi Univ. J. Sci. 2012, 25, 533–540. [Google Scholar]

- Imran, M.; Mativenga, P.T.; Kannan, S. Evaluation of the effects of tool geometry on tool wear and surface integrity in the micro drilling process for Inconel 718 alloy. Int. J. Mach. Mach. Mater. 2012, 11, 244–262. [Google Scholar] [CrossRef]

- Imran, M.; Mativenga, P.T.; Gholinia, A.; Withers, P.J. Evaluation of surface integrity in micro drilling process for nickel-based super alloy. Int. J. Adv. Manuf. Technol. 2011, 55, 465–476. [Google Scholar] [CrossRef]

- Sager, A.M.M. Experimental Investigation of Machining of Nickel Based Superalloy Inconel 625. Master’s Thesis, Karabuk University, Karabuk, Turkey, 2018. [Google Scholar]

- Attanasio, A. Micro drilling of hard-to-cut materials: An experimental analysis. Int. J. Mechatron. Manuf. Syst. 2017, 10, 299–320. [Google Scholar] [CrossRef]

- Li, L.; Diver, C.; Atkinson, J.; Giedl-Wagner, R.; Helml, H.J. Sequential laser and EDM micro-drilling for next generation fuel injection nozzle manufacture. CIRP Ann. Manuf. Technol. 2006, 55, 179–182. [Google Scholar] [CrossRef]

- Brown, R.T. Hybrid laser process for shaped turbine-airfoil cooling holes. Proc. ICALEO 2000, 73, 205–212. [Google Scholar]

- Khanafer, K.; Eltaggaz, A.; Deiab, L.; Agarwal, H.; Abdul-Latif, A. Toward sustainable micro-drilling of Inconel 718 superalloy using MQL-Nanofluid. Int. J. Adv. Manuf. Technol. 2020, 107, 3459–3469. [Google Scholar] [CrossRef]

- Ceritbinmez, F.; Günen, A.; Gürol, U.; Çam, G. A comparative study on drillability of Inconel 625 alloy fabricated by wire arc additive manufacturing. J. Manuf. Process. 2023, 89, 150–169. [Google Scholar] [CrossRef]

- Agrawal, V.; Gajrani, K.K.; Mote, R.G.; Barshilla, H.C.; Joshi, S.S. Wear analysis and tool life modeling in micro drilling of Inconel 718 superalloy. J. Tribol. 2022, 144, 101706. [Google Scholar] [CrossRef]

- Primeaux, P.A.; Zhang, B.; Meng, W.J. Performance of micro-drilling of hard Ni alloys using coated and uncoated WC/Co bits. Eng. Res. Express 2019, 1, 025046. [Google Scholar] [CrossRef]

- Kiswanto, G.; Azmi, M.; Mandala, A.; Ko, T.J. The effect of machining parameters to the surface roughness in low speed machining micro-milling Inconel 718. IOP Conf. Ser. Mater. Sci. Eng. 2019, 654, 012014. [Google Scholar] [CrossRef]

- Nair, M.H. Improving the Performance of Sequential Mechanical Microdrilling of Inconel 718 Alloy. Master’s Thesis, The University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Imran, M.; Mativenga, P.T.; Kannan, S.; Novoic, D. An experimental investigation of deep-hole microdrilling capability for a nickel-based superalloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 1589–1596. [Google Scholar] [CrossRef]

- Venkatesan, K.; Nagendra, K.U.; Anudeep, C.M.; Cotton, A.E. Experimental Investigation and Parametric Optimization on Hole Quality Assessment During Micro-drilling of Inconel 625 Superalloy. Arab. J. Sci. Eng. 2021, 46, 2283–2309. [Google Scholar] [CrossRef]

- Azim, S. Effect of Cutting Parameters on Micro Drilling Characteristics of Incoloy 825. Master’s Thesis, National Institute of Technology Rurkela, Rurkela, India, 2019. [Google Scholar]

- Khandtare, A.N.; Pawade, R.S.; Joshi, S. Surface integrity studies for straight and inclined hole in micro-drilling of thermal barrier coated Inconel 718: A turbine blade application. Precis. Eng. 2020, 66, 166–179. [Google Scholar] [CrossRef]

- Kwong, J.; Axinte, D.A.; Withers, P.J.; Hardy, M.C. Minor cutting edge–workpiece interactions in drilling of an advanced nickel-based superalloy. Int. J. Mach. Tools Manuf. 2009, 49, 645–658. [Google Scholar] [CrossRef]

- Venkatesan, K.; Devendiran, S.; Bhupatiraju, S.C.S.R.; Kolluru, S.; Kumar, C.P. Experimental investigation and optimization of micro-drilling parameters on Inconel 800 superalloy. Mater. Manuf. Process. 2020, 35, 1214–1227. [Google Scholar] [CrossRef]

- Shinde, I.; Borse, S.; Jadhav, M.L. Micromachining using Laser Beam Machining on Inconel 718—A Review. Int. Res. J. Eng. Technol. 2021, 8, 1241–1244. [Google Scholar]

- Okasha, M.M.; Mativenga, P.T.; Li, L. Sequential Laser Mechanical Microdrilling of Inconel 718 Alloy. J. Manuf. Sci. Eng. 2011, 133, 011008. [Google Scholar] [CrossRef]

- Moradi, M.; Mohazabpak, A.R. Statistical Modelling and Optimization of Laser Percussion Microdrilling of Inconel 718 Sheet Using Response Surface Methodology (RSM). Lasers Eng. 2018, 39, 313–331. [Google Scholar]

- Okasha, M.M.; Mativenga, P.P.; Driver, N.; Li, L. Sequential Laser and Mechanical Micro-Drilling of Ni Super-Alloy for Aerospace Application. CIRP Ann. 2010, 59, 199–202. [Google Scholar] [CrossRef]

- Hyacinth, S.X.; Natarajan, U.; Ramasubbu, N. A review of accuracy enhancement in microdrilling operation. Int. J. Adv. Manuf. Technol. 2015, 81, 199–217. [Google Scholar] [CrossRef]

- Pedroso, A.F.V.; Sousa, V.F.C.; Sebbe, N.P.V.; Silva, F.J.G.; Campilho, R.D.S.G.; Sales-Contini, R.C.M.; Jesus, A.M.P. A Comprehensive Review on the Conventional and Non-Conventional Machining and Tool-Wear Mechanisms of INCONEL®. Metals 2023, 13, 585. [Google Scholar] [CrossRef]

- Rahman, M.; Asad, A.B.M.A.; Wong, Y.S.; Jahan, M.P.; Masaki, T. Compound and Hybrid Micromachining Processes. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas, B., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 89–112. [Google Scholar]

- Sanikommu, N.; Bathe, R.; Joshi, A.S. Detection of breakthrough in laser percussion drilling. Lasers Eng. 2007, 17, 361–369. [Google Scholar]

- Ng, G.K.L.; Li, L. The effect of laser peak power and pulse width on the hole geometry repeatability in laser percussion drilling. Opt. Laser Technol. 2001, 33, 393–402. [Google Scholar] [CrossRef]

- Nath, A.K.; Hansdah, D.; Roy, S.; Roy, C.A. A study on laser drilling of thin steel sheet in air and underwater. J. Appl. Phys. 2010, 107, 123103. [Google Scholar] [CrossRef]

- Petrů, J.; Pagáč, M.; Grepl, M. Laser Beam Drilling of Inconel 718 and Its Effect on Mechanical Properties Determined by Static Uniaxial Tensile Testing at Room and Elevated Temperatures. Materials 2021, 14, 3052. [Google Scholar] [CrossRef] [PubMed]

- Dausinger, F. Precise Drilling with Short Pulsed Lasers, in High-power Lasers in Manufacturing. Proc. SPIE 2000, 3888, 180–187. [Google Scholar]

- Wang, Z.Y.; Rajurkar, K.P.; Fan, J.; Lei, S.; Shin, Y.C.; Petrescu, G. Hybrid machining of Inconel 718. Int. J. Mach. Tools Manuf. 2003, 43, 1391–1396. [Google Scholar] [CrossRef]

- Cheng, Y.; Gai, X.; Guan, R.; Jin, Y.; Lu, M.; Ding, Y. Tool wear intelligent monitoring techniques in cutting: A review. J. Mech. Sci. Technol. 2023, 37, 289–303. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Zhang, D. Performance evaluation of high-speed ultrasonic vibration cutting for improving machinability of Inconel 718 with coated carbide tools. Tribol. Int. 2021, 155, 106766. [Google Scholar] [CrossRef]

- Youssef, H.A.; Al-Makky, M.Y.; Al-Kadeem, R.A.; Shyha, I.S. Burr formation in drilling of miniature holes in brass. In Proceedings of the 8th International Conference on Production Engineering Design and Control, PEDAC’2004, Alexandria, Egypt, 27–29 December 2004; pp. 1–10. [Google Scholar]

- Dornfeld, D.A.; Kim, J.; Dechow, H.; Hewson, J.; Chen, L.J. Drilling Burr Formation in Titanium Alloy, Ti-6Al-4V. Ann. CIRP 1999, 48, 73–76. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, L.; Wang, C.; Huang, X.; Xie, J. Investigation of burr formation and its influence in micro-drilling hole of flexible printed circuit board. Circuit World 2020, 46, 221–228. [Google Scholar] [CrossRef]

- Ahn, Y.; Lee, S.H. Classification and prediction of burr formation in micro drilling of ductile metals. Int. J. Prod. Res. 2017, 55, 4833–4846. [Google Scholar] [CrossRef]

| Density (kg/m3) | Tensile Strength (MPa) | Elasticity Modulus (GPa) | Thermal Conductivity (W/m·K) | Poisson’s Ratio - |

|---|---|---|---|---|

| 8841 | 882 | 204 | 9.81 | 0.31 |

| Ni | Cr | Al | Mo | Nb | Ti | Co | Fe |

|---|---|---|---|---|---|---|---|

| 59.35 | 23.20 | 0.18 | 8.52 | 3.73 | 0.25 | 0.85 | 4.35 |

| Average Power (W) | Maximum Power (kW) | Impact Energy (J) | Pulse Frequency (Hz) | Pulse Duration (ms) | Beam Diameter (mm) |

|---|---|---|---|---|---|

| 300 | 12 | 150 | 0–100 | 0.31 | 0.6–2 |

| Test Number | Average Power Rate (%) | Pulse Frequency (Hz) | Pulse Duration Time (ms) | Beam Diameter (mm) |

|---|---|---|---|---|

| T1 | 60 | 20 | 1.5 | 0.6 |

| T2 | 60 | 10 | 1.5 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szwajka, K.; Zielińska-Szwajka, J.; Żaba, K.; Trzepieciński, T. An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy. Lubricants 2023, 11, 384. https://doi.org/10.3390/lubricants11090384

Szwajka K, Zielińska-Szwajka J, Żaba K, Trzepieciński T. An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy. Lubricants. 2023; 11(9):384. https://doi.org/10.3390/lubricants11090384

Chicago/Turabian StyleSzwajka, Krzysztof, Joanna Zielińska-Szwajka, Krzysztof Żaba, and Tomasz Trzepieciński. 2023. "An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy" Lubricants 11, no. 9: 384. https://doi.org/10.3390/lubricants11090384

APA StyleSzwajka, K., Zielińska-Szwajka, J., Żaba, K., & Trzepieciński, T. (2023). An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy. Lubricants, 11(9), 384. https://doi.org/10.3390/lubricants11090384