Hard-Anodized Aluminum Alloy: Wear Properties in Vegetable Oils

Abstract

:1. Introduction

2. Materials and Methods

2.1. Anodized Samples

2.2. Vegetable Oils

2.3. Tribological Tests

3. Results & Discussion

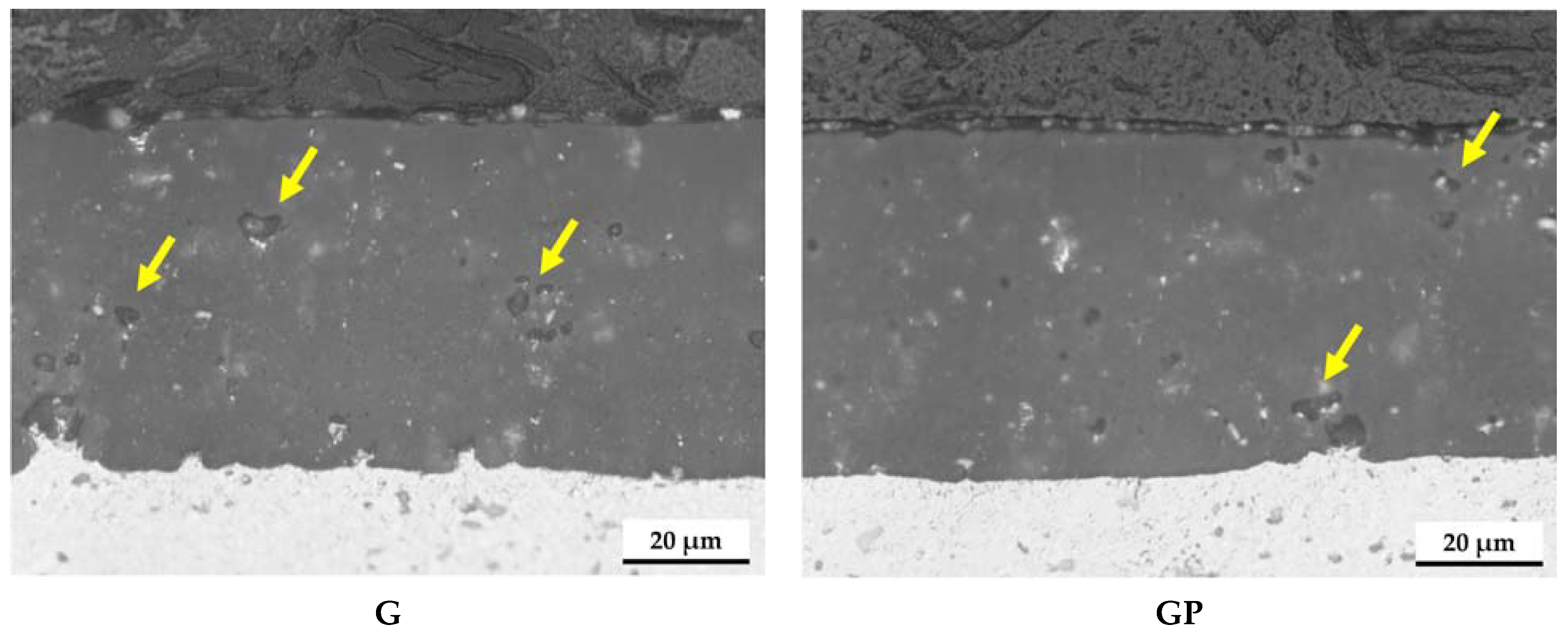

3.1. Anodized Samples

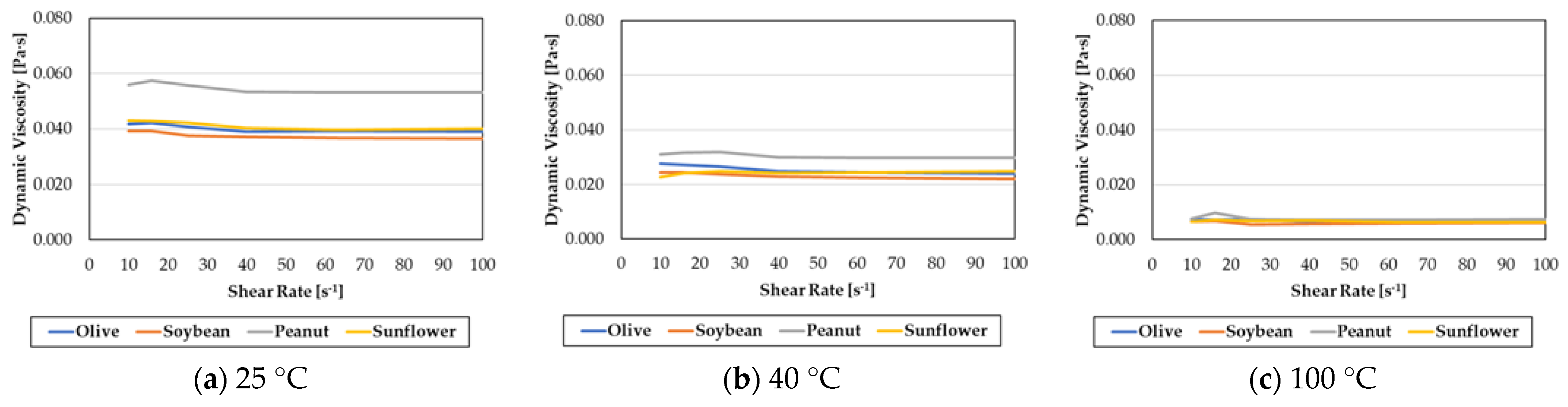

3.2. Vegetable Oils

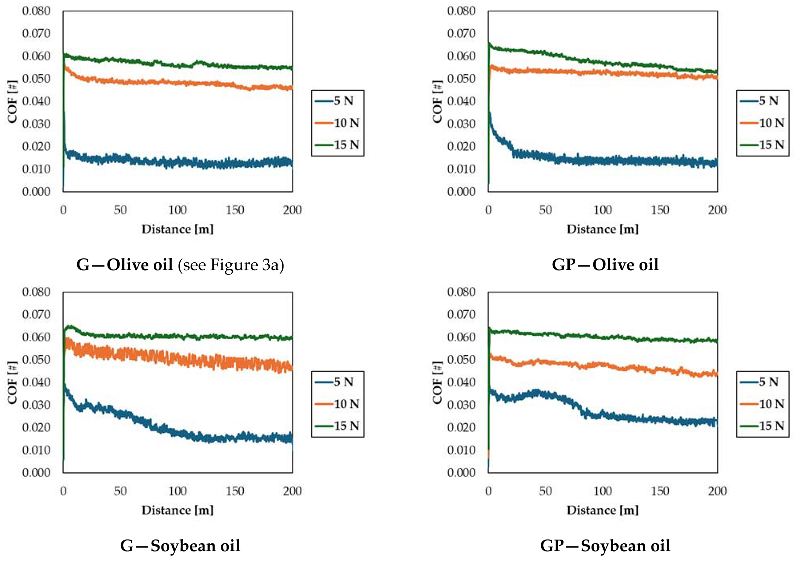

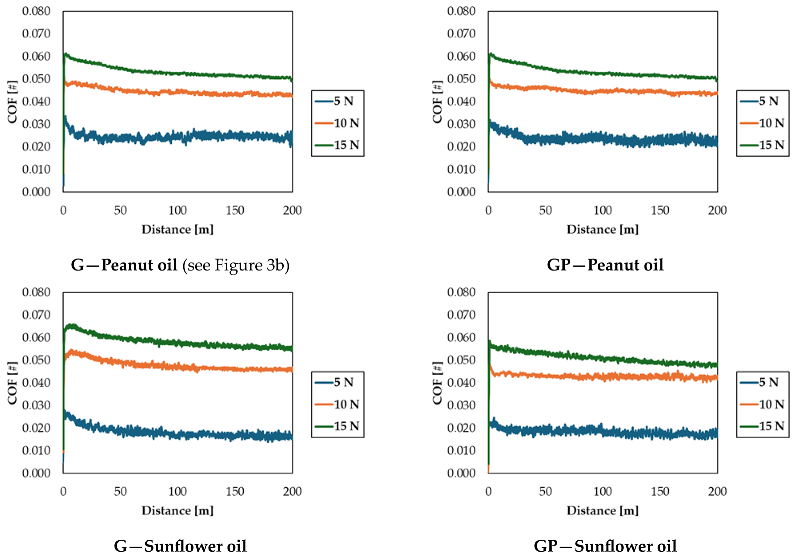

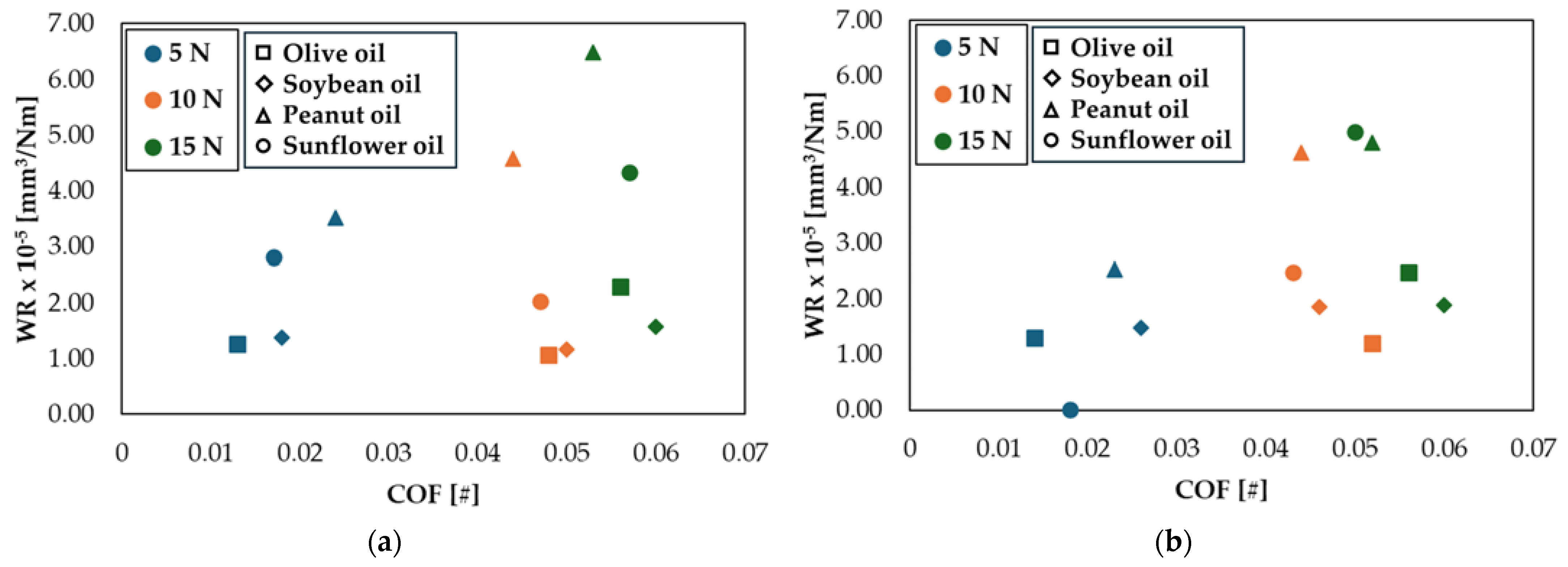

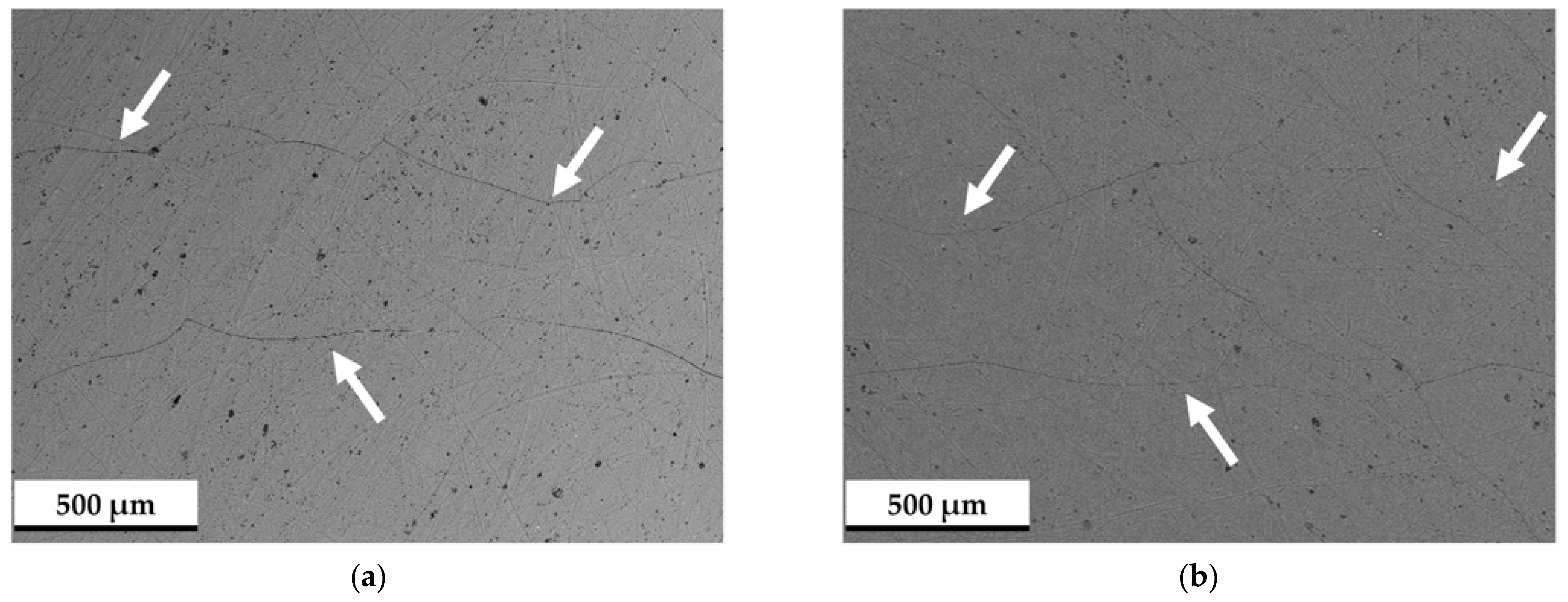

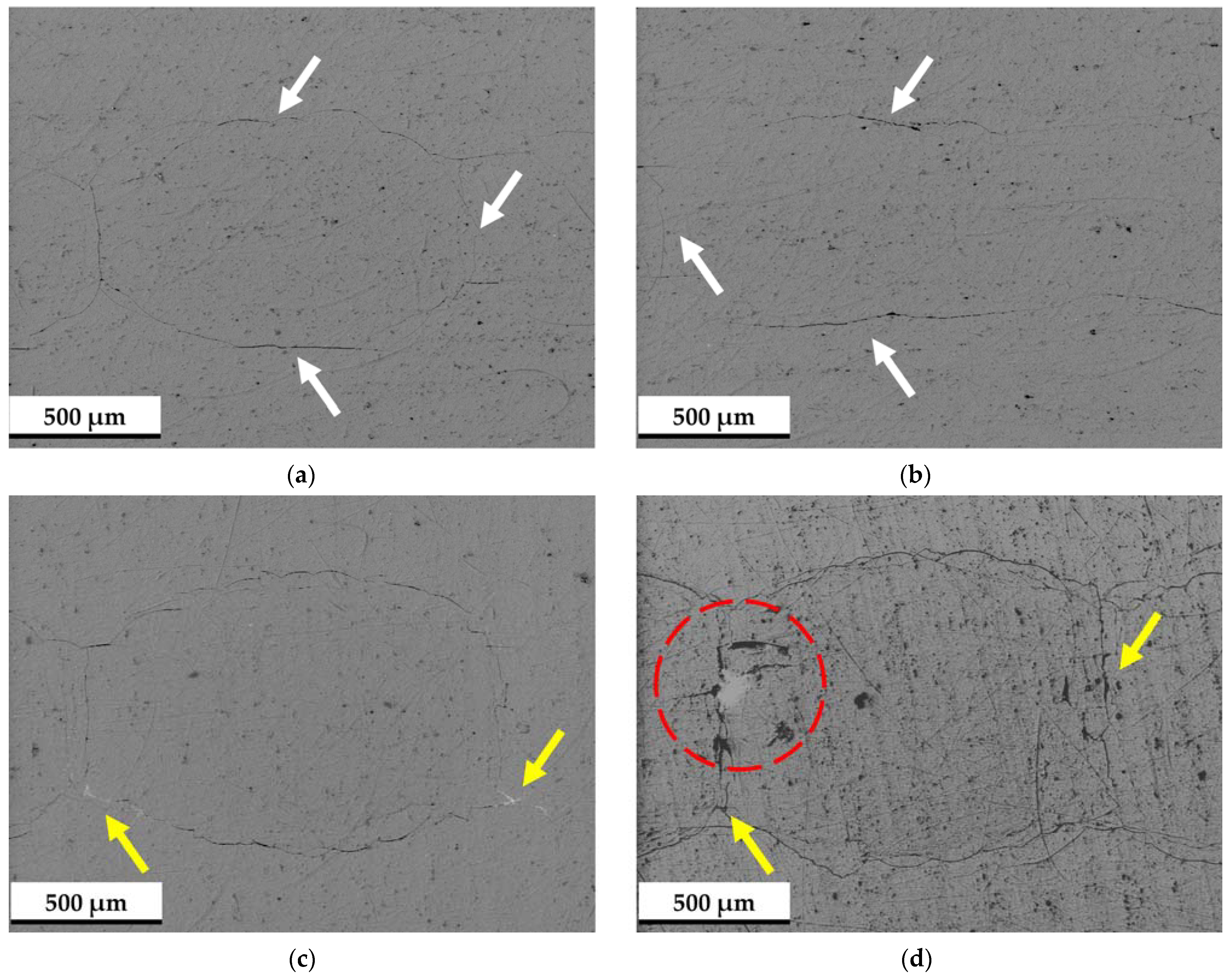

3.3. Tribological Characterization

4. Conclusions

- The two different sealing procedures did not affect the properties of G and GP anodized layers. Similar thickness values, Vickers microhardness values, and roughness parameters were obtained.

- The COF values followed different trends at the investigated normal loads. When a 15 N load was applied, the higher the UN of the vegetable oil, the higher the COF. At loads equal to 5 and 10 N, lubrication with peanut oil determined the lowest and the highest average values of the coefficient of friction, respectively.

- Two different tribological behaviors were suggested by WR values. The lowest values of the WR were obtained for G and GP samples using olive and soybean oils at each applied load, while peanut and sunflower oils determined the highest WR. The large standard deviations at 10 and 15 N suggested irregular-shaped wear tracks.

- Concerning wear mechanisms, at 5 N, wide longitudinal cracks along the sliding direction were detected as a result of the plastic deformation of the anodized layers. On the other hand, wavy-shaped profiles were found on the wear tracks at 10 and 15 N. These profiles were constituted by an alternation of pile-up and depressed areas with circular edges with cracked junctions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Rajasekaran, B.; Ganesh Sundara Raman, S.; Rama Krishna, L.; Joshi, S.V.; Sundararajan, G. Influence of Microarc Oxidation and Hard Anodizing on Plain Fatigue and Fretting Fatigue Behaviour of Al-Mg-Si Alloy. Surf. Coat. Technol. 2008, 202, 1462–1469. [Google Scholar] [CrossRef]

- Sola, R.; Tonelli, L.; Shashkov, P.; Bogdanoff, T.H.; Martini, C. Anodizing of AA6082-T5 by Conventional and Innovative Treatments: Microstructural Characterization and Dry Sliding Behaviour. Wear 2020, 458–459, 203423. [Google Scholar] [CrossRef]

- Mohitfar, S.H.; Mahdavi, S.; Etminanfar, M.; Khalil-Allafi, J. Characteristics and Tribological Behavior of the Hard Anodized 6061-T6 Al Alloy. J. Alloys Compd. 2020, 842, 155988. [Google Scholar] [CrossRef]

- Cotelli, C.M.; Sprague, J.A.; Smidt, F.A., Jr. Surface Engineering of Aluminum and Aluminum Alloys. In Surface Engineering; ASM International: Novelty, OH, USA, 1994; Volume 5, pp. 784–804. [Google Scholar]

- Kwolek, P. Hard Anodic Coatings on Aluminum Alloys. Adv. Manuf. Sci. Technol. 2017, 41, 35–46. [Google Scholar] [CrossRef]

- Zhang, X.X.; Jin, Y.X.; Wang, H.P.; Yang, Y. Development and Application of Porous Anodic Alumina Template. Appl. Mech. Mater. 2013, 320, 558–566. [Google Scholar] [CrossRef]

- Caliari, D.; Timelli, G.; Zabala, B.; Igartua, A. Microstructural and Tribological Investigations of Diecast and Hard Anodized AlSiCu Alloys. Surf. Coat. Technol. 2018, 352, 462–473. [Google Scholar] [CrossRef]

- Shang, Y.; Wang, L.; Liu, Z.; Niu, D.; Wang, Y.; Liu, C. The Effects of Different Sealing Techniques for Anodic Film of Al-12.7Si-0.7Mg Alloys. Int. J. Electrochem. Sci. 2016, 11, 5234–5244. [Google Scholar] [CrossRef]

- Ono, S.; Asoh, H. Mechanism of Hot Water Sealing of Anodic Films Formed on Aluminum. Corros. Sci. 2021, 181, 109221. [Google Scholar] [CrossRef]

- Mehdizade, M.; Soltanieh, M.; Eivani, A.R. Investigation of Anodizing Time and Pulse Voltage Modes on the Corrosion Behavior of Nanostructured Anodic Layer in Commercial Pure Aluminum. Surf. Coat. Technol. 2019, 358, 741–752. [Google Scholar] [CrossRef]

- Dobosz, I. Influence of the Anodization Conditions and Chemical Treatment on the Formation of Alumina Membranes with Defined Pore Diameters. J. Porous Mater. 2021, 28, 1011–1022. [Google Scholar] [CrossRef]

- Tsyntsaru, N.; Kavas, B.; Sort, J.; Urgen, M.; Celis, J.P. Mechanical and Frictional Behaviour of Nano-Porous Anodized Aluminium. Mater. Chem. Phys. 2014, 148, 887–895. [Google Scholar] [CrossRef]

- Hu, N.-N.; Ge, S.-R.; Fang, L. Tribological Properties of Nano-Porous Anodic Aluminum Oxide Template. J. Cent. South Univ. Technol. 2011, 18, 1004–1008. [Google Scholar] [CrossRef]

- Ali, I.; Quazi, M.M.; Zalnezhad, E.; Sarhan, A.A.D.; Sukiman, N.L.; Ishak, M. Hard Anodizing of Aerospace AA7075-T6 Aluminum Alloy for Improving Surface Properties. Trans. Indian Inst. Met. 2019, 72, 2773–2781. [Google Scholar] [CrossRef]

- Kong, D.; Wang, J.; Liu, H. Friction and Wear Performances of 7475 Aluminium Alloy after Anodic Oxidation. Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng. 2016, 45, 1122–1127. [Google Scholar] [CrossRef]

- Muthukumar, M.; Yadav, A.; Bobji, M.S. Wear Characteristics of Nanoporous Alumina and Copper Filled Nanocomposite Coatings. Wear 2020, 462–463, 203496. [Google Scholar] [CrossRef]

- Abedini, M.; Hanke, S. Improving the Wear Resistance of Aluminum by a Nickel-Filled Anodized Porous Alumina Layer. Wear 2023, 522, 204858. [Google Scholar] [CrossRef]

- Chen, S.; Kang, C.; Wang, J.; Liu, C.; Sun, K. Synthesis of Anodizing Composite Films Containing Superfine Al2O3 and PTFE Particles on Al Alloys. Appl. Surf. Sci. 2010, 256, 6518–6525. [Google Scholar] [CrossRef]

- Escobar, J.; Arurault, L.; Turq, V. Improvement of the Tribological Behavior of PTFE-Anodic Film Composites Prepared on 1050 Aluminum Substrate. Appl. Surf. Sci. 2012, 258, 8199–8208. [Google Scholar] [CrossRef]

- Maejima, M.; Saruwatari, K.; Takaya, M. Friction Behaviour of Anodic Oxide Film on Aluminum Impregnated with Molybdenum Sulfide Compounds. Surf. Coat. Technol. 2000, 132, 105–110. [Google Scholar] [CrossRef]

- Sliney, H.E. The Use of Silver in Self-Lubricating Coatings for Extreme Temperatures. ASLE Trans. 1986, 29, 370–376. [Google Scholar] [CrossRef]

- Shi, X.; Xu, Z.; Wang, M.; Zhai, W.; Yao, J.; Song, S.; ud Din, A.Q.; Zhang, Q. Tribological Behavior of TiAl Matrix Self-Lubricating Composites Containing Silver from 25 to 800 °C. Wear 2013, 303, 486–494. [Google Scholar] [CrossRef]

- Soffritti, C.; Fortini, A.; Nastruzzi, A.; Sola, R.; Merlin, M.; Garagnani, G.L. Dry Sliding Behavior of an Aluminum Alloy after Innovative Hard Anodizing Treatments. Materials 2021, 14, 3281. [Google Scholar] [CrossRef] [PubMed]

- Santecchia, E.; Cabibbo, M.; Hamouda, A.M.S.; Musharavati, F.; Popelka, A.; Spigarelli, S. Dry Sliding Tribological Properties of a Hard Anodized Aa6082 Aluminum Alloy. Metals 2020, 10, 207. [Google Scholar] [CrossRef]

- Nastruzzi, A.; Cicerchia, F.; Fortini, A.; Nastruzzi, C. Gold Hard Anodized (GHA) Materials with Antimicrobial Surface Properties: Mechanical, Tribological, and Microbiological Characterization. Emergent Mater. 2021, 4, 249–263. [Google Scholar] [CrossRef]

- Bahari, A.; Lewis, R.; Slatter, T. Friction and Wear Response of Vegetable Oils and Their Blends with Mineral Engine Oil in a Reciprocating Sliding Contact at Severe Contact Conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 244–258. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Rodríguez-Villalobos, M.; Maldonado-Cortés, D.; González, J.A.; Durán, R.D.J.; Ortega, J.A. Review of Vegetable Nanolubricants for Tribological Applications. Int. J. Mod. Manuf. Technol. 2022, 14, 333–343. [Google Scholar] [CrossRef]

- Luna, F.M.T.; Rocha, B.S.; Rola, E.M.; Albuquerque, M.C.G.; Azevedo, D.C.S.; Cavalcante, C.L. Assessment of Biodegradability and Oxidation Stability of Mineral, Vegetable and Synthetic Oil Samples. Ind. Crops Prod. 2011, 33, 579–583. [Google Scholar] [CrossRef]

- Lee, C.T.; Lee, M.B.; Mong, G.R.; Chong, W.W.F. A Bibliometric Analysis on the Tribological and Physicochemical Properties of Vegetable Oil–Based Bio-Lubricants (2010–2021). Environ. Sci. Pollut. Res. 2022, 29, 56215–56248. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable Oil-Based Lubricants—A Review of Oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Jen, T.C.; Lovell, M.R. The Influence of Fatty Acids on Tribological and Thermal Properties of Natural Oils as Sustainable Biolubricants. Tribol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Gerbig, Y.; Ahmed, S.I.U.; Gerbig, F.A.; Haefke, H. Suitability of Vegetable Oils as Industrial Lubricants. J. Synth. Lubr. 2004, 21, 177–191. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Merola, M.; Valašek, P.; Müller, M. Tribological Characterization of Vegetal Lubricants: Comparative Experimental Investigation on Jatropha curcas L. Oil, Rapeseed Methyl Ester Oil, Hydrotreated Rapeseed Oil. Tribol. Int. 2017, 109, 529–540. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A.P. The Lubrication Effect of Different Vegetable Oil-Based Greases on Steel-Steel Tribo-Pair. Biomass Convers. Biorefinery 2024, 14, 1993–2005. [Google Scholar] [CrossRef]

- UNI EN 573-3:2024. Available online: https://store.uni.com/en/uni-en-573-3-2024 (accessed on 2 November 2024).

- Ikeda, T.; Kinju, T.; Matsuo, Y. Method for Surface Treatment of Aluminum or Aluminum Alloys. EU Patent 1207220B1, 16 January 2008. [Google Scholar]

- Georgescu, C.; Deleanu, L.; Catalin Cristea, G. Tribological Behavior of Soybean Oil. In Soybean—Biomass, Yield and Productivity; IntechOpen: London, UK, 2019. [Google Scholar]

- Adhvaryu, A.; Biresaw, G.; Sharma, B.K.; Erhan, S.Z. Friction Behavior of Some Seed Oils: Biobased Lubricant Applications. Ind. Eng. Chem. Res. 2006, 45, 3735–3740. [Google Scholar] [CrossRef]

- Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C. Available online: https://www.astm.org/d2270-10r16.html (accessed on 2 November 2024).

- Straffelini, G. Friction and Wear: Methodologies for Design and Control; Springer: Cham, Switzerland, 2015; ISBN 978-3-319-05893-1. [Google Scholar]

- Hamrock, B.J.; Dowson, D.; Tallian, T.E. Ball Bearing Lubrication (The Elastohydrodynamics of Elliptical Contacts). J. Lubr. Technol. 1982, 104, 279–281. [Google Scholar] [CrossRef]

- Liu, S.; Peyronnel, A.; Wang, Q.J.; Keer, L.M. An Extension of the Hertz Theory for 2D Coated Components. Tribol. Lett. 2005, 18, 505–511. [Google Scholar] [CrossRef]

- Ortega-álvarez, R.; Hernández-Sierra, M.T.; Aguilera-Camacho, L.D.; Bravo-Sánchez, M.G.; Moreno, K.J.; García-Miranda, J.S. Tribological Performance of 100Cr6/8620 Steel Bearing System under Green Oil Lubrication. Metals 2022, 12, 362. [Google Scholar] [CrossRef]

- Dervishi, E.; McBride, M.; Edwards, R.; Gutierrez, M.; Li, N.; Buntyn, R.; Hooks, D.E. Mechanical and Tribological Properties of Anodic Al Coatings as a Function of Anodizing Conditions. Surf. Coat. Technol. 2022, 444, 128652. [Google Scholar] [CrossRef]

- Ofoegbu, S.U.; Fernandes, F.A.O.; Pereira, A.B. The Sealing Step in Aluminum Anodizing: A Focus on Sustainable Strategies for Enhancing Both Energy Efficiency and Corrosion Resistance. Coatings 2020, 10, 226. [Google Scholar] [CrossRef]

- Yoshikawa, D.S.; Terada, M.; Assis, S.L.; Costa, I.; Padilha, A.F. Correlation between Microstructure and Corrosion Behavior of Two Al-Fe-Si Alloys. Mater. Corros. 2016, 67, 286–296. [Google Scholar] [CrossRef]

- Scampone, G.; Russo, A.; Carminati, A.; Timelli, G. The Influence of the Electrolytic Bath on the Hard Anodizing of Diecast Al–Si–Cu Alloys. Results Surf. Interfaces 2022, 9, 100089. [Google Scholar] [CrossRef]

- Esteban, B.; Riba, J.R.; Baquero, G.; Rius, A.; Puig, R. Temperature Dependence of Density and Viscosity of Vegetable Oils. Biomass Bioenergy 2012, 42, 164–171. [Google Scholar] [CrossRef]

- Guo, B.; Liu, G. Mud Hydraulics Fundamentals. In Applied Drilling Circulation Systems; Elsevier: Amsterdam, The Netherlands, 2011; pp. 19–59. [Google Scholar]

- Zanini, N.; Suman, A.; Pinelli, M. Experimental Test on Centrifugal Pump Handling Mining Slurries. In Volume 9: Microturbines, Turbochargers, and Small Turbomachines; Oil and Gas Applications, Proceedings of the ASME Turbo Expo 2023: Turbomachinery Technical Conference and Exposition, Boston, MA, USA, 26–30 June 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Blau, P.J. On the Nature of Running-In. Tribol. Int. 2005, 38, 1007–1012. [Google Scholar] [CrossRef]

- Faes, J.; González, R.; Battez, A.H.; Blanco, D.; Fernández-González, A.; Viesca, J.L. Friction, Wear and Corrosion Behavior of Environmentally-Friendly Fatty Acid Ionic Liquids. Coatings 2021, 11, 21. [Google Scholar] [CrossRef]

- Guicciardi, S.; Melandri, C.; Lucchini, F.; De Portu, G. On Data Dispersion in Pin-on-Disk Wear Tests. Wear 2002, 252, 1001–1006. [Google Scholar] [CrossRef]

- Shibata, K.; Ii, T.; Yamaguchi, T.; Hokkirigawa, K. Tribological Behavior of Polyacetal Composite Filled with Rice Bran Ceramics Particles under Water Lubrication. J. Compos. Mater. 2018, 52, 2075–2084. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Hokkirigawa, K. Friction and Wear Properties of PEEK Resin Filled with RB Ceramics Particles under Water Lubricated Condition. Tribol. Online 2016, 11, 653–660. [Google Scholar] [CrossRef]

- Kerni, L.; Raina, A.; Haq, M.I.U. Friction and Wear Performance of Olive Oil Containing Nanoparticles in Boundary and Mixed Lubrication Regimes. Wear 2019, 426–427, 819–827. [Google Scholar] [CrossRef]

- Luo, X.; Wu, S.; Wang, D.; Yun, Y.; An, Q.; Li, C. Sustainable Development of Cutting Fluids: The Comprehensive Review of Vegetable Oil. J. Clean. Prod. 2024, 473, 143544. [Google Scholar] [CrossRef]

- Mannekote, J.K.; Kailas, S.V. The Effect of Oxidation on the Tribological Performance of Few Vegetable Oils. J. Mater. Res. Technol. 2012, 1, 91–95. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics and the Wear of Metals. Wear 1995, 190, 162–170. [Google Scholar] [CrossRef]

- Fouvry, S.; Kapsa, P.; Vincent, L. An Elastic-Plastic Shakedown Analysis of Fretting Wear. Wear 2001, 247, 41–54. [Google Scholar] [CrossRef]

- Kwolek, P.; Krupa, K.; Obłój, A.; Kocurek, P.; Wierzbińska, M.; Sieniawski, J. Tribological Properties of the Oxide Coatings Produced onto 6061-T6 Aluminum Alloy in the Hard Anodizing Process. J. Mater. Eng. Perform. 2018, 27, 3268–3275. [Google Scholar] [CrossRef]

| Designation | Anodizing Treatment | Sealing Parameters |

|---|---|---|

| G | G.H.A.® | 100 °C for 2 min/µm |

| GP | G.H.A.PLUS | 96 °C for 2 min/µm |

| Factors | Levels | |||

|---|---|---|---|---|

| Anodized layer | G | GP | - | - |

| Normal load [N] | 5 | 10 | 15 | - |

| Vegetable oil | Olive | Soybean | Peanut | Sunflower |

| N. of replicas | 3 | |||

| Young Modulus [GPa] | Poisson’s Ratio | Rq [µm] | |

|---|---|---|---|

| 100Cr6 (ball) | 210 1 | 0.30 1 | 0.03 1 |

| EN AW-4006 (disk/substrate) | 69 2 | 0.33 2 | Useless |

| Anodic oxide layer (disk/coating) | 90 3 | 0.24 3 | Measured |

| Thickness [µm] | HV0.01 | Ra [µm] | Rq [µm] | Rz [µm] | |

|---|---|---|---|---|---|

| G | 56 ± 1 | 494 ± 28 | 0.48 ± 0.02 | 0.65 ± 0.03 | 4.28 ± 0.38 |

| GP | 53 ± 2 | 500 ± 35 | 0.48 ± 0.06 | 0.64 ± 0.08 | 4.10 ± 0.92 |

| Saturated Fatty Acids | Unsaturated Fatty Acids | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vegetable Oil | C16:0 | C18:0 | C16:1 | C18:1 | C20:1 | C22:1 | C18:2 | C22:2 | C18:3 | UN | Density [g/cm3] | Viscosity Index |

| Olive | 0.1205 | 0.0274 | 0.0086 | 0.7186 | 0.0031 | 0.0000 | 0.1055 | 0.0000 | 0.0074 | 0.9635 | 0.942 ± 0.001 | 595 |

| Soybean | 0.1072 | 0.0436 | 0.0009 | 0.2432 | 0.0016 | 0.0000 | 0.5230 | 0.0000 | 0.0714 | 1.5059 | 0.949 ± 0.001 | 592 |

| Peanut | 0.0709 | 0.0243 | 0.0013 | 0.7351 | 0.0181 | 0.0000 | 0.0945 | 0.0000 | 0.0011 | 0.9468 | 0.948 ± 0.001 | 538 |

| Sunflower | 0.0647 | 0.0358 | 0.0010 | 0.2863 | 0.0013 | 0.0000 | 0.5980 | 0.0000 | 0.0009 | 1.4873 | 0.936 ± 0.001 | 578 |

| G | |||

|---|---|---|---|

| 5 N | 10 N | 15 N | |

| Olive | 0.013 ± 0.003 | 0.048 ± 0.001 | 0.056 ± 0.002 |

| Soybean | 0.018 ± 0.002 | 0.050 ± 0.002 | 0.060 ± 0.001 |

| Peanut | 0.024 ± 0.001 | 0.044 ± 0.003 | 0.053 ± 0.001 |

| Sunflower | 0.017 ± 0.003 | 0.047 ± 0.002 | 0.057 ± 0.003 |

| GP | |||

| 5 N | 10 N | 15 N | |

| Olive | 0.014 ± 0.003 | 0.052 ± 0.004 | 0.056 ± 0.001 |

| Soybean | 0.026 ± 0.003 | 0.046 ± 0.004 | 0.060 ± 0.002 |

| Peanut | 0.023 ± 0.003 | 0.044 ± 0.002 | 0.052 ± 0.001 |

| Sunflower | 0.018 ± 0.001 | 0.043 ± 0.001 | 0.050 ± 0.002 |

| hc [nm] | hmin [nm] | λ | ||

|---|---|---|---|---|

| 5 N | Olive | 25.8 | 20.5 | 0.031–0.032 |

| Soybean | 24.5 | 19.4 | 0.029–0.030 | |

| Peanut | 32.9 | 26.1 | 0.040–0.041 | |

| Sunflower | 26.3 | 20.9 | 0.032–0.033 | |

| 10 N | Olive | 24.7 | 19.5 | 0.029–0.030 |

| Soybean | 23.4 | 18.5 | 0.028–0.029 | |

| Peanut | 31.4 | 24.8 | 0.038–0.039 | |

| Sunflower | 25.1 | 19.8 | 0.030–0.031 | |

| 15 N | Olive | 24.0 | 18.9 | 0.028–0.029 |

| Soybean | 22.8 | 17.9 | 0.027–0.028 | |

| Peanut | 30.5 | 24.0 | 0.035–0.037 | |

| Sunflower | 24.5 | 19.3 | 0.029–0.030 |

| G | |||

|---|---|---|---|

| 5 N | 10 N | 15 N | |

| Olive | 1.25 ± 0.13 | 1.06 ± 0.20 | 2.28 ± 0.43 |

| Soybean | 1.37 ± 0.43 | 1.16 ± 0.13 | 1.57 ± 0.46 |

| Peanut | 3.50 ± 1.38 | 4.56 ± 3.15 | 6.47 ± 1.31 |

| Sunflower | 2.82 ± 1.35 | 2.03 ± 1.53 | 4.33 ± 1.80 |

| GP | |||

| 5 N | 10 N | 15 N | |

| Olive | 1.29 ± 0.34 | 1.20 ± 0.13 | 2.47 ± 0.47 |

| Soybean | 1.48 ± 0.64 | 1.85 ± 0.34 | 1.88 ± 0.05 |

| Peanut | 2.52 ± 1.25 | 4.61 ± 1.76 | 4.79 ± 0.69 |

| Sunflower | - | 2.48 ± 2.43 | 5.00 ± 4.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soffritti, C.; Fortini, A.; Baroni, E.; Merlin, M.; Garagnani, G.L. Hard-Anodized Aluminum Alloy: Wear Properties in Vegetable Oils. Lubricants 2024, 12, 383. https://doi.org/10.3390/lubricants12110383

Soffritti C, Fortini A, Baroni E, Merlin M, Garagnani GL. Hard-Anodized Aluminum Alloy: Wear Properties in Vegetable Oils. Lubricants. 2024; 12(11):383. https://doi.org/10.3390/lubricants12110383

Chicago/Turabian StyleSoffritti, Chiara, Annalisa Fortini, Enrico Baroni, Mattia Merlin, and Gian Luca Garagnani. 2024. "Hard-Anodized Aluminum Alloy: Wear Properties in Vegetable Oils" Lubricants 12, no. 11: 383. https://doi.org/10.3390/lubricants12110383

APA StyleSoffritti, C., Fortini, A., Baroni, E., Merlin, M., & Garagnani, G. L. (2024). Hard-Anodized Aluminum Alloy: Wear Properties in Vegetable Oils. Lubricants, 12(11), 383. https://doi.org/10.3390/lubricants12110383