Experimental Research on Pollution-Free Alcohol Cutting Fluid in Scratching of Single-Crystal Copper Material

Abstract

1. Introduction

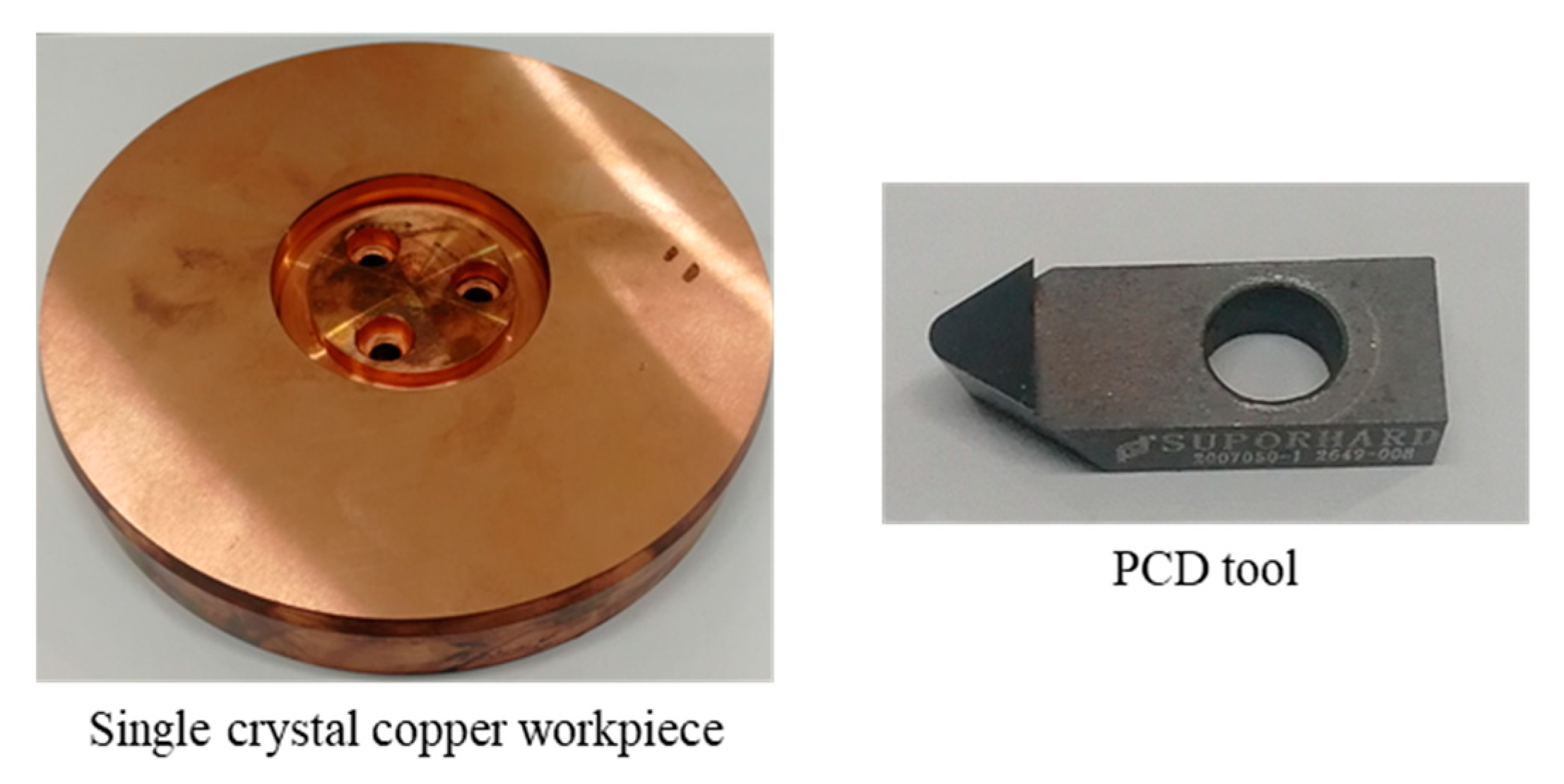

2. Experimental Procedures

3. Experimental Results and Discussions

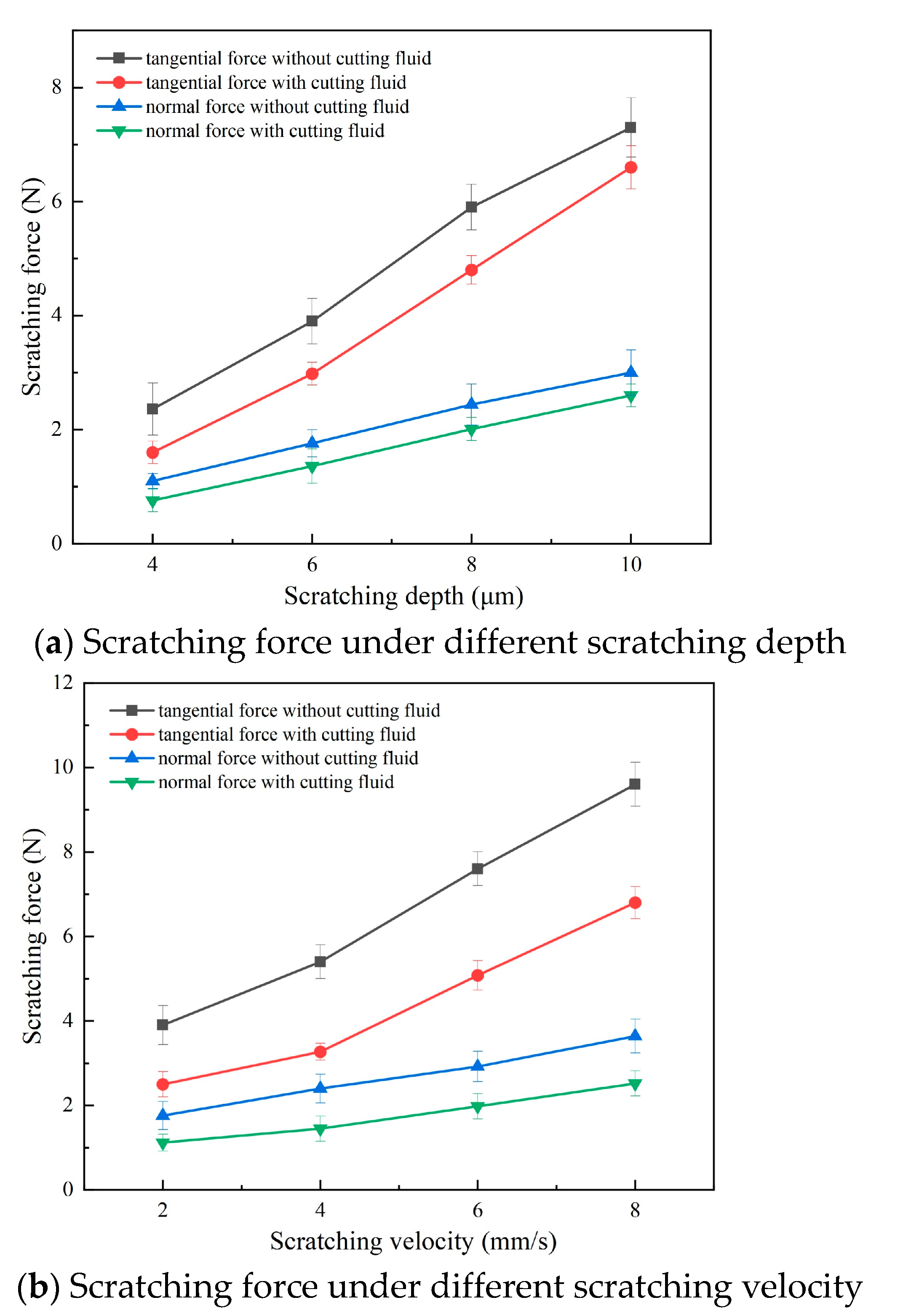

3.1. Effect of Alcohol Cutting Fluid on the Scratching Force

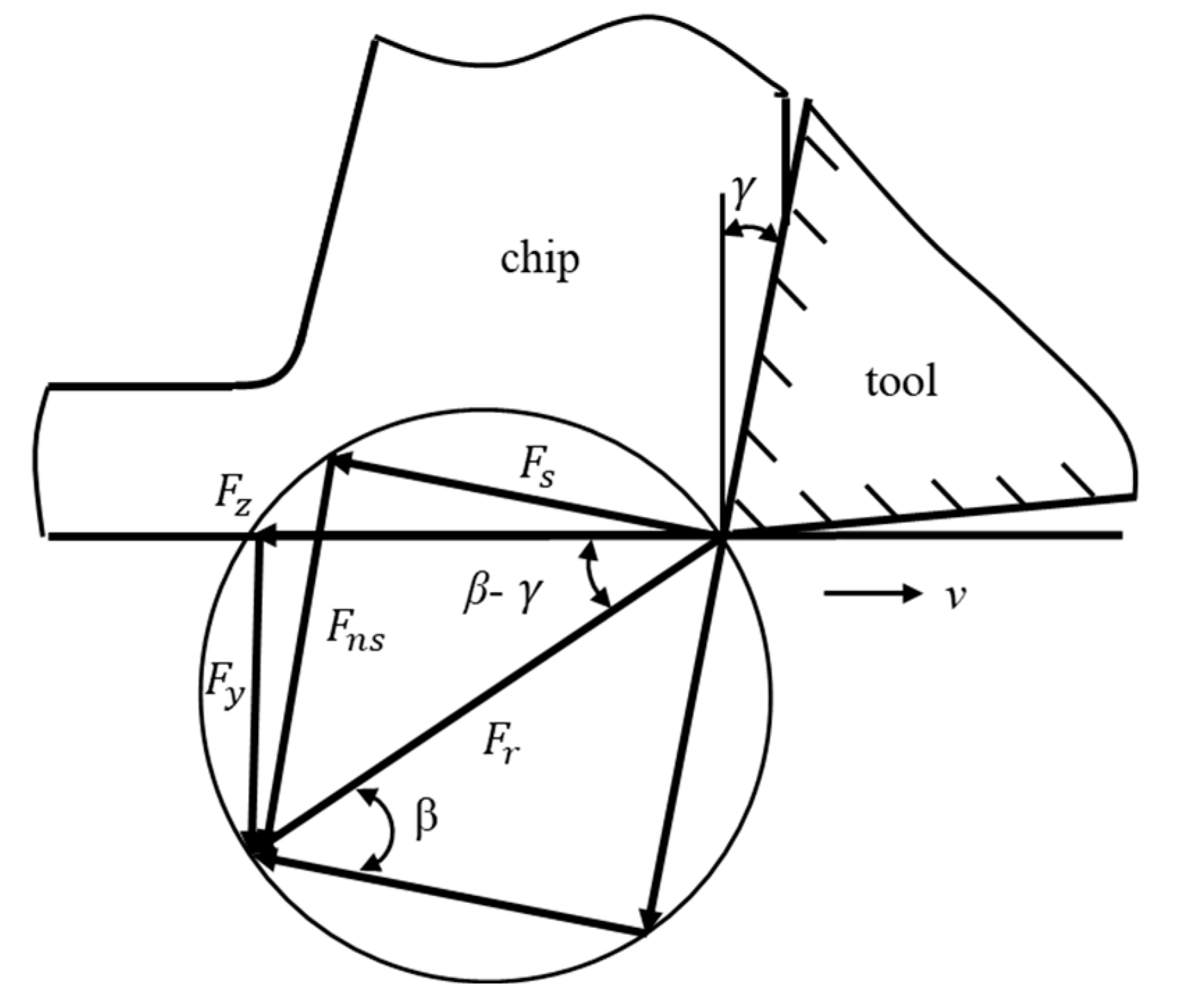

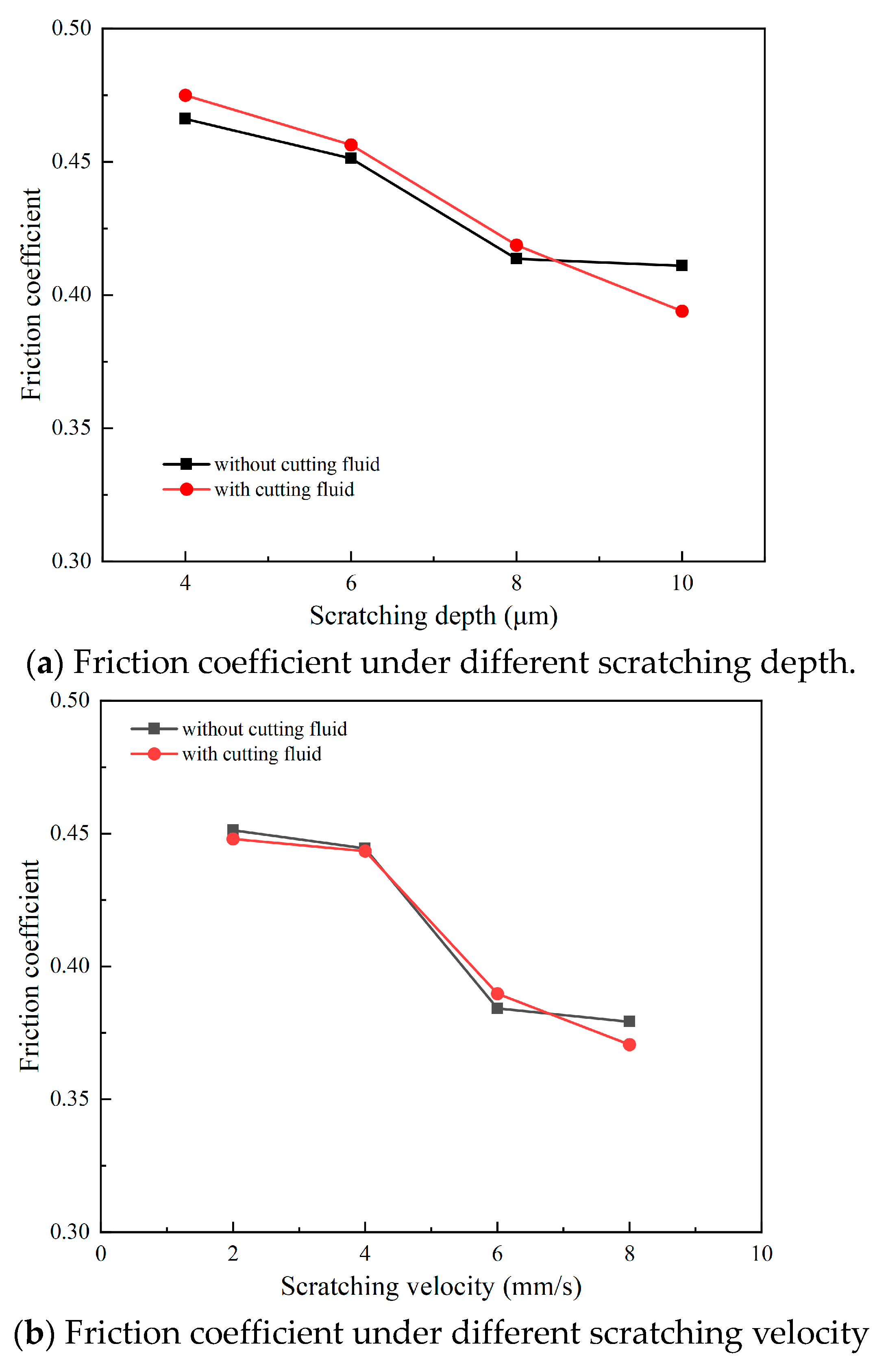

3.2. Effect of Alcohol Cutting Fluid on the Friction Coefficient

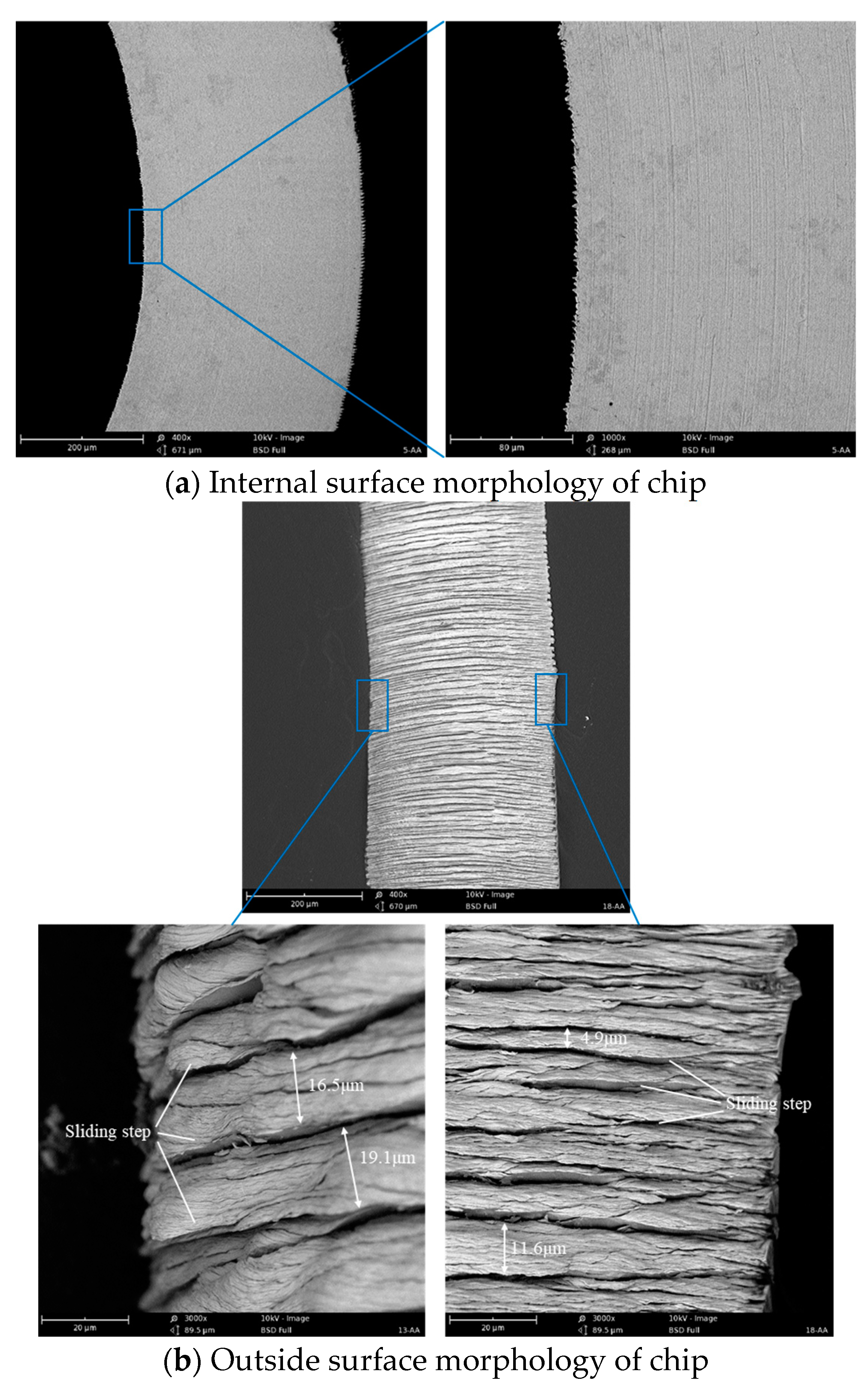

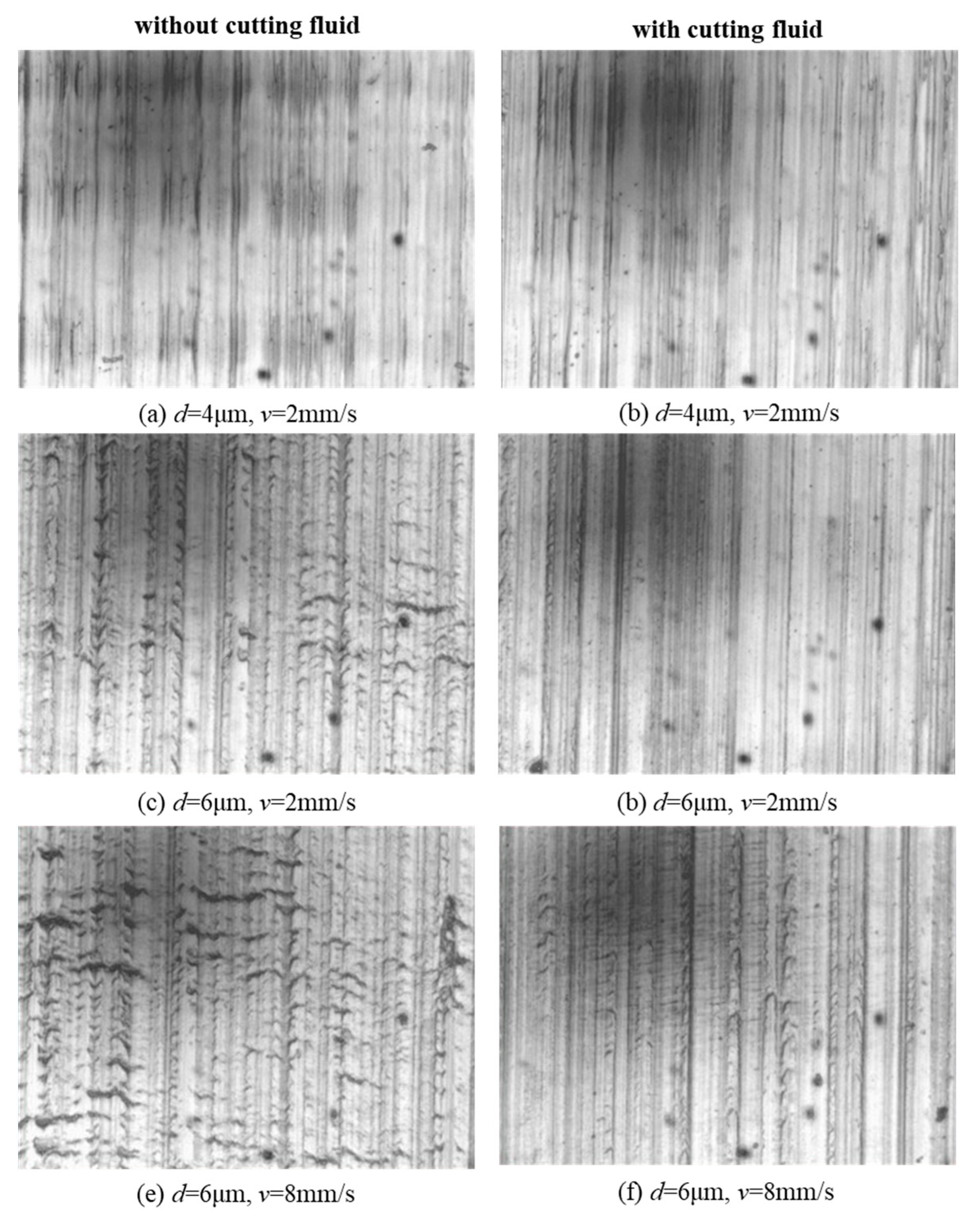

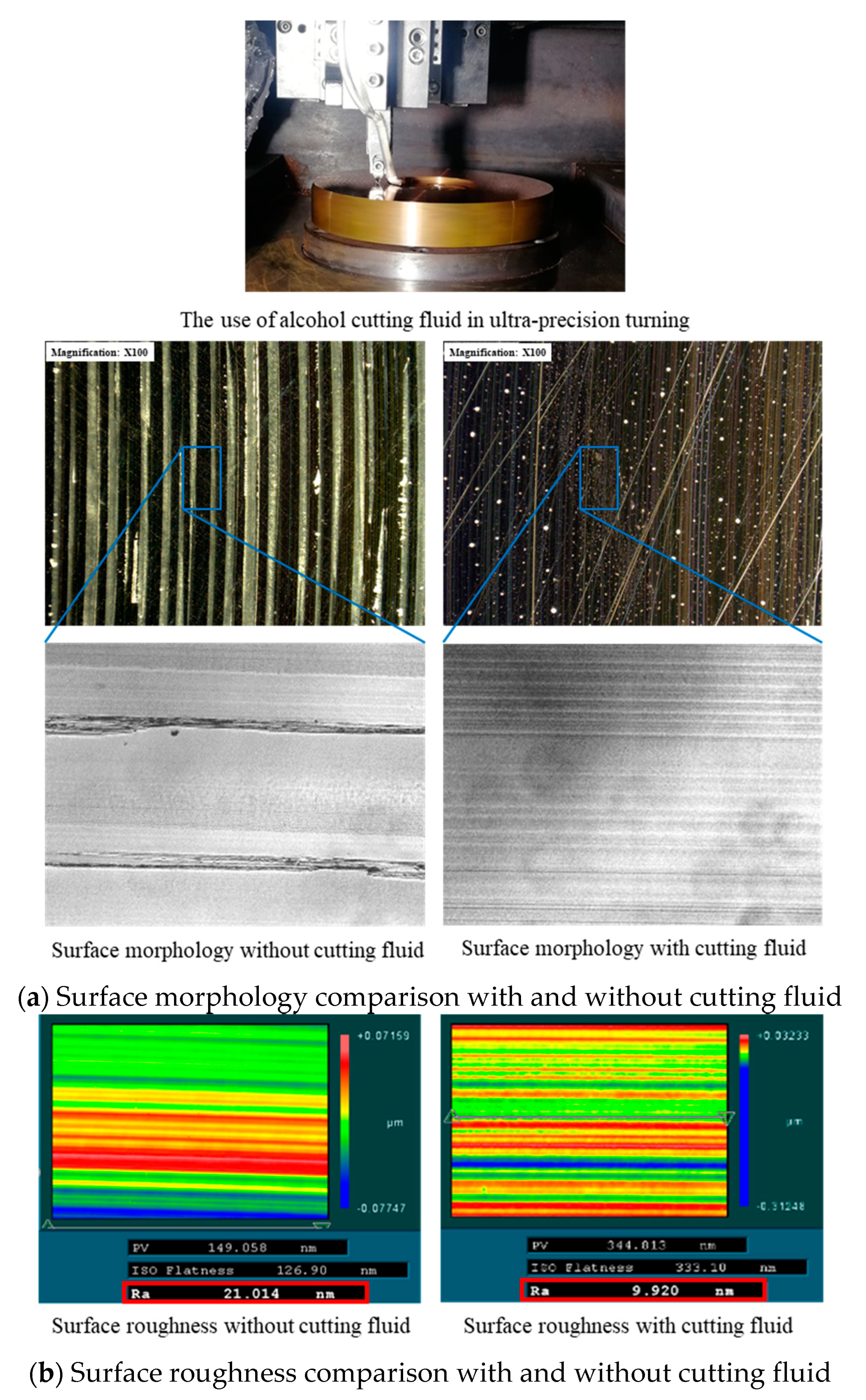

3.3. Effect of Alcohol Cutting Fluid on Chip Morphology and Surface Quality

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, B.L.; Zhang, H.; Wang, Z.D.; Wu, C.J. Preparation of Single Crystal Copper with Large Diameter and Evolution of Solidification Structure. Rare Met. Mater. Eng. 2011, 40, 198–201. [Google Scholar]

- Li, L.; Ma, T.; Yu, W.; Zhu, M.L.; Li, J.; Chen, Z.; Li, H.H.; Zhao, M.; Teng, J.H.; Tian, B.B.; et al. Fast growth of centimeter-scale single-crystal copper foils with high-index planes by the edge-incision effect. 2D Mater. 2021, 8, 035019. [Google Scholar] [CrossRef]

- Hao, Y.; Bharathi, M.; Wang, L.; Liu, Y.; Chen, H.; Nie, S.; Wang, X.; Chou, H.; Tan, C.; Fallahazad, B.; et al. The role of surface oxygen in the growth of large single-crystal graphene on copper. Science 2013, 342, 720–723. [Google Scholar] [CrossRef] [PubMed]

- Pang, Z.; Deng, B.; Liu, Z.; Peng, H.; Wei, Y. Defects guided wrinkling in graphene on copper substrate. Carbon 2019, 143, 736–742. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Z.; Dong, J.; Yi, D.; Niu, J.; Wu, M.; Lin, L.; Yin, R.; Li, M.; Zhou, J. Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil. Sci. Bull. 2017, 62, 1074–1080. [Google Scholar] [CrossRef]

- Arya, C.; De Silva, K.K.H.; Yoshimura, M. Adlayer-free large-area single-crystal CVD graphene growth on copper. J. Mater. Sci. Mater. Electron. 2020, 31, 21821–21831. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, H.; Zhang, L.; Shao, M.; Liu, H.; Huang, H. Molecular dynamics simulation of self-rotation effects on ultra-precision polishing of single-crystal copper. AIP Adv. 2013, 3, 102106. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Wang, S.J.; Zhu, Z.W. A review of surface roughness generation in ultra-precision machining. Int. J. Mach. Tools Manuf. 2015, 91, 76–95. [Google Scholar] [CrossRef]

- Zhu, P.Z.; Fang, F.Z. Study of the minimum depth of material removal in nanoscale mechanical machining of single crystalline copper. Comput. Mater. Sci. 2016, 118, 192–202. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, H.W.; Zhang, P.; Shi, C.L. Influences analysis of nanometric cutting single-crystal copper via molecular dynamics simulation. J. Comput. Theor. Nanosci. 2013, 10, 2462–2472. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; He, N.; Zhao, M.; Zhan, Z. Investigation on the influence of material microstructure on cutting force and burr formation in the micro cutting of copper. Int. J. Adv. Manuf. Technol. 2015, 79, 321–327. [Google Scholar] [CrossRef]

- Wang, Z.F.; Zhang, J.J.; Xu, Z.W.; Zhang, J.G.; Li, G.; Zhang, H.J.; Li, Z.Q.; ul Hassan, H.; Fang, F.Z.; Hartmaier, A.; et al. Crystal anisotropy-dependent shear angle variation in orthogonal cutting of single crystalline copper. Precis. Eng. 2020, 63, 41–48. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Han, J.H.; Chen, Y.B.; Xiong, J.; Wang, J.P.; Ran, J.Q. Generation mechanism and dual-dynamics simulation of surface patterns in single-point diamond turning of single-crystal copper. J. Manuf. Process. 2022, 75, 1023–1038. [Google Scholar] [CrossRef]

- Liu, H.T.; Zhu, X.F.; Sun, Y.Z.; Xie, W.K. Evolution of stacking fault tetrahedral and work hardening effect in copper single crystals. Appl. Surf. Sci. 2017, 422, 413–419. [Google Scholar] [CrossRef]

- Chen, M.J.; Xiao, G.B.; Lu, L.H.; Wu, C.Y. Mechanism of chip-formation in nanometric cutting of single-crystal copper by molecular dynamics. J. Comput. Theor. Nanosci. 2012, 9, 110–116. [Google Scholar] [CrossRef]

- Zhang, P.; Li, X.J.; Zhang, J.S.; Zhang, Y.; Huang, X.G.; Ye, G.G. Study on chip formation mechanism of single crystal copper using molecular dynamics simulations. Nanoscale Res. Lett. 2022, 17, 91. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.F.; Du, H.; Chen, J.B.; Chen, G.Y. Investigation of tool geometry in nanoscale cutting single-crystal copper by molecular dynamics simulation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 1208–1220. [Google Scholar] [CrossRef]

- Demiral, M.; Abbassi, F.; Mamedov, A. Deformation characteristics in micro-cutting of single crystal copper: Effect of cutting tool geometry and friction. J. Mech. Sci. Technol. 2022, 36, 1903–1912. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, Y.; Fang, C.F.; Zhu, L.F.; Jiang, F.; Sun, K.; Li, Y.; Lin, Y.Y. Experimental Investigation on the Machinability improvement in magnetic-field-assisted turning of single-crystal copper. Micromachines 2022, 13, 2147. [Google Scholar] [CrossRef]

- Singh, J.; Gill, S.S.; Dogra, M.; Singh, R. A review on cutting fluids used in machining processes. Eng. Res. Express 2021, 3, 012002. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Hynes, N.R.J.; Kumar, J.S.; Krolczyk, G.M. A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar]

- Jiang, Z.; Zhou, F.; Zhang, H.; Wang, Y.; Sutherland, J.W. Optimization of machining parameters considering minimum cutting fluid consumption. J. Clean. Prod. 2015, 108, 183–191. [Google Scholar] [CrossRef]

- Kui, G.W.A.; Islam, S.; Reddy, M.M.; Khandoker, N.; Chen, V.L.C. Recent progress and evolution of coolant usages in conventional machining methods: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 119, 3–40. [Google Scholar] [CrossRef]

- Tang, L.Z.; Zhang, Y.B.; Li, C.H.; Zhou, Z.M.; Nie, X.L.; Chen, Y.; Cao, H.J.; Liu, B.; Zhang, N.Q.; Said, Z.; et al. Biological stability of water-based cutting fluids: Progress and application. Chin. J. Mech. Eng. 2022, 35, 3. [Google Scholar] [CrossRef]

- Wu, X.F.; Li, C.H.; Zhou, Z.M.; Nie, X.L.; Chen, Y.; Zhang, Y.N.; Cao, H.J.; Liu, B.; Zhang, N.A.; Said, Z.; et al. Circulating purification of cutting fluid: An overview. Int. J. Adv. Manuf. Technol. 2021, 117, 2565–2600. [Google Scholar] [CrossRef]

- Baldin, V.; da Silva, L.R.R.; Machado, A.R.; Houck, C.F. State of the art of biodegradable nanofluids application in machining processes. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 1299–1336. [Google Scholar] [CrossRef]

- Gabriel, D.J.H.; Parthiban, M.; Kantharaj, I.; Beemkumar, N. A review on sustainable alternatives for conventional cutting fluid applications for improved machinability. Mach. Sci. Technol. 2023, 27, 157–207. [Google Scholar] [CrossRef]

- Katna, R.; Suhaib, M.; Agrawal, N. Performance of non-edible oils as cutting fluids for green manufacturing. Mater. Manuf. Process. 2023, 38, 1531–1548. [Google Scholar] [CrossRef]

- Saikiran, M.; Ravali, G.; Kumar, P. Comparative study of vegetable based and conventional cutting fluids in machining of copper alloys. Mater. Today Proc. 2019, 19, 611–614. [Google Scholar] [CrossRef]

- Rengiah, R.G. Effect of coconut oil-based cutting fluid on cutting performance during turning with minimal fluid application. Int. J. Manuf. Mater. Mech. Eng. 2022, 12, 1–14. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Rajurkar, K.P.; Sankar, M.R. Machining of hard materials using textured tool with minimum quantity nano-green cutting fluid. CIRP J. Manuf. Sci. Technol. 2021, 35, 410–421. [Google Scholar] [CrossRef]

- Tian, X.L.; Wu, Z.Y.; Yu, A.B. Mechanism of the high efficiency grinding fluid used for ceramics. Key Eng. Mater. 2006, 304–305, 214–217. [Google Scholar] [CrossRef]

- Sales, W.F.; Machado, A.R.; Bonney, J.; Ezugwu, E.O. Evaluation of cutting fluids using scratch tests and turning process. J. Braz. Soc. Mech. Sci. Eng. 2007, 29, 372–378. [Google Scholar] [CrossRef][Green Version]

- Shaw, M.C. Metal Cutting Principles; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

| Parameters | Value |

|---|---|

| Scratching depth d (μm) | 4, 6, 8, 10 |

| Scratching velocity v (mm/s) | 2, 4, 6, 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Li, B.; Sun, K.; Fang, C.; Shen, J. Experimental Research on Pollution-Free Alcohol Cutting Fluid in Scratching of Single-Crystal Copper Material. Lubricants 2024, 12, 333. https://doi.org/10.3390/lubricants12100333

Wu X, Li B, Sun K, Fang C, Shen J. Experimental Research on Pollution-Free Alcohol Cutting Fluid in Scratching of Single-Crystal Copper Material. Lubricants. 2024; 12(10):333. https://doi.org/10.3390/lubricants12100333

Chicago/Turabian StyleWu, Xian, Benchi Li, Ke Sun, Congfu Fang, and Jianyun Shen. 2024. "Experimental Research on Pollution-Free Alcohol Cutting Fluid in Scratching of Single-Crystal Copper Material" Lubricants 12, no. 10: 333. https://doi.org/10.3390/lubricants12100333

APA StyleWu, X., Li, B., Sun, K., Fang, C., & Shen, J. (2024). Experimental Research on Pollution-Free Alcohol Cutting Fluid in Scratching of Single-Crystal Copper Material. Lubricants, 12(10), 333. https://doi.org/10.3390/lubricants12100333