Applications of Phyllosilicates Mineral Powder as Anti-Wear Lubricating Materials in Lubricating Oil and Grease: A Review

Abstract

:1. Introduction

2. Tribological Behaviors of Phyllosilicates Mineral Powder

2.1. Muscovite

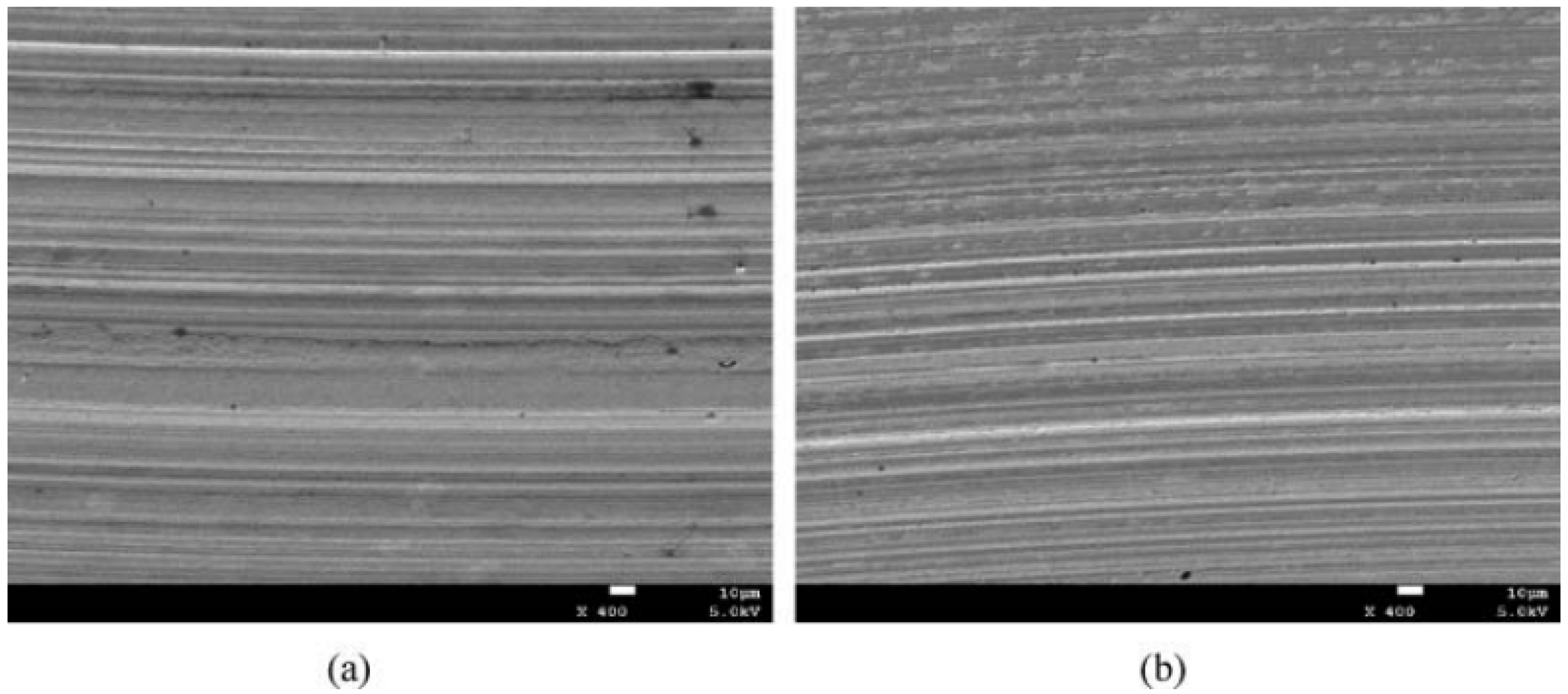

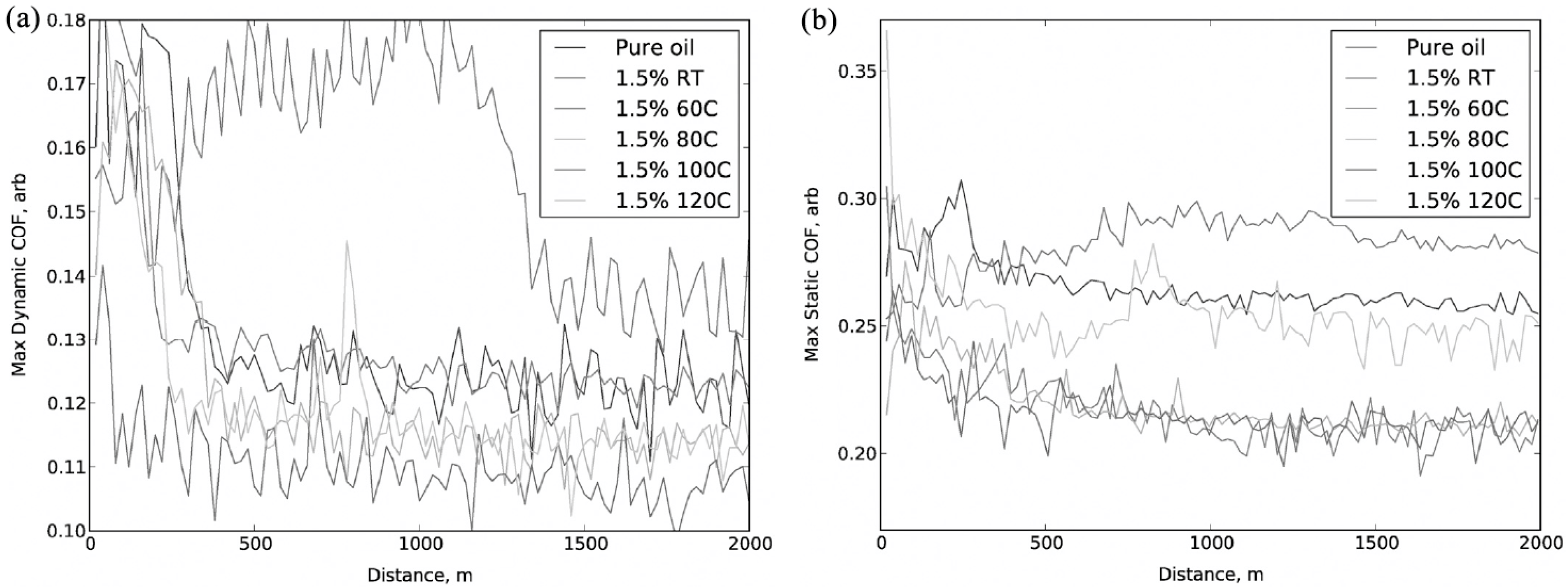

2.2. Talc

2.3. Montmorillonite

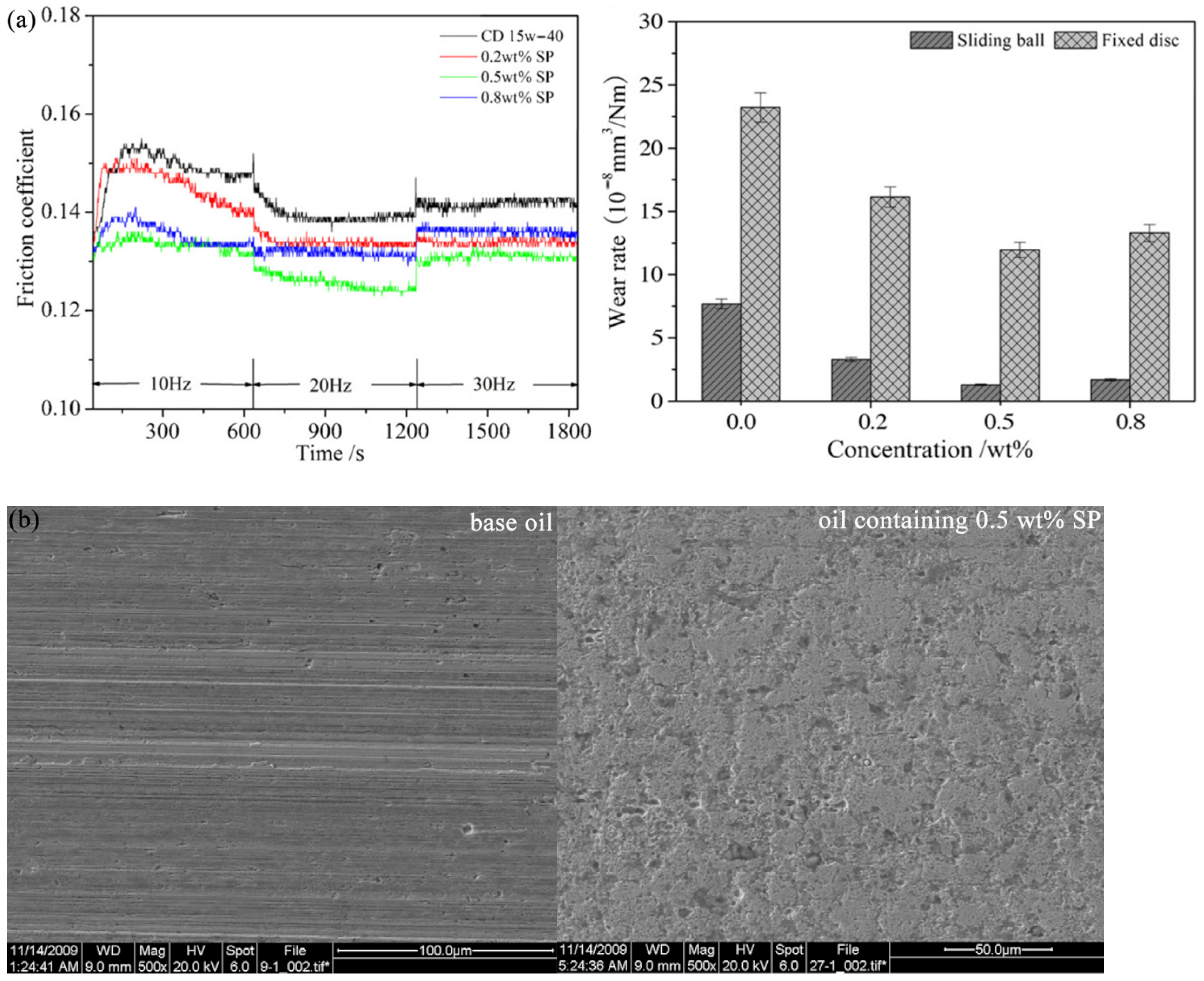

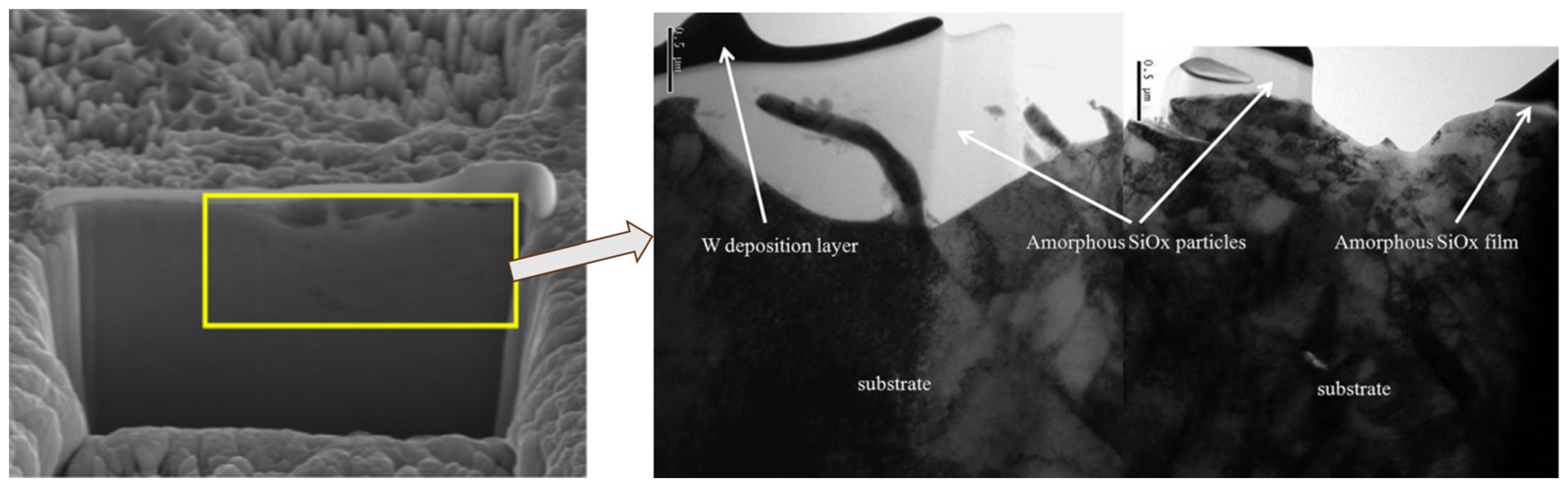

2.4. Serpentine

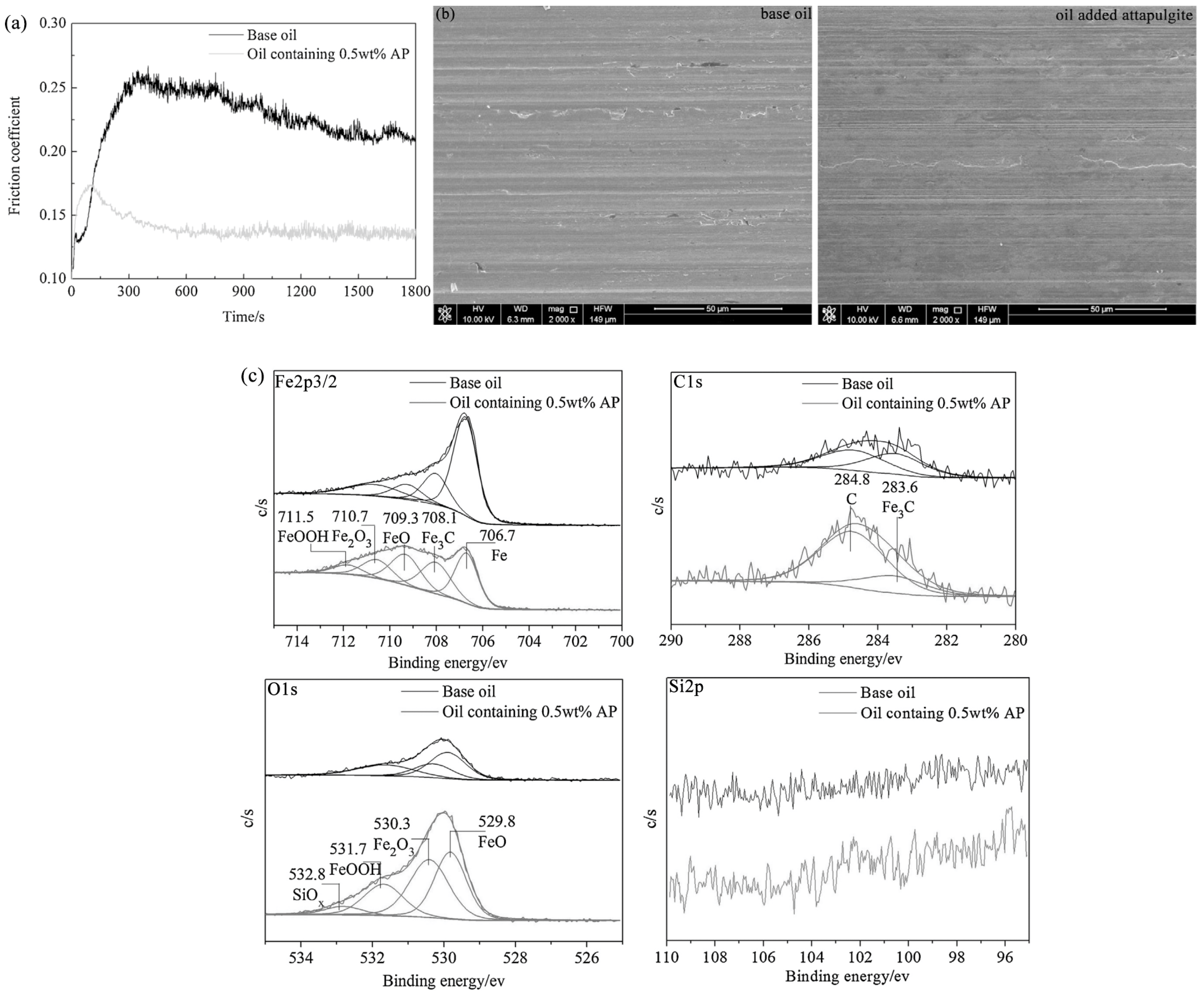

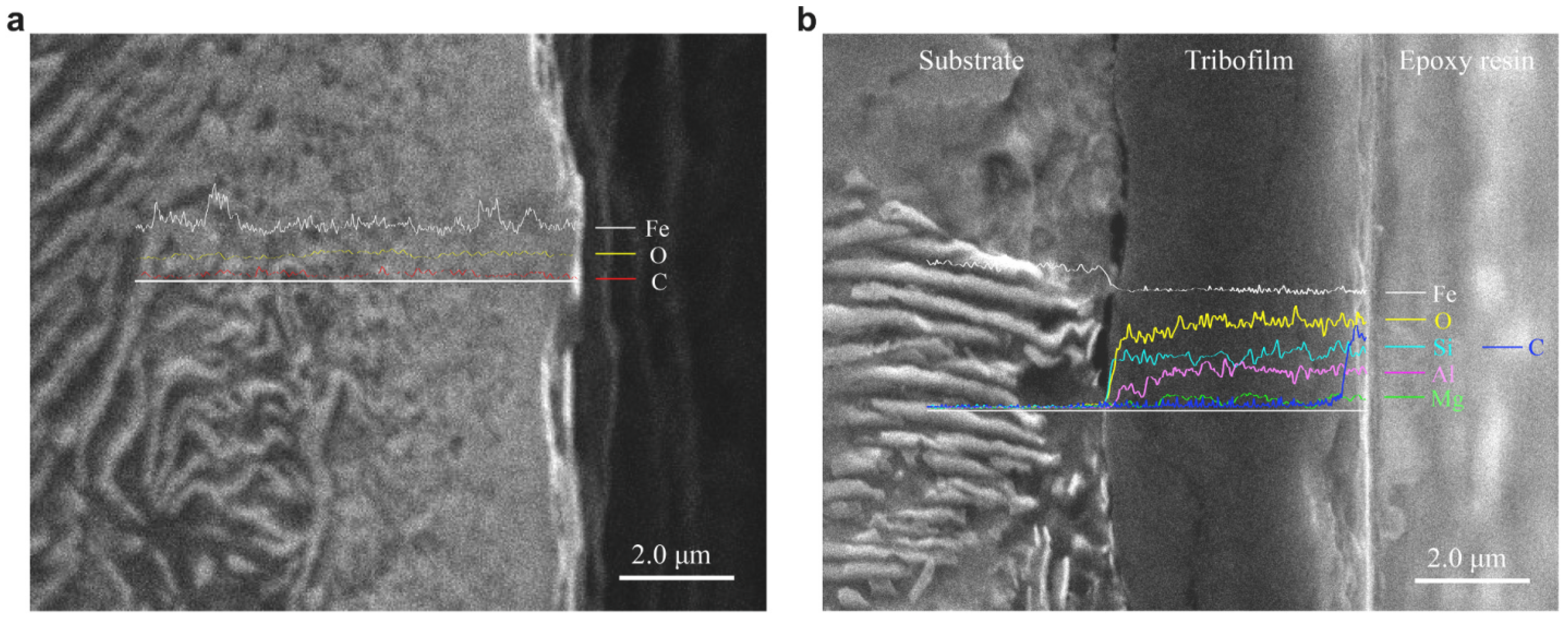

2.5. Attapulgite

3. Fundamental Mechanisms of Lubrication

3.1. Role of Layered Structure

3.2. Chemical Activity and Film Formation

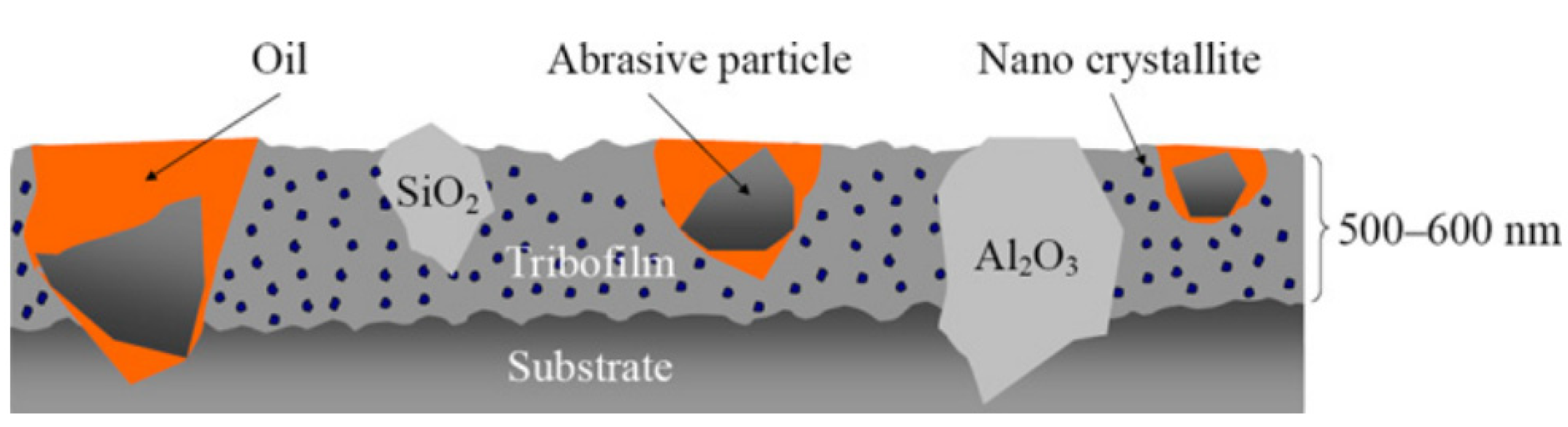

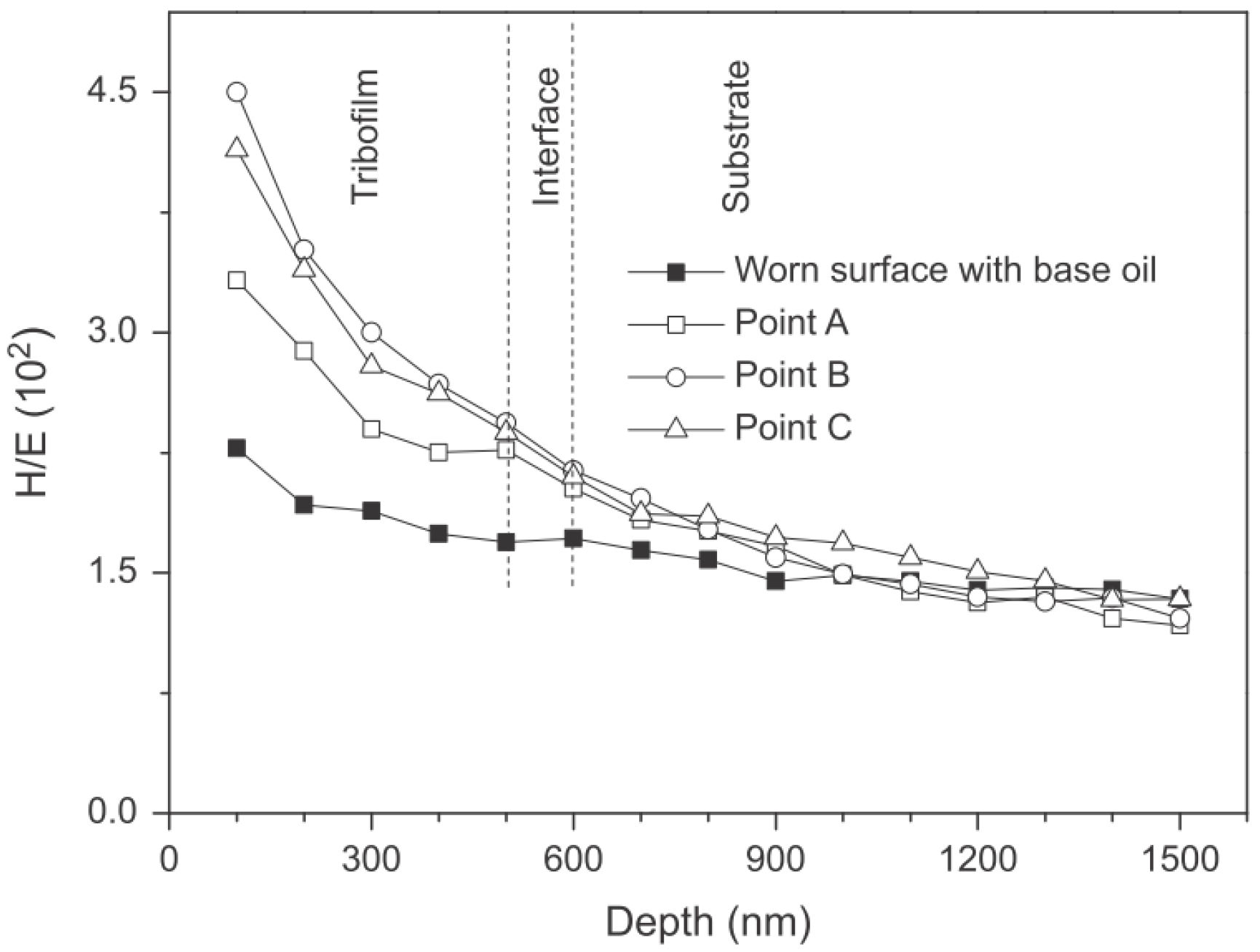

3.3. Self-Healing Ability

3.4. Synergistic Effects with Other Additives

3.5. Environmental Adaptability

4. Conclusions and Perspectives

- (1)

- For phyllosilicates mineral powder lubricating additives, the dispersion stability in lubricants is an important issue in its exertion of performance and practical application. Traditional organic modifiers, such as oleic acid, silane coupling agent, and so on are presently used to modify phyllosilicates mineral powder to improve their dispersion stability in lubricants. However, the improvement effect is not ideal. Consequently, how to prepare long-term equilibrium solid-liquid two-phase lubrication systems still needs further investigation.

- (2)

- Natural phyllosilicates mineral powder need to undergo several processes, including crushing, refining, purification, and organic modification, before being added to lubricating oils. Hence, the cost of phyllosilicates mineral powder as lubricating additives is high for industrial applications. Efforts are still needed to improve preparation efficiency and reduce the preparation costs of phyllosilicates mineral powder lubricating additives.

- (3)

- The friction-reducing and anti-wear improvement effect of phyllosilicates mineral powder is presently limited. The friction coefficient of the lubricants containing phyllosilicates mineral powder is mostly higher than 0.1. Further reduction of the friction coefficient, or even achieving superlubricity, is important for the research of phyllosilicates mineral powder as additives.

- (4)

- It has been found that tribofilms are generated on worn surfaces, but most discussions on tribological mechanisms are based on the characterization and analysis of the surfaces on the tribofilms. Little is known about the internal structure and formation process of the tribofilms. Hence, the friction-reducing and anti-wear mechanisms of phyllosilicates mineral powder are still unclear. Using more advanced detection equipment and simulation methods [61,62,63,64,65,66,67,68] for an in-depth revelation of the tribological mechanisms is needed in the future.

Author Contributions

Funding

Conflicts of Interest

References

- Abad, M.D.; Sánchez-López, J.C. Tribological properties of surface-modified Pd nanoparticles for electrical contacts. Wear 2013, 297, 943–951. [Google Scholar] [CrossRef]

- Chou, R.; Battez, A.H.; Cabello, J.J.; Viesca, J.L.; Osorio, A.; Sagastume, A. Tribological behavior of polyalphaolefin with the addition of nickel nanoparticles. Tribol. Int. 2010, 43, 2327–2332. [Google Scholar] [CrossRef]

- Guzman Borda, F.L.; Ribeiro de Oliveira, S.J.; Seabra Monteiro Lazaro, L.M.; Kalab Leiróz, A.J. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Qu, M.; Yao, Y.; He, J.; Ma, X.; Liu, S.; Feng, J.; Hou, L. Tribological performance of functionalized ionic liquid and Cu microparticles as lubricating additives in sunflower seed oil. Tribol. Int. 2016, 104, 166–174. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, L.; Feng, D.; Wang, H. Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition. Vacuum 2013, 87, 75–80. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, D. Preparation and tribological properties of unmodified and oleic acid-modified CuS nanorods as lubricating oil additives. Ceram. Int. 2017, 43, 4246–4251. [Google Scholar] [CrossRef]

- Hou, K.; Han, M.; Liu, X.; Wang, J.; He, Y.; Yang, S. In situ formation of spherical MoS2 nanoparticles for ultra-low friction. Nanoscale 2018, 10, 19979–19986. [Google Scholar] [CrossRef]

- Lu, Z.; Cao, Z.; Hu, E.; Hu, K.; Hu, X. Preparation and tribological properties of WS2 and WS2/TiO2 nanoparticles. Tribol. Int. 2019, 130, 308–316. [Google Scholar] [CrossRef]

- Tomala, A.; Ripoll, M.R.; Kogovšek, J.; Kalin, M.; Bednarska, A.; Michalczewski, R.; Szczerek, M. Synergisms and antagonisms between MoS2 nanotubes and representative oil additives under various contact conditions. Tribol. Int. 2019, 129, 137–150. [Google Scholar] [CrossRef]

- Wu, X.; Gong, K.; Zhao, G.; Lou, W.; Wang, X.; Liu, W. MoS2/WS2 Quantum Dots as High-Performance Lubricant Additive in Polyalkylene Glycol for Steel/Steel Contact at Elevated Temperature. Adv. Mater. Interfaces 2017, 5, 1700859. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, G.; Zhao, Q.; Gong, K.; Wang, X.; Liu, W.; Liu, W. Investigating the tribological performance of nanosized MoS2 on graphene dispersion in perfluoropolyether under high vacuum. RSC Adv. 2016, 6, 98606–98610. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Zhao, H.; Cai, G.; Zheng, X. Tribology properties of Al2O3/TiO2 nanocomposites as lubricant additives. Ceram. Int. 2014, 40, 10103–10109. [Google Scholar] [CrossRef]

- Ma, S.; Zheng, S.; Cao, D.; Guo, H. Anti-wear and friction performance of ZrO2 nanoparticles as lubricant additive. Particuology 2010, 8, 468–472. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Li, B.; Yang, M.; Zhang, X.; Guo, S.; Liu, G.; Zhai, M. Comparative evaluation of the lubricating properties of vegetable-oil-based nanofluids between frictional test and grinding experiment. J. Manuf. Process. 2017, 26, 94–104. [Google Scholar] [CrossRef]

- Xiang, L.; Gao, C.; Wang, Y.; Pan, Z.; Hu, D. Tribological and tribochemical properties of magnetite nanoflakes as additives in oil lubricants. Particuology 2014, 17, 136–144. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, B.; He, J.; Xia, X.; Pan, F. Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol. Int. 2016, 93, 63–70. [Google Scholar] [CrossRef]

- Li, J.; Luo, J. Superlow Friction of Graphite Induced by the Self-Assembly of Sodium Dodecyl Sulfate Molecular Layers. Langmuir 2017, 33, 12596–12601. [Google Scholar] [CrossRef]

- Nunn, N.; Mahbooba, Z.; Ivanov, M.G.; Ivanov, D.M.; Brenner, D.W.; Shenderova, O. Tribological properties of polyalphaolefin oil modified with nanocarbon additives. Diam. Relat. Mater. 2015, 54, 97–102. [Google Scholar] [CrossRef]

- Singh, H.; Bhowmick, H. Tribological behaviour of hybrid AMMC sliding against steel and cast iron under MWCNT-Oil lubrication. Tribol. Int. 2018, 127, 509–519. [Google Scholar] [CrossRef]

- Wang, B.; Hu, E.; Tu, Z.; David, K.D.; Hu, K.; Hu, X.; Yang, W.; Guo, J.; Cai, W.; Qian, W.; et al. Characterization and tribological properties of rice husk carbon nanoparticles Co-doped with sulfur and nitrogen. Appl. Surf. Sci. 2018, 462, 944–954. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Mao, J.; He, Y.; Luo, J. Synthesis of thermally reduced graphite oxide in sulfuric acid and its application as an efficient lubrication additive. Tribol. Int. 2017, 116, 303–309. [Google Scholar] [CrossRef]

- Du, P.; Chen, G.X.; Song, S.; Wu, J.; Gu, K.; Zhu, D.; Li, J. Effect of thermal activation on the tribological behaviors of muscovite particles as lubricant additives in lithium grease. Ind. Lubr. Tribol. 2018, 70, 538–543. [Google Scholar] [CrossRef]

- Daji, W.; Dachuan, Z.; Huafeng, L.; Guoxu, C. Tribological Properties of Muscovite/La2O3 Composite Powders as Lubricant Additives. Tribol. Trans. 2015, 58, 577–583. [Google Scholar] [CrossRef]

- Du, P.; Chen, G.; Song, S.; Chen, H.; Li, J.; Shao, Y. Tribological Properties of Muscovite, CeO2 and Their Composite Particles as Lubricant Additives. Tribol. Lett. 2016, 62, 29. [Google Scholar] [CrossRef]

- Rudenko, P.; Bandyopadhyay, A. Talc as friction reducing additive to lubricating oil. Appl. Surf. Sci. 2013, 276, 383–389. [Google Scholar] [CrossRef]

- Prasad, B.K.; Rathod, S.; Modi, O.P.; Yadav, M.S. Influence of talc concentration in oil lubricant on the wear response of a bronze journal bearing. Wear 2010, 269, 498–505. [Google Scholar] [CrossRef]

- Fei, J.; Qi, Y.; Luo, L.; Gu, Y.; Huang, J. Synergistic effect of talc/carbon spheres composite as oil-based additive enhancing the lubricating properties for steel-steel contact. Lubr. Sci. 2020, 32, 80–89. [Google Scholar] [CrossRef]

- Mobasher, A.; Khalil, A.; Khashaba, M.; Osman, T. Effect of MWCNTs/Talc powder nanoparticles on the tribological and thermal conductivity performance of calcium grease. Ind. Lubr. Tribol. 2019, 72, 9–14. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y.; Xi, X. Nano-montmorillonite-doped lubricating grease exhibiting excellent insulating and tribological properties. Friction 2017, 5, 219–230. [Google Scholar] [CrossRef]

- Li, Y.; Yang, R.; Hao, Q.; Lei, W. Tribological Properties of the Functionalized Graphene/Montmorillonite Nanosheets as a Lubricant Additive. Tribol. Lett. 2021, 69, 117. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, Y.; Gao, F.; Shi, P.; Xu, B.; Wu, Y. Sliding friction and wear behaviors of surface-coated natural serpentine mineral powders as lubricant additive. Appl. Surf. Sci. 2011, 257, 2540–2549. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, B.; Xu, Y.; Ba, Z.; Wang, Z. An amorphous SiO film tribo-induced by natural hydrosilicate powders on ferrous surface. Appl. Surf. Sci. 2013, 285, 759–765. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Shi, P.; Wang, H.; Wei, M.; Zhao, K.; Xu, B. Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear 2013, 297, 802–810. [Google Scholar] [CrossRef]

- Bai, Z.M.; Yang, N.; Guo, M.; Li, S. Antigorite: Mineralogical characterization and friction performances. Tribol. Int. 2016, 101, 115–121. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Yan, J.; Ren, T.; Zhao, Y. Tribological behaviours of surface-modified serpentine powder as lubricant additive. Ind. Lubr. Tribol. 2016, 68, 1–8. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Wei, X.; Liu, R.; Cao, Q. The effect of serpentine additive on energy-saving and auto-reconditioning surface layer formation. Ind. Lubr. Tribol. 2017, 69, 158–165. [Google Scholar] [CrossRef]

- Wang, B.; Zhong, Z.; Qiu, H.; Chen, D.; Li, W.; Li, S.; Tu, X. Nano Serpentine Powders as Lubricant Additive: Tribological Behaviors and Self-Repairing Performance on Worn Surface. Nanomaterials 2020, 10, 922. [Google Scholar] [CrossRef]

- Yu, H.L.; Xu, Y.; Shi, P.J.; Wang, H.M.; Zhang, W.; Xu, B.S. Effect of thermal activation on the tribological behaviours of serpentine ultrafine powders as an additive in liquid paraffin. Tribol. Int. 2011, 44, 1736–1741. [Google Scholar] [CrossRef]

- Yin, Y.L.; Yu, H.L.; Wang, H.M.; Song, Z.Y.; Zhang, Z.; Ji, X.C.; Cui, T.H.; Wei, M.; Zhang, W. Friction and wear behaviors of steel/ bronze tribopairs lubricated by oil with serpentine natural mineral additive. Wear 2020, 456–457, 203387. [Google Scholar] [CrossRef]

- Qi, X.; Jia, Z.; Yang, Y.; Fan, B. Characterization and auto-restoration mechanism of nanoscale serpentine powder as lubricating oil additive under high temperature. Tribol. Int. 2011, 44, 805–810. [Google Scholar] [CrossRef]

- Qi, X.; Lu, L.; Jia, Z.; Yang, Y.; Liu, H. Comparative tribological properties of magnesium hexasilicate and serpentine powder as lubricating oil additives under High temperature. Tribol. Int. 2012, 49, 53–57. [Google Scholar] [CrossRef]

- Qi, X.; Jia, Z.; Chen, H.; Yang, Y.; Wu, Z. Self-Repairing Characteristics of Serpentine Mineral Powder as an Additive on Steel–Chromium Plating Pair under High Temperature. Tribol. Trans. 2013, 56, 516–520. [Google Scholar] [CrossRef]

- Zhang, B.-S.; Xu, B.-S.; Xu, Y.; Gao, F.; Shi, P.-J.; Wu, Y.-X. CU nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribol. Int. 2011, 44, 878–886. [Google Scholar] [CrossRef]

- Zhao, F.; Bai, Z.; Fu, Y.; Zhao, D.; Yan, C. Tribological properties of serpentine, La(OH)3 and their composite particles as lubricant additives. Wear 2012, 288, 72–77. [Google Scholar] [CrossRef]

- Zhao, F.; Kasrai, M.; Sham, T.-K.; Bai, Z.; Zhao, D. Characterization of tribofilms derived from zinc dialkyl dithiophosphate and serpentine by X-ray absorption spectroscopy. Tribol. Int. 2014, 73, 167–176. [Google Scholar] [CrossRef]

- Qin, Y.; Wu, M.; Yang, G.; Yang, Y.; Zhao, L. Tribological Performance of Magnesium Silicate Hydroxide/Ni Composite as an Oil-Based Additive for Steel–Steel Contact. Tribol. Lett. 2021, 69, 19. [Google Scholar] [CrossRef]

- Li, Y.; Nan, F. Achieving long term anti-corrosion waterborne epoxy coating by attapulgite loaded octadecylamine/graphene nanocomposite. Polym. Test. 2023, 129, 108290. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Tang, X. Effect of natural attapulgite powders as lubrication additive on the friction and wear performance of a steel tribo-pair. Appl. Surf. Sci. 2014, 307, 86–91. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Li, Z. Tribological behaviors and wear mechanisms of ultrafine magnesium aluminum silicate powders as lubricant additive. Tribol. Int. 2015, 81, 199–208. [Google Scholar] [CrossRef]

- Yu, H.L.; Wang, H.M.; Yin, Y.L.; Song, Z.Y.; Zhou, X.Y.; Ji, X.C.; Wei, M.; Shi, P.J.; Bai, Z.M.; Zhang, W. Tribological behaviors of natural attapulgite nanofibers as an additive for mineral oil investigated by orthogonal test method. Tribol. Int. 2021, 153, 106562. [Google Scholar] [CrossRef]

- Nan, F.; Wang, D. Tribological Properties of Attapulgite Nanofiber as Lubricant Additive for Electric-Brush Plated Ni Coating. Lubricants 2023, 11, 204. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, Y.; Liu, Z. Study the Sensitivity of Solid Lubricating Additives to Attapulgite Clay Base Grease. Tribol. Lett. 2011, 42, 141–148. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Li, Z. Tribological Performance of Attapulgite Nano-fiber/Spherical Nano-Ni as Lubricant Additive. Tribol. Lett. 2014, 56, 531–541. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Li, Z. Effect of Cu Nanoparticles on the Tribological Performance of Attapulgite Base Grease. Tribol. Trans. 2015, 58, 1031–1038. [Google Scholar] [CrossRef]

- Nan, F.; Zhou, K.; Liu, S.; Pu, J.; Fang, Y.; Ding, W. Tribological properties of attapulgite/La2O3 nanocomposite as lubricant additive for a steel/steel contact. RSC Adv. 2018, 8, 16947–16956. [Google Scholar] [CrossRef]

- Nan, F.; Yin, Y. Improving of the tribological properties of attapulgite base grease with graphene. Lubr. Sci. 2021, 33, 380–393. [Google Scholar] [CrossRef]

- Wang, D.; Zeng, X.; Nan, F. Tribological behaviors of an attapulgite–graphene nanocomposite as an additive for mineral lubricating oil. RSC Adv. 2024, 14, 16411–16420. [Google Scholar] [CrossRef]

- Wang, K.; Wu, H.; Wang, H.; Liu, Y.; Yang, L.; Zhao, L. Tribological properties of novel palygorskite nanoplatelets used as oil-based lubricant additives. Friction 2020, 9, 332–343. [Google Scholar] [CrossRef]

- Sleptsova, S.A.; Laukkanen, S.; Tarasova, P.N. Properties and Structure of the Friction surface of PTFE/Layered Silicate Compo sites. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1079, 042033. [Google Scholar] [CrossRef]

- Vasilev, A.P.; Struchkova, T.S.; Nikiforov, L.A.; Okhlopkova, A.A.; Grakovich, P.N.; Shim, E.L.; Cho, J.-H. Mechanical and Tribological Properties of Polytetrafluoroethylene Composites with Carbon Fiber and Layered Silicate Fillers. Molecules 2019, 24, 224. [Google Scholar] [CrossRef]

- Abdulfatai, U.; Uzairu, A.; Uba, S.; Shallangwa, G.A. Molecular design of antioxidant lubricating oil additives via QSPR and analysis dynamic simulation method. Heliyon 2019, 5, e02880. [Google Scholar] [CrossRef] [PubMed]

- Baboukani, B.S.; Ye, Z.J.; Reyes, K.G.; Nalam, P.C. Prediction of Nanoscale Friction for Two-Dimensional Materials Using a Machine Learning Approach. Tribol. Lett. 2020, 68, 57. [Google Scholar] [CrossRef]

- Elkholy, A.E.; Rizk, S.A.; Rashad, A.M. Enhancing lubricating oil properties using novel quinazolinone derivatives: DFT study and molecular dynamics simulation. J. Mol. Struct. 2019, 1175, 788–796. [Google Scholar] [CrossRef]

- Kathmore, P.; Bachchhav, B.; Nandi, S.; Salunkhe, S.; Chandrakumar, P.; Nasr, E.A.; Kamrani, A. Prediction of Thrust Force and Torque for High-Speed Drilling of AL6061 with TMPTO-Based Bio-Lubricants Using Machine Learning. Lubricants 2023, 11, 356. [Google Scholar] [CrossRef]

- Qu, G.A.; Fang, H.L.; Liu, L.; Li, Y.; Zhang, S.W.; Yang, H.M.; Hu, L.T. High-performance protic ionic liquids as additives in lubricating oils with varying polarity. Tribol. Int. 2024, 191, 109157. [Google Scholar] [CrossRef]

- Usman, A.; Arif, S.; Raja, A.H.; Kouhia, R.; Almqvist, A.; Liwicki, M. Machine Learning Composite-Nanoparticle-Enriched Lubricant Oil Development for Improved Frictional Performance-An Experiment. Lubricants 2023, 11, 254. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.J. Machine Learning Decomposition Onset Temperature of Lubricant Additives. J. Mater. Eng. Perform. 2020, 29, 6605–6616. [Google Scholar] [CrossRef]

- Zheng, D.D.; Wang, X.B.; Zhang, M.; Liu, Z.G.; Ju, C. Anticorrosion and lubricating properties of a fully green lubricant. Tribol. Int. 2019, 130, 324–333. [Google Scholar] [CrossRef]

| Phyllosilicate Type | Chemical Structure | Physical/Chemical Properties | Pros | Cons | Tribological Mechanisms |

|---|---|---|---|---|---|

| Muscovite | KAl2[AlSl3O10] (OH)2 | Average coefficient of friction: 0.05–0.15 Average wear diameter: 30–50% reduction | Excellent heat resistance and chemical stability Forms an effective anti-wear protective layer | Higher preparation costs Surface modification may be required during application | Layer structure and formation of tribofilm |

| Talc | Mg6Si8O20(OH)4 | Average coefficient of friction: 0.03–0.10 Average wear diameter: 20–40% | Relatively low cost | Respirable particles can be harmful to health Performance degradation in extreme conditions | Formation of oxide transfer films |

| Montmorillonite | (Na,Ca)0.33(Al,Mg)2[Si4O10](OH)2·nH2O | Average coefficient of friction: 0.03–0.10 Average wear diameter: 20–40% | Excellent lubricity Relatively low cost | Requires specific surface treatments to improve performance | Layered structure and formation of protective tribofilm |

| Serpentine | Mg6[Si4O10] (OH)8 | Average coefficient of friction: 0.06–0.18 Average wear diameter: 25–50% | Good heat and corrosion resistance Forms a self-healing protective layer | Performance is strongly influenced by temperature and environmental conditions Further research is needed to optimize performance | Formation of a protective tribofilm |

| Attapulgite | Mg5Si8O20(OH)2(OH2)4⋅4H2O | Average coefficient of friction: 0.04–0.13 Average wear diameter: 20–40% | Excellent self-healing ability Excellent chemical stability | Sensitive to heat Further surface modification may be required to improve performance | Formation of a protective tribofilm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, N.; Nan, F. Applications of Phyllosilicates Mineral Powder as Anti-Wear Lubricating Materials in Lubricating Oil and Grease: A Review. Lubricants 2024, 12, 324. https://doi.org/10.3390/lubricants12090324

Jiang N, Nan F. Applications of Phyllosilicates Mineral Powder as Anti-Wear Lubricating Materials in Lubricating Oil and Grease: A Review. Lubricants. 2024; 12(9):324. https://doi.org/10.3390/lubricants12090324

Chicago/Turabian StyleJiang, Nan, and Feng Nan. 2024. "Applications of Phyllosilicates Mineral Powder as Anti-Wear Lubricating Materials in Lubricating Oil and Grease: A Review" Lubricants 12, no. 9: 324. https://doi.org/10.3390/lubricants12090324

APA StyleJiang, N., & Nan, F. (2024). Applications of Phyllosilicates Mineral Powder as Anti-Wear Lubricating Materials in Lubricating Oil and Grease: A Review. Lubricants, 12(9), 324. https://doi.org/10.3390/lubricants12090324