Fabrication of a Composite Groove Array Surface with Gradient Wettability Which Delivers Enhanced Lubrication Performance

Abstract

:1. Introduction

2. Materials and Methods

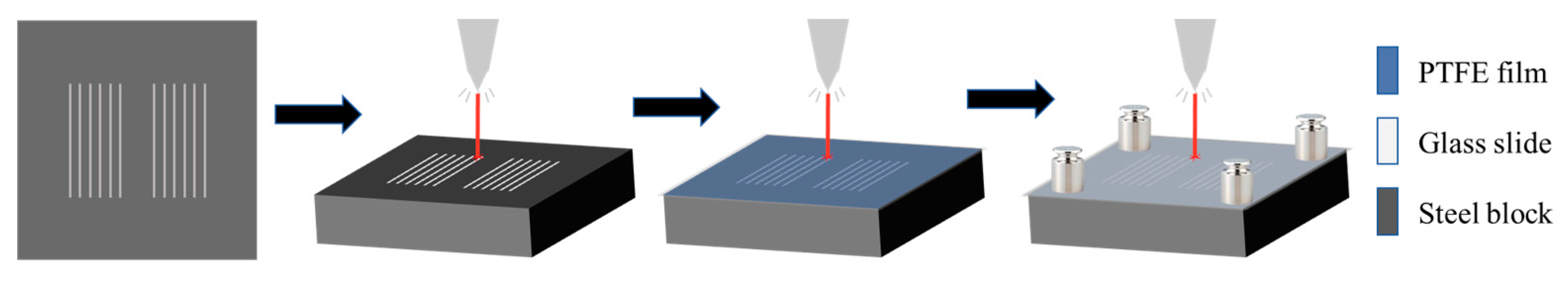

2.1. Sample Preparation

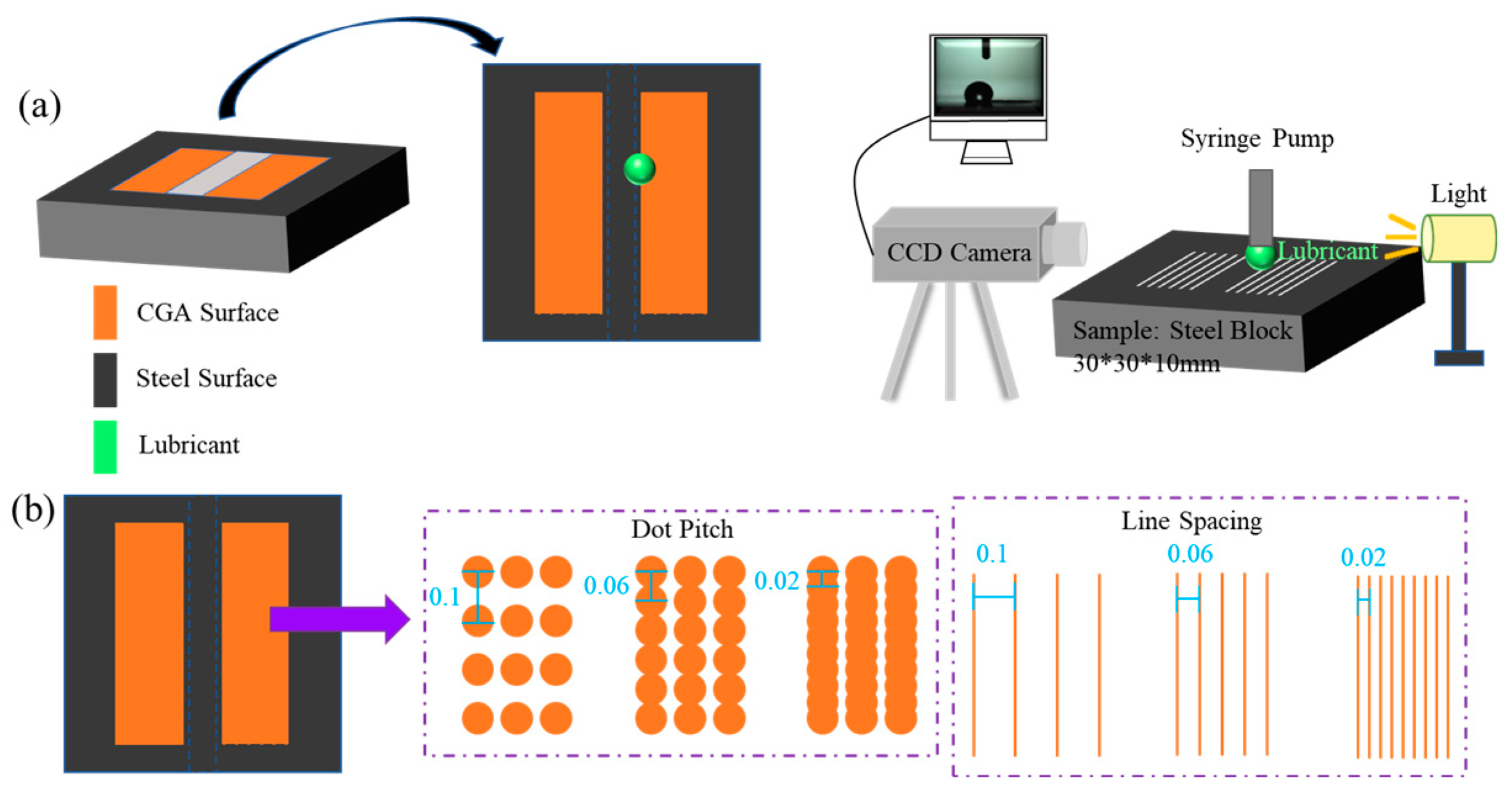

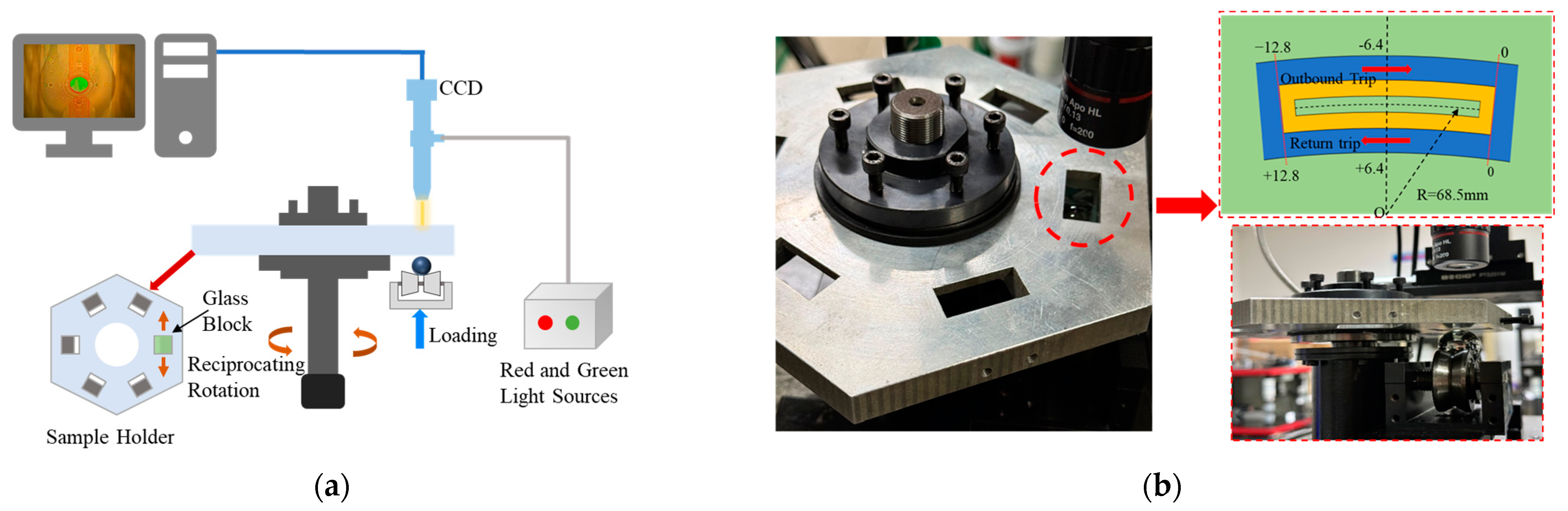

2.2. Measuring Equipment and Conditions

3. Results and Discussion

3.1. Effect of PTFE Coating Surface on the Driving Efficiency of Oil Droplets

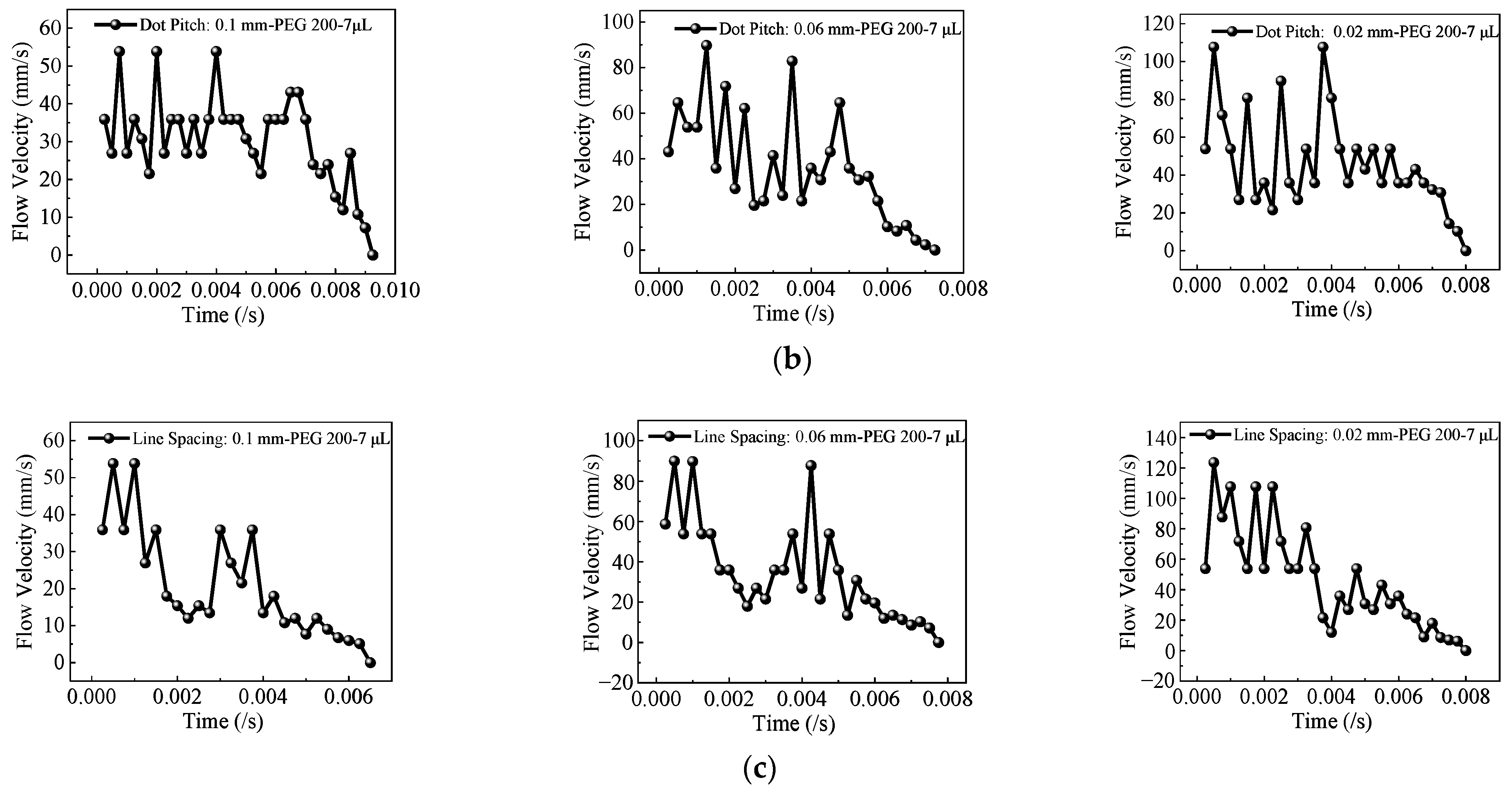

3.2. Lubricant-Driven Efficiency Analysis

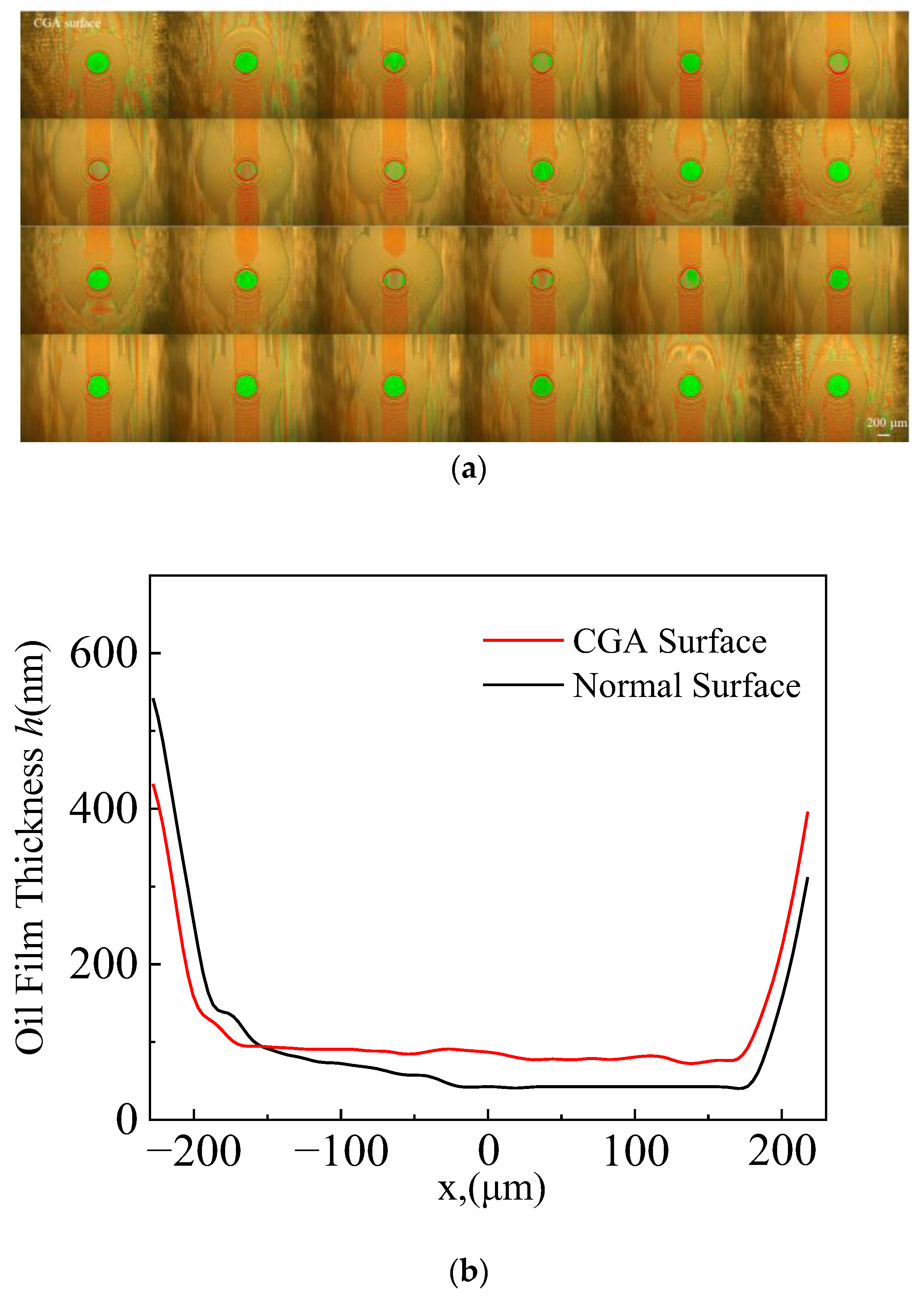

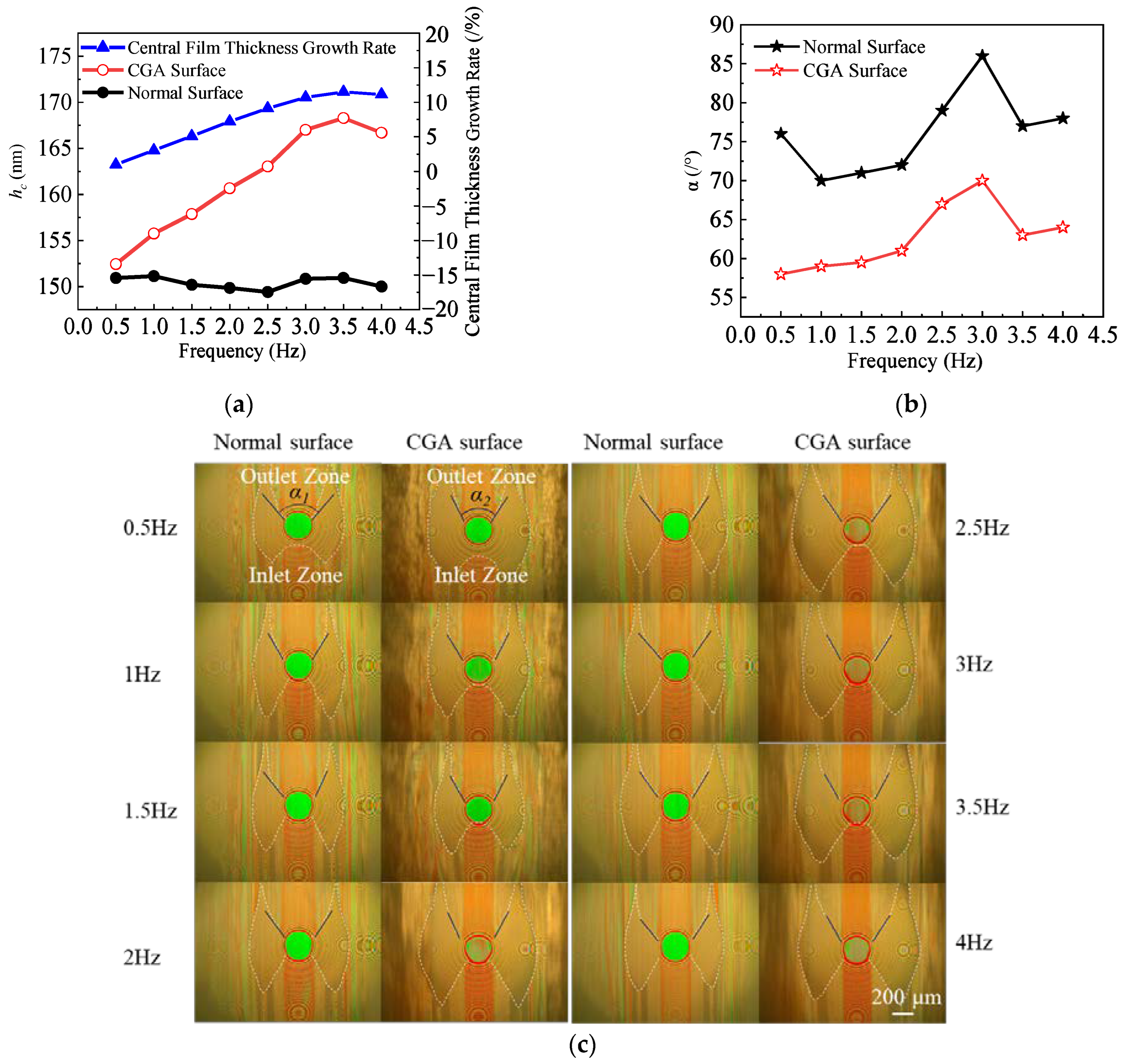

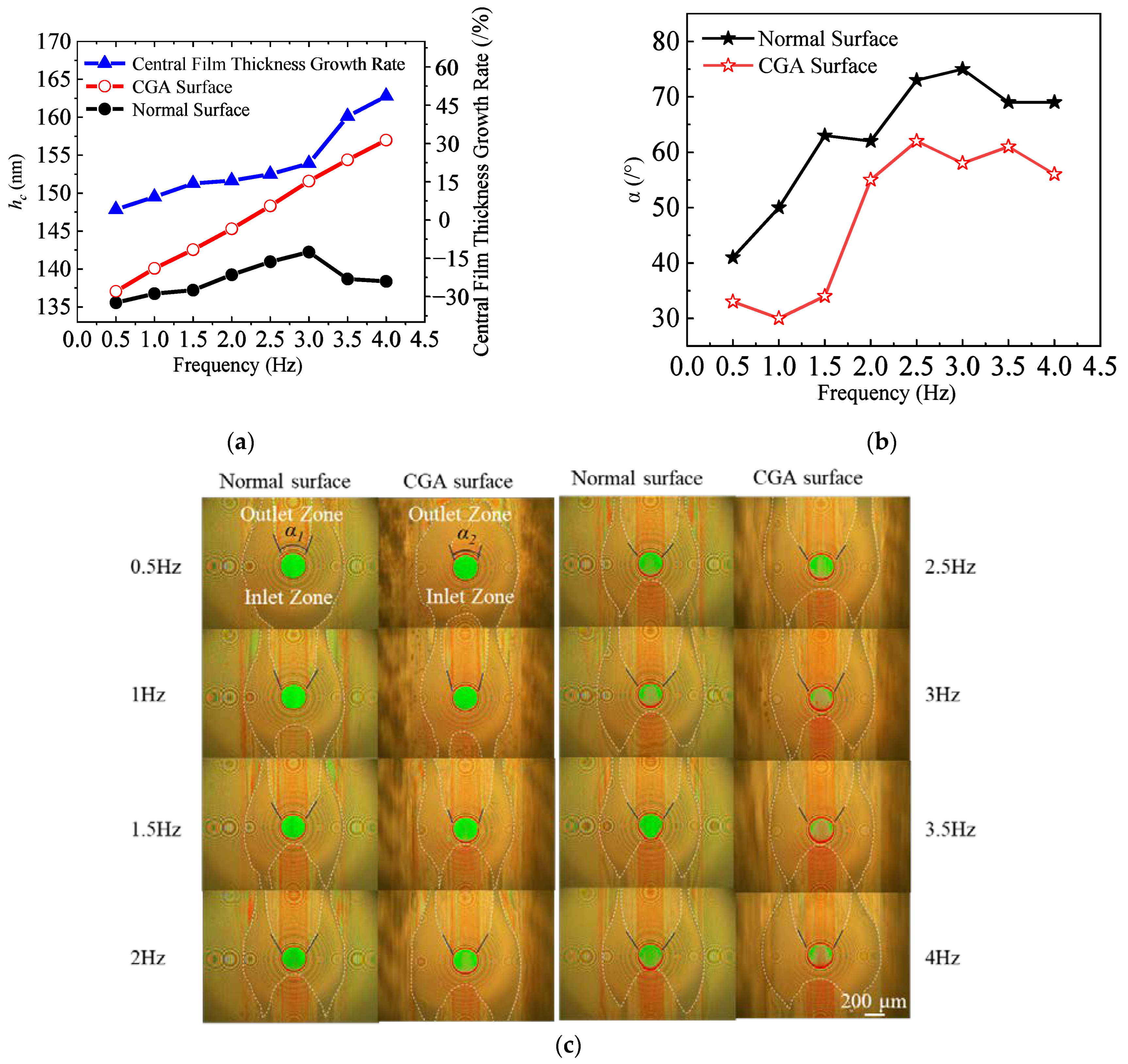

3.3. Investigation of Lubrication Enhancement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bull, S.J.; Rickerby, D. Failure modes in scratch adhesion testing: Some observations. In Surface Modification Technologies III; CRC Press: Boca Raton, FL, USA, 1989; pp. 153–169. [Google Scholar]

- Tsukruk, V.V.; Everson, M.P.; Lander, L.M.; Brittain, W.J. Nanotribological properties of composite molecular films: C60 anchored to a self-assembled monolayer. Langmuir 1996, 12, 3905–3911. [Google Scholar] [CrossRef]

- Etsion, I. Improving tribological performance of mechanical components by laser surface texturing. Tribol. Lett. 2004, 17, 733–737. [Google Scholar] [CrossRef]

- Kataoka, D.E.; Troian, S.M. Patterning liquid flow on the microscopic scale. Nature 1999, 402, 794–797. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G. A laser surface textured hydrostatic mechanical seal. Tribol. Trans. 2002, 45, 430–434. [Google Scholar] [CrossRef]

- He, Y.; Wang, L.; Wu, T.; Wu, Z.; Chen, Y.; Yin, K. Facile fabrication of hierarchical textures for substrate-independent and durable superhydrophobic surfaces. Nanoscale 2022, 14, 9392–9400. [Google Scholar] [CrossRef]

- Bartkowiak, T.; Peta, K.; Królczyk, J.B.; Niesłony, P.; Bogdan-Chudy, M.; Przeszłowski, Ł.; Trych-Wildner, A.; Wojciechowska, N.; Królczyk, G.M.; Wieczorowski, M. Wetting properties of polymer additively manufactured surfaces–Multiscale and multi-technique study into the surface-measurement-function interactions. Tribol. Int. 2025, 202, 110394. [Google Scholar] [CrossRef]

- Zhu, L.; Ni, C.; Yang, Z.; Liu, C. Investigations of micro-textured surface generation mechanism and tribological properties in ultrasonic vibration-assisted milling of Ti–6Al–4V. Precis. Eng. 2019, 57, 229–243. [Google Scholar] [CrossRef]

- Yao, X.; Guo, Y.; Gao, Y.; Hossain, K.R.; Ji, Z.; Lu, Z.; Wang, X.; Wang, Q.; Zhou, F. Additive manufacturing patterned self-lubricating polyimide surfaces. Tribol. Int. 2023, 189, 108972. [Google Scholar] [CrossRef]

- Du, G.; Guo, J.; Wang, J.; Bian, D.; Zhang, X. Tribological behavior of 3D printed nanofluid reinforced photosensitive self-lubricating polymer materials. Addit. Manuf. 2024, 80, 103959. [Google Scholar] [CrossRef]

- Xing, Y.; Luo, C.; Zhu, M.; Zhao, Y.; Ehmann, K.; Wu, Z.; Liu, L. Assessment of self-lubricating coated cutting tools fabricated by laser additive manufacturing technology for friction-reduction. J. Mater. Process. Technol. 2023, 318, 118010. [Google Scholar] [CrossRef]

- Willis, E. Surface finish in relation to cylinder liners. Wear 1986, 109, 351–366. [Google Scholar] [CrossRef]

- Xing, Y.; Luo, C.; Wan, Y.; Huang, P.; Wu, Z.; Zhang, K. Formation of bionic surface textures composed by microchannels using nanosecond laser on Si3N4-based ceramics. Ceram. Int. 2021, 47, 12768–12779. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Khani, S.; Haghighi, S.S.; Razfar, M.R.; Farahnakian, M. Improvement of thread turning process using micro-hole textured solid-lubricant embedded tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1727–1738. [Google Scholar] [CrossRef]

- Bayer, G.; Wandel, S.; Ayromlou, A.; Bader, N.; Poll, G. Influence of the meniscus on wear in grease-lubricated oscillating rolling contacts. Tribol. Int. 2024, 197, 109771. [Google Scholar] [CrossRef]

- Sommers, A.D.; Brest, T.J.; Eid, K.F. Topography-based surface tension gradients to facilitate water droplet movement on laser-etched copper substrates. Langmuir 2013, 29, 12043–12050. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. Combined friction and wear reduction in a reciprocating contact through laser surface texturing. Wear 2016, 358, 51–61. [Google Scholar] [CrossRef]

- Marian, V.G.; Gabriel, D.; Knoll, G.; Filippone, S. Theoretical and experimental analysis of a laser textured thrust bearing. Tribol. Lett. 2011, 44, 335–343. [Google Scholar] [CrossRef]

- Vidyasagar, K.E.C.; Pandey, R.K.; Kalyanasundaram, D. Improvement of deep groove ball bearing’s performance using a bionic textured inner race. J. Bionic Eng. 2021, 18, 974–990. [Google Scholar] [CrossRef]

- Tala-Ighil, N.; Fillon, M.; Maspeyrot, P. Effect of textured area on the performances of a hydrodynamic journal bearing. Tribol. Int. 2011, 44, 211–219. [Google Scholar] [CrossRef]

- Li, Z.; Yin, S.; Zhang, Q.; Zhang, X.; Zhang, H. Analysis of Lubrication Characteristics and Friction Test of Texture Topography of Angular Contact Ball Bearing Based on Computational Fluid Dynamics. Lubricants 2025, 13, 41. [Google Scholar] [CrossRef]

- Liu, K.; Ding, Q.; Peng, H.; Guan, K.; Xi, X.; Kong, N.; Liao, M. Tribological Properties of Multilayer DLC/MoS2 Nanocomposite Coatings on Microtextured Titanium Alloy Surfaces. Lubricants 2024, 12, 374. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Liu, C.L.; Guo, F.; Wong, P.L.; Li, X.M. Tribological behaviour of surfaces with stepped wettability under limited lubricant supply. Tribol. Int. 2020, 141, 105880. [Google Scholar] [CrossRef]

- Li, X.M.; Guo, F.; Wong, P.L.; Zhao, Y. Regulation of lubricant supply by wettability gradient in rolling EHL contacts. Tribol. Int. 2018, 120, 565–574. [Google Scholar] [CrossRef]

- Liu, C.; Guo, F.; Wong, P.; Li, X. Laser pattern-induced unidirectional lubricant flow for lubrication track replenishment. Friction 2022, 10, 1234–1244. [Google Scholar] [CrossRef]

- Zhang, H.; Dai, S.; Liu, Y.; Zhu, Y.; Xu, Y.; Li, B.; Dong, G. Fishbone-like micro-textured surface for unidirectional spreading of droplets and lubricity improvement. Tribol. Int. 2024, 198, 109932. [Google Scholar] [CrossRef]

- Hirayama, T.; Ikeda, M.; Suzuki, T.; Matsuoka, T.; Sawada, H.; Kawahara, K. Effect of nanotexturing on increase in elastohydrodynamic lubrication oil film thickness. J. Tribol. 2014, 136, 031501. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Zhang, H.; Gou, H.; Dong, G. Wedge-shaped lyophilic pattern on superlyophobic surface for unidirectional liquid guidance and lubrication enhancement. Tribol. Int. 2024, 194, 109552. [Google Scholar] [CrossRef]

- Wu, C.; Yang, K.; Ni, J.; Lu, S.; Yao, L.; Li, X. Investigations for vibration and friction torque behaviors of thrust ball bearing with self-driven textured guiding surface. Friction 2023, 11, 894–910. [Google Scholar] [CrossRef]

- Wu, C.; Zheng, C.; Teal, P.D.; Han, Y.; Xu, J.; Li, X. Investigation on the performances of thrust ball bearing with a novel oil self-transportation biomimetic composite guiding surface. Alex. Eng. J. 2025, 110, 579–594. [Google Scholar] [CrossRef]

- Liu, C.; Guo, F.; Li, X.; Wong, P.; Poll, G.; Liu, M. Enhancement of lubricant replenishment under limited lubricant supply in rolling bearings. Tribol. Lett. 2024, 72, 6. [Google Scholar] [CrossRef]

- Liu, H.C.; Guo, F.; Guo, L.; Wong, P.L. A dichromatic interference intensity modulation approach to measurement of lubricating film thickness. Tribol. Lett. 2015, 58, 15. [Google Scholar] [CrossRef]

| Wavelength (nm) | Pulse Width (fs) | Frequency (kHz) | Scanning Speed (mm/s) | First Laser Ablation Energy (%) | Second Laser Ablation Energy (%) |

|---|---|---|---|---|---|

| 1064 | 400 | 20 | 15 | 65–75 | 68–80 |

| Lubricant | Dynamic Viscosity (mPa·s @ 20 °C) |

|---|---|

| PEG200 | 54.7 |

| PEG500 | 122.6 |

| Polyester | 132.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Liu, C.; Li, X.; Guo, F.; Zhu, K. Fabrication of a Composite Groove Array Surface with Gradient Wettability Which Delivers Enhanced Lubrication Performance. Lubricants 2025, 13, 193. https://doi.org/10.3390/lubricants13050193

Zhang T, Liu C, Li X, Guo F, Zhu K. Fabrication of a Composite Groove Array Surface with Gradient Wettability Which Delivers Enhanced Lubrication Performance. Lubricants. 2025; 13(5):193. https://doi.org/10.3390/lubricants13050193

Chicago/Turabian StyleZhang, Tianrui, Chenglong Liu, Xinming Li, Feng Guo, and Kongmin Zhu. 2025. "Fabrication of a Composite Groove Array Surface with Gradient Wettability Which Delivers Enhanced Lubrication Performance" Lubricants 13, no. 5: 193. https://doi.org/10.3390/lubricants13050193

APA StyleZhang, T., Liu, C., Li, X., Guo, F., & Zhu, K. (2025). Fabrication of a Composite Groove Array Surface with Gradient Wettability Which Delivers Enhanced Lubrication Performance. Lubricants, 13(5), 193. https://doi.org/10.3390/lubricants13050193