Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient

Abstract

1. Introduction

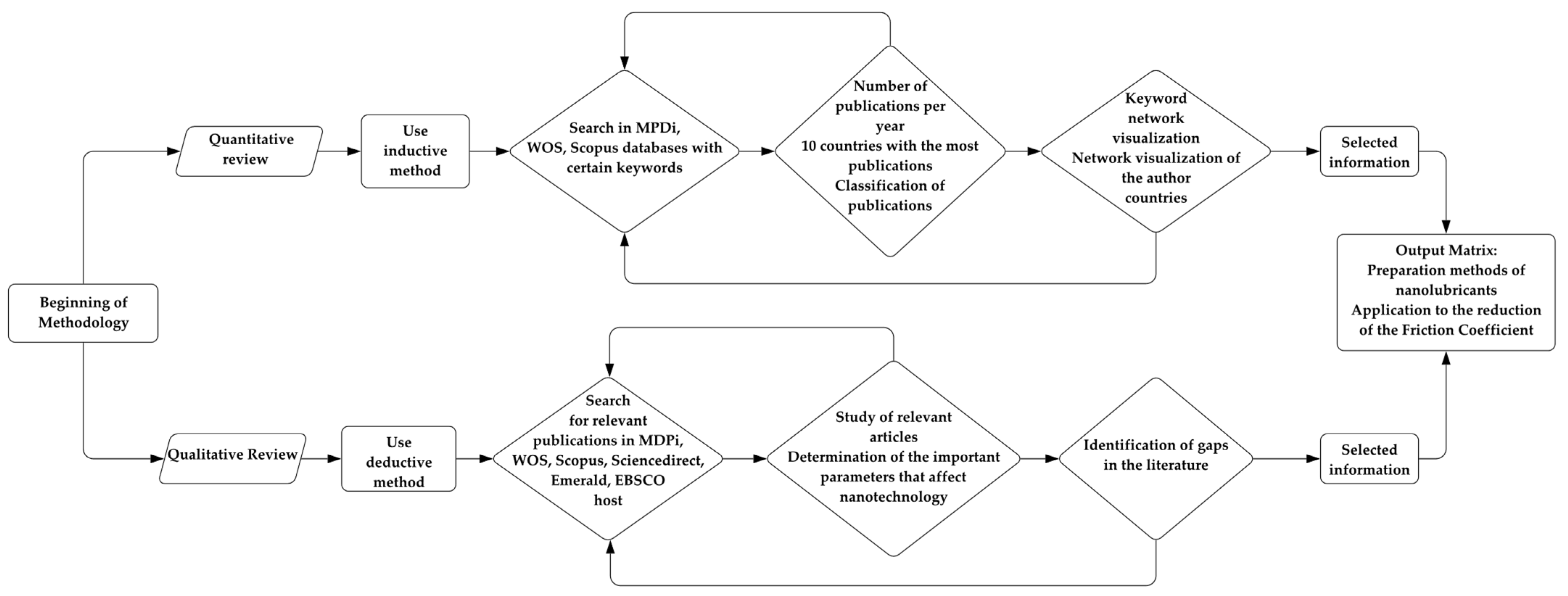

2. Materials and Methods

3. Preparation of Nano-Lubricants

3.1. Methods for the Preparation of Nano-Lubricants

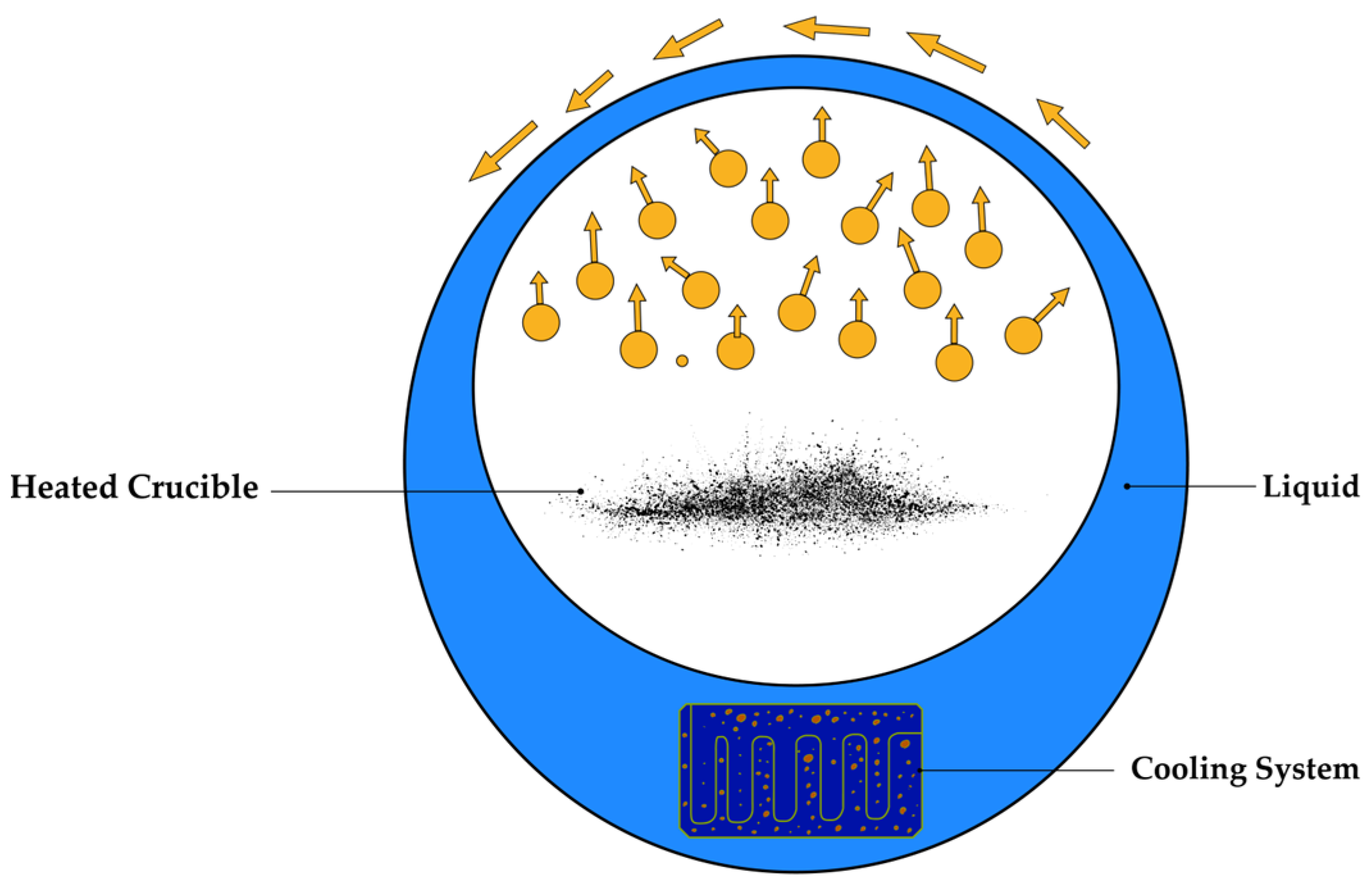

3.1.1. One-Step Method

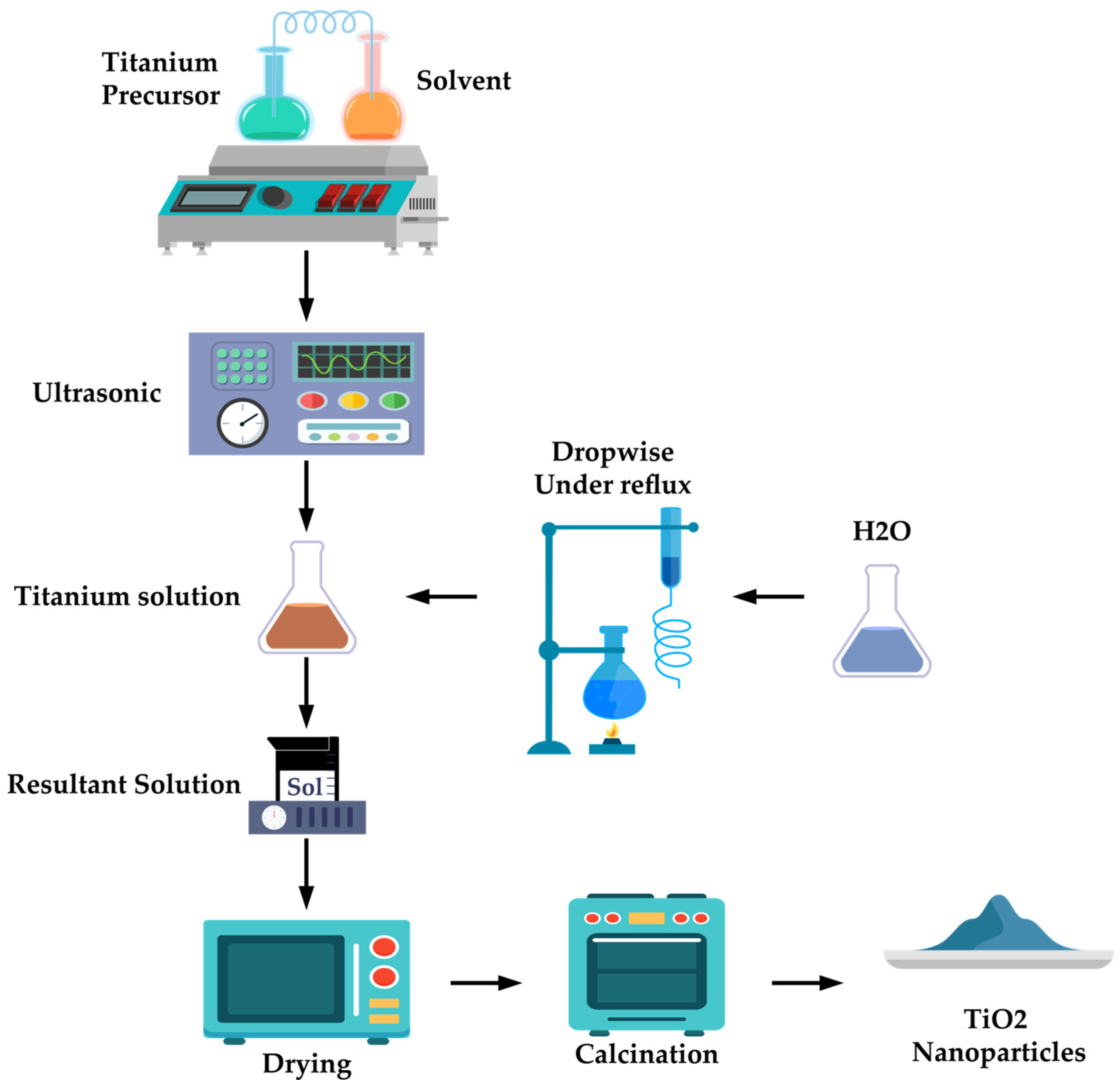

3.1.2. Two-Step Method

3.2. Nanofluid Stability

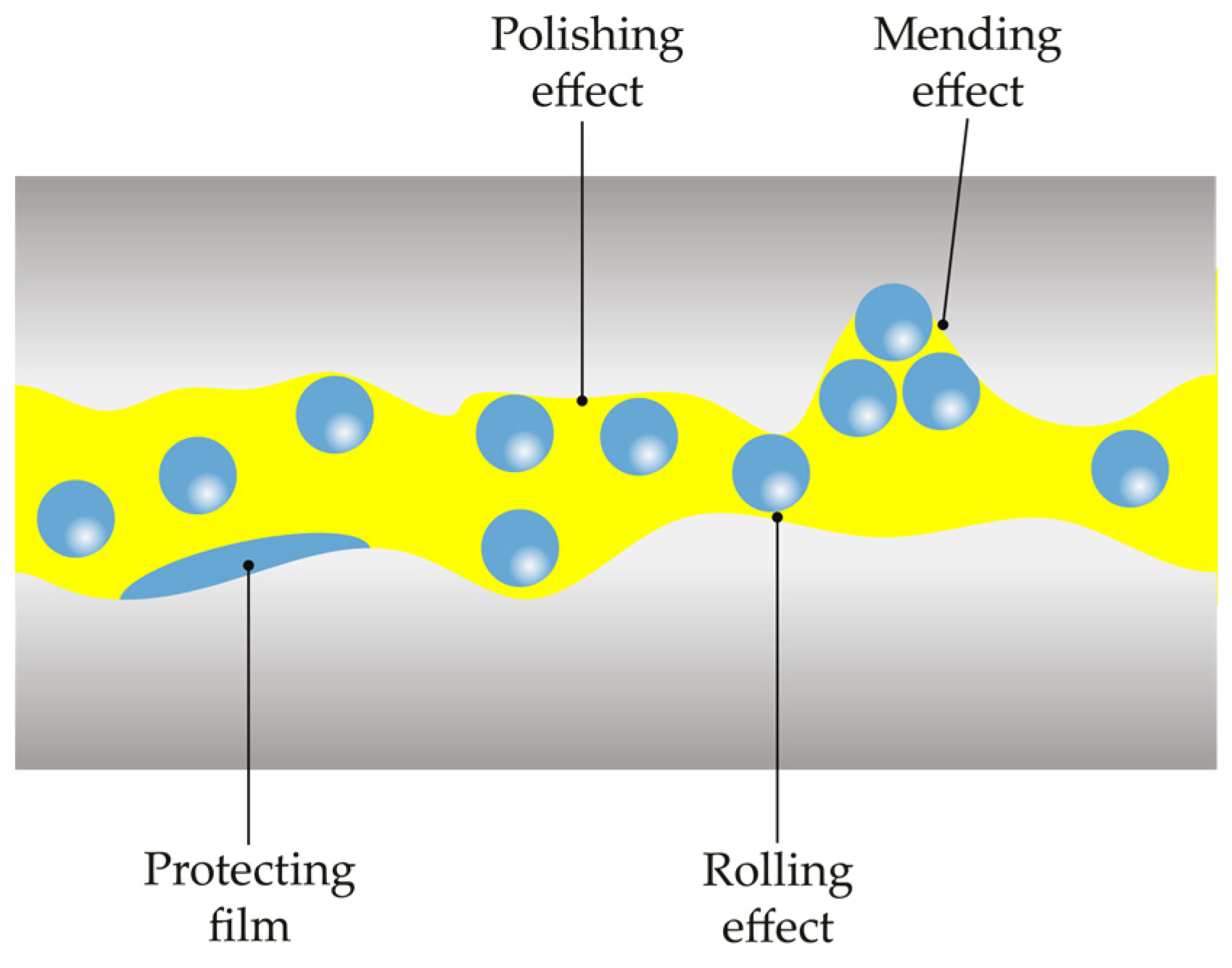

4. Influence of Nanoparticles on Lubricants

5. Result Analysis

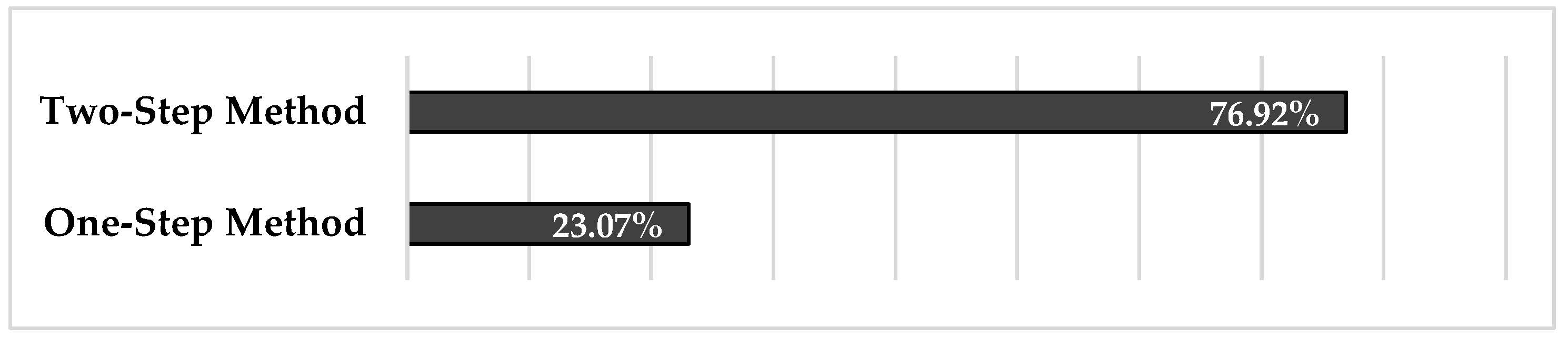

5.1. Preparation Methods

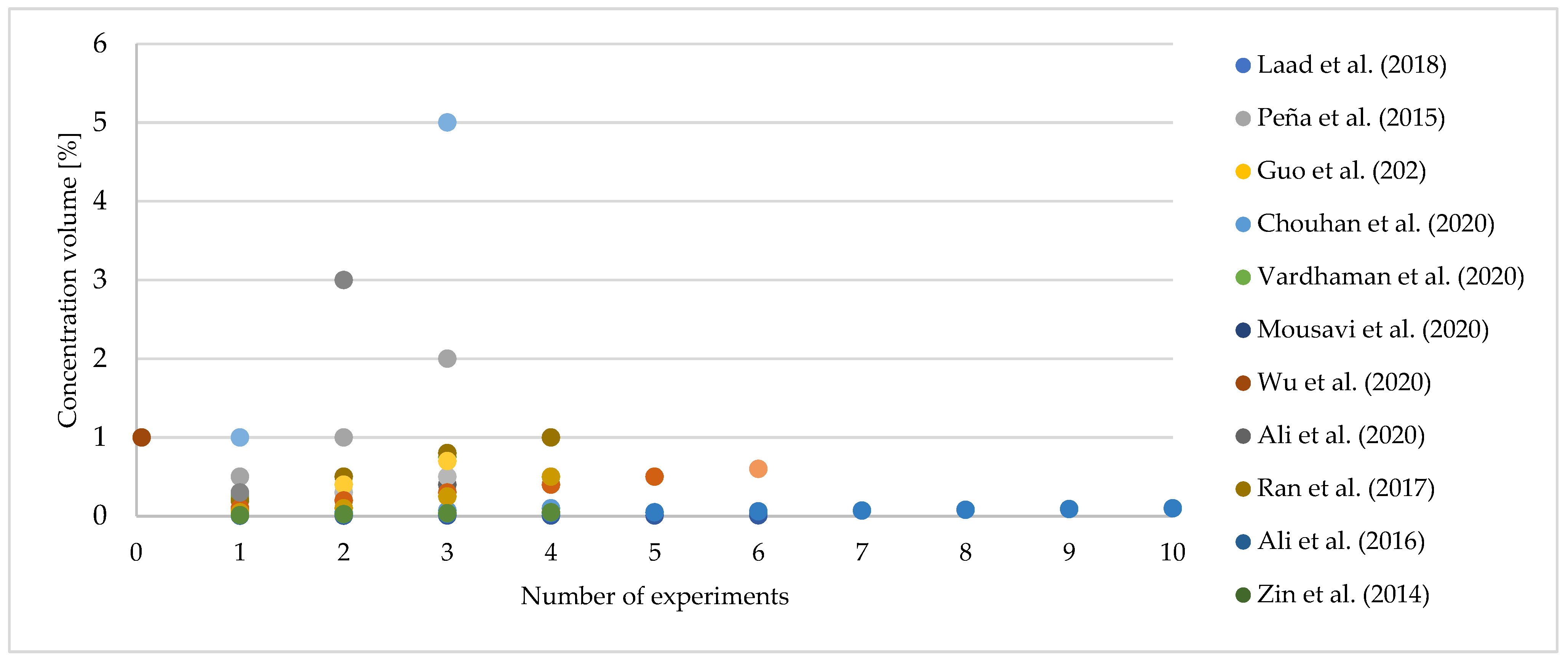

5.2. Reduction in the Coefficient of Friction

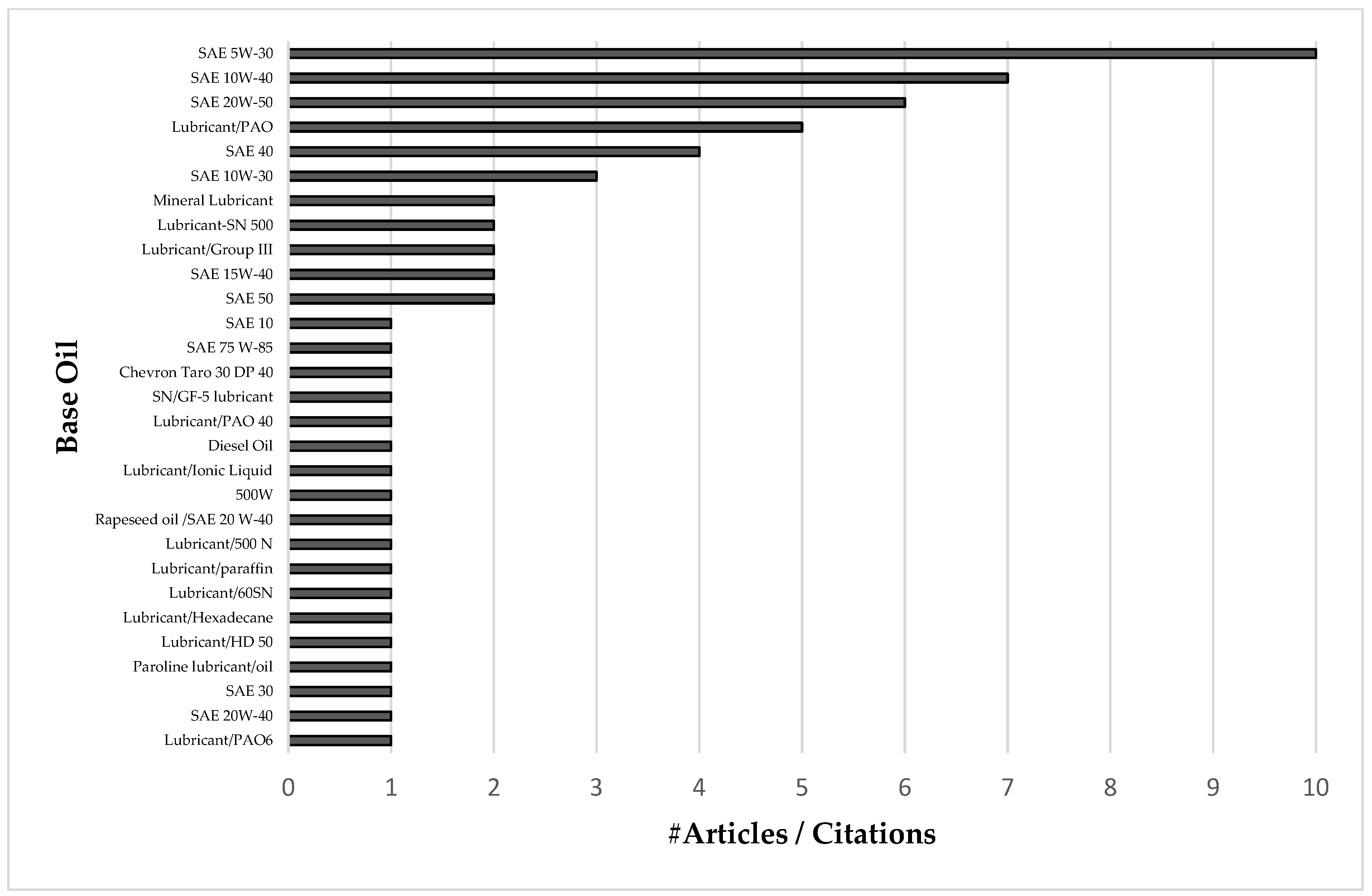

5.3. Base Lubricants

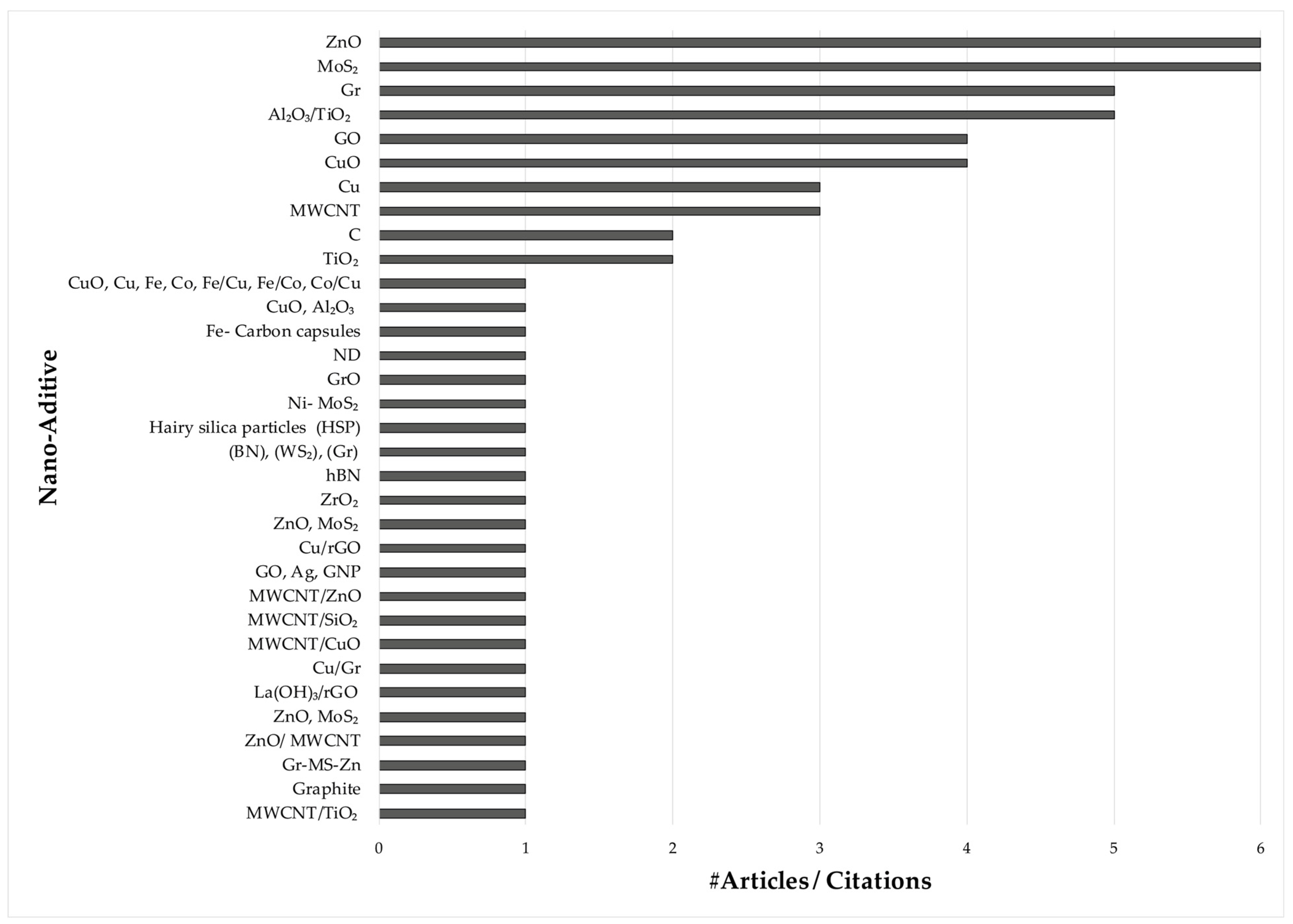

5.4. Nano-Additives

6. Discussion

7. Conclusions

8. Future Perspectives

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pawashe, A.; Kalkundri, S.; Chavan, C.; Arunachalam, R. Fault Diagnosis of Engine Lubrication System. In Proceedings of the 2017 International conference on Microelectronic Devices, Circuits and Systems (ICMDCS), Vellore, India, 10–12 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Daud, S.M.; Najib, M.S.; Zahed, N. Classification of Lubricant Oil Odor-Profile Using Case-Based Reasoning. In Proceedings of the 2016 IEEE Conference on Systems, Process and Control (ICSPC 2016), Melaka, Malaysia, 16–18 December 2016; Institute of Electrical and Electronics Engineers Inc.: Chennai, India, 2017; pp. 207–212. [Google Scholar]

- Garud, V.U.; Gavhane, K.; Tiwari, H.U.; Bhoite, S.; Sangale, N.; Patil, S.; Ghadage, S. Integrated Wireless Online Oil Condition Monitoring System for i C Engine. In Proceedings of the International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT 2016), Chennai, India, 3–5 March 2016; pp. 209–214. [Google Scholar]

- Sharma, S.; Das, S.; Virmani, J.; Sharma, M.; Singh, S.; Das, A. IoT Based Dipstick Type Engine Oil Level and Impurities Monitoring System: A Portable Online Spectrophotometer. In Proceedings of the 2019 4th International Conference on Internet of Things: Smart Innovation and Usages (IoT-SIU), Ghaziabad, India, 18–19 April 2019; pp. 1–4. [Google Scholar]

- Kamal, R.S.; Ahmed, N.S.; Nasser, A.M. Study the Efficiency of Some Compounds as Lubricating Oil Additives. Appl. Petrochem. Res. 2013, 3, 1–8. [Google Scholar] [CrossRef]

- Idros, M.F.M.; Ali, S.; Islam, M.S. Optical Behavior of Transmission Oil Lubricant for Degradation Monitoring. In Proceedings of the 2011 IEEE Student Conference on Research and Development (SCOReD 2011), Cyberjaya, Malaysia, 19–20 December 2011; pp. 225–228. [Google Scholar]

- Bravo-Imaz, I.; Garcia-Arribas, A.; Gorritxategi, E.; Arnaiz, A.; Barandiaran, J.M. Magnetoelastic Viscosity Sensor for On-Line Status Assessment of Lubricant Oils. IEEE Trans. Magn. 2013, 49, 113–116. [Google Scholar] [CrossRef]

- Kuzema, O.S.; Kuzema, P.O. Effect of the Duration of Car Engine Operation on the Mechanical Contaminants in Its Lubricant. In Proceedings of the 2017 IEEE 7th International Conference Nanomaterials: Application & Properties (NAP), Odessa, Ukraine, 10–15 September 2017; pp. 01PCSI03-1–01PCSI03-4. [Google Scholar]

- Sanga, R.; Sivaramakrishna, M.; Srinivasan, V.S.; Prabhakara Rao, G. Design and Development of Opto-Resistive Type Quasi-Digital Sensor and Instrument to In-Situ Monitoring of the Quality of Lubricant Oil. In Proceedings of the INDICON 2018—15th IEEE India Council International Conference, Coimbatore, India, 16–18 December 2018. [Google Scholar]

- Li, Y.; Zuo, Y.; Yi, X.; Liu, H. Research on Engine Lubricant Detection Technology Based on On-Line Visual Technology. In Proceedings of the 2021 IEEE International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Weihai, China, 13–15 August 2021; pp. 87–93. [Google Scholar]

- Holmberg, K.; Erdemir, A. The Impact of Tribology on Energy Use and CO2 Emission Globally and in Combustion Engine and Electric Cars. Tribol. Int. 2019, 135, 389–396. [Google Scholar] [CrossRef]

- Yu, H.-L.; Xu, Y.; Shi, P.-J.; Xu, B.-S.; Wang, X.-L.; Liu, Q. Tribological Properties and Lubricating Mechanisms of Cu Nanoparticles in Lubricant. Trans. Nonferrous Met. Soc. China 2008, 18, 636–641. [Google Scholar] [CrossRef]

- Ghaednia, H.; Hossain, M.S.; Jackson, R.L. Tribological Performance of Silver Nanoparticle–Enhanced Polyethylene Glycol Lubricants. Tribol. Trans. 2016, 59, 585–592. [Google Scholar] [CrossRef]

- Das, L.; Aggarwal, M.; Rajkumar, K.; Aravindan, S.; Gupta, M. Tribological Properties of Magnesium Nano-Alumina Composites under Nano-Graphite Lubrication. Tribol. Trans. 2012, 55, 334–344. [Google Scholar] [CrossRef]

- Laad, M.; Jatti, V.K.S. Titanium Oxide Nanoparticles as Additives in Engine Oil. J. King Saud. Univ.-Eng. Sci. 2018, 30, 116–122. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, G.; Zhao, Q.; Gong, K.; Wang, X.; Liu, W.; Liu, W. Investigating the Tribological Performance of Nanosized MoS2 on Graphene Dispersion in Perfluoropolyether under High Vacuum. RSC Adv. 2016, 6, 98606–98610. [Google Scholar] [CrossRef]

- Sgroi, M.F.; Asti, M.; Gili, F.; Deorsola, F.A.; Bensaid, S.; Fino, D.; Kraft, G.; Garcia, I.; Dassenoy, F. Engine Bench and Road Testing of an Engine Oil Containing MoS2 Particles as Nano-Additive for Friction Reduction. Tribol. Int. 2017, 105, 317–325. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lapsker, I.; Volovik, Y.; Nepomnyashchy, O.; Lvovsky, M.; Popovitz-Biro, R.; Feldman, Y.; Tenne, R. Tribological Properties of WS2 Nanoparticles under Mixed Lubrication. Wear 2003, 255, 785–793. [Google Scholar] [CrossRef]

- Kedzierski, M.A. Viscosity and Density of Aluminum Oxide Nanolubricant. Int. J. Refrig. 2013, 36, 1333–1340. [Google Scholar] [CrossRef]

- Ingole, S.; Charanpahari, A.; Kakade, A.; Umare, S.S.; Bhatt, D.V.; Menghani, J. Tribological Behavior of Nano TiO2 as an Additive in Base Oil. Wear 2013, 301, 776–785. [Google Scholar] [CrossRef]

- Koide, T.; Fukami, T.; Hisada, H.; Inoue, M.; Carriere, J.; Heyler, R.; Katori, N.; Okuda, H.; Goda, Y. Identification of Pseudopolymorphism of Magnesium Stearate by Using Low-Frequency Raman Spectroscopy. Org. Process Res. Dev. 2016, 20, 1906–1910. [Google Scholar] [CrossRef]

- Lee, C.G.; Hwang, Y.J.; Choi, Y.M.; Lee, J.K.; Choi, C.; Oh, J.M. A Study on the Tribological Characteristics of Graphite Nano Lubricants. Int. J. Precis. Eng. Manuf. 2009, 10, 85–90. [Google Scholar] [CrossRef]

- Ramón-Raygoza, E.D.; Rivera-Solorio, C.I.; Giménez-Torres, E.; Maldonado-Cortés, D.; Cardenas-Alemán, E.; Cué-Sampedro, R. Development of Nanolubricant Based on Impregnated Multilayer Graphene for Automotive Applications: Analysis of Tribological Properties. Powder Technol. 2016, 302, 363–371. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Afrand, M.; Rostamian, S.H.; Toghraie, D. Examination of Rheological Behavior of MWCNTs/ZnO-SAE40 Hybrid Nano-Lubricants under Various Temperatures and Solid Volume Fractions. Exp. Therm. Fluid. Sci. 2017, 80, 384–390. [Google Scholar] [CrossRef]

- Afrand, M.; Nazari Najafabadi, K.; Akbari, M. Effects of Temperature and Solid Volume Fraction on Viscosity of SiO2-MWCNTs/SAE40 Hybrid Nanofluid as a Coolant and Lubricant in Heat Engines. Appl. Therm. Eng. 2016, 102, 45–54. [Google Scholar] [CrossRef]

- Kotia, A.; Chowdary, K.; Srivastava, I.; Ghosh, S.K.; Ali, M.K.A. Carbon Nanomaterials as Friction Modifiers in Automotive Engines: Recent Progress and Perspectives. J. Mol. Liq. 2020, 310, 113200. [Google Scholar] [CrossRef]

- Das, S.K.; Putra, N.; Thiesen, P.; Roetzel, W. Temperature Dependence of Thermal Conductivity Enhancement for Nanofluids. J. Heat. Transf. 2003, 125, 567–574. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Ghazali, M.F. Tribological Performance of Al2O3–SiO2/PAG Composite Nanolubricants for Application in Air-Conditioning Compressor. Wear 2022, 492–493, 204238. [Google Scholar] [CrossRef]

- Singh, S.; Chattopadhyaya, S.; Pramanik, A.; Gupta, N. Influence of Nano-Particle on the Wear Behaviour of Thin Film Coatings A Review. Int. J. Appl. Eng. Res. 2018, 13, 4053–4058. [Google Scholar]

- Igor, U.; Dzhardimalieva, G. The Conjugate Thermolysis—Thermal Polymerization of Metal Chelate Monomers and Thermolysis of Polymers Formed In Situ. In Nanomaterials Preparation by Thermolysis of Metal Chelates; Springer: Berlin/Heidelberg, Germany, 2018; pp. 351–423. ISBN 978-3-319-93404-4. [Google Scholar]

- Du, F.; Li, C.; Li, D.; Sa, X.; Yu, Y.; Li, C.; Yang, Y.; Wang, J. Research Progress Regarding the Use of Metal and Metal Oxide Nanoparticles as Lubricant Additives. Lubricants 2022, 10, 196. [Google Scholar] [CrossRef]

- Mello, V.S.; Faria, E.A.; Alves, S.M.; Scandian, C. Enhancing Cuo Nanolubricant Performance Using Dispersing Agents. Tribol. Int. 2020, 150, 106338. [Google Scholar] [CrossRef]

- Wang, S.; Chen, D.; Hong, Q.; Gui, Y.; Cao, Y.; Ren, G.; Liang, Z. Surface Functionalization of Metal and Metal Oxide Nanoparticles for Dispersion and Tribological Applications—A Review. J. Mol. Liq. 2023, 389, 122821. [Google Scholar] [CrossRef]

- Nyholm, N.; Espallargas, N. Functionalized Carbon Nanostructures as Lubricant Additives—A Review. Carbon 2023, 201, 1200–1228. [Google Scholar] [CrossRef]

- Zou, J.; Wu, J.; Wang, Y.; Deng, F.; Jiang, J.; Zhang, Y.; Liu, S.; Li, N.; Zhang, H.; Yu, J.; et al. Additive-Mediated Intercalation and Surface Modification of MXenes. Chem. Soc. Rev. 2022, 51, 2972–2990. [Google Scholar] [CrossRef] [PubMed]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-Containing Nanomaterials as Lubricant Additives: State-of-the-Art and Future Development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef]

- Guaregua M., J.A.; Squitieri, E.; Mujica, V. A Computational Study of the Stability Ratios of Spherical Coloidal Particles. J. Mol. Struct. THEOCHEM 2006, 769, 165–170. [Google Scholar] [CrossRef]

- Yang, L.; Ji, W.; Mao, M.; Huang, J.N. An Updated Review on the Properties, Fabrication and Application of Hybrid-Nanofluids along with Their Environmental Effects. J. Clean. Prod. 2020, 257, 120408. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of Nanoparticles in Lubricating Oil: A Critical Review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Azman, N.F.; Samion, S. Dispersion Stability and Lubrication Mechanism of Nanolubricants: A Review. Int. J. Precis. Eng. Manuf.-Green. Technol. 2019, 6, 393–414. [Google Scholar] [CrossRef]

- Jamal-Abad, M.T.; Zamzamian, A.; Dehghan, M. Experimental Studies on the Heat Transfer and Pressure Drop Characteristics of Cu-Water and Al-Water Nanofluids in a Spiral Coil. Exp. Therm. Fluid. Sci. 2013, 47, 206–212. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, R.; Song, W.; Liu, L.; Li, J. One-Step Method to Prepare Core-Shell Magnetic Nanocomposite Encapsulating Silver Nanoparticles with Superior Catalytic and Antibacterial Activity. J. Colloid. Interface Sci. 2022, 607, 1730–1740. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Liu, H.; Zhou, H.; Hong, M. One-Step Fabrication of Metal Nanoparticles on Polymer Film by Femtosecond LIPAA Method for SERS Detection. Talanta 2021, 228, 122204. [Google Scholar] [CrossRef]

- Yu, W.; France, D.M.; Routbort, J.L.; Choi, S.U.S. Review and Comparison of Nanofluid Thermal Conductivity and Heat Transfer Enhancements. Heat. Transf. Eng. 2008, 29, 432–460. [Google Scholar] [CrossRef]

- Lo, C.H.; Tsung, T.T.; Chen, L.C.; Su, C.H.; Lin, H.M. Fabrication of Copper Oxide Nanofluid Using Submerged Arc Nanoparticle Synthesis System (SANSS). J. Nanoparticle Res. 2005, 7, 313–320. [Google Scholar] [CrossRef]

- Lo, C.H.; Tsung, T.T.; Chen, L.C. Shape-Controlled Synthesis of Cu-Based Nanofluid Using Submerged Arc Nanoparticle Synthesis System (SANSS). J. Cryst. Growth 2005, 277, 636–642. [Google Scholar] [CrossRef]

- Kim, M.; Osone, S.; Kim, T.; Higashi, H.; Seto, T. Synthesis of Nanoparticles by Laser Ablation: A Review. KONA Powder Part. J. 2017, 2017, 80–90. [Google Scholar] [CrossRef]

- Liu, P.S.; Cai, W.P.; Wan, L.X.; Shi, M.D.; Luo, X.D.; Jing, W.P. Fabrication and Characteristics of Rutile TiO2 Nanoparticles Induced by Laser Ablation. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2009, 19, s743–s747. [Google Scholar] [CrossRef]

- Liang, C.H.; Shimizu, Y.; Sasaki, T.; Koshizaki, N. Preparation of Ultrafine TiO2 Nanocrystals via Pulsed-Laser Ablation of Titanium Metal in Surfactant Solution. Appl. Phys. A Mater. Sci. Process 2005, 80, 819–822. [Google Scholar] [CrossRef]

- Cao, J.; Du, B.; Wu, L.; Zhang, W.; Pan, Y.; Ye, Y.; Shen, R.; Zhou, B. The Influence of Aluminum Nanoparticles on the Laser Ablation Characteristics of Hydroxylamine Nitrate-Based Liquid Propellants. Acta Astronaut. 2022, 197, 169–178. [Google Scholar] [CrossRef]

- Chang, H.; Jwo, C.S.; Lo, C.H.; Kao, M.J.; Pai, S.H. A Study of Process Optimization Using the Combined Submerged Arc Nanoparticle Synthesis System for Preparing TiO2 Nanoparticle Suspension. J. Alloys Compd. 2007, 434–435, 668–671. [Google Scholar] [CrossRef]

- Chen, L.C. Preparation of TiO2 Nanoparticles by Submerged Arc Nanoparticle Synthesis System. J. Alloys Compd. 2010, 495, 476–480. [Google Scholar] [CrossRef]

- Chang, H.; Liu, M.K. Fabrication and Process Analysis of Anatase Type TiO2 Nanofluid by an Arc Spray Nanofluid Synthesis System. J. Cryst. Growth 2007, 304, 244–252. [Google Scholar] [CrossRef]

- Chang, H.; Jwo, C.; Fan, P.; Pai, S. Process Optimization and Material Properties for Nanofluid Manufacturing. Int. J. Adv. Manuf. Technol. 2007, 34, 300–306. [Google Scholar] [CrossRef]

- Khan, M.A.; Nayan, N.; Ahmad, M.K.; Fhong, S.C.; Mohamed Ali, M.S.; Mustafa, M.K.; Tahir, M. Interface Study of Hybrid CuO Nanoparticles Embedded ZnO Nanowires Heterojunction Synthesized by Controlled Vapor Deposition Approach for Optoelectronic Devices. Opt. Mater. 2021, 117, 111132. [Google Scholar] [CrossRef]

- Hoyos-Palacio, L.M.; Cuesta Castro, D.P.; Ortiz-Trujillo, I.C.; Botero Palacio, L.E.; Galeano Upegui, B.J.; Escobar Mora, N.J.; Carlos Cornelio, J.A. Compounds of Carbon Nanotubes Decorated with Silver Nanoparticles via In-Situ by Chemical Vapor Deposition (CVD). J. Mater. Res. Technol. 2019, 8, 5893–5898. [Google Scholar] [CrossRef]

- Ali, H.M.; Babar, H.; Shah, T.R.; Sajid, M.U.; Qasim, M.A.; Javed, S. Preparation Techniques of TiO2 Nanofluids and Challenges: A Review. Appl. Sci. 2018, 8, 587. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, C.Y.; Wang, B.X. Effect of Nanoparticle Aggregation on the Thermal Radiation Properties of Nanofluids: An Experimental and Theoretical Study. Int. J. Heat Mass Transf. 2020, 154, 119690. [Google Scholar] [CrossRef]

- Tarafdar, A.; Sirohi, R.; Negi, T.; Singh, S.; Badgujar, P.C.; Shahi, N.C.; Kumar, S.; Sim, S.J.; Pandey, A. Nanofluid research advances: Preparation, characteristics and applications in food processing. Food Res. Int. 2021, 150, 110751. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A Review on Nanofluids: Preparation, Stability Mechanisms, and Applications. J. Nanomater. 2011, 2012, 1–17. [Google Scholar] [CrossRef]

- Supiyani; Agusnar, H.; Sugita, P.; Nainggolan, I. Preparation sodium silicate from rice husk to synthesize silica nanoparticles by sol-gel method for adsorption water in analysis of methamphetamine. S. Afr. J. Chem. Eng. 2022, 40, 80–86. [Google Scholar] [CrossRef]

- Khan, S.A.; Zahera, M.; Khan, I.A.; Khan, M.S.; Azam, A.; Arshad, M.; Syed, A.; Nasif, O.; Elgorban, A.M. Photocatalytic degradation of methyl orange by cadmium oxide nanoparticles synthesized by the sol-gel method. Optik 2022, 251, 168401. [Google Scholar] [CrossRef]

- Shojaei, B.; Miri, R.; Bazyari, A.; Thompson, L.T. Asphaltene adsorption on MgO, CaO, SiO2, and Al2O3 nanoparticles synthesized via the Pechini-type Sol−Gel method. Fuel 2022, 321, 124136. [Google Scholar] [CrossRef]

- Behnajady, M.A.; Eskandarloo, H.; Modirshahla, N.; Shokri, M. Investigation of the effect of sol-gel synthesis variables on structural and photocatalytic properties of TiO2 nanoparticles. Desalination 2011, 278, 10–17. [Google Scholar] [CrossRef]

- Sadetskaya, A.V.; Bobrysheva, N.P.; Osmolowsky, M.G.; Osmolovskaya, O.M.; Voznesenskiy, M.A. Correlative experimental and theoretical characterization of transition metal doped hydroxyapatite nanoparticles fabricated by hydrothermal method. Mater. Charact. 2021, 173, 110911. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Li, G.H.; Jin, Y.X.; Zhang, J.; Zhang, L.D. Hydrothermal synthesis and photoluminescence of TiO2 nanowires. Chem. Phys. Lett. 2002, 365, 300–304. [Google Scholar] [CrossRef]

- Suzuki, Y.; Yoshikawa, S. Synthesis and Thermal Analyses of TiO2-Derived Nanotubes Prepared by the Hydrothermal Method. J. Mater. Res. 2004, 19, 982–985. [Google Scholar] [CrossRef]

- Gan, Y.X.; Jayatissa, A.H.; Yu, Z.; Chen, X.; Li, M. Hydrothermal Synthesis of Nanomaterials. J. Nanomater. 2020, 2020, 1–3. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. Heat transfer enhancement and pressure drop characteristics of TiO2-water nanofluid in a double-tube counter flow heat exchanger. Int. J. Heat Mass Transf. 2009, 52, 2059–2067. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Enhanced thermal conductivity of TiO2—Water based nanofluids. Int. J. Therm. Sci. 2005, 44, 367–373. [Google Scholar] [CrossRef]

- Mo, S.; Chen, Y.; Jia, L.; Luo, X. Investigation on crystallization of TiO2–water nanofluids and deionized water. Appl. Energy 2012, 93, 65–70. [Google Scholar] [CrossRef]

- Tajik, B.; Abbassi, A.; Saffar-Avval, M.; Najafabadi, M.A. Ultrasonic properties of suspensions of TiO2 and Al2O3 nanoparticles in water. Powder Technol. 2012, 217, 171–176. [Google Scholar] [CrossRef]

- Leena, M.; Srinivasan, S. Synthesis and ultrasonic investigations of titanium oxide nanofluids. J. Mol. Liq. 2015, 206, 103–109. [Google Scholar] [CrossRef]

- Sandhya, M.; Ramasamy, D.; Sudhakar, K.; Kadirgama, K.; Harun, W.S.W. Ultrasonication an intensifying tool for preparation of stable nanofluids and study the time influence on distinct properties of graphene nanofluids—A systematic overview. Ultrason. Sonochem. 2021, 73, 105479. [Google Scholar] [CrossRef] [PubMed]

- Imarah, A.O.; Csuka, P.; Bataa, N.; Decsi, B.; Sánta-Bell, E.; Molnár, Z.; Balogh-Weiser, D.; Poppe, L. Magnetically Agitated Nanoparticle-Based Batch Reactors for Biocatalysis with Immobilized Aspartate Ammonia-Lyase. Catalysts 2021, 11, 483. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, S.R.; Kim, D. Thermal Conductivity of Metal-Oxide Nanofluids: Particle Size Dependence and Effect of Laser Irradiation. J. Heat Transf. 2007, 129, 298–307. [Google Scholar] [CrossRef]

- Saleh, R.; Putra, N.; Wibowo, R.E.; Septiadi, W.N.; Prakoso, S.P. Titanium dioxide nanofluids for heat transfer applications. Exp. Therm. Fluid Sci. 2014, 52, 19–29. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sarkar, I.; Behera, D.K.; Pal, S.K.; Chakraborty, S. Experimental investigation on the effect of dispersant addition on thermal and rheological characteristics of TiO2 nanofluid. Powder Technol. 2017, 307, 10–24. [Google Scholar] [CrossRef]

- Wen, D.; Ding, Y. Formulation of nanofluids for natural convective heat transfer applications. Int. J. Heat Fluid Flow 2005, 26, 855–864. [Google Scholar] [CrossRef]

- Bhambi, S.; Agarwal, V.K. Sub Atmospheric Pool Boiling and Experimental Heat Transferof Alumina Nanofluids. Mater. Today Proc. 2019, 18, 1495–1509. [Google Scholar] [CrossRef]

- Wang, X.-Q.; Mujumdar, A.S. Heat transfer characteristics of nanofluids: A review. Int. J. Therm. Sci. 2007, 46, 1–19. [Google Scholar] [CrossRef]

- Khanafer, K.; Vafai, K.; Lightstone, M. Buoyancy-driven heat transfer enhancement in a two-dimensional enclosure utilizing nanofluids. Int. J. Heat Mass Transf. 2003, 46, 3639–3653. [Google Scholar] [CrossRef]

- Wei, B.; Zou, C.; Li, X. Experimental investigation on stability and thermal conductivity of diathermic oil based TiO2 nanofluids. Int. J. Heat Mass Transf. 2017, 104, 537–543. [Google Scholar] [CrossRef]

- Shao, X.; Chen, Y.; Mo, S.; Cheng, Z.; Yin, T. Dispersion Stability of TiO2-H2O Nanofluids Containing Mixed Nanotubes and Nanosheets. Energy Procedia 2015, 75, 2049–2054. [Google Scholar] [CrossRef][Green Version]

- Ghadimi, A.; Saidur, R.; Metselaar, H.S.C. A review of nanofluid stability properties and characterization in stationary conditions. Int. J. Heat Mass Transf. 2011, 54, 4051–4068. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, J.K.; Lee, C.H.; Jung, Y.M.; Cheong, S.I.; Lee, C.G.; Ku, B.C.; Jang, S.P. Stability and thermal conductivity characteristics of nanofluids. Thermochim. Acta 2007, 455, 70–74. [Google Scholar] [CrossRef]

- Liu, Z.-Q.; Ma, J.; Cui, Y.-H. Carbon nanotube supported platinum catalysts for the ozonation of oxalic acid in aqueous solutions. Carbon 2008, 46, 890–897. [Google Scholar] [CrossRef]

- Deng, K.; Chen, S.; Song, H. Chiral recognition of tryptophan enantiomers with UV–Vis spectrophotometry approach by using L-cysteine modified ZnFe2O4 nanoparticles in the presence of Cu2+. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 270, 120847. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Kwon, L.; Kim, S.; Lee, J. Performance evaluation of nano-lubricants of fullerene nanoparticles in refrigeration mineral oil. Curr. Appl. Phys. 2009, 9, e128–e131. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, L.; Sun, J. Production of aqueous colloidal dispersions of carbon nanotubes. J. Colloid Interface Sci. 2003, 260, 89–94. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Kim, J.-W.; Kim, B.G. A New Parameter to Control Heat Transport in Nanofluids: Surface Charge State of the Particle in Suspension. J. Phys. Chem. B 2006, 110, 4323–4328. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-J.; Zhu, D.-S.; Yang, S. Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids. Chem. Phys. Lett. 2009, 470, 107–111. [Google Scholar] [CrossRef]

- Lee, J.-H.; Hwang, K.S.; Jang, S.P.; Lee, B.H.; Kim, J.H.; Choi, S.U.S.; Choi, C.J. Effective viscosities and thermal conductivities of aqueous nanofluids containing low volume concentrations of Al2O3 nanoparticles. Int. J. Heat Mass Transf. 2008, 51, 2651–2656. [Google Scholar] [CrossRef]

- Keblinski, P.; Eastman, J.A.; Cahill, D.G. Nanofluids for Thermal Transport. Mater. Today 2005, 8, 36–44. [Google Scholar] [CrossRef]

- Wei, X.; Zhu, H.; Kong, T.; Wang, L. Synthesis and thermal conductivity of Cu2O nanofluids. Int. J. Heat Mass Transf. 2009, 52, 4371–4374. [Google Scholar] [CrossRef]

- Wang, X.-J.; Li, X.-F. Influence of PH on Nanofluids’ Viscosity and Thermal Conductivity. Chin. Phys. Lett. 2009, 26, 056601. [Google Scholar]

- Liu, M.-S.; Lin, M.C.-C.; Huang, I.-T.; Wang, C.-C. Enhancement of thermal conductivity with carbon nanotube for nanofluids. Int. Commun. Heat Mass Transf. 2005, 32, 1202–1210. [Google Scholar] [CrossRef]

- Liu, M.-S.; Lin, M.C.-C.; Tsai, C.Y.; Wang, C.-C. Enhancement of thermal conductivity with Cu for nanofluids using chemical reduction method. Int. J. Heat Mass Transf. 2006, 49, 3028–3033. [Google Scholar] [CrossRef]

- Hong, K.S.; Hong, T.-K.; Yang, H.-S. Thermal conductivity of Fe nanofluids depending on the cluster size of nanoparticles. Appl. Phys. Lett. 2006, 88, 031901. [Google Scholar] [CrossRef]

- Chan, Y.; Steckel, J.S.; Snee, P.T.; Caruge, J.-M.; Hodgkiss, J.M.; Nocera, D.G.; Bawendi, M.G. Blue semiconductor nanocrystal laser. Appl. Phys. Lett. 2005, 86, 1–3. [Google Scholar] [CrossRef]

- Hajjar, Z.; Rashidi, A.M.; Ghozatloo, A. Enhanced thermal conductivities of graphene oxide nanofluids. Int. Commun. Heat Mass Transf. 2014, 57, 128–131. [Google Scholar] [CrossRef]

- Wei, X.; Wang, L. Synthesis and thermal conductivity of microfluidic copper nanofluids. Particuology 2010, 8, 262–271. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, C.; Tang, Y.; Wang, J.; Ren, B.; Yin, Y. Preparation and thermal conductivity of suspensions of graphite nanoparticles. Carbon 2007, 45, 226–228. [Google Scholar] [CrossRef]

- Oh, D.-W.; Jain, A.; Eaton, J.K.; Goodson, K.E.; Lee, J.S. Thermal conductivity measurement and sedimentation detection of aluminum oxide nanofluids by using the 3ω method. Int. J. Heat Fluid Flow 2008, 29, 1456–1461. [Google Scholar] [CrossRef]

- Wang, H.; Sen, M. Analysis of the 3-omega method for thermal conductivity measurement. Int. J. Heat Mass Transf. 2009, 52, 2102–2109. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Essa, F.A.; Abdelkareem, M.A.A.; Elagouz, A.; Sharshir, S.W. Friction and Wear Reduction Mechanisms of the Reciprocating Contact Interfaces Using Nanolubricant Under Different Loads and Speeds. J. Tribol. 2018, 140, 127862. [Google Scholar] [CrossRef]

- Fei, J.; Zhao, B.; Li, C.; Liu, T.; Zhou, M. Carbon spheres wrapped with 2D covalent organic polymer as lubricant additives for enhancing tribological properties. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 633, 127862. [Google Scholar] [CrossRef]

- Alazemi, A.A. Experimental Study of the Lubrication Mechanism of Micro-Spherical Solid Particles between Flat Surfaces. Lubricants 2021, 9, 81. [Google Scholar] [CrossRef]

- Gu, Y.; Fei, J.; Huang, J.; Zhang, L.; Qu, M.; Zheng, X. Carbon microspheres coated with graphene oxide nanosheets as oil-based additives for tribological applications. Mater. Today Commun. 2020, 25, 101271. [Google Scholar] [CrossRef]

- Shen, Y.; Lei, W.; Tang, W.; Ouyang, T.; Liang, L.; Tian, Z.Q.; Shen, P.K. Synergistic friction-reduction and wear-resistance mechanism of 3D graphene and SiO2 nanoblend at harsh friction interface. Wear 2022, 488–489, 204175. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, L.; Cheng, G.; Yuan, N.; Ding, J.; Pesika, N.S. Water-Based Lubrication of Hard Carbon Microspheres as Lubricating Additives. Tribol. Lett. 2018, 66, 148. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, X.; Li, J. Graphene Lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

- Rabaso, P.; Ville, F.; Dassenoy, F.; Diaby, M.; Afanasiev, P.; Cavoret, J.; Vacher, B.; Le Mogne, T. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 2014, 320, 161–178. [Google Scholar] [CrossRef]

- Greco, A.; Mistry, K.; Sista, V.; Eryilmaz, O.; Erdemir, A. Friction and wear behaviour of boron based surface treatment and nano-particle lubricant additives for wind turbine gearbox applications. Wear 2011, 271, 1754–1760. [Google Scholar] [CrossRef]

- Battez, A.H.; Rico, J.F.; Arias, A.N.; Rodriguez, J.V.; Rodriguez, R.C.; Fernandez, J.D. The tribological behaviour of ZnO nanoparticles as an additive to PAO6. Wear 2006, 261, 256–263. [Google Scholar] [CrossRef]

- Battez, A.H.; González, R.; Felgueroso, D.; Fernández, J.E.; Fernández, M.d.R.; García, M.A.; Peñuelas, I. Wear prevention behaviour of nanoparticle suspension under extreme pressure conditions. Wear 2007, 263, 1568–1574. [Google Scholar] [CrossRef]

- Hernández Battez, A.; González, R.; Viesca, J.L.; Fernández, J.E.; Díaz Fernández, J.M.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Cho, Y.; Park, J.; Ku, B.; Lee, J.; Park, W.-G.; Lee, J.; Kim, S.H. Synergistic effect of a coating and nano-oil lubricant on the tribological properties of friction surfaces. Int. J. Precis. Eng. Manuf. 2012, 13, 97–102. [Google Scholar] [CrossRef]

- Sui, T.; Song, B.; Zhang, F.; Yang, Q. Effect of Particle Size and Ligand on the Tribological Properties of Amino Functionalized Hairy Silica Nanoparticles as an Additive to Polyalphaolefin. J. Nanomater. 2015, 2015, 492401. [Google Scholar] [CrossRef]

- Koshy, C.P.; Rajendrakumar, P.K.; Thottackkad, M.V. Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS 2 nanoparticles at elevated temperatures. Wear 2015, 330–331, 288–308. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Thottackkad, M.V.; Perikinalil, R.K.; Kumarapillai, P.N. Experimental evaluation on the tribological properties of coconut oil by the addition of CuO nanoparticles. Int. J. Precis. Eng. Manuf. 2012, 13, 111–116. [Google Scholar] [CrossRef]

- Azman, S.S.N.; Zulkifli, N.W.M.; Masjuki, H.; Gulzar, M.; Zahid, R. Study of tribological properties of lubricating oil blend added with graphene nanoplatelets. J. Mater. Res. 2016, 31, 1932–1938. [Google Scholar] [CrossRef]

- Schiøtz, J.; Jacobsen, K.W. A Maximum in the Strength of Nanocrystalline Copper. Science 2003, 301, 1357–1359. [Google Scholar] [CrossRef] [PubMed]

- Peña-Parás, L.; Taha-Tijerina, J.; Garza, L.; Maldonado-Cortés, D.; Michalczewski, R.; Lapray, C. Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 2015, 332–333, 1256–1261. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Vacher, B.; Ohmae, N.; Martin, J.M.; Epicier, T. Anti-wear and Friction Reducing Mechanisms of Carbon Nano-onions as Lubricant Additives. Tribol. Lett. 2008, 30, 69–80. [Google Scholar] [CrossRef]

- Kolodziejczyk, L.; Martínez-Martínez, D.; Rojas, T.C.; Fernández, A.; Sánchez-López, J.C. Surface-modified Pd nanoparticles as a superior additive for lubrication. J. Nanoparticle Res. 2007, 9, 639–645. [Google Scholar] [CrossRef]

- Peng, D.X.; Chen, C.H.; Kang, Y.; Chang, Y.P.; Chang, S.Y. Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant. Ind. Lubr. Tribol. 2010, 62, 111–120. [Google Scholar] [CrossRef]

- Peng, D.X.; Kang, Y.; Chen, S.K.; Shu, F.; Chang, Y.P. Dispersion and tribological properties of liquid paraffin with added aluminum nanoparticles. Ind. Lubr. Tribol. 2010, 62, 341–348. [Google Scholar] [CrossRef]

- Akbulut, M. Nanoparticle-Based Lubrication Systems. J. Powder Met. Min. 2012, 1, 1–3. [Google Scholar] [CrossRef]

- Chou, R.; Battez, A.H.; Cabello, J.J.; Viesca, J.L.; Osorio, A.; Sagastume, A. Tribological behavior of polyalphaolefin with the addition of nickel nanoparticles. Tribol. Int. 2010, 43, 2327–2332. [Google Scholar] [CrossRef]

- Viesca, J.L.; Hernández Battez, A.; González, R.; Chou, R.; Cabello, J.J. Antiwear properties of carbon-coated copper nanoparticles used as an additive to a polyalphaolefin. Tribol. Int. 2011, 44, 829–833. [Google Scholar] [CrossRef]

- La, D.D.; Truong, T.N.; Pham, T.Q.; Vo, H.T.; Tran, N.T.; Nguyen, T.A.; Nadda, A.K.; Nguyen, T.T.; Chang, S.W.; Chung, W.J.; et al. Scalable Fabrication of Modified Graphene Nanoplatelets as an Effective Additive for Engine Lubricant Oil. Nanomaterials 2020, 10, 877. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.K.A.; Xianjun, H. Role of bis(2-ethylhexyl) phosphate and Al2O3/TiO2 hybrid nanomaterials in improving the dispersion stability of nanolubricants. Tribol. Int. 2021, 155, 106767. [Google Scholar] [CrossRef]

- Liu, K.N.; Zhang, Y.; Dai, F.; Sun, W. Improved heat transfer of the engine oil by changing it to hybrid nanofluid: Adding hybrid nano-powders. Powder Technol. 2021, 383, 56–64. [Google Scholar] [CrossRef]

- Singh, J.P.; Singh, S.; Nandi, T.; Ghosh, S.K. Development of graphitic lubricant nanoparticles based nanolubricant for automotive applications: Thermophysical and tribological properties followed by IC engine performance. Powder Technol. 2021, 387, 31–47. [Google Scholar] [CrossRef]

- Guo, J.; Peng, R.; Du, H.; Shen, Y.; Li, Y.; Li, J.; Dong, G. The Application of Nano-MoS2 Quantum Dots as Liquid Lubricant Additive for Tribological Behavior Improvement. Nanomaterials 2020, 10, 200. [Google Scholar] [CrossRef]

- Chouhan, A.; Sarkar, T.K.; Kumari, S.; Vemuluri, S.; Khatri, O.P. Synergistic lubrication performance by incommensurately stacked ZnO-decorated reduced graphene oxide/MoS2 heterostructure. J. Colloid Interface Sci. 2020, 580, 730–739. [Google Scholar] [CrossRef]

- Vardhaman, B.S.A.; Amarnath, M.; Ramkumar, J.; Mondal, K. Enhanced tribological performances of zinc oxide/MWCNTs hybrid nanomaterials as the effective lubricant additive in engine oil. Mater. Chem. Phys. 2020, 253, 123447. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heris, S.Z.; Estellé, P. Experimental comparison between ZnO and MoS2 nanoparticles as additives on performance of diesel oil-based nano lubricant. Sci. Rep. 2020, 10, 5813. [Google Scholar] [CrossRef]

- Kałużny, J.; Waligórski, M.; Szymański, G.M.; Merkisz, J.; Różański, J.; Nowicki, M.; Al Karawi, M.; Kempa, K. Reducing friction and engine vibrations with trace amounts of carbon nanotubes in the lubricating oil. Tribol. Int. 2020, 151, 106484. [Google Scholar] [CrossRef]

- Wu, B.; Song, H.; Li, C.; Song, R.; Zhang, T.; Hu, X. Enhanced tribological properties of diesel engine oil with Nano-Lanthanum hydroxide/reduced graphene oxide composites. Tribol. Int. 2020, 141, 105951. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X.; Abdelkareem, M.A.A. Anti-wear properties evaluation of frictional sliding interfaces in automobile engines lubricated by copper/graphene nanolubricants. Friction 2020, 8, 905–916. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, G.; Xie, G. Ultralow concentration of graphene oxide nanosheets as oil-based lubricant additives. Appl. Surf. Sci. 2019, 498, 143683. [Google Scholar] [CrossRef]

- Paul, G.; Shit, S.; Hirani, H.; Kuila, T.; Murmu, N.C. Tribological behavior of dodecylamine functionalized graphene nanosheets dispersed engine oil nanolubricants. Tribol. Int. 2018, 131, 605–619. [Google Scholar] [CrossRef]

- Ghasemi, R.; Fazlali, A.; Mohammadi, A.H. Effects of TiO2 nanoparticles and oleic acid surfactant on the rheological behavior of engine lubricant oil. J. Mol. Liq. 2018, 268, 925–930. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Abdelkareem, M.A.A.; Gulzar, M.; Elsheikh, A.H. Novel approach of the graphene nanolubricant for energy saving via anti-friction/wear in automobile engines. Tribol. Int. 2018, 124, 209–229. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Fuming, P.; Younus, H.A.; Abdelkareem, M.A.A.; Essa, F.A.; Elagouz, A.; Xianjun, H. Fuel economy in gasoline engines using Al2O3/TiO2 nanomaterials as nanolubricant additives. Appl. Energy 2018, 211, 461–478. [Google Scholar] [CrossRef]

- Esfe, M.H.; Saedodin, S.; Rejvani, M.; Shahram, J. Experimental investigation, model development and sensitivity analysis of rheological behavior of ZnO/10W40 nano-lubricants for automotive applications. Phys. E Low-Dimens. Syst. Nanostruct. 2017, 90, 194–203. [Google Scholar] [CrossRef]

- Sepyani, K.; Afrand, M.; Esfe, M.H. An experimental evaluation of the effect of ZnO nanoparticles on the rheological behavior of engine oil. J. Mol. Liq. 2017, 236, 198–204. [Google Scholar] [CrossRef]

- Ran, X.; Yu, X.; Zou, Q. Effect of Particle Concentration on Tribological Properties of ZnO Nanofluids. Tribol. Trans. 2016, 60, 154–158. [Google Scholar] [CrossRef]

- Moghaddam, M.A.; Motahari, K. Experimental investigation, sensitivity analysis and modeling of rheological behavior of MWCNT-CuO (30–70)/SAE40 hybrid nano-lubricant. Appl. Therm. Eng. 2017, 123, 1419–1433. [Google Scholar] [CrossRef]

- Wu, H.; Qin, L.; Dong, G.; Hua, M.; Yang, S.; Zhang, J. An investigation on the lubrication mechanism of MoS2 nano sheet in point contact: The manner of particle entering the contact area. Tribol. Int. 2017, 107, 48–55. [Google Scholar] [CrossRef]

- Esfe, M.H.; Afrand, M.; Yan, W.-M.; Yarmand, H.; Toghraie, D.; Dahari, M. Effects of temperature and concentration on rheological behavior of MWCNTs/SiO 2 (20–80)-SAE40 hybrid nano-lubricant. Int. Commun. Heat Mass Transf. 2016, 76, 133–138. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Bicheng, C.; Turkson, R.F.; Qingping, C. Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 2016, 364–365, 270–281. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A. Dynamic viscosity of MWCNT/ZnO–engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Y.; Yang, G.; Zhang, S.; Yu, L.; Zhang, P. Tribological properties of oleic acid-modified zinc oxide nanoparticles as the lubricant additive in poly-alpha olefin and diisooctyl sebacate base oils. RSC Adv. 2016, 6, 69836–69844. [Google Scholar] [CrossRef]

- Zheng, D.; Cai, Z.-B.; Shen, M.-X.; Li, Z.-Y.; Zhu, M.-H. Investigation of the tribology behaviour of the graphene nanosheets as oil additives on textured alloy cast iron surface. Appl. Surf. Sci. 2016, 387, 66–75. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Supercritical Fluid Synthesis and Tribological Applications of Silver Nanoparticle-decorated Graphene in Engine Oil Nanofluid. Sci. Rep. 2016, 6, 31246. [Google Scholar] [CrossRef]

- Mungse, H.P.; Kumar, N.; Khatri, O.P. Synthesis, dispersion and lubrication potential of basal plane functionalized alkylated graphene nanosheets. RSC Adv. 2015, 5, 25565–25571. [Google Scholar] [CrossRef]

- Jia, Z.; Chen, T.; Wang, J.; Ni, J.; Li, H.; Shao, X. Synthesis, characterization and tribological properties of Cu/reduced graphene oxide composites. Tribol. Int. 2015, 88, 17–24. [Google Scholar] [CrossRef]

- Zin, V.; Agresti, F.; Barison, S.; Colla, L.; Mercadelli, E.; Fabrizio, M.; Pagura, C. Tribological Properties of Engine Oil with Carbon Nano-horns as Nano-additives. Tribol. Lett. 2014, 55, 45–53. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G.; Ellappan, R. Bio-lubricant-biodiesel combination of rapeseed oil: An experimental investigation on engine oil tribology, performance, and emissions of variable compression engine. Energy 2014, 72, 618–627. [Google Scholar] [CrossRef]

- Wan, Q.; Jin, Y.; Sun, P.; Ding, Y. Rheological and tribological behaviour of lubricating oils containing platelet MoS2 nanoparticles. J. Nanoparticle Res. 2014, 16, 2386. [Google Scholar] [CrossRef]

- Ettefaghi, E.-O.; Ahmadi, H.; Rashidi, A.; Nouralishahi, A.; Mohtasebi, S.S. Preparation and thermal properties of oil-based nanofluid from multi-walled carbon nanotubes and engine oil as nano-lubricant. Int. Commun. Heat Mass Transf. 2013, 46, 142–147. [Google Scholar] [CrossRef]

- Ettefaghi, E.-O.; Rashidi, A.; Ahmadi, H.; Mohtasebi, S.S.; Pourkhalil, M. Thermal and rheological properties of oil-based nanofluids from different carbon nanostructures. Int. Commun. Heat Mass Transf. 2013, 48, 178–182. [Google Scholar] [CrossRef]

- Demas, N.G.; Timofeeva, E.V.; Routbort, J.L.; Fenske, G.R. Tribological Effects of BN and MoS2 Nanoparticles Added to Polyalphaolefin Oil in Piston Skirt/Cylinder Liner Tests. Tribol. Lett. 2012, 47, 91–102. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Sankaranarayanan, V.; Ramaprabhu, S. Graphene-Based Engine Oil Nanofluids for Tribological Applications. ACS Appl. Mater. Interfaces 2011, 3, 4221–4227. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Arulraj, A.; Sridewi, N. Tribological performance of hexagonal boron nitride (hBN) as nano-additives in military grade diesel engine oil. Mater. Today Proc. 2021, 50, 70–73. [Google Scholar] [CrossRef]

- Charoo, M.S.; Hanief, M. Improving the tribological characteristics of a lubricating oil by nano sized additives. Mater. Today Proc. 2020, 28, 1205–1209. [Google Scholar] [CrossRef]

- Rasheed, A.K.; Khalid, M.; Javeed, A.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Heat transfer and tribological performance of graphene nanolubricant in an internal combustion engine. Tribol. Int. 2016, 103, 504–515. [Google Scholar] [CrossRef]

- Vyavhare, K.; Timmons, R.B.; Erdemir, A.; Edwards, B.L.; Aswath, P.B. Tribochemistry of fluorinated ZnO nanoparticles and ZDDP lubricated interface and implications for enhanced anti-wear performance at boundary lubricated contacts. Wear 2021, 474–475, 203717. [Google Scholar] [CrossRef]

- Avilés, M.-D.; Pamies, R.; Sanes, J.; Bermúdez, M.-D. Graphene-Ionic Liquid Thin Film Nanolubricant. Nanomaterials 2020, 10, 535. [Google Scholar] [CrossRef] [PubMed]

- Mello, V.S.; Trajano, M.F.; Guedes, A.E.D.S.; Alves, S.M. Comparison between the Action of Nano-Oxides and Conventional EP Additives in Boundary Lubrication. Lubricants 2020, 8, 54. [Google Scholar] [CrossRef]

- Cheng, Z.-L.; Li, W.; Wu, P.-R.; Liu, Z. Study on structure-activity relationship between size and tribological properties of graphene oxide nanosheets in oil. J. Alloys Compd. 2017, 722, 778–784. [Google Scholar] [CrossRef]

- Ivanov, M.; Shenderova, O. Nanodiamond-based nanolubricants for motor oils. Curr. Opin. Solid State Mater. Sci. 2017, 21, 17–24. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Elagouz, A.; Essa, F.A.; Abdelkareem, M.A.A. Minimizing of the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoparticles. J. Nanoparticle Res. 2016, 18, 377. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiza, R.; Prosyčevas, I.; Kreivaitis, R. Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heris, S.Z.; Estellé, P. Viscosity, tribological and physicochemical features of ZnO and MoS2 diesel oil-based nanofluids: An experimental study. Fuel 2021, 293, 120481. [Google Scholar] [CrossRef]

- Tóth, D.; Szabó, Á.I.; Kuti, R. Tribological properties of nano-sized ZrO2 ceramic particles in automotive lubricants. FME Trans. 2021, 49, 36–43. [Google Scholar] [CrossRef]

- Beheshti, A.; Huang, Y.; Ohno, K.; Blakey, I.; Stokes, J.R. Improving tribological properties of oil-based lubricants using hybrid colloidal additives. Tribol. Int. 2020, 144, 106130. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heris, S.Z. Experimental investigation of ZnO nanoparticles effects on thermophysical and tribological properties of diesel oil. Int. J. Hydrog. Energy 2020, 45, 23603–23614. [Google Scholar] [CrossRef]

- Xue, C.Y.; Wang, S.R.; Wang, Y.; Wang, G.Q.; Yan, X.Y. The Influence of Nanocomposite Carbon Additive on Tribological Behavior of Cylinder Liner/Piston Ring. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Mechanical and Aeronautical Engineering (ICMAE 2018), Bangkok, Thailand, 13–16 December 2018; Institute of Physics Publishing: Beijing, China, 2019; Volume 491. [Google Scholar]

- Scherge, M.; Böttcher, R.; Kürten, D.; Linsler, D. Multi-Phase Friction and Wear Reduction by Copper Nanopartices. Lubricants 2016, 4, 36. [Google Scholar] [CrossRef]

- Asnida, M.; Hisham, S.; Awang, N.W.; Amirruddin, A.K.; Noor, M.M.; Kadirgama, K.; Ramasamy, D.; Najafi, G.; Tarlochan, F. Copper (II) oxide nanoparticles as additve in engine oil to increase the durability of piston-liner contact. Fuel 2018, 212, 656–667. [Google Scholar] [CrossRef]

- Rajendhran, N.; Palanisamy, S.; Periyasamy, P.; Venkatachalam, R. Enhancing of the tribological characteristics of the lubricant oils using Ni-promoted MoS2 nanosheets as nano-additives. Tribol. Int. 2018, 118, 314–328. [Google Scholar] [CrossRef]

- Borda, F.L.G.; de Oliveira, S.J.R.; Lazaro, L.M.S.M.; Leiróz, A.J.K. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Jeng, Y.-R.; Huang, Y.-H.; Tsai, P.-C.; Hwang, G.-L. Tribological Performance of Oil-Based Lubricants with Carbon-Fe Nanocapsules Additive. Tribol. Trans. 2015, 58, 924–929. [Google Scholar] [CrossRef]

- Zhang, B.-S.; Xu, B.-S.; Xu, Y.; Gao, F.; Shi, P.-J.; Wu, Y.-X. CU nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribol. Int. 2011, 44, 878–886. [Google Scholar] [CrossRef]

- Nurchi, C.; Buonvino, S.; Arciero, I.; Melino, S. Sustainable Vegetable Oil-Based Biomaterials: Synthesis and Biomedical Ap-plications. Int. J. Mol. Sci. 2023, 24, 2153. [Google Scholar] [CrossRef] [PubMed]

- Taha-Tijerina, J.J.; Aviña, K.; Padilla-Gainza, V.; Akundi, A. Halloysite Reinforced Natural Esters for Energy Applications. Lubricants 2023, 11, 65. [Google Scholar] [CrossRef]

- Gupta, H.S.; Sehgal, R.; Wani, M.F. Formulation and characterization of eco-friendly Mahua and Linseed oil-based nanolubricants by incorporating h-BN nano-additives. Environ. Dev. Sustain. 2024, 1–21. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Muralidharan, K. Performance, Emission, and Catalytic Activity Analysis of AL2O3 and CEO2 Nano-Additives on Diesel Engines Using Mahua Biofuel for a Sustainable Environment. ACS Omega 2023, 8, 5692–5701. [Google Scholar] [CrossRef] [PubMed]

| Author | Method Used | Stirring Process | Stirring Time | |

|---|---|---|---|---|

| Two Steps | One Step | |||

| Ali et al. [134] | * | Ultrasound/Magnetic Stirring | 6 h | |

| Liu et al. [135] | * | Ultrasound | 3 h | |

| Singh et al. [136] | * | Ultrasound | 1.5 h | |

| Guo et al. [137] | * | Ultrasound | 30 min | |

| La et al. [133] | * | Magnetic Stirring/Ultrasound | 3 h/12 h | |

| Chouchan et al. [138] | * | Magnetic Stirring | 8 h | |

| Vardhaman et al. [139] | * | Ultrasound | 2 h | |

| Mousavi et al. [140] | * | Ultrasound | 45 min | |

| Kałuzny et al. [141] | * | Ultrasound | 1 h | |

| Mello et al. [32] | * | Magnetic Stirring | 7 h | |

| Wu et al. [142] | * | Ultrasound | 1 h | |

| Ali et al. [143] | * | Magnetic Stirring | 4 h | |

| Wang et al. [144] | * | Ultrasound | 1 h | |

| Paul et al. [145] | * | Ultrasound | 6 h | |

| Ghasemi et al. [146] | * | Magnetic Stirring/Ultrasound | 15 min/20 min | |

| Ali et al. [147] | * | Magnetic Stirring | 4 h | |

| Ali et al. [148] | * | Magnetic Stirring | 4 h | |

| Hemmat et al. [149] | * | Ultrasound | 3 h | |

| Sgroi et al. [17] | * | Ultrasound | 5 h | |

| Sepyani et al. [150] | * | Ultrasound | 5 h | |

| Ran et al. [151] | * | Magnetic Stirring/Ultrasound | 20 min/30 min | |

| Moghaddam et al. [152] | * | Ultrasound | 1 h | |

| Wu et al. [153] | * | Ultrasound | 40 min | |

| Hemmat et al. [154] | * | Magnetic Stirring | 2 h | |

| Ali et al. [155] | * | Magnetic Stirring | 4 h | |

| Asadi et al. [156] | * | Magnetic Stirring/ Ultrasound | 2 h/1 h | |

| Wu et al. [157] | * | Magnetic Stirring | 1 h | |

| Zheng et al. [158] | * | Magnetic Stirring/ Ultrasound | 10 min/ 15 min | |

| Meng et al. [159] | * | Ultrasound | 5 h | |

| Mungse et al. [160] | * | Ultrasound | 4 h | |

| Koshy et al. [120] | * | Ultrasound | 1 h | |

| Jia et al. [161] | * | Ultrasound | 2 h | |

| Zin et al. [162] | * | Ultrasound | 1 h | |

| Arumugam et al. [163] | * | Ultrasound | 2 h | |

| Wan et al. [164] | * | Magnetic Stirring | 30 min | |

| Ettefaghi et al. [165] | * | Ultrasound | 1 h | |

| Ettefaghi et al. [166] | * | Magnetic Stirring | 3 h | |

| Demas et al. [167] | * | Ultrasound | 2 h | |

| Eswaraiah et al. [168] | * | Ultrasound | 1 h | |

| Author | Concentration [%] |

|---|---|

| Singh et al. [136] | 0.3 |

| Thachnatharen et al. [169] | 0.025 |

| Vyavhare et al. [172] | 0.33 |

| Charoo et al. [170] | 0.5 |

| Avilés et al. [173] | 0.5 |

| Mello et al. [174] | 0.5 |

| Kamal et al. [5] | 0.1 |

| Cheng et al. [175] | 0.04 |

| Wu et al. [153] | 1 |

| Ivanov et al. [176] | 0.016 |

| Rasheed et al. [171] | 0.01 |

| Ali et al. [177] | 0.25 |

| Padgurskas et al. [178] | 0.5 |

| Demas et al. [167] | 3 |

| Author | Effective Concentration [%] |

|---|---|

| Mousavi et al. [179] | 0.7 |

| Tóth et al. [180] | 0.4 |

| Chouhan et al. [138] | 0.05 |

| Wu et al. [142] | 0.1 |

| Beheshti et al. [181] | 0.3 |

| Vardhaman et al. [139] | 0.25 |

| Mousavi et al. [140] | 0.4 |

| Guo et al. [137] | 0.3 |

| Mousavi et al. [182] | 0.4 |

| Paul et al. [145] | 0.1 |

| Ali et al. [143] | 0.4 |

| Xue et al. [183] | 3 |

| Ali et al. [143] | 0.4 |

| Asnida et al. [185] | 0.008 |

| Laad et al. [15] | 0.5 |

| Rajendhran et al. [186] | 0.5 |

| Borda et al. [187] | 0.3 |

| Ran et al. [151] | 0.5 |

| Ali et al. [188] | 0.25 |

| Ali et al. [155] | 0.1 |

| Scherge et al. [184] | 3 |

| Jeng et al. [189] | 0.07 |

| Peña et al. [125] | 2 |

| Zin et al. [162] | 0.01 |

| Zhang et al. [190] | 0.0375 |

| Base Lubricant | #Articles/Citations |

|---|---|

| Lubricant/PAO6 | [134] |

| SAE 20W-40 | [135] |

| SAE 30 | [136] |

| Paroline Lubricant/Oil | [137] |

| Lubricant/HD 50 | [133] |

| SAE 10W-40 | [138,139,146,149,156,159,160] |

| SAE 40 | [140,152,162,179] |

| SAE 5W-30 | [17,141,143,145,147,148,155,176,177,188] |

| Lubricant/PAO | [32,157,158,161,166] |

| SAE 20W-50 | [142,165,166,169,170,171] |

| Lubricant/Hexadecane | [144] |

| SAE 50 | [150,154] |

| Lubricant/60SN | [151] |

| Lubricant/Paraffin | [153] |

| Lubricant/500 N | [120] |

| Rapeseed Oil/SAE 20 W-40 | [163] |

| SAE 15W-40 | [164,190] |

| 500W | [168] |

| Lubricant/Group III | [172,180] |

| SAE 10W-30 | [15,181,185] |

| Lubricant/Ionic Liquid | [173] |

| Diesel Oil | [182] |

| Lubricant/PAO40 | [174] |

| SN/GF-5 Lubricant | [183] |

| Lubricant/SN 500 | [175,186] |

| Lubricant/Mineral | [187,189] |

| Chevron Taro 30 DP 40 | [184] |

| SAE 75 W-85 | [125] |

| SAE 10 | [178] |

| Nano-Additive | #Articles/Citations |

|---|---|

| Al2O3/TiO2 | [134,148,155,177,188] |

| MWCNT/TiO2 | [135] |

| Graphite | [136] |

| MoS2 | [17,120,137,153,164,167] |

| Gr | [133,147,158,171,173] |

| Gr-MS-Zn | [138] |

| ZnO/MWCNT | [139] |

| ZnO/MoS2 | [140] |

| MWCNT | [141,165,166] |

| CuO | [32,163,174,185] |

| La(OH)3/rGO | [142] |

| Cu/Gr | [143] |

| GO | [144,145,160,168] |

| TiO2 | [15,146] |

| ZnO | [149,150,151,157,172,182] |

| MWCNT/CuO | [152] |

| MWCNT/SiO2 | [153] |

| MWCNT/ZnO | [156] |

| GO/Ag/GNP | [159] |

| Cu/rGO | [161] |

| C | [162,183] |

| ZnO/MoS2 | [179] |

| ZrO2 | [180] |

| hBN | [169] |

| (BN), (WS2), (Gr) | [170] |

| Hairy Silica Particles (HSPs) | [181] |

| Ni- MoS2 | [186] |

| Cu | [184,187,190] |

| GrO | [175] |

| ND | [176] |

| Fe (Carbon Capsules) | [189] |

| CuO/Al2O3 | [125] |

| CuO, Cu, Fe, Co, Fe/Cu, Fe/Co, Co/Cu | [178] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia Tobar, M.; Contreras Urgiles, R.W.; Jimenez Cordero, B.; Guillen Matute, J. Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient. Lubricants 2024, 12, 166. https://doi.org/10.3390/lubricants12050166

Garcia Tobar M, Contreras Urgiles RW, Jimenez Cordero B, Guillen Matute J. Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient. Lubricants. 2024; 12(5):166. https://doi.org/10.3390/lubricants12050166

Chicago/Turabian StyleGarcia Tobar, Milton, Rafael Wilmer Contreras Urgiles, Bryan Jimenez Cordero, and Julio Guillen Matute. 2024. "Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient" Lubricants 12, no. 5: 166. https://doi.org/10.3390/lubricants12050166

APA StyleGarcia Tobar, M., Contreras Urgiles, R. W., Jimenez Cordero, B., & Guillen Matute, J. (2024). Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient. Lubricants, 12(5), 166. https://doi.org/10.3390/lubricants12050166