Effects of Gold Mine Tailings as an Additive on the Tribological Performance of Lubricating Polyurea Grease

Abstract

1. Introduction

2. Experimental

2.1. Treatment of Gold Mine Tailings

2.2. Preparation of Lubricating Greases

2.3. Characterization of Greases

2.4. Tribological Performance Testing

3. Results and Discussion

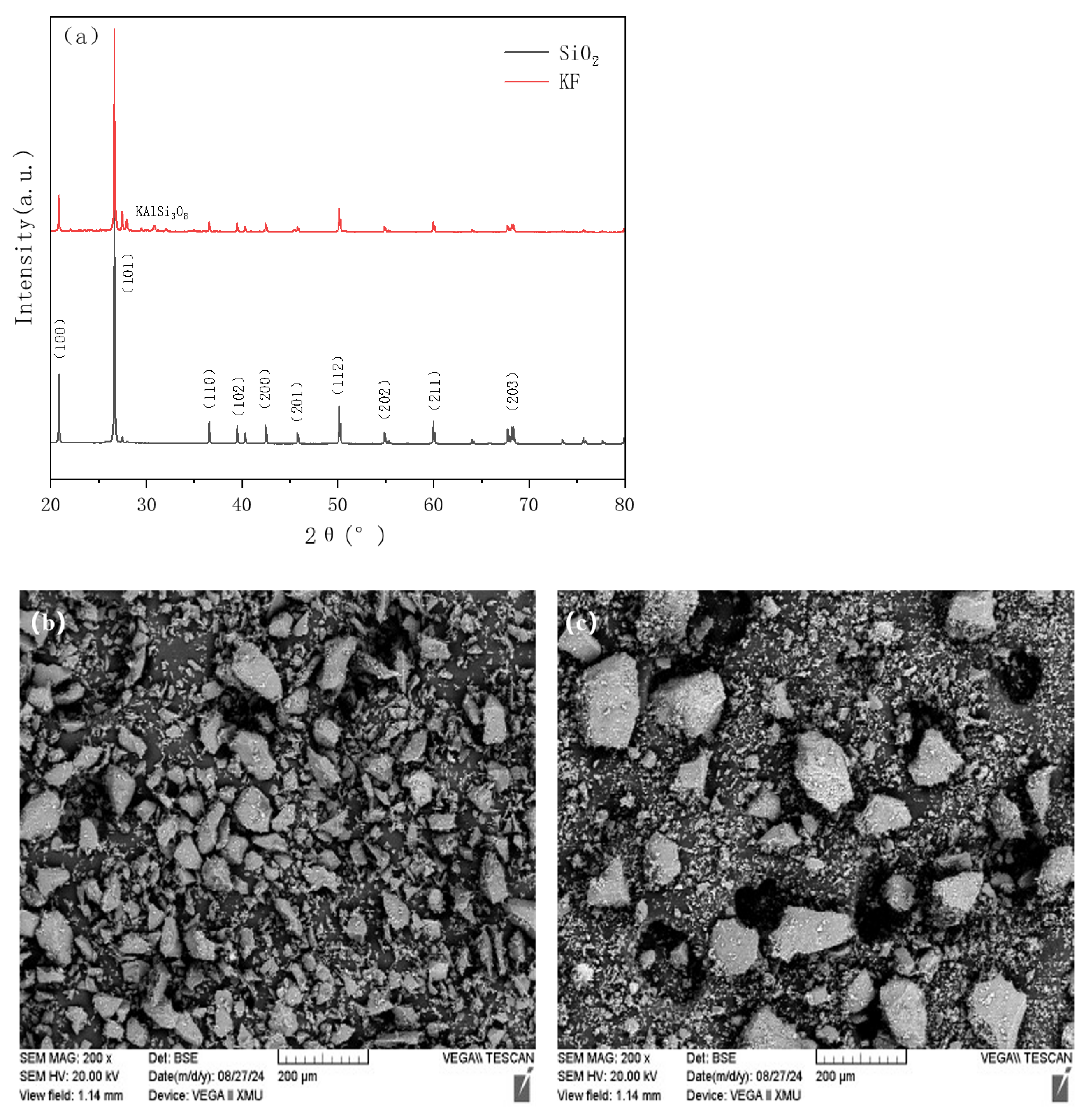

3.1. Characterization of Tailings and SiO2 Particles

3.2. Effects of the Additive Amount on the Physicochemical Properties of Greases

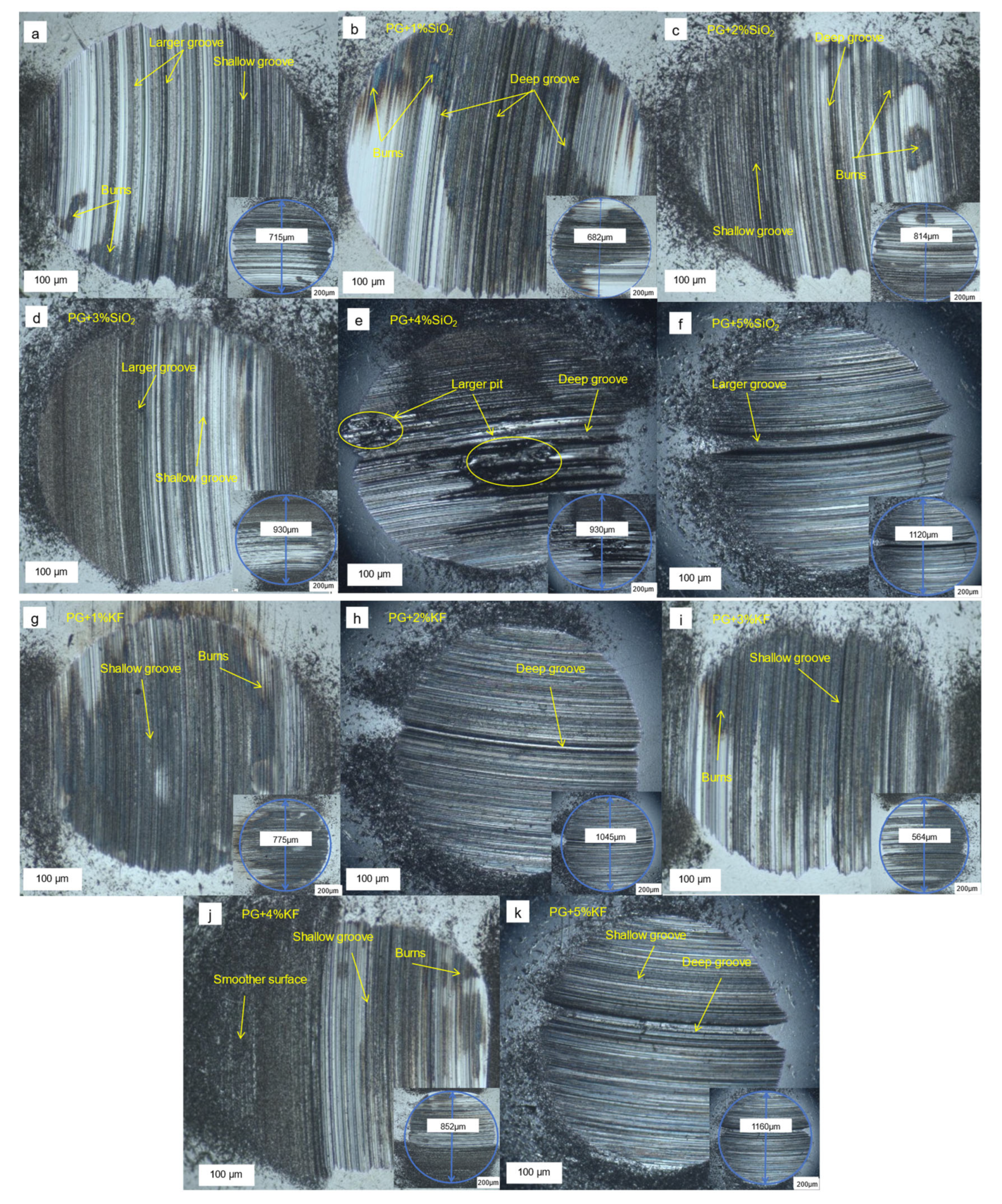

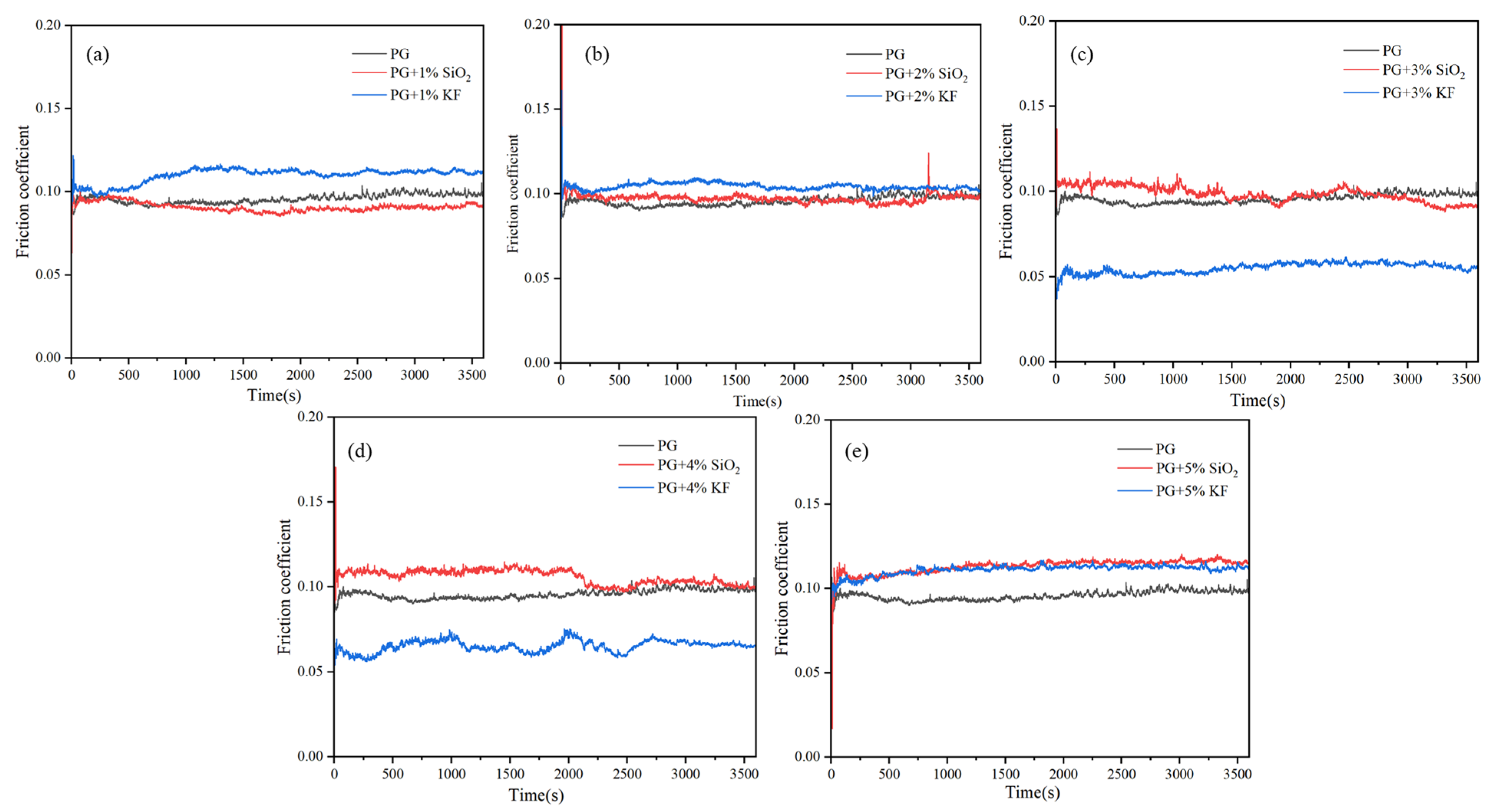

3.3. Friction Performance of Greases

3.4. Microstructure of Greases

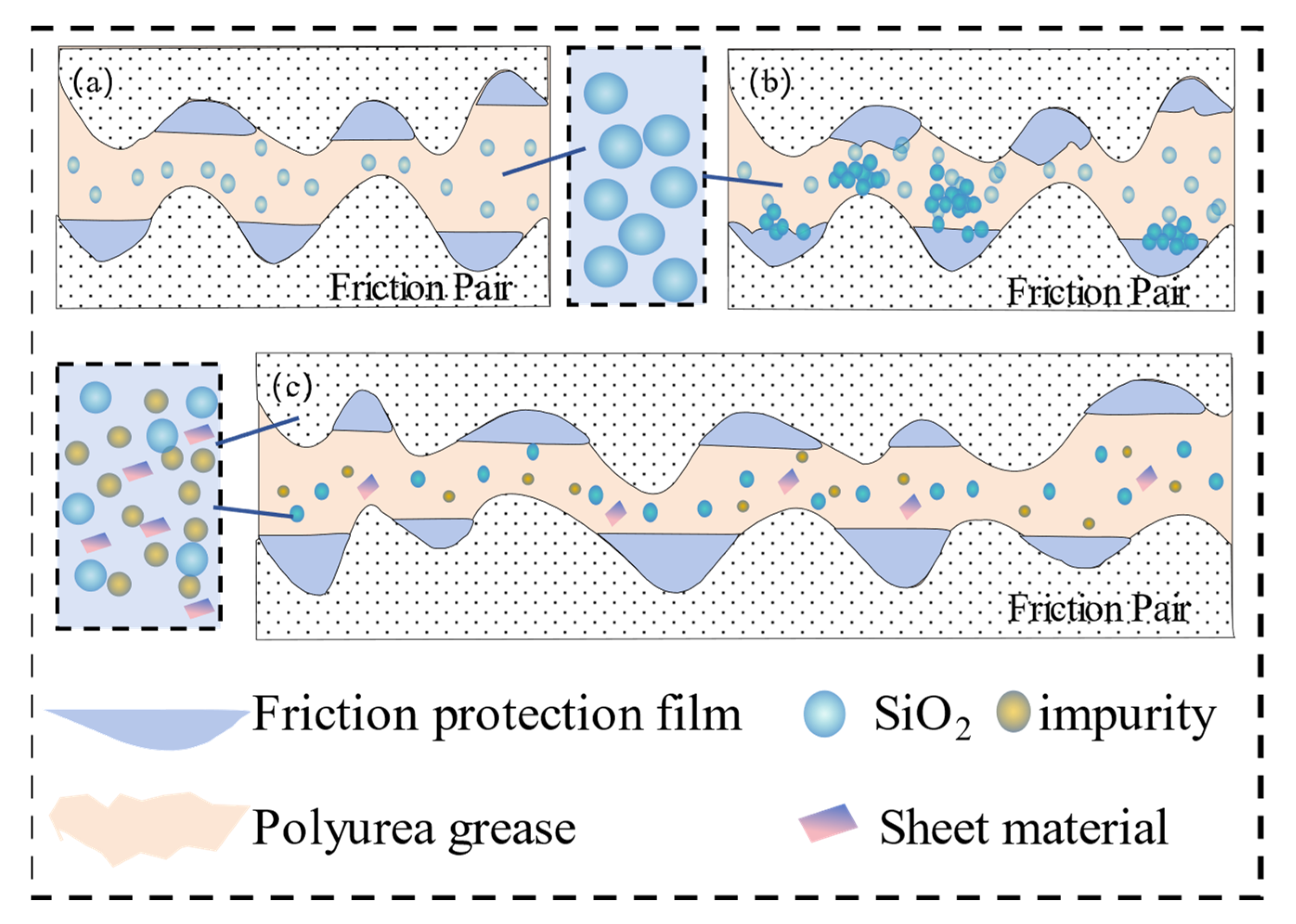

3.5. Analysis of Friction and Wear Mechanisms

4. Conclusions

- (1)

- The addition of SiO2 and tailings, when used separately, significantly reduced both the COF and WSD of the base PG. At a SiO2 concentration of 1%, optimal tribological performance was observed, with reductions of 5.3% and 4.6% in the COF and WSD, respectively, relative to the base grease. In contrast, the best performance with tailings was achieved at a concentration of 3%, corresponding to reductions of 43.2% in the COF and 21.1% in the WSD compared with the base grease.

- (2)

- SEM analysis and observations of the steel ball wear surfaces revealed that SiO2 primarily acted by filling the grooves created by wear during friction. In addition to SiO2, the tailings contained layered materials such as illite and silicoaluminate, which not only helped fill these grooves but also formed a protective film on the friction surface. This film exerted polishing and grinding effects on the friction pair, further reducing friction. The combination of these two mechanisms significantly enhanced the anti-wear and friction-reducing properties of the grease.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Z.; Xie, X.; Wang, P.; Hu, Y.; Cheng, H. Heavy metal pollution caused by small-scale metal ore mining activities: A case study from a polymetallic mine in South China. Sci. Total Environ. 2018, 639, 217–227. [Google Scholar] [CrossRef] [PubMed]

- Cacciuttolo, C.; Cano, D.; Custodio, M. Socio-Environmental Risks Linked with Mine Tailings Chemical Composition: Promoting Responsible and Safe Mine Tailings Management Considering Copper and Gold Mining Experiences from Chile and Peru. Toxics 2023, 11, 462. [Google Scholar] [CrossRef] [PubMed]

- Dey, A.; Rumman, R.; Wakjira, T.G.; Jindal, A.; Bediwy, A.G.; Islam, M.S.; Alam, M.S.; Al Martini, S.; Sabouni, R. Towards net-zero emission: A case study investigating sustainability potential of geopolymer concrete with recycled glass powder and gold mine tailings. J. Build. Eng. 2024, 86, 108683. [Google Scholar] [CrossRef]

- Ahmed, T.; Elchalakani, M.; Basarir, H.; Karrech, A.; Sadrossadat, E.; Yang, B. Development of ECO-UHPC utilizing gold mine tailings as quartz sand alternative. Clean. Eng. Technol. 2021, 4, 100176. [Google Scholar] [CrossRef]

- Hu, P.; Zhang, Y.; Zhou, Y.; Ma, X.; Wang, X.; Tong, W.; Luan, X.; Chu, P.K. Preparation and effectiveness of slow-release silicon fertilizer by sintering with iron ore tailings. Environ. Prog. Sustain. Energy 2017, 37, 1011–1019. [Google Scholar] [CrossRef]

- Qian, L.; Lin, H.; Li, B.; Dong, Y. Physicochemical characteristics and microbial communities of rhizosphere in complex amendment-assisted soilless revegetation of gold mine tailings. Chemosphere 2023, 320, 138052. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, X.; Su, H.; Zhao, Q.; Wang, X.; Lou, W.; Zhang, S. Effect of Mass Fraction on Rheological Behaviors and Tribological Properties of Nano-Silica Greases. Tribology 2023, 43, 916–927. [Google Scholar]

- Chen, L.; Chen, G.; Li, H. The Tribological Properties of Silicon Dioxide Powder as Additives in Lithium Base Greases. Lubr. Eng. 2014, 39, 9–14. [Google Scholar]

- Shuvalov, S.A.; Porfiryev, Y.V.; Kolybelsky, D.S.; Zaychenko, V.A.; Popov, P.S.; Gushchin, P.A.; Mishurov, A.S.; Petrova, D.A.; Vinokurov, V.A. Nanoscale Functional Additives Application in the Low Temperature Greases. Polymers 2021, 13, 3749. [Google Scholar] [CrossRef] [PubMed]

- Nizam, M.K.; Mohd Razmi, M.S.; Mohd Ramli, N.; Razali, M.N. Formulation of Food-Grade Grease Using Paraffin Oil, Fumed Silica, and Chitosan. Mater. Sci. Forum 2022, 1069, 211–218. [Google Scholar] [CrossRef]

- Drabik, J.; Trzos, M. Polymer-silica additive as a modifier of tribological properties of ecological grease, improvement of fatigue resistance. Lubr. Sci. 2020, 33, 133–141. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, K.; Feng, X.; Wang, Y. Tribological properties of modified kaolin doped polymer as polytetrafluoroethylene grease additive. Tribol. Int. 2022, 173, 107612. [Google Scholar] [CrossRef]

- Qu, J.; Qu, H.; Wen, Z.; Luo, Y. Self-repairing properties of complex titanium grease containing hydroxyl silicate. Tribol. Int. 2020, 149, 105685. [Google Scholar]

- GB/T 3498-2008; Petrolum Products—Determination of Dropping Point of Lubricating Greases (Wide Temperature Range). National Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB 7325-1987; Petroleum Products-Lubricating Greases and Oils-Determination of Evaporation Loss. National Standardization Administration of the People’s Republic of China: Beijing, China, 1987.

- GB/T 269-1991; Lubricating Grease and Petrolatum-Determination of Cone Penetration, General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 1991.

- SH/T 0109-2004; Petroleum Products and Lubricants-Determination of Water Washout Characteristics of Lubricating Greases. National Development and Reform Commission: Beijing, China, 2004.

- Wu, C.; Li, S.; Chen, Y.; Yao, L.; Li, X.; Ni, J. Tribological properties of chemical composite and physical mixture of ZnO and SiO2 nanoparticles as grease additives. Appl. Surf. Sci. 2023, 612, 155932. [Google Scholar] [CrossRef]

- Wu, C.; Li, S.; Ni, J.; Yao, L.; Xia, Q. Effect of structure of ZnO and SiO2 core-shell composite nanoparticles as lubricant additive on tribological properties of greases. Appl. Surf. Sci. 2024, 657, 159745. [Google Scholar] [CrossRef]

- Peng, D.X.; Chen, C.H.; Kang, Y.; Chang, Y.P.; Chang, S.Y. Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant. Ind. Lubr. Tribol. 2010, 62, 111–120. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, H.; Shi, X.; Xue, Y.; Huang, Q. Tribological performances of α-Zrp as the additive of the grease used for mine hoisting wire rope. Wear 2022, 504–505, 204428. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, H.; Shi, X.; Xue, Y.; Huang, Q. Effect of TiCMXenes additive on the tribological properties of lithium grease at different temperatures. Wear 2023, 526–527, 204953. [Google Scholar] [CrossRef]

- Li, Q. Tribological Properties of Several Silicate Powder as Grease Additives. Master’s Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar]

- Rawat, S.S.; Harsha, A.P.; Deepak, A.P. Tribological performance of paraffin grease with silica nanoparticles as an additive. Appl. Nanosci. 2019, 9, 305–315. [Google Scholar] [CrossRef]

- Chen, L.; Chen, G.-X.; Chen, H.-L.; Liu, Y. Study on Tribological Performance of Lithium Grease Using Ultrafine Silicon Material (Si-Al Type) as Additive. Pet. Refin. Chem. Ind. 2014, 45, 78–84. [Google Scholar]

| Additive Level | National Lubricating Grease Institute (NLGI) Grade | Cone Penetration (0.1 mm) | Dropping Point (°C) | Oil Evaporation Loss Rate (%) | Water Washout Loss Rate (%) | PB/N |

|---|---|---|---|---|---|---|

| PG | #1 | 338 | 333 | 0.120 | 6.70 | 196 |

| 1% KF | #1 | 323 | 330.3 | 0.236 | 6.30 | 392 |

| 2% KF | #1 | 319 | 336.3 | 0.120 | 4.80 | 441 |

| 3% KF | #1 | 315 | 333.3 | 0.350 | 4.72 | 588 |

| 4% KF | #1 | 312 | 332.3 | 0.186 | 3.30 | 392 |

| 5% KF | #2 | 292 | 336.3 | 0.348 | 3.13 | 392 |

| 1% SiO2 | #1 | 333 | 334.3 | 1.680 | 6.33 | 196 |

| 2% SiO2 | #1 | 330 | 337.0 | 0.240 | 5.80 | 235 |

| 3% SiO2 | #1 | 328 | 339.7 | 1.900 | 5.26 | 235 |

| 4% SiO2 | #1 | 326 | 337.3 | 0.156 | 4.50 | 491 |

| 5% SiO2 | #1 | 322 | >343 | 0.230 | 4.24 | 588 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, H.; Wang, R.; Zhang, B.; Wang, J.; Wang, W.; He, X. Effects of Gold Mine Tailings as an Additive on the Tribological Performance of Lubricating Polyurea Grease. Lubricants 2025, 13, 159. https://doi.org/10.3390/lubricants13040159

Liu X, Wang H, Wang R, Zhang B, Wang J, Wang W, He X. Effects of Gold Mine Tailings as an Additive on the Tribological Performance of Lubricating Polyurea Grease. Lubricants. 2025; 13(4):159. https://doi.org/10.3390/lubricants13040159

Chicago/Turabian StyleLiu, Xiaodong, Heping Wang, Rongshe Wang, Binglong Zhang, Jiqing Wang, Wei Wang, and Xihong He. 2025. "Effects of Gold Mine Tailings as an Additive on the Tribological Performance of Lubricating Polyurea Grease" Lubricants 13, no. 4: 159. https://doi.org/10.3390/lubricants13040159

APA StyleLiu, X., Wang, H., Wang, R., Zhang, B., Wang, J., Wang, W., & He, X. (2025). Effects of Gold Mine Tailings as an Additive on the Tribological Performance of Lubricating Polyurea Grease. Lubricants, 13(4), 159. https://doi.org/10.3390/lubricants13040159