Abstract

Titanium alloys are difficult to machine and have poor tribological properties. Nanoparticles have good cooling and lubricating properties, which can be used in metal cutting fluid. The lubrication characteristics of the two-dimensional materials Ti3C2TX MXene and graphene oxide in water-based fluid for titanium alloys were comparatively investigated in this paper. Graphene oxide had smaller friction coefficients and wear volume than Ti3C2TX MXene nanofluid. As to the mechanism, MXene easily formed TiO2 for the tribo-chemical reaction, which accelerated wear. Moreover, GO nanofluid can form a more uniform and stable friction layer between the frictional interface, which reduces the friction coefficient and decreases the adhesive wear. The effects of different surfactants on the lubricating properties of MXene were further investigated. It was found that the cationic surfactant Hexadecyl trimethyl ammonium chloride (1631) had the lowest friction coefficient and anti-wear properties for the strong electrostatic attraction with MXene nanoparticles. The results of this study indicate that 2D nanoparticles, especially graphene oxide, could improve the lubricating properties of titanium alloys. It provides insight into the application of water-based nanofluids for difficult-to-machine materials to enhance surface quality and cutting efficiency. The developed nanofluid, which can lubricate titanium alloys, effectively has very broad applications in prospect.

1. Introduction

Due to the low thermal conductivity and high chemical activity, titanium alloys are difficult to cut materials with high cutting temperatures and short tool lives. Moreover, titanium alloys have poor tribological properties such as high and unstable friction force, severe adhesive wear, and low wear resistance [1,2,3]. Traditional oil lubricants have little effect on titanium alloys, which need to be improved [4]. Nanoparticles are proven to have good cooling and lubricating properties, which can be used in metal cutting fluid. The lubrication and heat transfer properties of the nanofluids are enhanced; thus, the cutting efficiency can be improved [5,6]. The emerging environmentally friendly nanoparticles are considered substitutes for the organic additives used in the cutting fluid.

Two-dimensional nanomaterials have excellent mechanical and tribological properties because of their high Young’s modulus, high surface-to-volume ratios, and low friction force between the atomic layers [7,8,9,10]. Many 2D nanoparticles are hydrophobic and cannot be dispersed uniformly and stably in water. For titanium alloys, water-based lubricant is the optimal choice considering the thermal effect. Graphene oxide (GO) nanoparticles are synthesized with abundant surface functional groups such as hydroxyl, epoxide, carbonyl, and carboxyl groups so that GO can be dispersed in water naturally [11]. The lubricating properties of GO in water have been investigated by many researchers. GO nanoparticles with extremely thin layered structures can form an adsorption film that provides low shear stress and prevents interactions between friction pairs [12]. In addition, graphene particles can form an interfacial chemical reaction film with the frictional surface to prevent direct contact and alleviate wear [13]. Song studied the lubrication and anti-wear properties of graphene oxide on a steel ball and plate and found that a thin tribo-chemical friction film was formed to bear the load [14]. Kumar investigated the lubrication properties of GO on steel balls and aluminum discs and demonstrated that the graphene oxide layer, as a two-dimensional nanomaterial, forms a conformal protective film on the sliding contact interface and can be easily sheared off, thus reducing frictional wear [15].

Except for graphene oxide, MXene is an emerging two-dimensional material that has high electrical conductivity, excellent hydrophilicity, and rich surface chemistry [16,17,18]. Ti3C2TX, as the most studied member of the MXenes, has good dispersibility in water with hydroxyl- and oxygen-terminated groups [19,20]. The monolayer MXene showed good lubricating properties and can be used as a lubricant additive as well [21,22,23]. The tribological properties of Ti3C2(OH)2 nanosheets as additives in 100SN base oil were investigated by Zhang [24]. The results showed that the friction coefficient was decreased with Ti3C2(OH)2 nanosheets, which was attributed to the stable tribofilm formed on the steel surface. Liu demonstrated that highly exfoliated Ti3C2TX MXene nanosheets exhibited excellent lubrication in PAO 8 base oil using steel balls and steel disks as friction pairs [25]. Lian proved the friction reduction and anti-wear of Ti3C2 MXene between copper and steel and the mechanism was attributed to the hindering effect of Ti3C2 coatings and the carbon-rich lubricating transferred film between the contact interfaces [26]. Most of the literature reports on the friction of MXene are in oil-based lubrication. There is limited research on the effectiveness of MXene nanoparticles as water-based lubricant additives. Moreover, similar to other two-dimensional materials, MXene nanosheets are prone to restacking or aggregation [27,28]. Surfactants are added to the aqueous MXene nanofluid to improve the stability and dispersibility due to the interaction of MXene sheets with surfactant functional groups during hydrothermal processes [29,30].

As two-dimensional materials with the same size, the frictional performances of GO and MXene were comparatively studied as well. Nguyen found that the friction coefficient of Ti3C2 MXene was about 0.3 higher than that of the GO-based systems [31,32,33]. Ching used tetradecylphosphonic acid (TDPA)-modified Ti3C2TX and GO as nanohybrid lubricant additives in PAO 6 and found that TDPA-Ti3C2TX/GO was an efficient friction reduction and antiwear additive on steel pairs [34]. Macknojia also found that MXene/graphene oxide nanocomposites could reduce friction and wear on steel surfaces due to the formation of a dense hard stiff dangling-bond-saturated tribolayer [35]. A common feature among these studies is using ferrous metals as friction pairs. There is limited research on difficult-to-cut metals such as titanium alloys. Shuang investigated the performance of GO nanofluid in Ti-6Al-4V turning and demonstrated that GO nanofluid resulted in much lower surface roughness and cutting temperatures as compared to conventional coolants [36]. Sadeghi et al. developed a bilayer coating based on GO and polyvinylpyrrolidone (PVP) using electrophoretic deposition and found that the GO coating greatly improved the wear resistance and reduced the friction coefficient of titanium alloys [37]. However, these studies on titanium alloys only focus on GO and there is a lack of comparative studies on Ti3C2TX MXene and GO in water-based lubrication.

In summary, while scholars have achieved significant progress in the tribological field of 2D nanomaterials, there is limited research on the application of GO and MXene water-based nanofluids in lubricating titanium alloys and on the micro-scale mechanisms for nonferrous metal. Therefore, the objective of this study is to evaluate the effectiveness of GO and MXene nanoparticles in water-based lubricants for Ti-6Al-4V and to analyze the lubrication mechanisms of 2D nanofluids. Tribological experiments and surface analysis were designed to compare the lubricity of GO and Ti3C2TX MXene nanofluid on Ti-6Al-4V. In addition, surfactants that contribute to improving MXene dispersion were further explored. The nanofluid investigated in this work broads the scope of developing effective metal-cutting fluid to improve the working performance of titanium alloys.

2. Experiment

2.1. Nanofluid Preparation

Castor oil sulfated sodium salt (CSS) solution was chosen as the lubricant base stock for titanium alloy. CSS solution has demonstrated the ability to reduce friction coefficients and the adhesive wear of titanium alloys in our previous work [38]. Nevertheless, additional improvements are necessary to enhance the lubricating and cooling capabilities of CSS solutions for practical applications. In this work, two types of two-dimensional nanoparticles Ti3C2TX MXene and graphene oxide (GO) were selected as nano-additives for lubricating titanium alloys.

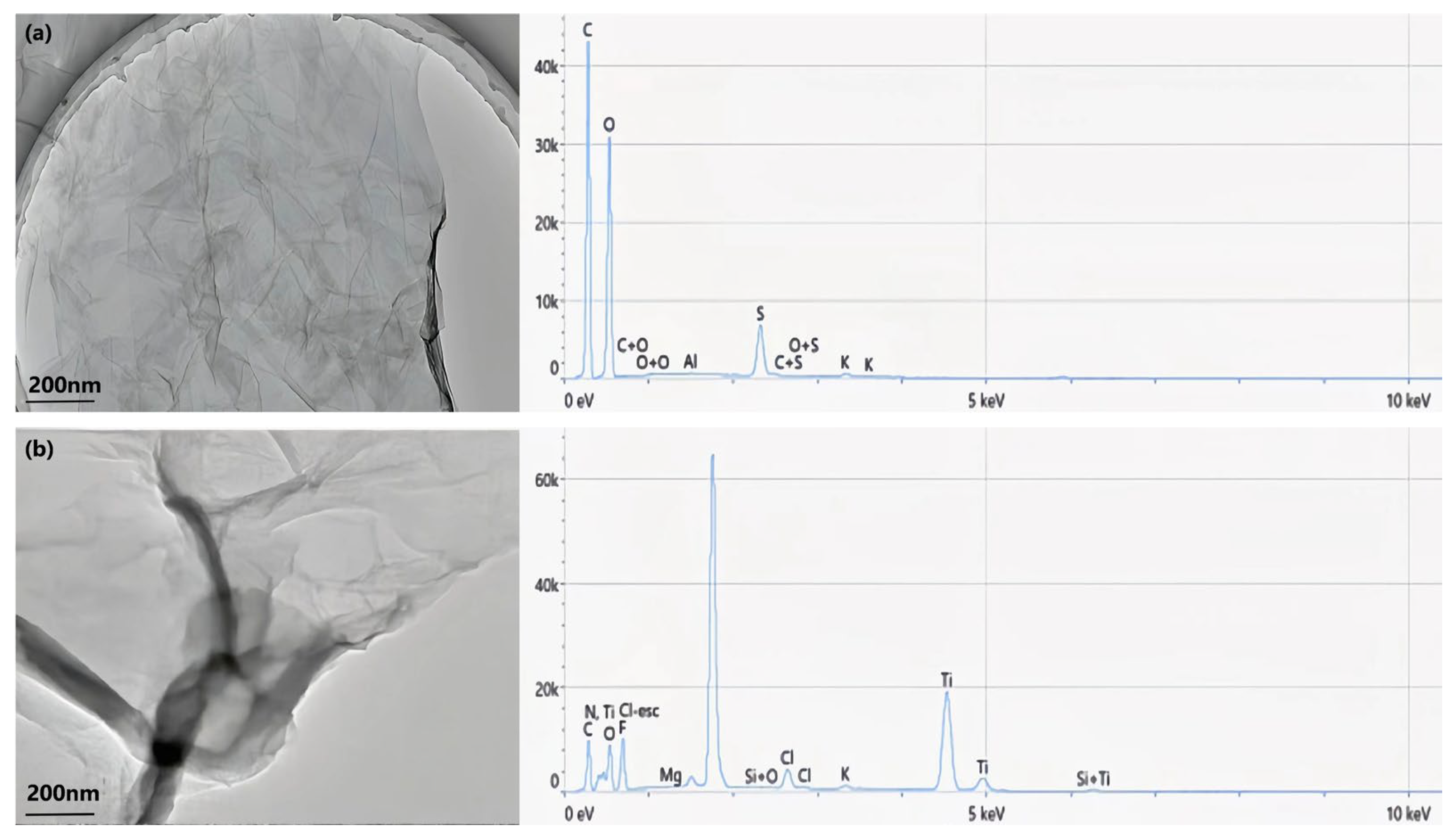

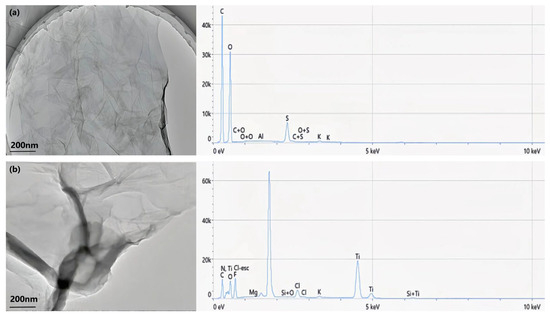

Graphene oxide was purchased from Nanjing XFNANO Materials Tech Co., Ltd., Nanjing, China, and the MXene was purchased from Foshan XINXI Technology Co., Ltd., Foshan, China. The microscopic morphology and EDS analysis of the two nanoparticles were observed and shown in Figure 1. The relevant parameters of these two nanoparticles are given in Table 1. Graphene oxide had a diameter of about 500 nm–5 µm and a thickness of about 0.8–1.2 nm, which was monolayer. The diameter of Ti3C2TX MXene was 500 nm–2 µm and the thickness was about 1 nm, being monolayer as well. The preparation of nanofluids involved a two-step process to disperse the nanoparticles into the CSS aqueous solution with 10 wt%. The nanoparticle fraction used was 1 wt%. Prior to the frictional tests, the mixture underwent 20 min of ultrasonic vibration for effective dispersion.

Figure 1.

The microtopography and EDS analysis of the nanoparticles (a) graphene oxide and (b) Ti3C2TX MXene.

Table 1.

Properties of the nanoparticles provided by the manufacturer.

2.2. Experimental Setup and Materials

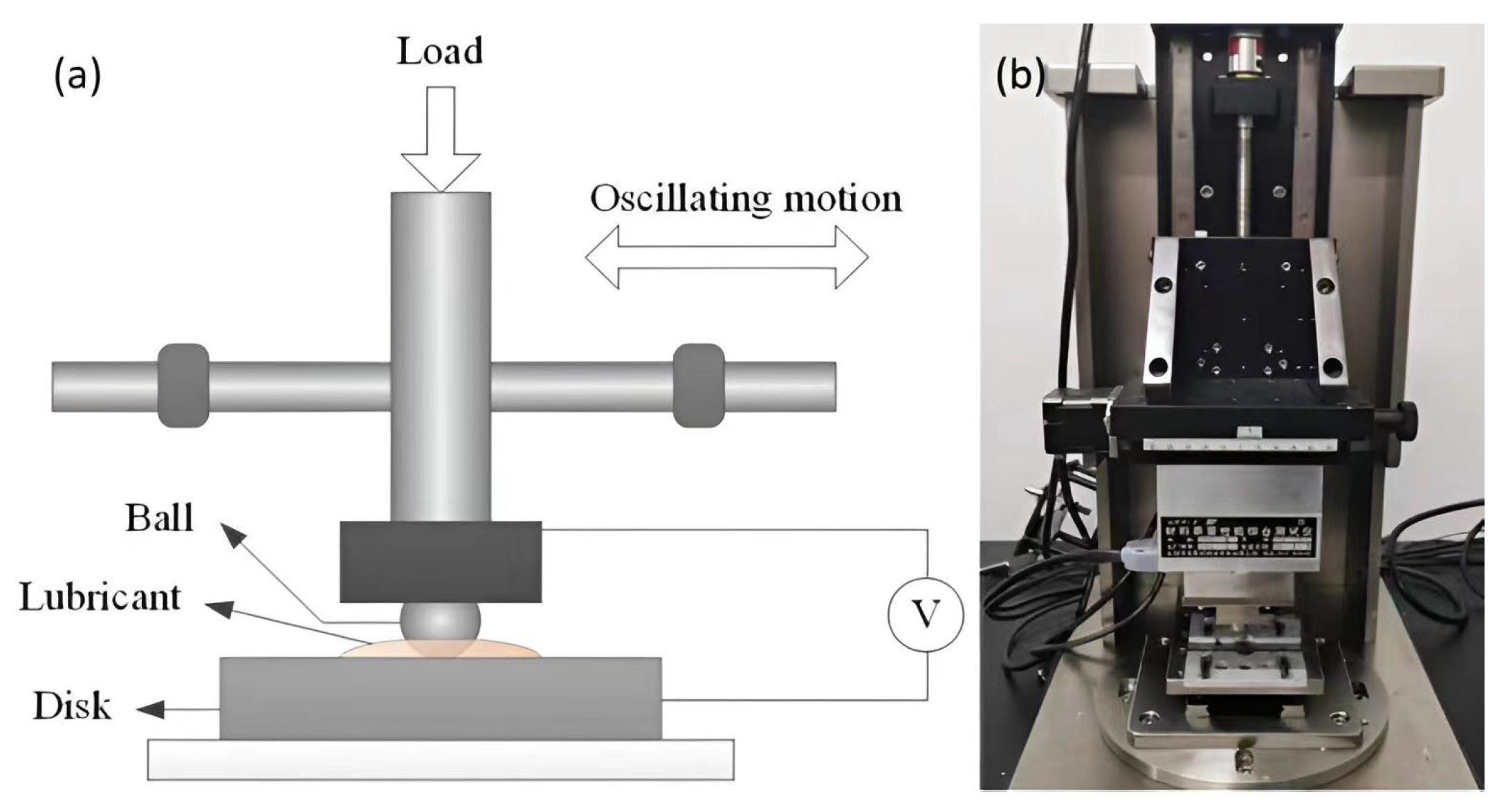

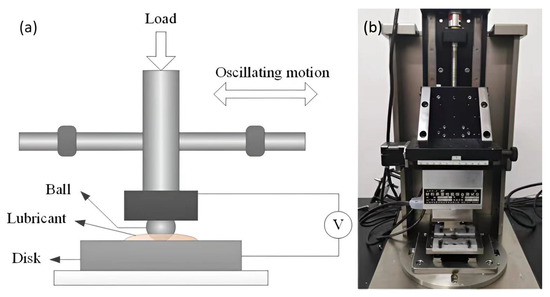

To evaluate the lubricating properties of the two kinds of nanofluids, frictional tests were conducted using a reciprocating tribometer (CFT-I, Licp, Lanzhou, China), as shown in Figure 2. Ti-6Al-4V alloy discs with a hardness of HRC 35 were chosen as the lower specimen. The chemical composition of Ti-6Al-4V alloy was detailed in Table 2, while its mechanical parameters were listed in Table 3. Before frictional tests, all the specimens were polished to ensure that their surface roughness (Sa) was less than 40 nm (tested by the LEXT™OLS5100 laser scanning confocal microscope (Olympus, Tokyo, Japan)). Considering that cemented carbide was the ideal tool material for machining titanium alloys [39], YG8 (WC-Co) balls with a hardness of 89 HRA, diameter of 10 mm, and surface roughness (Sa) of 25 nm were selected as the upper specimen. Each sample was ultrasonically cleaned with acetone and ethanol for 10 min before the test. The upper ball moved reciprocally on a stationary disk with an amplitude of 4 mm and a frequency of 1 Hz for 10 min. A normal load of 50 N was applied and the maximum Hertzian contact pressure was 7.5 GPa. Before the reciprocating motion, 0.2 mL of lubricant was dropped on the surface of the disc. Each experiment was repeated more than three times to ensure the accuracy of the results. The final friction coefficient curves were the averaging data and the relative error was kept within 1%.

Figure 2.

(a) The schematic diagram and (b) the photo of the CFT-I tribo-tester.

Table 2.

Chemical compositions of Ti-6Al-4V titanium alloy (wt%).

Table 3.

The mechanical parameters of the Ti-6Al-4V titanium alloy.

After the frictional test, the worn samples were cleaned and observed using a laser scanning confocal microscope (LEXTTMOLS5100, Olympus, Japan) to measure the wear volume. Each test was repeated three times and the average wear volume was calculated. A scanning electron microscope equipped with an energy-dispersive X-ray spectroscopy (FEI, Hillsboro, OR, USA) was used to explore the microscopic morphology of the worn surface. In addition, the chemical composition of the worn surfaces was analyzed by X-ray photoelectron spectroscopy (EscaLab 250Xi, TFS, Durham, NC, USA).

3. Results and Discussion

3.1. Lubrication Properties of Ti3C2TX MXene and Graphene Oxide (GO) Nanoparticles with Different Concentrations

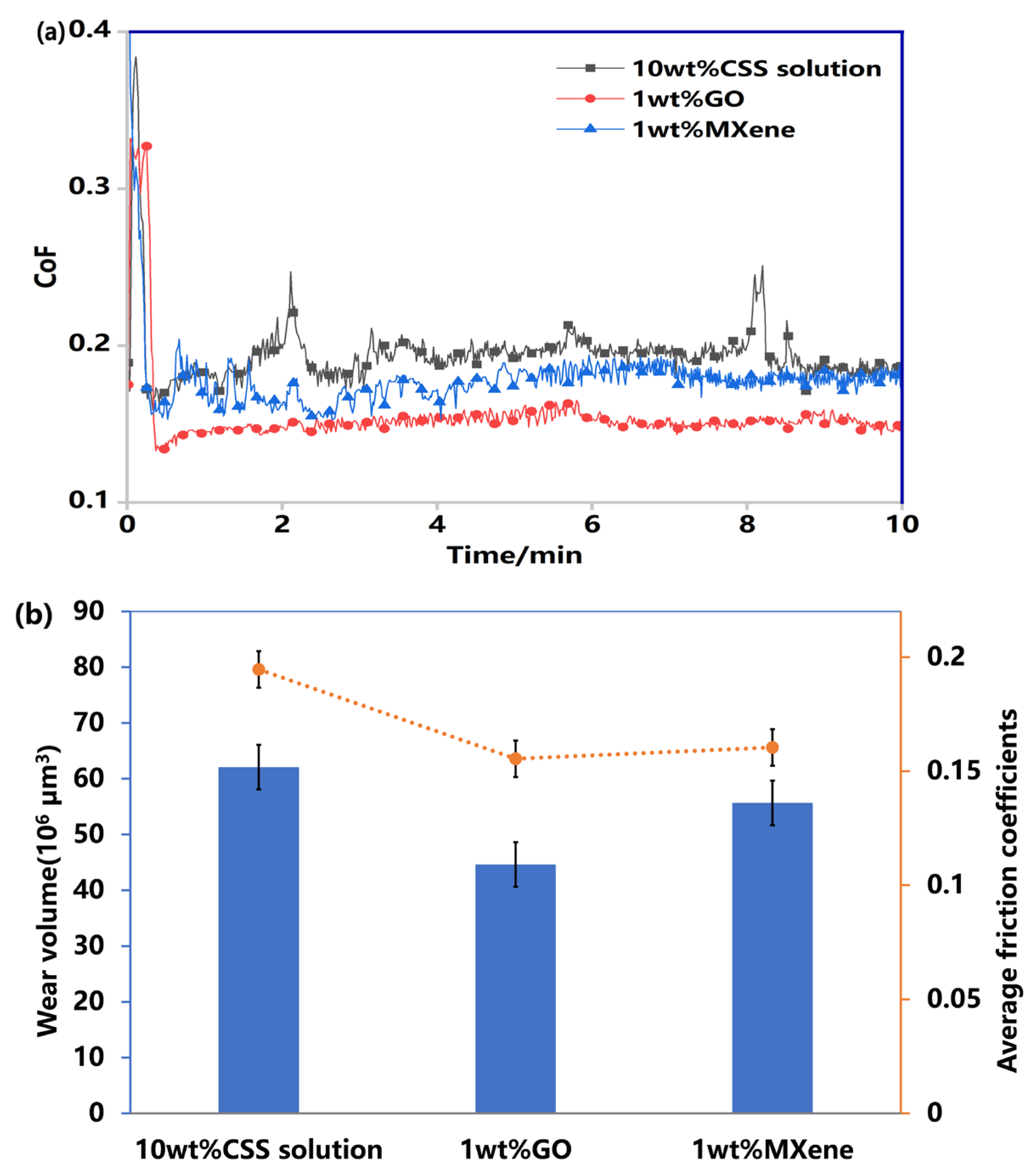

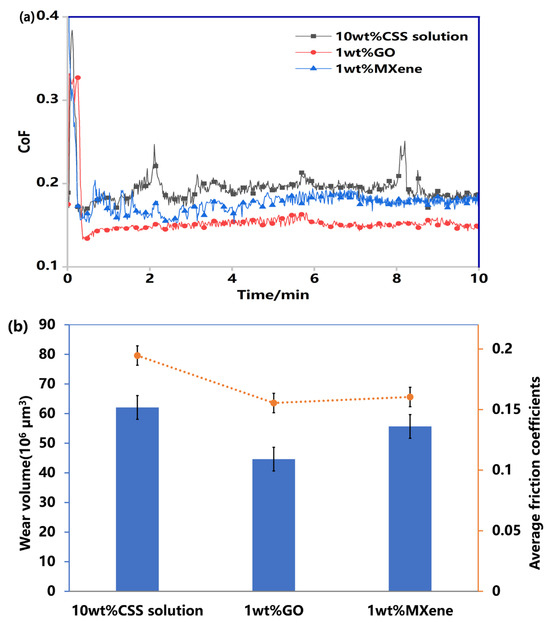

The friction curves of Ti3C2TX MXene and graphene oxide (GO) nanofluids are shown in Figure 3a. It can be seen that the friction coefficients of the two kinds of nanofluids were lower than that of the CSS solution without nanoparticles. The COF remained stable after the running-in period, indicating that the nanofluids promoted the lubrication of titanium alloys. The average COF of GO and Ti3C2TX MXene were 0.155 and 0.179, respectively. So GO exhibited better lubrication than Ti3C2TX MXene for titanium alloy. Compared with other metal oxide nanoparticles such as Al2O3 and ZnO [40], the friction coefficient of GO was the lowest as well for the special monolayer structure. The wear volume of titanium alloy disc after frictional tests was measured and the results were shown in Figure 3b. Titanium alloy was so easy to wear that after 10 min reciprocation sliding, serious wear tracks were obtained on the titanium disc even with the lubrication of CSS solution. When GO was added, the wear volume was reduced to 4.46 × 107 µm3, 28.1% smaller than that of the CSS without nanoparticles. Whereas, the wear volume lubricated by MXene nanofluid was 5.57 × 107 µm3, which was bigger than GO. It indicated that GO nanofluid had better anti-wear ability than MXene nanofluid.

Figure 3.

(a) Friction coefficient and (b) wear volume and average friction coefficients of the two kinds of nanofluids and CSS solutions.

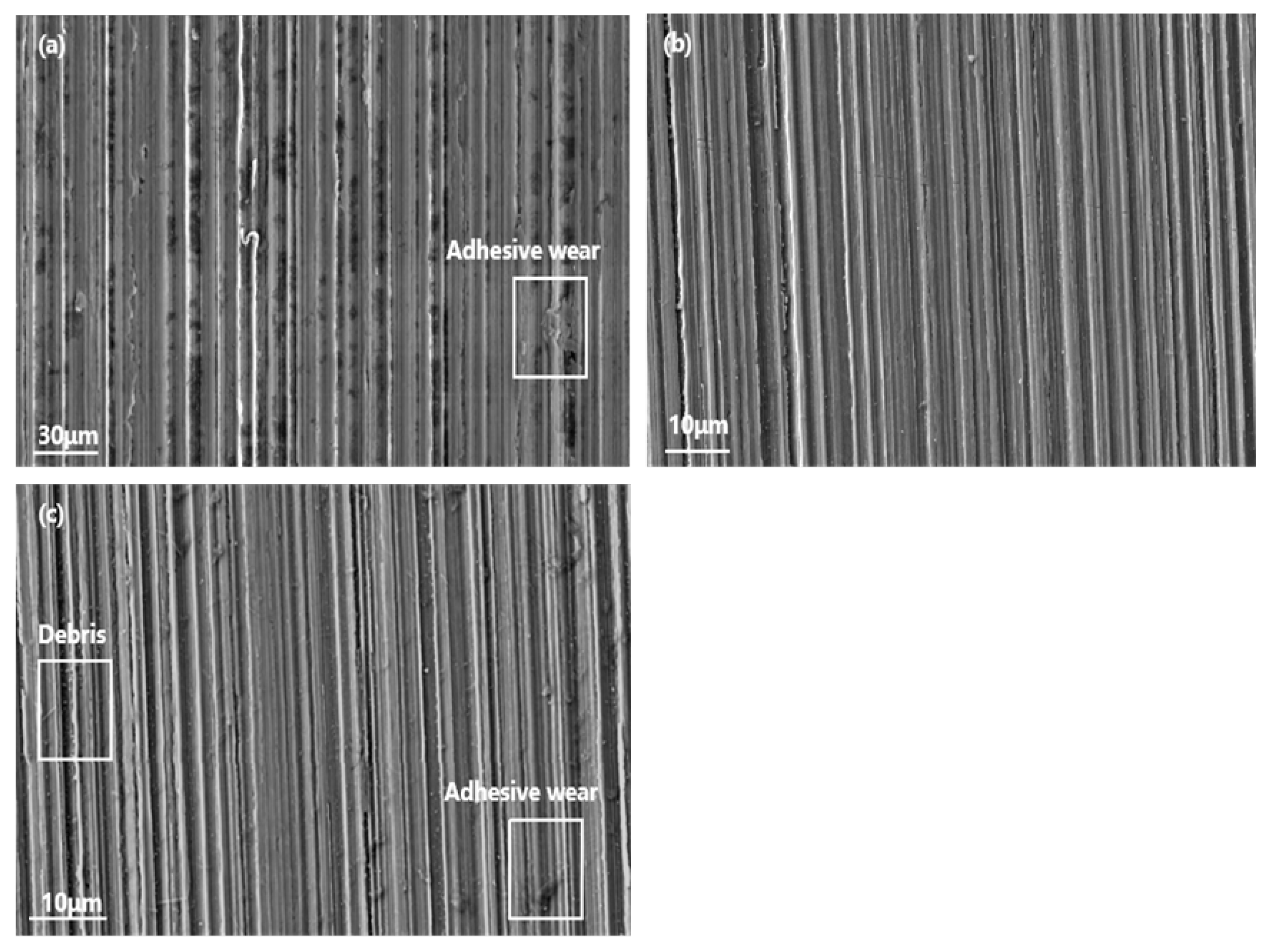

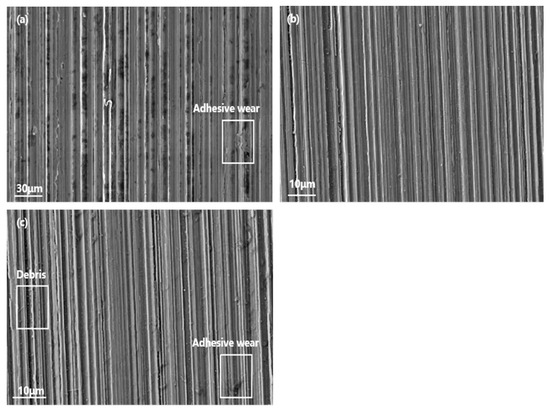

A scanning electron microscope (SEM) was used to observe the microscopic morphology of the worn titanium discs. As shown in Figure 4a, the surface lubricated by CSS solution without nanoparticles was the worst with obvious adhesive wear. There were clear scratches and plow furrows on the worn surfaces. The surface lubricated by MXene nanofluid (Figure 4c) was better than that of CSS solution without nanoparticles. But some adhesive wear and debris can be seen as well. By contrast, the surface lubricated by GO nanofluid was the best without obvious grooves and scratches seen in Figure 4b. Adhesive wear and furrow wear were greatly reduced for the good lubricating condition with GO nanofluid. Considering both the friction coefficients and wear lubricated by the two kinds of 2D nanofluids, GO exhibited a better lubrication effect with the smallest COF and wear volume.

Figure 4.

SEM morphology of the tracks on Ti-6Al-4V lubricated by (a) 10%CSS solution, (b) graphene oxide, and (c) Ti3C2TX MXene.

Both the GO and MXene nanoparticles used were monolayer with almost the same size but the lubricating properties for titanium alloys were different, which needed to be further investigated. It is speculated that the single-layer GO structure is more prone to adhere to the titanium alloy surface, thus forming a more protective adsorption film. Whereas, MXene has relatively poor lubrication performance due to its tendency to accumulate and aggregate [28].

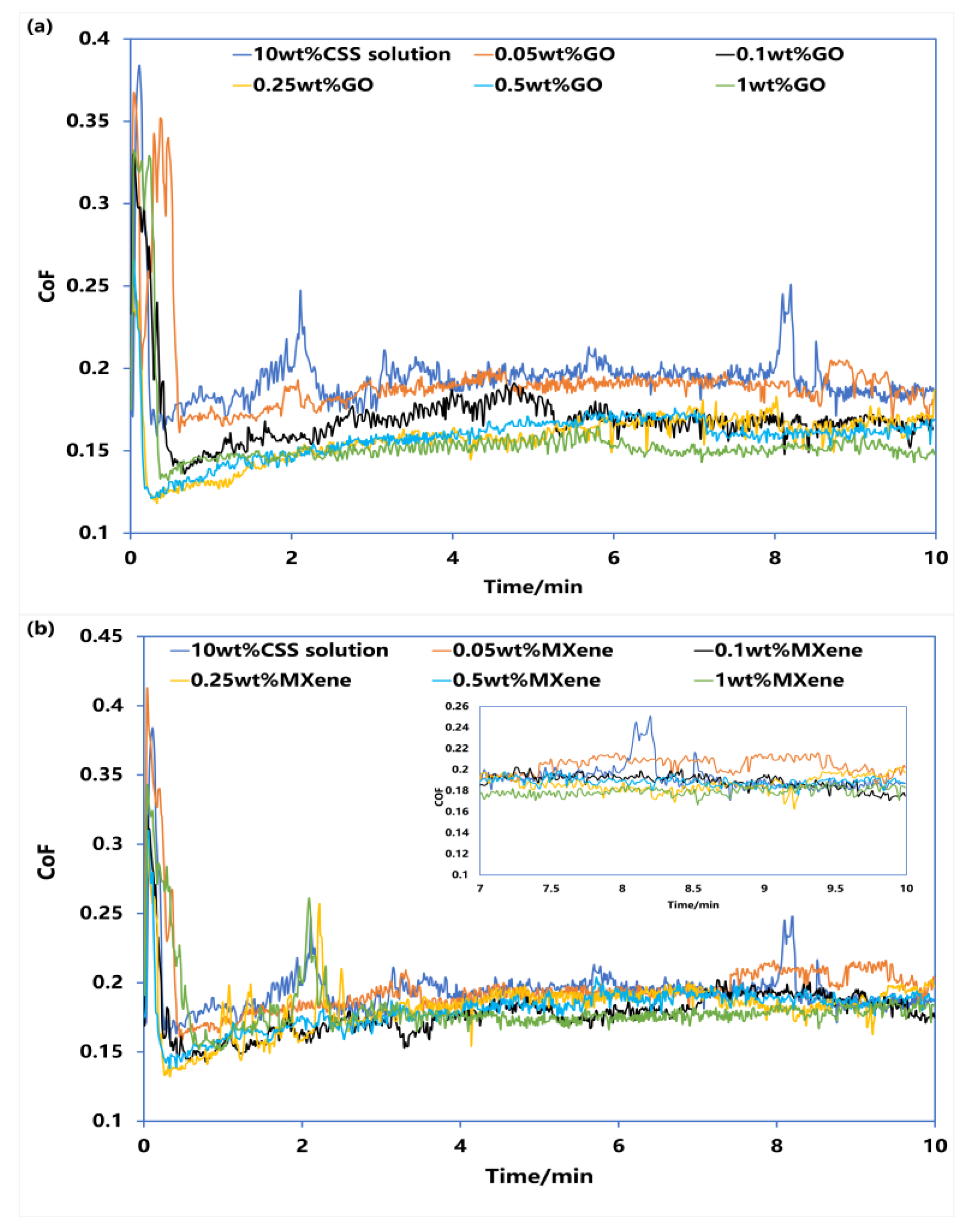

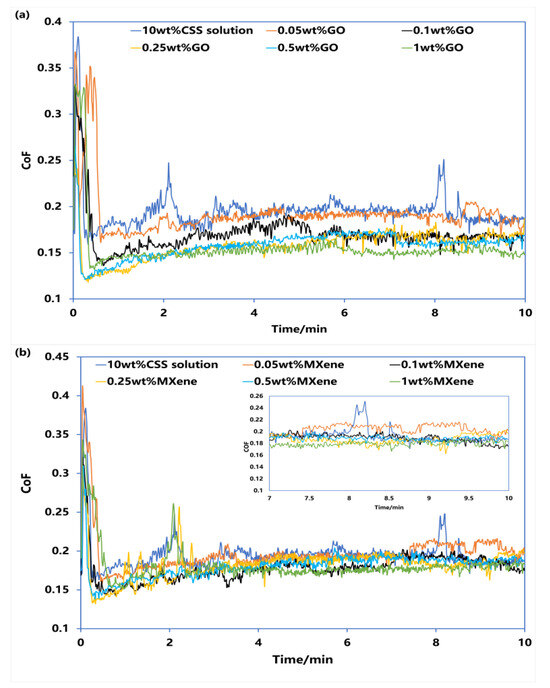

Concentration is an important factor that influences the working properties of nanoparticles. Different concentrations of GO and MXene nanofluids were prepared. Figure 5 shows the friction coefficient of various nanofluids with nanoparticles being 0, 0.05 wt%, 0.1 wt%, 0.25 wt%, 0.5 wt%, and 1 wt%. It can be seen from Figure 5a that when the concentration of GO was 0.05%, it had almost no friction reduction with COF the same as the CSS solution without nanoparticles. It meant that the amount of GO was not enough to work well. When the concentration of GO reached 0.1 wt%, the COF decreased to 0.158. With the amount of GO increasing, the COF was kept the same without decreasing anymore. It can be concluded that 0.1wt% was enough for GO to lubricate titanium alloy. For MXene, as shown in Figure 5b, when the concentration was 0.05%, it did not work for the unstable COF the same as that without nanoparticles. As the concentration of MXene increased to 0.1 wt%, the COF decreased to 0.186. The COF did not decrease with the increase in the MXene content. It was speculated that the amount of nanoparticles that can be dissolved in water was limited so that the surplus nanoparticles no longer contributed to friction reduction. It can be concluded that 0.1 wt% was the optimal concentration for GO and MXene nanoparticles to lubricate titanium alloy in the CSS aqueous solution.

Figure 5.

Friction coefficient of (a) GO and (b) Ti3C2TX MXene nanofluids with different concentrations.

3.2. Lubrication Mechanisms

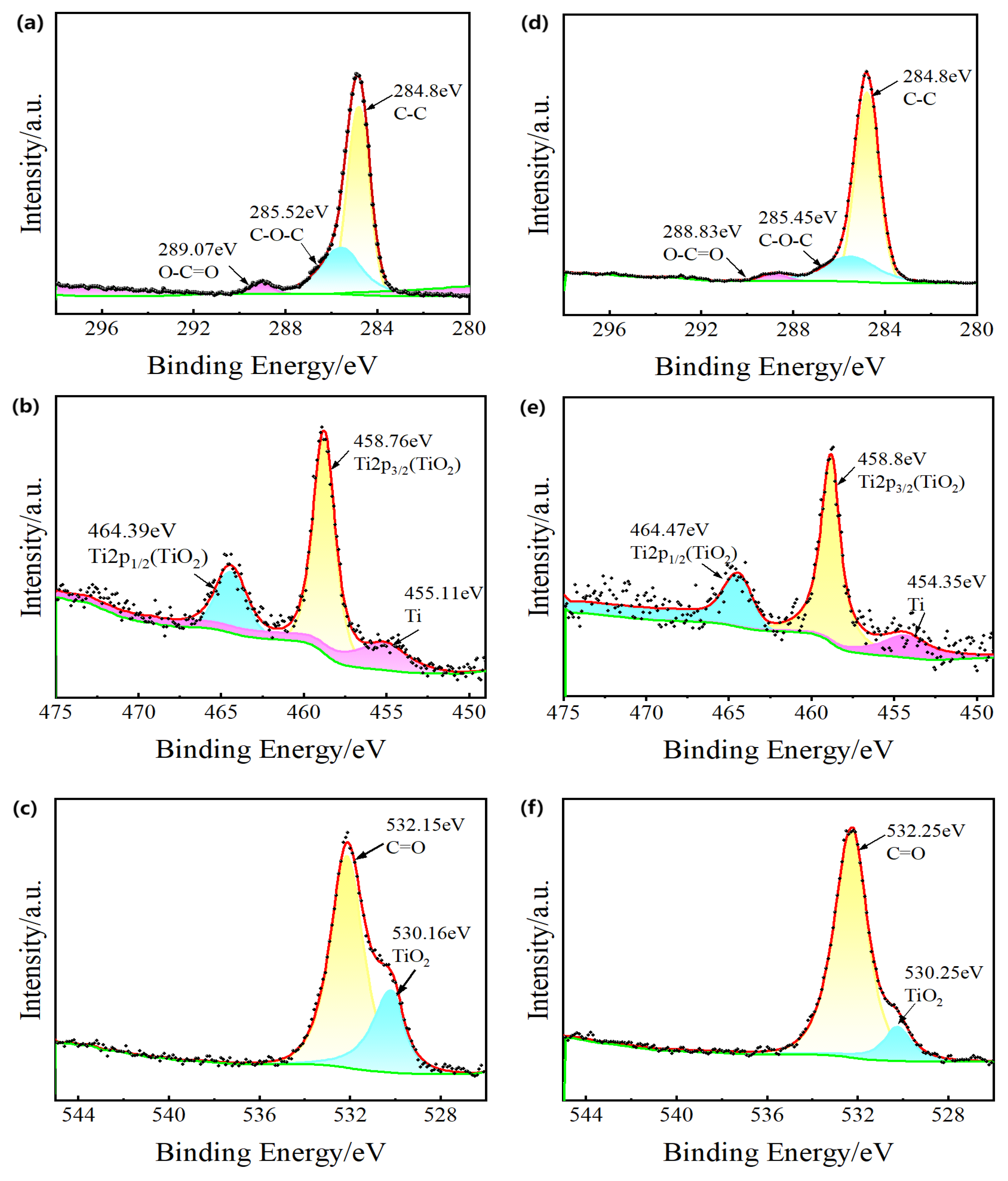

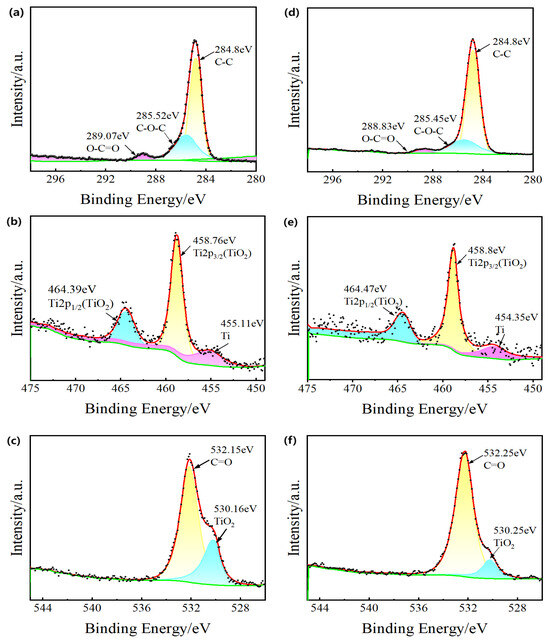

To elucidate how the monolayer nanoparticles interact with the titanium surface and reveal the lubrication mechanism, XPS was used to analyze the elemental states and binding modes of the worn titanium surface. Detailed high-resolution XPS scans of C1s, Ti2p, and O1s of the surfaces lubricated by GO and MXene nanofluid were recorded and the results are shown in Figure 6. The binding energy peaks of C1s appeared at about 284.8 eV, 286 eV, and 288.5 eV, indicating the presence of C-C, C-O-C, and O-C=O. The binding energy peaks of Ti2p appeared at about 454.5 eV, 458.8 eV, and 464.5 eV, which correspond to Ti, Ti2p3/2 (TiO2), and Ti2p1/2 (TiO2), respectively. The peaks of O1s appeared at 530 eV and 532 eV, corresponding to TiO2 and C=O, respectively. Taking the XPS peaks lubricated by these two kinds of nanofluids for comparison, there was no significant difference. However, the O1s spectrograms of the two types of nanofluids showed that the relative content of TiO2 lubricated by MXene nanofluid was greater than that of the GO nanofluid. The more newly formed TiO2 was due to the breakage or tribochemical degradation of Ti2C3Tx nanosheets induced by pressure and friction [41]. Ti3C2 and dissolved oxygen generated TiO2 and amorphous carbon under thermal or mechanical activation conditions. The interfacial adhesion behaviors were directly affected by contact surface material [42,43]. For titanium alloy discs, the generated TiO2 tended to adhere to the titanium surface, which accelerated the wear of Ti-6Al-4V based on the principle of the dissolution in a similar material [4]. Moreover, the MXene nanosheets are prone to restacking or aggregation [27,28]. The agglomeration resulted in its deposition on the friction surface. The decreased effective surface area diminished the contact area with the friction surface and chemical reactivity, thus reducing the lubricating effect [44,45]. Compared to Ti3C2TX MXene, GO can form a more stable friction layer. According to Sun’s research, the average adhesion energy of GO was approximately 182.9 mJ/m2 higher than that of the MXene (93.46 mJ/m2). And the specific surface area of GO was significantly higher than that of Ti3C2TX MXene [46]. Furthermore, oxygen/hydroxyl-enriched GO nanoflakes were more likely to interact with tribopairs’ surfaces through electrostatic interactions. So GO showed a relatively higher adhesive ability than that of MXene nanoflakes. A robuster lubricating film was formed when lubricated by GO nanofluid.

Figure 6.

XPS spectrograms C1s, Ti2p, and O1s after lubrication with (a–c) Ti3C2TX MXene and (d–f) GO nanofluids.

Based on the experimental research and analysis described above, the different lubricating mechanism of GO and Ti3C2TX MXene under boundary lubrication for titanium alloy was revealed. On one hand, the adhesion behavior of nanoflakes affected the lubricating properties of GO and Ti3C2TX MXene. GO nanofluid can form a more uniform and stable friction layer between the frictional interface, which reduces the friction coefficient and decreases the adhesive wear. On the other hand, Ti3C2TX MXene was easy to aggregate and degrade to TiO2, which accelerated the wear of titanium alloy. The combined effects of these factors prevented MXene from forming a stable friction layer, resulting in relatively poor friction performance.

3.3. Lubricating Properties of MXene with Different Types of Surfactants

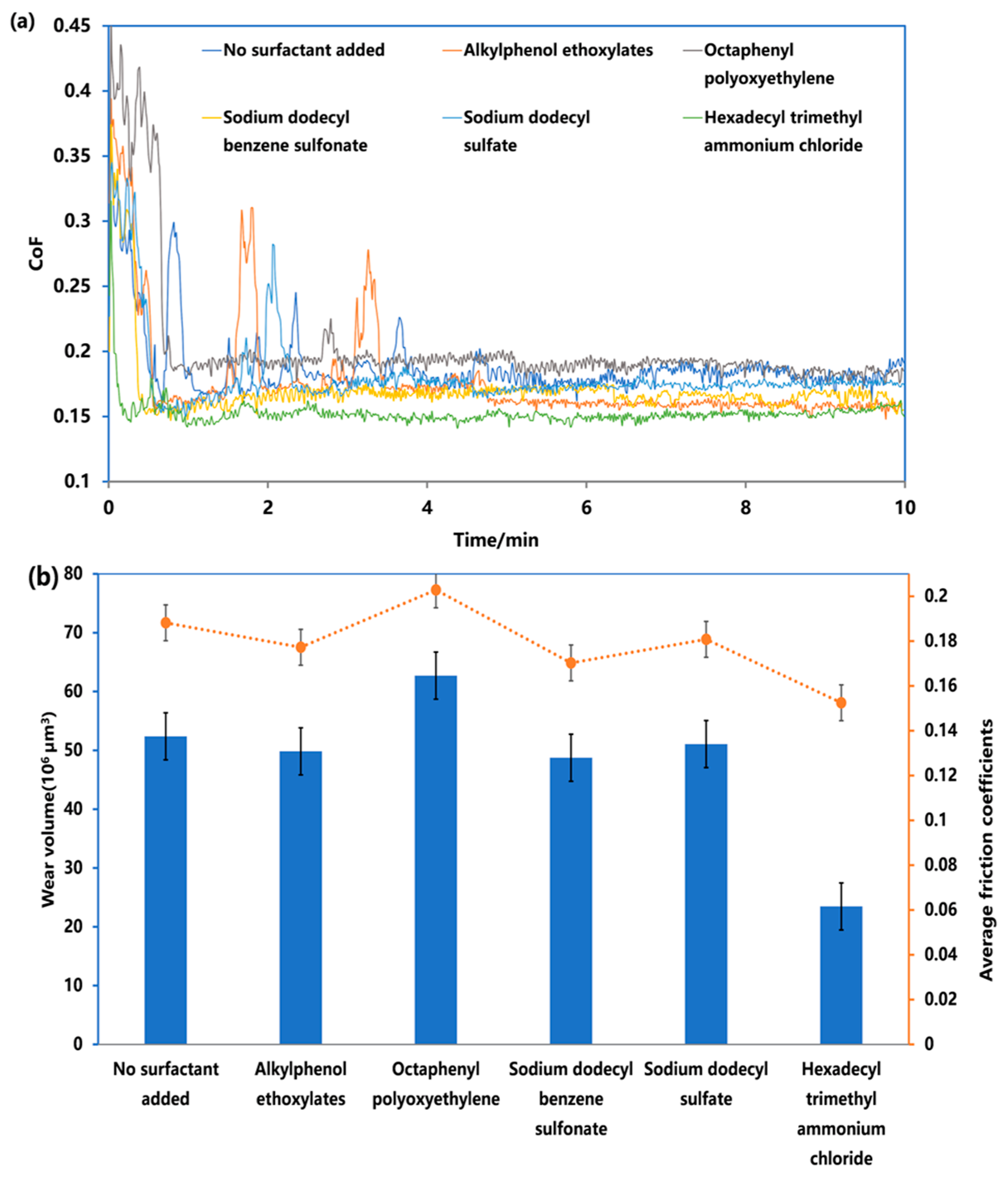

In order to improve the friction reduction and anti-wear abilities of MXene, different types of surfactants were added to 0.1 wt% Ti3C2TX MXene nanofluid to examine the effect of dispersibility on the lubrication properties. Three kinds of surfactant—nonionic, anionic, and cationic surfactant—were chosen to promote the dispersion of MXene nanoparticles in the water-based solution. The relevant parameters of these surfactants are given in Table 4. Alkylphenol ethoxylates (APE-10) and Octaphenyl polyoxyethylene (OP-10) were nonionic surfactants with HLB values of 13.2 and 14.5 separately. Sodium dodecyl benzene sulfonate (SDBS) and Sodium dodecyl sulfate (SDS) were anionic surfactants with HLB values of 10.638 and 40. Hexadecyl trimethyl ammonium chloride (1631) was a cationic surfactant with a relative molecular mass of 320 and an HLB value of 15.8.

Table 4.

Properties of surfactants provided by the manufacturer.

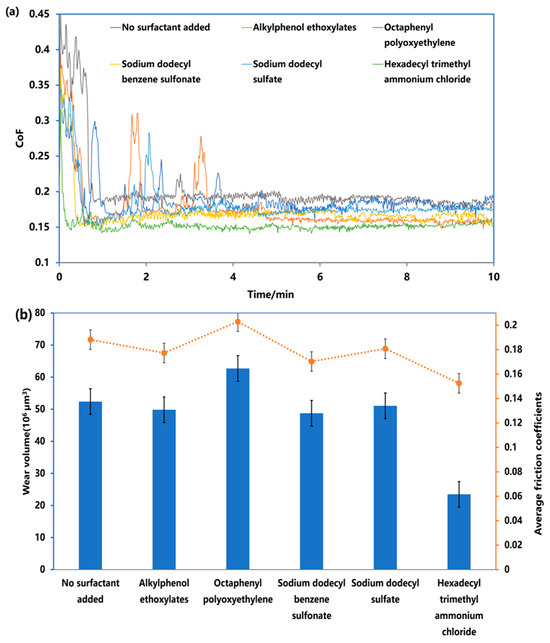

The friction coefficients of nanofluids with different surfactants are shown in Figure 7a. It can be seen that the friction coefficient of MXene nanofluid was reduced to some extent with the addition of surfactants. The COF of the solution with Alkylphenol ethoxylates (APE-10), Octaphenyl polyoxyethylene (OP-10), Sodium dodecyl benzene sulfonate (SDBS), Sodium dodecyl sulfate (SDS), and Hexadecyl trimethyl ammonium chloride (1631) surfactant was 0.177, 0.203, 0.170, 0.181, and 0.152, respectively. The Ti3C2TX MXene nanofluid with Hexadecyl trimethyl ammonium chloride (1631) exhibited the lowest COF, which was a 19% decrease compared to that without surfactant. The worn surface of the titanium disk after the frictional test was observed and the wear volume is shown in Figure 7b. It can be seen that the nanofluid with the addition of Hexadecyl trimethyl ammonium chloride (1631) had the best anti-wear ability, with a minimum wear volume of 2.3 × 107 µm3, which was 55.2% smaller than that without surfactant. Whereas, the nanofluids with Alkylphenol ethoxylates (APE-10), Sodium dodecyl sulfate (SDS), and Sodium dodecyl benzene sulfonate (SDBS) did not show significant anti-wear improvement. Moreover, the nanofluid with Octaphenyl polyoxyethylene (OP-10) even increased the wear of the titanium alloy, with a maximum wear volume of 6.27 × 107 µm3. Compared with GO nanofluid, MXene with the cationic surfactant 1631 exhibited almost the same friction coefficient. It indicated that the dispersibility and stability of MXene in aqueous solution was enhanced by the cationic surfactant. The effective surface area and reactivity of the MXene nanoparticles were increased so that a more stable tribological layer was formed. It was speculated that the dispersion and adsorption characteristics of the 2D nanomaterials played a significant role in friction reduction.

Figure 7.

(a) Friction coefficient and (b) wear volume and average friction coefficients of nanofluids with different surfactants.

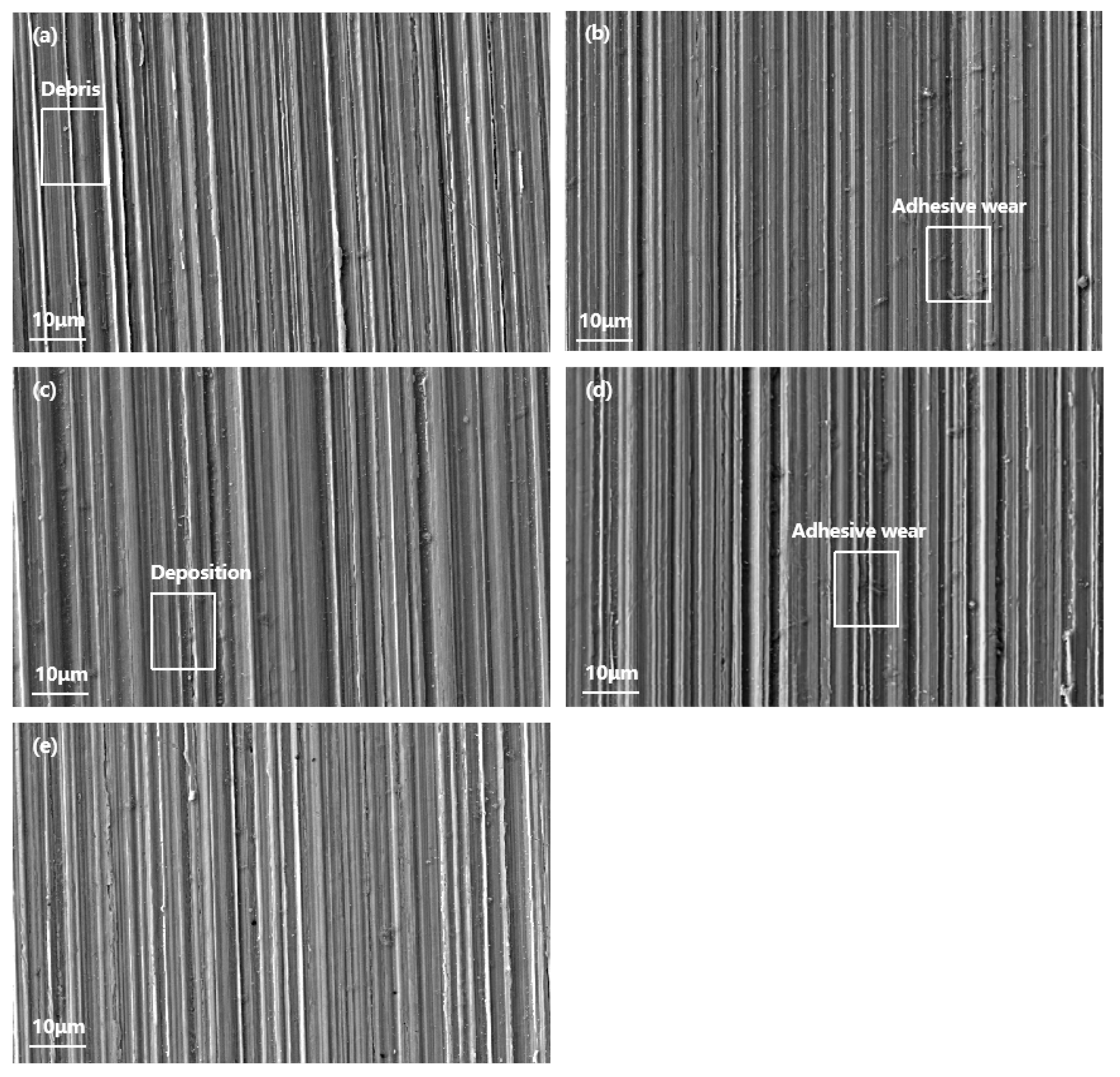

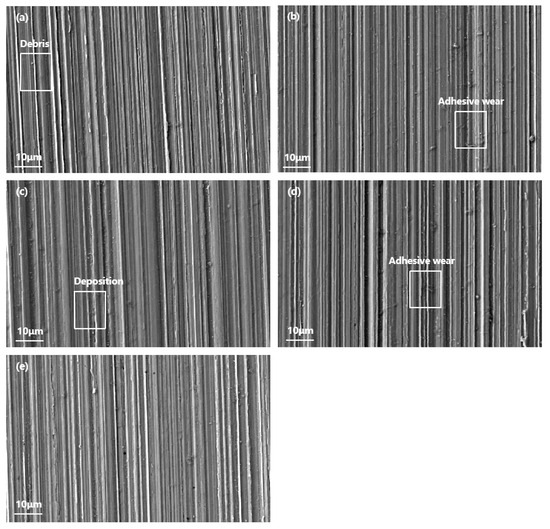

SEM images of the wear scar on titanium disks lubricated by MXene nanofluids with different kinds of surfactants are shown in Figure 8. Obvious scratches, plow furrows, more chips, and adhesive wear can be observed on the titanium surface lubricated by Octaphenyl polyoxyethylene (OP-10) and Sodium dodecyl sulfate (SDS) solution. The surface lubricated by Alkylphenol ethoxylates (APE-10) and Sodium dodecyl benzene sulfonate (SDBS) was slightly better. But, there was some debris in Figure 8a and deposition in Figure 8c. Compared with the four kinds of surfactants, the titanium surface lubricated by Hexadecyl trimethyl ammonium chloride (1631) solution was the best with fewer grooves and adhesive wear marks (Figure 8e). It can be concluded that the lubricating properties of MXene could be improved by the cationic surfactant.

Figure 8.

SEM morphology of the trajectories on Ti-6Al-4V, consisting of (a) Alkylphenol ethoxylates (APE-10), (b) Octaphenyl polyoxyethylene (OP-10), (c) Sodium dodecyl benzene sulfonate (SDBS), (d) Sodium dodecyl sulfate (SDS), and (e) Hexadecyl trimethyl ammonium chloride (1631).

Surfactants can improve the dispersion stability of MXene in CSS aqueous solution [47]. However, the addition of different types of surfactants resulted in different COF and anti-wear abilities. As nonionic surfactants, Alkylphenol ethoxylates (APE-10) and Octaphenyl polyoxyethylene (OP-10) had little effect on the friction reduction and anti-wear ability, which may be due to the instability of the main London forces in the friction test [48]. Sodium dodecyl benzene sulfonate (SDBS) and Sodium dodecyl sulfate (SDS) were anionic surfactants that carried negative charges. The surface of Ti3C2TX MXene generally carries a negative charge as well [49]. When anionic surfactants were added to the MXene solution, the interaction force between them was dominated by electrostatic repulsion, which prevented the surfactant molecules from being adsorbed on the MXene lamellae [50]. At the same time, a high concentration of particle aggregation existed in the local area between MXene lamellae [51]. In the practical application of MXenes, the presence of excess Sodium dodecyl sulfate (SDS) may be considered as contamination [52]. MXene nanofluid with cationic surfactant Hexadecyl trimethyl ammonium chloride (1631) had the lowest COF and best surface morphology. Hexadecyl trimethyl ammonium chloride (1631) was a cationic surfactant that typically possesses a hydrophilic head group and a hydrophobic tail chain, carrying an overall positive charge. When cationic surfactants were mixed with Ti3C2TX MXene, the surfactant molecules were tightly adsorbed on the surface of MXene due to the electrostatic attraction force. The interacting forces between MXene layers were relatively weak compared to electrostatic attraction, which reduced the tendency of MXene to aggregation [53,54]. Furthermore, when surfactant molecules adsorbed on the surface of MXene, the hydrophobic tail chains extended outward, forming a layer of steric hindrance. This layer can prevent direct contact between MXene sheets, reduce aggregation, and enhance the dispersibility and lubricity of MXene.

4. Conclusions

The lubricating properties of two kinds of 2D nanoparticles, Ti3C2TX MXene and graphene oxide (GO), in water-based lubrication for titanium alloys were investigated and the following conclusions were drawn:

- Both Ti3C2TX MXene and GO monolayer 2D nanoparticles could reduce the COF and wear volume of the CSS water solution, which could be used in the base stock to improve the lubricity of titanium alloys. But the boundary lubrication performances of Ti3C2TX MXene and GO have some differences. The average COFs of GO and Ti3C2TX MXene were 0.155 and 0.179, respectively. The wear volume lubricated by GO was smaller than that of Ti3C2TX MXene. Moreover, the adhesive wear was reduced and good surface quality was achieved by lubricating by GO nanofluid. GO exhibited better lubrication and anti-wear ability than Ti3C2TX MXene nanofluid;

- The XPS analysis showed that more TiO2 was generated inside the wear scar lubricated by Ti3C2TX MXene nanofluid, which was degraded by the MXene nanoparticles. The aggregation and generated TiO2 accelerated the wear of titanium alloy. Moreover, the adhesion behavior of nanoflakes affected the lubricating properties of GO and Ti3C2TX MXene. GO nanofluid can form a more uniform and stable friction layer between the frictional interface, which reduces the friction coefficient and decreases the adhesive wear;

- The effect of different types of surfactants on MXene nanofluids was investigated. Nonionic surfactants had little effect on friction reduction and antiwear capabilities and the addition of OP-10 to MXene even promoted the wear of the titanium alloys. Anionic surfactants could reduce the COF and wear volume to a small extent. Only the cationic surfactant 1613 minimized the COF to 0.152 and reduced the wear volume by 55.2%. The dispersion of MXene nanoparticles was promoted by the cationic surfactant due to the strong electrostatic attraction force.

The application of water-based GO and Ti3C2TX MXene nanofluids in the machining of Ti-6Al-4V alloy has not been reported yet. This paper provides insights into applying GO and Ti3C2TX MXene nanofluids to difficult-to-machine materials to improve cutting efficiency and surface quality. Two-dimensional nanomaterials are expected to replace the traditional organic polar compounds containing sulfur, phosphorus, and chlorine elements, which have negative effects on the environment and human health. The developed green lubricant additives have a broad industrial application in prospect.

Author Contributions

Conceptualization, Y.Y.; methodology, L.S. and Z.D.; validation, H.Y.; formal analysis, Y.Y. and Z.D.; software, Y.M.; investigation, Y.T. and H.Z.; data curation, Y.T.; writing—original draft preparation, Y.T.; writing—review and editing, Y.Y. and F.L.; visualization, Z.D.; supervision, L.S. and F.L.; project administration, F.L.; funding acquisition, Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (Grant No. 2022YFB3403801), the National Natural Science Foundation of China (Grant No. 52005010), and the Project of Cultivation for Young Top-motch Talents of Beijing Municipal Institutions (Grant No. BPHR202203035).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

| CSS | Castor oil sulfated sodium salt |

| APE-10 | Alkylphenol ethoxylates |

| OP-10 | Octaphenyl polyoxyethylene |

| SDBS | Sodium dodecyl benzene sulfonate |

| SDS | Sodium dodecyl sulfate |

| 1631 | Hexadecyl trimethyl ammonium chloride |

| MR | relative molecular mass |

| HLB | hydrophilic-lipophilic balance |

References

- Dong, H. Tribological properties of titanium-based alloys. In Surface Engineering of Light Alloys; Woodhead Publishing: Sawston, UK, 2010; pp. 58–80. [Google Scholar]

- Gupta, M.K.; Etri, H.E.; Korkmaz, M.E.; Ross, N.S.; Krolczyk, G.M.; Gawlik, J.; Yaşar, N.; Pimenov, D.Y. Tribological and surface morphological characteristics of titanium alloys: A review. Arch. Civ. Mech. Eng. 2022, 22, 72. [Google Scholar] [CrossRef]

- García-Martínez, E.; Miguel, V.; Martínez-Martínez, A.; Manjabacas, M.C.; Coello, J. Sustainable lubrication methods for the machining of titanium alloys: An overview. Materials 2019, 12, 3852. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Tribological properties of titanium alloys under lubrication of SEE oil and aqueous solutions. Tribol. Int. 2017, 109, 40–47. [Google Scholar] [CrossRef]

- Sujith, S.V.; Mulik, R.S. Surface integrity and flank wear response under pure coconut oil-Al2O3 nano minimum quantity lubrication turning of Al-7079/7 wt%-TiC in situ metal matrix composites. J. Tribol. 2022, 144, 051701. [Google Scholar] [CrossRef]

- Yi, M.; Qiu, J.; Xu, W. Tribological performance of ultrathin MoS2 nanosheets in formulated engine oil and possible friction mechanism at elevated temperatures. Tribol. Int. 2022, 167, 107426. [Google Scholar] [CrossRef]

- Borgaonkar, A.V.; Potdar, S.B.; Kale, S. Mechanical and tribological characteristics of two-Dimensional (2D) nanomaterials. In New Advances in Materials Technologies; Apple Academic Press: Palm Bay, FL, USA, 2024; pp. 105–121. [Google Scholar]

- Zhang, X.; Ren, T.; Li, Z. Recent advances of two-dimensional lubricating materials: From tunable tribological properties to applications. J. Mater. Chem. A 2023, 11, 9239–9269. [Google Scholar] [CrossRef]

- Chimene, D.; Alge, D.L.; Gaharwar, A.K. Two-dimensional nanomaterials for biomedical applications: Emerging trends and future prospects. Adv. Mater. 2015, 27, 7261–7284. [Google Scholar] [CrossRef] [PubMed]

- Manu, B.R.; Gupta, A.; Jayatissa, A.H. Tribological properties of 2D materials and composites—A review of recent advances. Materials 2021, 14, 1630. [Google Scholar] [CrossRef]

- Szabó, T.; Szeri, A.; Dékány, I. Composite graphitic nanolayers prepared by self-assembly between finely dispersed graphite oxide and a cationic polymer. Carbon 2005, 43, 87–94. [Google Scholar] [CrossRef]

- Kinoshita, H.; Nishina, Y.; Alias, A.A.; Fujii, M. Tribological properties of monolayer graphene oxide sheets as water-based lubricant additives. Carbon 2014, 66, 720–723. [Google Scholar] [CrossRef]

- Senatore, A.; D’Agostino, V.; Petrone, V.; Ciambelli, P.; Sarno, M. Graphene oxide nanosheets as effective friction modifier for oil lubricant: Materials, methods, and tribological results. Int. Sch. Res. Not. 2013, 2013, 425809. [Google Scholar] [CrossRef]

- Song, H.J.; Li, N. Frictional behavior of oxide graphene nanosheets as water-base lubricant additive. Appl. Phys. A 2011, 105, 827–832. [Google Scholar] [CrossRef]

- Kumar, P.; Wani, M.F. Tribological characterisation of graphene oxide as lubricant additive on hypereutectic Al-25Si/steel tribopair. Tribol. Trans. 2018, 61, 335–346. [Google Scholar] [CrossRef]

- Naguib, M.; Come, J.; Dyatkin, B.; Presser, V.; Taberna, P.L.; Simon, P.; Barsoum, M.W.; Gogotsi, Y. MXene: A promising transition metal carbide anode for lithium-ion batteries. Electrochem. Commun. 2012, 16, 61–64. [Google Scholar] [CrossRef]

- Wang, J.; Ma, H.; Liu, Y.; Xie, Z.; Fan, Z. MXene-based humidity-responsive actuators: Preparation and properties. ChemPlusChem 2021, 86, 406–417. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Sun, T.; Xie, X.; Jiang, W.; Li, J.; Tian, B.; Su, C. Oxygen-functionalized ultrathin Ti3C2Tx MXene for enhanced electrocatalytic hydrogen evolution. ChemPlusChem 2019, 12, 1368–1373. [Google Scholar] [CrossRef] [PubMed]

- Hope, M.A.; Forse, A.C.; Griffith, K.J.; Lukatskaya, M.R.; Ghidiu, M.; Gogotsi, Y.; Grey, C.P. NMR reveals the surface functionalisation of Ti3C2 MXene. Phys. Chem. Chem. Phys. 2016, 18, 5099–5102. [Google Scholar] [CrossRef] [PubMed]

- Halim, J.; Cook, K.M.; Naguib, M.; Eklund, P.; Gogotsi, Y.; Rosen, J.; Barsoum, M.W. X-ray photoelectron spectroscopy of select multi-layered transition metal carbides (MXenes). Appl. Surf. Sci. 2016, 362, 406–417. [Google Scholar] [CrossRef]

- Boidi, G.; de Queiróz, J.C.F.; Profito, F.J.; Rosenkranz, A. Ti3C2Tx MXene nanosheets as lubricant additives to lower friction under high loads, sliding ratios, and elevated temperatures. ACS Appl. Nano Mater. 2022, 6, 729–737. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, Y.; Wang, D.; Xu, Q. Nano friction and adhesion properties on Ti3C2 and Nb2C MXene studied by AFM. Tribol. Int. 2021, 153, 106646. [Google Scholar] [CrossRef]

- Yin, X.; Jin, J.; Chen, X.; Rosenkranz, A.; Luo, J. Ultra-wear-resistant MXene-based composite coating via in situ formed nanostructured tribofilm. ACS Appl. Mater. Interfaces 2019, 11, 32569–32576. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xue, M.; Yang, X.; Wang, Z.; Luo, G.; Huang, Z.; Sui, X.; Li, C. Preparation and tribological properties of Ti3C2(OH)2 nanosheets as additives in base oil. RSC Adv. 2015, 5, 2762–2767. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Dong, S.; Ye, Z.; Wei, Y. Synthesis and tribological property of Ti3C2Tx nanosheets. J. Mater. Sci. 2017, 52, 2200–2209. [Google Scholar] [CrossRef]

- Lian, W.; Mai, Y.; Liu, C.; Zhang, L.; Li, S.; Jie, X. Two-dimensional Ti3C2 coating as an emerging protective solid-lubricant for tribology. Ceram. Int. 2018, 44, 20154–20162. [Google Scholar] [CrossRef]

- Arjun, A.M.; Shinde, M.; Slaughter, G. Application of MXene in the electrochemical detection of neurotransmitters: A review. IEEE Sens. J. 2023, 23, 16456–16466. [Google Scholar] [CrossRef]

- Zhao, M.Q.; Xie, X.; Ren, C.E.; Makaryan, T.; Anasori, B.; Wang, G.; Gogotsi, Y. Hollow MXene spheres and 3D macroporous MXene frameworks for Na-ion storage. Adv. Mater. 2017, 29, 1702410. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Tan, K.H.; Aslfattahi, N.; Arifutzzaman, A.; Saidur, R.; Al-Sulaiman, F.A. Optical, stability and energy performance of water-based MXene nanofluids in hybrid PV/thermal solar systems. Sol. Energy 2020, 204, 32–47. [Google Scholar] [CrossRef]

- Tu, S.; Li, J.; Zhang, X.; Liu, X.; Tang, J. Effect of surfactants on the morphology of ferroelectric crystals grown from MXene. AIP Adv. 2021, 11, 115121. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Chung, K.H. Assessment of tribological properties of Ti3C2 as a water-based lubricant additive. Materials 2020, 13, 5545. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Liu, Y.; Yang, L.; Chen, L. 2D nano-materials beyond graphene: From synthesis to tribological studies. Appl. Nanosci. 2020, 10, 3353–3388. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.L.; Rosenkranz, A. Layered 2D nanomaterials to tailor friction and wear in machine elements—A review. Adv. Mater. Interfaces 2022, 9, 2101622. [Google Scholar] [CrossRef]

- Feng, Q.; Yang, J.; Dou, M.; Zou, S.; Wei, L.; Huang, F. Modified Ti3C2Tx MXene/GO Nanohybrids: An efficient lubricating additive for tribological applications. Arab. J. Sci. Eng. 2023, 49, 10349–10361. [Google Scholar] [CrossRef]

- Macknojia, A.Z.; Ayyagari, A.; Shevchenko, E.; Berman, D. MXene/graphene oxide nanocomposites for friction and wear reduction of rough steel surfaces. Sci. Rep. 2023, 13, 11057. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.; Mo, J.; Ding, S. Experimental investigation on the performance and mechanism of graphene oxide nanofluids in turning Ti-6Al-4V. J. Manuf. Process. 2019, 43, 164–174. [Google Scholar]

- Sadeghi, M.; Kharaziha, M.; Salimijazi, H.R. Double layer graphene oxide-PVP coatings on the textured Ti6Al4V for improvement of frictional and biological behavior. Surf. Coat. Technol. 2019, 374, 656–665. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Lubricity and adsorption of castor oil sulfated sodium salt emulsion solution on titanium alloy. Tribol. Lett. 2019, 67, 61. [Google Scholar] [CrossRef]

- Sartori, S.; Ghiotti, A.; Bruschi, S. Solid lubricant-assisted minimum quantity lubrication and cooling strategies to improve Ti6Al4V machinability in finishing turning. Tribol. Int. 2018, 118, 287–294. [Google Scholar] [CrossRef]

- Yang, Y.; Luan, H.; Liu, F.; Si, L.; Yan, H.; Zhang, C. Investigation of the lubrication performance of γ-Al2O3/ZnO hybrid nanofluids for titanium alloy. Metals 2023, 13, 1701. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Liu, Y.; Ge, X.; Zhang, J.; Luo, J. In-situ formation of tribofilm with Ti3C2Tx MXene nanoflakes triggers macroscale superlubricity. Tribol. Int. 2021, 154, 106695. [Google Scholar] [CrossRef]

- Marian, M.; Almqvist, A.; Rosenkranz, A.; Fillon, M. Numerical micro-texture optimization for lubricated contacts—A critical discussion. Friction 2022, 10, 1772–1809. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Bai, P.; Jia, W.; Xu, Q.; Meng, Y.; Ma, L.; Tian, Y. Surface wettability effect on aqueous lubrication: Van der Waals and hydration force competition induced adhesive friction. J. Colloid Interface Sci. 2021, 599, 667–675. [Google Scholar] [CrossRef]

- Hsu, S.M. Molecular basis of lubrication. Tribol. Int. 2004, 37, 553–559. [Google Scholar] [CrossRef]

- Wu, Z.; Shang, T.; Deng, Y.; Tao, Y.; Yang, Q.H. The assembly of MXenes from 2D to 3D. Adv. Sci. 2020, 7, 1903077. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Song, Q.; Liu, K.; Zhang, Q.; Tao, Z.; Ye, J. Comparative study on boundary lubrication of Ti3C2T x MXene and graphene oxide in water. Friction 2023, 11, 1641–1659. [Google Scholar] [CrossRef]

- Bao, Z.; Bing, N.; Zhu, X.; Xie, H.; Yu, W. Ti3C2Tx MXene contained nanofluids with high thermal conductivity, super colloidal stability and low viscosity. Chem. Eng. J. 2021, 406, 126390. [Google Scholar] [CrossRef]

- Gao, T.; Li, C.; Zhang, Y.; Yang, M.; Jia, D.; Jin, T.; Hou, Y.; Li, R. Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol. Int. 2019, 131, 51–63. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, D.; Bai, T.; Liu, H.; Zheng, Y.; Liu, C.; Shen, C. Electrostatic self-assembled NiFe2O4/Ti3C2Tx MXene nanocomposites for efficient electromagnetic wave absorption at ultralow loading level. Adv. Compos. Hybrid Mater. 2021, 4, 602–613. [Google Scholar] [CrossRef]

- Eftekhari, M.; Schwarzenberger, K.; Javadi, A.; Eckert, K. The influence of negatively charged silica nanoparticles on the surface properties of anionic surfactants: Electrostatic repulsion or the effect of ionic strength. Phys. Chem. Chem. Phys. 2020, 22, 2238–2248. [Google Scholar] [CrossRef]

- Elimelech, M.; Gregory, J.; Jia, X. Particle Deposition and Aggregation: Measurement, Modelling and Simulation; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Fan, B.; Zhao, X.; Zhang, P.; Wei, Y.; Qiao, N.; Yang, B.; Soomro, R.A.; Zhang, R.; Xu, B. Effect of sodium dodecyl sulfate on stability of MXene aqueous dispersion. Adv. Sci. 2023, 10, 2300273. [Google Scholar] [CrossRef]

- Han, T.; Zhang, C.; Luo, J. Macroscale superlubricity enabled by hydrated alkali metal ions. Langmuir 2018, 34, 11281–11291. [Google Scholar] [CrossRef]

- Javadian, S.; Kakemam, J. Intermicellar interaction in surfactant solutions: A review study. J. Mol. Liquids 2017, 242, 115–128. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).