Investigating the Performance of Glass Fibre-Reinforced Polymer (GFRP) in the Marine Environment for Tidal Energy: Velocity, Particle Size, Impact Angle and Exposure Time Effects

Abstract

:1. Introduction

2. Methodology

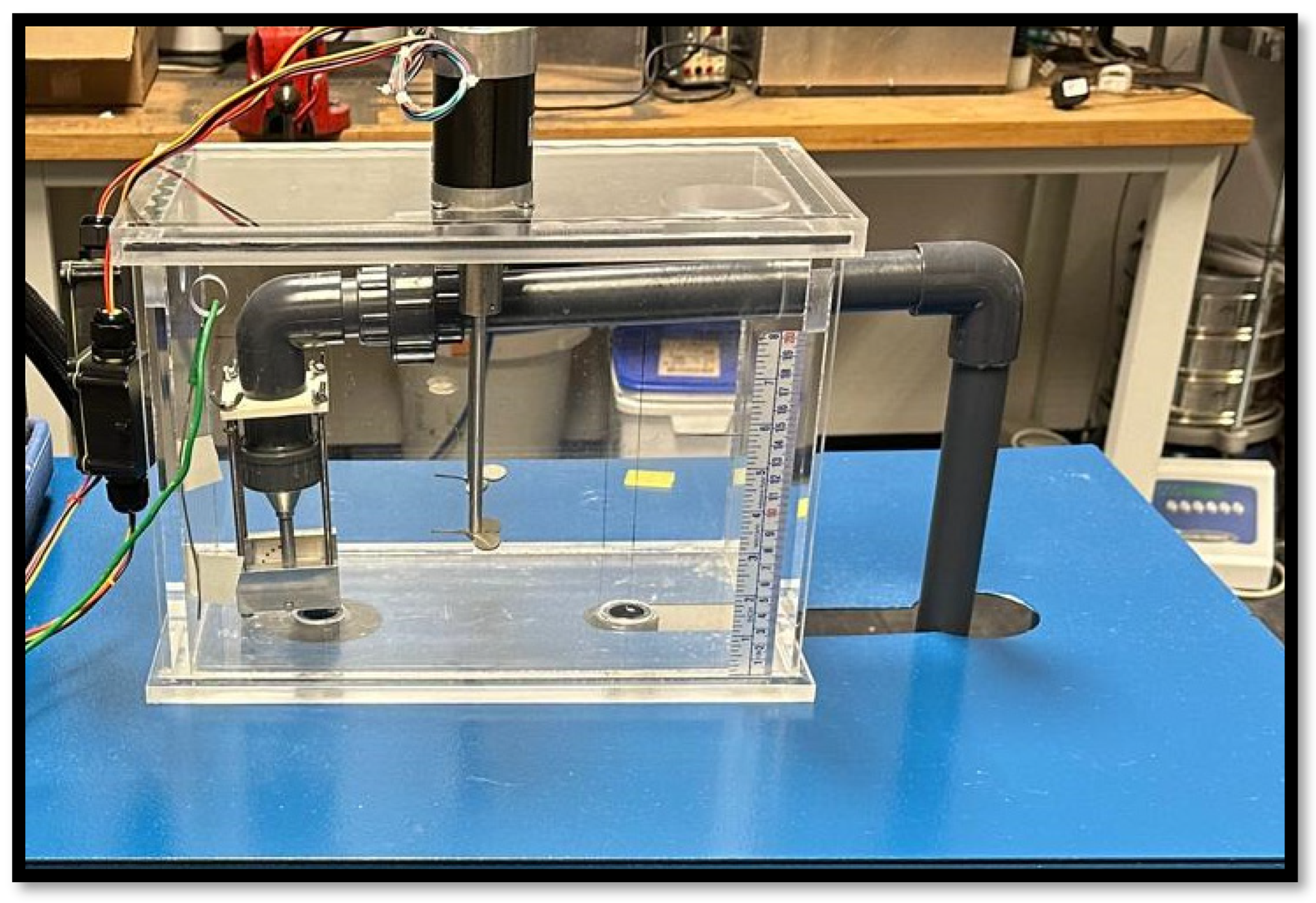

2.1. Slurry Erosion Impingement Rig

2.2. Material Selection

2.3. Experiment Approach

3. Results

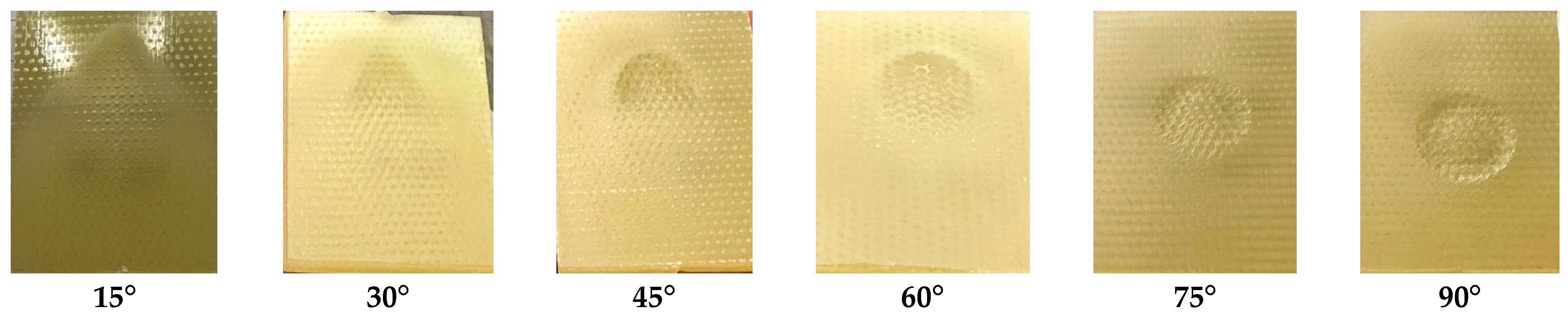

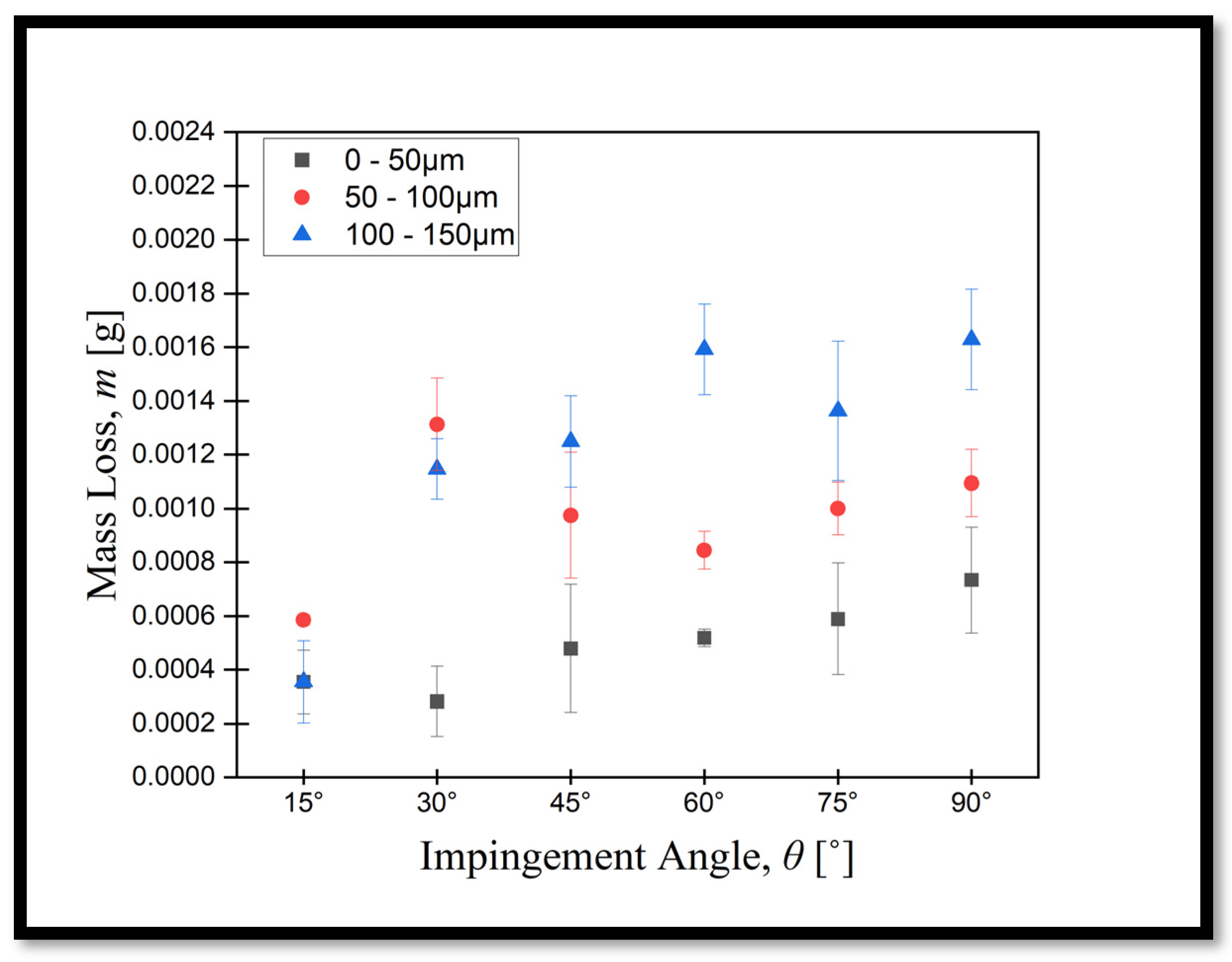

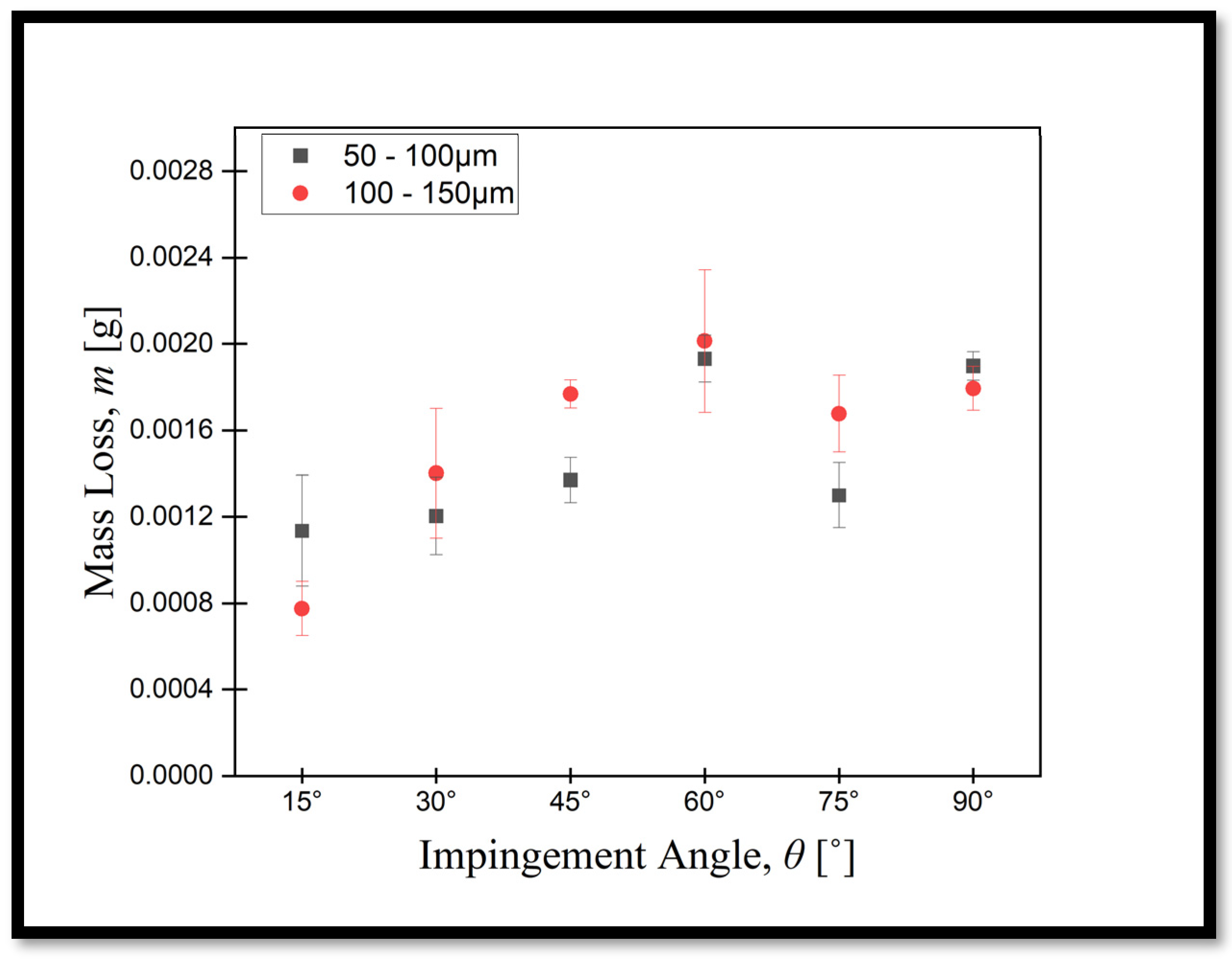

3.1. Mass Loss Measurement for 14 Days (336 h) Pre-Exposure

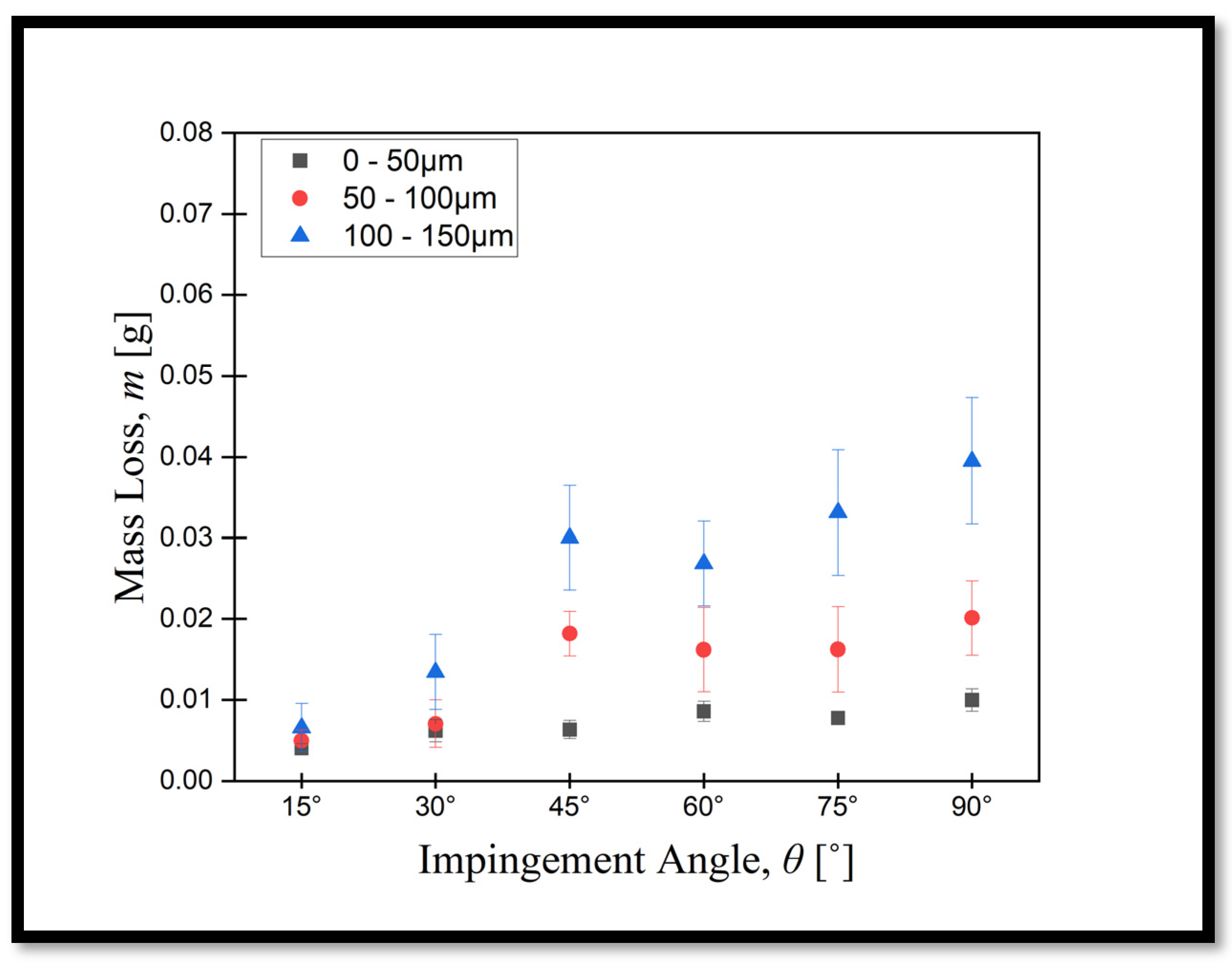

3.2. Mass Loss Measurement for 91 Days (2184 h) Pre-Exposure

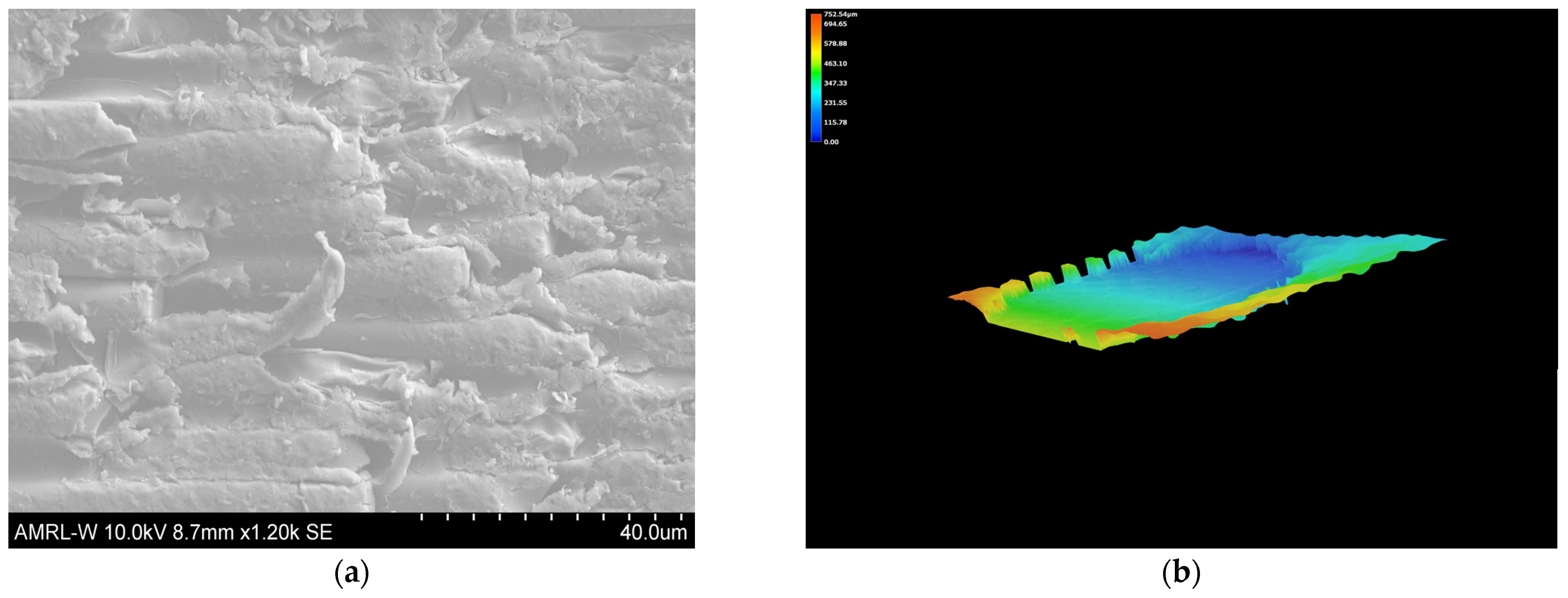

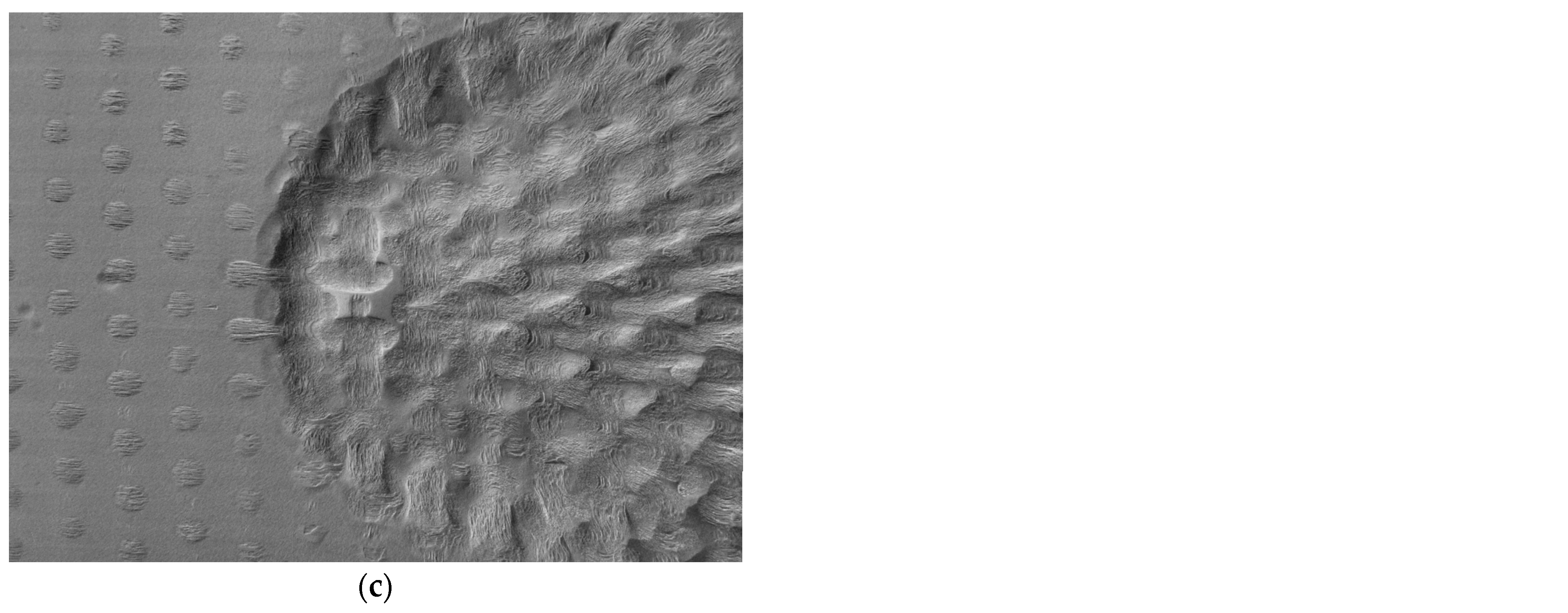

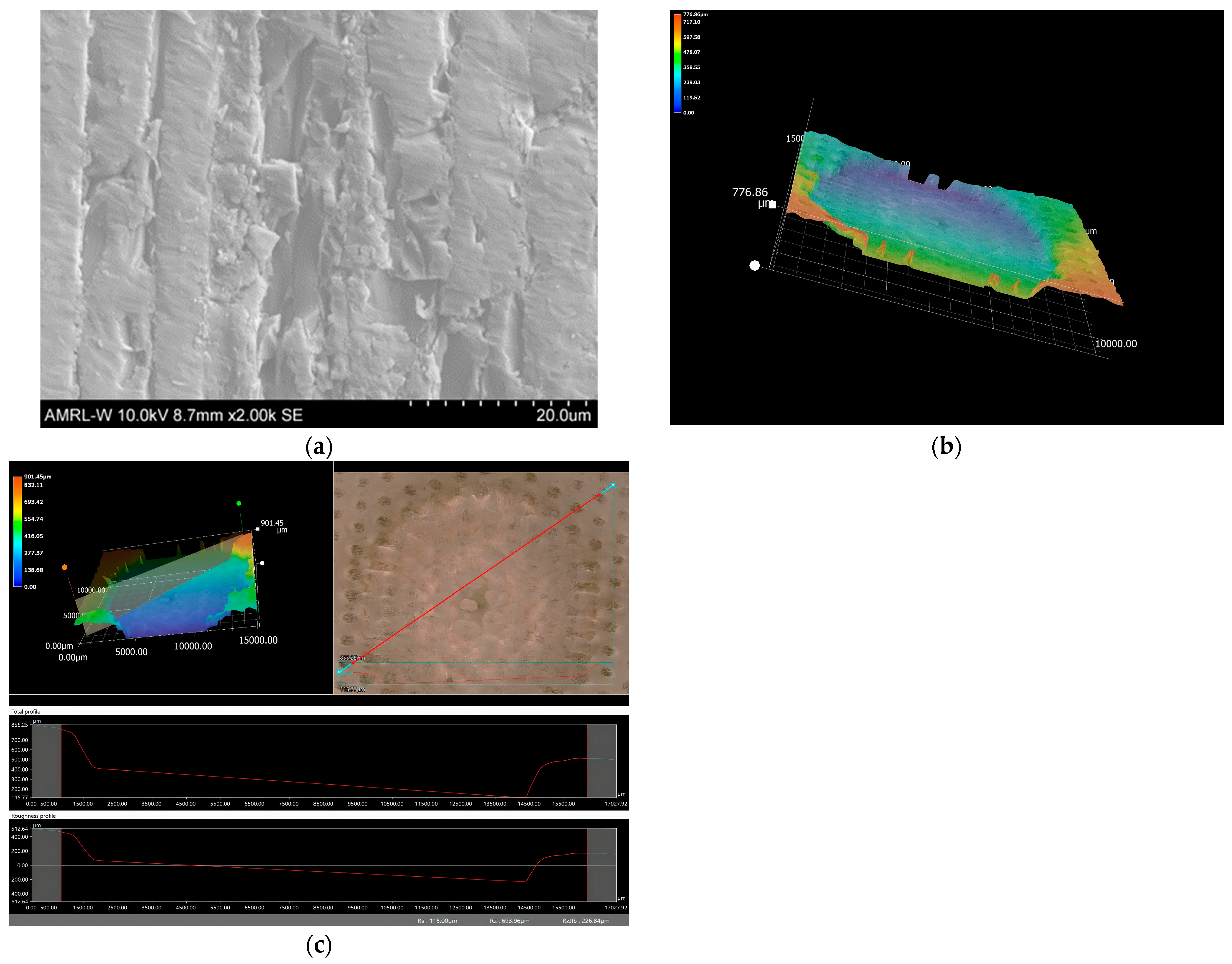

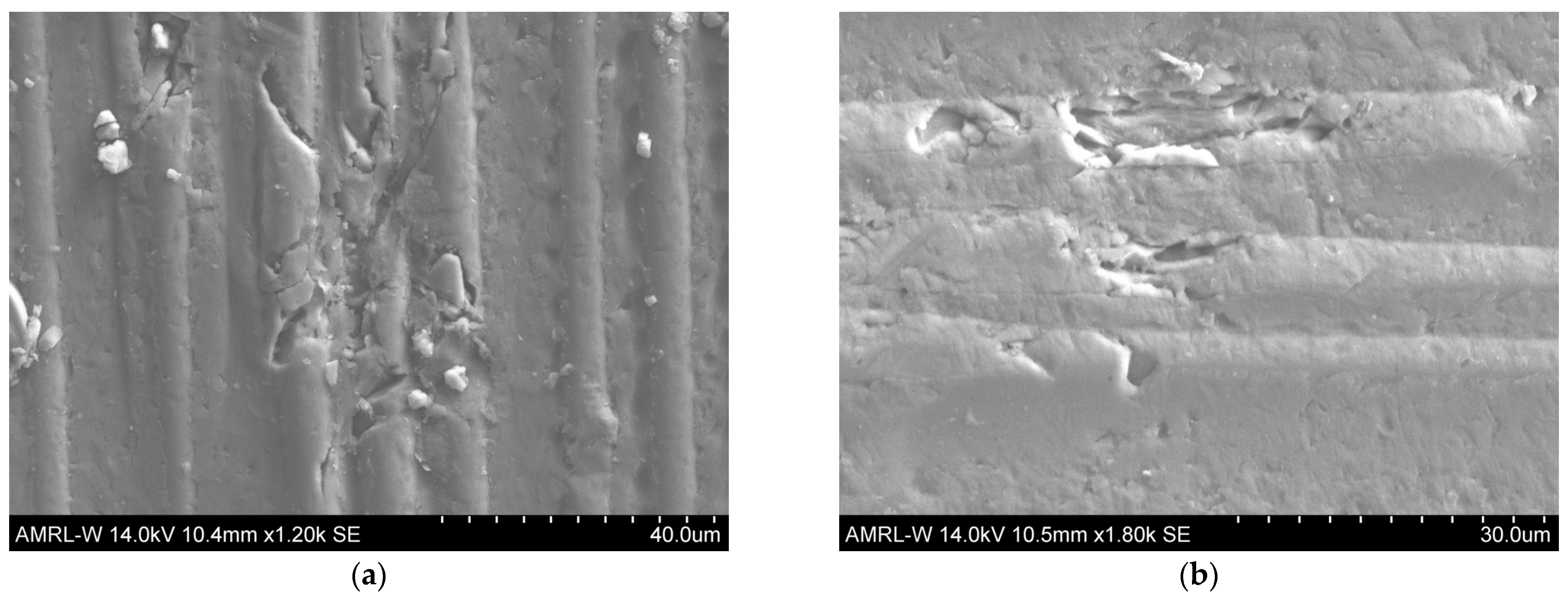

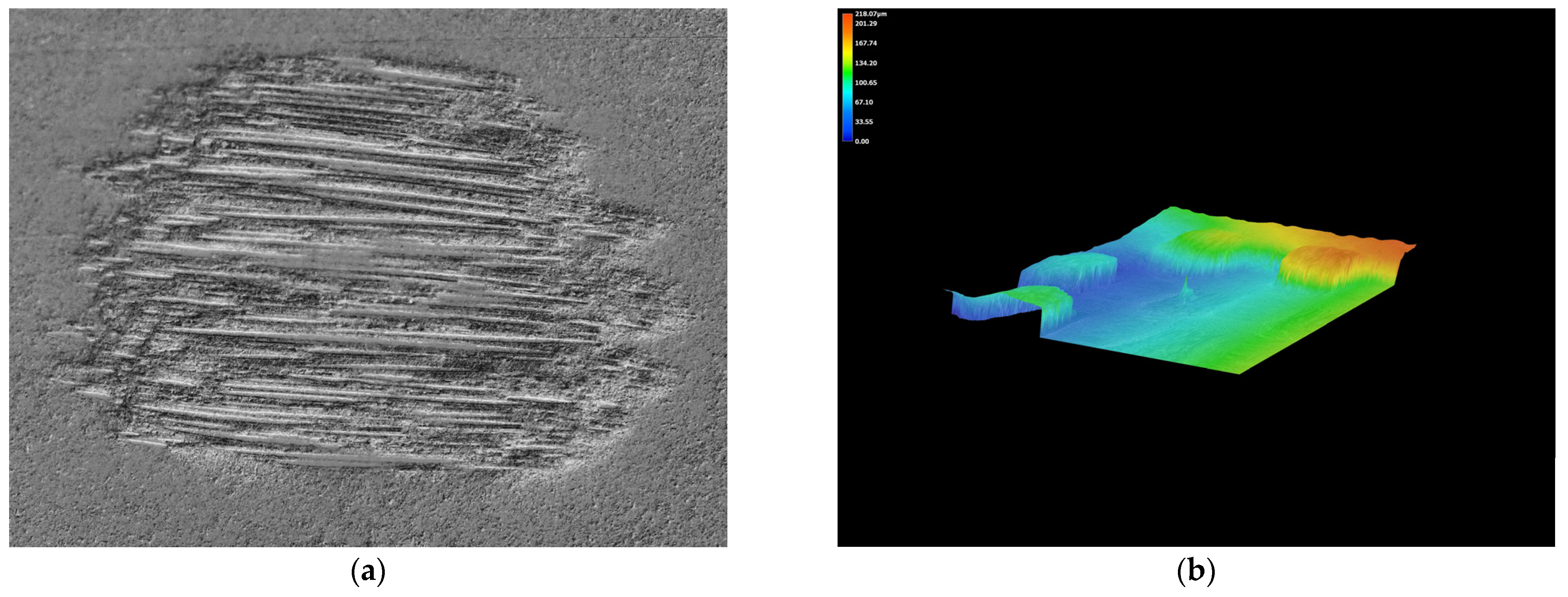

3.3. Scanning Electron Microscope (SEM) and Depth Profiling Analysis

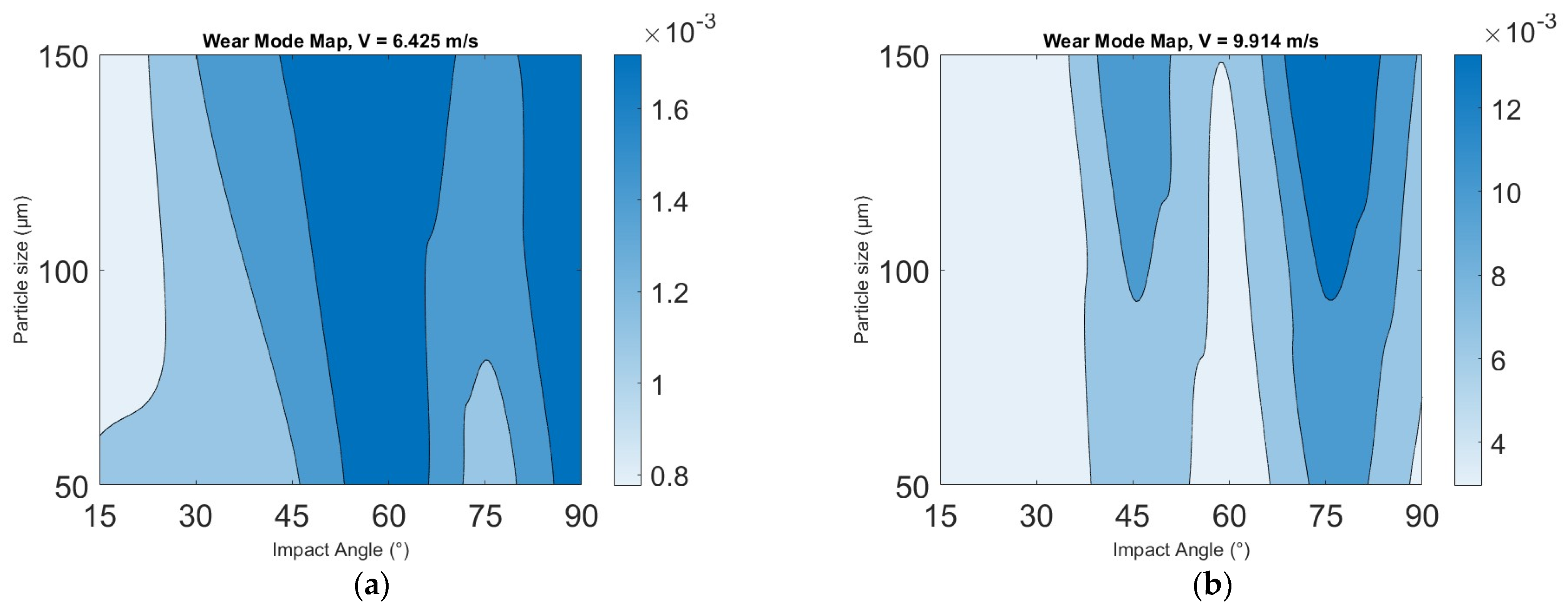

3.4. Erosion Wastage Maps

4. Discussion

4.1. Trends on the Effect of Particle Size, Velocity, Impact Angle and Exposure Time

4.2. Microscopy Analysis of Erosion Mechanisms

4.3. Erosion Maps and Potential Applications

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cagney, D.; Gruet, R.; Europe, O.E. Powering Homes Today, Powering Nations Tomorrow. ETIP Ocean. 2019. Available online: https://www.oceanenergy-europe.eu/wp-content/uploads/2019/04/ETIP-Ocean-Integrated-Strategy-2019-LR.pdf (accessed on 25 October 2024).

- Hassan, E.; Zekos, I.; Jansson, P.; Pečur, T.; Floreani, C.; Robert, C.; O’Bradaigh, C.; Stack, M. Erosion Mapping of Through-Thickness Toughened Powder Epoxy Gradient Glass-Fiber-Reinforced Polymer (GFRP) Plates for Tidal Turbine Blades. Lubricants 2021, 9, 22. [Google Scholar] [CrossRef]

- Shiekh Elsouk, M.; Santa Cruz, A.; Guillou, S. Review on the characterization and selection of the advanced materials for tidal turbine blades. In Proceedings of the 7th International Conference on Ocean Energy, Normandy, France, 12–13 June 2018; pp. 12–14. [Google Scholar]

- Grogan, D.M.; Leen, S.B.; Kennedy, C.R.; Brádaigh, C.Ó. Design of composite tidal turbine blades. Renew Energy 2013, 57, 151–162. [Google Scholar] [CrossRef]

- Alam, P.; Robert, C.; Brádaigh, C.M.Ó. Tidal turbine blade composites-A review on the effects of hygrothermal aging on the properties of CFRP. Compos. Part B Eng. 2018, 149, 248–259. [Google Scholar] [CrossRef]

- Rasool, G.; Johnstone, C.; Stack, M.M. Tribology of tidal turbine blades: Impact angle effects on erosion of polymeric coatings in sea water conditions. In Proceedings of the 2016: Asian Wave and Tidal Energy Conference (AWTEC), Singapore, 25–27 October 2016. [Google Scholar]

- McEwen, L.N.; Evans, R.; Meunier, M. Cost-effective tidal turbine blades. In Proceedings of the 4th International Conference on Ocean Energy, Dublin, Ireland, 17–19 October 2012; Volume17. [Google Scholar]

- Fukushima, K.; Cai, H.; Nakada, M.; Miyano, Y. Determination of time-temperature shift factor for long-term life prediction of polymer composites. In Proceedings of the ICCM 2009, Manchester, UK, 24–26 July 2009; Volume 17. [Google Scholar]

- Plota, A.; Masek, A. Lifetime prediction methods for degradable polymeric materials—A short review. Materials 2020, 13, 4507. [Google Scholar] [CrossRef] [PubMed]

- Abdellah, M.Y. Comparative study on prediction of fracture toughness of CFRP laminates from size effect law of open hole specimen using cohesive zone model. Eng. Fract. Mech. 2018, 191, 277–285. [Google Scholar] [CrossRef]

- Hassan, M.K.; Redhwi, A.M.N.; Mohamed, A.F.; Backar, A.H.; Abdellah, M.Y. Investigation of Erosion/Corrosion Behavior of GRP under Harsh Operating Conditions. Polymers 2022, 14, 5388. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, Z. Effects of Seawater Environment on the Degradation of GFRP Composites by Molecular Dynamics Method. Polymers 2022, 14, 2804. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Zhang, G. Durability of basalt fibers and composites in corrosive environments. J. Compos. Mater. 2015, 49, 873–887. [Google Scholar] [CrossRef]

- Ediriweera, M.; Chladek, J.; Ratnayake, C. Effect of impact angle, exposure time, and particle size on impact erosion. Part. Sci. Technol. 2021, 39, 10–18. [Google Scholar] [CrossRef]

- Javaheri, V.; Porter, D.; Kuokkala, V.-T. Slurry erosion of steel–Review of tests, mechanisms and materials. Wear 2018, 408, 248–273. [Google Scholar] [CrossRef]

- Tsai, W.; Humphrey, J.; Cornet, I.; Levy, A. Experimental measurement of accelerated erosion in a slurry pot tester. Wear 1981, 68, 289–303. [Google Scholar] [CrossRef]

- Lindgren, M.; Perolainen, J. Slurry pot investigation of the influence of erodent characteristics on the erosion resistance of austenitic and duplex stainless steel grades. Wear 2014, 319, 38–48. [Google Scholar] [CrossRef]

- Bhushan, B. Principles and Applications of Tribology; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Salik, J.; Buckley, D.H. Effects of Erodant Particle Shape and Various Heat Treatments on Erosion Resistance of Plain Carbon Steel; No. E-326; NASA: Washington, DC, USA, 1981.

- Hutchings, I.; Shipway, P. Tribology: Friction and Wear of Engineering Materials; Butterworth-Heinemann: Oxford, UK, 1995. [Google Scholar]

- Arjula, S.; Harsha, A. Study of erosion efficiency of polymers and polymer composites. Polym. Test. 2006, 25, 188–196. [Google Scholar] [CrossRef]

- Patnaik, A.; Biswas, S.; Kaundal, R.; Satapathy, A. Damage assessment of short glass fiber reinforced polyester composites: A comparative study. In Nanocomposites with Unique Properties and Applications in Medicine and Industry; IntechOpen: London, UK, 2011. [Google Scholar]

- Bhat, R.; Mohan, N.; Sharma, S.; Rao, S. Influence of seawater absorption on the hardness of glass fiber/polyester composite. J. Comput. Mech. Manag 2022, 1, 1–11. [Google Scholar] [CrossRef]

- Holbourne Industrial Plastics. Industrial Laminates & Industrial Engineering Plastics|Holbourne. Holbourne Industrial Plastics|Suppliers of Engineering Plastics to the UK, Europe, USA and Asia, 6 March 2012. Available online: https://www.holbourne.co.uk/ (accessed on 25 October 2024).

- The International Organization for Standardization. Available online: https://www.iso.org/home.html (accessed on 25 October 2024).

- International Electrotechnical Commission (IEC). Available online: https://webstore.iec.ch/en/ (accessed on 25 October 2024).

- Wensink, H.; Elwenspoek, M.C. A closer look at the ductile–brittle transition in solid particle erosion. Wear 2002, 253, 1035–1043. [Google Scholar] [CrossRef]

- Lim, S. Recent developments in wear-mechanism maps. Tribol. Int. 1998, 31, 87–97. [Google Scholar] [CrossRef]

- Rasool, G.; Stack, M.M. Some views on the mapping of erosion of coated composites in tidal turbine simulated conditions. Tribol. Trans. 2019, 62, 512–523. [Google Scholar] [CrossRef]

- Sparks, A.; Hutchings, I. Transitions in the erosive wear behaviour of a glass ceramic. Wear 1991, 149, 99–110. [Google Scholar] [CrossRef]

- Rajendran, S.; Palani, G.; Karthik Babu, N.; Veerasimman, A.P.; Yang, Y.-L.; Shanmugam, V. Solid particle erosion in fibre composites: A review. J. Reinf. Plast. Compos. 2024, 07316844241255007. [Google Scholar] [CrossRef]

- Macdonald, J.; Stack, M.M. Generating composite material maps from numerical simulation of hailstone impact. J. Bio-Tribo-Corros. 2024, 10, 57. [Google Scholar] [CrossRef]

- Ritchie, F.; Jana, B.; Zekos, I.; Stack, M. On the construction methodology of microabrasion-corrosion maps using theoretical approaches. J. Bio-Tribo-Corros. 2024, 10, 18. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Impingement Angle | 15°, 30°, 45°, 60°, 75°, 90° |

| Solution | Water, Salt, and Sand |

| Water Tank Capacity (Litre) | 13 |

| Salinity (wt %) | 3.5 |

| Sand Concentration (wt%) | 3 |

| Test Duration (min) | 60 |

| Ageing Duration (Days) | 14 (336 h) & 91 (2184 h) |

| Temperature (°C) | 10 ± 1 |

| Sand Particle Size (µm) | 0–50, 50–100, 100–150 |

| Impact Velocity (ms−1) | 6.425, 9.914, 12.5 |

| Technical Data | Units | Test Method | Values |

|---|---|---|---|

| Colour | - | - | Light Green |

| Specific Gravity | g/cm3 | ISO 1183 [25] | 1.95 |

| Water Absorption | mg | ISO 62 [25] | 5.5 |

| Temperature Index | °C | IEC 60216 [26] | 130 |

| Mechanical Properties | |||

| Flexural Strength | MPa | ISO 178 [25] | 500 |

| Compressive Strength | MPa | ISO 604 [25] | - |

| Impact Strength Charpy | kJ/M 2 | ISO 179 [25] | 60 |

| Tensile Strength | MPa | ISO 527 [25] | 450 |

| Electrical Properties | |||

| Insulation Resistance | MΩ | IEC 60893 [26] | 1.0 × 10⁹ |

| Breakdown Voltage | kV | IEC 60243 [26] | 42 |

| Dielectric Strength | kV/mm | IEC 60243 [26] | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Algaddaime, T.F.; Hassan, E.; Stack, M.M. Investigating the Performance of Glass Fibre-Reinforced Polymer (GFRP) in the Marine Environment for Tidal Energy: Velocity, Particle Size, Impact Angle and Exposure Time Effects. Lubricants 2024, 12, 375. https://doi.org/10.3390/lubricants12110375

Algaddaime TF, Hassan E, Stack MM. Investigating the Performance of Glass Fibre-Reinforced Polymer (GFRP) in the Marine Environment for Tidal Energy: Velocity, Particle Size, Impact Angle and Exposure Time Effects. Lubricants. 2024; 12(11):375. https://doi.org/10.3390/lubricants12110375

Chicago/Turabian StyleAlgaddaime, Talal F., Emadelddin Hassan, and Margaret M. Stack. 2024. "Investigating the Performance of Glass Fibre-Reinforced Polymer (GFRP) in the Marine Environment for Tidal Energy: Velocity, Particle Size, Impact Angle and Exposure Time Effects" Lubricants 12, no. 11: 375. https://doi.org/10.3390/lubricants12110375

APA StyleAlgaddaime, T. F., Hassan, E., & Stack, M. M. (2024). Investigating the Performance of Glass Fibre-Reinforced Polymer (GFRP) in the Marine Environment for Tidal Energy: Velocity, Particle Size, Impact Angle and Exposure Time Effects. Lubricants, 12(11), 375. https://doi.org/10.3390/lubricants12110375