The Effect of Ethanol Fuel-Diluted Lubricants on the Friction of Oil Control Ring Conjunction: A Combined Analytical and Experimental Investigation

Abstract

1. Introduction

2. Methodology

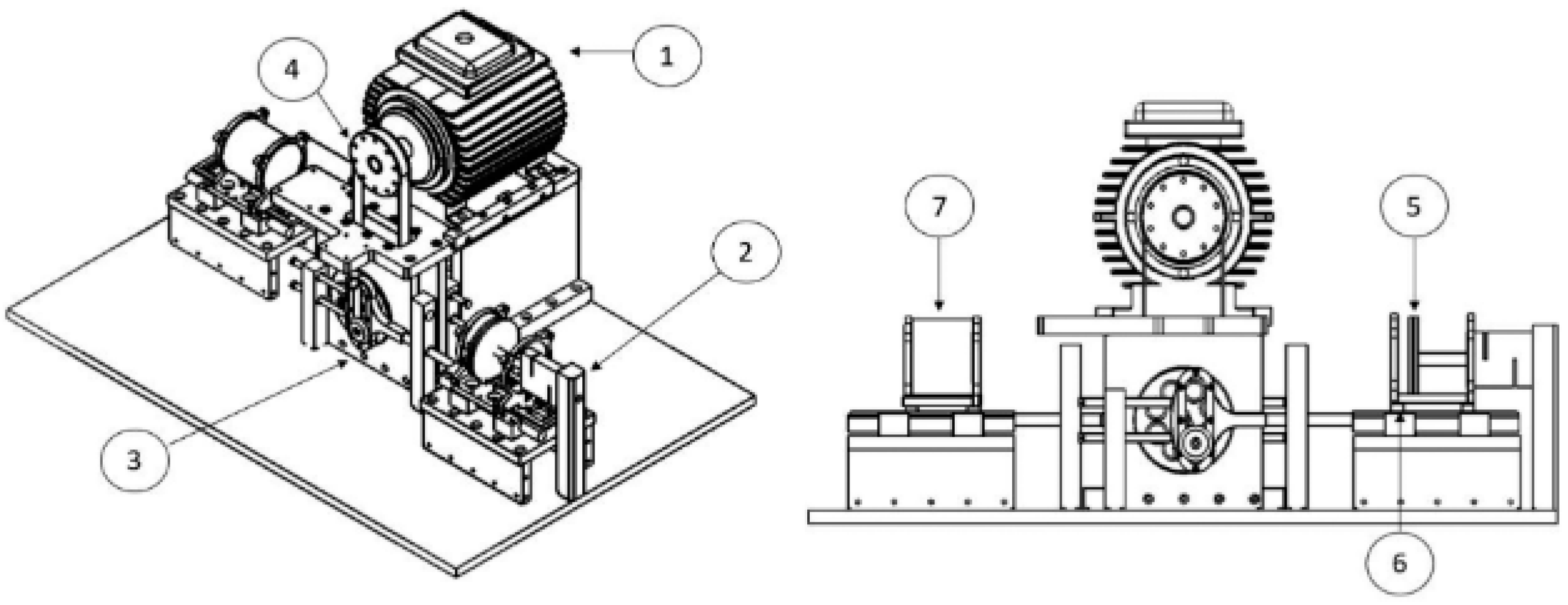

2.1. Experimental Piston Ring Test Facility

2.2. Analytical Mixed Lubrication Model

| Parameter | Ring Coating, TiN | Bore Coating, Nickel Ceramic | Unit |

|---|---|---|---|

| Young’s modulus of elasticity | 251 | 165 | GPa |

| Poisson ratio | 0.25 | 0.31 | -- |

| Density | 5220 | 5175 | kg m−3 |

| Coating thickness | 1.5–3 | 50–70 | µm |

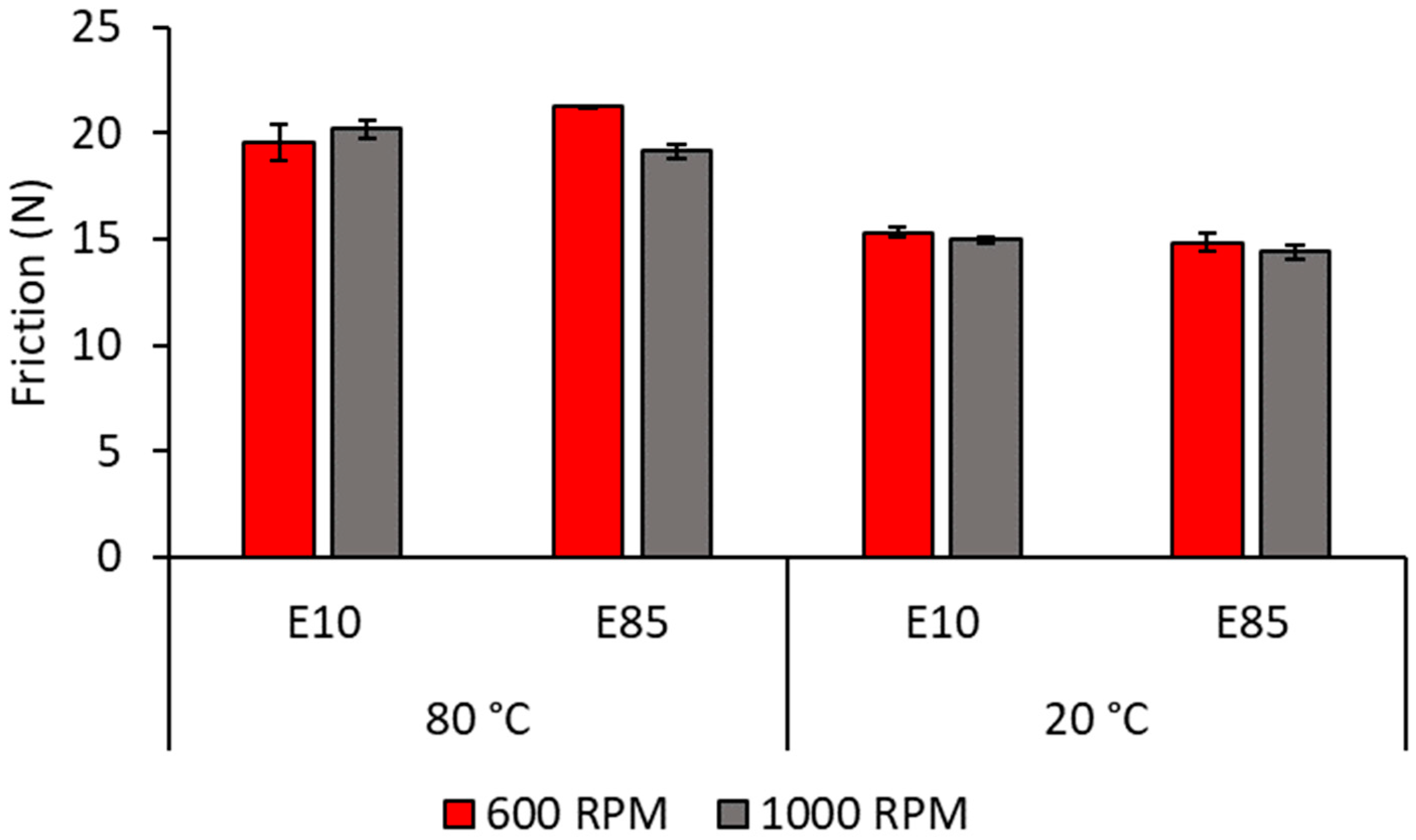

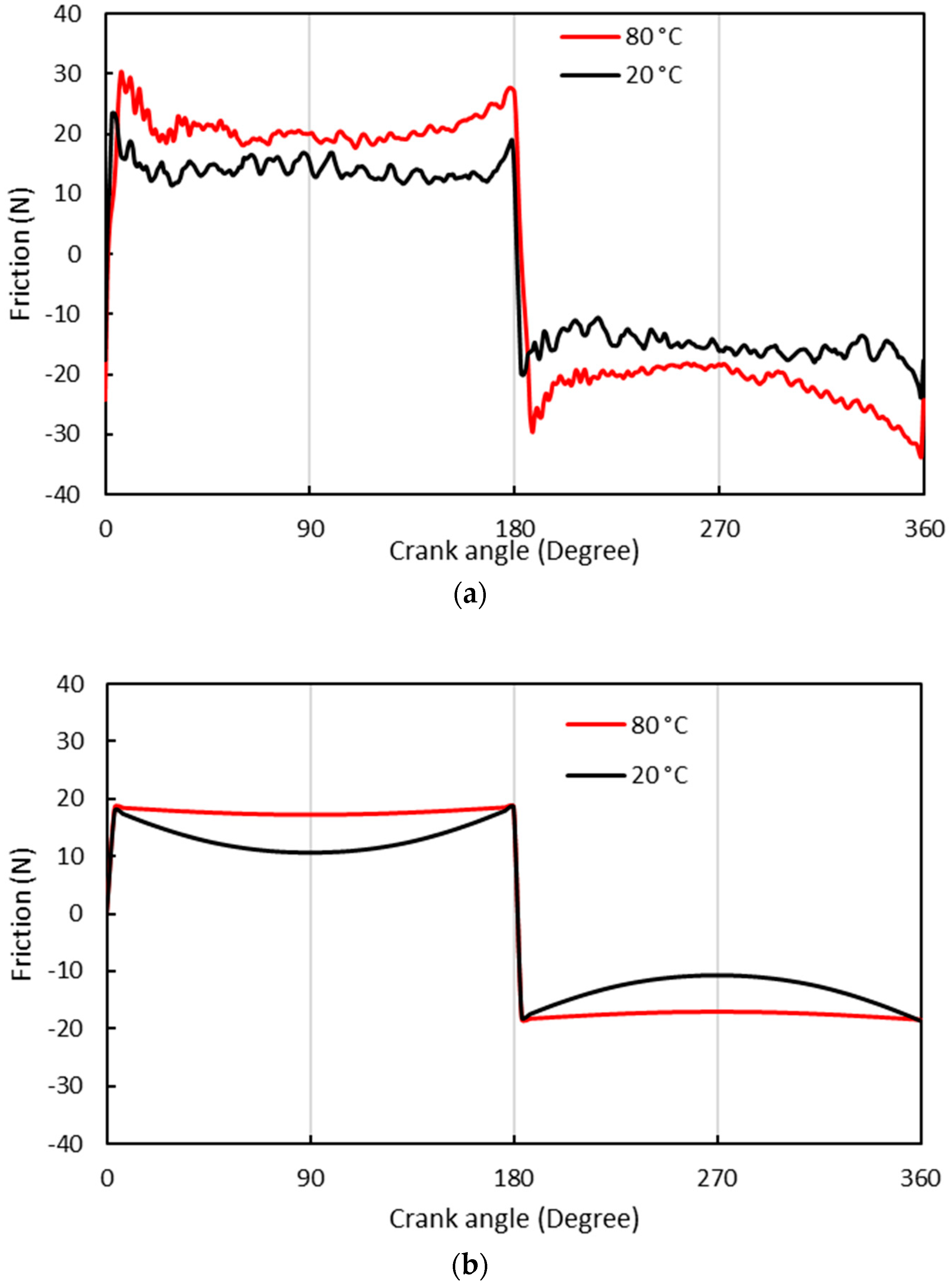

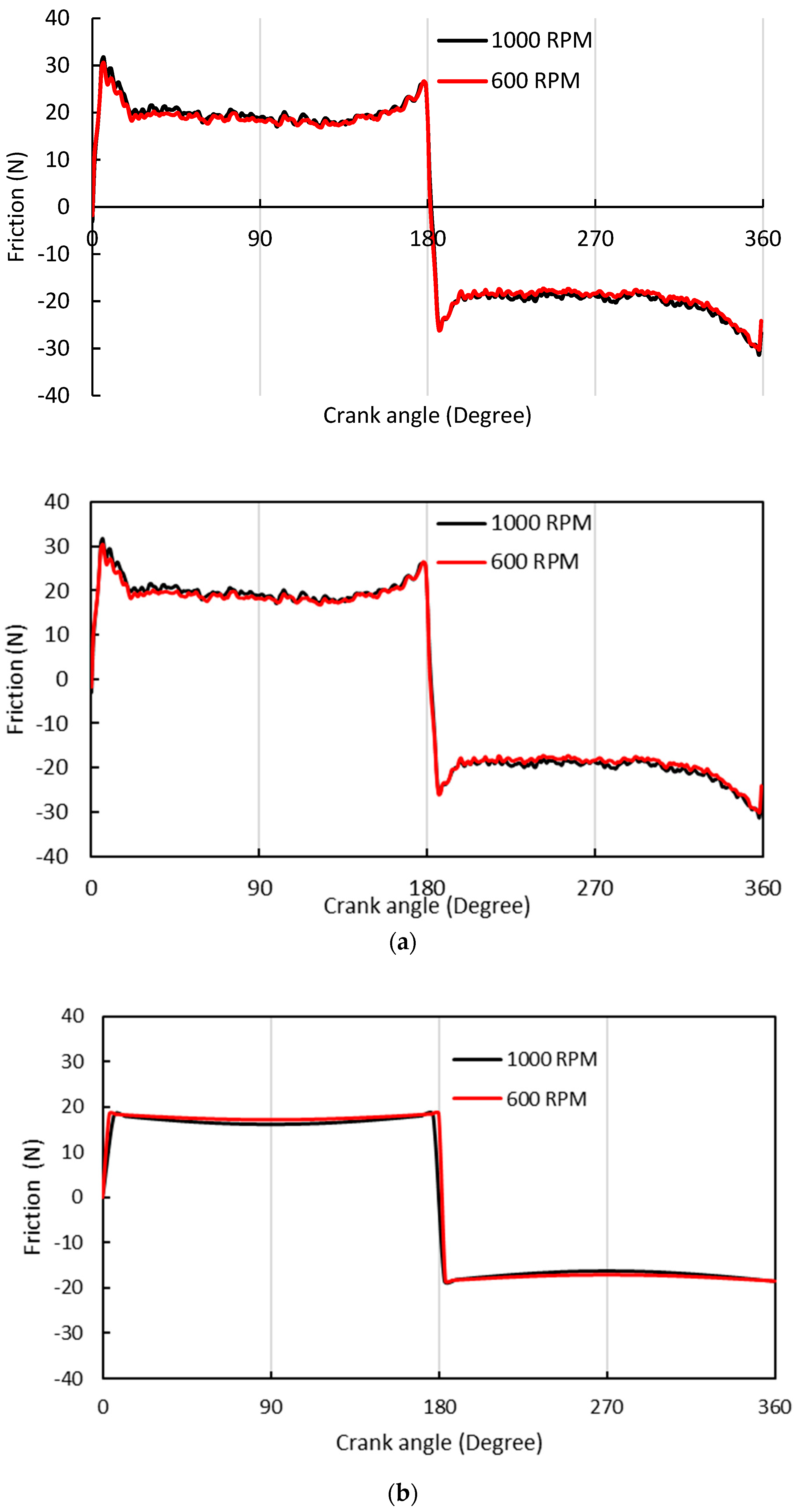

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Roman symbols: | |

| Real contact area | |

| Ring contact half-width | |

| Young’s Moduli of elasticity of contacting surfaces | |

| Total contact friction | |

| Boundary friction | |

| Viscous contact friction | |

| Lubricant film thickness | |

| Minimum film thickness | |

| Ring circumferential length | |

| Ring crown radius | |

| Crank-pin radius | |

| Time | |

| Sliding velocity | |

| Load carried by asperity interactions | |

| Hydrodynamic contact reaction | |

| Total contact load | |

| Axial direction (direction of lubricant entraining motion) | |

| Greek symbols: | |

| Average asperity tip radius | |

| Dynamic viscosity of the lubricant | |

| Asperity density per unit area | |

| Stribeck’s oil film parameter | |

| Poisson’s ratio of contacting solids | |

| Coefficient of friction | |

| Root mean square roughness of counter faces | |

| Characteristic shear stress of the lubricant | |

| Angular velocity | |

| Coefficient of boundary shear strength of asperities |

References

- Profito, F.J.; Tomanik, E.; Zachariadis, D.C. Effect of cylinder liner wear on the mixed lubrication regime of TLOCRs. Tribol. Int. 2016, 93, 723–732. [Google Scholar] [CrossRef]

- Söderfjäll, M.; Almqvist, A.; Larsson, R. A model for twin land oil control rings. Tribol. Int. 2016, 95, 475–482. [Google Scholar] [CrossRef]

- Söderfjäll, M.; Almqvist, A.; Larsson, R. Component test for simulation of piston ring–cylinder liner friction at realistic speeds. Tribol. Int. 2016, 104, 57–63. [Google Scholar] [CrossRef]

- Liu, Y.; Kim, D.; Westerfield, Z.; Meng, Z.; Tian, T. A comprehensive study of the effects of honing patterns on twin-land oil control rings friction using both a numerical model a floating liner engine. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 229–255. [Google Scholar] [CrossRef]

- Westerfield, Z.; Tian, T.; Liu, Y.; Kim, D. A study of the friction of oil control rings using the floating liner engine. SAE Int. J. Engines 2016, 9, 1807–1824. [Google Scholar] [CrossRef]

- Kikuhara, K.; Koeser, P.S.; Tian, T. Effects of a cylinder liner microstructure on lubrication condition of a twin-land oil control ring and a piston skirt of an internal combustion engine. Tribol. Lett. 2022, 70, 1–15. [Google Scholar] [CrossRef]

- Tian, T.; Wong, V.W.; Heywood, J.B. Modeling the dynamics and lubrication of three piece Oil control rings is internal combustion engines. SAE Trans. 1998, 107, 1989–2006. [Google Scholar]

- Zhang, W.; Ahling, S.; Tian, T. Modeling the Three Piece Oil Control Ring Dynamics and Oil Transport in Internal Combustion Engines; SAE Technical Paper No. 2021-01-0345; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Li, M.; Tian, T. Effect of blowby on the leakage of the three-piece oil control ring and subsequent oil transport in upper ring-pack regions in internal combustion engines. Lubricants 2022, 10, 250. [Google Scholar] [CrossRef]

- Mochizuki, K.; Sasaki, R.; Iijima, N.; Usui, M. Prediction and Experimental Verification for Oil Transport Volume around Three-Piece Type Oil Control Ring Affecting Lubricating Oil Consumption. SAE Int. J. Adv. Curr. Pract. Mobil. 2022, 5, 595–609. [Google Scholar] [CrossRef]

- Tomlinson, K.; Davison, S.; King, P.; Howell-Smith, S.; Slatter, T.; Morris, N. On the Role of Friction Modifier Additives in the Oil Control Ring and Piston Liner Contact. J. Tribol. 2024, 146, 042201. [Google Scholar] [CrossRef]

- Cheng, W.K.; Hamrin, D.; Heywood, J.B.; Hochgreb, S.; Min, K.; Norris, M. An Overview of Hydrocarbon Emissions Mechanisms in Spark-Ignition Engines; SAE International: Warrendale, PA, USA, 1993. [Google Scholar]

- Tung, S.C.; Gao, H. Tribological investigation of piston ring coatings operating in an alternative fuel and engine oil blend. Tribol. Trans. 2002, 45, 381–389. [Google Scholar] [CrossRef]

- Tung, S.C.; Gao, H. Tribological characteristics and surface interaction between piston ring coatings and a blend of energy-conserving oils and ethanol fuels. Wear 2003, 255, 1276–1285. [Google Scholar] [CrossRef]

- Costa, H.L.; Cousseau, T.; Souza, R.M. Current knowledge on friction, lubrication, and wear of ethanol-fuelled engines—A review. Lubricants 2023, 11, 292. [Google Scholar] [CrossRef]

- Ajayi, O.O.; Lorenzo-Martin, C.; Fenske, G.; Corlett, J.; Murphy, C.; Przesmitzki, S. Bioderived fuel blend dilution of marine engine oil and impact on friction and wear behavior. J. Tribol. 2016, 138, 021603. [Google Scholar] [CrossRef]

- dos Santos, R.M.; Alves, S.M. Effect of fuel contamination on tribological properties of flex-fuel engines lubricating oils. Surf. Topogr. Metrol. Prop. 2022, 10, 044004. [Google Scholar] [CrossRef]

- Khuong, L.S.; Masjuki, H.H.; Zulkifli, N.W.M.; Mohamad, E.N.; Kalam, M.A.; Alabdulkarem, A.; Arslan, A.; Mosarof, M.H.; Syahir, A.Z.; Jamshaid, M. Effect of gasoline–bioethanol blends on the properties and lubrication characteristics of commercial engine oil. RSC Adv. 2017, 7, 15005–15019. [Google Scholar] [CrossRef]

- De Silva, P.R.; Priest, M.; Lee, P.M.; Coy, R.C.; Taylor, R.I. Tribometer investigation of the frictional response of piston rings when lubricated with the separated phases of lubricant contaminated with the gasoline engine biofuel ethanol and water. Tribol. Lett. 2011, 43, 107–120. [Google Scholar] [CrossRef]

- Costa, H.L.; Spikes, H.A. Impact of ethanol on the formation of antiwear tribofilms from engine lubricants. Tribol. Int. 2016, 93, 364–376. [Google Scholar] [CrossRef]

- Costa, H.L.; Evangelista, K.S.; Cousseau, T.; Acero, J.S.R.; Kessler, F. Use of XANES and XPS to investigate the effects of ethanol contamination on anti-wear ZDDP tribofilms. Tribol. Int. 2021, 159, 106997. [Google Scholar] [CrossRef]

- Lenauer, C.; Tomastik, C.; Wopelka, T.; Jech, M. Piston ring wear and cylinder liner tribofilm in tribotests with lubricants artificially altered with ethanol combustion products. Tribol. Int. 2015, 82, 415–422. [Google Scholar] [CrossRef]

- Banerji, A.; Lukitsch, M.J.; Alpas, A.T. Friction reduction mechanisms in cast iron sliding against DLC: Effect of biofuel (E85) diluted engine oil. Wear 2016, 368, 196–209. [Google Scholar] [CrossRef]

- Cousseau, T.; Acero, J.S.R.; Sinatora, A. Tribological response of fresh and used engine oils: The effect of surface texturing, roughness and fuel type. Tribol. Int. 2016, 100, 60–69. [Google Scholar] [CrossRef]

- Hamdan, S.H.; Chong, W.W.F.; Ng, J.H.; Chong, C.T.; Rajoo, S. A study of the tribological impact of biodiesel dilution on engine lubricant properties. Process Saf. Environ. Prot. 2017, 112, 288–297. [Google Scholar] [CrossRef]

- Forder, M.D.; Morris, N.; King, P.; Balakrishnan, S.; Howell-Smith, S. An experimental investigation of low viscosity lubricants on three piece oil control rings cylinder liner friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 2261–2271. [Google Scholar] [CrossRef]

- Haddad, S.D.; Tjan, K.T. An analytical study of offset piston and crankshaft designs and the effect of oil film on piston slap excitation in a diesel engine. Mech. Mach. Theory 1995, 30, 271–284. [Google Scholar] [CrossRef]

- Gohar, R.; Rahnejat, H. Fundamentals of Tribology, 3rd ed.; World Scientific: Singapore, 2018. [Google Scholar]

- Furuhama, S.; Takiguchi, M.; Tomizawa, K. Effect of piston and piston ring designs on the piston friction forces in diesel engines. SAE Trans. 1981, 3018–3030. [Google Scholar]

- Greenwood, J.A.; Tripp, J.H. The contact of two nominally flat rough surfaces. Proc. Inst. Mech. Eng. J. Mech. Eng. Sci. 1970, 185, 625–633. [Google Scholar] [CrossRef]

- Gore, M.; Morris, N.; Rahmani, R.; Rahnejat, H.; King, P.D.; Howell-Smith, S. A combined analytical-experimental investigation of friction in cylinder liner inserts under mixed and boundary regimes of lubrication. Lubr. Sci. 2017, 29, 293–316. [Google Scholar] [CrossRef]

- Dolatabadi, N.; Forder, M.; Morris, N.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S. Influence of advanced cylinder coatings on vehicular fuel economy and emissions in piston compression ring conjunction. Appl. Energy 2020, 259, 114129. [Google Scholar] [CrossRef]

- Leighton, M.; Morris, N.; Rahmani, R.; Rahnejat, H. Surface specific asperity model for prediction of friction in boundary and mixed regimes of lubrication. Meccanica 2017, 52, 21–33. [Google Scholar] [CrossRef]

- Dolatabadi, N.; Rahmani, R.; Rahnejat, H.; Garner, C.P.; Brunton, C. Performance of poly alpha olefin nanolubricant. Lubricants 2020, 8, 17. [Google Scholar] [CrossRef]

- Rahmani, R.; Rahnejat, H. Enhanced performance of optimised partially textured load bearing surfaces. Tribol. Int. 2018, 117, 272–282. [Google Scholar] [CrossRef]

- Eyring, H. The activated complex in chemical reactions. J. Chem. Phys. 1935, 3, 107–115. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Evans, D.C.B. The shear properties of Langmuir-blodgett layers. Proc. Roy. Soc. Lond. Ser. A Math. Phys. Sci. 1982, 380, 389–407. [Google Scholar]

- Frottier, V.; Heywood, J.B.; Hochgreb, S. Measurement of gasoline absorption into engine lubricating oil. SAE Trans. 1996, 1114–1121. [Google Scholar]

- Smith, O.M.E. In-Cylinder Fuel and Lubricant Effects on Gasoline Engine Friction. Ph.D. Dissertation, University of Leeds, Leeds, UK, 2007. [Google Scholar]

- Shayler, P.J.; Winborn, L.D.; Scarisbrick, A. The Build-Up of Oil Dilution by Gasoline and the Influence of Vehicle Usage Pattern; SAE Technical Paper 2000-01-2838; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Kollman, K.; Gürtler, T.; Land, K.; Warnecke, W.; Müller, H.D. Extended Oil Drain Intervals—Conservation of Resources or Reduction of Engine Life (Part II). SAE Trans. 1998, 107, 738–758. [Google Scholar]

- Bergstra, R.J.; Givens, W.A.; Maxwell, W.L.; Richman, W.H. Advanced Synthetic Passenger Vehicle Engine Oils for Extended Oil Drain Performance. SAE Trans. 1998, 107, 759–772. [Google Scholar]

- Taylor, R.I. Fuel-lubricant interactions: Critical review of recent work. Lubricants 2021, 9, 92. [Google Scholar] [CrossRef]

- Colli, G.B.; Castejon, D.; Salvetti, A.; Volpato, O. Heated Injector Cold Start System for Flex-Fuel Motorcycles; SAE Technical Paper No. 2010-36-0156; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Huang, Y.; Huang, S.; Huang, R.; Hong, G. Spray and evaporation characteristics of ethanol and gasoline direct injection in non-evaporating, transition and flash-boiling conditions. Energy Convers. Manag. 2016, 108, 68–77. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Density | 855 @15 °C | kg·m−3 |

| Kinematic viscosity | 67.61 @40 °C, 12.25 @100 °C | cSt |

| Pressure–viscosity coefficient | 10 | GPa−1 |

| Characteristic shear stress | 2 | MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morris, N.; Byrne, S.; Forder, M.; Dolatabadi, N.; King, P.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S. The Effect of Ethanol Fuel-Diluted Lubricants on the Friction of Oil Control Ring Conjunction: A Combined Analytical and Experimental Investigation. Lubricants 2024, 12, 150. https://doi.org/10.3390/lubricants12050150

Morris N, Byrne S, Forder M, Dolatabadi N, King P, Rahmani R, Rahnejat H, Howell-Smith S. The Effect of Ethanol Fuel-Diluted Lubricants on the Friction of Oil Control Ring Conjunction: A Combined Analytical and Experimental Investigation. Lubricants. 2024; 12(5):150. https://doi.org/10.3390/lubricants12050150

Chicago/Turabian StyleMorris, Nicholas, Sean Byrne, Michael Forder, Nader Dolatabadi, Paul King, Ramin Rahmani, Homer Rahnejat, and Sebastian Howell-Smith. 2024. "The Effect of Ethanol Fuel-Diluted Lubricants on the Friction of Oil Control Ring Conjunction: A Combined Analytical and Experimental Investigation" Lubricants 12, no. 5: 150. https://doi.org/10.3390/lubricants12050150

APA StyleMorris, N., Byrne, S., Forder, M., Dolatabadi, N., King, P., Rahmani, R., Rahnejat, H., & Howell-Smith, S. (2024). The Effect of Ethanol Fuel-Diluted Lubricants on the Friction of Oil Control Ring Conjunction: A Combined Analytical and Experimental Investigation. Lubricants, 12(5), 150. https://doi.org/10.3390/lubricants12050150