Brake Wear and Airborne Particle Mass Emissions from Passenger Car Brakes in Dynamometer Experiments Based on the Worldwide Harmonized Light-Duty Vehicle Test Procedure Brake Cycle

Abstract

1. Introduction

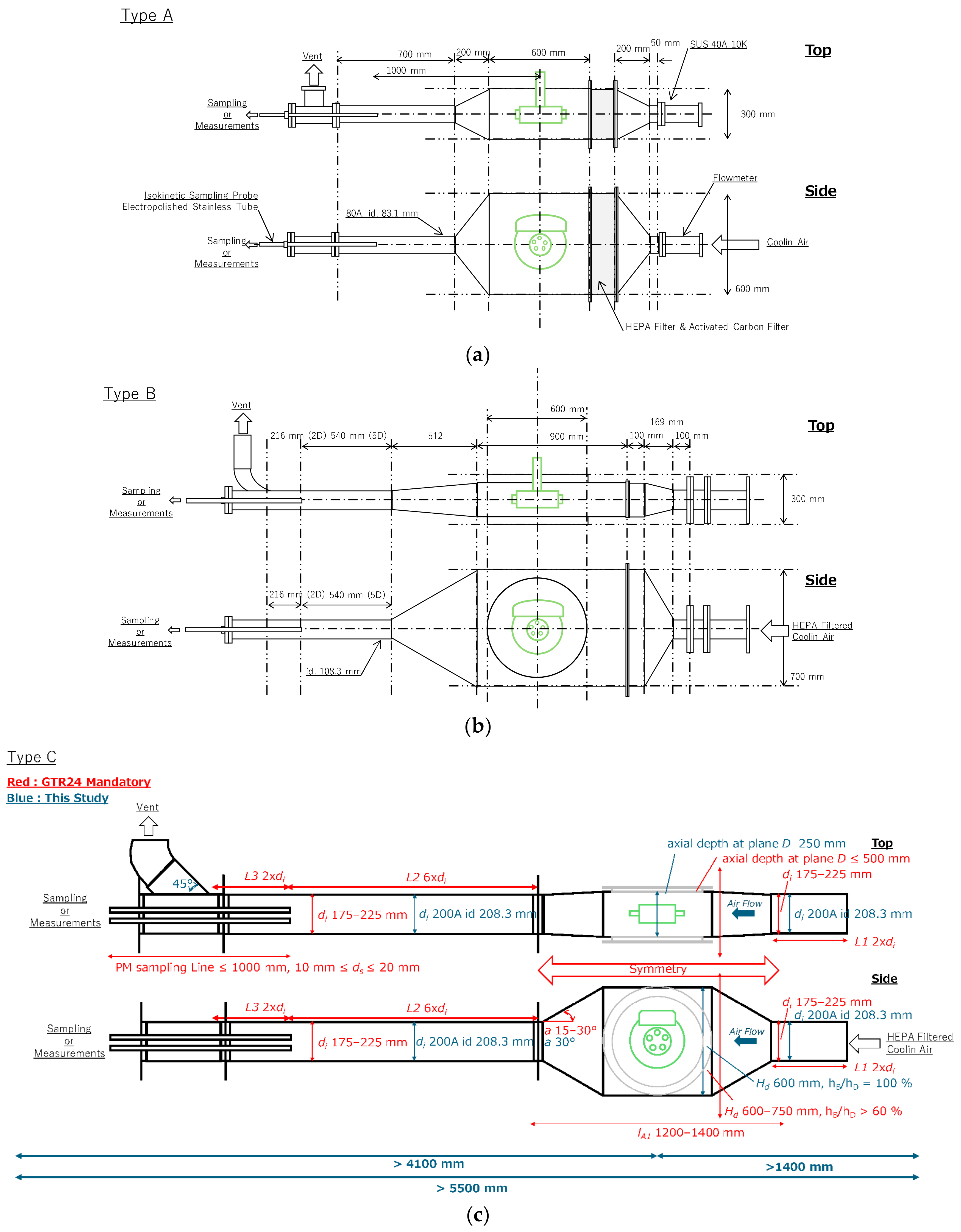

2. Experimental Methods

2.1. Dynamometer Experiments

2.2. Brake Wear and Particle Mass Measurements

3. Results and Discussion

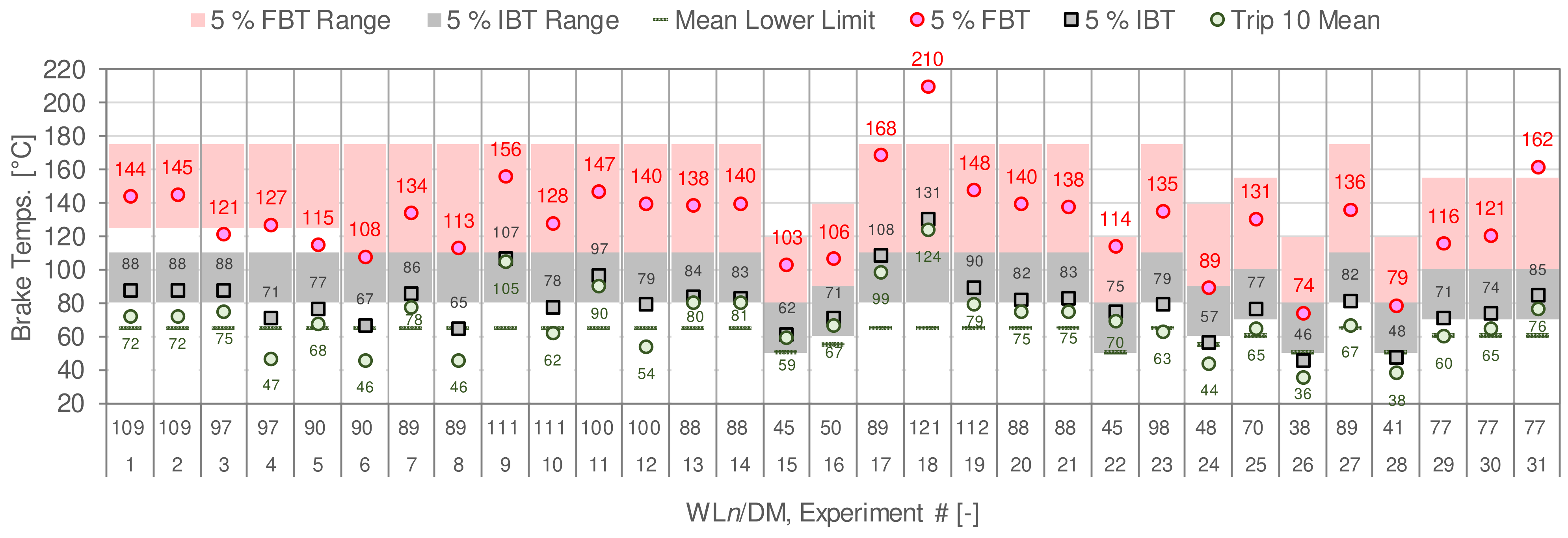

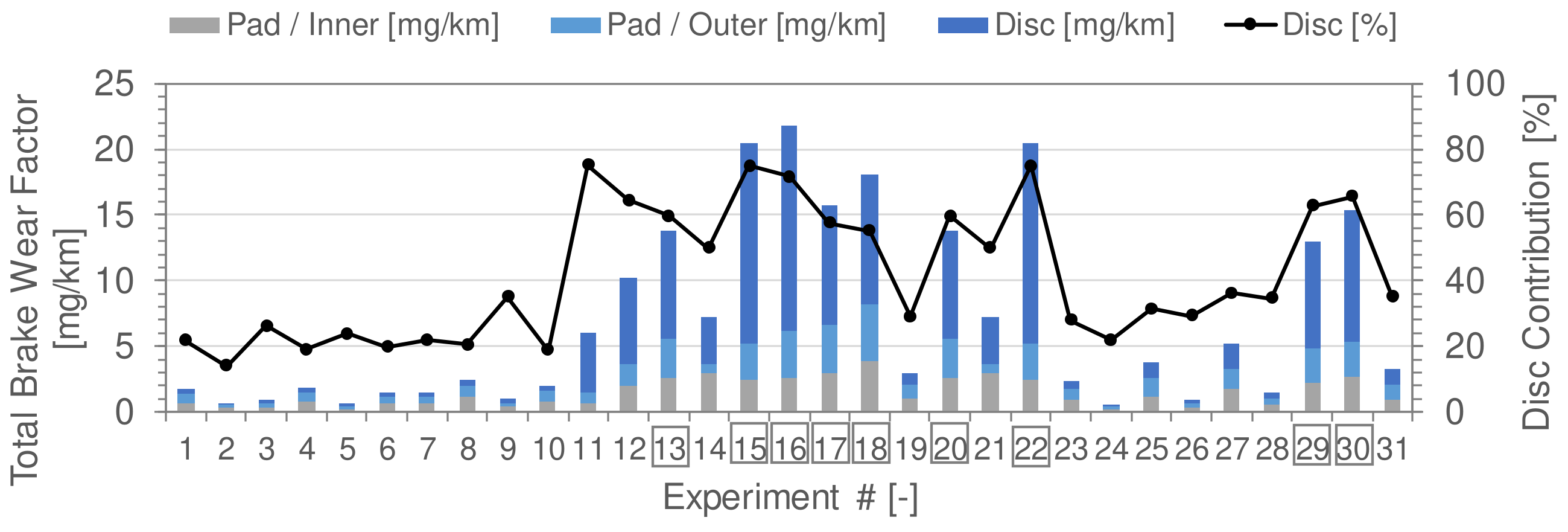

3.1. Brake Wear Factor Measurement

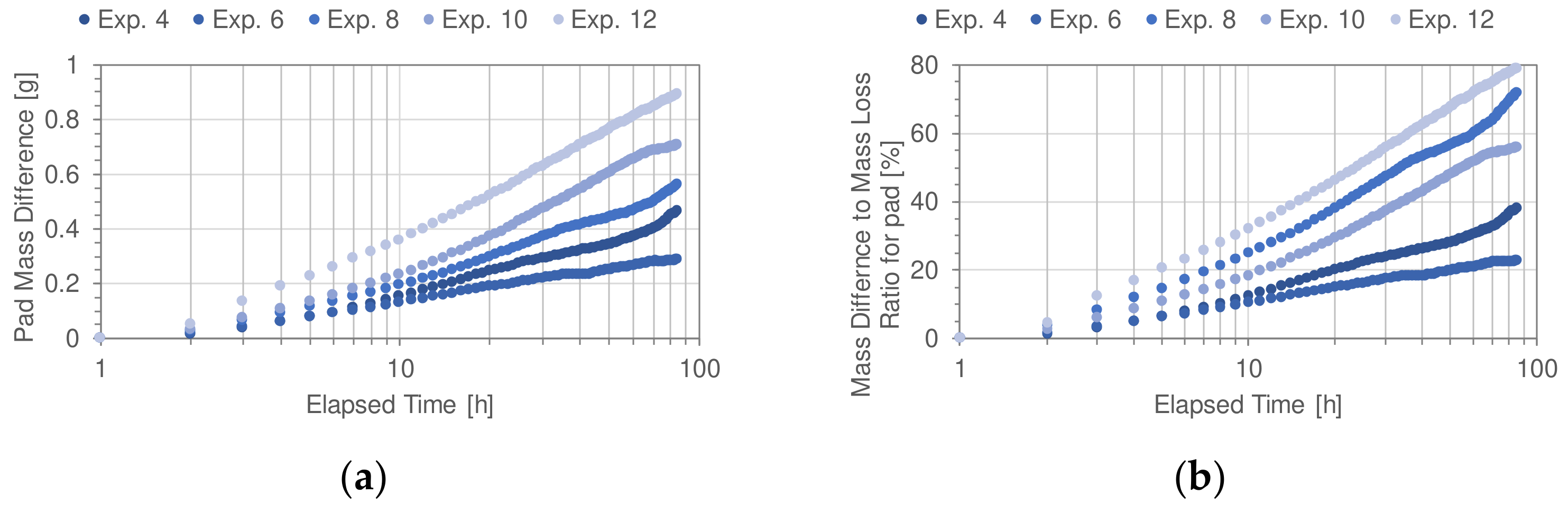

3.1.1. Storage Stability for Wear Weighting

3.1.2. Brake Wear Factors

3.2. Particle Mass Measurement

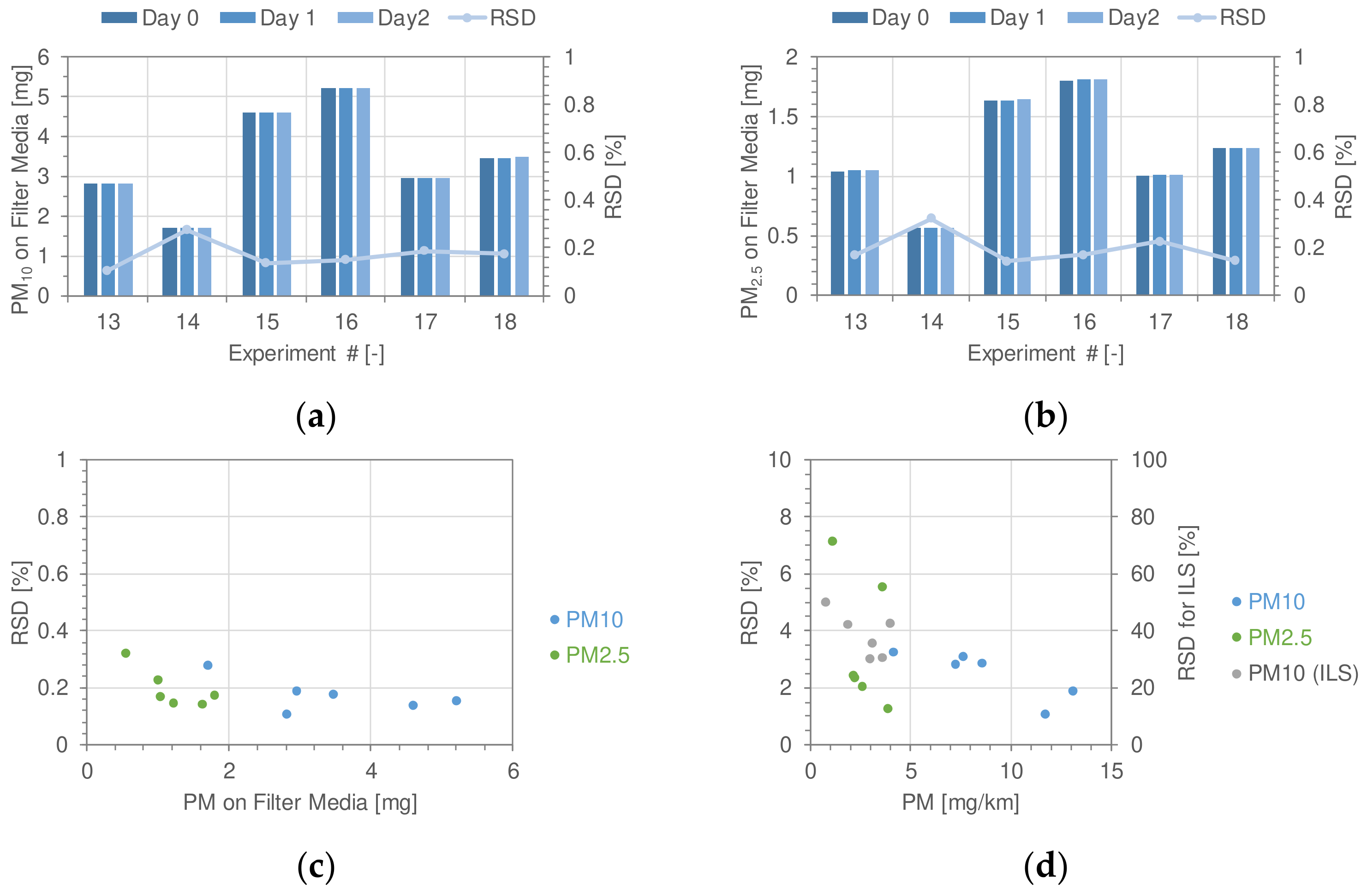

3.2.1. Storage Stability for Particle Mass Weighing

3.2.2. Collection Device for Particle Mass Measurement

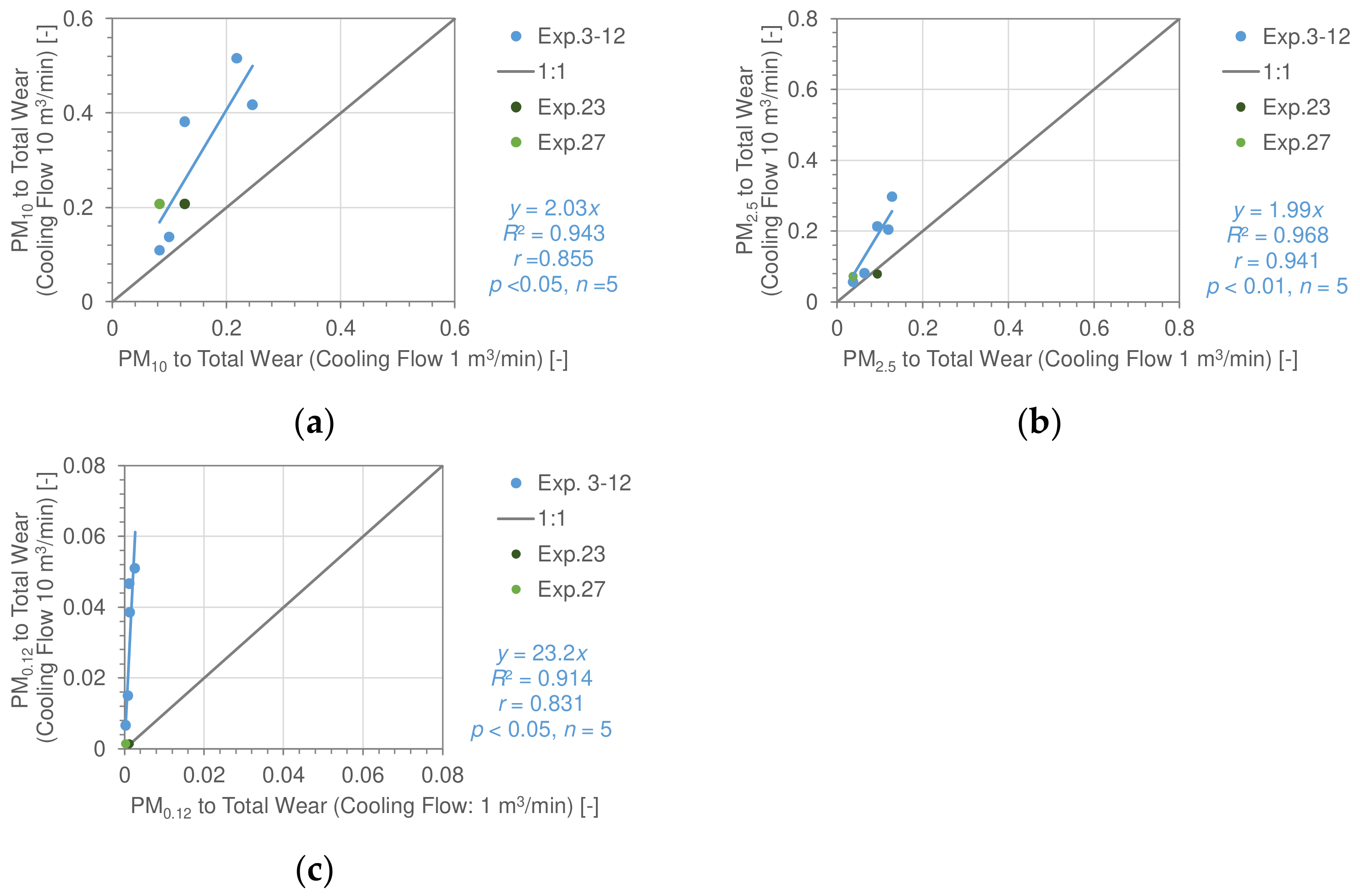

3.2.3. Cooling Air Flow Effect for Particle Mass Emissions

3.3. Comparison of Particle Mass Emissions and Brake Wear Factors

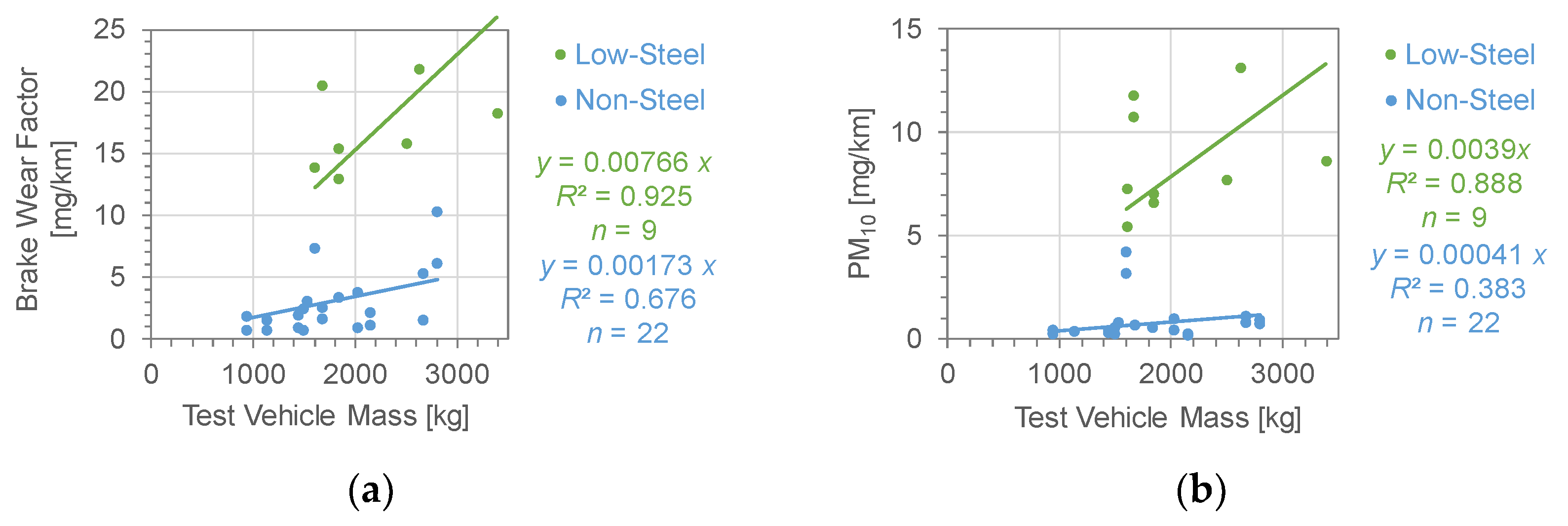

3.3.1. Particle Mass Emissions and Effect of Test Vehicle Mass

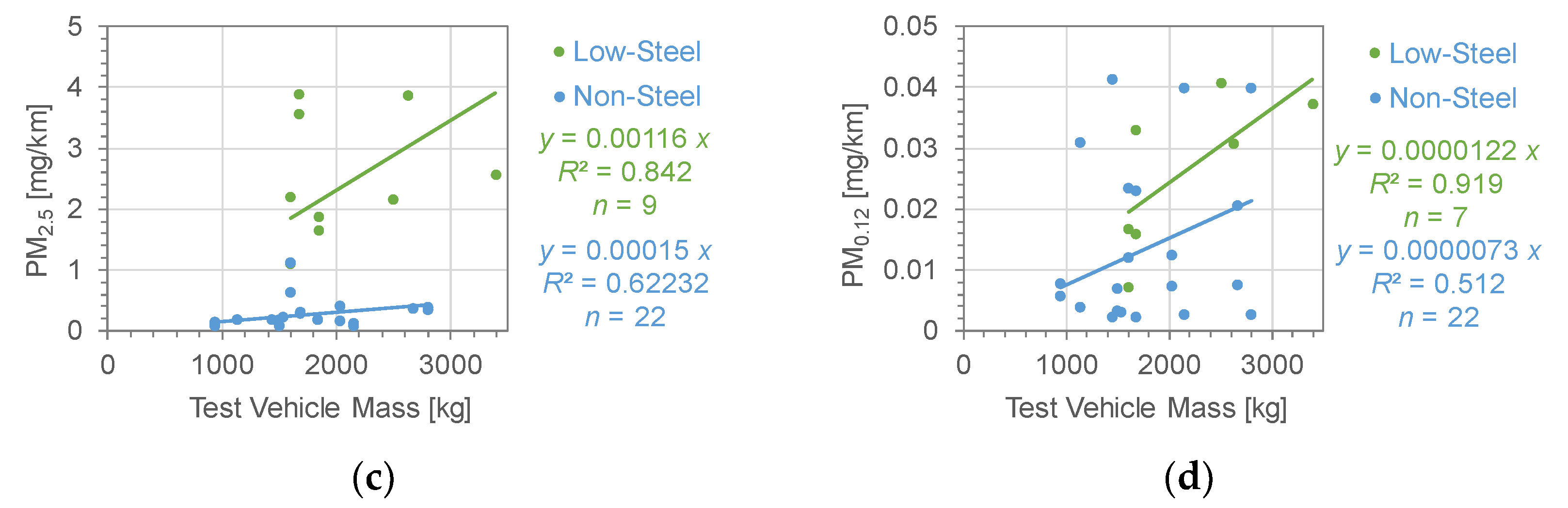

3.3.2. Particle Mass Emissions Correlated with Brake Wear Factors

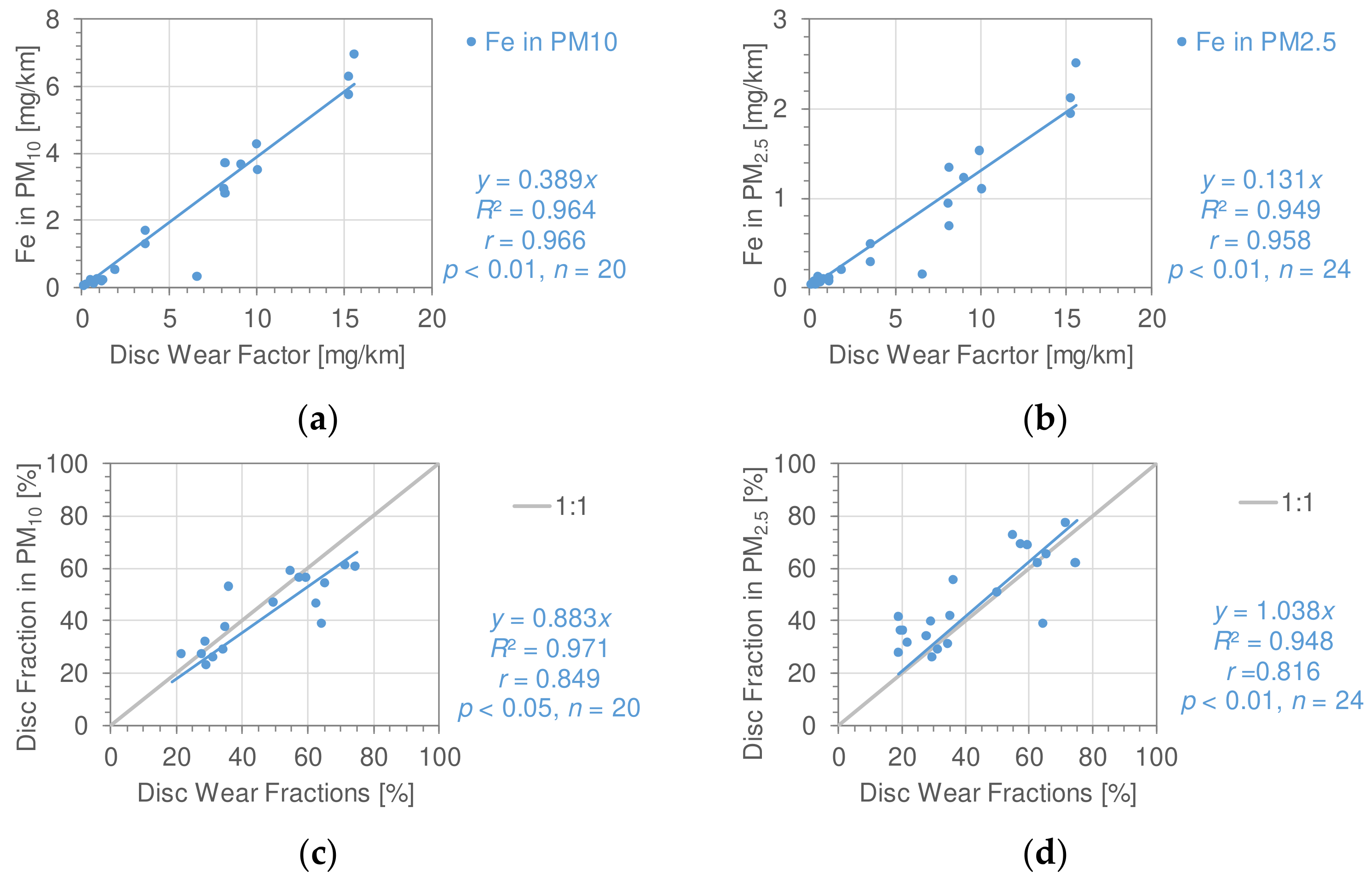

3.3.3. Disc Wear Contribution to Particle Mass Emissions

3.4. Comparison of Elements in Brake Pads and Particulate Matter Emissions

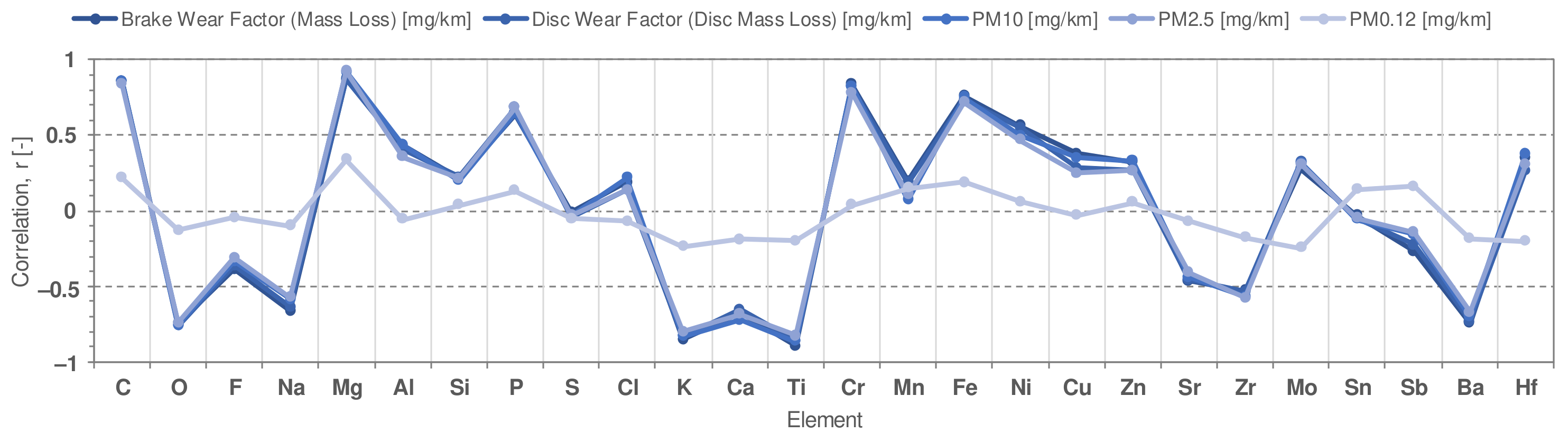

3.4.1. Correlation between Elements in Brake Pads and Particulate Matter Emissions

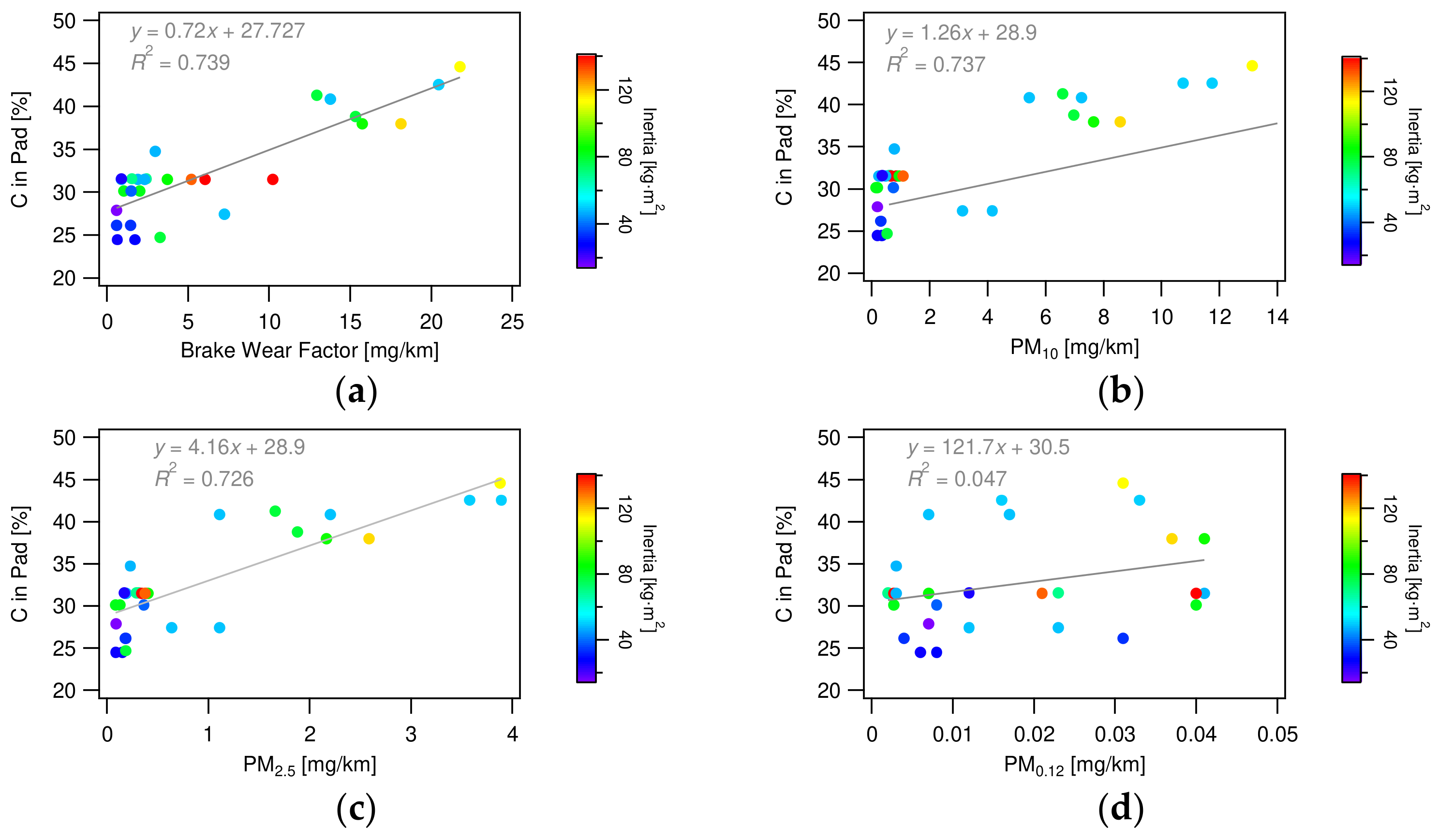

3.4.2. Carbon

3.4.3. Magnesium

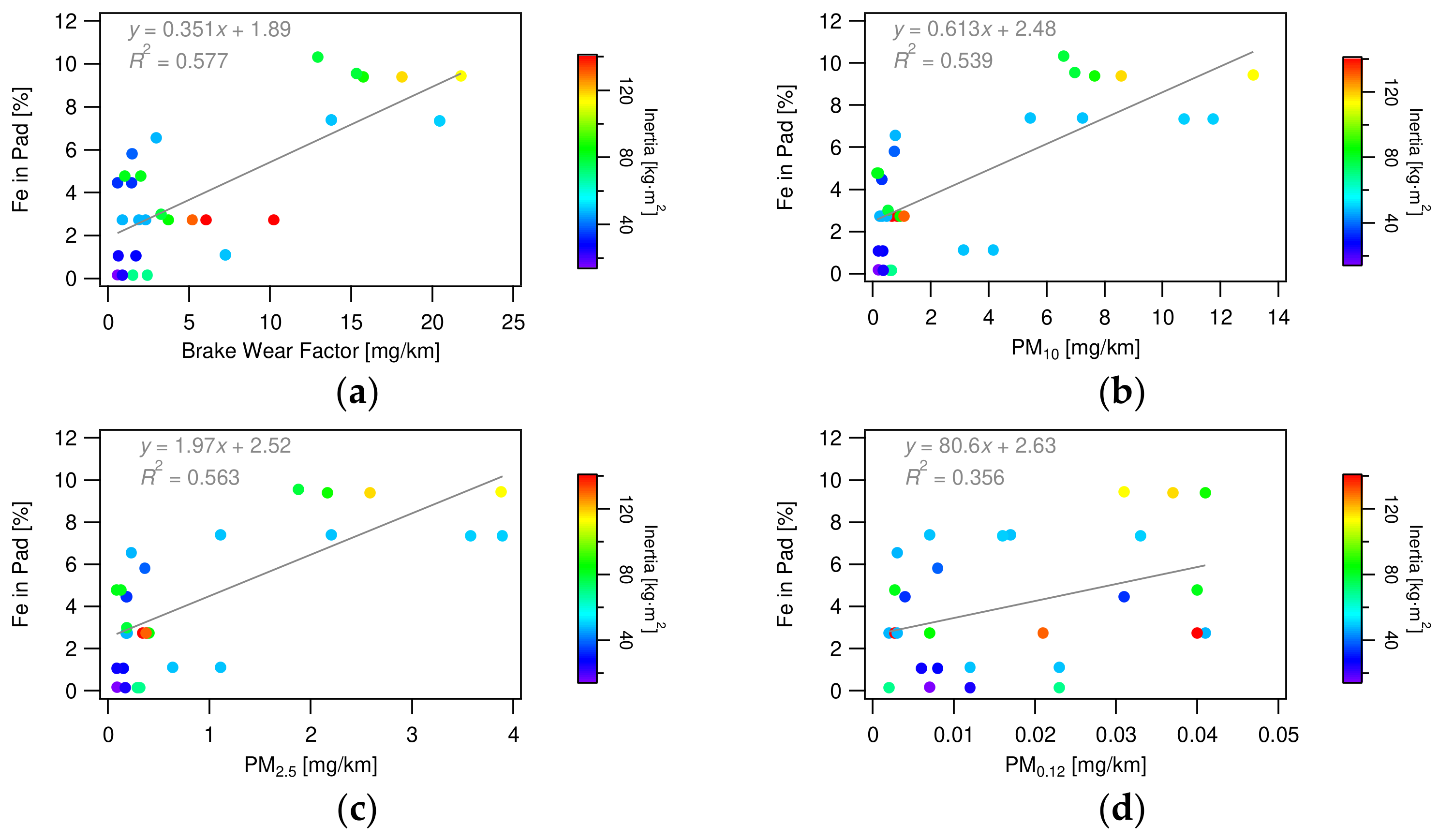

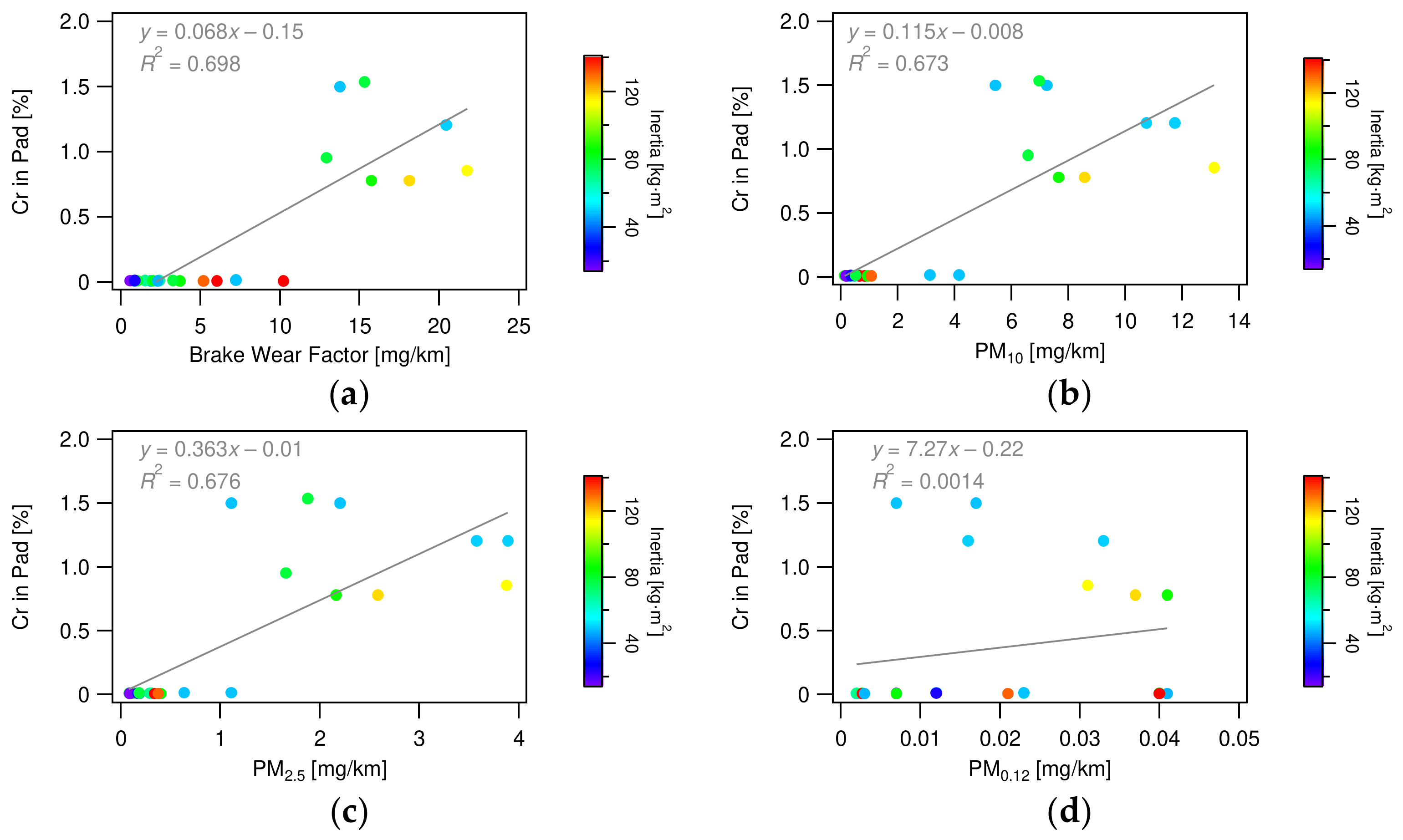

3.4.4. Iron and Chromium

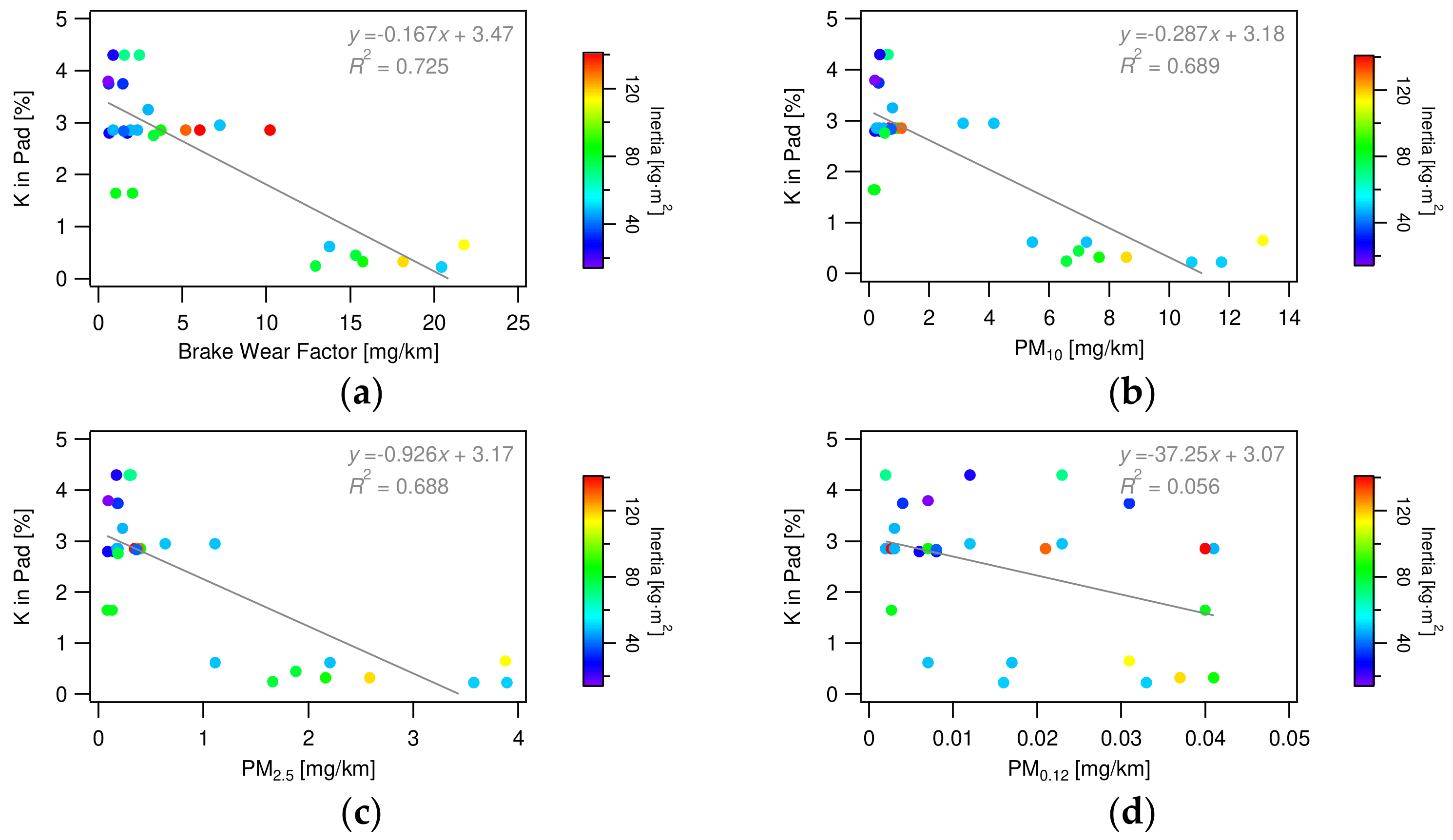

3.4.5. Titanium and Potassium

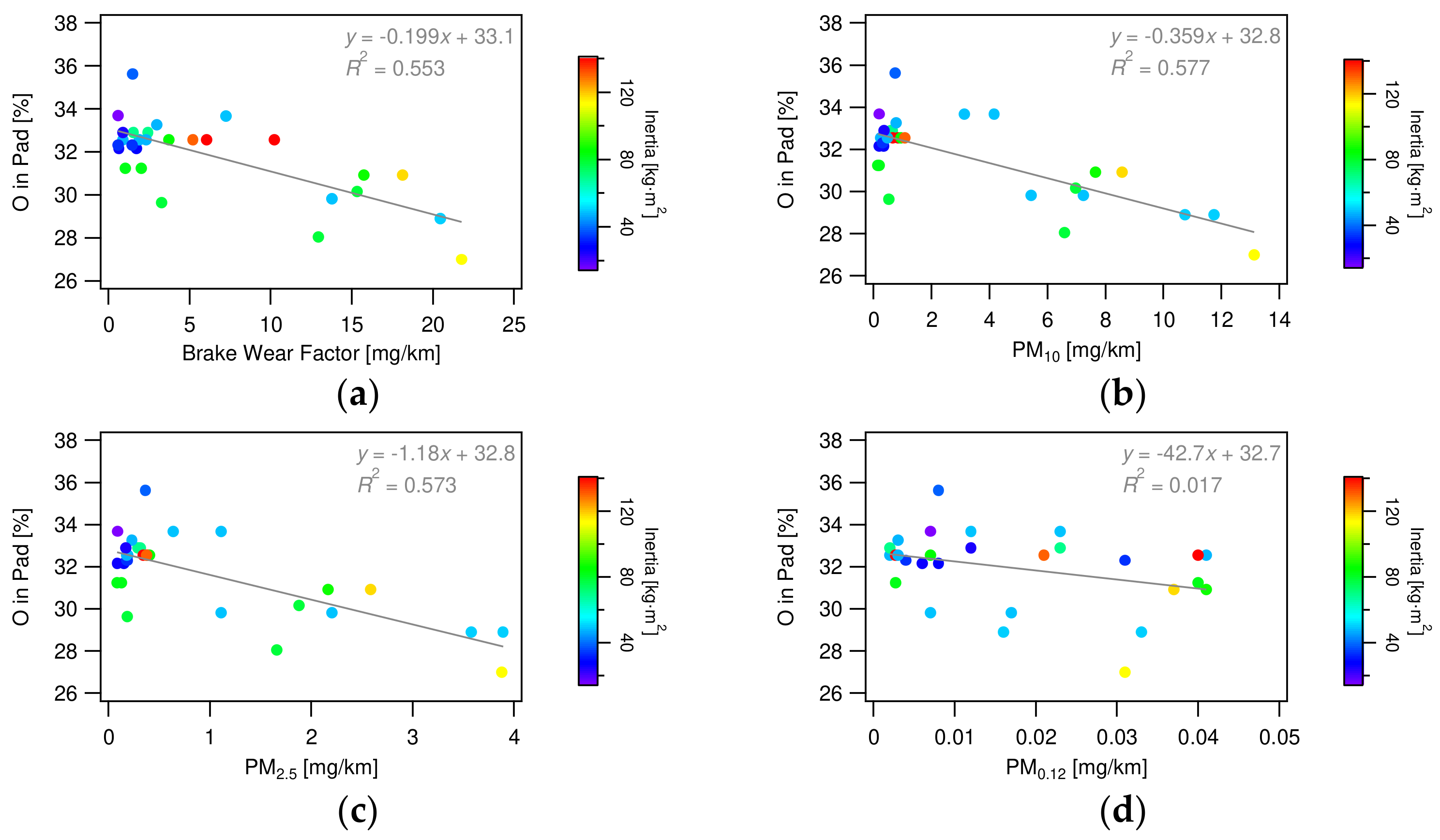

3.4.6. Oxygen

3.4.7. Barium

4. Conclusions

- The ratio of mass difference to mass loss increased from 16.2% to 51.2% after the 24 h soak required by the GTR24 regulation as compared to the 1 h soak measurement. Therefore, in our experiments, we measured the mass of the pads and discs within one hour after the test and with a brake temperature below 30 °C.

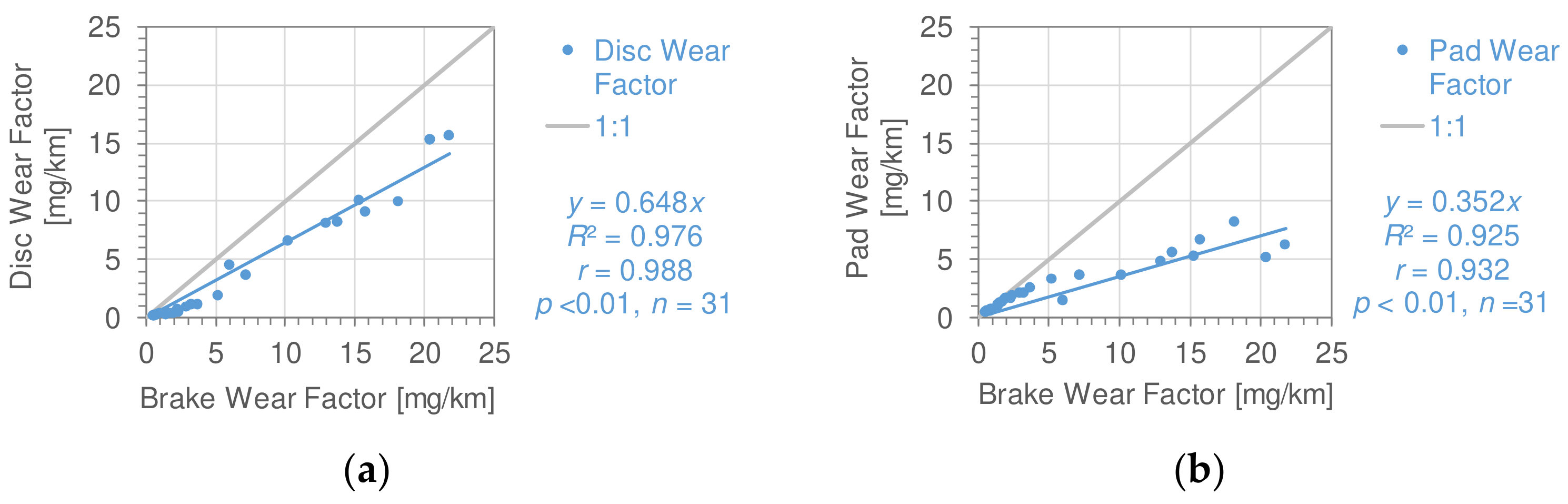

- Based on the mass loss measurements, we found that the disc and pad wear factors accounted for 64.8% and 35.2%, respectively, of the brake wear factor.

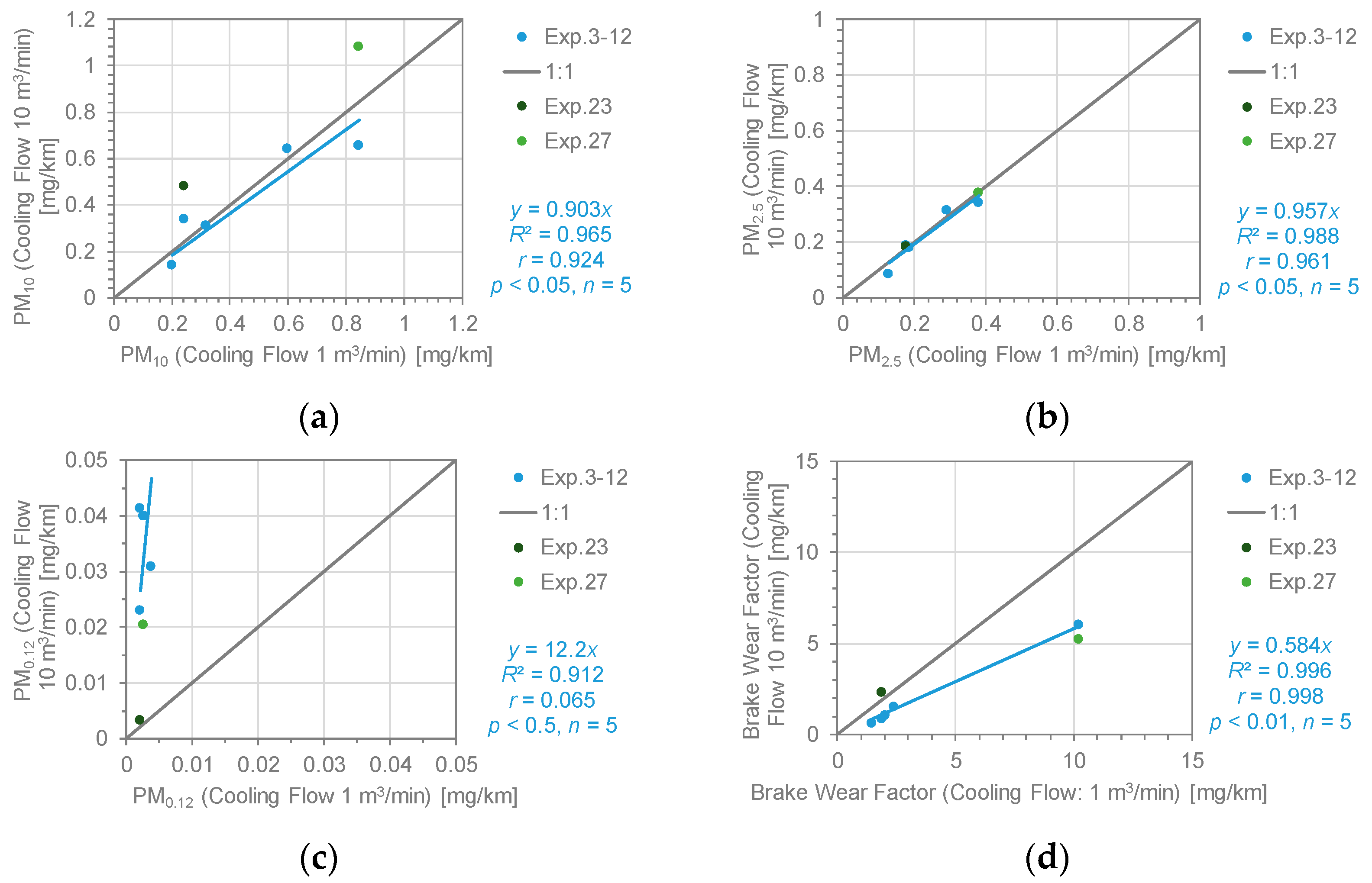

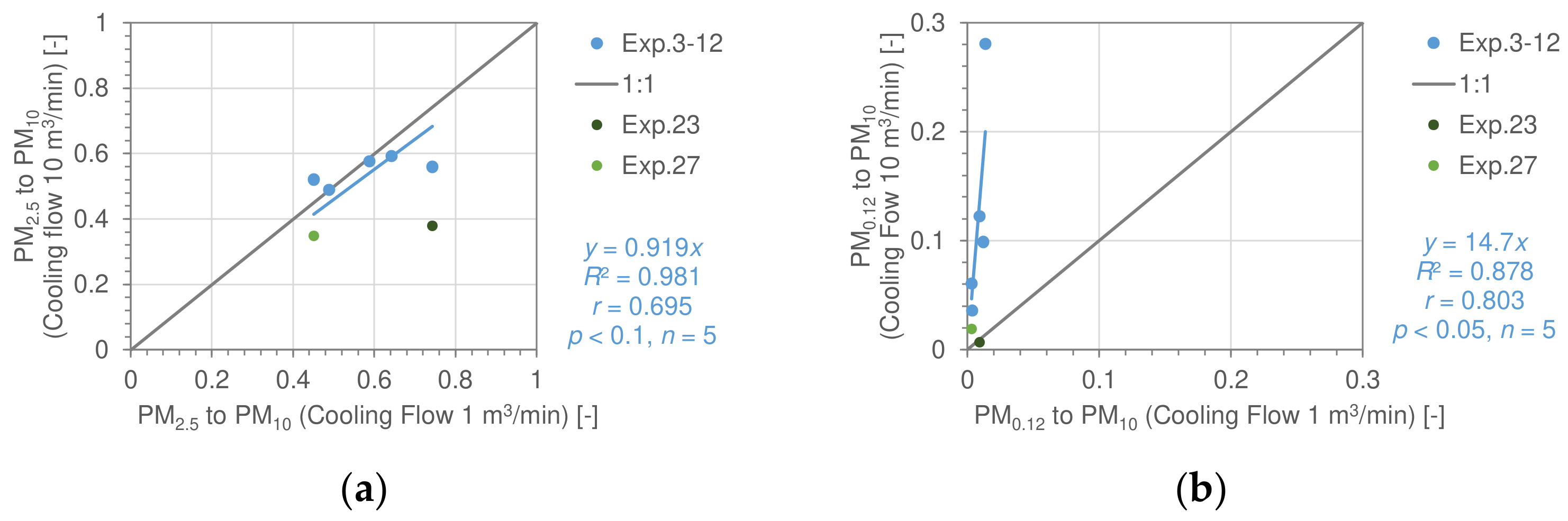

- Based on the sampling method required by the JASO C470 method, there were no significant differences between cooling air flow rates for PM10, PM2.5, and brake wear particle emissions; however, the total brake wear factor was 58.3% lower at the high flow rate (10 m3/min) compared to the low flow rate (1 m3/min). We also observed that PM0.12 with high cooling air flow rate conditions tended to be 12.2 times higher than low cooling air flow rate conditions.

- Low-steel pads had a PM10 emission of 3.9 mg/km per brake per 1000 kg of vehicle mass, with a large variance, similar to the results of previous studies. There was also a large variation in the correlation between inertia and PM10 emissions, which was also in agreement with the findings of previous studies. In contrast, a PM10 emission of 0.4 mg/km per brake per 1000 kg of vehicle mass was obtained for the non-steel (NAO) pads, which is much lower than that of low-steel pads.

- For brake wear factors, based on mass loss measurements, 14.0–74.8% of wear particles originated from discs, 14.0–64.4% from non-steel pads, and 55.0–74.8% from low-steel pads. The contribution of disc wear determined from the iron concentration in the brake wear particles was approximately similar to the mass loss measurements, although there was a large variation.

- The correlation coefficients of the mass content of elements in the pads for the brake wear factor, disc wear factor, PM10, and PM2.5 were very similar; C, Mg, Cr, and Fe mainly had high positive correlation coefficients, and O, K, Ti, and Ba mainly had high negative ones.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Experimental Conditions

| Experiment # | Test Vehicle Mass | Brake Force Distributions | Test Inertia | Rolling Radius | Wln/dm | Air Flow/Directions | Enclosure/Tunnel Types |

|---|---|---|---|---|---|---|---|

| kg | % | kg-m2 | mm | - | m3/min | ||

| 1 | 943 | 80 | 28.2 | 293 | 109.0 | 1.0, CCW | A |

| 2 | 943 | 80 | 26.7 | 285 | 109.0 | 1.0, CCW | A |

| 3 | 1443 | 80 | 48.3 | 310 | 96.7 | 10.0, CCW | A |

| 4 | 1443 | 80 | 48.3 | 310 | 96.7 | 1.0, CCW | A |

| 5 | 1133 | 80 | 33.8 | 293 | 90.5 | 10.0, CCW | A |

| 6 | 1133 | 80 | 33.8 | 293 | 90.5 | 1.0, CCW | A |

| 7 | 1683 | 80 | 69.7 | 345 | 88.7 | 10.0, CCW | A |

| 8 | 1683 | 80 | 69.7 | 345 | 88.7 | 1.0, CCW | A |

| 9 | 2153 | 80 | 82.1 | 331 | 111.0 | 10.0, CCW | A |

| 10 | 2153 | 80 | 82.1 | 331 | 111.0 | 1.0, CCW | A |

| 11 | 2803 | 80 | 140.9 | 380 | 99.8 | 10.0, CCW | A |

| 12 | 2803 | 80 | 140.9 | 380 | 99.8 | 1.0, CCW | A |

| 13 | 1600 | 71.6 | 49.3 | 314.5 | 87.6 | 8.2, CW | B |

| 14 | 1600 | 71.6 | 49.3 | 314.5 | 87.6 | 8.2, CW | B |

| 15 | 1668 | 68 | 50.8 | 321 | 44.9 | 8.2, CW | B |

| 16 | 2623 | 67 | 112.1 | 383 | 50.3 | 8.2, CW | B |

| 17 | 2500 | 67 | 86.7 | 345 | 89.2 | 8.2, CW | B |

| 18 | 3390 | 67 | 117.6 | 345 | 120.8 | 8.2, CW | B |

| 19 | 1533 | 77 | 47.8 | 305 | 111.8 | 4.1, CCW | C |

| 20 | 1600 | 71.6 | 49.3 | 314.5 | 87.6 | 8.0, CCW | C |

| 21 | 1600 | 71.6 | 49.3 | 314.5 | 87.6 | 8.0, CCW | C |

| 22 | 1668 | 68 | 50.8 | 321 | 44.9 | 8.0, CCW | C |

| 23 | 1500 | 77 | 48.3 | 310 | 97.6 | 7.7, CCW | C |

| 24 | 1500 | 23 | 14.4 | 310 | 47.7 | 7.7, CCW | C |

| 25 | 2030 | 77 | 84.7 | 353 | 70.0 | 7.7, CCW | C |

| 26 | 2030 | 23 | 25.3 | 353 | 37.8 | 7.7, CCW | C |

| 27 | 2670 | 77 | 129.8 | 381 | 89.4 | 7.7, CCW | C |

| 28 | 2670 | 23 | 38.8 | 381 | 41.0 | 7.7, CCW | C |

| 29 | 1840 | 77 | 77.7 | 355 | 77.2 | 8.2, CCW | C |

| 30 | 1840 | 77 | 77.7 | 355 | 77.2 | 8.2, CCW | C |

| 31 | 1840 | 77 | 77.7 | 355 | 77.2 | 4.1, CCW | C |

Appendix B. Elements in the Brake Pads

| Experiment # | Type | C | O | F | Na | Mg | Al | Si | P | S | Cl | K | Ca | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass Percent [%] | ||||||||||||||

| 1 | Non-steel | 24.5 | 32.2 | 1.3 | 0.2 | 0.2 | 0.6 | 3.7 | 0.01 | 1.3 | 2.8 | 6.7 | 9.8 | |

| 2 | Non-steel | 24.5 | 32.2 | 1.3 | 0.2 | 0.2 | 0.6 | 3.7 | 0.01 | 1.3 | 2.8 | 6.7 | 9.8 | |

| 3 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 4 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 5 | Non-steel | 26.2 | 32.3 | 2.0 | 0.2 | 0.9 | 1.3 | 2.7 | 0.02 | 1.4 | 3.7 | 2.4 | 10.0 | |

| 6 | Non-steel | 26.2 | 32.3 | 2.0 | 0.2 | 0.9 | 1.3 | 2.7 | 0.02 | 1.4 | 3.7 | 2.4 | 10.0 | |

| 7 | Non-steel | 31.6 | 32.9 | 0.1 | 0.2 | 2.0 | 0.3 | 1.3 | 0.003 | 2.3 | 0.02 | 4.3 | 3.0 | 9.0 |

| 8 | Non-steel | 31.6 | 32.9 | 0.1 | 0.2 | 2.0 | 0.3 | 1.3 | 0.003 | 2.3 | 0.02 | 4.3 | 3.0 | 9.0 |

| 9 | Non-steel | 30.1 | 31.2 | 1.6 | 0.3 | 0.5 | 0.8 | 2.8 | 0.01 | 1.5 | 0.01 | 1.6 | 2.8 | 7.1 |

| 10 | Non-steel | 30.1 | 31.2 | 1.6 | 0.3 | 0.5 | 0.8 | 2.8 | 0.01 | 1.5 | 0.01 | 1.6 | 2.8 | 7.1 |

| 11 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 12 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 13 | Low-steel | 40.8 | 29.8 | 0.4 | 3.7 | 4.5 | 2.1 | 0.08 | 1.6 | 0.06 | 0.6 | 0.2 | 0.1 | |

| 14 | Non-steel | 27.4 | 33.7 | 0.7 | 0.1 | 2.3 | 0.7 | 3.1 | 0.03 | 1.5 | 0.09 | 3.0 | 1.7 | 7.1 |

| 15 | Low-steel | 42.5 | 28.9 | 0.3 | 0.1 | 6.1 | 0.6 | 3.7 | 0.15 | 1.7 | 0.02 | 0.2 | 0.4 | 0.1 |

| 16 | Low-steel | 44.6 | 27.0 | 0.6 | 0.04 | 7.4 | 2.9 | 1.1 | 0.01 | 0.9 | 0.02 | 0.6 | 0.7 | 2.0 |

| 17 | Low-steel | 38.0 | 30.9 | 0.3 | 4.5 | 0.8 | 2.9 | 0.02 | 2.2 | 0.02 | 0.3 | 0.4 | 0.1 | |

| 18 | Low-steel | 38.0 | 30.9 | 0.3 | 4.5 | 0.8 | 2.9 | 0.02 | 2.2 | 0.02 | 0.3 | 0.4 | 0.1 | |

| 19 | Non-steel | 34.7 | 33.3 | 0.1 | 0.1 | 2.7 | 0.9 | 2.9 | 0.01 | 1.2 | 0.02 | 3.3 | 0.9 | 5.9 |

| 20 | Low-steel | 40.8 | 29.8 | 0.4 | 3.7 | 4.5 | 2.1 | 0.08 | 1.6 | 0.06 | 0.6 | 0.2 | 0.1 | |

| 21 | Non-steel | 27.4 | 33.7 | 0.7 | 0.1 | 2.3 | 0.7 | 3.1 | 0.03 | 1.5 | 0.09 | 3.0 | 1.7 | 7.1 |

| 22 | Low-steel | 42.5 | 28.9 | 0.3 | 0.1 | 6.1 | 0.6 | 3.7 | 0.15 | 1.7 | 0.02 | 0.2 | 0.4 | 0.1 |

| 23 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 24 | Non-steel | 27.9 | 33.7 | 0.1 | 0.3 | 0.8 | 0.3 | 1.2 | 0.01 | 2.7 | 0.02 | 3.8 | 3.2 | 11.6 |

| 25 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 26 | Non-steel | 31.6 | 32.9 | 0.1 | 0.2 | 2.0 | 0.3 | 1.3 | 0.003 | 2.3 | 0.02 | 4.3 | 3.0 | 9.0 |

| 27 | Non-steel | 31.5 | 32.6 | 0.6 | 0.1 | 1.0 | 0.6 | 2.3 | 0.02 | 1.5 | 0.01 | 2.9 | 4.6 | 7.3 |

| 28 | Non-steel | 30.1 | 35.6 | 3.7 | 0.3 | 2.8 | 1.0 | 2.8 | 0.02 | 1.5 | 2.8 | 1.4 | 5.6 | |

| 29 | Low-steel | 41.3 | 28.0 | 0.2 | 1.9 | 3.2 | 1.7 | 0.01 | 1.4 | 0.01 | 0.2 | 1.4 | 0.1 | |

| 30 | Low-steel | 38.8 | 30.2 | 0.1 | 0.05 | 2.5 | 1.0 | 4.3 | 0.05 | 2.4 | 0.05 | 0.4 | 0.7 | 0.1 |

| 31 | Non-steel | 24.7 | 29.6 | 0.7 | 0.1 | 0.9 | 0.6 | 1.9 | 0.03 | 2.3 | 0.03 | 2.8 | 3.7 | 6.4 |

| Experiment # | Type | Cr | Mn | Fe | Ni | Cu | Zn | Sr | Zr | Mo | Sn | Sb | Ba | Hf |

| Mass Percent [%] | ||||||||||||||

| 1 | Non-steel | 0.05 | 1.1 | 0.002 | 1.9 | 0.03 | 0.07 | 7.6 | 1.2 | 4.2 | 0.7 | |||

| 2 | Non-steel | 0.05 | 1.1 | 0.002 | 1.9 | 0.03 | 0.07 | 7.6 | 1.2 | 4.2 | 0.7 | |||

| 3 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.2 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 4 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.2 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 5 | Non-steel | 0.04 | 4.5 | 0.003 | 0.002 | 1.4 | 0.05 | 2.6 | 2.7 | 5.5 | 0.1 | |||

| 6 | Non-steel | 0.04 | 4.5 | 0.003 | 0.002 | 1.4 | 0.05 | 2.6 | 2.7 | 5.5 | 0.1 | |||

| 7 | Non-steel | 0.01 | 0.01 | 0.1 | 0.004 | 0.005 | 1.1 | 0.18 | 3.9 | 7.4 | 0.1 | |||

| 8 | Non-steel | 0.01 | 0.01 | 0.1 | 0.004 | 0.005 | 1.1 | 0.18 | 3.9 | 7.4 | 0.1 | |||

| 9 | Non-steel | 0.01 | 0.06 | 4.8 | 0.005 | 0.7 | 0.05 | 0.07 | 5.7 | 2.5 | 5.6 | 0.1 | ||

| 10 | Non-steel | 0.01 | 0.06 | 4.8 | 0.005 | 0.7 | 0.05 | 0.07 | 5.7 | 2.5 | 5.6 | 0.1 | ||

| 11 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.2 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 12 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.2 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 13 | Low-steel | 1.50 | 0.05 | 7.4 | 0.02 | 3.1 | 1.9 | 0.002 | 0.02 | 0.1 | 1.7 | |||

| 14 | Non-steel | 0.01 | 0.01 | 1.1 | 0.01 | 1.9 | 0.02 | 0.1 | 8.3 | 1.2 | 4.5 | 1.2 | ||

| 15 | Low-steel | 1.20 | 0.07 | 7.3 | 0.01 | 0.02 | 0.01 | 0.07 | 1.8 | 2.5 | ||||

| 16 | Low-steel | 0.85 | 0.06 | 9.4 | 0.02 | 0.008 | 1.2 | 0.001 | 0.03 | 0.5 | 0.0 | |||

| 17 | Low-steel | 0.78 | 0.08 | 9.4 | 0.007 | 2.7 | 1.6 | 0.06 | 0.003 | 2.2 | 2.8 | |||

| 18 | Low-steel | 0.78 | 0.08 | 9.4 | 0.007 | 2.7 | 1.6 | 0.06 | 0.003 | 2.2 | 2.8 | |||

| 19 | Non-steel | 0.05 | 6.6 | 0.01 | 1.8 | 0.06 | 0.3 | 1.1 | 4.0 | |||||

| 20 | Low-steel | 1.50 | 0.05 | 7.4 | 0.02 | 3.1 | 1.9 | 0.002 | 0.02 | 0.1 | 1.7 | |||

| 21 | Non-steel | 0.01 | 0.01 | 1.1 | 0.01 | 1.8 | 0.02 | 0.1 | 8.3 | 1.2 | 4.5 | 1.2 | ||

| 22 | Low-steel | 1.20 | 0.07 | 7.3 | 0.01 | 0.02 | 0.01 | 0.07 | 1.8 | 2.5 | ||||

| 23 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.19 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 24 | Non-steel | 0.01 | 0.01 | 0.2 | 0.005 | 0.005 | 1.2 | 0.2 | 4.3 | 8.4 | 0.1 | |||

| 25 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.2 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 26 | Non-steel | 0.01 | 0.01 | 0.1 | 0.004 | 0.005 | 1.1 | 0.2 | 3.9 | 7.4 | 0.1 | |||

| 27 | Non-steel | 0.01 | 0.09 | 2.7 | 0.01 | 0.002 | 0.2 | 0.08 | 5.9 | 0.4 | 1.4 | 3.6 | 0.5 | |

| 28 | Non-steel | 0.04 | 5.8 | 0.002 | 0.01 | 0.05 | 0.1 | 6.2 | ||||||

| 29 | Low-steel | 0.95 | 0.05 | 10.3 | 0.007 | 2.4 | 1.8 | 0.004 | 1.0 | 3.6 | 0.4 | |||

| 30 | Low-steel | 1.54 | 0.05 | 9.6 | 0.01 | 2.5 | 1.0 | 0.05 | 0.01 | 1.0 | 0.4 | 1.4 | 1.8 | |

| 31 | Non-steel | 0.01 | 0.10 | 3.0 | 0.01 | 0.005 | 0.02 | 0.1 | 12.2 | 0.2 | 1.6 | 6.0 | 2.7 | |

Appendix C. Elements in the Brake Discs

| Experiment # | C | O | Si | P | S | Mn | Fe | Ni | Cu | Zn |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass Percent [%] | ||||||||||

| 1 | 3.7 | 12.6 | 2.1 | 0.03 | 0.2 | 0.6 | 79.4 | 0.01 | 0.1 | 0.09 |

| 2 | 3.7 | 12.6 | 2.1 | 0.03 | 0.2 | 0.6 | 79.4 | 0.01 | 0.1 | 0.09 |

| 3 | 3.9 | 11.6 | 1.8 | 0.03 | 0.1 | 0.5 | 81.1 | 0.02 | 0.06 | 0.01 |

| 4 | 3.9 | 11.6 | 1.8 | 0.03 | 0.1 | 0.5 | 81.1 | 0.02 | 0.06 | 0.01 |

| 5 | 3.5 | 14.0 | 1.8 | 0.02 | 0.2 | 0.5 | 78.4 | 0.03 | 0.07 | |

| 6 | 3.5 | 14.0 | 1.8 | 0.02 | 0.2 | 0.5 | 78.4 | 0.03 | 0.07 | |

| 7 | 9.7 | 3.1 | 1.9 | 0.05 | 0.1 | 0.6 | 83.9 | 0.02 | 0.04 | 0.02 |

| 8 | 9.7 | 3.1 | 1.9 | 0.05 | 0.1 | 0.6 | 83.9 | 0.02 | 0.04 | 0.02 |

| 9 | 3.8 | 16.7 | 2.0 | 0.02 | 0.4 | 0.5 | 74.4 | 0.02 | 0.3 | 0.01 |

| 10 | 3.8 | 16.7 | 2.0 | 0.02 | 0.4 | 0.5 | 74.4 | 0.02 | 0.3 | 0.01 |

| 11 | 3.8 | 6.7 | 1.8 | 0.03 | 0.1 | 0.6 | 86.5 | 0.02 | 0.05 | 0.01 |

| 12 | 3.8 | 6.7 | 1.8 | 0.03 | 0.1 | 0.6 | 86.5 | 0.02 | 0.05 | 0.01 |

| 13 | 10.8 | 1.4 | 1.7 | 0.03 | 0.1 | 0.6 | 84.7 | 0.05 | 0.2 | |

| 14 | 10.8 | 1.4 | 1.7 | 0.03 | 0.1 | 0.6 | 84.7 | 0.05 | 0.2 | |

| 15 | 10.9 | 2.6 | 1.6 | 0.05 | 0.1 | 0.8 | 82.9 | 0.05 | 0.5 | 0.01 |

| 16 | 9.2 | 6.7 | 1.6 | 0.04 | 0.1 | 0.6 | 80.9 | 0.05 | 0.2 | 0.01 |

| 17 | 4.8 | 13.5 | 1.5 | 0.03 | 0.2 | 0.7 | 77.8 | 0.05 | 0.7 | 0.05 |

| 18 | 4.8 | 13.5 | 1.5 | 0.03 | 0.2 | 0.7 | 77.8 | 0.05 | 0.7 | 0.05 |

| 19 | 3.9 | 11.6 | 1.8 | 0.03 | 0.1 | 0.5 | 81.1 | 0.02 | 0.06 | 0.01 |

| 20 | 10.8 | 1.4 | 1.7 | 0.03 | 0.1 | 0.6 | 84.7 | 0.05 | 0.2 | |

| 21 | 10.8 | 1.4 | 1.7 | 0.03 | 0.1 | 0.6 | 84.7 | 0.05 | 0.2 | |

| 22 | 10.9 | 2.6 | 1.6 | 0.05 | 0.1 | 0.8 | 82.9 | 0.05 | 0.5 | 0.01 |

| 23 | 3.9 | 11.6 | 1.8 | 0.03 | 0.1 | 0.5 | 81.1 | 0.02 | 0.06 | 0.01 |

| 24 | 4.0 | 10.1 | 1.7 | 0.03 | 0.2 | 0.6 | 82.3 | 0.01 | 0.05 | 0.04 |

| 25 | 4.1 | 13.5 | 1.7 | 0.03 | 0.1 | 0.5 | 79.0 | 0.02 | 0.03 | 0.02 |

| 26 | 3.5 | 8.7 | 1.7 | 0.03 | 0.2 | 0.6 | 84.6 | 0.04 | 0.02 | |

| 27 | 3.8 | 6.7 | 1.8 | 0.03 | 0.1 | 0.6 | 86.5 | 0.02 | 0.05 | 0.01 |

| 28 | 3.2 | 8.8 | 1.8 | 0.03 | 0.1 | 0.5 | 84.8 | 0.02 | 0.04 | 0.01 |

| 29 | 9.7 | 3.1 | 1.9 | 0.05 | 0.1 | 0.6 | 83.9 | 0.02 | 0.04 | 0.02 |

| 30 | 9.7 | 3.1 | 1.9 | 0.05 | 0.1 | 0.6 | 83.9 | 0.02 | 0.04 | 0.02 |

| 31 | 9.7 | 3.1 | 1.9 | 0.05 | 0.1 | 0.6 | 83.9 | 0.02 | 0.04 | 0.02 |

References

- Maricq, M.M. Engine, Aftertreatment, Fuel Quality and Non-tailpipe Achievements to Lower Gasoline Vehicle PM Emissions: Literature Review and Future Prospects. Sci. Total Environ. 2023, 866, 161225. [Google Scholar] [CrossRef] [PubMed]

- Fussell, J.C.; Franklin, M.; Green, D.C.; Gustafsson, M.; Harrison, R.M.; Hicks, W.; Kelly, F.J.; Kishta, F.; Miller, M.R.; Mudway, I.S.; et al. A Review of Road Traffic-Derived Non-Exhaust Particles: Emissions, Physicochemical Characteristics, Health Risks, and Mitigation Measures. Environ. Sci. Technol. 2022, 56, 6813–6835. [Google Scholar] [CrossRef] [PubMed]

- Grigoratos, T.; Martini, G. Brake Wear Particle Emissions: A Review. Environ. Sci. Pollut. Res. 2015, 22, 2491–2504. [Google Scholar] [CrossRef] [PubMed]

- Grange, S.K.; Fischer, A.; Zellweger, C.; Alastuey, A.; Querol, X.; Jaffrezo, J.-L.; Weber, S.; Uzu, G.; Hueglin, C. Switzerland’s PM10 and PM2.5 Environmental increments show the Importance of Non-exhaust Emissions. Atmos. Environ. X 2021, 12, 100145. [Google Scholar] [CrossRef]

- Piscitello, A.; Bianco, C.; Casasso, A.; Sethi, R. Non-exhaust Traffic Emissions: Sources, Characterization, and Mitigation Measures. Sci. Total Environ. 2021, 766, 144440. [Google Scholar] [CrossRef] [PubMed]

- Grigoratos, T.; Mathissen, M.; Vedula, R.; Mamakos, A.; Agudelo, C.; Gramstat, S.; Giechaskiel, B. Interlaboratory Study on Brake Particle Emissions—Part I: Particulate Matter Mass Emissions. Atmosphere 2023, 14, 498. [Google Scholar] [CrossRef]

- ECE/TRANS/180/Add.24. UN Global Technical Regulation No. 24 Laboratory Measurement of Brake Emissions for Light-Duty Vehicles. Update on 17 July 2023. Available online: https://unece.org/sites/default/files/2023-07/ECE-TRANS-180-Add.24.docx (accessed on 8 May 2024).

- JASO C470; Passenger Car—Measurement Method for Brake Wear Particle Emissions. Society of Automotive Engineers of Japan Inc.: Tokyo, Japan, 31 March 2020.

- Regulation (EU) 2024/1257 of the European Parliament and of the Council. Document 32024R1257. Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L_202401257 (accessed on 8 May 2024).

- Mellios, G.; Ntziachristos, L. Non-Exhaust Emissions: Evaporation & Brake Wear Control. 2021. Available online: https://circabc.europa.eu/sd/a/1c0efc15-8507-4797-9647-97c12d82fa28/AGVES-2021-04-08-EVAP_Non-Exh.pdf (accessed on 22 November 2022).

- Shibata, Y.; Morikawa, T. Review of the JCAP/JATOP Air Quality Model Study in Japan. Atmosphere 2021, 12, 943. [Google Scholar] [CrossRef]

- Kasai, A. Measures to Reduce Emissions of Particulate Matter from Motor Vehicles. J. Jpn. Soc. Atmos. Environ. 2017, 52, A91–A96. (In Japanese) [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Mathissen, M.; Grochowicz, J.; Schmidt, C.; Vogt, R.; Zum Hagen, F.H.F.; Grabiec, T.; Steven, H.; Grigoratos, T. A Novel Real-World Braking Cycle for Studying Brake Wear Particle Emissions. Wear 2018, 414–415, 219–226. [Google Scholar] [CrossRef]

- Chan, D.; Stachowiak, G.W. Review of Automotive Brake Friction Materials. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 953–966. [Google Scholar] [CrossRef]

- Österle, W.; Dmitriev, A.I. The Role of Solid Lubricants for Brake Friction Materials. Lubricants 2016, 4, 5. [Google Scholar] [CrossRef]

- Joo, B.S.; Chang, Y.H.; Seo, H.J.; Jang, H. Effects of Binder Resin on Tribological Properties and Particle Emission of Brake Linings. Wear 2019, 434–435, 202995. [Google Scholar] [CrossRef]

- Park, J.; Gweon, J.; Seo, H.; Song, W.; Lee, J.J.; Choi, J.; Kim, Y.C.; Jang, H. Effect of Space Fillers in Brake Friction Composites Airborne Particle Emission: A Case Study with BaSO4, Ca(OH)2, and CaCO3. Tribol. Int. 2021, 165, 107334. [Google Scholar] [CrossRef]

- Joo, B.S.; Jara, D.C.; Seo, H.J.; Jang, H. Influences of The Average Molecular Weight of Phenolic Resin and Potassium Titanate Morphology on Particulate Emissions from Brake Linings. Wear 2020, 450–451, 203243. [Google Scholar] [CrossRef]

- Park, J.; Song, W.; Gweon, J.; Seo, H.; Lee, J.J.; Jang, H. Size Effect of Zircon Particles in Brake Pads on the Composition and Size Distribution of Emitted Particulate Matter. Tribol. Int. 2021, 160, 106995. [Google Scholar] [CrossRef]

- Park, J.; Joo, B.; Seo, H.; Song, W.; Lee, J.J.; Lee, W.K.; Jang, H. Analysis of Wear Induced Particle Emissions from Brake Pads during the Worldwide Harmonized Light Vehicles Test Procedure (WLTP). Wear 2021, 466–467, 203539. [Google Scholar] [CrossRef]

- Sanders, P.G.; Xu, N.; Dalka, T.M.; Maricq, M.M. Airborne Brake Wear Debris: Size Distributions, Composition, and a Comparison of Dynamometer and Vehicle Tests. Environ. Sci. Technol. 2003, 37, 4060–4069. [Google Scholar] [CrossRef]

- Woo, S.H.; Kim, Y.; Lee, S.; Choi, Y.; Lee, S. Characteristics of Brake Wear Particle (BWP) Emissions under Various Test Driving Cycles. Wear 2021, 480–481, 203936. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Grigoratos, T.; Dilara, P.; Karageorgiou, T.; Ntziachristos, L.; Samaras, Z. Light-Duty Vehicle Brake Emission Factors. Atmosphere 2024, 15, 97. [Google Scholar] [CrossRef]

- Woo, S.-H.; Jang, H.; Na, M.Y.; Chang, H.J.; Lee, S. Characterization of Brake Particles Emitted from Non-Asbestos Organic and Low-Metallic Brake Pads under Normal and Harsh Braking Conditions. Atmos. Environ. 2022, 278, 119089. [Google Scholar] [CrossRef]

- Storch, L.; Hamatschek, C.; Hesse, D.; Feist, F.; Bachmann, T.; Eichler, P.; Grigoratos, T. Comprehensive Analysis of Current Primary Measures to Mitigate Brake Wear Particle Emissions from Light-Duty Vehicles. Atmosphere 2023, 14, 712. [Google Scholar] [CrossRef]

- Davin, E.A.T.; Cristol, A.-L.; Beaurain, A.; Dufrénoy, P.; Zaquen, N. Differences in Wear and Material Integrity of NAO and Low-Steel Brake Pads under Severe Conditions. Materials 2021, 14, 5531. [Google Scholar] [CrossRef]

- Perricone, G.; Matějka, V.; Alemani, M.; Valota, G.; Bonfanti, A.; Ciotti, A.; Olofsson, U.; Söderberg, A.; Wahlström, J.; Nosko, O.; et al. A Concept for Reducing PM10 Emissions for Car Brakes by 50%. Wear 2018, 396, 135–145. [Google Scholar] [CrossRef]

- Agudelo, C.; Vedula, R.; Collier, S.; Stanard, A. Brake Particulate Matter Emissions Measurements for Six Light-Duty Vehicles Using Inertia Dynamometer Testing. SAE Int. J. Adv. Curr. Prac. Mobil. 2021, 3, 994–1019. [Google Scholar] [CrossRef]

- Aranganathan, N.; Mahale, V.; Bijwe, U. Effects of Aramid Fiber Concentration on the Friction and Wear Characteristics of Non-Asbestos Organic Friction Composites using Standardized Braking Tests. Wear 2016, 354–355, 69–77. [Google Scholar] [CrossRef]

- Kato, T.; Magario, A. The Wear of Aramid Fiber Reinforced Brake Pads: The Role of Aramid Fibers. Tribo Trans. 1994, 37, 559–565. [Google Scholar] [CrossRef]

- Song, W.; Park, J.; Choi, J.; Lee, J.J.; Jang, H. Effects of Reinforcing Fibers on Airborne Particle Emissions from Brake Pads. Wear 2021, 484–485, 203996. [Google Scholar] [CrossRef]

- Okayama, K.; Kishimoto, H.; Hiratsuka, K. Tribo-Reduction of Metal Oxides by Tribo-Degradation of Phenolic Resin in Brake Pads. Trans. Jpn. Soc. Mech. Eng. C 2013, 79, 2558–2570, (In Japanese with English Figures and Tables). [Google Scholar] [CrossRef]

- JIS D 0210:1995; General Rules of Brake Test Method of Automobiles and Motor Cycles. Japanese Standards Association: Tokyo, Japan, 2022.

- Hagino, H.; Oyama, M.; Sasaki, S. Laboratory Testing of Airborne Brake Wear Particle Emissions using a Dynamometer System under Urban City Driving Cycles. Atmos. Environ. 2016, 131, 269–278. [Google Scholar] [CrossRef]

- Hagino, H.; Iwata, A.; Okuda, T. Iron Oxide and Hydroxide Speciation in Emissions of Brake Wear Particles from Different Friction Materials Using an X-ray Absorption Fine Structure. Atmosphere 2024, 15, 49. [Google Scholar] [CrossRef]

- Hagino, H. Feasibility of Measuring Brake-Wear Particle Emissions from a Regenerative-Friction Brake Coordination System via Dynamometer Testing. Atmosphere 2024, 15, 75. [Google Scholar] [CrossRef]

- Sinha, A.; Ischia, G.; Menapace, C.; Gialanella, S. Experimental Characterization Protocols for Wear Products from Disc Brake Materials. Atmosphere 2020, 11, 1102. [Google Scholar] [CrossRef]

- Kenny, L.C.; Gussman, R.; Meyer, M. Development of a Sharp-Cut Cyclone for Ambient Aerosol Monitoring Applications. Aerosol Sci. Technol. 2000, 32, 338–358. [Google Scholar] [CrossRef]

- Spada, N.J.; Yatkin, S.; Giacomo, J.; Trzepla, K.; Hyslop, N.P. Evaluating IMPROVE PM2.5 Element Measurements. J. Air Waste Manag. Assoc. 2023, 73, 843–852. [Google Scholar] [CrossRef] [PubMed]

- Namgung, H.G.; Kim, J.B.; Woo, S.H.; Park, S.; Kim, M.; Kim, M.S.; Bae, G.N.; Park, D.; Kwon, S.B. Generation of Nanoparticles from Friction between Railway Brake Disks and Pads. Environ. Sci. Technol. 2016, 50, 3453–3461. [Google Scholar] [CrossRef]

- Hinds, W.C.; Yifang, Z. Chapter 4—Particle Size Statics. In Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; pp. 65–94. ISBN 978-1-119-49406-5. [Google Scholar]

- Durand, T.; Bau, S.; Morele, Y.; Matera, V.; Bémer, D.; Rousset, D. Quantification of Low Pressure Impactor Wall Deposits during Zinc Nanoparticle Sampling. Aerosol Air Qual. Res. 2014, 14, 1812–1821. [Google Scholar] [CrossRef]

- Mamakos, A.; Kolbeck, K.; Arndt, M.; Schröder, T.; Bernhard, M. Particle Emissions and Disc Temperature Profiles from a Commercial Brake System Tested on a Dynamometer under Real-World Cycles. Atmosphere 2021, 12, 377. [Google Scholar] [CrossRef]

- Andersson, J.; Kramer, L.J.; Campbell, M.; Marshall, I.; Norris, J.; Southgate, J.; de Vries, S.; Waite, G. A Practical Approach for On-Road Measurements of Brake Wear Particles from a Light-Duty Vehicle. Atmosphere 2024, 15, 224. [Google Scholar] [CrossRef]

- Bondorf, L.; Köhler, L.; Grein, T.; Epple, F.; Philipps, F.; Aigner, M.; Schripp, T. Airborne Brake Wear Emissions from a Battery Electric Vehicle. Atmosphere 2023, 14, 488. [Google Scholar] [CrossRef]

- Farwick Zum Hagen, F.H.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. On-Road Vehicle Measurements of Brake Wear Particle Emissions. Atmos. Environ. 2019, 217, 116943. [Google Scholar] [CrossRef]

- Iijima, A.; Sato, K.; Yano, K.; Kato, M.; Kozawa, K.; Furuta, N. Emission Factor for Antimony in Brake Abrasion Dusts as One of the Major Atmospheric Antimony Sources. Environ. Sci. Technol. 2008, 42, 2937–2942. [Google Scholar] [CrossRef] [PubMed]

- Hulskotte, J.; Roskam, G.D.; Denier van der Gon, H. Elemental Composition of Current Automotive Braking Materials and derived Air Emission Factors. Atmos. Environ. 2014, 99, 436–445. [Google Scholar] [CrossRef]

- Sakamoto, T.; Yoshida, C.; Yoshikawa, K.; Takada, H.; Nakamura, I. The Role of Tramp Elements of Cast Pig Iron. J. Jpn. Foundry Eng. Soc. 1981, 53, 466–471. (In Japanese) [Google Scholar] [CrossRef]

- Gramstat, S.; Mertens, T.; Waninger, R.; Lugovyy, D. Impacts on Brake Particle Emission Testing. Atmosphere 2020, 11, 1132. [Google Scholar] [CrossRef]

- Kimoto, K. Current Trends and Development of Phenolic Resins Used for Riction Materials. J. Netw. Poly. Jpn. 2014, 35, 211–217, (In Japanese with English Figures and Tables). [Google Scholar] [CrossRef]

- Nidhi, J.; Bijwe, N.; Mazumdar, N. Influence of Amount and Modification of Resin on Fade and Recovery Behavior of Non-Asbestos Organic (NAO) Friction Materials. Tribol. Lett. 2006, 23, 215–222. [Google Scholar] [CrossRef]

- Öztürk, B.; Öztürk, S. Effects of Resin Type and Fiber Length on the Mechanical and Tribological Properties of Brake Friction Materials. Tribol. Lett. 2011, 42, 339–350. [Google Scholar] [CrossRef]

- Mizuta, K.; Nishizawa, Y.; Sugimoto, K.; Okayama, K.; Hase, A. Evaluation of Friction Phenomena of Brake Pads by Acoustic Emission Method. SAE Int. J. Commer. Veh. 2014, 7, 703–709. [Google Scholar] [CrossRef]

- Masotti, D.; Ferreira, N.; Neis, P.; Menetrier, A.; Matozo, L.; Varante, P. Evaluation of Creep Groan Phenomena of Brake Pad Materials Using Different Abrasive Particles; SAE Technical Paper; SAE International: Pittsburgh, PA, USA, 2014. [Google Scholar] [CrossRef]

- Masotti, D.; Gomes, T.R.; Ordoñez, M.F.C.; Al-Qureshi, H.A.; Farias, M.C.M. Effect of Abrasives’ Characteristics on Brake Squeal Noise Generation. Wear 2023, 518–519, 204618. [Google Scholar] [CrossRef]

- Eriksson, M.; Bergman, F.; Jacobson, S. On the Nature of Tribological Contact in Automotive Brakes. Wear 2002, 252, 26–36. [Google Scholar] [CrossRef]

- Hiratsuka, K.; Yoshida, T. The Twin-Ting Tribometer—Characterizing Sliding Wear of Metals Excluding the Effect of Contact Configurations. Wear 2011, 270, 742–750. [Google Scholar] [CrossRef]

- Berthier, Y. Third-Body Reality—Consequences and Use of the Third-Body Concept to Solve Friction and Wear Problems. In Wear—Materials, Mechanisms and Practice; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2014; pp. 291–316. [Google Scholar] [CrossRef]

- Lee, J.-J.; Lee, J.-A.; Kwon, S.; Kim, J.-J. Effect of Different Reinforcement Materials on the Formation of Secondary Plateaus and Friction Properties in Friction Materials for Automobiles. Tribol. Int. 2018, 120, 70–79. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.J.; Basch, R.H.; Fash, J.W. The Effect of Metal Fibers on the Friction Performance of Automotive Brake Friction Materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Yanar, H.; Purcek, G.; Ayar, H.H. Effect of Steel Fiber Addition on the Mechanical and Tribological Behavior of the Composite Brake Pad Materials. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 012018. [Google Scholar] [CrossRef]

- Halberstadt, M.L.; Rhee, S.K.; Mansfield, J.A. Effects of Potassium Titanate Fiber on the Wear of Automotive Brake Linings. Wear 1978, 46, 109–126. [Google Scholar] [CrossRef]

- Kim, Y.C.; Cho, M.H.; Kim, S.J.; Jang, H. The Effect of Phenolic Resin, Potassium Titanate, and CNSL on the Tribological Properties of Brake Friction Materials. Wear 2008, 264, 204–210. [Google Scholar] [CrossRef]

- Cho, K.H.; Cho, M.H.; Kim, S.J.; Jang, H. Tribological Properties of Potassium Titanate in the Brake Friction Material; Morphological Effects. Tribol. Lett. 2008, 32, 59–66. [Google Scholar] [CrossRef]

- Jara, D.C.; Jang, H. Synergistic Effects of the Ingredients of Brake Friction Materials on Friction and Wear: A Case Study on Phenolic Resin and Potassium Titanate. Wear 2019, 430–431, 222–232. [Google Scholar] [CrossRef]

- Daimon, E.; Nomoto, T.; Inada, K.; Ogawa, H.; Kitada, K.; O’Doherty, J. Chemical Effects of Titanate Compounds on the Thermal Reactions of Phenolic Resins in Friction Materials—Part 3; SAE Technical Paper 2013-01-2025; SAE International: Pittsburgh, PA, USA, 2013. [Google Scholar] [CrossRef]

- Kim, S.J.; Cho, M.H.; Lim, D.-S.; Jang, H. Synergistic Effects of Aramid Pulp and Potassium Titanate Whiskers in the Automotive Friction Material. Wear 2001, 251, 1484–1491. [Google Scholar] [CrossRef]

- Okayama, K.; Fujikawa, H. Friction Material for Brake. Japanese Patent JP2005273770A, 24 March 2004. [Google Scholar]

- Singh, T. Comparative Performance of Barium Sulphate and Cement by-pass Dust on Tribological Properties of Automotive Brake Friction Composites. Alex. Eng. J. 2023, 72, 339–349. [Google Scholar] [CrossRef]

- Fang, T.; Kapur, S.; Edwards, K.C.; Hagino, H.; Wingen, L.M.; Perraud, V.; Thomas, A.E.; Bliss, B.; Herman, D.A.; Ruiz, A.D.V.; et al. Aqueous OH Radical Production by Brake Wear Particles. Environ. Sci. Technol. Lett. 2024, 11, 315–322. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hagino, H. Brake Wear and Airborne Particle Mass Emissions from Passenger Car Brakes in Dynamometer Experiments Based on the Worldwide Harmonized Light-Duty Vehicle Test Procedure Brake Cycle. Lubricants 2024, 12, 206. https://doi.org/10.3390/lubricants12060206

Hagino H. Brake Wear and Airborne Particle Mass Emissions from Passenger Car Brakes in Dynamometer Experiments Based on the Worldwide Harmonized Light-Duty Vehicle Test Procedure Brake Cycle. Lubricants. 2024; 12(6):206. https://doi.org/10.3390/lubricants12060206

Chicago/Turabian StyleHagino, Hiroyuki. 2024. "Brake Wear and Airborne Particle Mass Emissions from Passenger Car Brakes in Dynamometer Experiments Based on the Worldwide Harmonized Light-Duty Vehicle Test Procedure Brake Cycle" Lubricants 12, no. 6: 206. https://doi.org/10.3390/lubricants12060206

APA StyleHagino, H. (2024). Brake Wear and Airborne Particle Mass Emissions from Passenger Car Brakes in Dynamometer Experiments Based on the Worldwide Harmonized Light-Duty Vehicle Test Procedure Brake Cycle. Lubricants, 12(6), 206. https://doi.org/10.3390/lubricants12060206