Compatibility Study of Polyamide (PA6) with Lubricant Bases for Electric Vehicle Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

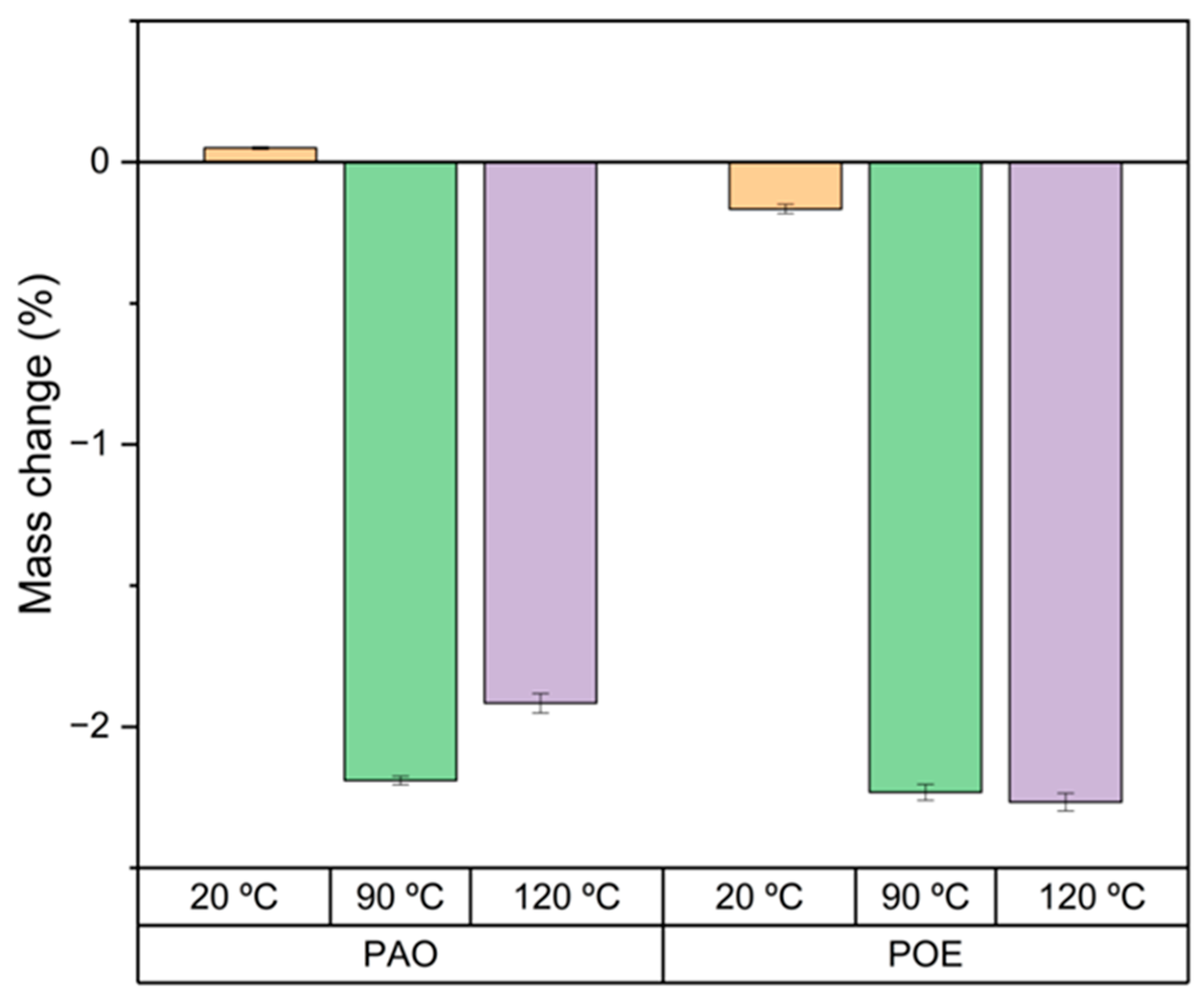

2.2.1. Measurement of Mass Changes

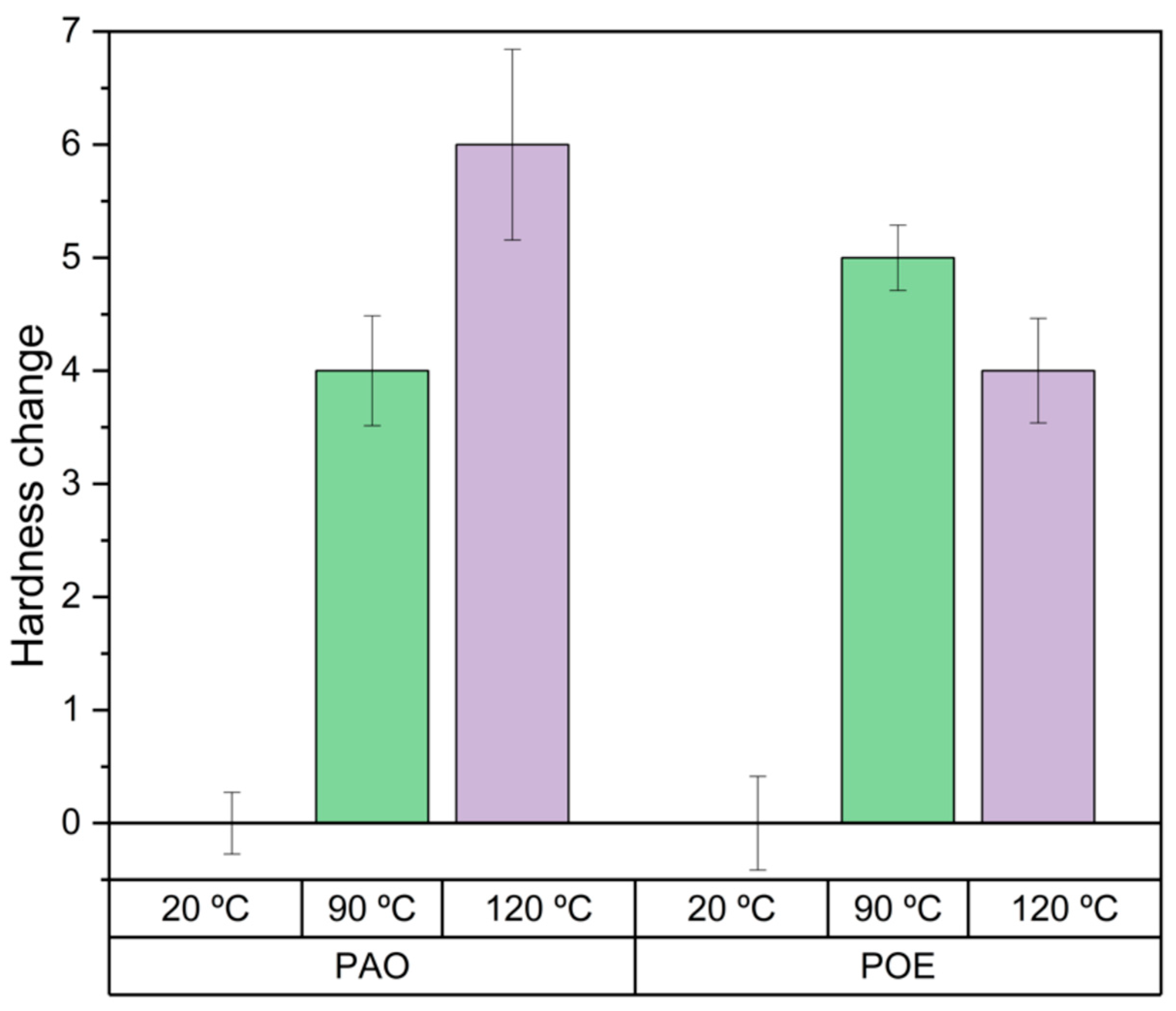

2.2.2. Measurement of Hardness Changes

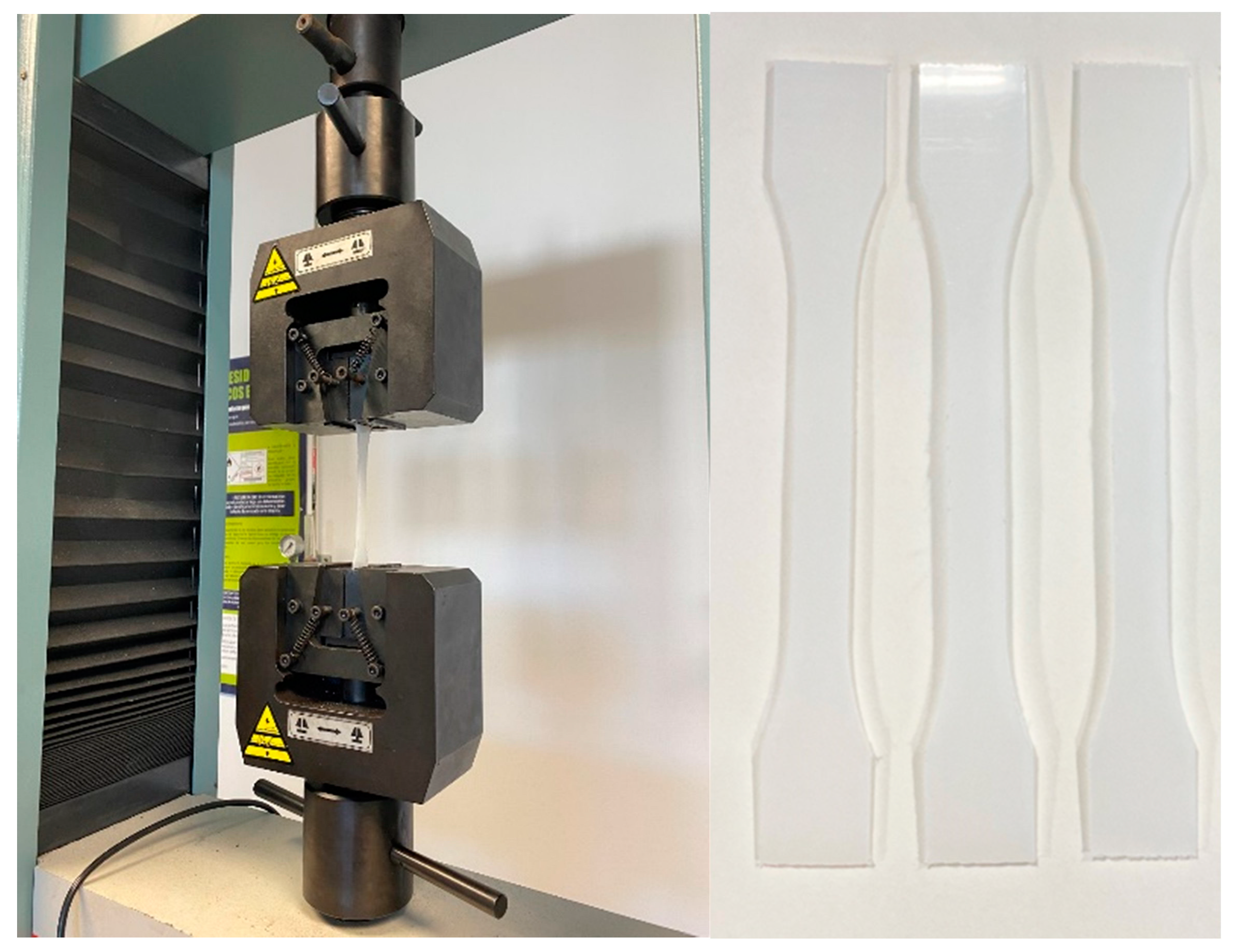

2.2.3. Measurement of Tensile Strength and Elongation Changes

2.2.4. Fourier Transform Infrared of Polyamide—FTIR

2.2.5. Crystallinity

2.2.6. X-ray Diffraction—XRD

3. Results

3.1. Mass Change

3.2. Hardness Change

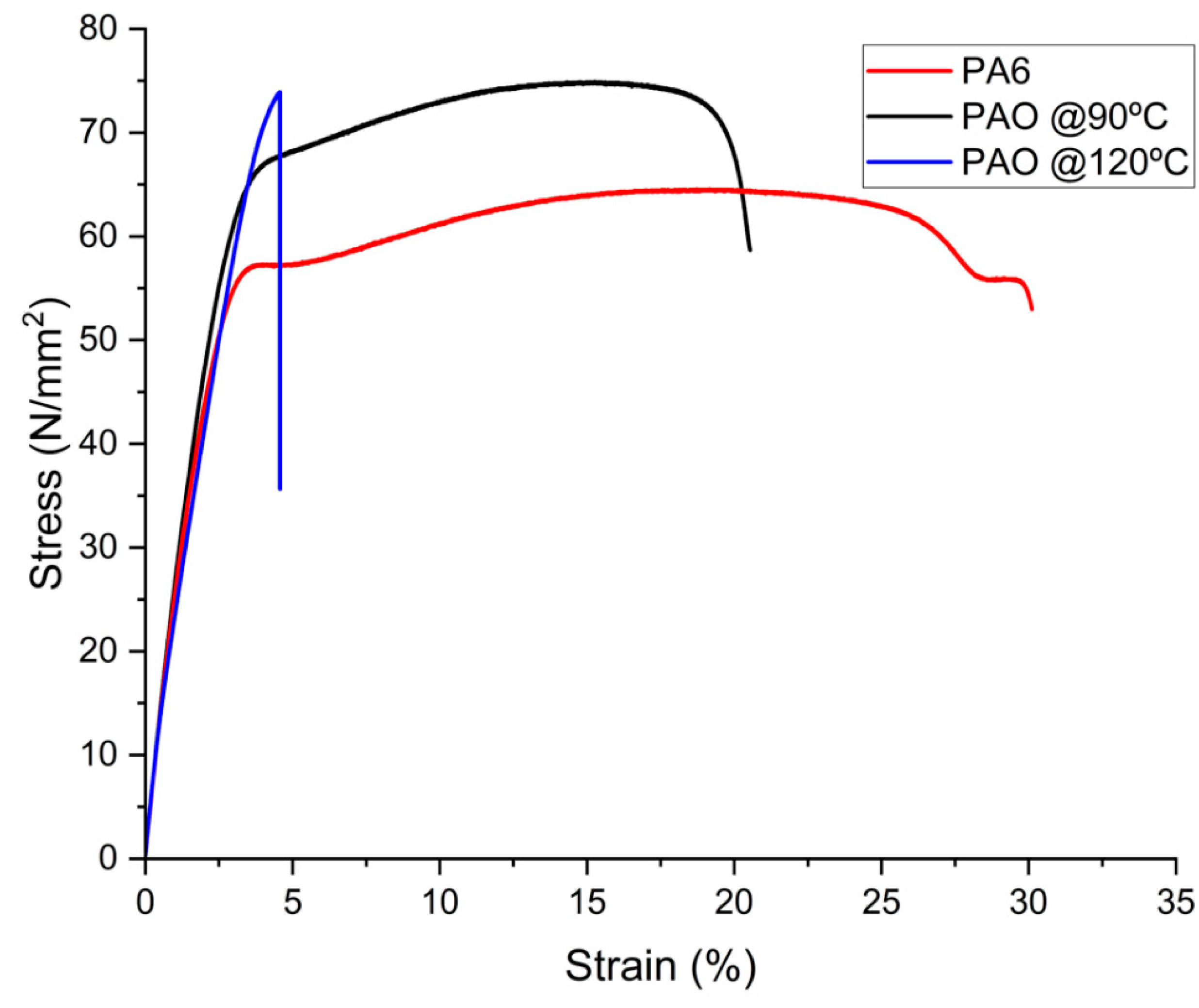

3.3. Tensile Test

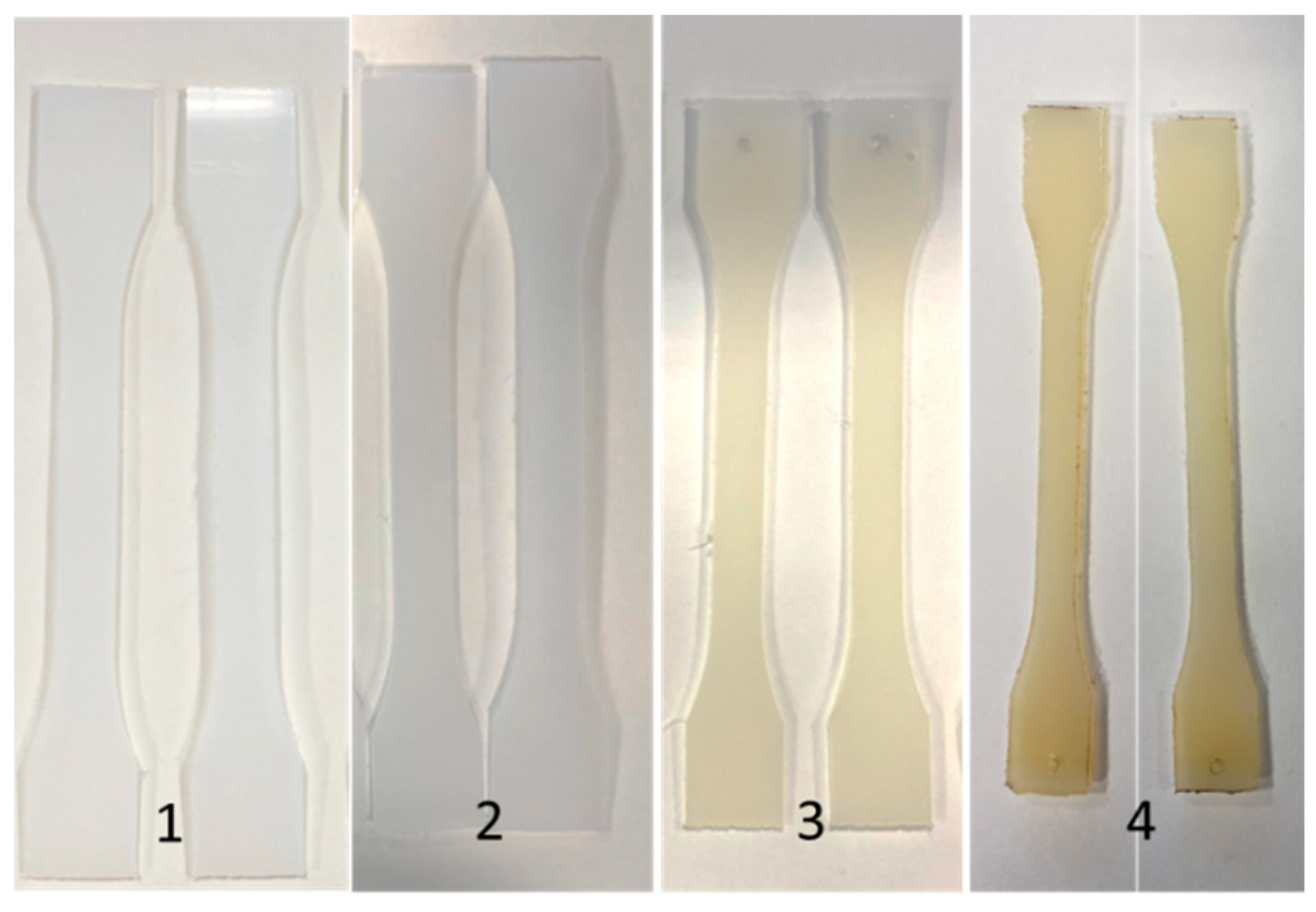

3.4. Color Change

3.5. Chemistry Characterization

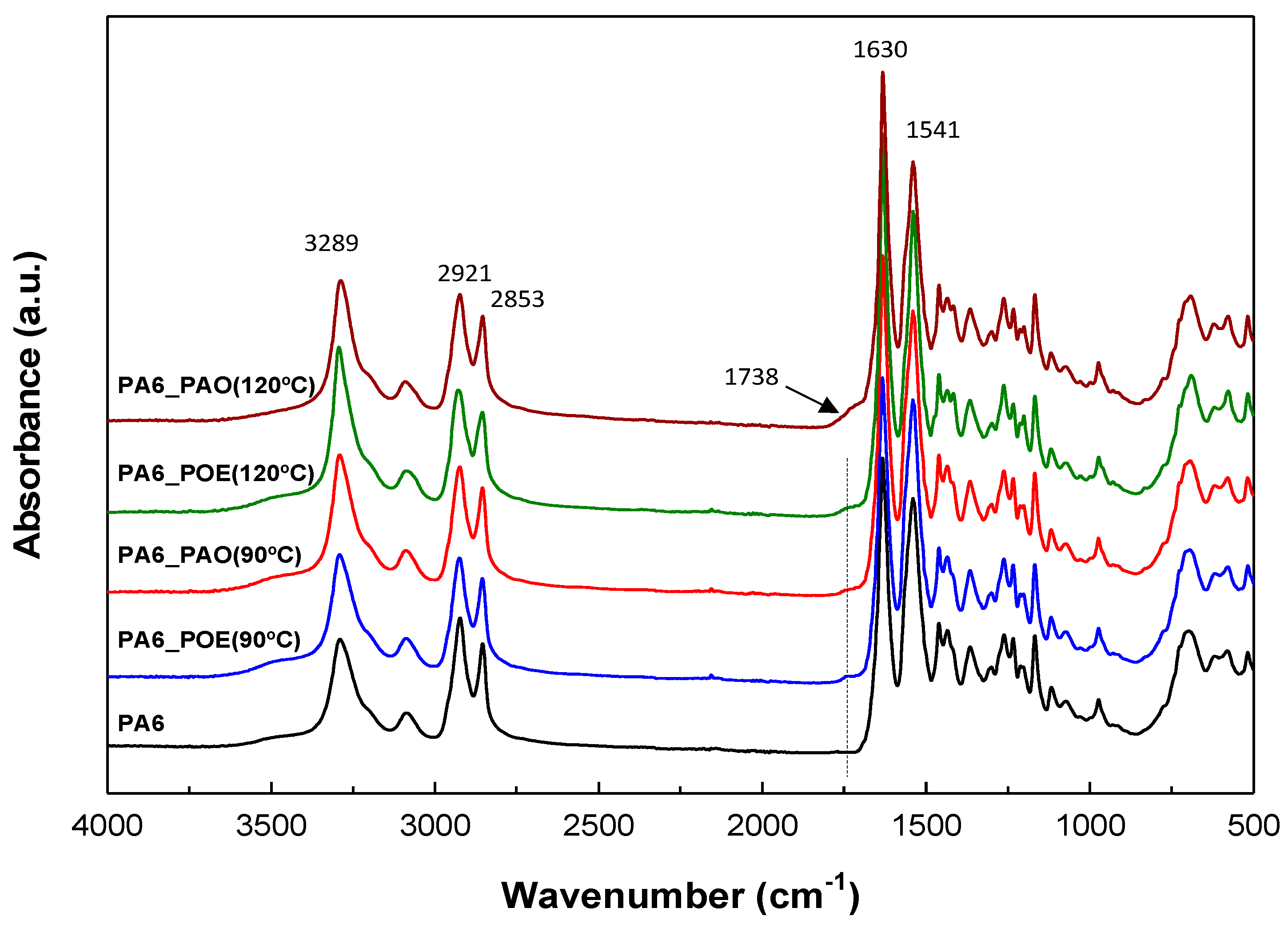

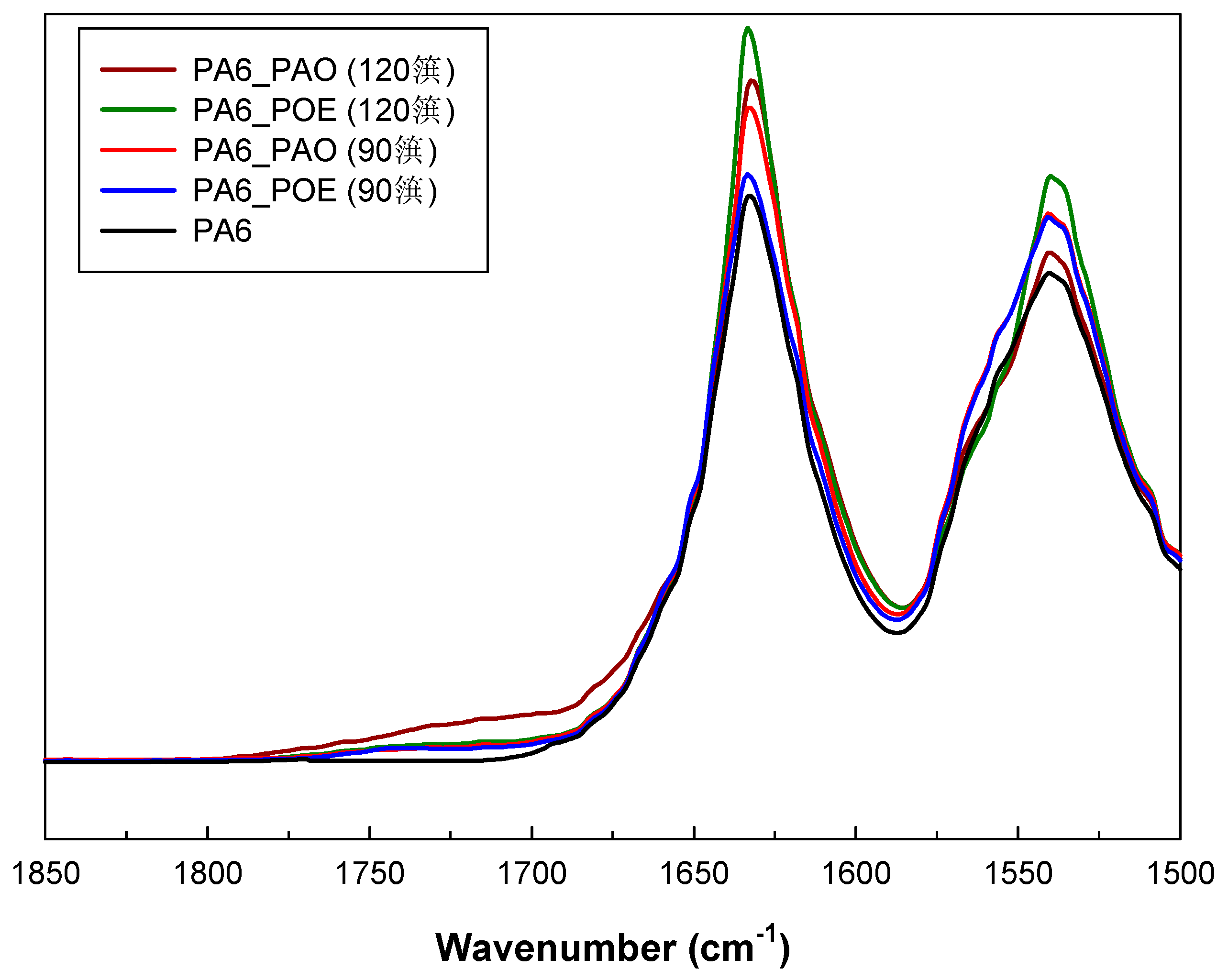

3.5.1. Fourier Transform Infrared of Polyamide—FTIR

3.5.2. X-ray Diffraction—XRD

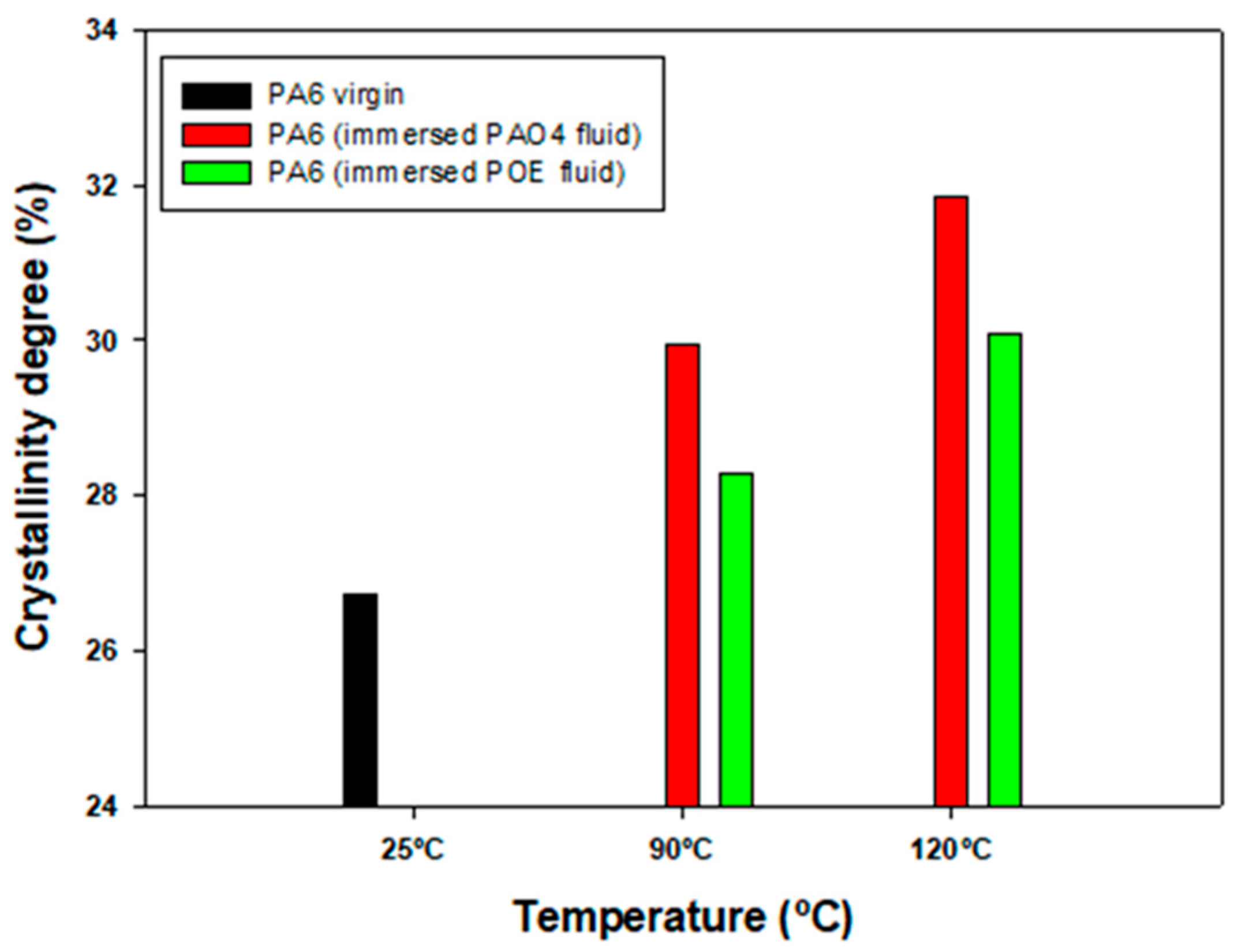

3.5.3. Crystallinity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fuels and Lubricants TC 3 Driveline and Chassis Lubrication, Fluid for Automotive Electrified Drivetrains, 2022. Available online: https://www.sae.org/standards/content/J3200_202210/ (accessed on 15 May 2023).

- Rémi, D.; Juhasz, J.R. Assessment of immersion cooling fluids for electric vehicle battery thermal management. In Proceedings of the 32nd Electric Vehicle Symposium (EVS32), Lyon, France, 19–22 May 2019. [Google Scholar]

- Immersed-Cooling Concepts for Electric Vehicle Battery Packs Using Viscoelastic Heat Transfer Liquids (I-BAT)|I-BAT|Project|Fact sheet|H2020|CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/899659 (accessed on 4 December 2023).

- Sundin, D.W.; Sponholtz, S. Thermal management of Li-ion batteries with single-phase liquid immersion cooling. IEEE Open J. Veh. Technol. 2020, 1, 82–92. [Google Scholar] [CrossRef]

- Williams, N.P.; Trimble, D.; O’Shaughnessy, S.M. Thermal Management of Lithium-ion Batteries for Electric Vehicles through Immersion Cooling. In Proceedings of the 22nd InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, ITHERM, Orlando, FL, USA, 30 May–2 June 2023. [Google Scholar] [CrossRef]

- Narita, K.; Takekawa, D. Lubricants Technology Applied to Transmissions in Hybrid Electric Vehicles and Electric Vehicles, SAE Technical Papers; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.H.; Lee, M.Y. A novel dielectric fluid immersion cooling technology for Li-ion battery thermal management. Energy Convers Manag. 2021, 229, 113715. [Google Scholar] [CrossRef]

- Roe, C.; Feng, X.; White, G.; Li, R.; Wang, H.; Rui, X.; Li, C.; Zhang, F.; Null, V.; Parkes, M.; et al. Immersion cooling for lithium-ion batteries – A review. J. Power Sources 2022, 525, 231094. [Google Scholar] [CrossRef]

- Tormos, B.; Bermúdez, V.; Ruiz, S.; Alvis-Sanchez, J. Degradation Effects of Base Oils after Thermal and Electrical Aging for EV Thermal Fluid Applications. Lubricants 2023, 11, 241. [Google Scholar] [CrossRef]

- Szewczyk, R.; Wicks, R.; Martin, R. Comparison of Synthetic and Natural Esters with Focus on Thermal Aspects of Insulation Systems. In Proceedings of the CIRED 2021—The 26th International Conference and Exhibition on Electricity Distribution, Virtual Event, 20–23 September 2021; pp. 142–146. [Google Scholar]

- Narvaez, J. Thermal Conductivity of Poly-alpha-olefin (pao)-Based Nanofluids. Master’s Thesis, University of Dayton, Dayton, OH, USA, 2010. [Google Scholar]

- Benda, R.; Bullen, J.; Plomer, A. Synthetics basics: Polyalphaolefins–Base fluids for high-performance lubricants. J. Synth. Lubr. 1996, 13, 41–57. [Google Scholar] [CrossRef]

- Lin, L.; Kedzierski, M.A. Density and viscosity of a polyol ester lubricant: Measurement and molecular dynamics simulation. Int. J. Refrig. 2020, 118, 188–201. [Google Scholar] [CrossRef] [PubMed]

- Kondo, M.Y.; Montagna, L.S.; Morgado GF, D.M.; Castilho AL, G.D.; Batista LA PD, S.; Botelho, E.C.; Costa, M.L.; Passador, F.R.; Rezende, M.C.; Ribeiro, M.V. Recent advances in the use of Polyamide-based materials for the automotive industry. Polímeros 2022, 32. [Google Scholar] [CrossRef]

- Global $53.32 Billion Polyamide Markets to 2028. Available online: https://www.globenewswire.com/news-release/2021/10/22/2319003/28124/en/Global-53-32-Billion-Polyamide-Markets-to-2028-Increasing-Demand-from-the-Automobile-Industry-Growing-Demand-from-End-use-Industries.html (accessed on 15 April 2023).

- Durbin, T.D.; Karavalakis, G.; Norbeck, J.M.; Park, C.S.; Castillo, J.; Rheem, Y.; Bumiller, K.; Yang, J.; Van, V.; Hunter, K. Material compatibility evaluation for elastomers, plastics, and metals exposed to ethanol and butanol blends. Fuel 2016, 163, 248–259. [Google Scholar] [CrossRef]

- Müller, M.; Šleger, V.; Čedík, J.; Pexa, M. Research on the Material Compatibility of Elastomer Sealing O-Rings. Polymers 2022, 14, 3323. [Google Scholar] [CrossRef] [PubMed]

- Eyerer, S.; Eyerer, P.; Eicheldinger, M.; Tübke, B.; Wieland, C.; Spliethoff, H. Theoretical analysis and experimental investigation of material compatibility between refrigerants and polymers. Energy 2018, 163, 782–799. [Google Scholar] [CrossRef]

- McGuire, N. Test Methods for Evaluation of Electric Vehicle Drivetrain Fluids; Society of Tribologists and Lubrication Engineers—STLE: Park Ridge, IL, USA, 2023. [Google Scholar]

- ASTM D7216; Standard Test Method for Determining Automotive Engine Oil Compatibility with Typical Seal Elastomers. ASTM International: West Conshohocken, PA, USA, 2023.

- Baldi, L.D.; Iamazaki, E.T.; Atvars, T.D. Evaluation of the polarity of polyamide surfaces using the fluorescence emission of pyrene. Dye. Pigment. 2008, 76, 669–676. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2021.

- Bandrup, J.; Immergut, E. Polymer Handbook, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 1989. [Google Scholar]

- Tian, R.; Li, K.; Lin, Y.; Lu, C.; Duan, X. Characterization Techniques of Polymer Aging: From Beginning to End. Chem. Rev. 2023, 123, 3007–3088. [Google Scholar] [CrossRef] [PubMed]

- Palmer, R.J. Polyamides, Plastics. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Shi, K.; Ye, L.; Li, G. Thermal oxidative aging behavior and stabilizing mechanism of highly oriented polyamide 6. J. Therm. Anal. Calorim. 2016, 126, 795–805. [Google Scholar] [CrossRef]

- Do, C.H.; Pearce, E.M.; Bulkin, B.J.; Reimschuessel, H.K. FT–IR spectroscopic study on the thermal and thermal oxidative degradation of nylons. J. Polym. Sci. Part A Polym. Chem. 1987, 25, 2409–2424. [Google Scholar] [CrossRef]

- Porubská, M.; Szöllős, O.; Kóňová, A.; Janigová, I.; Jašková, M.; Jomová, K.; Chodák, I. FTIR spectroscopy study of polyamide-6 irradiated by electron and proton beams. Polym. Degrad. Stab. 2012, 97, 523–531. [Google Scholar] [CrossRef]

- Dong, W.; Gijsman, P. Influence of temperature on the thermo-oxidative degradation of polyamide 6 films. Polym. Degrad. Stab. 2010, 95, 1054–1062. [Google Scholar] [CrossRef]

| Fluid | ν 40 °C | ν 100 °C | Viscosity Index |

|---|---|---|---|

| PAO | 17.90 mm²/s | 4.03 mm²/s | 125 |

| POE | 19.84 mm²/s | 4.45 mm²/s | 140 |

| PA6 w/o Immersion | PA6 Immersed PAO | PA6 Immersed POE | |||||

|---|---|---|---|---|---|---|---|

| Temp. | 20 °C | 90 °C | 120 °C | 20 °C | 90 °C | 120 °C | |

| Tensile strength (MPa) | 63.74 ± 1.28 | 58.10 ± 2.09 | 74.97 ± 0.43 | 70.08 ± 4.66 | 60.22 ± 3.21 | 75.69 ± 0.72 | 76.25 ± 0.13 |

| Strain at break (%) | 31.71 ± 1.92 | 158.78 ± 13.76 | 21.70 ± 1.91 | 3.52 ± 0.45 | 163.43 ± 13.39 | 24.79 ± 1.69 | 23.27 ± 2.09 |

| PA6 Immersed PAO | PA6 Immersed POE | |||||

|---|---|---|---|---|---|---|

| Immersion Temp. | 20 °C | 90 °C | 120 °C | 20 °C | 90 °C | 120 °C |

| Tensile strength change (%) | −8.85 | 17.62 | 9.95 | −5.52 | 18.75 | 19.63 |

| Ultimate elongation change (%) | 400.73 | −31.57 | −88.90 | 415.39 | −21.82 | −26.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tormos, B.; Bermúdez, V.; Balaguer, A.; Giménez, E. Compatibility Study of Polyamide (PA6) with Lubricant Bases for Electric Vehicle Applications. Lubricants 2024, 12, 54. https://doi.org/10.3390/lubricants12020054

Tormos B, Bermúdez V, Balaguer A, Giménez E. Compatibility Study of Polyamide (PA6) with Lubricant Bases for Electric Vehicle Applications. Lubricants. 2024; 12(2):54. https://doi.org/10.3390/lubricants12020054

Chicago/Turabian StyleTormos, Bernardo, Vicente Bermúdez, Adbeel Balaguer, and Enrique Giménez. 2024. "Compatibility Study of Polyamide (PA6) with Lubricant Bases for Electric Vehicle Applications" Lubricants 12, no. 2: 54. https://doi.org/10.3390/lubricants12020054

APA StyleTormos, B., Bermúdez, V., Balaguer, A., & Giménez, E. (2024). Compatibility Study of Polyamide (PA6) with Lubricant Bases for Electric Vehicle Applications. Lubricants, 12(2), 54. https://doi.org/10.3390/lubricants12020054