Laboratory Test of a Gear Hydraulic Pump during the Application of an Environmentally Friendly Hydraulic Fluid with Constant Pressure and Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Conditions for Measuring Flow Characteristics

2.2. Hydraulic Fluid Contamination Measurement

- Kinematic Viscosity—Spectro VISC Q300 (Spectro Scientific, Chelmsford, MA, USA),

- Acidity number—FluidScan Q1000 (Spectro Scientific, Chelmsford, MA, USA) and Titra—Lube Tan Test Kit (DEXSIL, Hamden, CT, USA).

3. Results

4. Conclusions

- (1).

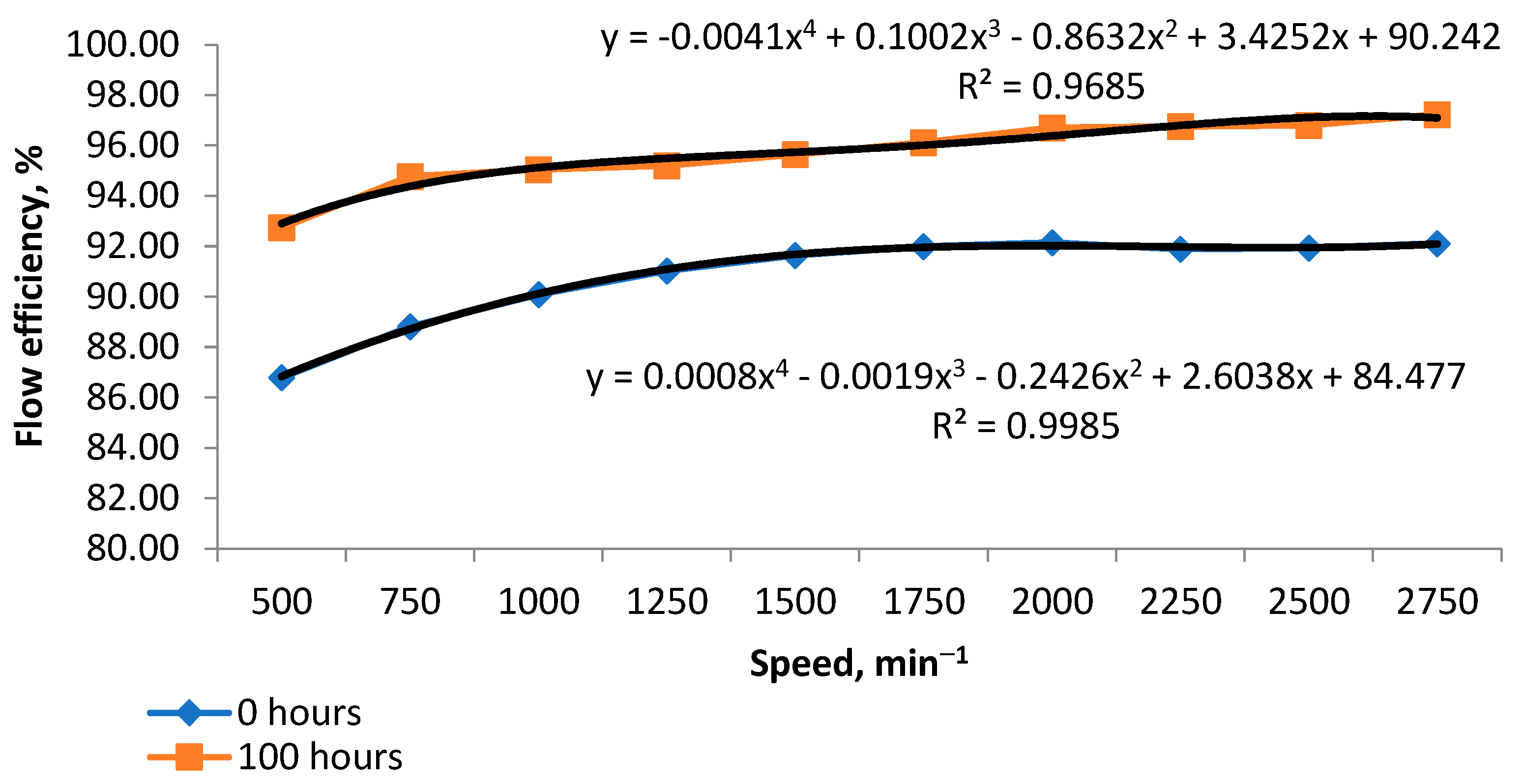

- At the beginning of the laboratory test, the flow efficiency of the gear hydraulic pump at rated speed was 90.85%. After 25 h, the flow efficiency reached 98.82%. The above fact demonstrates that, after 25 h, the break-in phase of the gear hydraulic pump was completed.

- (2).

- After the completion of the laboratory test (100 h), the flow efficiency of the tooth hydraulic pump reached 99.42%. Compared to the time of measuring the flow characteristics after 25 h, there was a slight decrease in the flow efficiency of the tooth hydraulic pump, but this decrease is within the inaccuracy of the flow meter shown in Figure 2.

- (3).

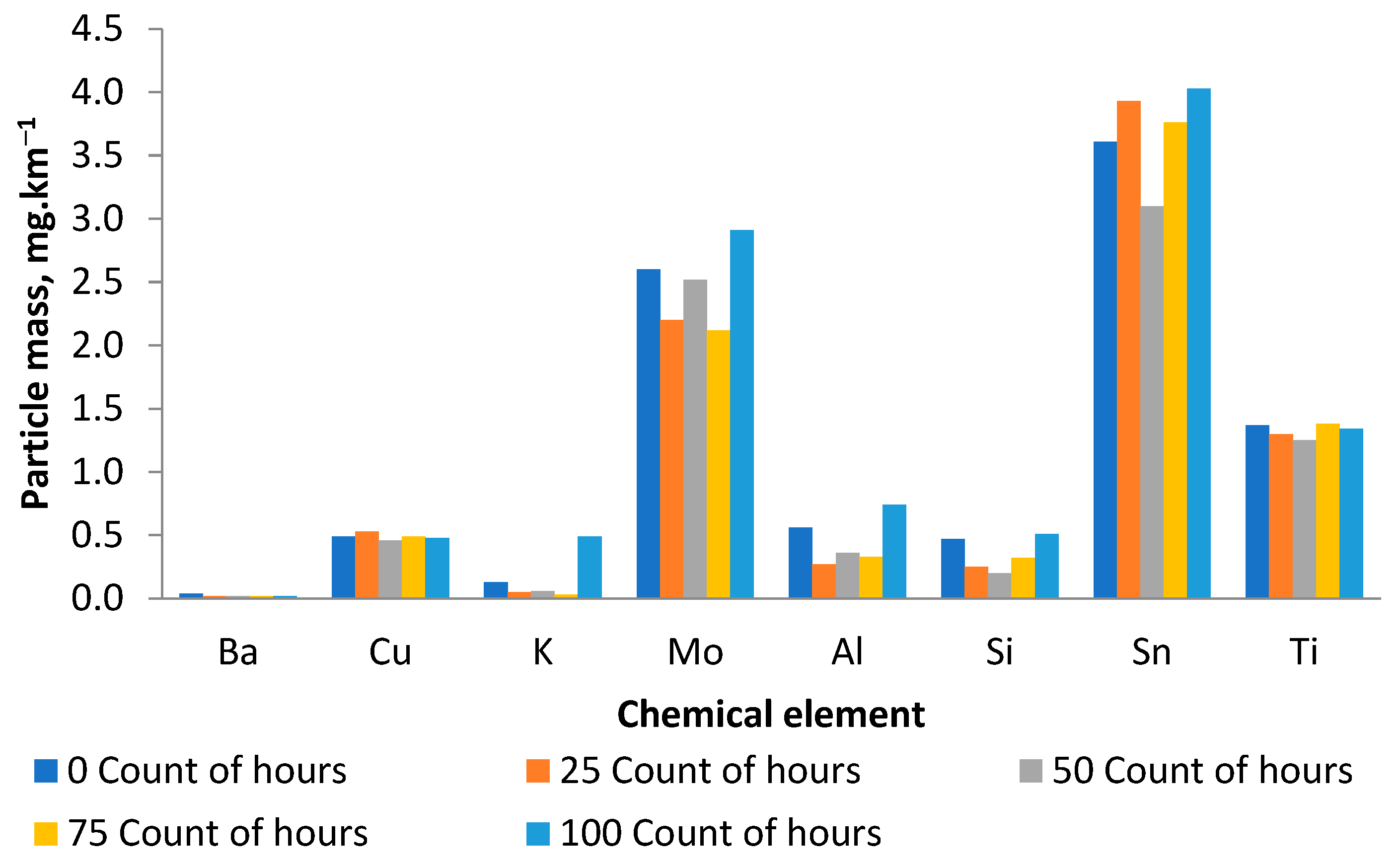

- The largest increases in pollutant elements were found for potassium (K), tin (Sn) and sodium (Na). The above elements are mainly found in bearing and sleeve deposits. The increase is not significant, hence only operational wear of the gear hydraulic pump occurs.

- (4).

- We can confirm the presence of cutting, sliding, fatigue and non-metallic particles based on the LaserNet Fines evaluation.

- (5).

- The kinematic viscosity at 40 °C and at 100 °C did not exceed the limit value of 20% set by ISO 15380:2016.

- (6).

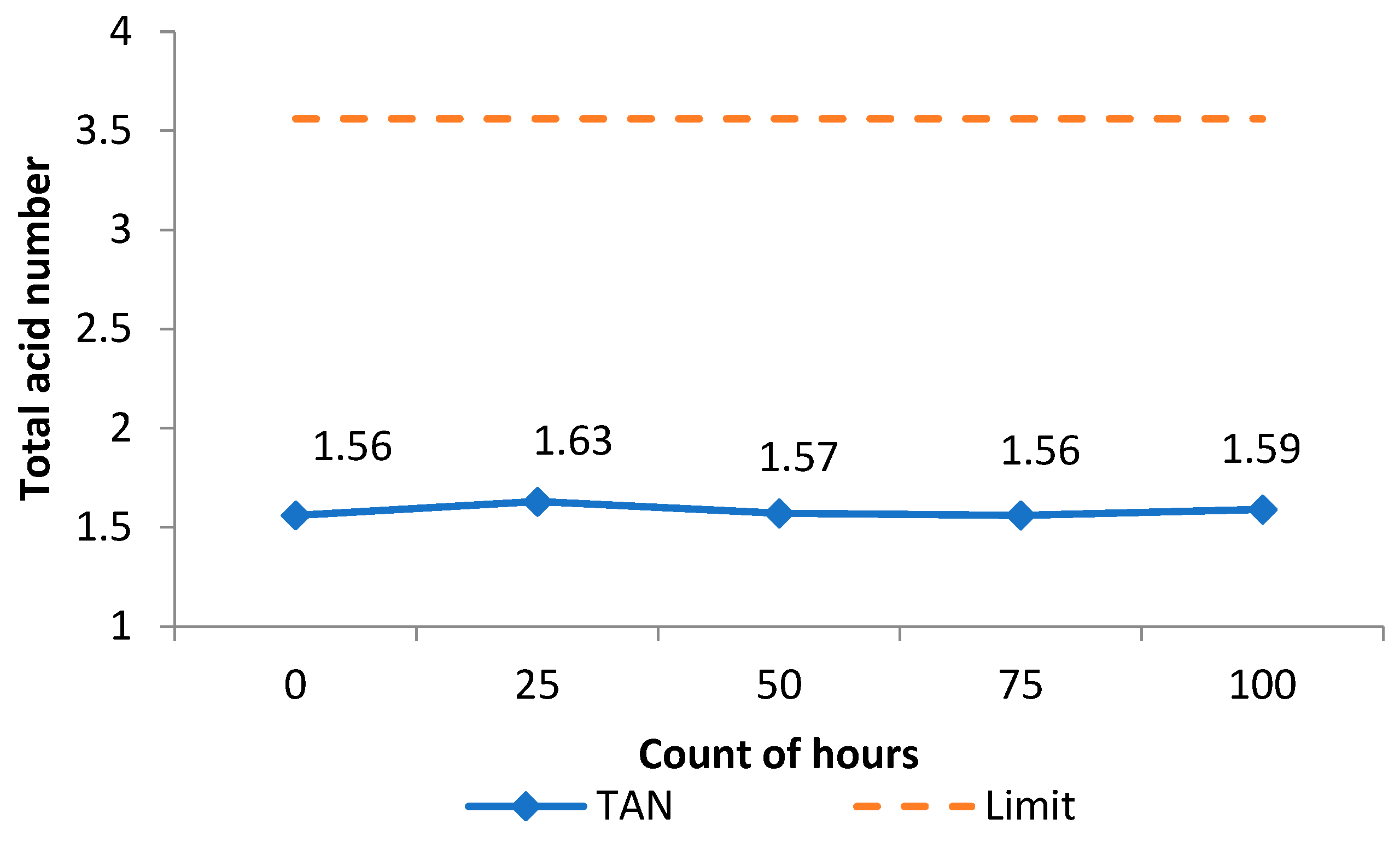

- The acid number of the hydraulic fluid did not exceed the limit value given by ISO 15380:2016.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zharkevich, O.; Nikonova, T.; Gierz, L.; Reshetnikova, O.; Berg, A.; Warguła, L.; Berg, A.; Wieczorek, B.; Lykowski, W.; Nurzhanova, O. Improving the Design of a Multi-Gear Pump Switchgear Using CFD Analysis. Appl. Sci. 2024, 14, 5394. [Google Scholar] [CrossRef]

- Bilalov, R.; Smetannikov, O. Numerical Study of the Hydrodynamics of an External Gear Pump. J. Appl. Mech. Tech. Phys. 2022, 63, 1284–1293. [Google Scholar] [CrossRef]

- Liu, J.; Meng, S.; Zhou, X.; Gu, L. A Hydraulic Axial Piston Pump Fault Diagnosis Based on Instantaneous Angular Velocity under Non-Stationary Conditions. Lubricants 2023, 11, 406. [Google Scholar] [CrossRef]

- Findeisen, D.; Helduser, S. Ölhydraulik; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Nikolov, N.; Mitov, A.; Kralov, I. Advanced 2D Computational Fluid Dynamics Model of an External Gear Pump Considering Relief Grooves. Appl. Sci. 2024, 14, 4299. [Google Scholar] [CrossRef]

- Zardin, B.; Natali, E.; Borghi, M. Evaluation of the Hydro-Mechanical Efficiency of External Gear Pumps. Energies 2019, 12, 2468. [Google Scholar] [CrossRef]

- Zhao, X.; Vacca, A. Multi-domain simulation and dynamic analysis of the 3D loading and micromotion of continuous-contact helical gear pumps. Mech. Syst. Signal Process. 2022, 163, 108116. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, D.; Yang, G.; Pan, Q.; Shi, W.; Zhao, R. Optimization of Hydraulic Efficiency and Internal Flow Characteristics of a Multi-Stage Pump Using RBF Neural Network. Water 2024, 16, 1488. [Google Scholar] [CrossRef]

- Stawiński, L.; Kosucki, A.; Cebulak, M.; Górniak vel Górski, A.; Grala, M. Investigation of the influence of hydraulic oil temperature on the variablespeed pump performance. Eksploat. I Niezawodn. Maint. Reliab. 2022, 24, 289–296. [Google Scholar] [CrossRef]

- Kosiba, J.; Tkáč, Z.; Jablonický, J.; Shcherbak, V.; Ganushchak-Yefimenko, L.; Paumer, M.; Bukoros, T.; Čurgaliová, G.; Zachar, M. Experimental testing of the influence of the operating loading on the flow characteristics of hydraulic pump. Eksploat. I Niezawodn.–Maint. Reliab. 2022, 24, 19. [Google Scholar] [CrossRef]

- Tian, Z.K.; Li, H.R.; Sun, J.; Li, B.C. Degradation state identification method of hydraulic pump based on improved MF-DFA and SSM-FCM. Chin. J. Sci. Instrum. 2016, 37, 1851–1860. [Google Scholar]

- Ranganathan, G.; Hillson Samuel Raj, T.; Mohan Ram, P.V. Wear characterisation of small PM rotors and oil pump bearings. Tribol. Int. 2004, 37, 1–9. [Google Scholar] [CrossRef]

- Novak, N.; Trajkovski, A.; Polajnar, M.; Kalin, M.; Majdič, F. Wear of hydraulic pump with real particles and medium test dust. Wear 2023, 523, 532–533. [Google Scholar] [CrossRef]

- Guo, R.; Li, Y.; Shi, Y.; Li, H.; Zhao, J.; Gao, D. Research on Identification Method of Wear Degradation of External Gear Pump Based on Flow Field Analysis. Sensors 2020, 20, 4058. [Google Scholar] [CrossRef]

- Peng, Z.; Kessissoglou, N.J.; Cox, M. A study of the effect of contaminant particles in lubricants using wear debris and vibration condition monitoring techniques. Wear 2005, 258, 205101. [Google Scholar] [CrossRef]

- Klarecki, K.; Rabsztyn, D.; Czop, P. Modeling of Filtration Phenomenon in Hydrostatic Drives. Machines 2024, 12, 417. [Google Scholar] [CrossRef]

- Zio, E.; Peloni, G. Particle filtering prognostic estimation of the remaining useful life of nonlinear components. Reliab. Eng. Syst. Saf. 2011, 96, 403–409. [Google Scholar] [CrossRef]

- Siddique, M.A.A.; Kim, Y.-J.; Baek, S.-M.; Baek, S.-Y.; Han, T.-H.; Kim, W.-S.; Kim, Y.-S.; Lim, R.-G.; Choi, Y. Development of the Reliability Assessment Process of the Hydraulic Pump for a 78 kW Tractor during Major Agricultural Operations. Agriculture 2022, 12, 1609. [Google Scholar] [CrossRef]

- Novaković, B.; Radovanović, L.; Zuber, N.; Radosav, D.; Đorđević, L.; Kavalić, M. Analysis of the influence of hydraulic fluid quality on external gear pump performance. Eksploat. I Niezawodn. Maint. Reliab. 2022, 24, 260–268. [Google Scholar] [CrossRef]

- Corvaglia, A.; Ferrari, A.; Rundo, M.; Vento, O. Three-dimensional model of an external gear pump with an experimental evaluation of the flow ripple. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1097–1105. [Google Scholar] [CrossRef]

- Okoro, E.E.; Iwuajoku, S.; Sanni, S.E. Performance Evaluation of Biodiesel Produced from Waste Tire Pyrolytic Oil as a Lubricant Additive in Oil Drilling Systems. Recycling 2020, 5, 29. [Google Scholar] [CrossRef]

- Hashim, W.M.; Al-Salihi, H.A.; Al Zubaidi, F.N. Effects of temperature on the properties of HL32 oil in conventional hydraulic actuators. Heliyon 2022, 8. [Google Scholar] [CrossRef] [PubMed]

- ASTM D6866; Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. ASTM: West Conshohocken, PA, USA, 2002.

- DKD-K-04701; Calibration of Flow Rate Meter. DKD: Braunschweig, Germany, 2014.

- DIN EN ISO 9001; Quality Management Systems. ISO: Geneva, Switzerland, 2015.

- ASTM D6595; Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry. ASTM: West Conshohocken, PA, USA, 2017.

- Yoshida, N.; Inaguma, N. Mathematical Analysis of Efficiencies in Hydraulic Pumps for Automatic Transmissions. SAE Int. J. Passeng. Cars-Mech. Syst. Vol. 2013, 6, 54–73. [Google Scholar] [CrossRef]

- Inaguma, Y.; Yoshida, N. Variation in Driving Torque and Vane Friction Torque in a Balanced Vane Pump; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- ISO 15380:2016; Lubricants, Industrial Oils and Related Products (class L)—Family H (Hydraulic Systems)—Specifications for Hydraulic Fluids in Categories HETG, HEPG, HEES and HEPR. ISO: Geneva, Switzerland, 2015.

- Non-Newtonian Models. Available online: https://www.simscale.com/docs/simulation-setup/materials/non-newtonian-models/ (accessed on 29 July 2024).

- Decote, P.A.P.; Negris, L.; Vidoto, A.P.; Mendes, L.A.N.; Floresm, E.M.M.; Vicente, M.A.; Santos, M.F.P. Determination of the total acid number of Brazilian crude oil samples: Theoretical and experimental evaluation of three standard methods. Fuel 2022, 313, 122642. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | |

|---|---|---|---|

| Actual displacement | cm3 | 17.24 | |

| Inlet pressure | min. | MPa | −0.03 |

| max. | MPa | 0.05 | |

| Maximum pressure | MPa | 29 | |

| Speed | nominal | min−1 | 1500 |

| minimum | min−1 | 350 | |

| maximum | min−1 | 3200 | |

| Flow at nominal speed | min−1 | 23.5 | |

| Maximum input power | kW | 33.6 | |

| Nominal input power | kW | 16.1 | |

| Volumetric flow rate at maximum speed | dm3.min−1 | 54.3 | |

| Volumetric flow rate at nominal speed | dm3.min−1 | 23.2 | |

| Volumetric efficiency | % | 92 | |

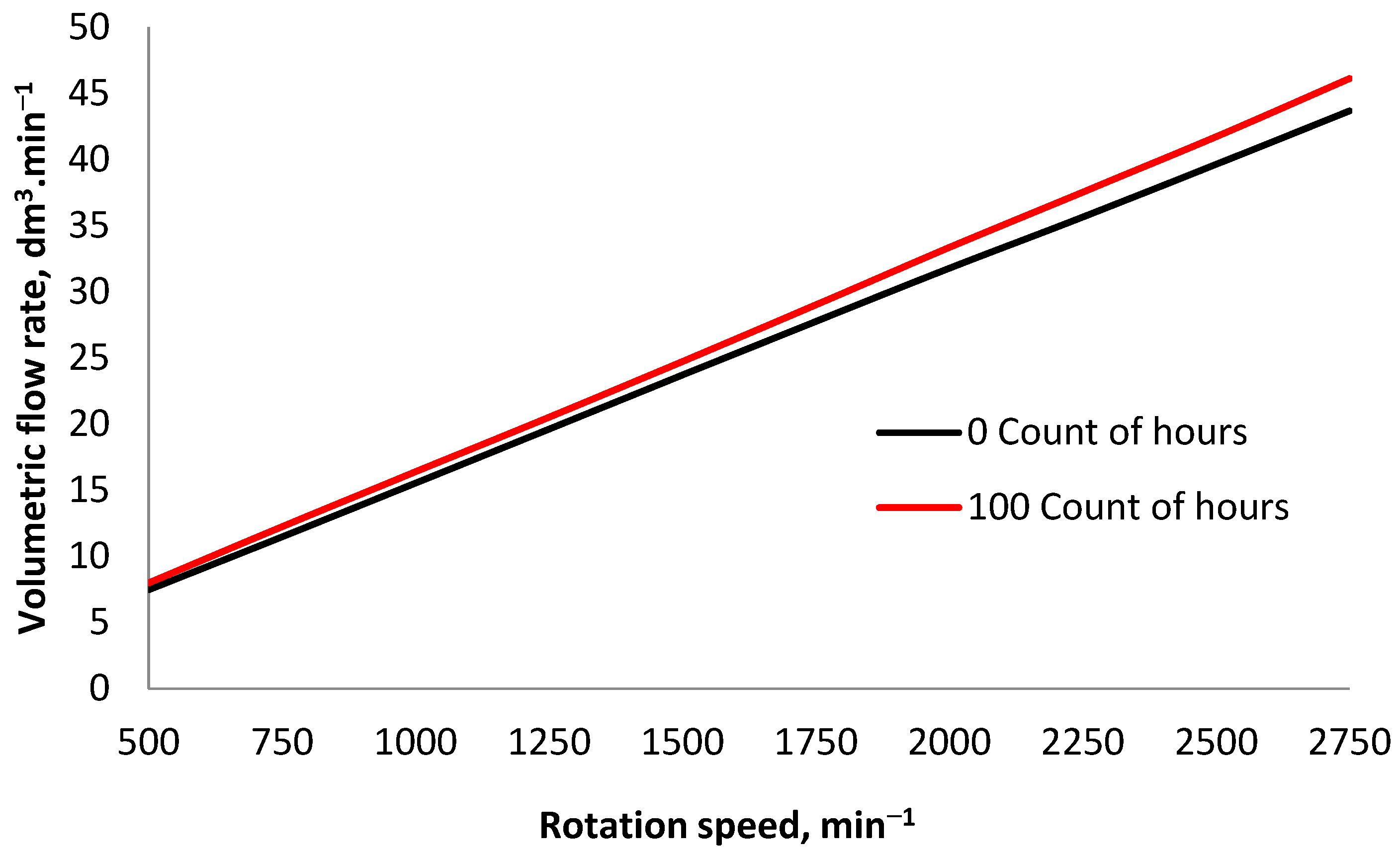

| Speed, min−1 | Count of Hours | ||||

|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | 100 | |

| 500 | 7.48 | 7.73 | 7.86 | 7.95 | 7.99 |

| 750 | 11.48 | 11.74 | 11.91 | 12.12 | 12.25 |

| 1000 | 15.53 | 15.79 | 15.91 | 16.19 | 16.39 |

| 1250 | 19.62 | 19.96 | 20.34 | 20.36 | 20.52 |

| 1500 | 23.70 | 23.88 | 23.99 | 24.58 | 24.73 |

| 1750 | 27.75 | 28.42 | 28.62 | 28.85 | 29.00 |

| 2000 | 31.77 | 32.98 | 33.08 | 33.28 | 33.34 |

| 2250 | 35.64 | 37.29 | 37.38 | 37.49 | 37.53 |

| 2500 | 39.62 | 41.47 | 41.51 | 41.67 | 41.72 |

| 2750 | 43.67 | 45.74 | 45.80 | 45.94 | 46.10 |

| Number of Hours Worked | Abrasion Particles (20 µm–100 µm) | |||

|---|---|---|---|---|

| Cutting Particles | Slippery Particles | Fatigue Particles | Non-Metallic Particles | |

| 0 | 24.3 | 27.2 | 21.3 | 31.8 |

| 25 | 25.6 | 30.1 | 23.8 | 33.1 |

| 50 | 28.8 | 30.2 | 24.2 | 35.7 |

| 75 | 29.1 | 35.3 | 24.6 | 36.1 |

| 100 | 30.2 | 36.1 | 28.7 | 38.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosiba, J.; Tkáč, Z.; Jablonický, J.; Čurgaliová, G.; Tulík, J.; Halenár, M. Laboratory Test of a Gear Hydraulic Pump during the Application of an Environmentally Friendly Hydraulic Fluid with Constant Pressure and Temperature. Lubricants 2024, 12, 304. https://doi.org/10.3390/lubricants12090304

Kosiba J, Tkáč Z, Jablonický J, Čurgaliová G, Tulík J, Halenár M. Laboratory Test of a Gear Hydraulic Pump during the Application of an Environmentally Friendly Hydraulic Fluid with Constant Pressure and Temperature. Lubricants. 2024; 12(9):304. https://doi.org/10.3390/lubricants12090304

Chicago/Turabian StyleKosiba, Ján, Zdenko Tkáč, Juraj Jablonický, Gabriela Čurgaliová, Juraj Tulík, and Marek Halenár. 2024. "Laboratory Test of a Gear Hydraulic Pump during the Application of an Environmentally Friendly Hydraulic Fluid with Constant Pressure and Temperature" Lubricants 12, no. 9: 304. https://doi.org/10.3390/lubricants12090304

APA StyleKosiba, J., Tkáč, Z., Jablonický, J., Čurgaliová, G., Tulík, J., & Halenár, M. (2024). Laboratory Test of a Gear Hydraulic Pump during the Application of an Environmentally Friendly Hydraulic Fluid with Constant Pressure and Temperature. Lubricants, 12(9), 304. https://doi.org/10.3390/lubricants12090304